High-entropy alloy and method for preparing high-entropy alloy block through powder metallurgy method

A high-entropy alloy and powder metallurgy technology, applied in the field of materials, can solve the problems of void product size, as-cast alloy composition segregation, coarse structure, etc., and achieve the effect of improving performance, uniform composition and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

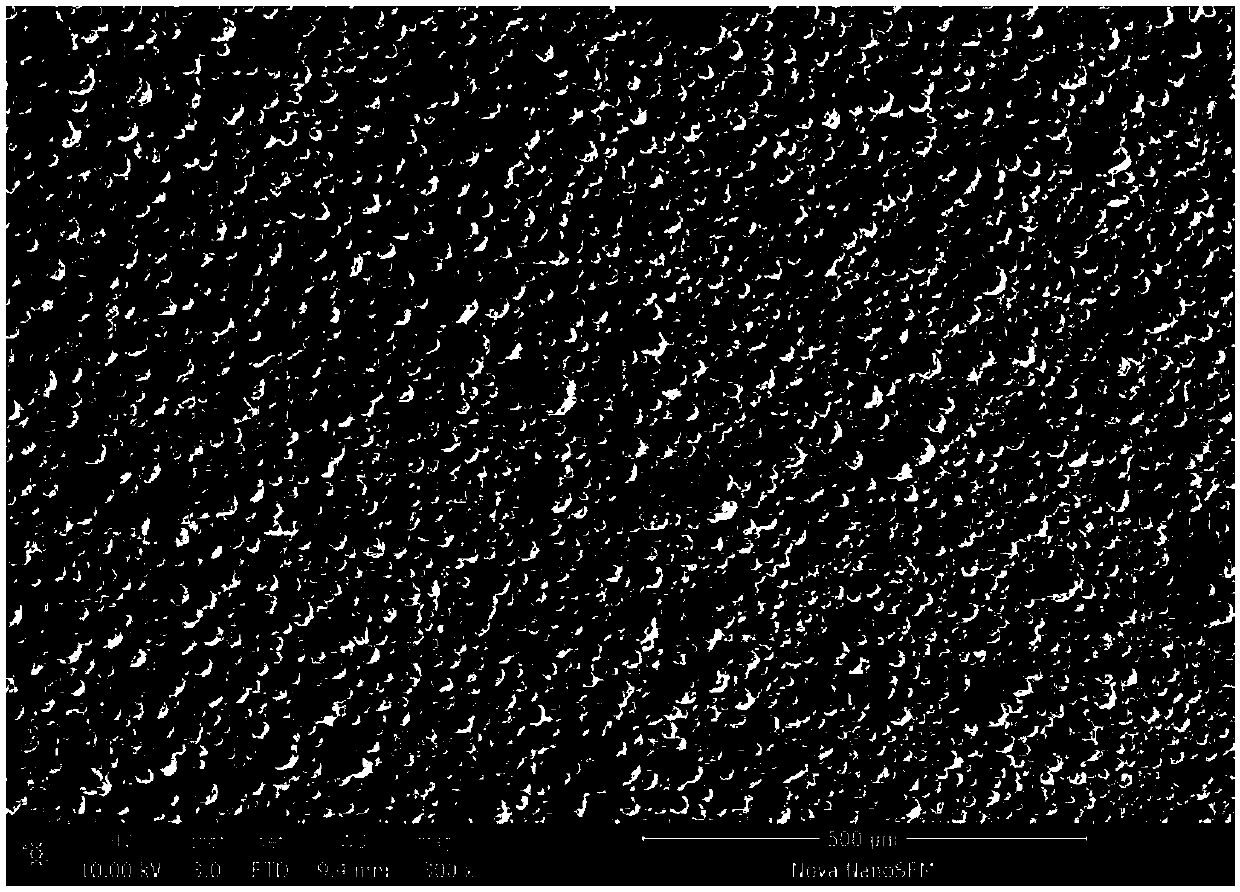

[0034] First, the ratio of alloy powder raw materials (mole fraction): 19.2% iron, 19.2% cobalt, 19.2% chromium, 19.2% nickel, 19.2% manganese, 4% nitrogen, after mixing evenly, carry out ball milling according to the ball milling design process parameters, after ball milling Alloy powder such as figure 1 , The particle shape is spherical or nearly spherical with uniform particle size, and the particle size range is 20-30 μm.

[0035] Secondly, the ball-milled high-entropy alloy powder is placed in a high-strength graphite mold for vacuum hot-press sintering. The sintering process parameters are: heating rate 8°C / min, sintering temperature 900°C, holding time 1h, constant pressure 50Mpa .

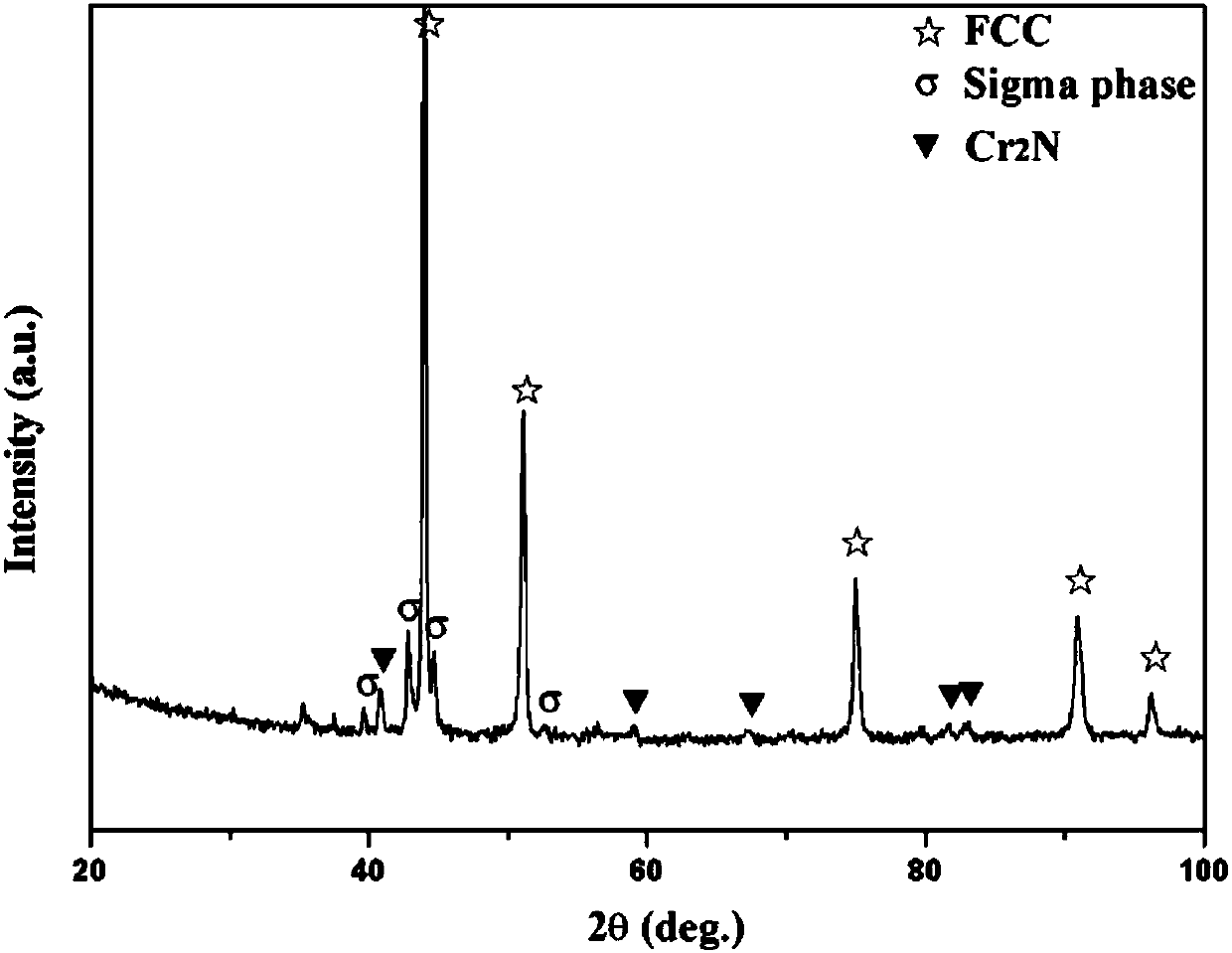

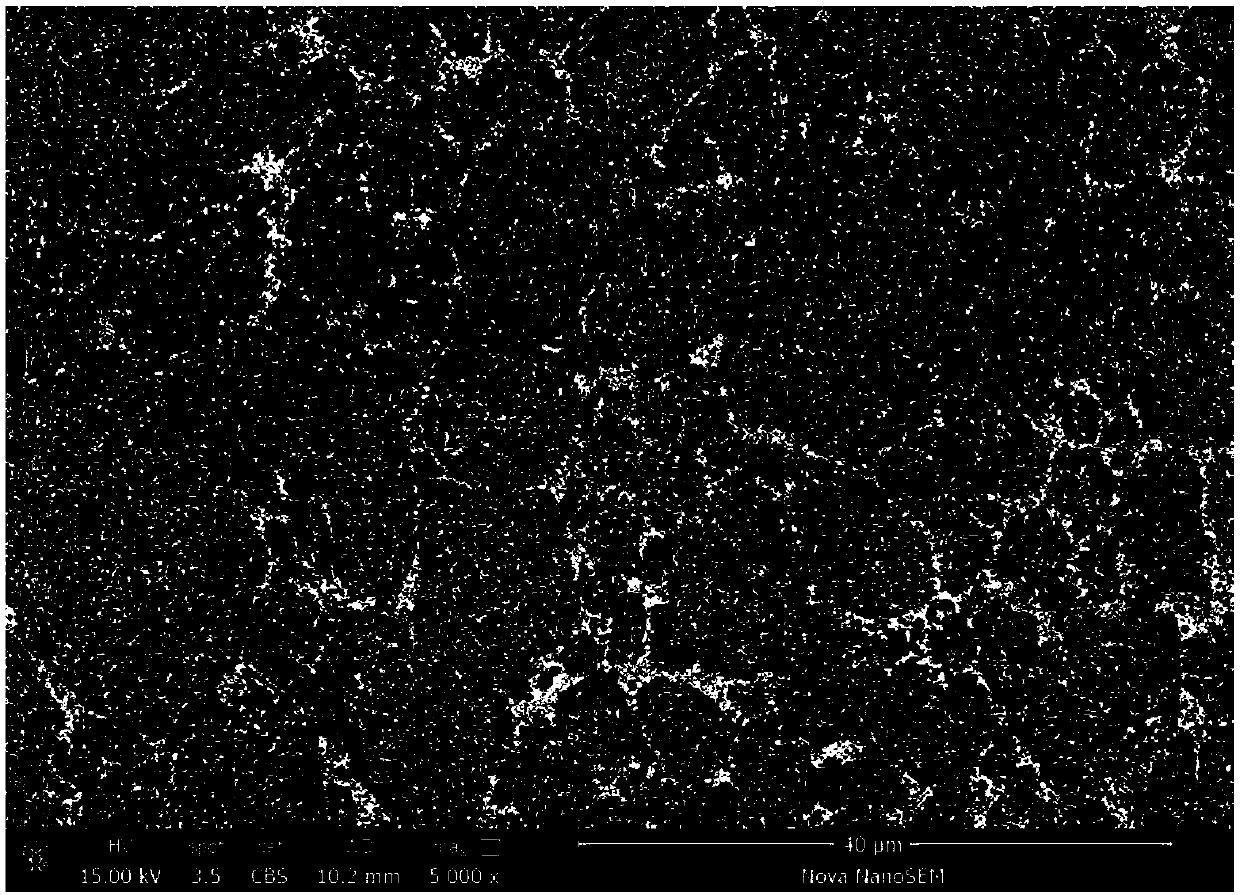

[0036] The XRD spectrum of the sintered bulk high-entropy alloy is as follows: figure 2 As shown, the microstructure morphology (SEM) is as image 3 As shown, the microhardness is 485HV, and its room temperature compressive mechanical properties are as follows Figure 4 , where the com...

no. 2 example

[0039] First, the ratio of alloy powder raw materials (mole fraction): 19.2% iron, 19.2% cobalt, 19.2% chromium, 19.2% nickel, 19.2% manganese, 4% nitrogen, after mixing evenly, carry out ball milling according to the ball milling design process parameters, after ball milling Alloy powder such as figure 1 , The particle shape is spherical or nearly spherical with uniform particle size, and the particle size range is 20-30 μm.

[0040] Secondly, the ball-milled high-entropy alloy powder was placed in a high-strength graphite mold for spark plasma sintering. The sintering process parameters were: heating rate 70°C / min, sintering temperature 900°C, holding time 10min, constant pressure 50Mpa.

[0041] Finally, cool down with the furnace.

no. 3 example

[0043] First, the ratio of alloy powder raw materials (mole fraction): 19.2% iron, 19.2% cobalt, 19.2% chromium, 19.2% nickel, 19.2% manganese, 4% nitrogen, after mixing evenly, carry out ball milling according to the ball milling design process parameters, after ball milling Alloy powder such as figure 1 , The particle shape is spherical or nearly spherical with uniform particle size, and the particle size range is 20-30 μm.

[0044] The ball-milled high-entropy alloy powder is placed in a high-strength graphite mold for vacuum hot isostatic pressing sintering. The sintering process parameters are: heating rate 8°C / min, sintering temperature 900°C, holding time 1h, constant pressure 50MPa .

[0045] Finally, cool down with the furnace.

[0046] The invention adopts a powder metallurgy method to prepare a nitrogen-containing FeCoCrNiMn high-entropy alloy, and uses the powder metallurgy method to obtain a high-entropy alloy with uniform structure and fine crystal grains, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com