High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

A synthetic cast iron, high wear-resistant technology, applied in the direction of grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of difficult to meet the requirements of environmental protection, high cost of cupola, etc., to save steel consumption , Product quality improvement, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

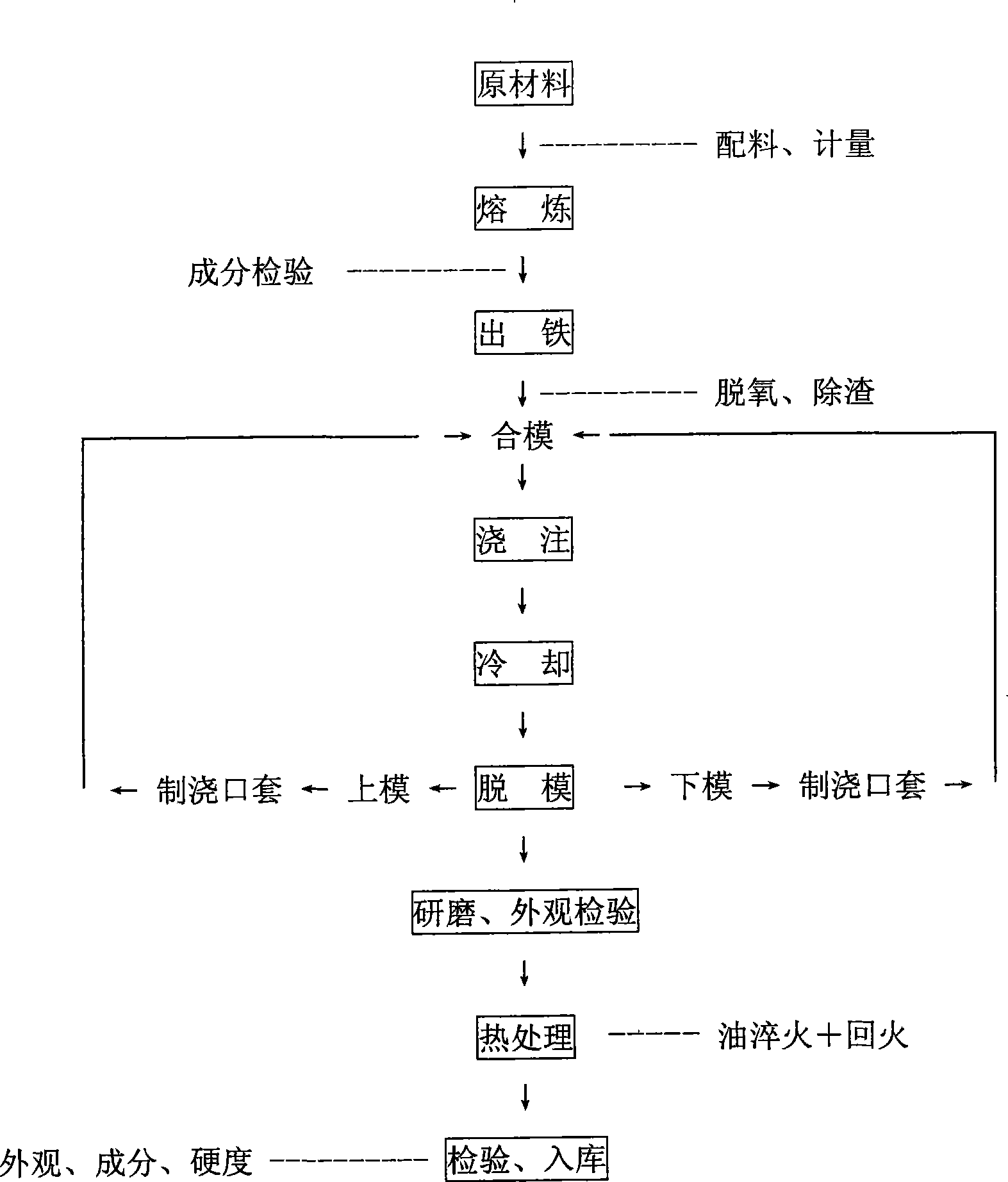

Method used

Image

Examples

Embodiment Construction

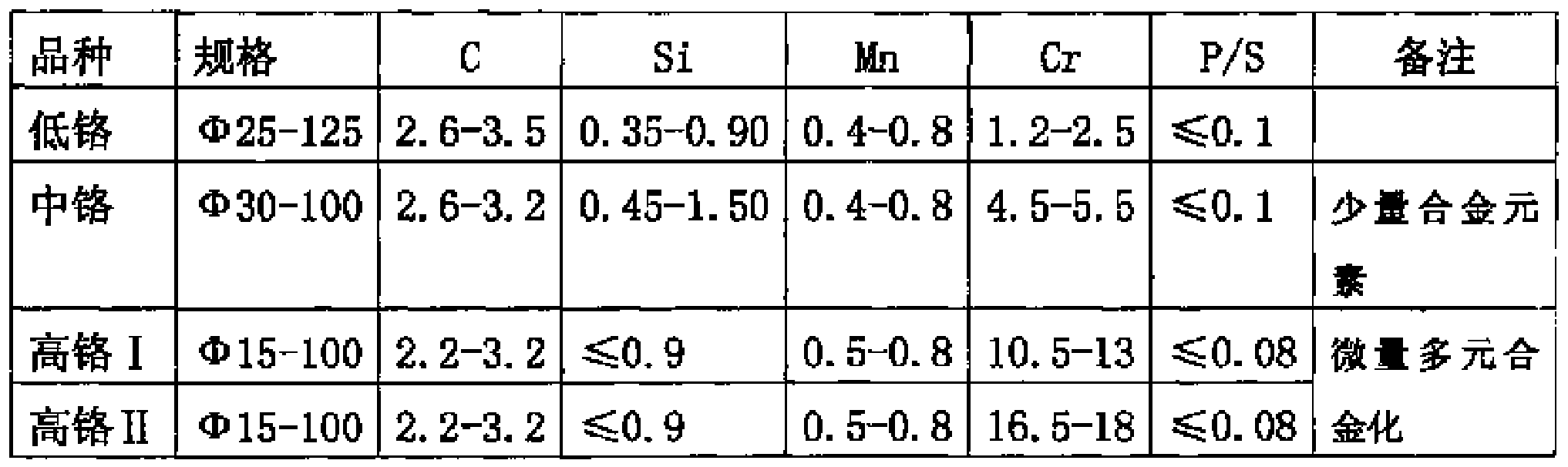

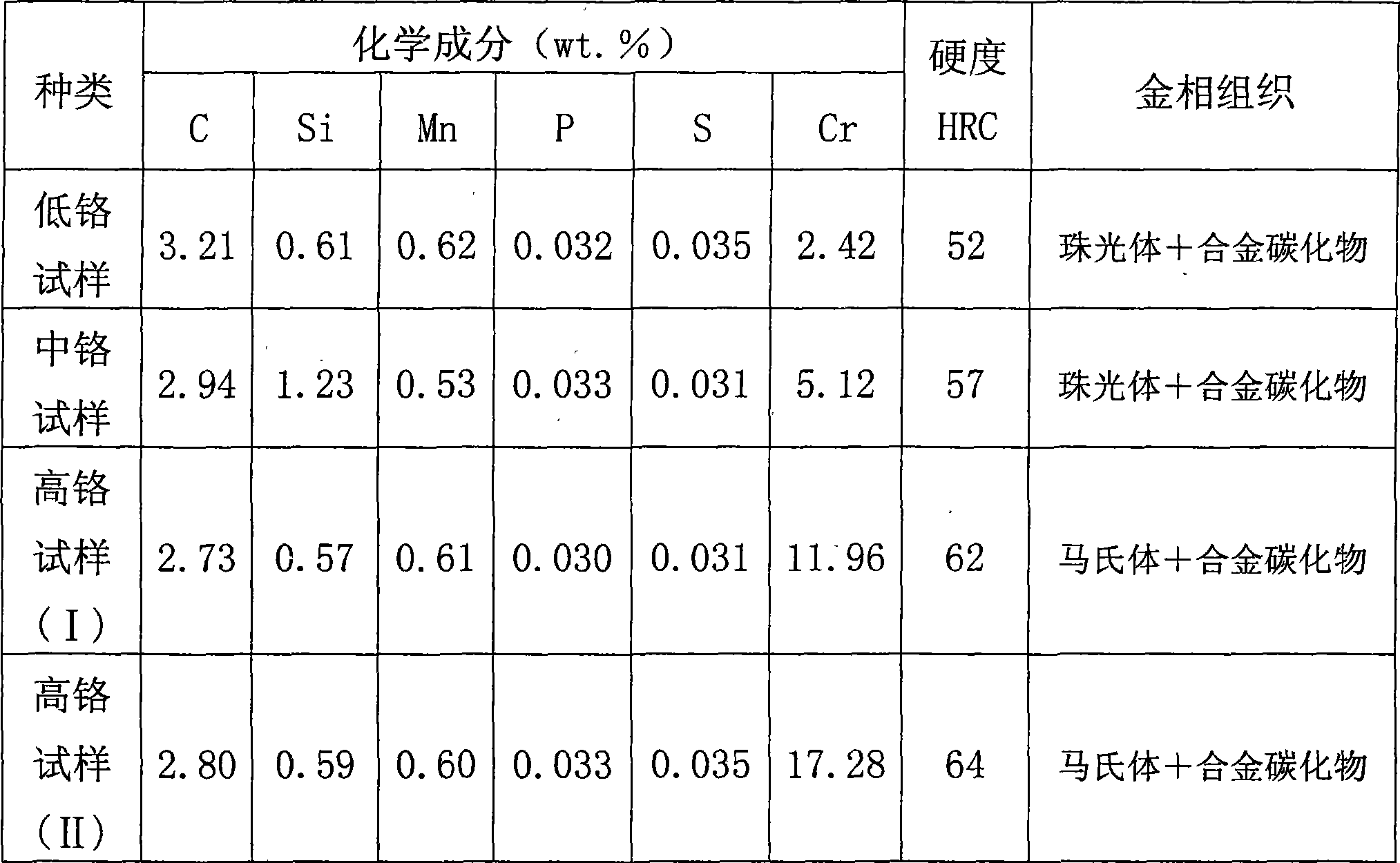

[0022] Three kinds of synthetic cast iron grinding balls with high chromium, medium chromium and low chromium are used for sampling detection, see the table below. Three samples were taken from each group, tested separately, and the average value of the test data of each group was taken.

[0023] List of inspection data of high chromium, medium chromium and low chromium synthetic cast iron grinding balls

[0024]

[0025] According to the above experimental data, it can be proved that the high wear-resistant recycled synthetic cast iron grinding ball containing the chemical composition of the present invention has improved wear resistance compared with No. 45 steel forged steel ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com