Ultrahigh-strength and ductility low-cost titanium alloy and preparation method and application thereof

A titanium alloy, low-cost technology, applied in the field of alloys, can solve the problems of increasing the cost of titanium alloy raw materials, limiting the application range of titanium alloys, poor strength and plasticity ratio, etc., to achieve good work hardening rate, wide application value, ideal yield intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

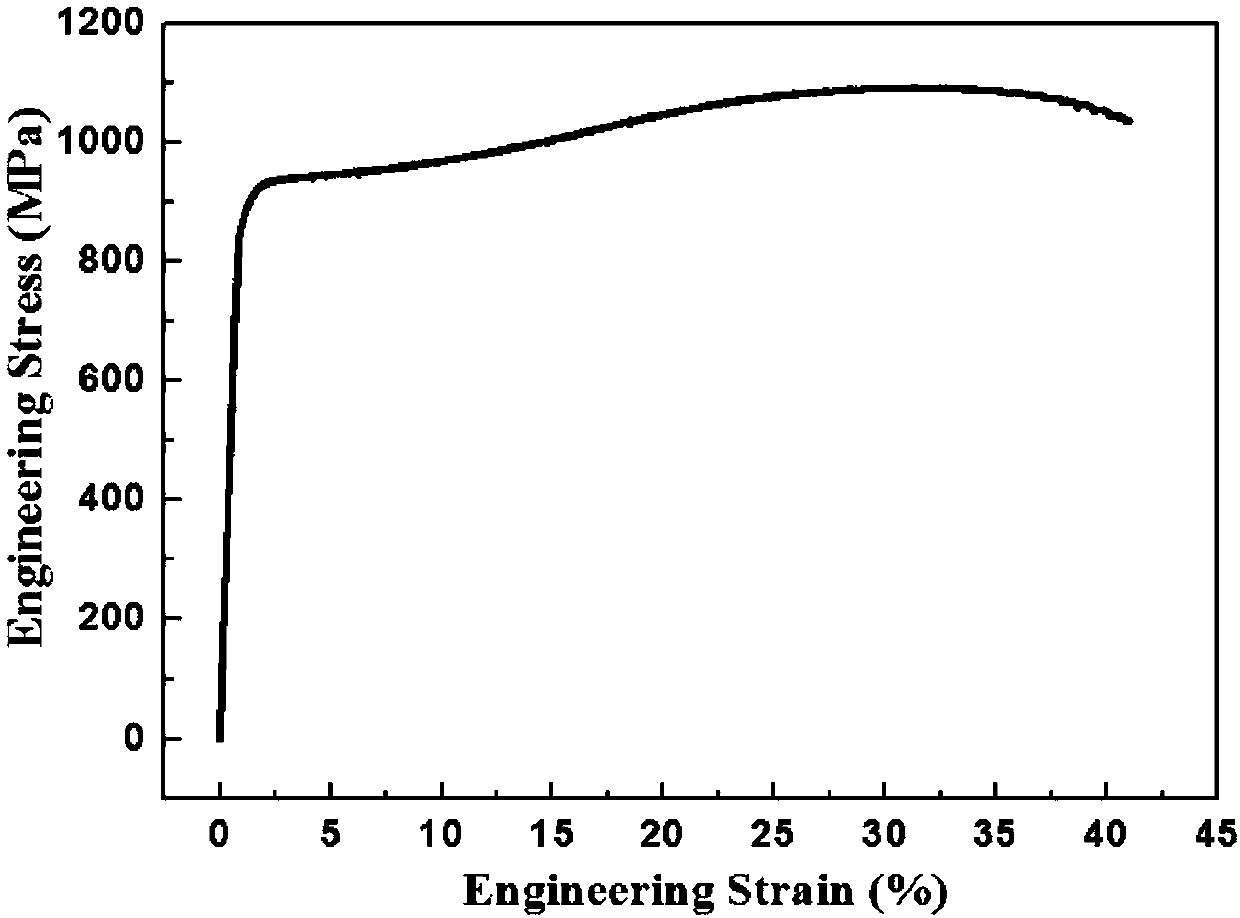

[0025] This embodiment provides a low-cost titanium alloy with ultra-high strength and plasticity, and its chemical composition is Mo7%, Cr 4%, Al 4%, Fe 1%, and the balance is Ti.

[0026] The ultra-high-strength plastic product low-cost titanium alloy provided in this example is prepared by the following method:

[0027] (1) According to the weight percentage of each component, respectively weigh the sponge Ti particles, the master alloy Al-Mo, the master alloy Mo-Fe and the master alloy Cr-Fe;

[0028] (2) Stir and mix the weighed raw materials evenly and press them into consumable electrode blocks, and use tungsten sub-arc welding to weld between the electrode blocks. The purity of argon gas used for welding is 99.99%; vacuum is used The consumable electric arc furnace is smelted three times to prepare ingots;

[0029] (3) After skinning the ingot, removing the riser and the bottom, the ingot is subjected to a homogenization heat treatment at 1050° C. for 12 hours in a va...

Embodiment 2

[0038] This embodiment provides an ultra-high-strength plastic product low-cost titanium alloy, the chemical composition of which is Mo6%, Cr 4%, Al 4%, Fe 2%, and the balance is Ti.

[0039] The preparation method is the same as in Example 1.

[0040] The alloy's with The values are 2.35 and 2.77 respectively, and the [Mo]eq is 14.2. The alloy belongs to the metastable β-type titanium alloy. It can be seen from the test that the titanium alloy provided in this embodiment has excellent tensile strength and elongation, and the strength-plasticity product is ≥ 45 GPa·%.

Embodiment 3

[0042] This embodiment provides a low-cost titanium alloy with ultra-high strength and plasticity, and its chemical composition is composed of Mo7%, Cr 3%, Al 3%, Fe 1%, and the balance is Ti.

[0043] The preparation method is the same as in Example 1.

[0044] The alloy's with The values are 2.38 and 2.78 respectively, and the [Mo]eq is 11.7. The alloy belongs to the metastable β-type titanium alloy. It can be seen from the test that the titanium alloy provided in this embodiment has excellent tensile strength and elongation, and the strength-plasticity product is ≥ 45 GPa·%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com