Heat treatment process for Q&P980 steel

A technology of Q&P980 and process, which is applied in the field of heat treatment process of Q&P980 steel, can solve the problems that the process parameters cannot be reasonably matched with each other, and achieve the effects of short heat treatment process time, good application prospects and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Derust and degrease the Q&P980 cold-rolled steel plate, and clean it to avoid uneven heating during heat treatment.

[0022] (1) Austenitization: heat the pretreated Q&P980 cold-rolled steel plate at 800°C for 5 minutes;

[0023] (2) Quenching: quickly cool down to 240°C after the heat preservation is over, and the heat preservation time is 8s;

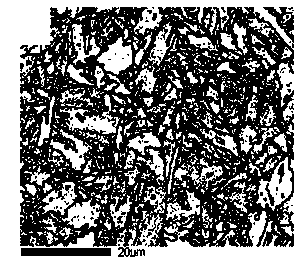

[0024] (3) Partitioning: Partitioning after quenching, the partitioning temperature is between 380°C and the partitioning time is between 60s, and finally water quenching is carried out to obtain Q&P980 steel with enhanced performance. Its EBSD diagram and TEM diagram are as follows figure 1 with figure 2 It can be seen from the EBSD calculation software that the volume fraction of the FCC phase, that is, the retained austenite, is above 15%; from the TEM images, it can also be seen that a large number of film-like distributions and retained austenite between martensite laths.

[0025] After testing, its tensile strength is ...

Embodiment 2

[0027] Derust and degrease the Q&P980 cold-rolled steel plate, and clean it to avoid uneven heating during heat treatment.

[0028] (1) Austenitization: heat the pretreated Q&P980 cold-rolled steel plate at 820°C for 2 minutes;

[0029] (2) Quenching: quickly cool down to 230°C after the heat preservation is over, and the heat preservation time is 5s;

[0030] (3) Partitioning: Partitioning is carried out after quenching, the partitioning temperature is between 420°C and the partitioning time is between 30s, and finally water quenching is carried out to obtain Q&P980 steel with enhanced performance.

[0031] After testing, its tensile strength is 1054MPa, its elongation after fracture is 23.8%, and its strength and plasticity are 25085MPa%, which is much higher than that of traditional Q&P steel.

Embodiment 3

[0033] Derust and degrease the Q&P980 cold-rolled steel plate, and clean it to avoid uneven heating during heat treatment.

[0034] (1) Austenitization: heat the pretreated Q&P980 cold-rolled steel plate at 810°C for 3 minutes;

[0035] (2) Quenching: quickly cool down to 250°C after the heat preservation is over, and the heat preservation time is 10s;

[0036] (3) Partitioning: Partitioning is carried out after quenching, the partitioning temperature is between 400°C and the partitioning time is between 45s, and finally water quenching is carried out to obtain Q&P980 steel with enhanced performance.

[0037] After testing, its tensile strength is 1043MPa, its elongation after fracture is 24%, and its strength and plasticity are 25032MPa%, which is much higher than that of traditional Q&P steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com