Boron carbon nitrogen trielement coexudation method

A boron-carbon-nitrogen ternary and carbon-nitrogen ternary technology, which is applied in the field of chemical heat treatment of metal surfaces, can solve the problems of dimensional deformation of the infiltrated workpiece, complicated process and high toxicity, and achieves small deformation of the workpiece and simple equipment and process. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Most of the driven discs and shock absorbing discs in automobile clutches are stamped and formed with 08F materials. Take DSΦ350 as an example: the effective size is Φ300×3.2mm, and the boronizing agent is calculated by weight percentage, consisting of 2% La rare earth chloride and 10% boron carbide. , Potassium fluoroborate 15%, binder carboxymethyl cellulose 2%, and silicon carbide the rest. It is prepared by hydrolyzing the above components, mixing them uniformly, and drying at 200°C to form a block with a particle size of 15mm.

[0017] 1. Heat treatment tooling conditions

[0018] RJQ-105-9 well-type gas carburizing furnace is adopted, with radial combined molds, and the workpieces are hung vertically, 240 pieces per furnace, and 200-240 pieces on the beam.

[0019] 2. Heat treatment process

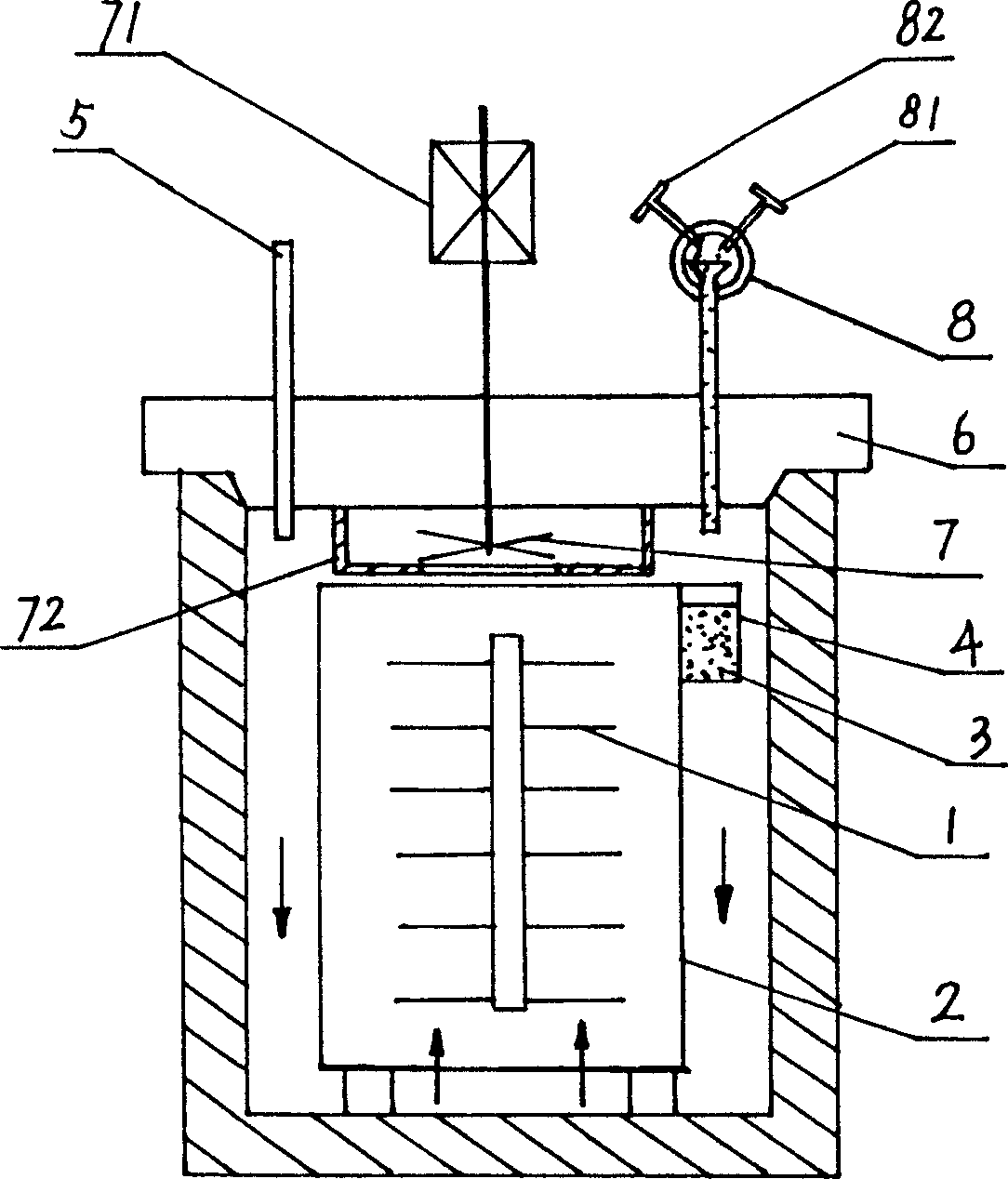

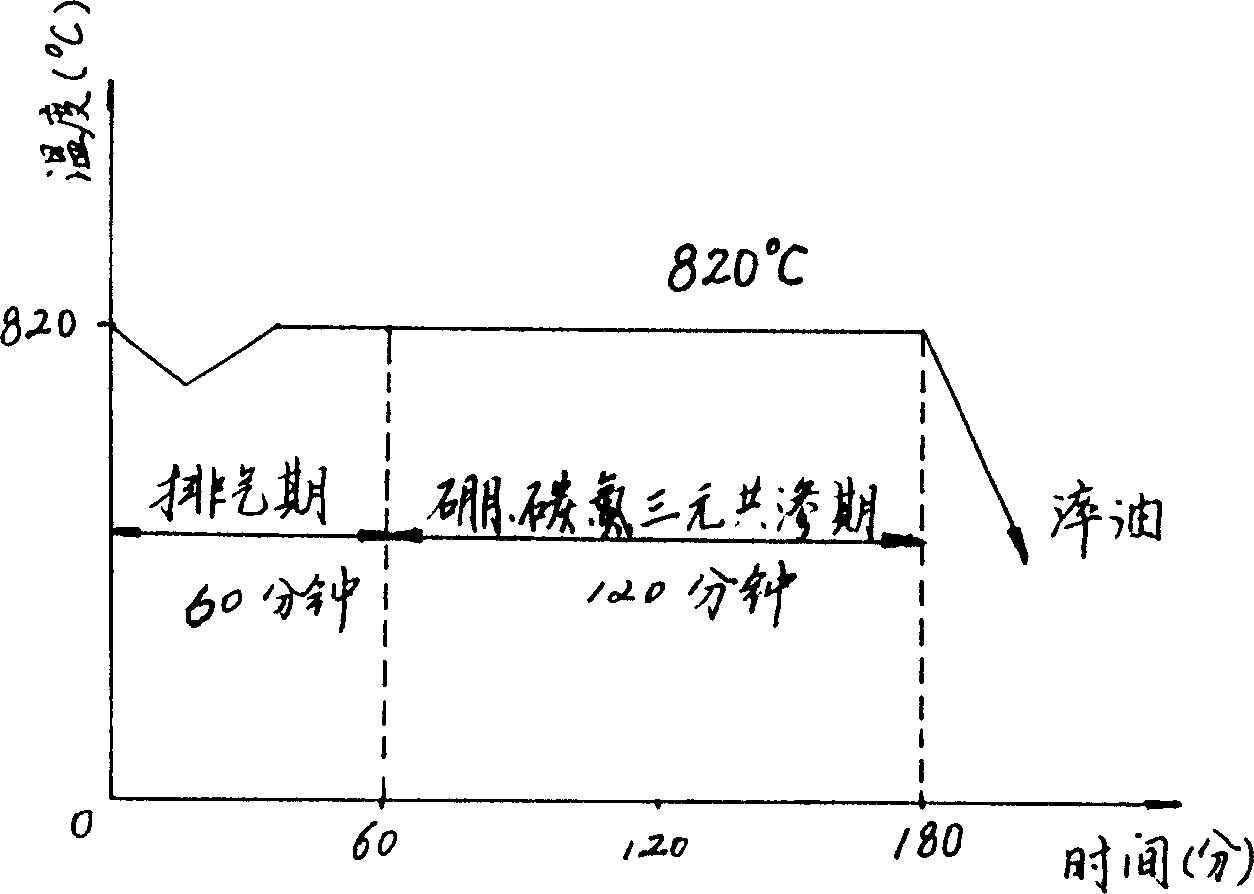

[0020] like figure 1 The shown boron, carbon and nitrogen ternary co-infiltration device adopts well-type gas carburizing furnace. Open and place, place in the infiltratin...

Embodiment 2

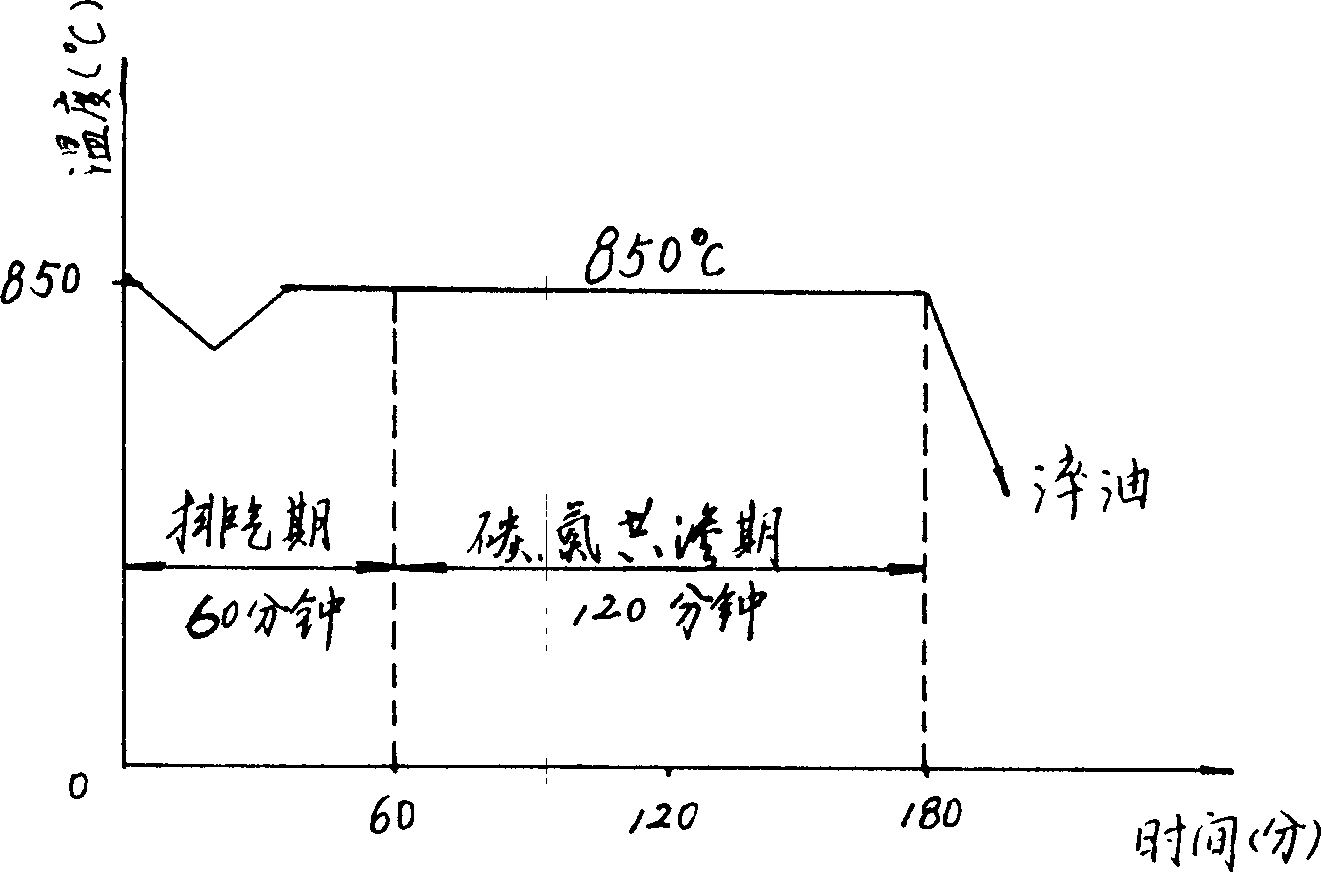

[0029] The difference from Example 1 is:

[0030] 40Cr steel is used as the base material, and boron, carbon, and nitrogen three-component co-infiltration are carried out on the surface. The boronizing agent is calculated by weight percentage, and its chemical composition is Ce chloride rare earth 3%, boron carbide 12%, potassium fluoroborate 20%, The binder starch is 3%, and the remainder of silicon carbide is prepared by hydrolyzing the above-mentioned components, mixing them uniformly, drying them at 300°C into lumps, and the particle size is 10mm; Formamide dripping speed is 4 ml / min, co-infiltration temperature is 880°C, co-infiltration time is 100 minutes, oil cooling; dosage of penetrating agent is 500 grams, infiltration speed is 0.2mm / hour, infiltration layer thickness is 0.33mm, microhardness HV 0.490 1100.

[0031] The commonly used mold material is Cr12MoV, and its cost is about 17,000 yuan / ton, and it is easy to be brittle. The co-infiltration 40Cr steel of the ...

Embodiment 3

[0033] The difference from Example 1 is:

[0034] 20 steel is used as the base material, and boron, carbon and nitrogen ternary co-infiltration are carried out on its surface. The boronizing agent is calculated by weight percentage, and its chemical composition is Ce chloride rare earth 1.5%, boron carbide 5%, potassium fluoroborate 10%, The binder dextrin is 1%, and the rest of silicon carbide is prepared by hydrolyzing the above-mentioned components, mixing them uniformly, and drying at 150°C to form a block with a particle size of 20mm.

[0035] The dropping speed of acetone is 10 ml / min, and the dropping speed of dimethylformamide is 6 ml / min; the total infiltration temperature is 780°C, the total infiltration time is 120 minutes, water cooling; the amount of infiltration agent is 450 grams, and the infiltration speed is 0.15mm / hours, the thickness of the infiltrated layer is 0.3mm, and the microhardness is HV 0.490 1050.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com