Novel 5CrW2SiBAlN shock-resisting tool steel

An impact-resistant tool steel technology, applied in the field of impact-resistant tool steel, can solve the problems of not being a low-carbon energy-saving product, increasing the quenching temperature, and consuming more energy, and achieving the effect of saving a lot of energy and reducing the quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

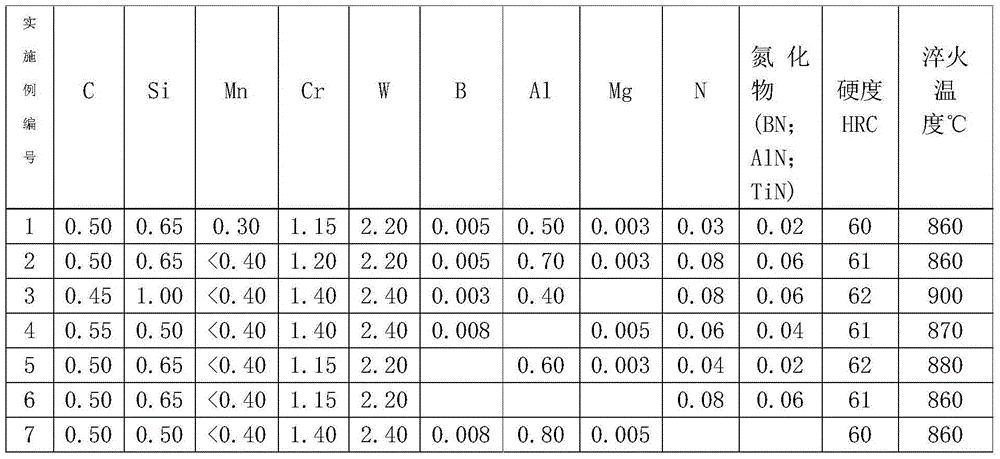

Embodiment 1

[0026] In the 5CrW2SiBAlN alloy tool steel provided by the present invention, it comprises by mass parts:

[0027] C_0.50, Si_0.65, Mn_0.30, Cr_1.15, W_2.20, B_0.005, Al_0.50,

[0028] Mg_0.003, N_0.03, nitride_0.02, the balance is Fe and unavoidable impurities.

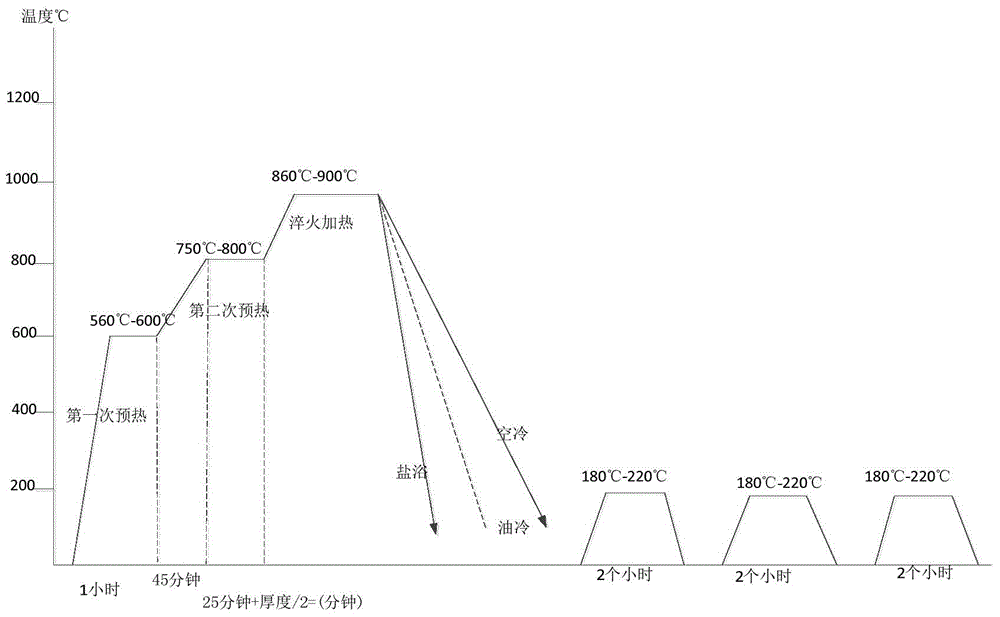

[0029] The steps of the above-mentioned novel 5CrW2SiBAlN alloy tool steel heat treatment process are as follows:

[0030] (1) Preheating: Preheat all the raw materials at a temperature of 560°C to 600°C, and the preheating time is 60 minutes;

[0031] (2) Quenching heating: the quenching heating temperature is 860 ℃ ~ 900 ℃, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 ~ 30 minutes;

[0032] (3) Tempering: Tempering temperature is 180°C to 220°C, and then air cooled to room temperature.

Embodiment 2

[0034] In the 5CrW2SiBAlN alloy tool steel provided by the present invention, it comprises by mass parts:

[0035] C_0.50, Si_0.65, Mn_<0.40, Cr_1.20, W_2.20, B_0.005, Al_0.70,

[0036] Mg_0.003, N_0.08, nitride_0.06, the balance is Fe and unavoidable impurities.

[0037] The steps of the above-mentioned novel 5CrW2SiBAlN alloy tool steel heat treatment process are as follows:

[0038] (1) Preheating for the first time: Preheat all raw materials at a temperature of 560°C to 600°C, and the preheating time is 60 minutes;

[0039](2), the second preheating: after the first preheating, carry out the second preheating, then quenching, the second preheating temperature is 750 ℃ ~ 800 ℃, the second preheating time is 40 ~ 50 minute.

[0040] (3) Quenching heating: the quenching heating temperature is 860 ℃ ~ 900 ℃, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 ~ 30 minutes;

[0041] (4) Tempering for the first time: the tempering tempe...

Embodiment 3

[0044] In the 5CrW2SiBAlN alloy tool steel provided by the present invention, it comprises by mass parts:

[0045] C_0.45, Si_1.00, Mn_<0.40, Cr_1.40, W_2.40B_0.003,

[0046] Al_0.40, N_0.08, nitride_0.08, the balance is Fe and unavoidable impurities.

[0047] The steps of the above-mentioned novel 5CrW2SiBAlN alloy tool steel heat treatment process are as follows:

[0048] (1) Preheating for the first time: Preheat all raw materials at a temperature of 560°C to 600°C, and the preheating time is 60 minutes;

[0049] (2), the second preheating: after the first preheating, carry out the second preheating, then quenching, the second preheating temperature is 750 ℃ ~ 800 ℃, the second preheating time is 40 ~ 50 minute.

[0050] (3) Quenching heating: the quenching heating temperature is 860 ℃ ~ 900 ℃, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 ~ 30 minutes;

[0051] (4) Tempering for the first time: the tempering temperature is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com