Cold-rolled aluminum alloy sheet for bottle can with excellent neck part formability and process for producing the cold-rolled aluminum alloy sheet

A cold-rolled sheet and formability technology, applied in the field of aluminum alloy cold-rolled sheet, can solve problems such as easy wrinkles and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

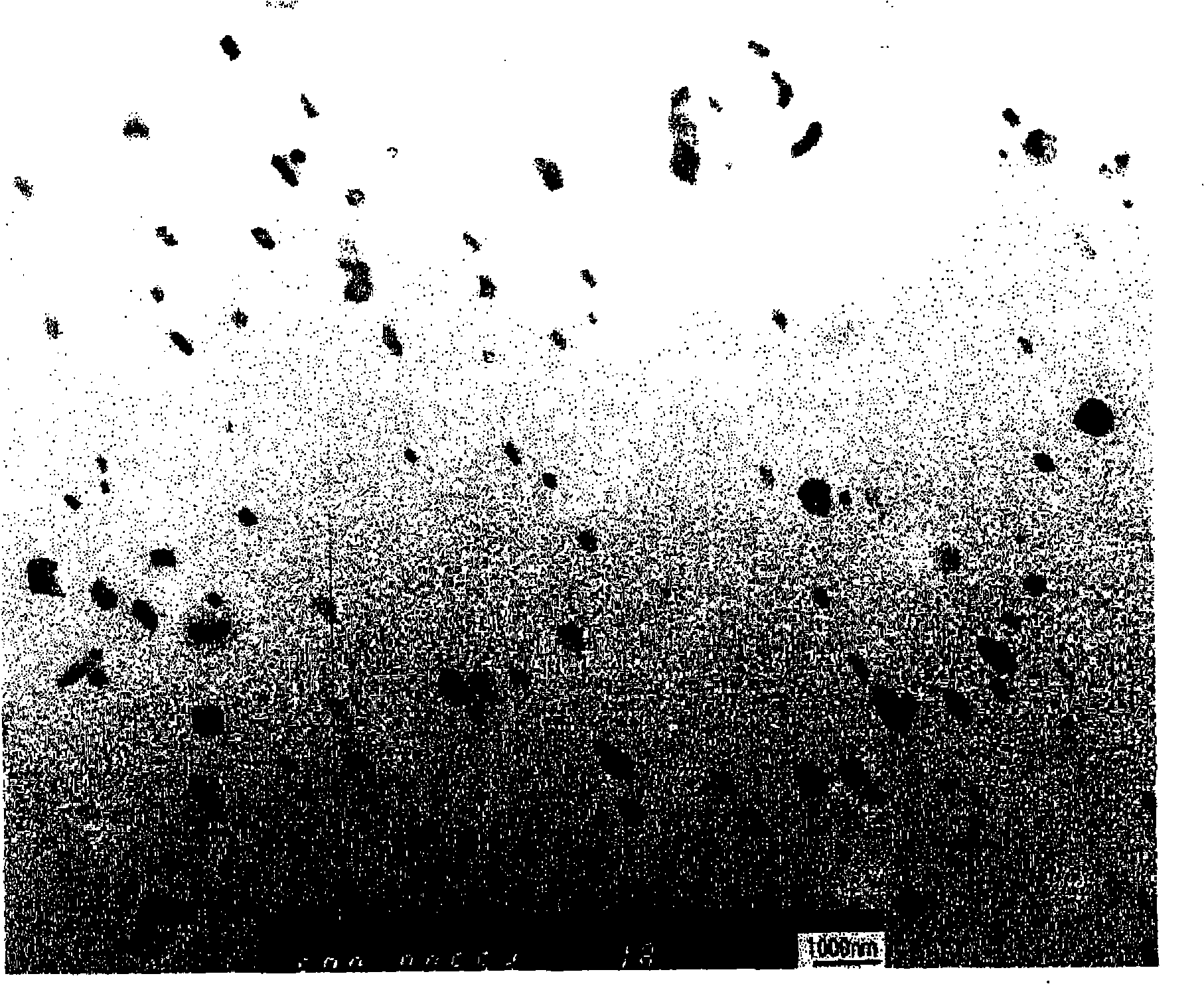

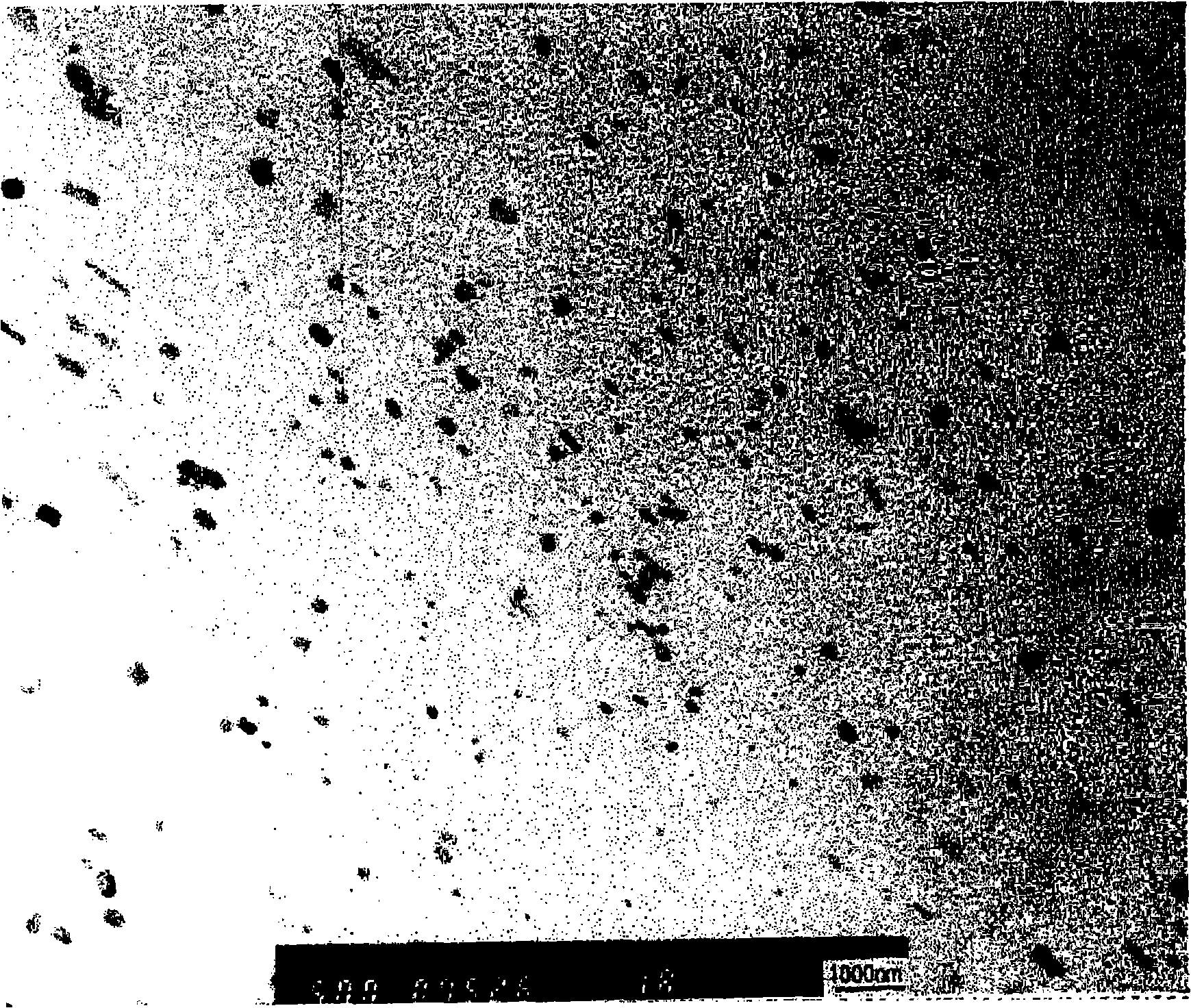

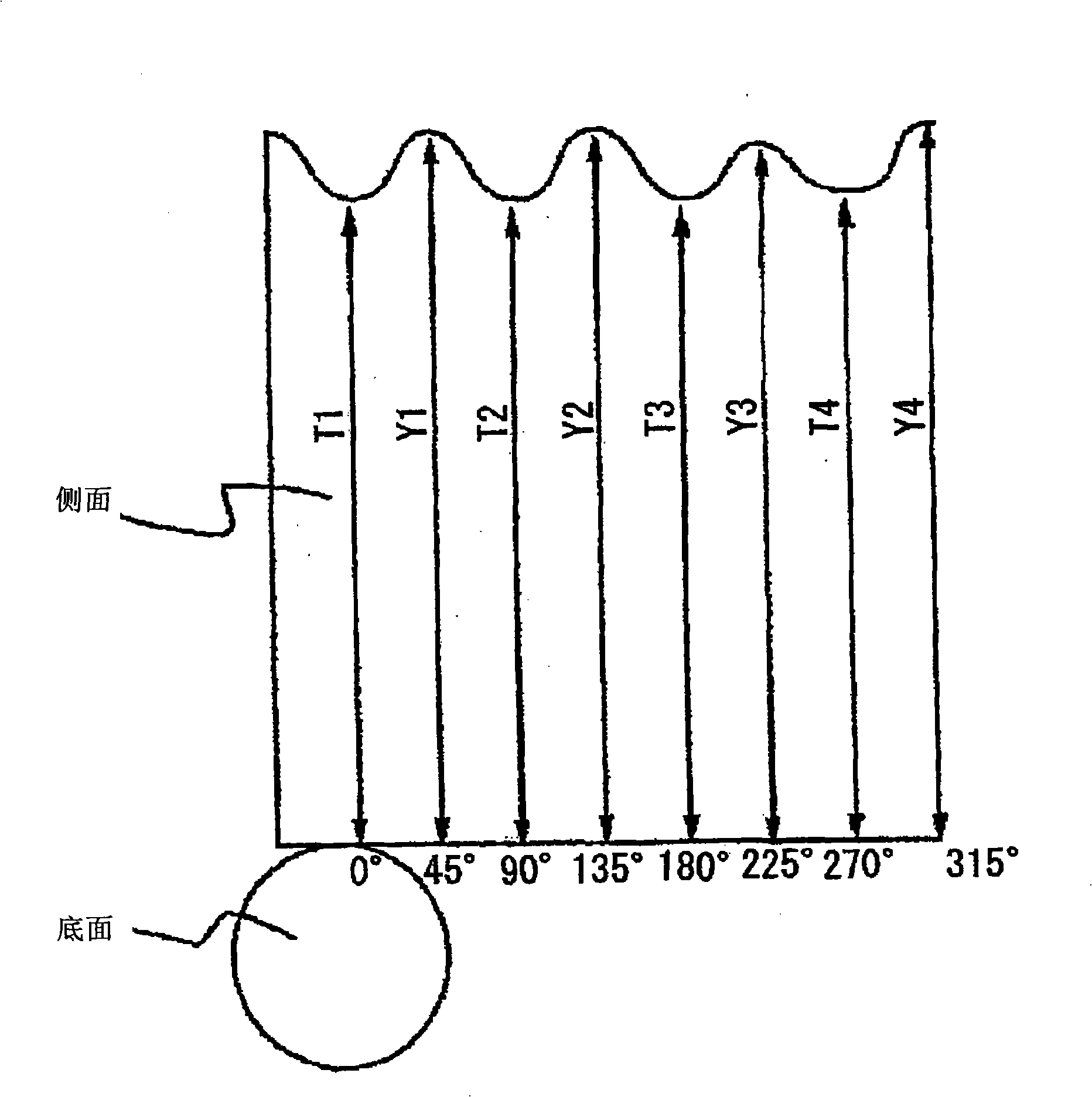

Image

Examples

Embodiment

[0130] In addition to the aluminum base metal, can scraps are also used as melting raw materials, and the melting of Al alloys with the composition A to N shown in the following Table 1 (inventive examples: A to D, comparative examples E to N) was carried out. Melting was performed, and an ingot having a plate thickness of 600 mm and a width of 2100 mm was produced by the DC casting method. Also, the contents of elements indicated by "-" in Table 1 indicate below the detection limit.

[0131] In this ingot, as shown in Table 1, as the total amount of other elements, both the inventive example and the comparative example contain unavoidable impurity elements, and the total content of these elements contains Zr, Bi, Sn, Ga, V, Co, Ni, Ca, Mo, Be, Pb, and W are 0.03% or more.

[0132] Soaking treatment was performed on the ingots with these compositional compositions under the conditions shown in Tables 2 and 4. Here, the rate of temperature increase in the soaking treatment re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com