Zero trans fat acid corn oil and refining process thereof

A technology of trans fatty acid and corn oil, applied in the direction of fat oil/fat refining, fat production, edible oil/fat, etc., can solve the adverse effects of central nervous system development, increase blood viscosity and cohesion, and increase blood cholesterol level To achieve the effect of shortening the deodorization time, lowering the deodorization temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

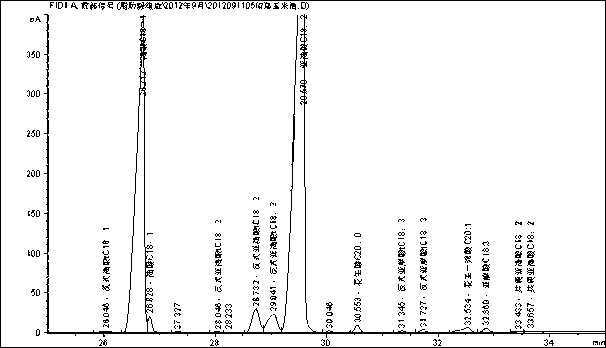

Embodiment 1

[0028] In the alkali refining process, firstly heat corn crude oil to 40°C, then add food-grade phosphoric acid with a concentration of 75%, accounting for 0.05%-0.2% of the oil, acid treatment for 20 minutes, and the acid-treated mixture is mixed with lye And reaction, lye concentration 15Bé, reaction time 15 minutes, carry out centrifugation. Continuous tubular dewaxing is adopted, and the corn oil after alkali refining is crystallized and dewaxed through 12 crystallization tubes. For the remaining crystallization tubes, the crystallization tubes are wrapped with condensation coils, the temperature of the oil is gradually lowered to 5°C, and the temperature of the oil is kept for 4 hours for crystallization and crystal growth, and then the oil temperature is raised to 20°C for filtration. The dewaxed corn oil is pumped into the decolorization tower for decolorization, the decolorization temperature is 118°C, the amount of activated clay added is 2.5% of the oil weight, the d...

Embodiment 2

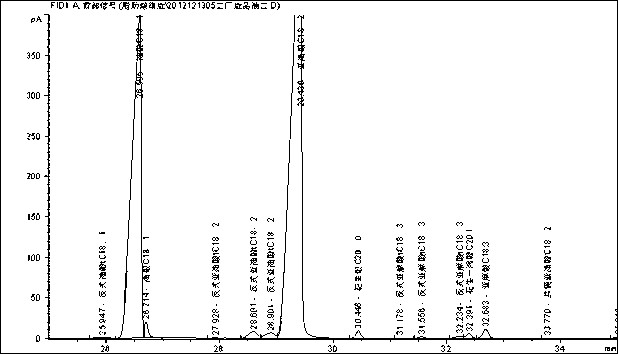

[0032] In the alkali refining process, firstly heat corn crude oil to 40°C, then add food-grade phosphoric acid with a concentration of 75%, accounting for 0.05%-0.2% of the oil, acid treatment for 25 minutes, and the acid-treated mixture is mixed with lye And reaction, lye concentration 15Bé, reaction time 10 minutes, carry out centrifugation. Continuous tubular dewaxing is adopted, and the corn oil after alkali refining is crystallized and dewaxed through 12 crystallization tubes. For the remaining crystallization tubes, the crystallization tubes are wrapped with condensation coils, the temperature of the oil is gradually lowered to 5°C, and the temperature of the oil is kept for 4 hours for crystallization and crystal growth, and then the oil temperature is raised to 20°C for filtration. The dewaxed corn oil is pumped into the decolorization tower for decolorization, the decolorization temperature is 115°C, the amount of activated clay added is 2.5% of the oil weight, the d...

Embodiment 3

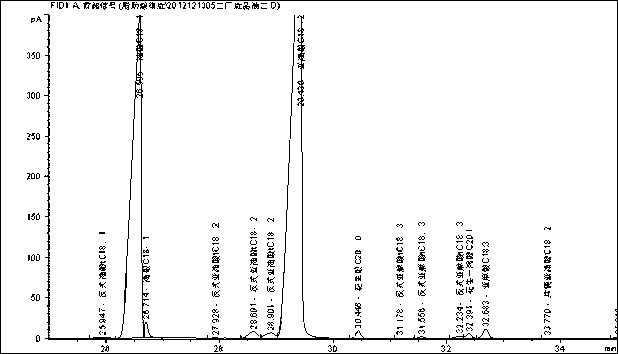

[0035] In the alkali refining process, firstly heat corn crude oil to 40°C, then add food-grade phosphoric acid with a concentration of 75%, accounting for 0.05%-0.2% of the oil, acid treatment for 30 minutes, and the acid-treated mixture is mixed with lye And reaction, lye concentration 15Bé, reaction time 10 minutes, carry out centrifugation. Continuous tubular dewaxing is adopted, and the corn oil after alkali refining is crystallized and dewaxed through 12 crystallization tubes. For the remaining crystallization tubes, the crystallization tubes are wrapped with condensation coils, the temperature of the oil is gradually lowered to 5°C, and the temperature of the oil is kept for 4 hours for crystallization and crystal growth, and then the oil temperature is raised to 20°C for filtration. The dewaxed corn oil is pumped into the decolorization tower for decolorization, the decolorization temperature is 120°C, the amount of activated clay added is 2.5% of the oil weight, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com