Steel plate for hot stamping, hot stamping process and hot-stamped member

一种热冲压成形、成形构件的技术,应用在汽车用高强韧构件,新的热冲压成形用钢板领域,能够解决不利热冲压成形构件生产、构件温度精确度与均匀性难以控制等问题,达到构件温度均匀与组织性能一致性节约、奥氏体化温度低、高屈服强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in more detail with reference to Examples. The examples are intended to explain exemplary embodiments of the present invention, and the present invention is not limited to these examples.

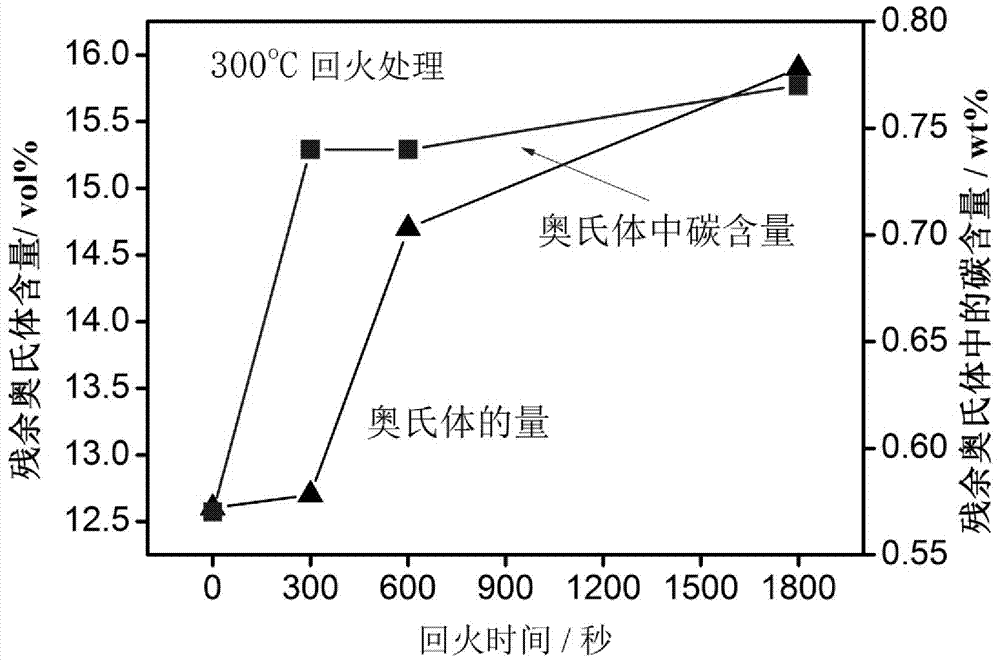

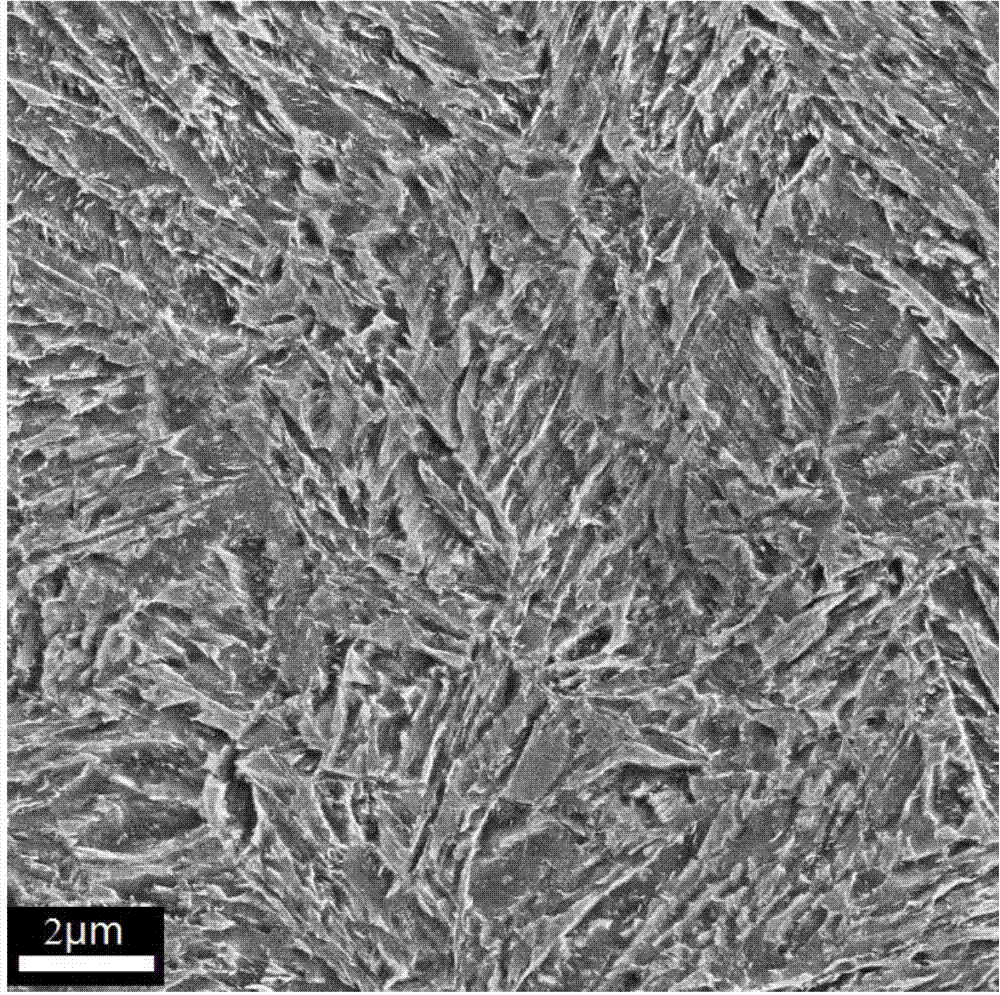

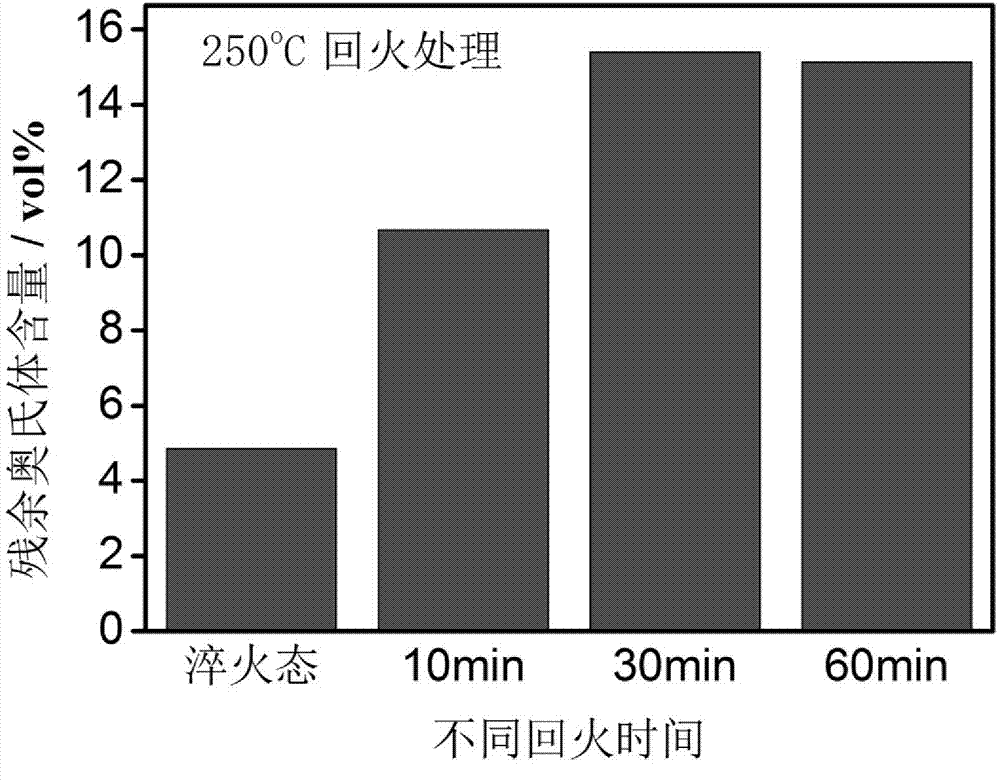

[0029] The invention provides a steel plate which can be galvanized and directly hot-stamped and a formed component of the steel plate, a method for producing the formed component, and a heat treatment method for improving the strength and toughness of the hot-stamped formed component. The shaped member may have a yield strength of 1200 MPa or more, a tensile strength of 1600 MPa or more, and an elongation of 10% or more. The heating temperature of the method for producing shaped components is low, which can greatly save energy. The galvanized steel sheet can be used for direct hot stamping and maintain sufficient strength. When producing formed parts, it is quenched to 150~260°C below the starting temperature of martensitic tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal tensile yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com