High-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and production method thereof

A technology of high-strength plastic product and production method, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of selective oxidation of alloy elements and poor performance, reduce selective oxidation and improve production Efficiency, effect of improving platability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The high-strength plastic product of this embodiment, high-platability fine-grained hot-dip galvanized DP steel, its chemical composition is: C is 0.11wt.%, Mn is 2.1wt.%, Si is <0.005wt.%, Al is 0.35 wt.%, P is 0.06wt.%, Ni is 0.02wt.%, Nb is 0.04wt.%, S is ≤0.005wt.%, and the balance is Fe

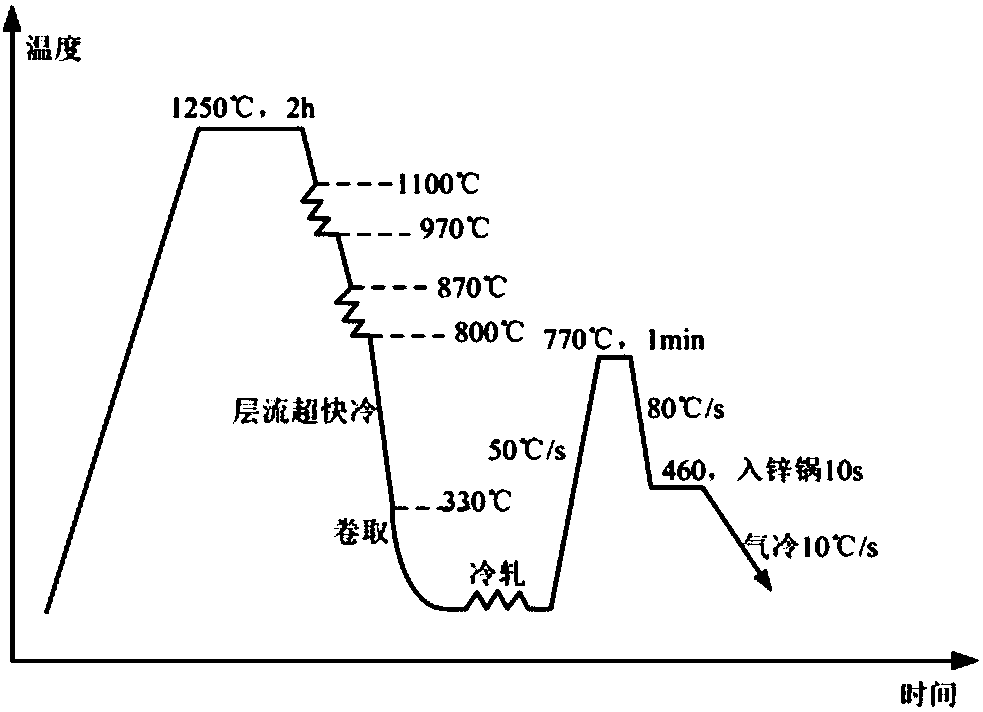

[0024] The production method of the high-strength plastic product of the present embodiment, high-platability fine-grain hot-dip galvanized DP steel is carried out according to the following steps:

[0025] (1) According to the mass percentage: C 0.11%, Mn 2.1%, Si<0.005%, Al 0.35%, P 0.06%, Ni0.02%, Nb 0.04%, S<0.005%, the balance is the set composition of Fe To smelt molten steel, cast a 65Kg billet in a vacuum induction furnace, cut the head and tail of the billet and heat it to 1230°C for 2 hours, forge a rectangular billet with a cross-section of 80mm×80mm at this temperature, and then process it into a 80mm billet with a sawing machine A rectangular billet of ×80mm×100mm is...

Embodiment 2

[0029] The high-strength plastic product of this embodiment, high-platability fine-grain hot-dip galvanized DP steel, its chemical composition is: C is 0.09wt.%, Mn is 2.0wt.%, Si is <0.005wt.%, Al is 0.33 wt.%, P is 0.07wt.%, Ni is 0.03wt.%, Nb is 0.05wt.%, S is ≤0.005wt.%, and the balance is Fe

[0030] The production method of the high-strength plastic product of the present embodiment, high-platability fine-grain hot-dip galvanized DP steel is carried out according to the following steps:

[0031](1) According to the mass percentage: C 0.09%, Mn 2.0%, Si<0.005%, Al 0.33%, P 0.07%, Ni0.03%, Nb 0.05%, S<0.005%, the balance is the set composition of Fe To smelt molten steel, cast a 65Kg billet in a vacuum induction furnace, heat the billet to 1250°C for 2.5 hours, and forge a rectangular billet with a cross-section of 66mm×66mm at this temperature, and then process it with a sawing machine A rectangular billet of 66mm×66mm×80mm is used for hot rolling. In the first stage, h...

Embodiment 3

[0035] The high-strength plastic product of this embodiment, high-platability fine-grain hot-dip galvanized DP steel, its chemical composition is: C is 0.12wt.%, Mn is 2.3wt.%, Si is <0.005wt.%, Al is 0.37 wt.%, P is 0.06wt.%, Ni is 0.02wt.%, Nb is 0.04wt.%, S is ≤0.005wt.%, and the balance is Fe

[0036] The production method of the high-strength plastic product of the present embodiment, high-platability fine-grain hot-dip galvanized DP steel is carried out according to the following steps:

[0037] (1) According to the mass percentage: C 0.12%, Mn 2.3%, Si<0.005%, Al 0.37%, P 0.06%, Ni0.02%, Nb 0.04%, S<0.005%, the balance is the set composition of Fe To smelt molten steel, cast a 65Kg billet in a vacuum induction furnace, cut the head and tail of the billet and heat it to 1270°C for 2.3 hours, forge a rectangular billet with a cross-section of 60mm×60mm at this temperature, and then process it with a sawing machine. A rectangular billet of 60mm×60mm×80mm is used for hot r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strong plastic product | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com