Method for preparing manganese chilled bainitic steel

A bainitic steel and manganese-based technology, applied in the field of alloy steel, can solve problems such as failure to achieve quenching to improve microstructure and mechanical properties, failure to properly solve problems such as quenching deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

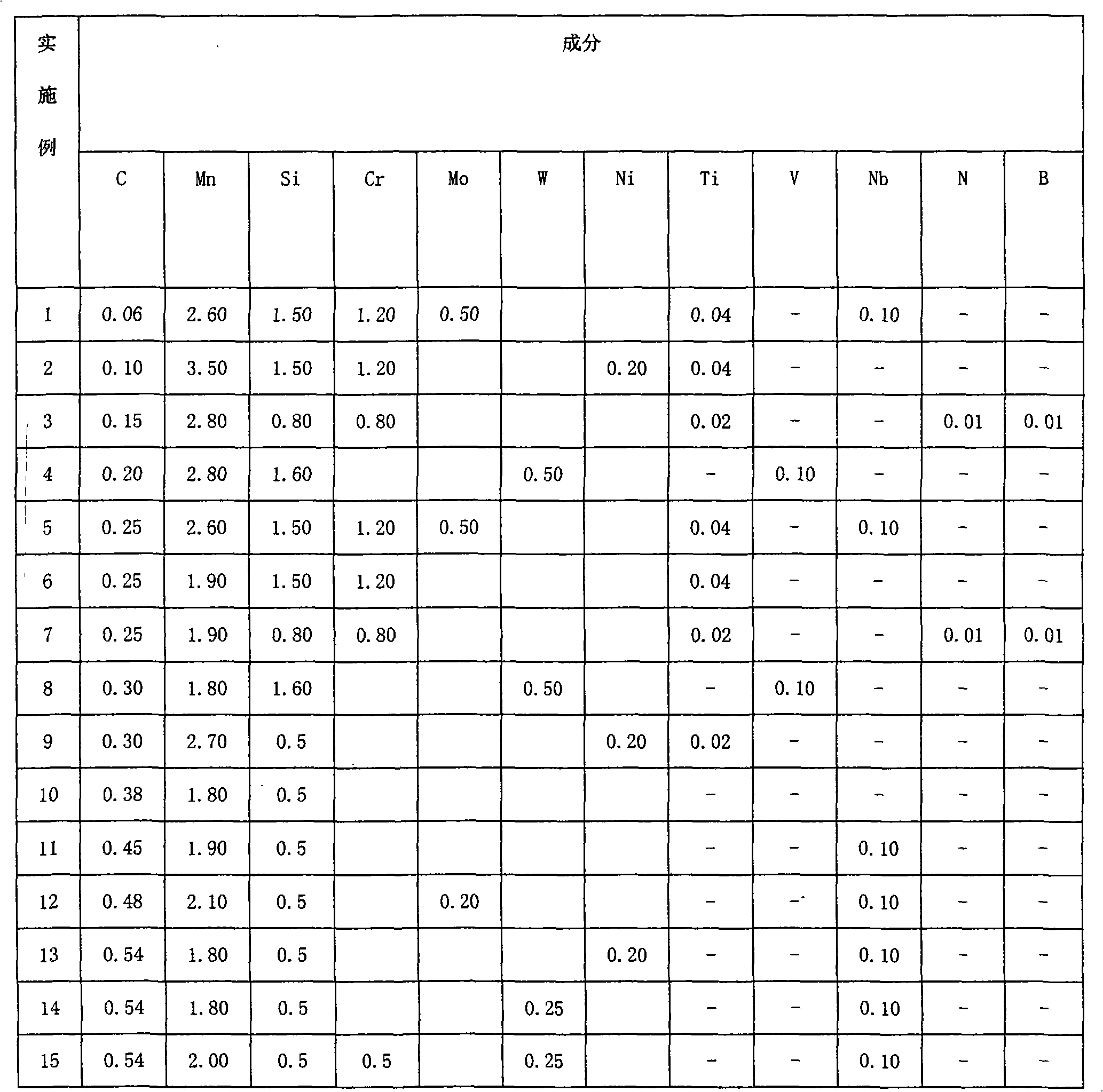

[0024] The preparation method of the manganese series quenched bainite steel proposed by the present invention, after smelting with the conventional steelmaking process, the weight percentage of each component in the steel can be:

[0025] C: 0.06-0.54%

[0026] Mn: 1.80-3.50%

[0027] Si: 0.20-1.80%

[0028] Cr: 0-1.60%

[0029] Mo: 0-3.00%

[0030] W: 0-3.00%

[0031] Ni: 0-3.00%

[0032] Ti: 0-0.12%

[0033] V: 0-0.12%

[0034] Nb: 0-0.12%

[0035] N 0-0.02%

[0036] B: 0-0.01%

[0037] The remainder is Fe;

[0038] Forging, rolling or casting the above steel into products, air cooling to 480°C-700°C, then water cooling or oil cooling or saline cooling to 200°C-250°C (or reheating to 30°C above the austenite transformation critical point -50°C, air cooling to 480°C-700°C, then water cooling or oil cooling or saline solution cooling to 200°C-250°C), then take out air cooling or slowly cool to room temperature; heat the above products to 200°C-600°C , keep warm fo...

Embodiment 1

[0041] The preparation method of embodiment 1 is as follows:

[0042] (1) Carry out conventional steelmaking with a converter or an electric furnace, after forging, rolling or casting, air-cool to 480°C, then water-cool to 250°C, and then air-cool to room temperature;

[0043] (2) Heat the above product to 200°C, keep it warm for 5 hours and carry out tempering treatment.

Embodiment 2

[0044] The preparation method of embodiment 2 is as follows:

[0045] (1) Carry out conventional steelmaking with a converter or an electric furnace, after forging, rolling or casting, air-cool to 500°C, then water-cool to 250°C, and then air-cool to room temperature;

[0046] (2) Heat the above product to 350°C, keep it warm for 3 hours and carry out tempering treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com