Automobile drive axle ring gear heat treatment process

An internal gear and drive axle technology, which is applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc. The effect of infiltration temperature, increased coverage, and low quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

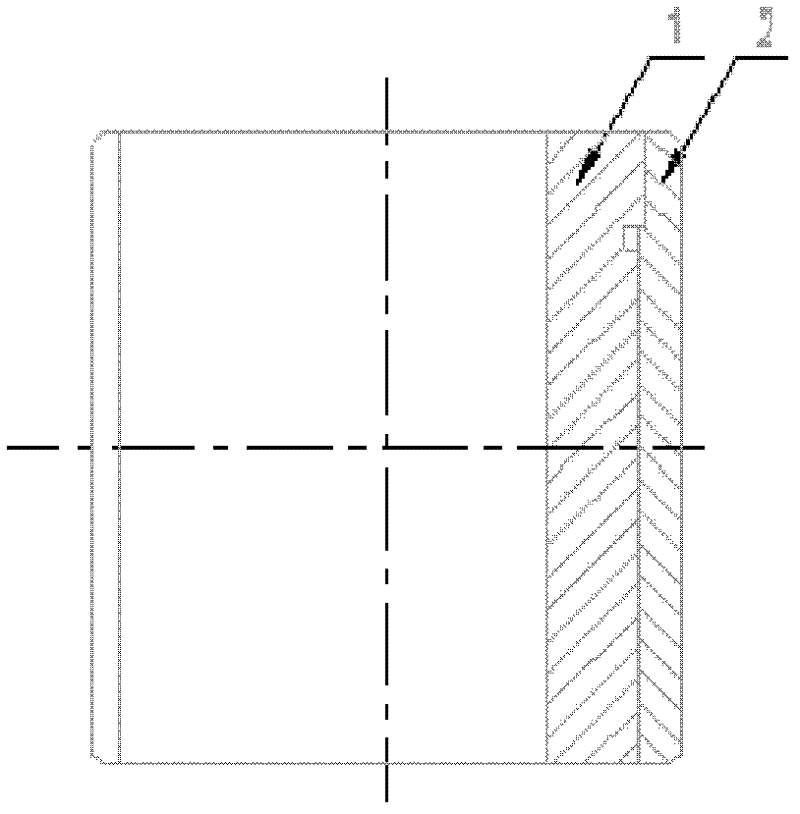

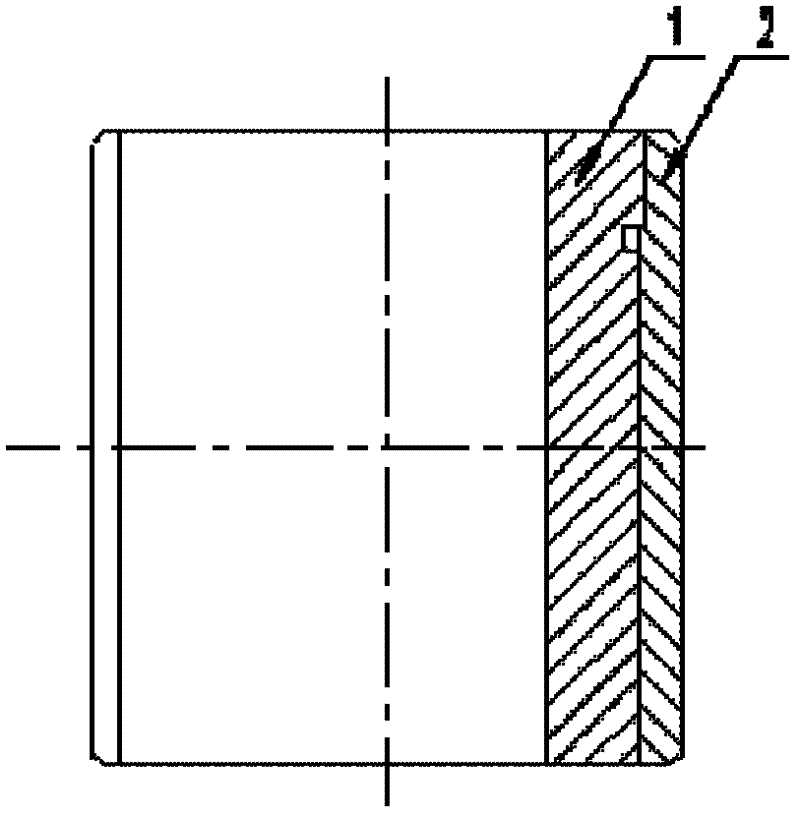

[0022] A heat treatment process for the inner ring gear of an automobile drive axle, as shown in the figure, in the figure, the mandrel 1, the inner ring gear 2; including carbonitriding→quenching→cleaning→tempering→correcting deformation processing steps, and also includes the following steps : After the low-temperature carbonitriding process and before the quenching process, immediately put the deformed mandrel into the inner ring gear, and the diameter of the mandrel 1 is 2 teeth of the inner ring gear after low-temperature carbonitriding and direct quenching 100.02% to 100.03% of the diameter of the top circle, and the outer surface of the mandrel 1 is processed with shaped teeth. When the shaped teeth quench the inner ring gear, the quenching oil will have more contact surfaces with the inner ring gear and its own flow will be smoother, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com