Patents

Literature

374 results about "Automotive manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

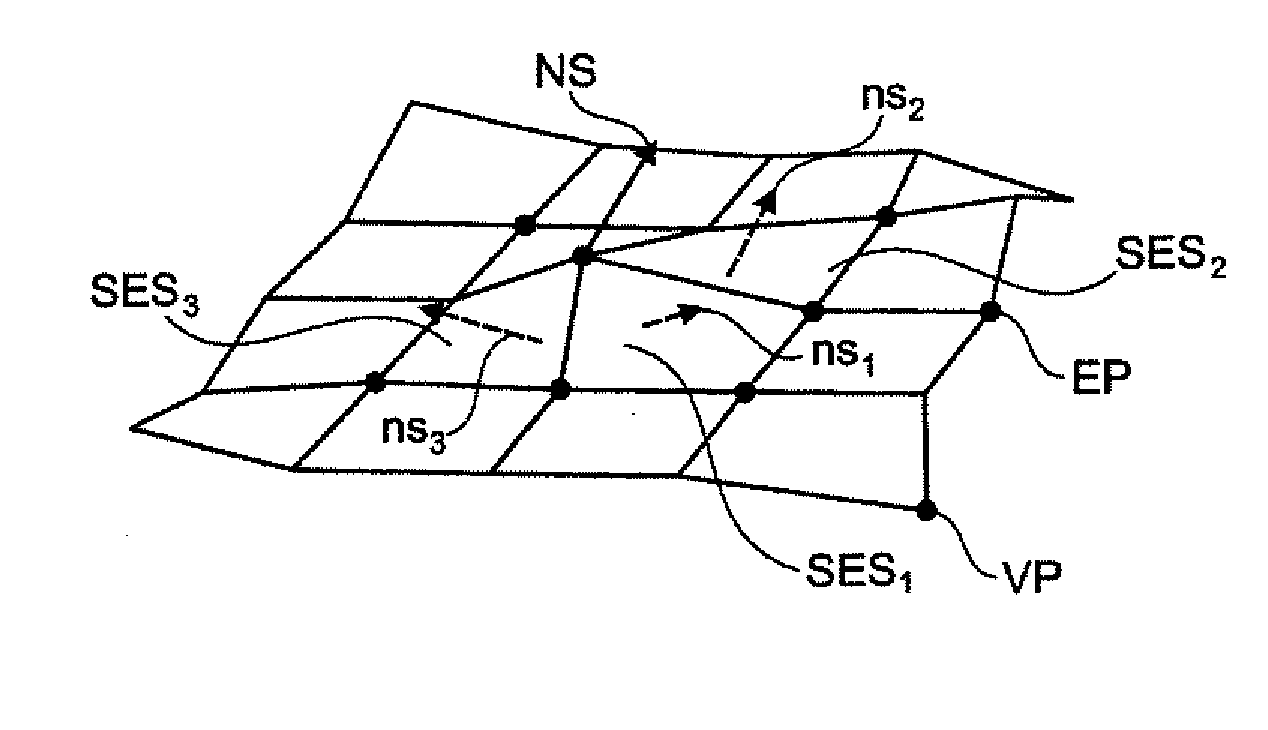

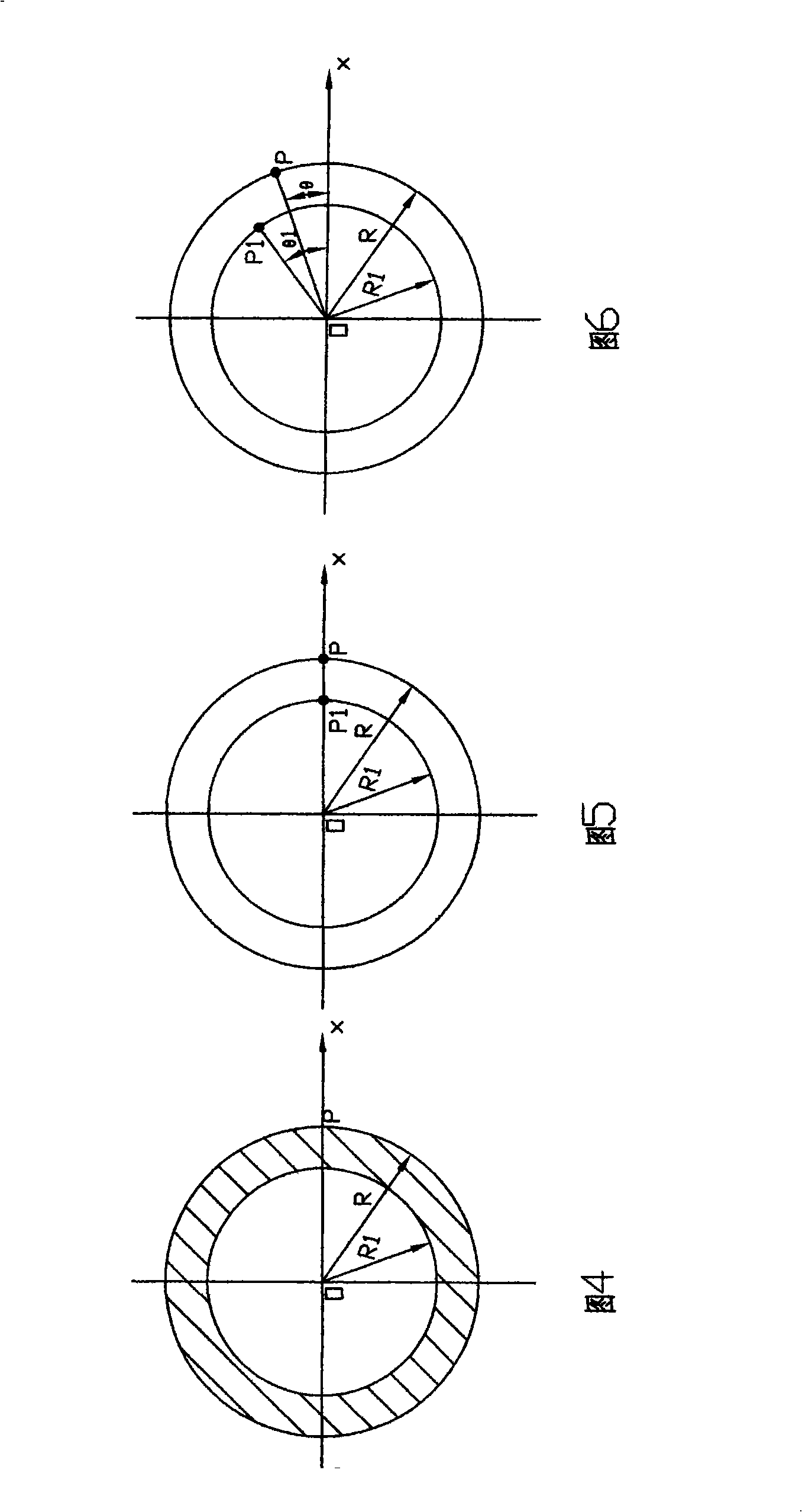

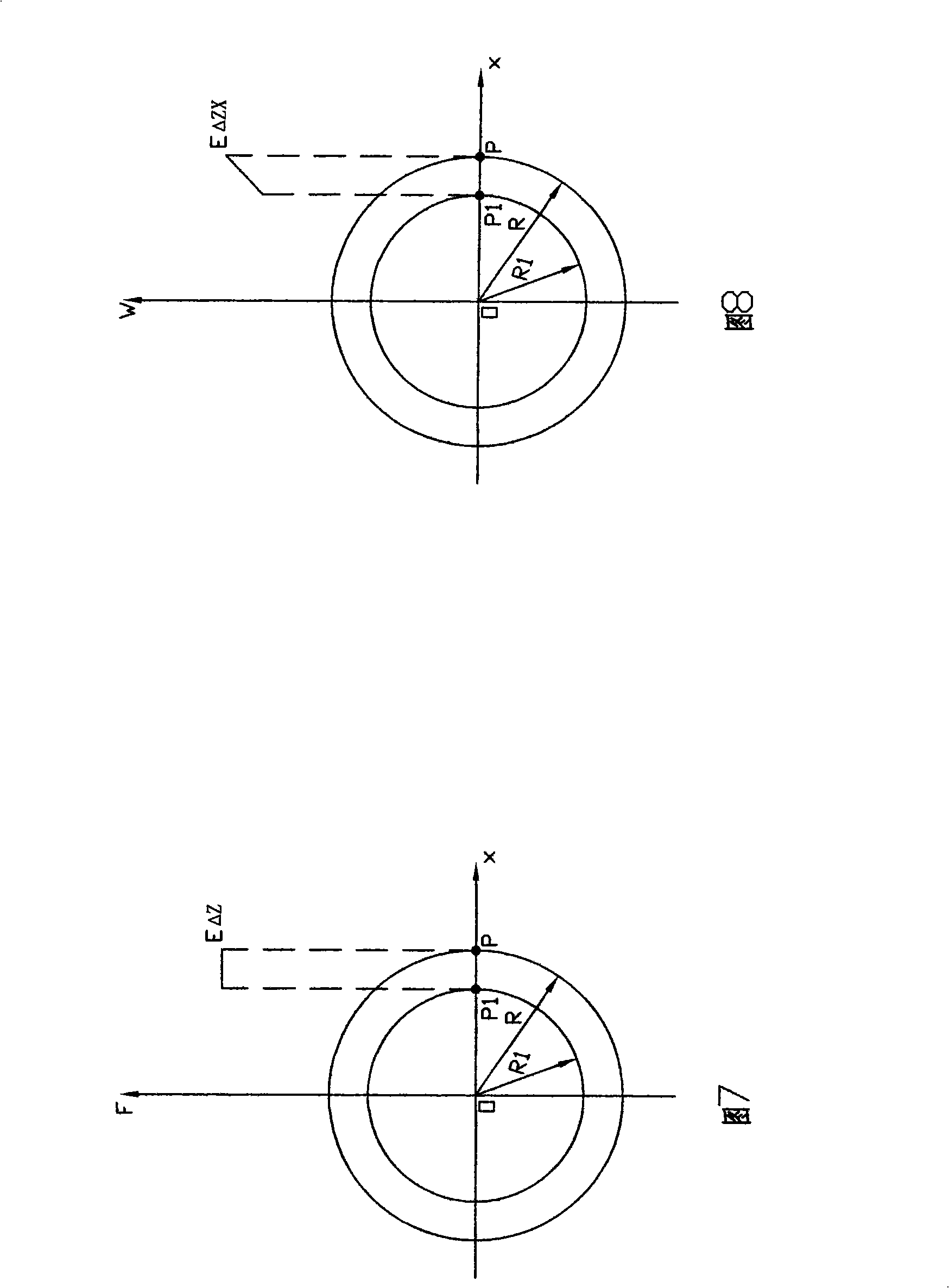

Method of visualizing geometric uncertainties

InactiveUS20100268515A1Rapid assessmentEfficient executionComputation using non-denominational number representationComplex mathematical operationsMesh geometryTest procedures

A method of constructing an enveloping mesh geometry (EMG) for a plurality of sample mesh geometries (MG). The enveloping mesh geometry is a geometric representation of the mean of the probability distribution underlying the sample space from which the enveloping mesh geometry (MG) have been drawn. The method is based on estimating probability densities fj using the kernel density method. The method further comprises constructing, based on the enveloping mesh geometry (EMG) so constructed, further enveloping mesh geometries (EMG-α) related to the α-Quantiles of the probability distribution. The enveloping mesh geometries (EMG, MG-α) are suitable for development and test procedures in aircraft and automotive manufacturing processes.

Owner:EADS DEUT GMBH

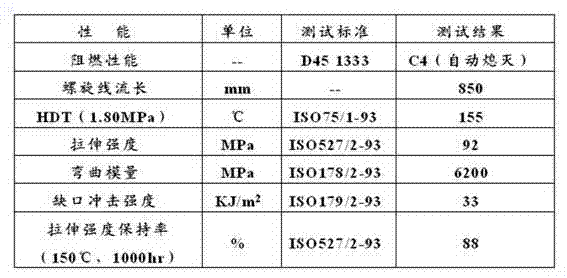

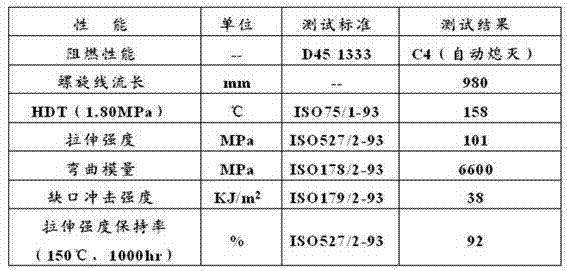

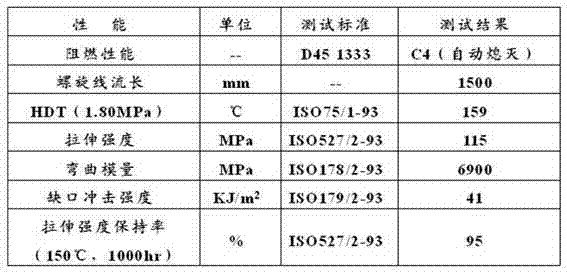

Halogen-free flame-retardant long glass fiber reinforced polypropylene material and preparation method thereof

The invention relates to a halogen-free flame-retardant long glass fiber reinforced polypropylene material, which comprises the following raw materials in percentage by weight: 49 to 88.8 percent of polypropylene, 0.1 to 0.5 percent of thermal stabilizer, 0.1 to 0.5 percent of lubricating agent, 5 to 20 percent of halogen-free flame retardant, 1 to 5 percent of glass fiber compatilizer and 5 to 25 percent of long glass fiber, wherein the polypropylene is high fluidity polypropylene. The invention also relates to a preparation method for the polypropylene material. The preparation method comprises the following steps of: preparing a long glass fiber master batch and a halogen-free flame-retardant master batch, mixing the two master batches uniformly, and thus obtaining the polypropylene material, wherein when the polypropylene material is used, the polypropylene material is directly used for injection molding of parts. The polypropylene material has excellent flame-retardant property and dimensional stability, high mechanical strength, low shrinkage rate and good creep resistance and thermal oxidation resistance, is suitable for injection molding of thin-wall large pieces and automotive part products with complex structures such as automotive engine bottom guard plates, front-end modules, instrument panel frameworks and the like, saves the automobile manufacturing cost, and is environment-friendly.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

780MPa-grade cold-rolled hot-dip galvanized dual-phase steel and preparation method thereof

InactiveCN102433509AChemically stableHigh strengthHot-dipping/immersion processesUltimate tensile strengthDual-phase steel

The invention provides 780MPa-grade cold-rolled hot-dip galvanized dual-phase steel which comprises the following chemical components by weight percent: 0.10%-0.15% of C, not more than 0.05% of Si, 1.8%-2.0% of Mn, 0.03%-0.04% of Nb, 0.2%-0.35% of Cr, 0.2%-0.25% of Mo, not more than 0.01% of P, not more than 0.01% of S, 0.02%-0.07% of Alt, not more than 0.005% of N and the balance of Fe and impurities. The invention further discloses a preparation method of the cold-rolled dual-phase steel. The dual-phase steel produced according to the chemical components and the preparation method provided by the invention is stable in chemical components and has high strength and excellent elongation rate; and the dual-phase steel can reduce the dead weight of an automobile, reduce oil consumption and further increase the corrosion resistance of the automobile when the dual-phase steel is applied to automobile manufacturing industry.

Owner:SHOUGANG CORPORATION

Super-high strength cold rolled steel and manufacturing method thereof

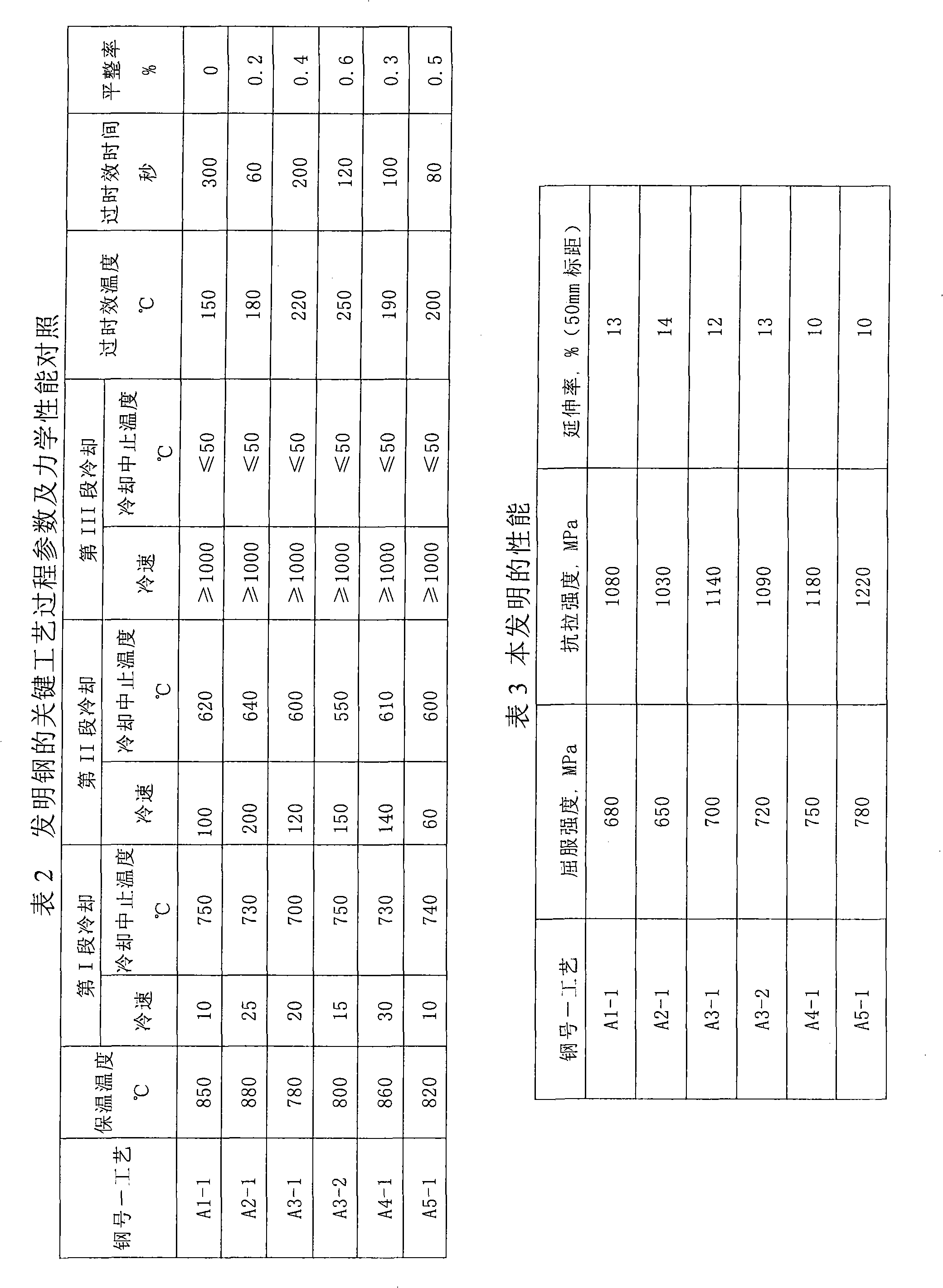

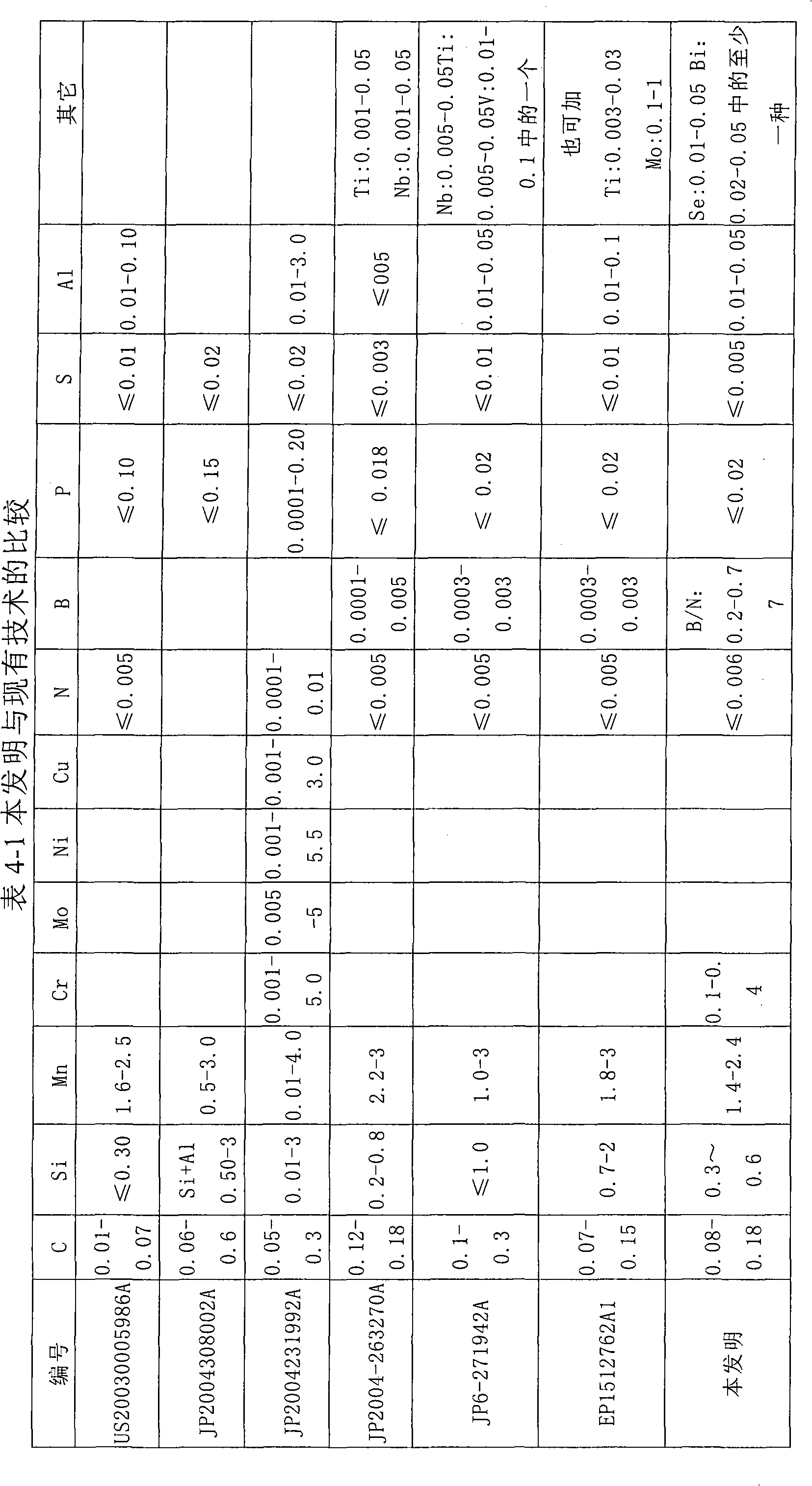

The invention discloses super-high strength cold rolled steel or steel plate, which comprises the following chemical components in percent by weight: 0.08 to 0.18 percent of C, 0.1 to 0.6 percent of Si, 1.4 to 2.4 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, 0.01 to 0.05 percent of A1, less than or equal to 0.006 percent of N, 0.2 to 0.77 percent of B / N and the balance of Fe and inevitable impurities. A manufacturing method for the super-high strength cold rolled steel comprises the following steps: performing hot rolling, wherein the finishing temperature is between 830 and 930 DEG C and the coiling temperature is between 550 and 650 DEG C; performing cold rolling, wherein the rolling reduction is 40 to 70 percent; performing continuous annealing, namely holding the temperature between 780 and 880 DEG C, cooling the steel to be between 700 and 750 DEG C with air at a rate of between 10 and 30 DEG C / s, cooling the steel to be between 550 and 640 DEG C by air blast at the cooling rate of between 60 and 200 DEG C / s, cooling the steel to be below 100 DEG C at the cooling rate greater than 500 DEG C / s and heating the steel to be between 150 and 250 DEG C to perform tempering for 60 to 300s; washing the steel with weak acid; and levelling the steel by 0 to 0.6 percent. Thus the obtained super-high strength band steel or steel plate with high processability can be applied to structures or enhanced parts for automobile manufacturing.

Owner:BAOSHAN IRON & STEEL CO LTD

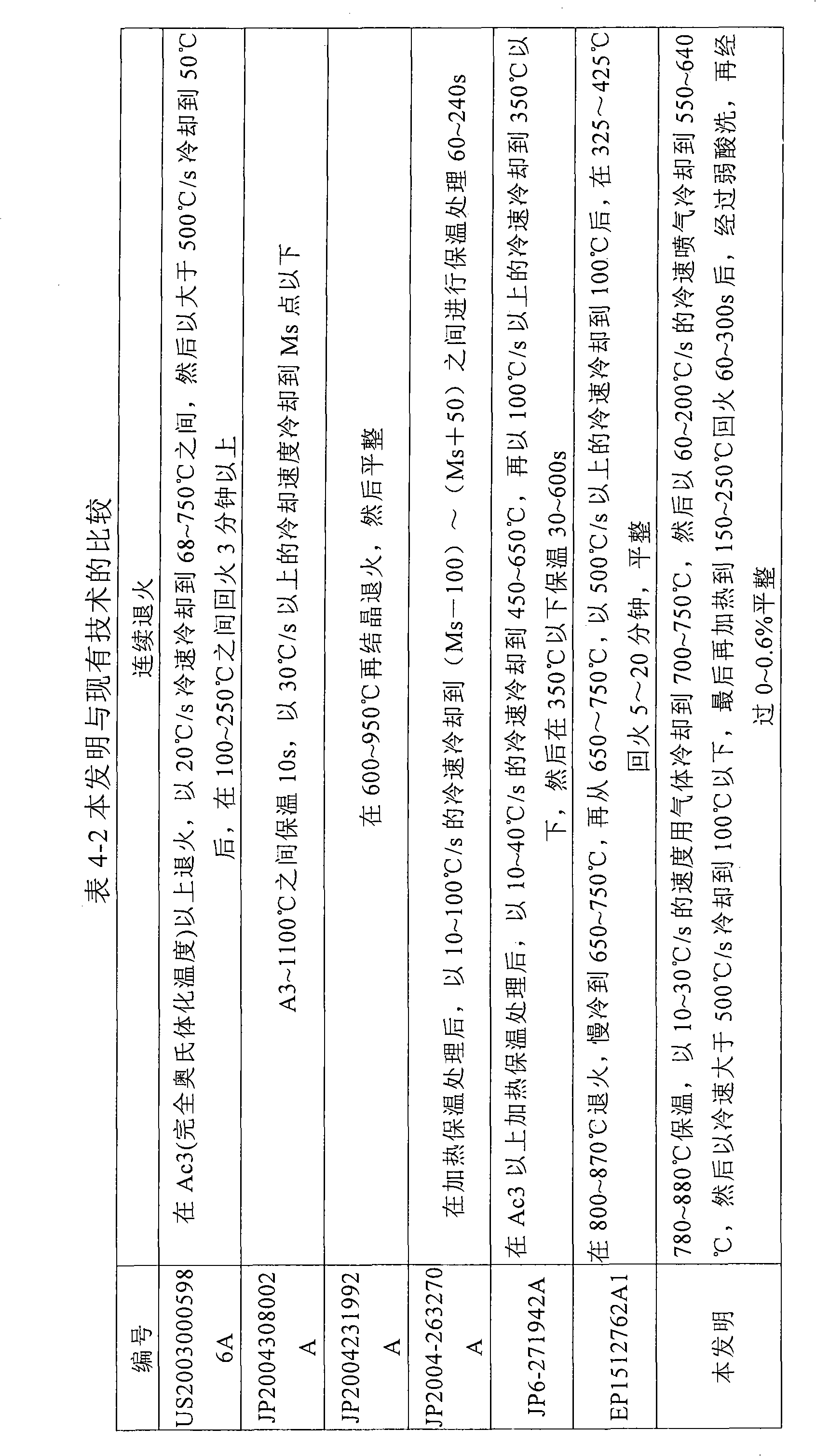

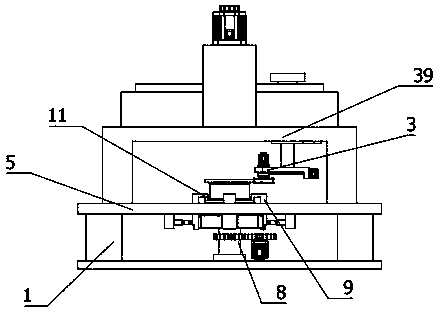

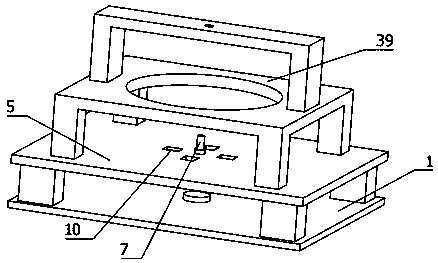

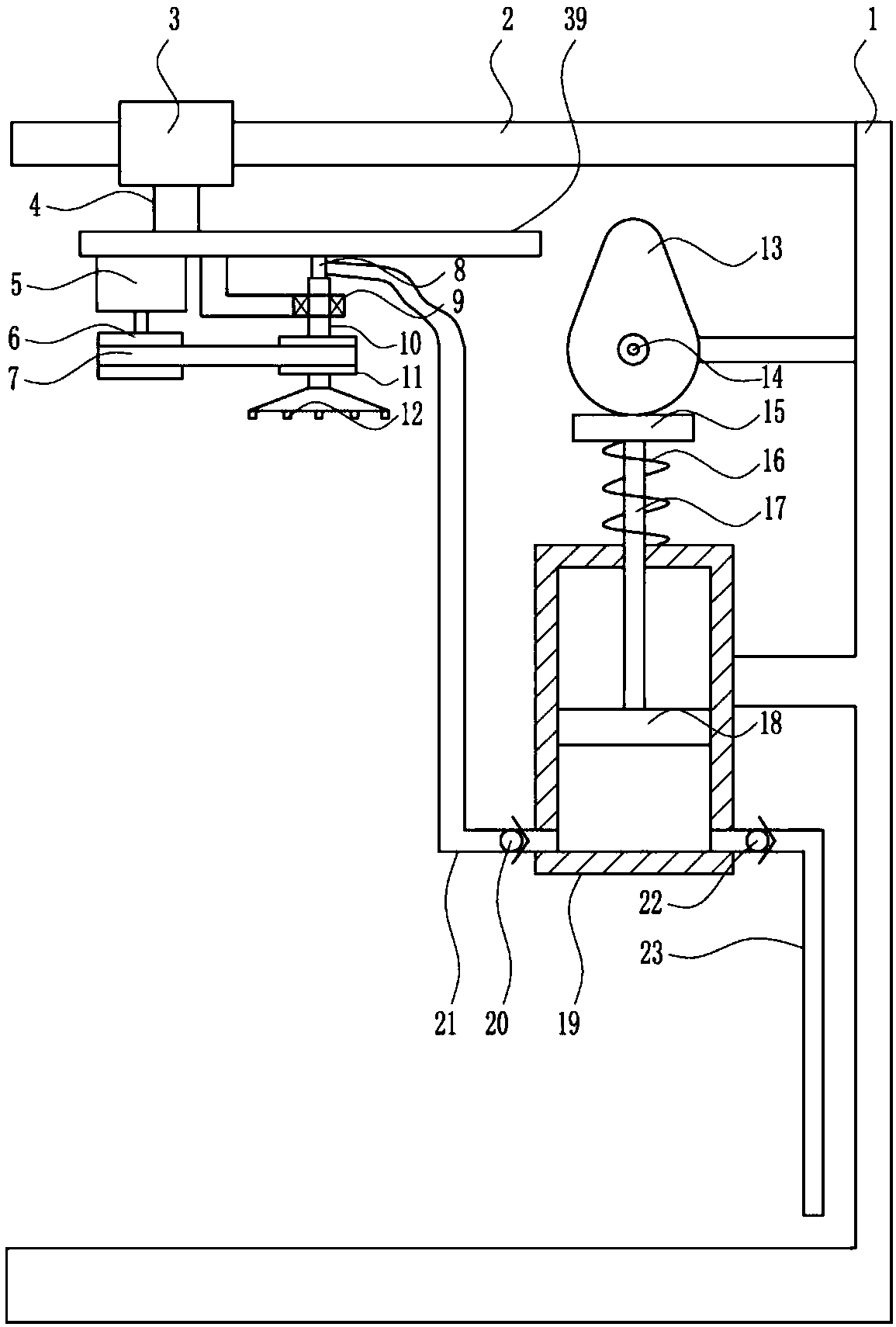

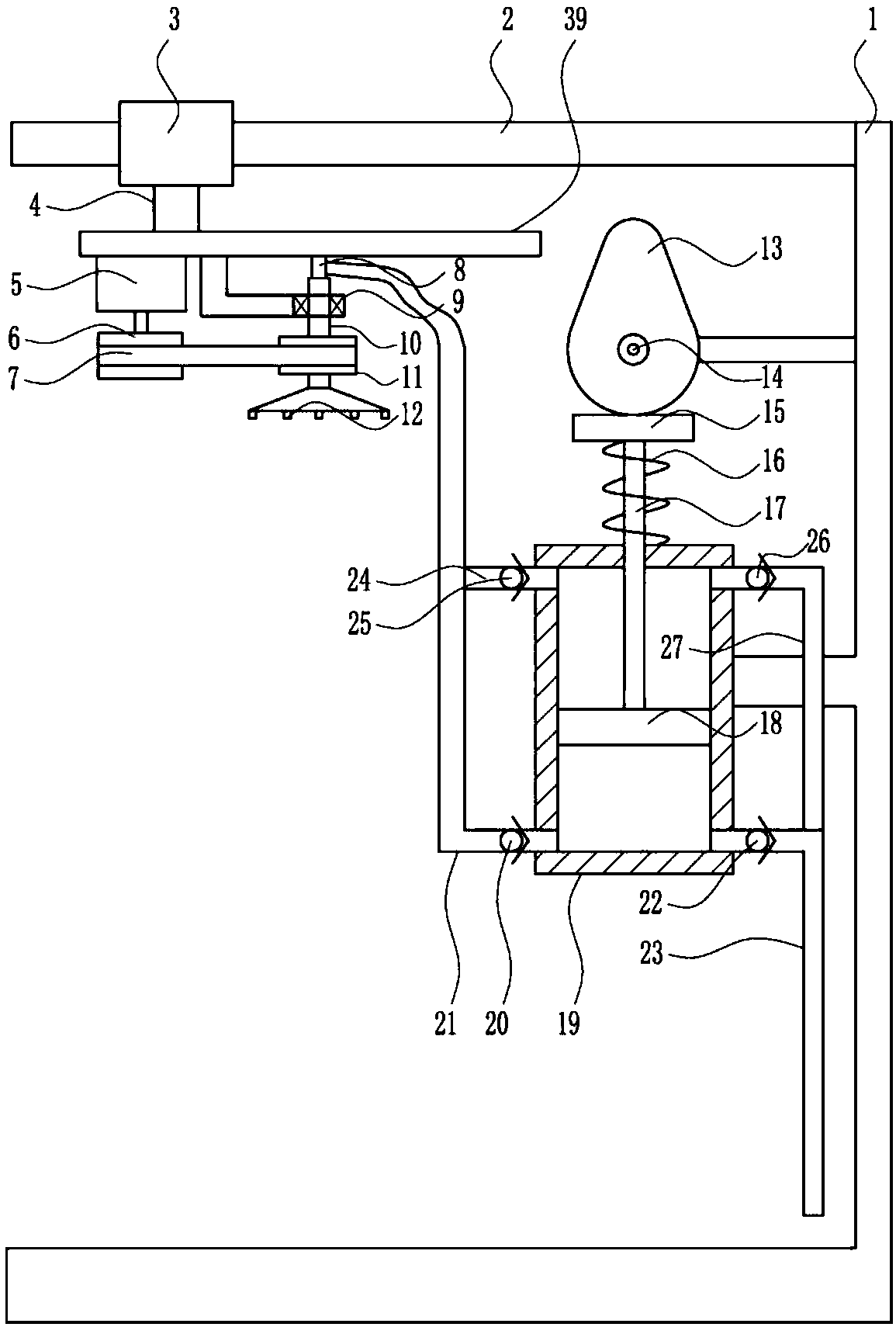

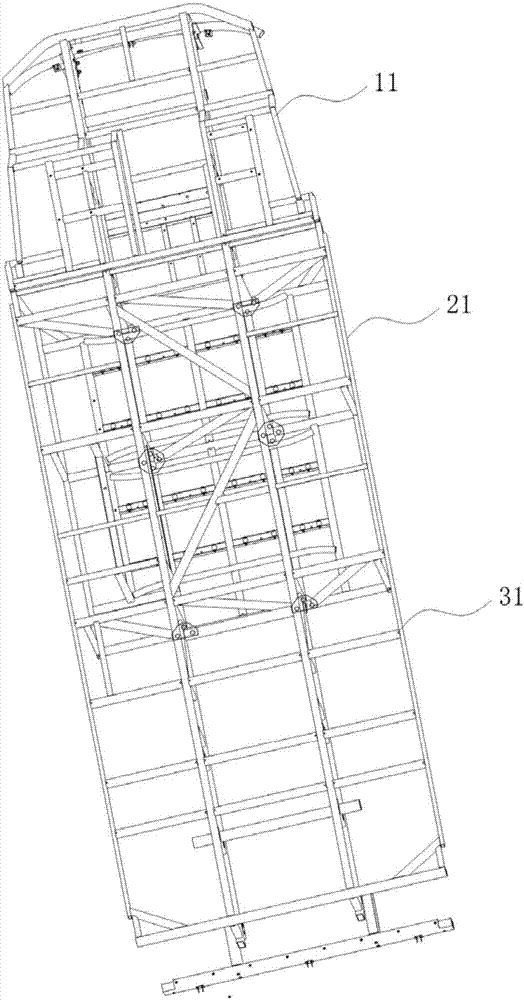

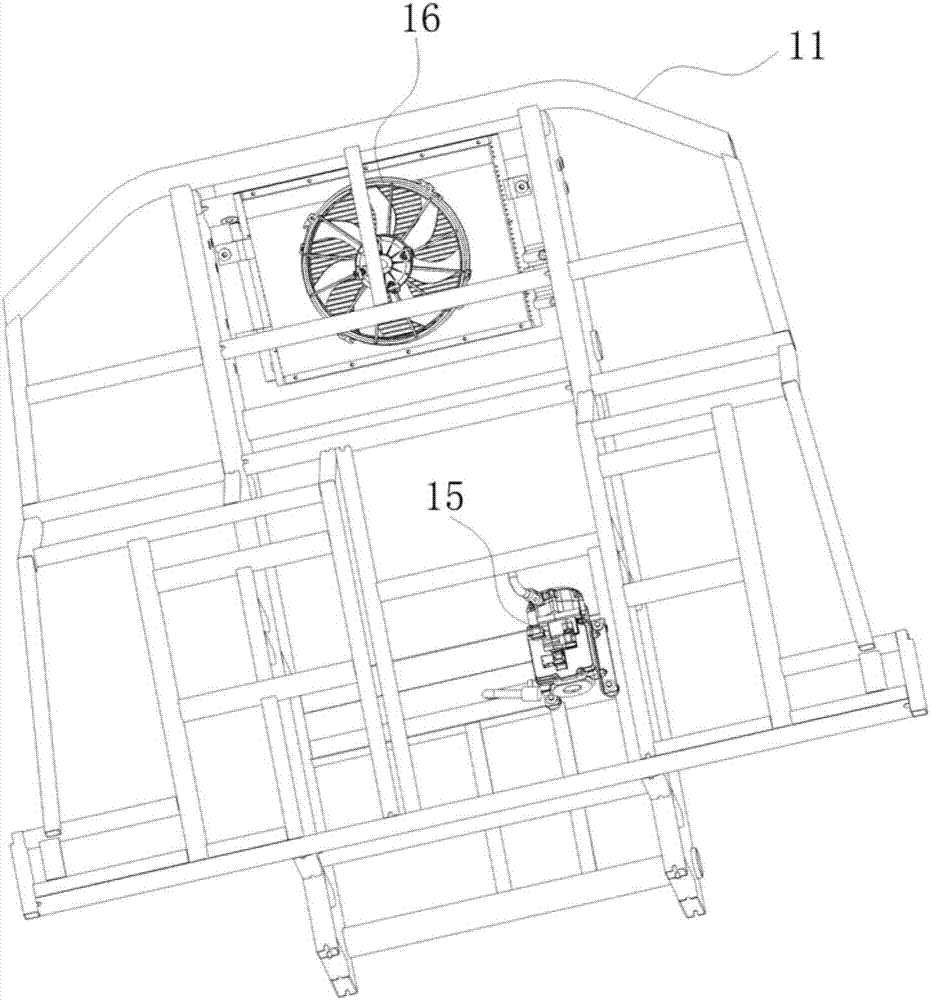

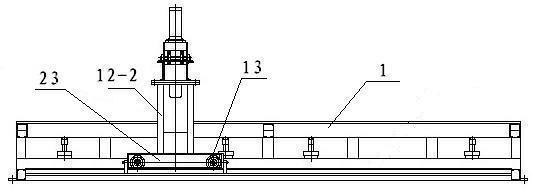

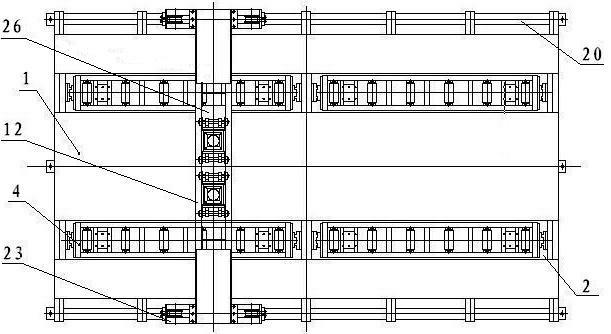

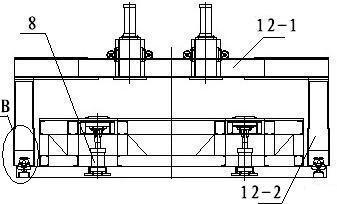

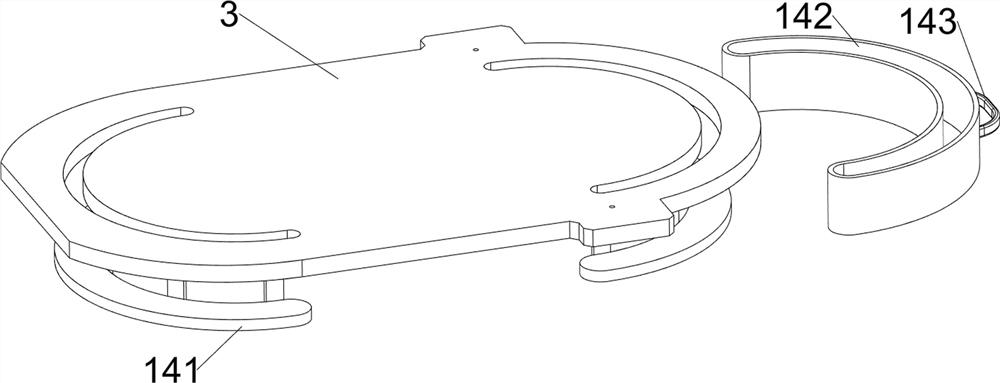

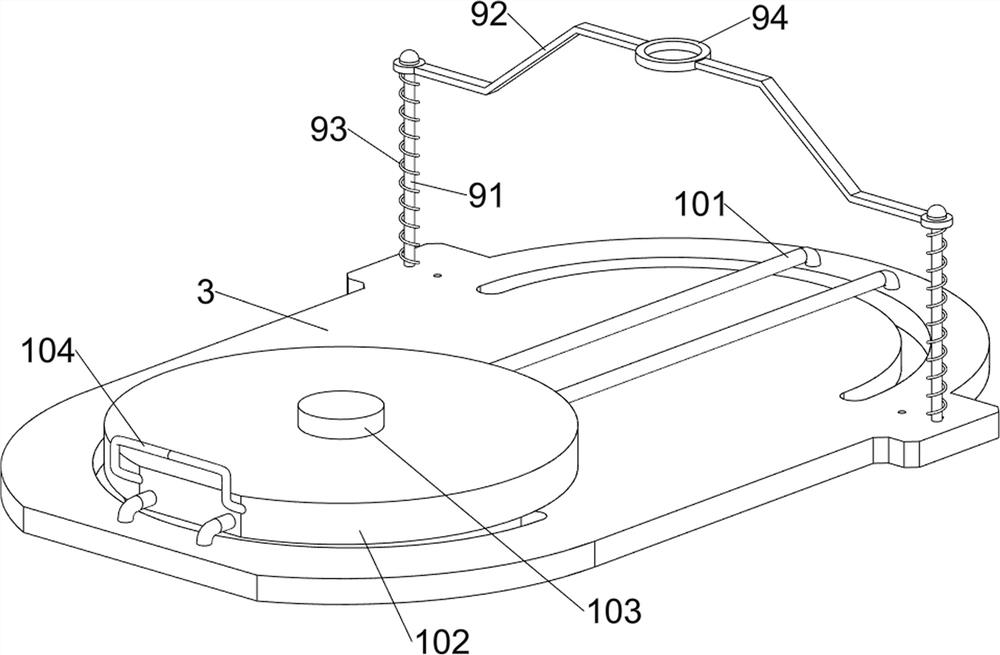

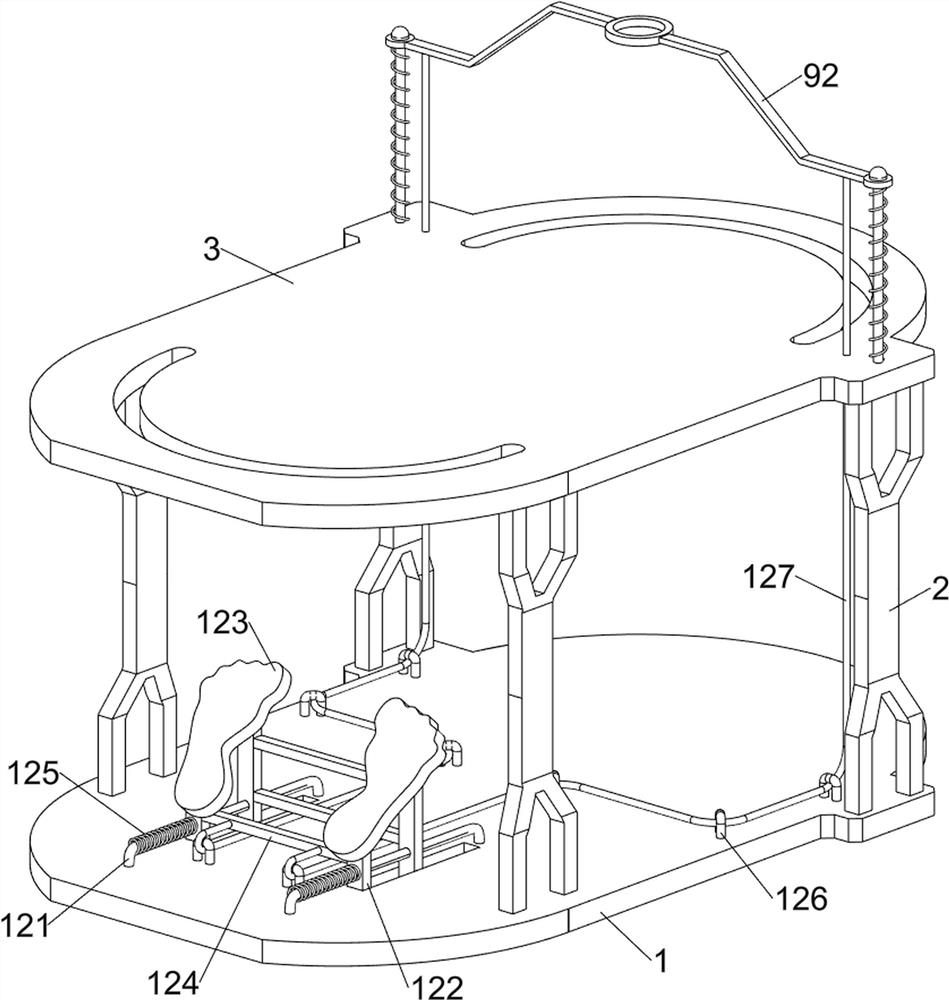

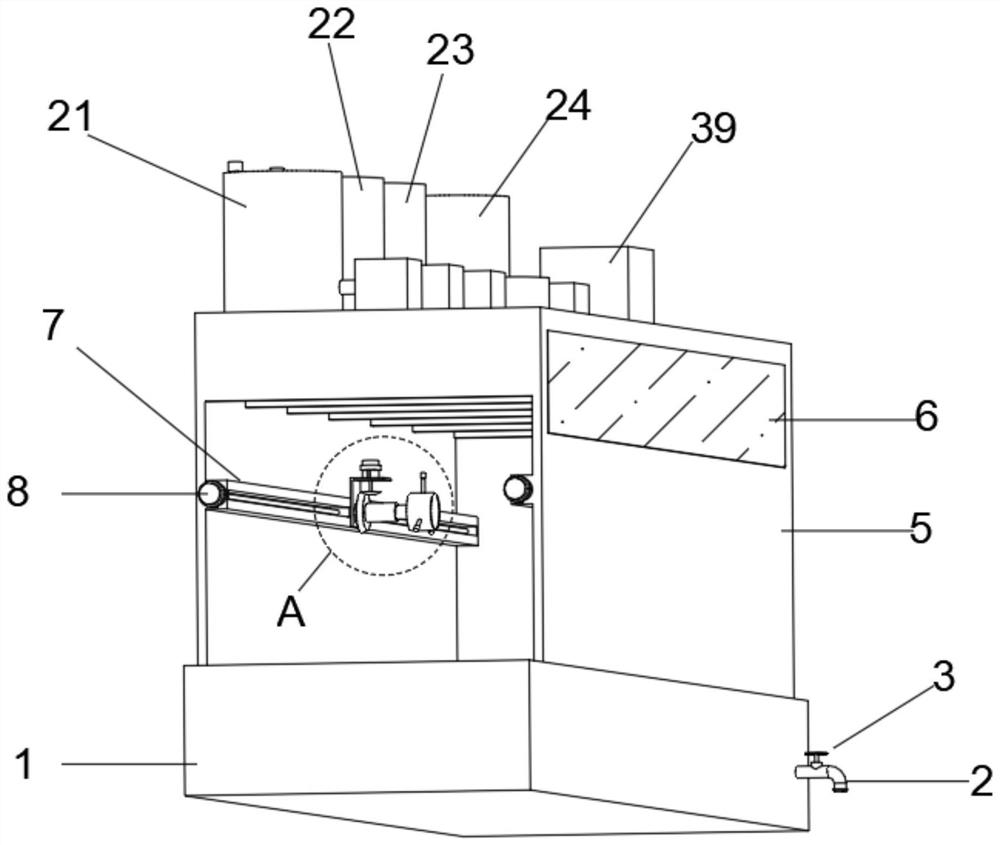

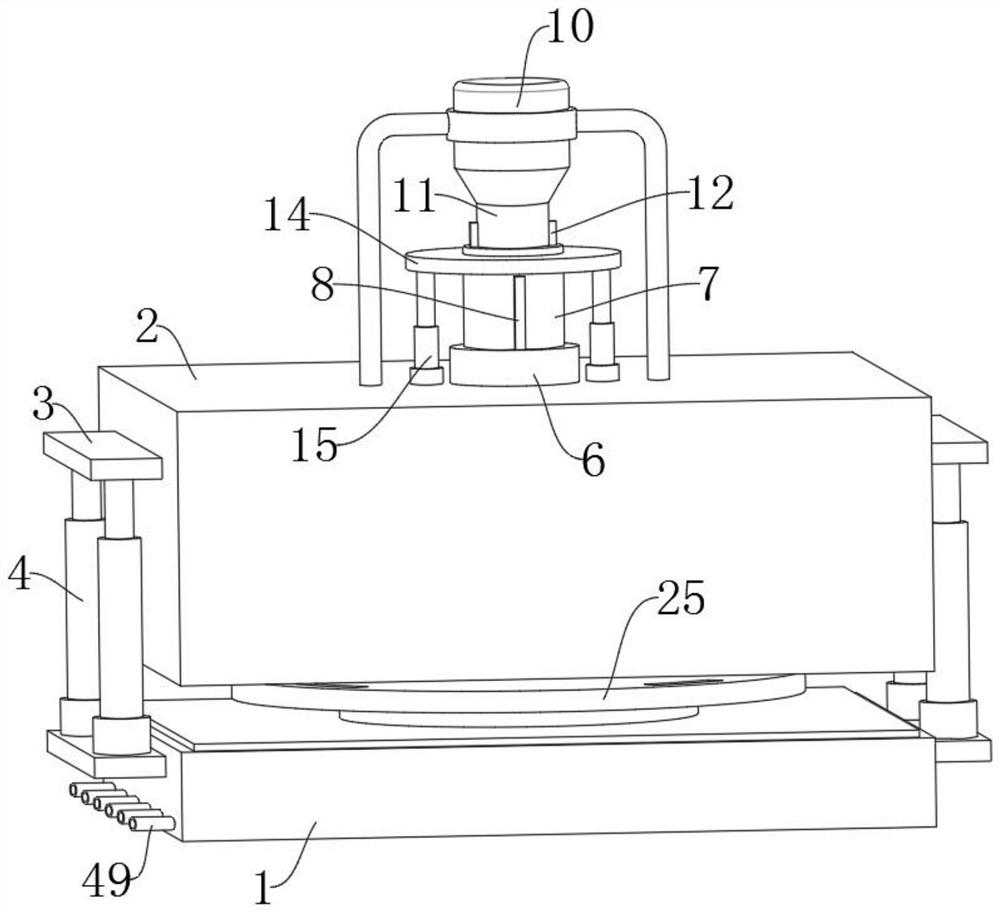

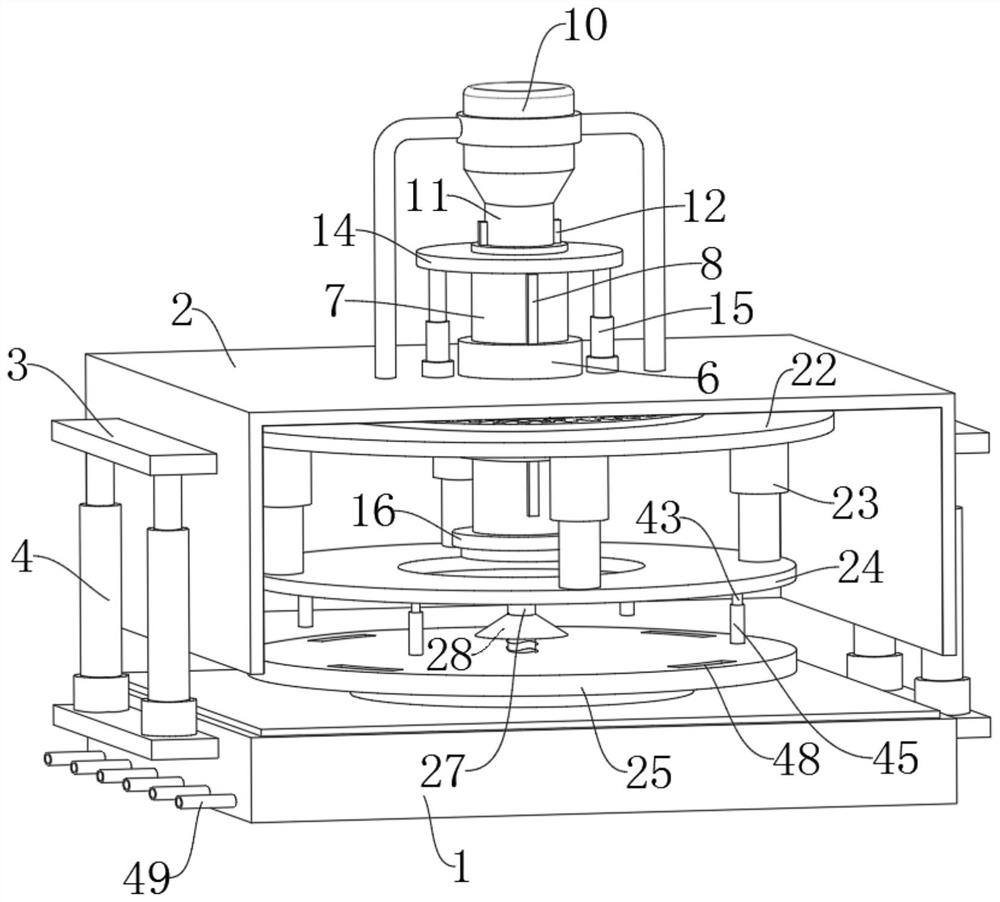

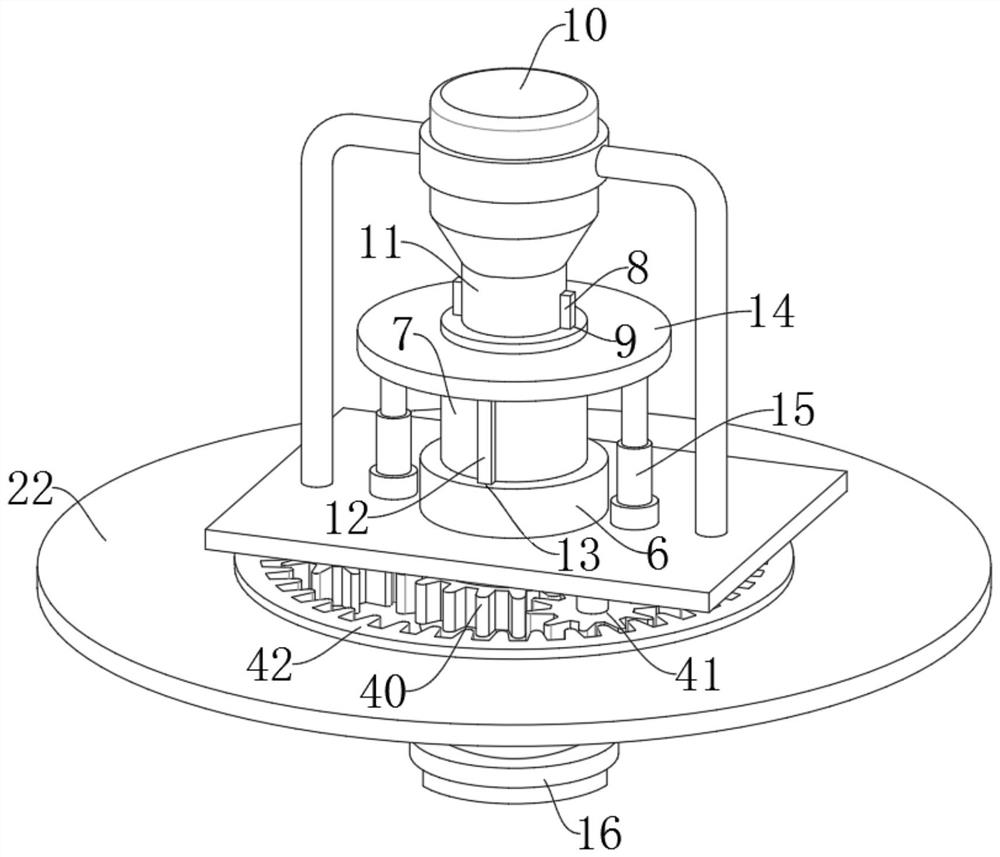

High-precision positioning, clamping and polishing equipment for multiple types of hubs

ActiveCN111085916AGrinding is precise and fastWith automatic production capacityEdge grinding machinesGrinding carriagesEngineeringMachine

The invention relates to the field of automobile manufacturing, in particular to high-precision positioning, clamping and polishing equipment for multiple types of hubs. The equipment comprises a machine frame, a positioning and clamping mechanism, a polishing mechanism and a rotary driving mechanism. A working platform is horizontally arranged on the machine frame, a mounting frame is arranged atthe top of the machine frame, the mounting frame is positioned over the working platform, the positioning and clamping mechanism is installed inside the machine frame and positioned below the workingplatform, the rotary driving mechanism is installed at the top of the mounting frame, the polishing mechanism is arranged at the output end of the rotary driving mechanism, and the polishing mechanism comprises a polishing head capable of polishing the outer edges of the hubs. The high-precision positioning, clamping and polishing equipment for the multiple types of hubs can machine different types of hubs, has automatic production capacity, greatly reduces labor intensity, can accurately and quickly polish the outer edges of the hubs, improves product quality, improves working efficiency, improves equipment applicability, and reduces production cost.

Owner:杭州润德车轮制造有限公司

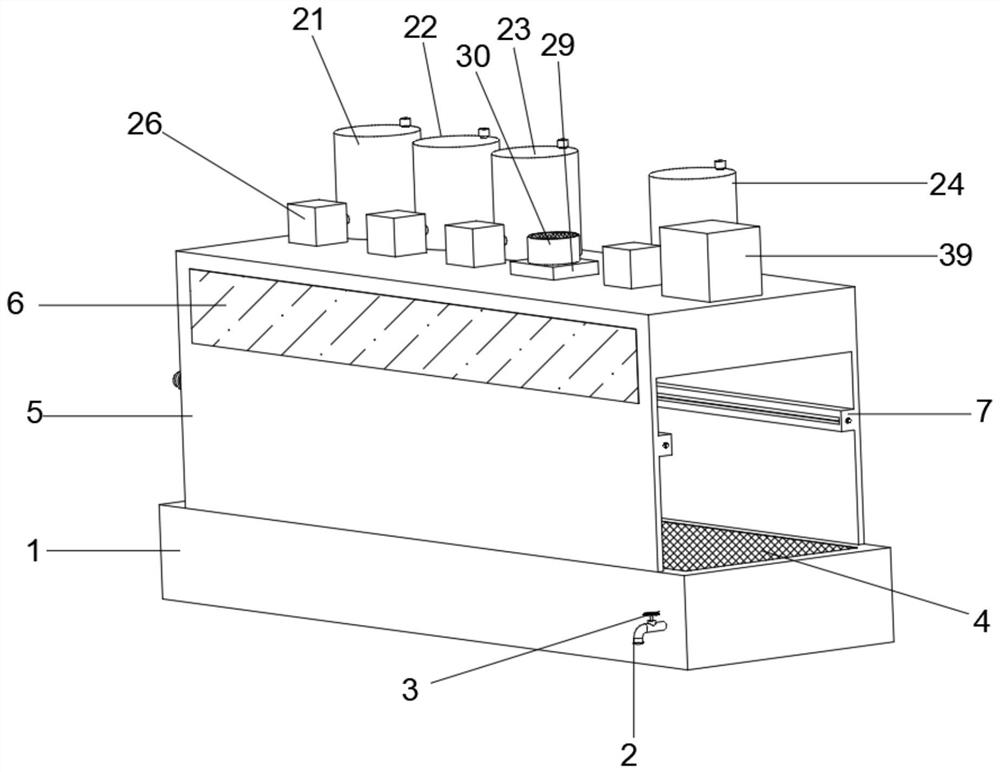

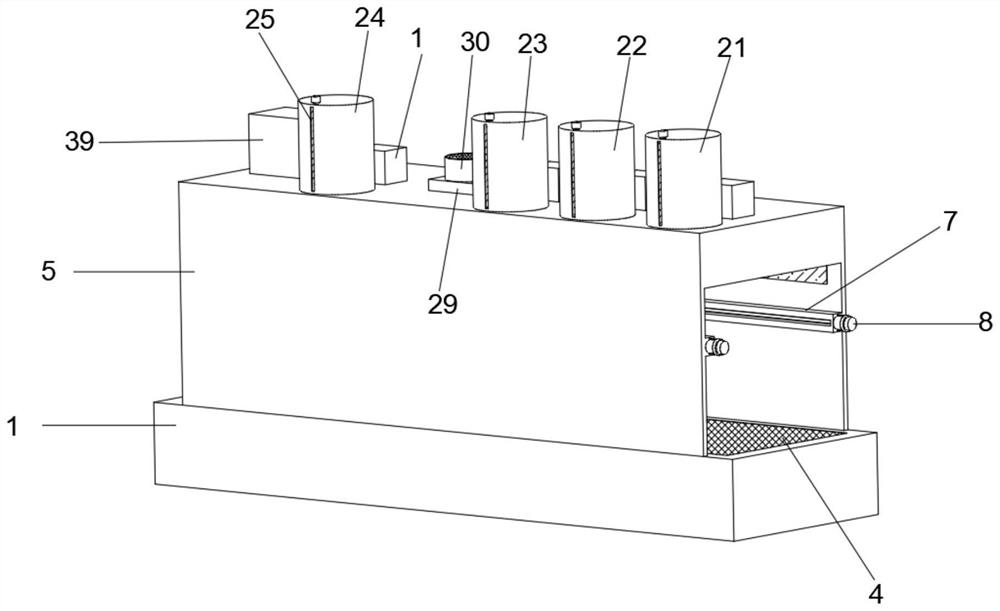

Part surface paint spraying device for automobile manufacturing

ActiveCN108080188ANice appearanceEnsure personal safetySpraying apparatusFixed frameMotor vehicle part

The invention relates to a paint spraying device, in particular to a part surface paint spraying device for automobile manufacturing and aims to realize convenience in use, labor saving and time saving of the part surface paint spraying device for automobile manufacturing. The part surface paint spraying device for automobile manufacturing comprises a fixing frame, a slide rod, a slide sleeve, a first connection block, a first motor, a first belt pulley, a first connection belt, a connection pipe, a first bearing, a hollow rotating shaft and the like. The slide sleeve is slidably mounted on the slide rod which is mounted on the upper portion of the fixing frame, and a supporting plate is mounted at the lower end of the first connection block which is mounted on the lower portion of the slide sleeve. The part surface paint spraying device has advantages of convenience in use, labor saving, time saving, quick in automobile part paint spraying operation, high in practicality and saving ofa great quantity of manpower, processed finished products are attractive in appearance, uniformity in paint spraying and safety in use are achieved, and personal safety of workers is guaranteed.

Owner:广州聚晟宏科技有限公司

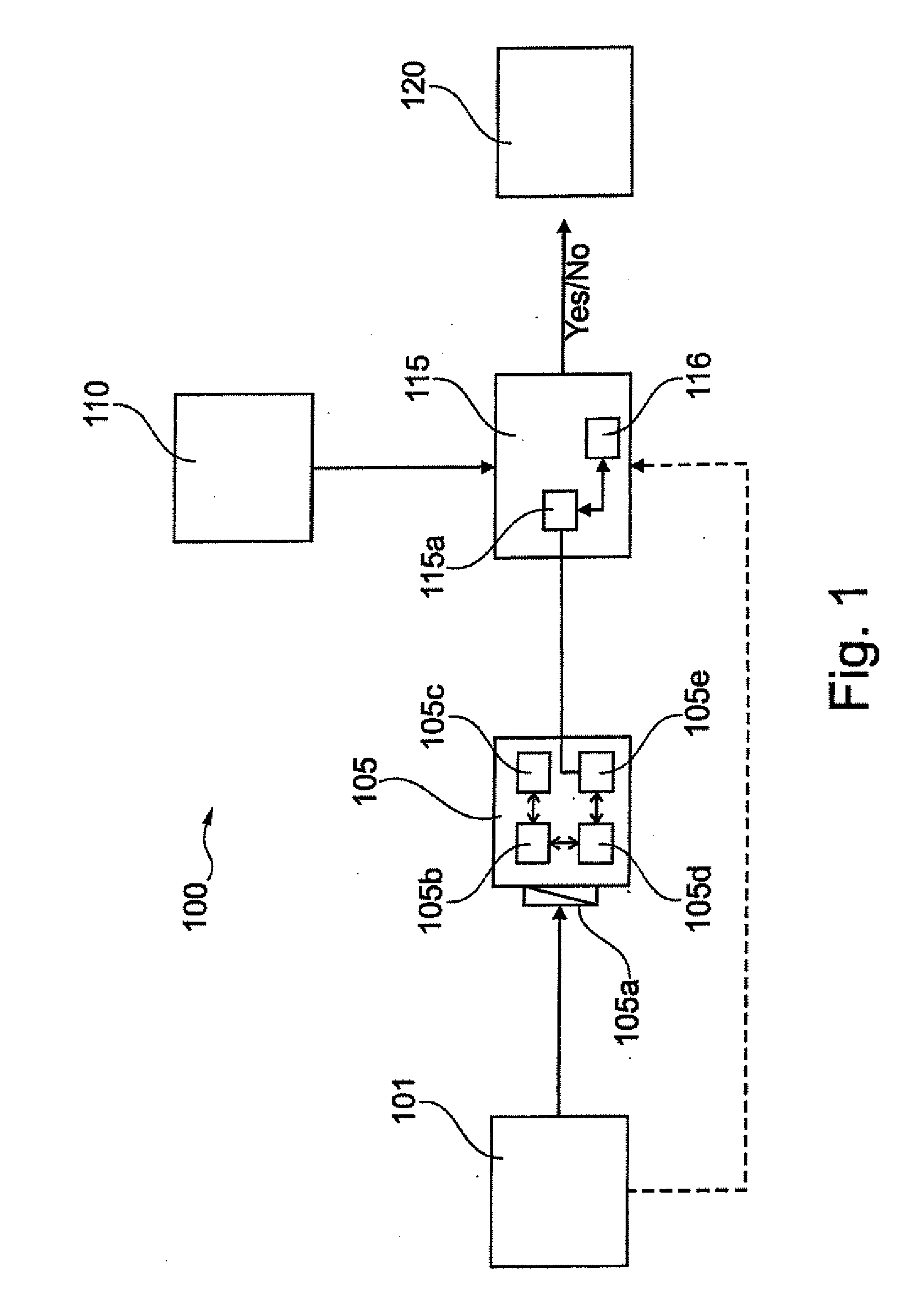

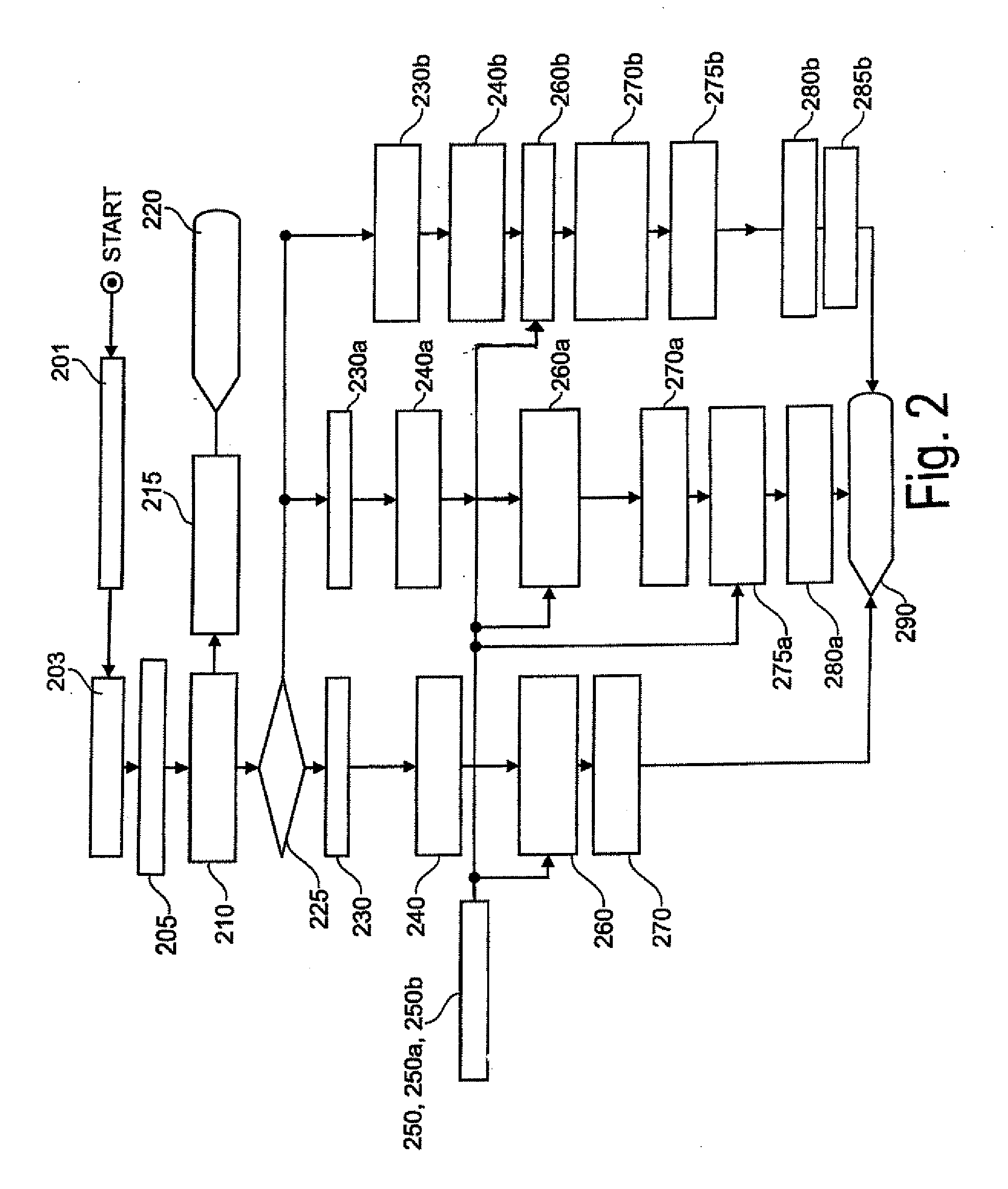

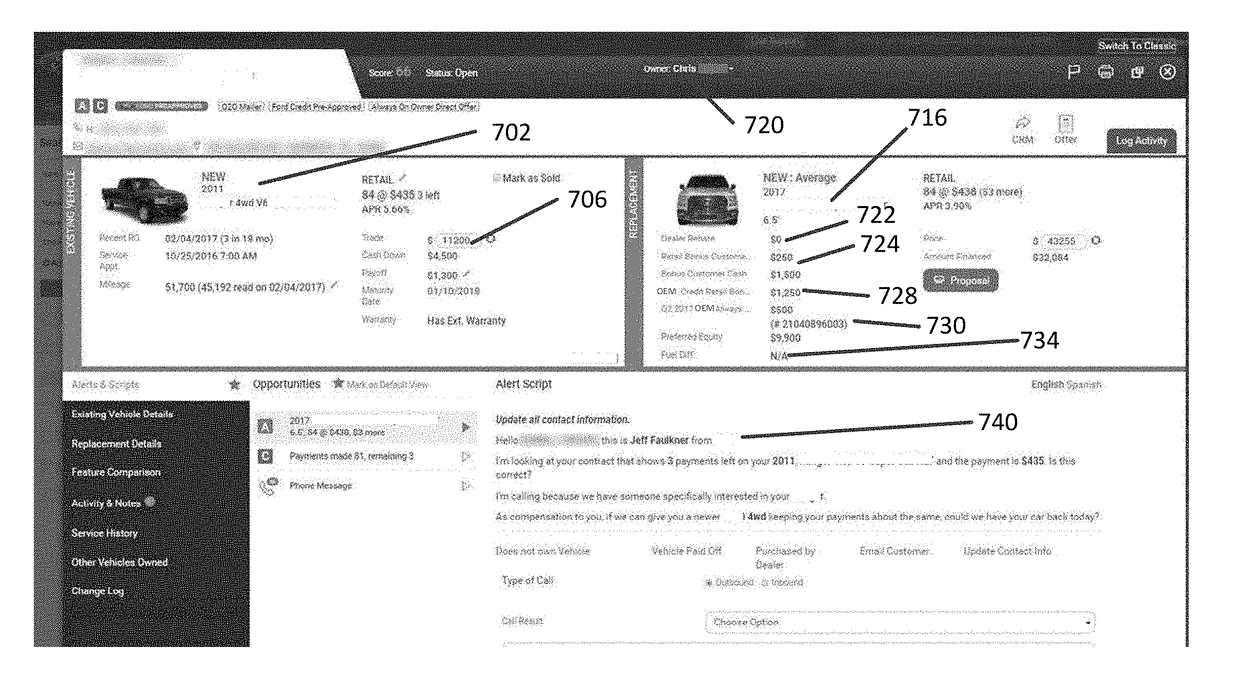

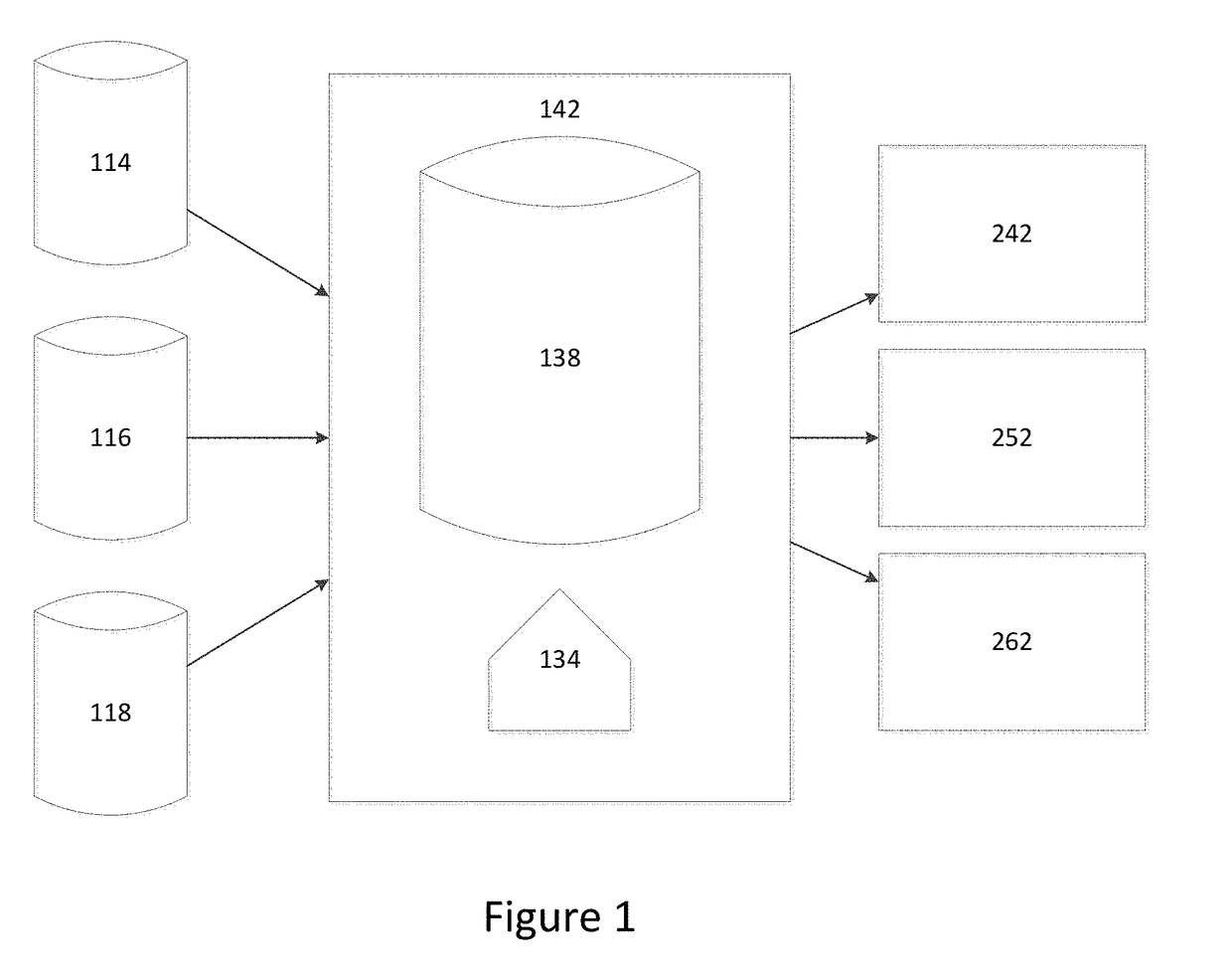

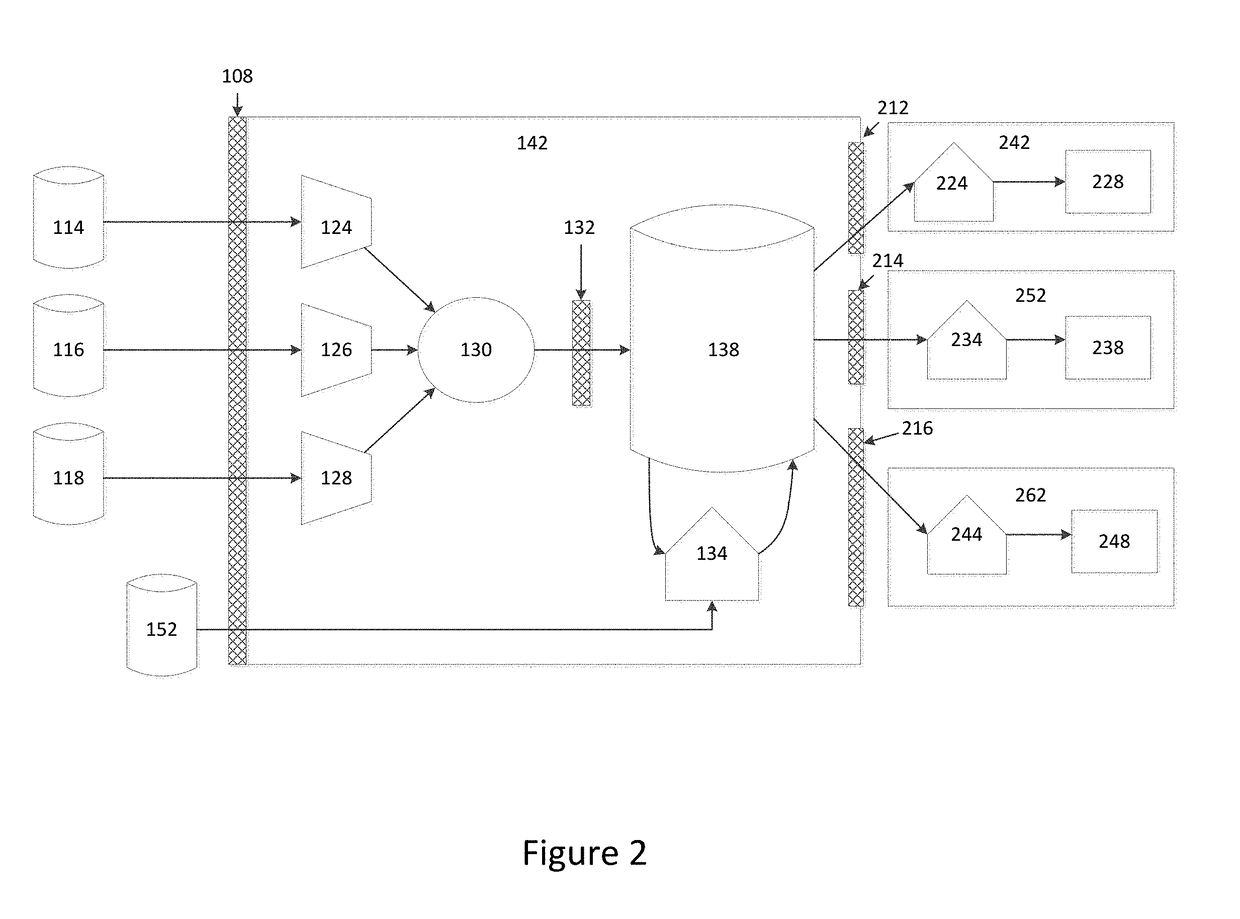

Visual discovery tool for automotive manufacturers with network encryption, data conditioning, and prediction engine

ActiveUS20180108058A1Efficient solutionImplement extensionsCustomer relationshipDigital data information retrievalAuthorization certificateDisplay device

A visual discovery tool for automotive manufacturing with network encryption, data conditioning, and prediction can include an extraction device configured to receive data records from application-specific file source databases. The tool can further include a vehicle alert database that receives the vehicle records from the plurality of extraction databases. The visual discovery tool can include at least one hardware processor in communication with the extraction device and the vehicle alert database. The tool can be configured to selectively restrict access to an interactive display based on whether a client device receives authorization credentials.

Owner:AUTOALERT

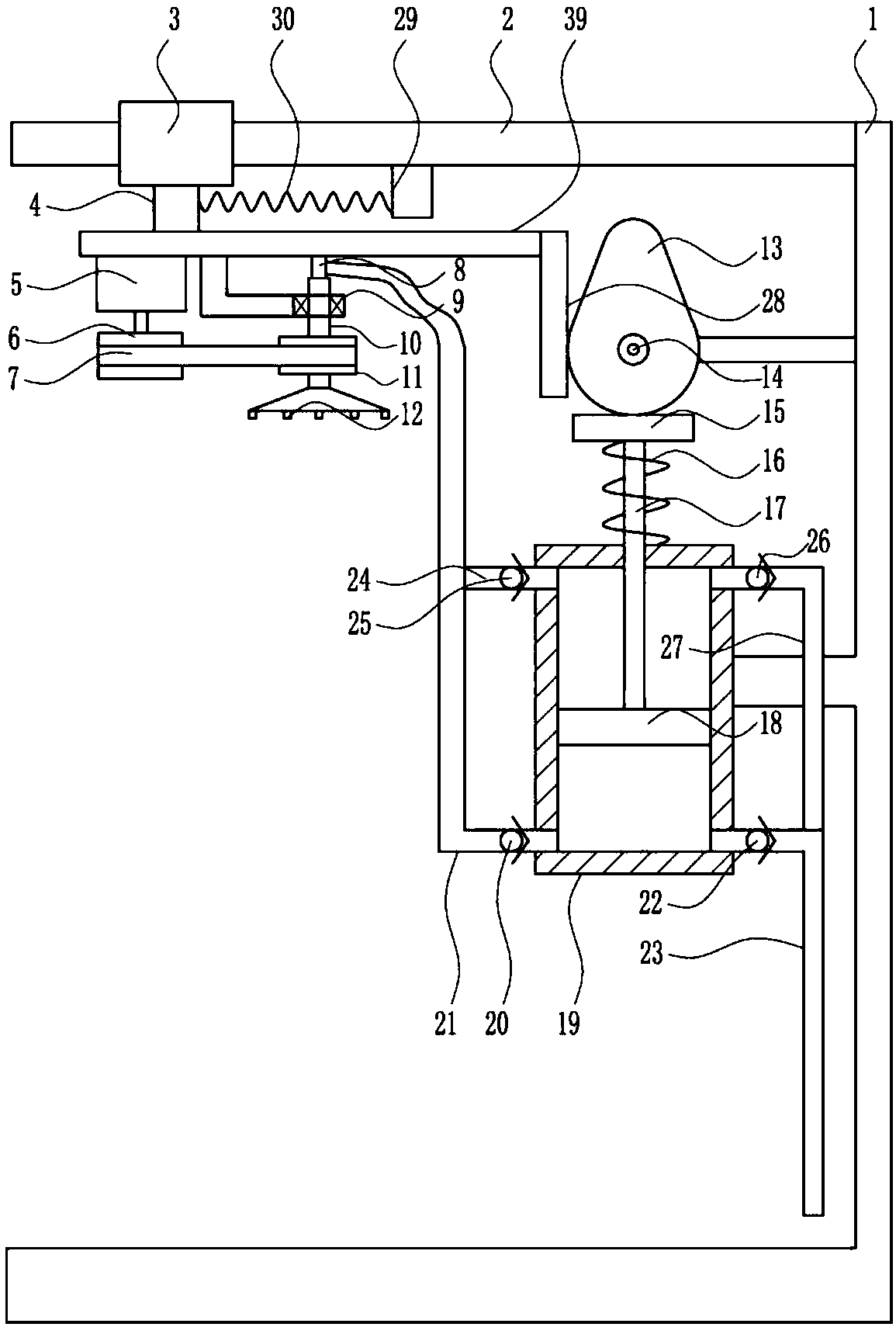

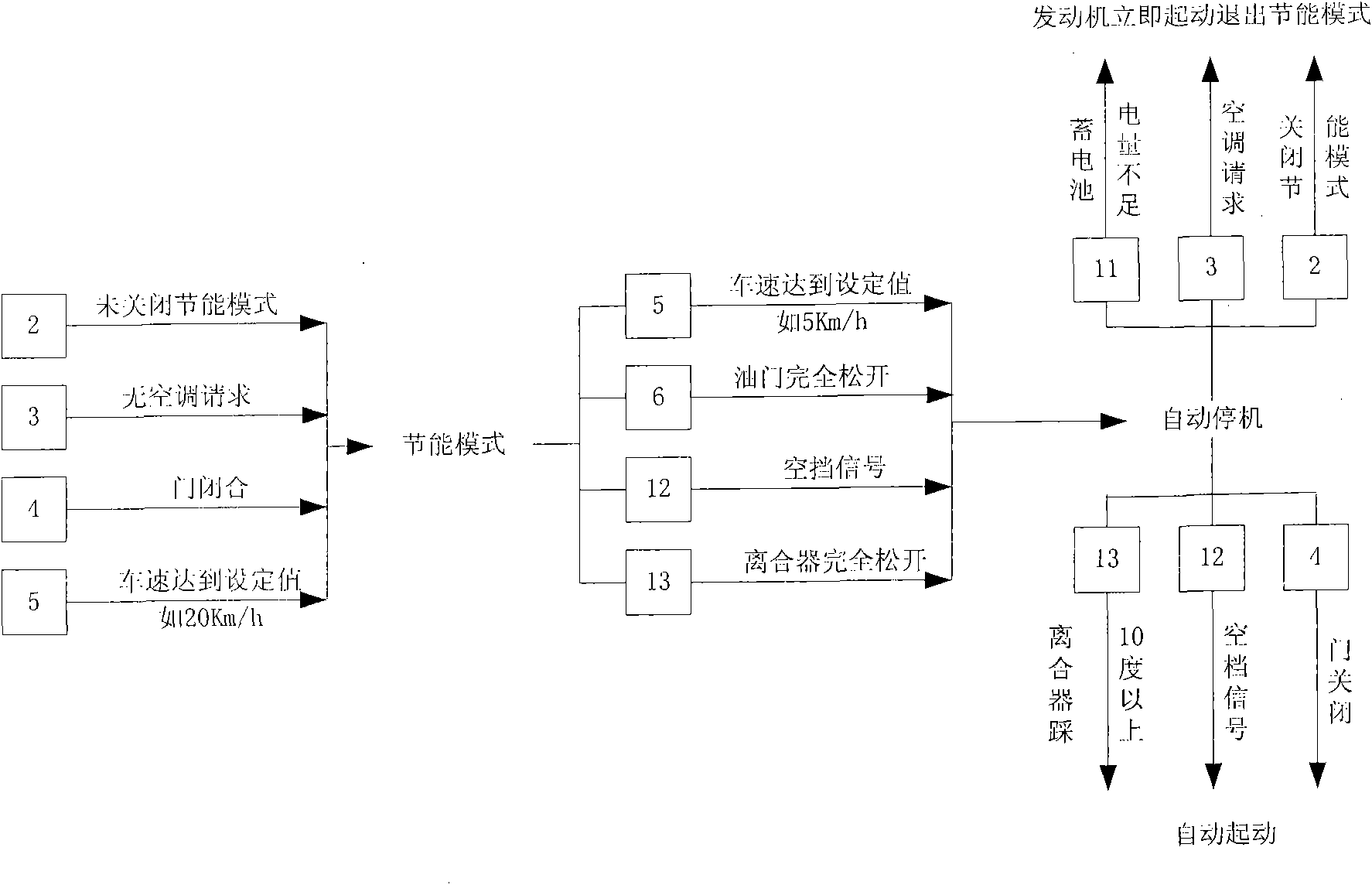

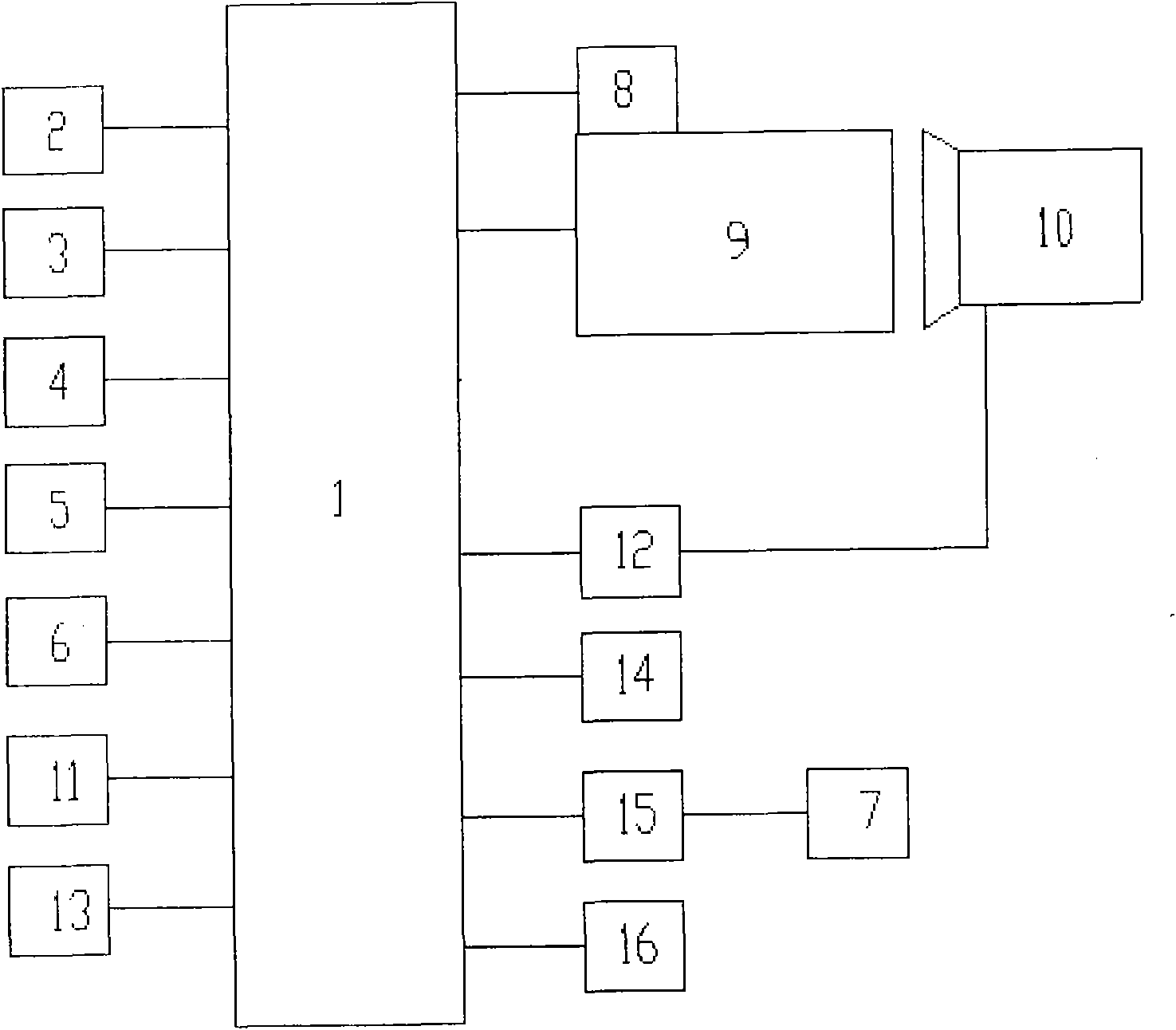

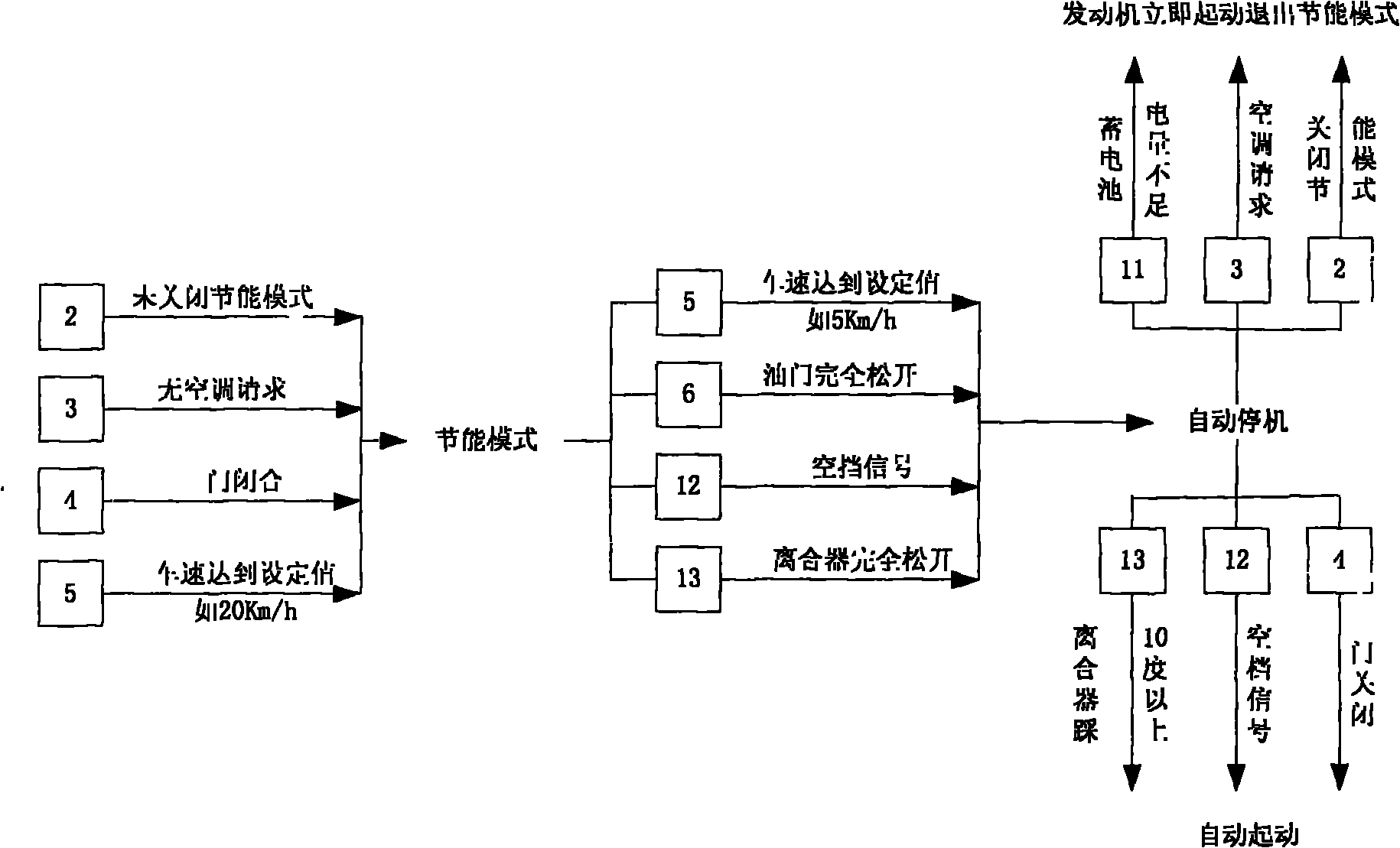

Automobile energy-saving control system and control method thereof

ActiveCN101982357AEnsure driving safetySolve the situation of vain fuel consumptionDead stateControl system

The invention discloses an automobile energy-saving control system which belongs to the field of automobile manufacturing. The control method of the automobile energy-saving control system comprises: an engine controller is used for acquiring a speed signal, a throttle signal, a neutral position signal and a clutch pedal signal; if the speed signal acquired by the engine controller is greater than zero and less than or equal to a second trigger speed setting value and the engine controller also simultaneously acquires a throttle complete release signal, the neutral position signal and a clutch pedal complete release signal, the engine is controlled to automatically stop; or else, the engine is controlled to run as usual. According to the invention, the defect of oil waste in the idle state during traveling at ordinary times can be solved by changing the idle state into the engine dead state, thus the goals of energy saving and emission reduction are realized.

Owner:CHERY AUTOMOBILE CO LTD

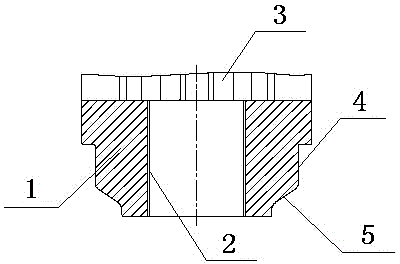

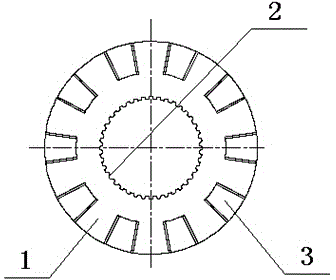

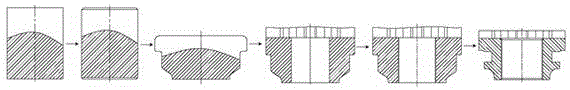

Production process of automotive middle-rear axle transmission meshing sleeve

The invention discloses a production process of an automotive middle-rear axle transmission meshing sleeve. The production process comprises the following steps of step 1, feeding; step 2, blank forming; step 3, shot blasting; step 4, coating heating; step 5, heating and upsetting; step 6, warm forging extrusion and residual heat annealing; step 7, cold extrusion on a straight tooth spline arranged on the inner wall of a middle hole; step 8, shot blasting and turning according to design drawings; step 9, carburizing and quenching and step 10, sandblasting and oil coating packaging. According to the production process of the automotive middle-rear axle transmission meshing sleeve, the warm extrusion is combined with the cold extrusion to forge the end surface tooth shape and the straight tooth spline which is arranged on the inner wall of the middle hole, the milling machining on the end surface tooth shape and the straight tooth spline which is arranged on the inner wall of the middle hole does not need to be performed after forging, and accordingly the production processes are less, the cutting quantities are less, the tooth shape forging extrusion forming is high in accuracy and high in density, the impact resistance is good, the quality is good, and accordingly the technical requirements of the automotive middle-rear axle transmission meshing sleeve are fully met and meanwhile the production process conforms to the development trend of the current automotive manufacturing.

Owner:江苏威鹰机械有限公司

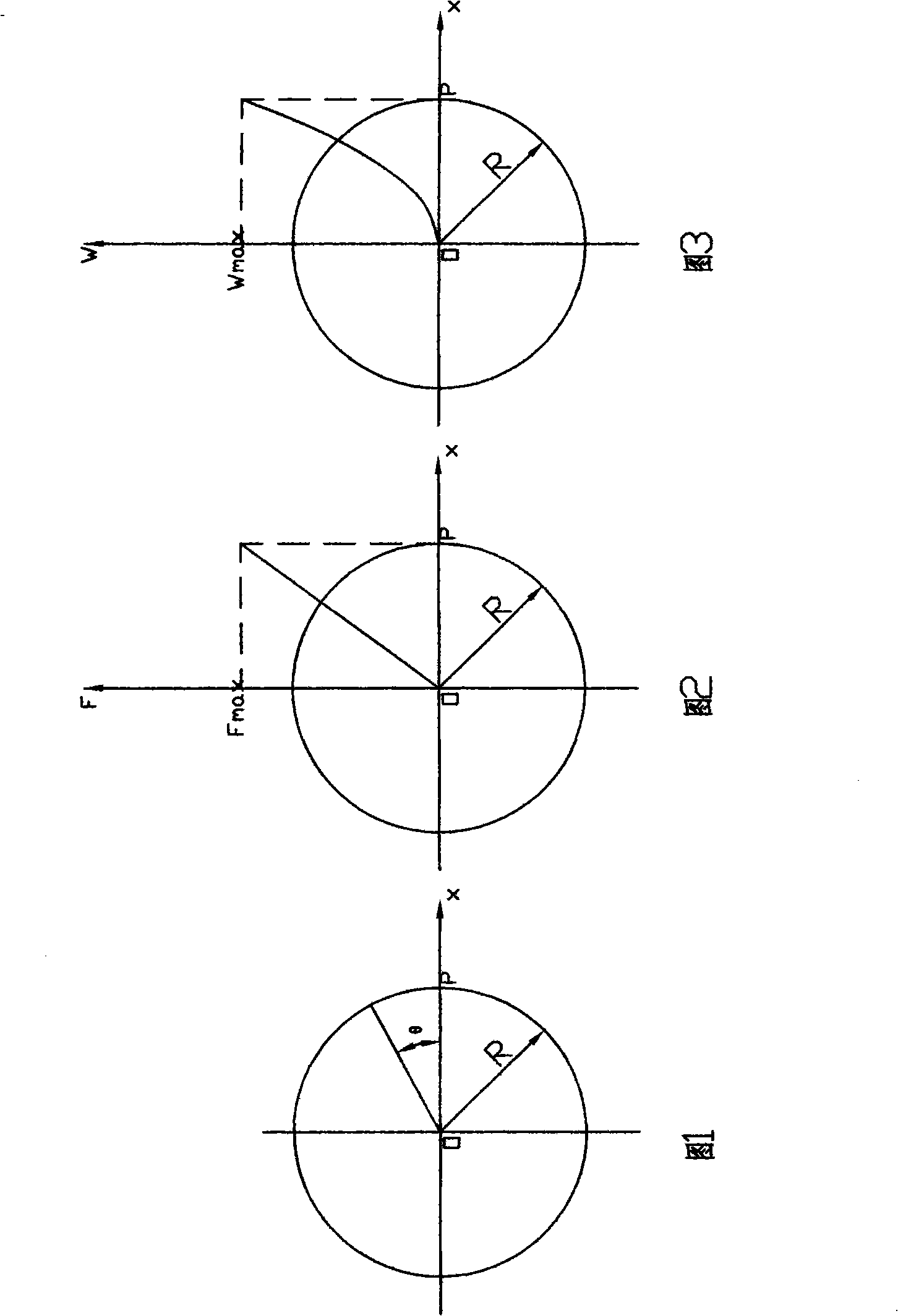

Compressional deformation strengthened flexible hollow half axle and fabrication process thereof

InactiveCN101348055AReduce driving noiseReduce vibrationAxle unitsManufacturing technologyMetallic materials

The invention belongs to the field of automobile manufacturing, relating to a jackshaft part in an automobile power transmission system and the manufacturing technology thereof. The process adopts hyposteel bars of normalized condition as the raw stock, and heats the bar raw stock to 900 DEG C for extrusion molding. The entire extrusion molding process comprises the following extrusion technology: forward extrusion molding technology, overall backward extrusion molding technology, long-hole extrusion molding technology, drawing-down extrusion molding technology and diameter extension extrusion technology; wherein, the number of the working steps of the extrusion technique required in the extrusion molding procedures of the jackshaft parts with different structures and dimensions is different; the temperature of the metal material reduces from 900 DEG C to 100 DEG C; the extrusion workpiece, the shape and dimension of which is similar to that of jackshaft part finished product, is obtained, and the part is manufactured after mechanical cutting processing procedure, alignment and inspection procedures. After the entire extrusion molding is finished, the bending strength, shear strength and impact ductility of the extrusion workpiece are superior to the mechanical performance index of a test bar of the same material which is subject to hardening and tempering as well as heat treatment, and the tensile strength is similar to the test bar of the same material which is subject to hardening and tempering as well as heat treatment; the elastic torsion angle of the hollow jackshaft is larger than 120 degrees.

Owner:邓晓光

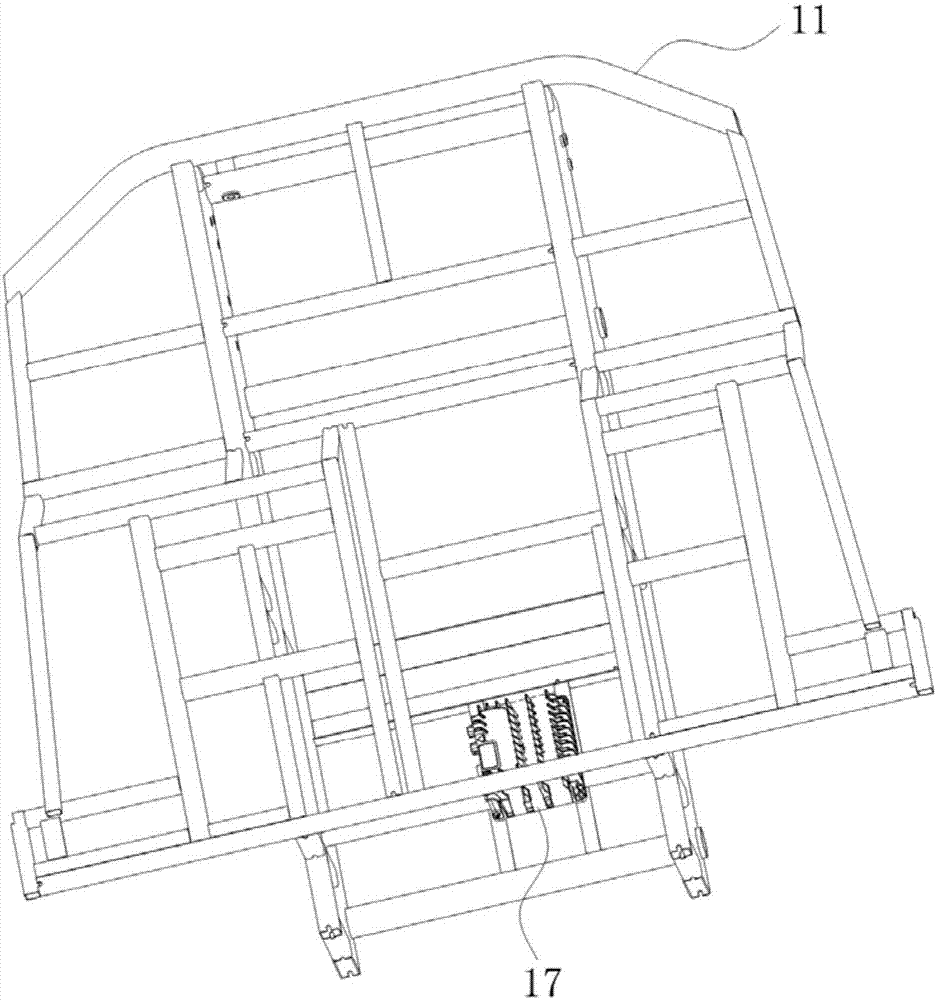

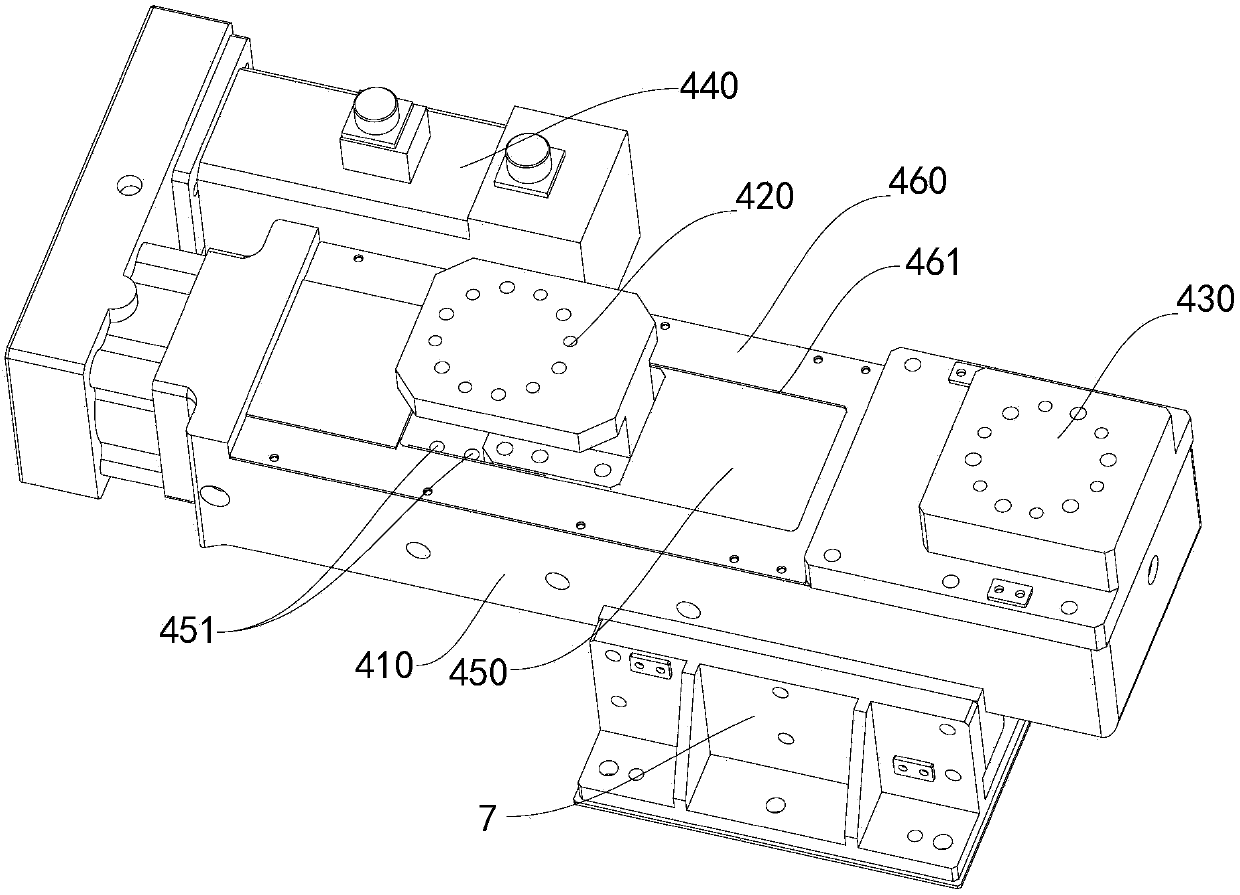

Modular chassis and electric vehicle

PendingCN107878565AFlexible restructuringNo need for restructuringAir-treating devicesElectric propulsion mountingVehicle frameElectric vehicle

The invention relates to the field of vehicle manufacturing, in particular to a modular chassis and an electric vehicle. The modular chassis comprises a chassis front-section module, a chassis middle-section module and a chassis rear-section module; the two ends of the chassis middle-section module are correspondingly connected with the chassis front-section module and the chassis rear-section module, and the chassis front-section module comprises a chassis front-section vehicle frame; the chassis middle-section module comprises a chassis middle-section vehicle frame with one end being connected with the chassis front-section vehicle frame; and the chassis rear-section module comprises a chassis rear-section vehicle frame with one end being connected with the other end of the chassis middle-section vehicle frame, and the electric vehicle comprises the modular chassis. According to the modular chassis and the electric vehicle, the chassis is divided into the three modules of the front module, the middle module and the rear module, when each section of module is designed, a fixing bracket is tailored to each part in the modules, flexible remanufacturing can be conducted, all spaces around the chassis can be reasonably utilized, remanufacturing on the overall chassis is not required, and the remanufacturing efficiency is improved.

Owner:SUZHOU AUTO TECH

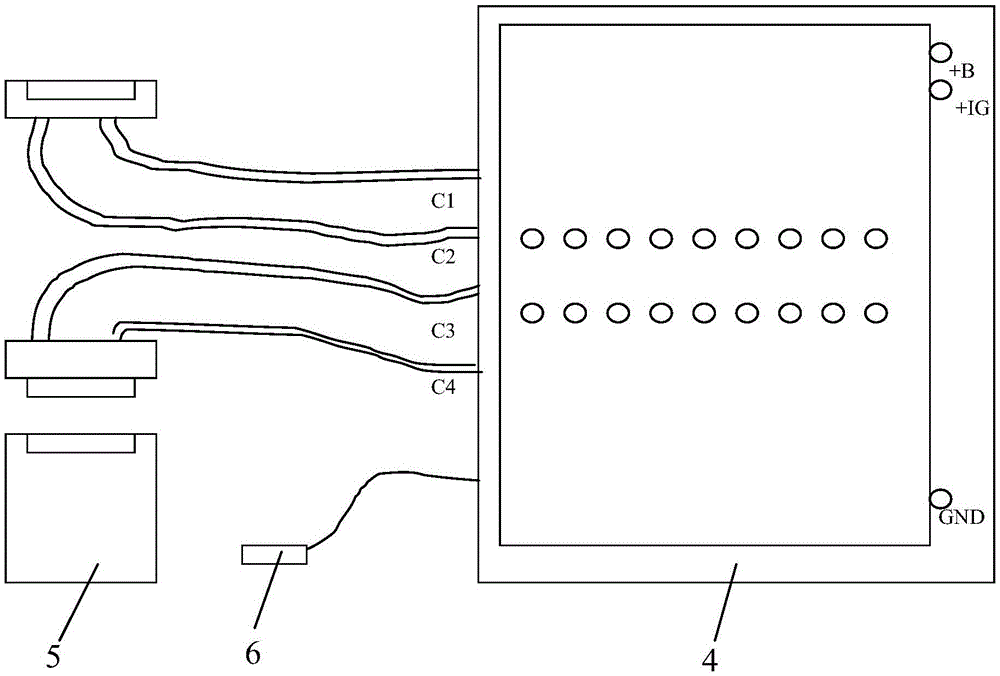

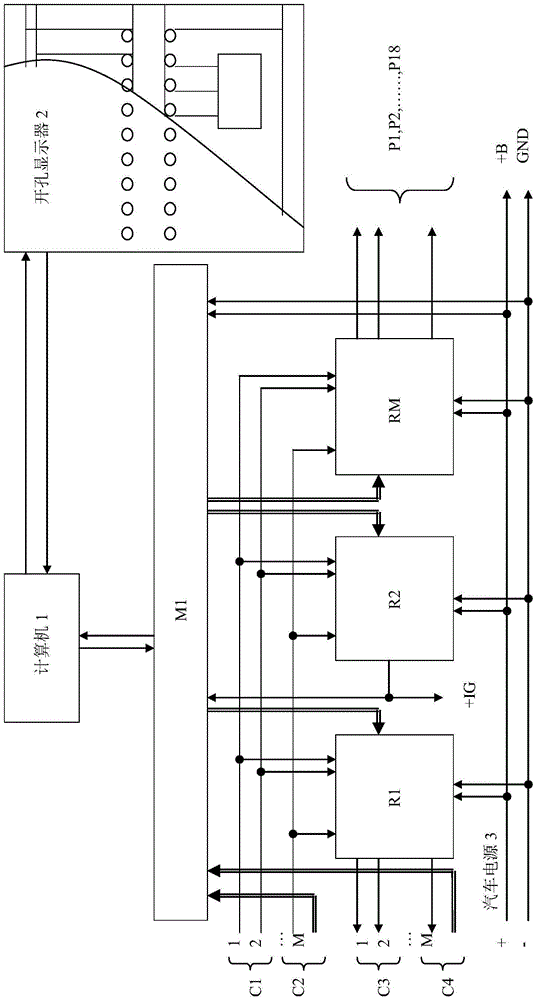

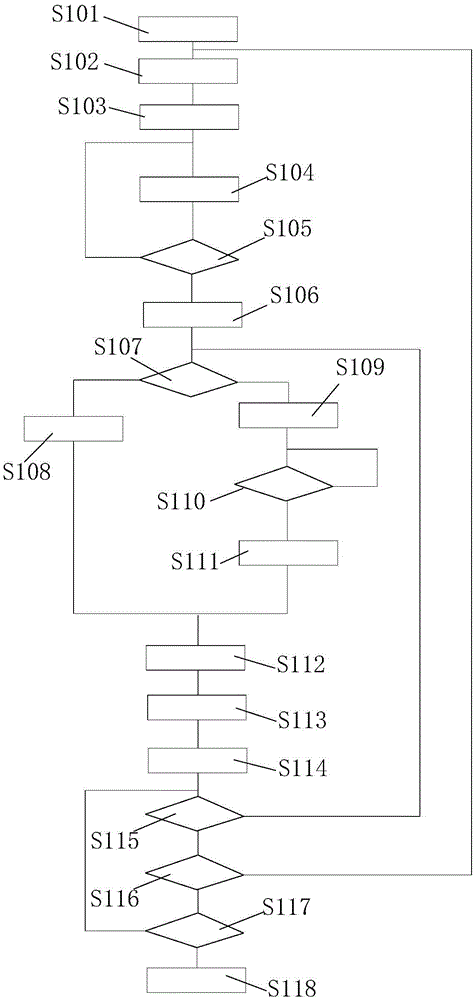

Tester for automotive electronic control system and testing method thereof

InactiveCN105676840AWide applicabilityElectric testing/monitoringElectronic control systemCar manufacturing

The invention discloses a tester for an automotive electronic control system and a testing method thereof. The tester comprises a testing box including a computer, a control module, M first interface terminals, M second interface terminals, M electrical lines, N test terminals and a relay matrix. All electrical lines are connected with the corresponding first interface terminals and second interface terminals. The control module controls connection or disconnection of the electrical lines. The relay matrix includes M*N third relays. A plurality of circuit diagrams and databases corresponding to the circuit diagrams are stored into the computer; the circuit diagrams have ECU pin data; and the databases are databases of correspondence relations between the ECU pins and the testing terminals. According to the invention, definition of the testing terminals on the testing panel can be replaced automatically according to the ECU pin data of the selected specific circuit diagrams; and different anode and cathode joint groups are replaced in a cooperative mode. Therefore, wide application of the tester and method to different automobile manufacturers, different automobiles, and different electrical control systems can be realized.

Owner:王志欣

Welding process equipment for self-discharging mining carriage floor

InactiveCN102489907AImprove production efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProcess equipmentDevice form

The invention discloses welding process equipment for a self-discharging mining carriage floor, which relates to the technical field of special automobile manufacture and comprises a main welding platform, a portal frame and at least one clamping device. The surface of the main welding platform is provided with a plurality of openings, and a roller frame with a plurality of rollers at the top is mounted in each opening and connected with a driving cylinder for driving the roller frame to extend out of or retract into the top of the main welding platform. The portal frame comprises a beam, vertical columns, wheel carriers and travelling wheels, wherein the vertical columns are connected to two ends of the beam, one wheel carrier is arranged at the lower end of each vertical column, the travelling wheels are mounted on the two wheel carriers, and the portal frame crosses over the upper surface of the main welding platform and is mounted on rails on two sides of the main welding platform through the travelling wheels. Each clamping device formed by connecting a clamping cylinder with a mounting frame for the clamping cylinder is mounted on the beam through pulleys. Compared with the prior art, the welding process equipment has the advantages that the carriage floor is high in production efficiency and fine in quality, the labor intensity of workers is low, and safety is high.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

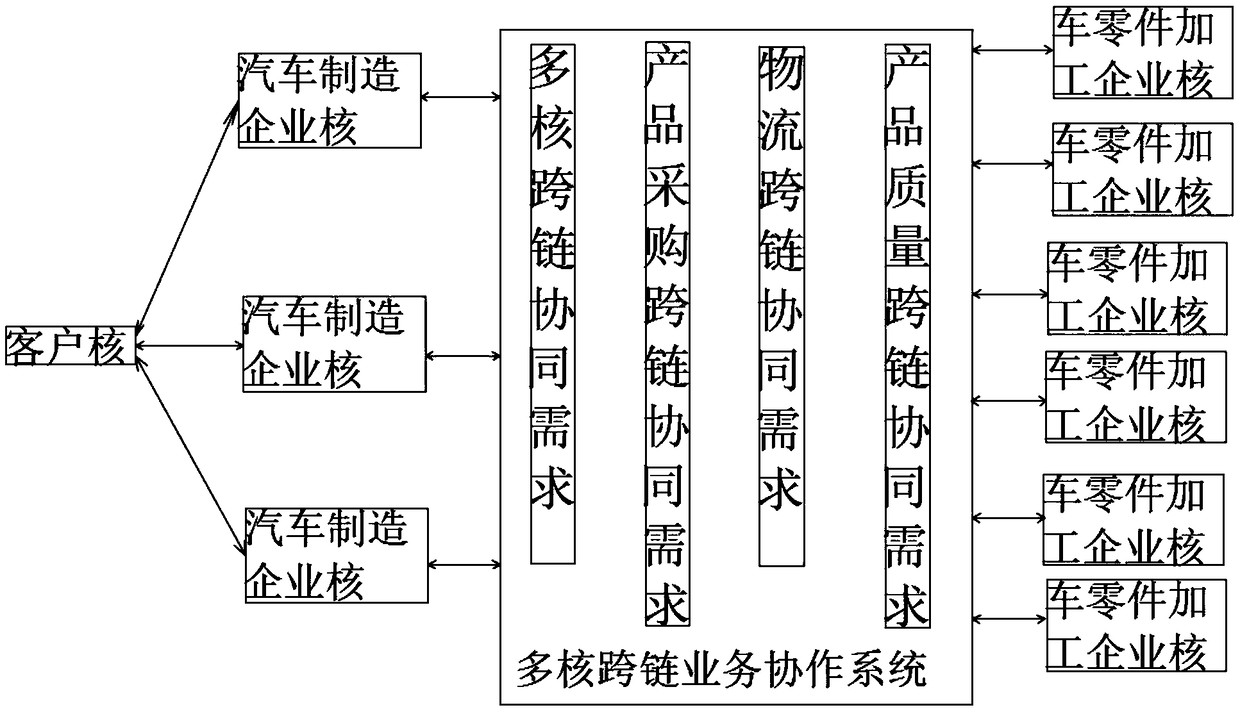

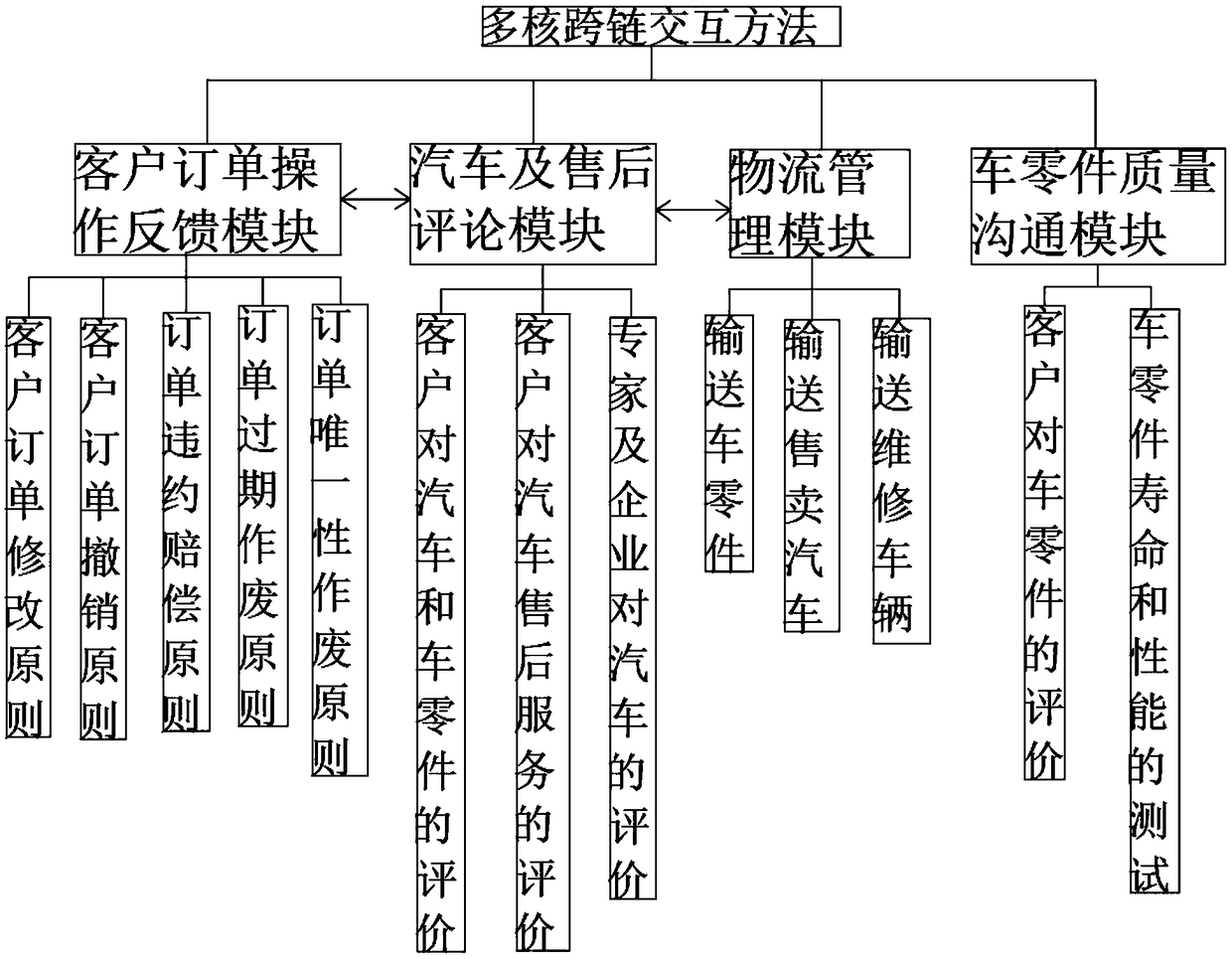

A multi-core cross-chain service cooperation system and an interactive method based on a cloud platform

InactiveCN109389370AGuaranteed to be manufactured at all timesGuaranteed assemblyOffice automationManufacturing computing systemsLogistics managementLogistic management

The invention discloses a multi-core cross-chain service cooperation system and an interactive method based on a cloud platform, including cloud platforms. cross-chain business collaboration includesthe collaboration between the customer core and the automotive manufacturing enterprise core, the multi-core and cross-chain business cooperation system between the automobile manufacturing enterprises and the automobile parts processing enterprises. The interaction method includes: setting up the interaction between between an automobile and after-sale comment module, a customer order operation feedback module, a logistics management module, and a vehicle part quality communication module on the cloud platform; service cooperation among automobile manufacturing enterprise nuclear, machiningenterprise of automobile parts, and customer cores reflects the diversity of choices and collaboration, the customer order operation feedback module safeguards the interests and rights of customers and automobile enterprises. Customer or expert evaluation can provide the improvement direction for automobile manufacturing enterprises and parts processing enterprises, and promote the automobile industry to advance, innovate and develop continuously.

Owner:CHENGDU UNIV OF INFORMATION TECH

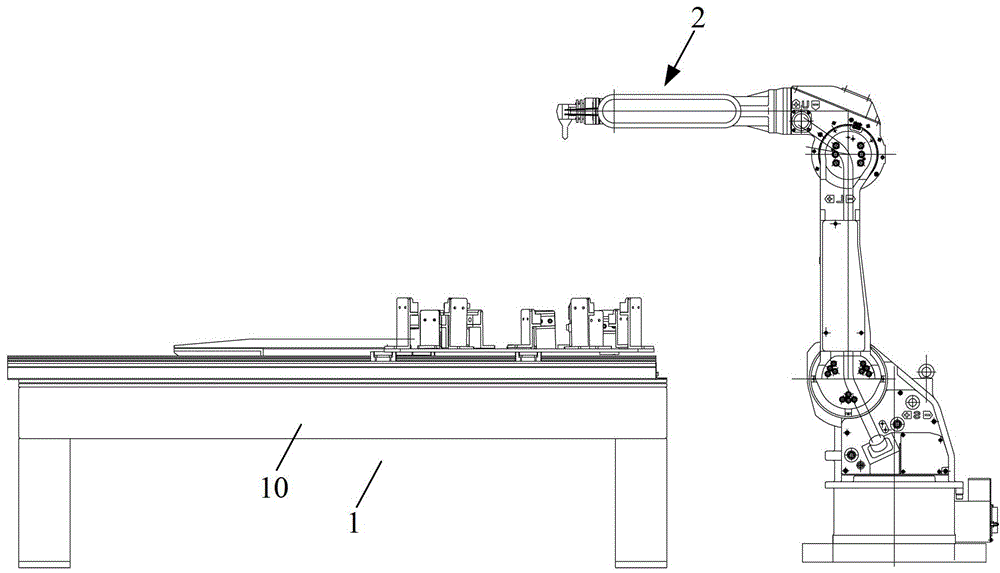

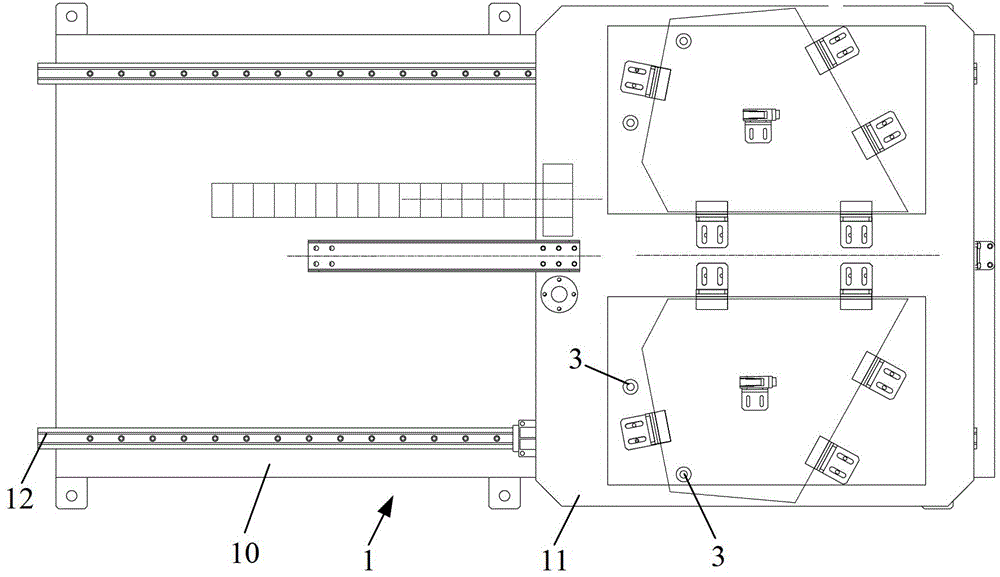

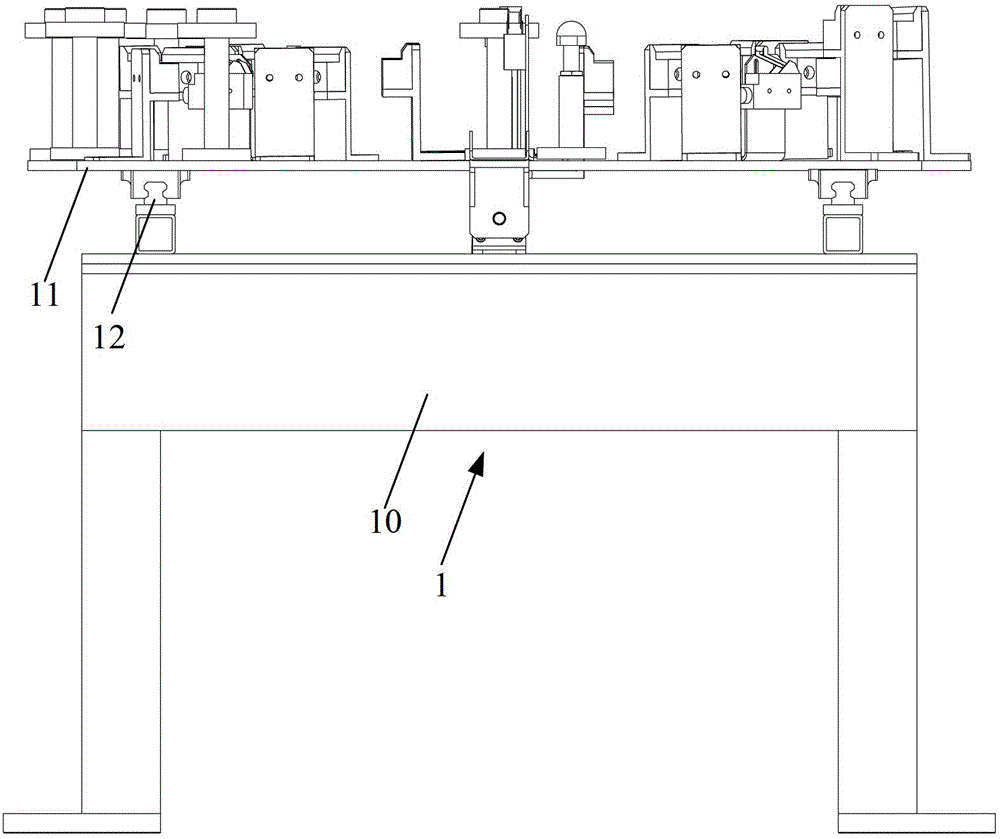

Conveying system of automobile side window

The invention discloses a conveying system of an automobile side window and relates to the technical field of automotive manufacturing process equipment, in order that sizes of the side windows with different types can be automatically identified before automatically gluing. The conveying system of the automobile side window comprises an automatic gluing robot, and a platform which is used for fixing the side window; the platform is provided with a plurality of sensors; and each sensor is used for identifying the side window with one size and type, and is electrically connected with the automatic gluing robot. The conveying system of the automobile side window is mainly suitable for the automotive manufacturing process.

Owner:GREAT WALL MOTOR CO LTD

Big data-based full-period monitoring and analysis system for production quality of automobile part products in automobile manufacturing industry

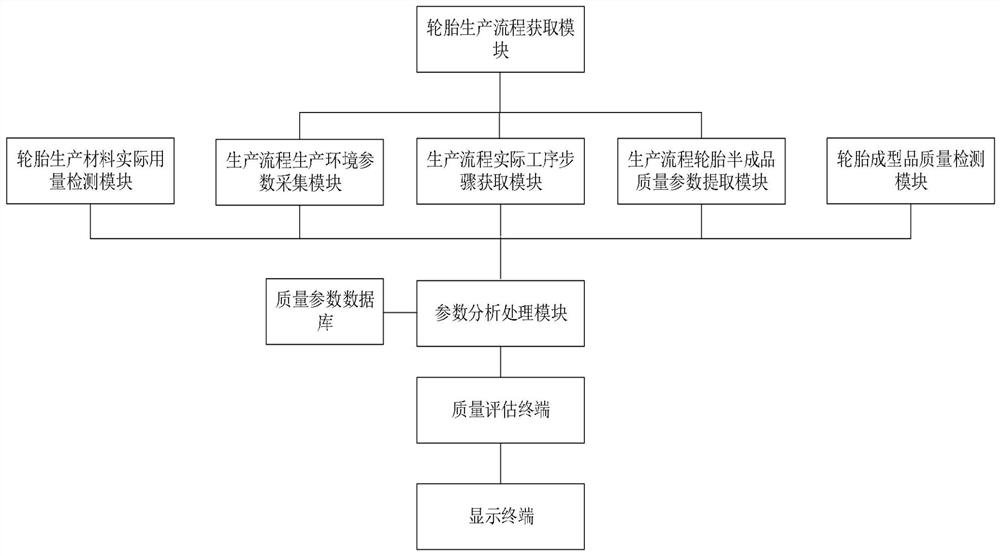

InactiveCN113065784AImplement quality assessmentImprove accuracyResourcesManufacturing computing systemsEvaluation resultProcess engineering

The invention discloses a big data-based full-period monitoring and analysis system for the production quality of automobile part products in the automobile manufacturing industry. The monitoring and analysis system comprises a tire production material actual dosage detection module, a tire production process acquisition module, a production process production environment parameter acquisition module, a production process actual process step acquisition module, a production process tire semi-finished product quality parameter extraction module, a tire molding product quality detection module, a quality parameter database, a parameter analysis processing module, a quality evaluation terminal and a display terminal. According to the monitoring and analysis system, the actual use amount of production materials required to be used in the tire production process, the production environment parameters of each tire production flow, the process steps, the quality parameters of semi-finished products and the quality parameters of tire molding products are detected, so that the comprehensive quality evaluation coefficient of the tire is counted, the comprehensive quality evaluation of the tire is realized, the evaluation index range is expanded by the evaluation mode, and the accuracy of the evaluation result is improved.

Owner:义乌市禾煜智能装备科技有限公司

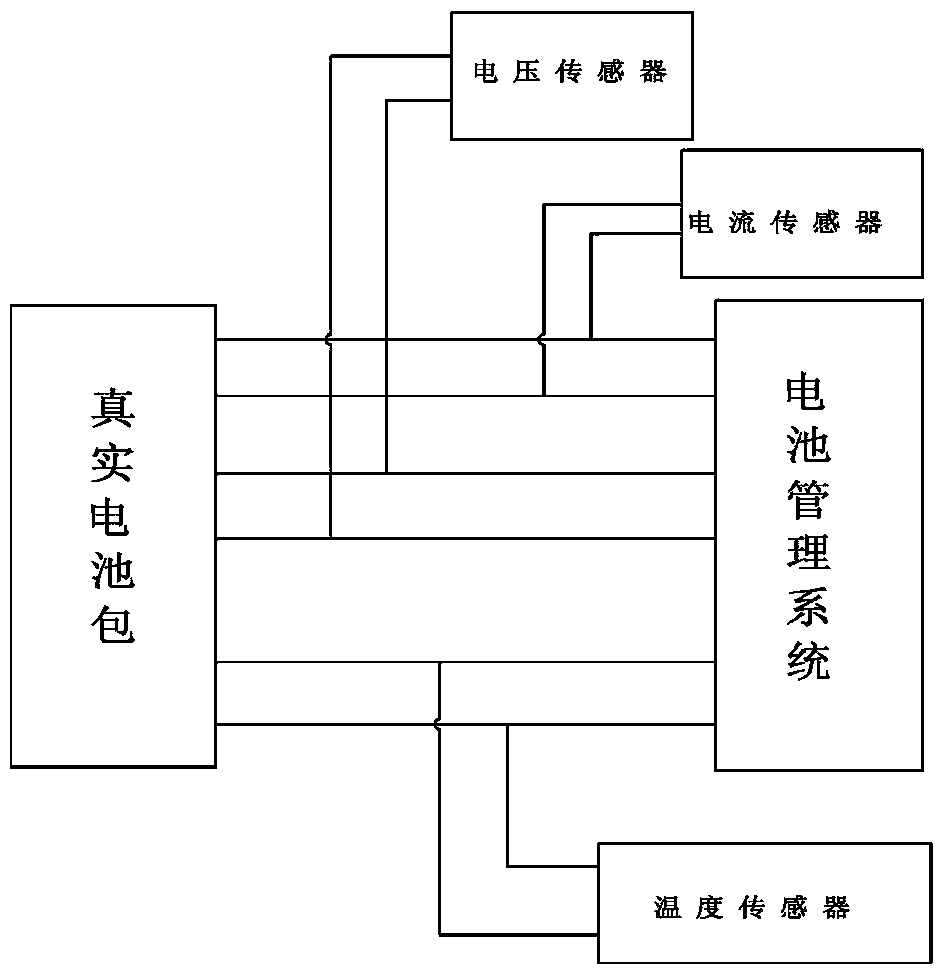

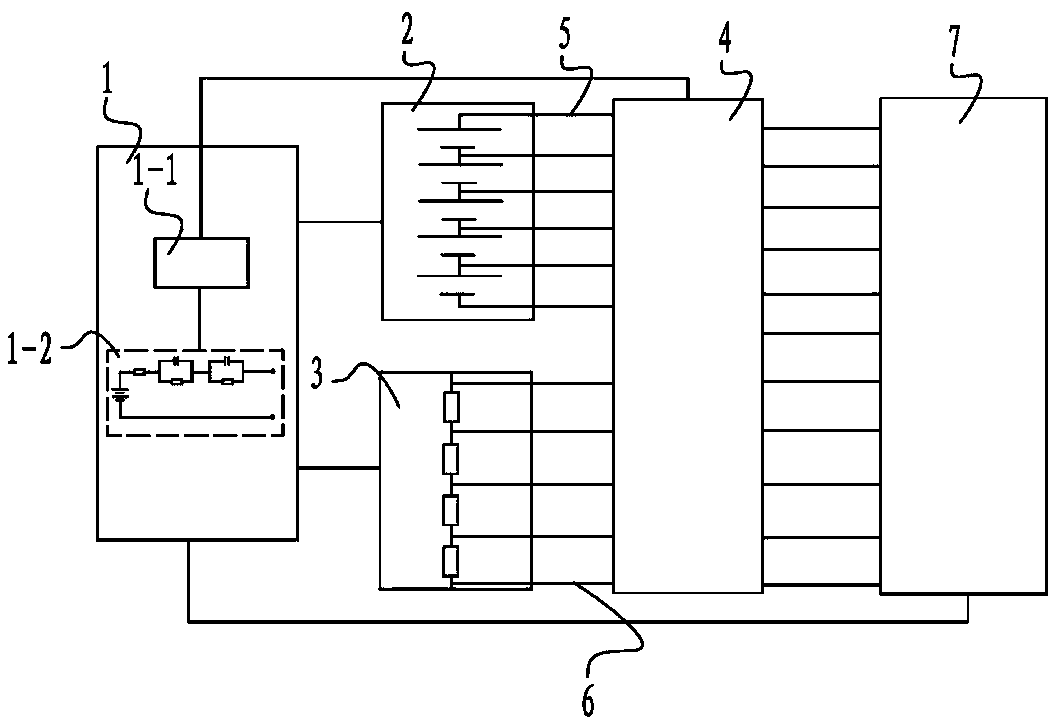

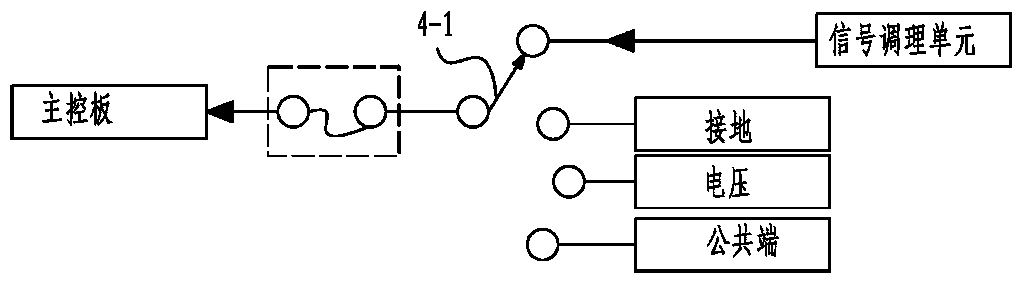

Physical detecting function testing method of battery testing system

InactiveCN109856484AReduce manufacturing costElectrical testingCar manufacturingElectrical connection

The invention, which relates to the technical field of electric vehicle manufacturing, discloses a physical detecting function testing method of a battery testing system. The method comprises: step one, carrying out physical detection accuracy testing; step two, carrying out battery state abnormality testing; step three, carrying out invalid value testing; and step four, carrying out electrical connection failure testing. Therefore, problems of high cost and low safety in the prior art are solved.

Owner:DONGFENG LIUZHOU MOTOR

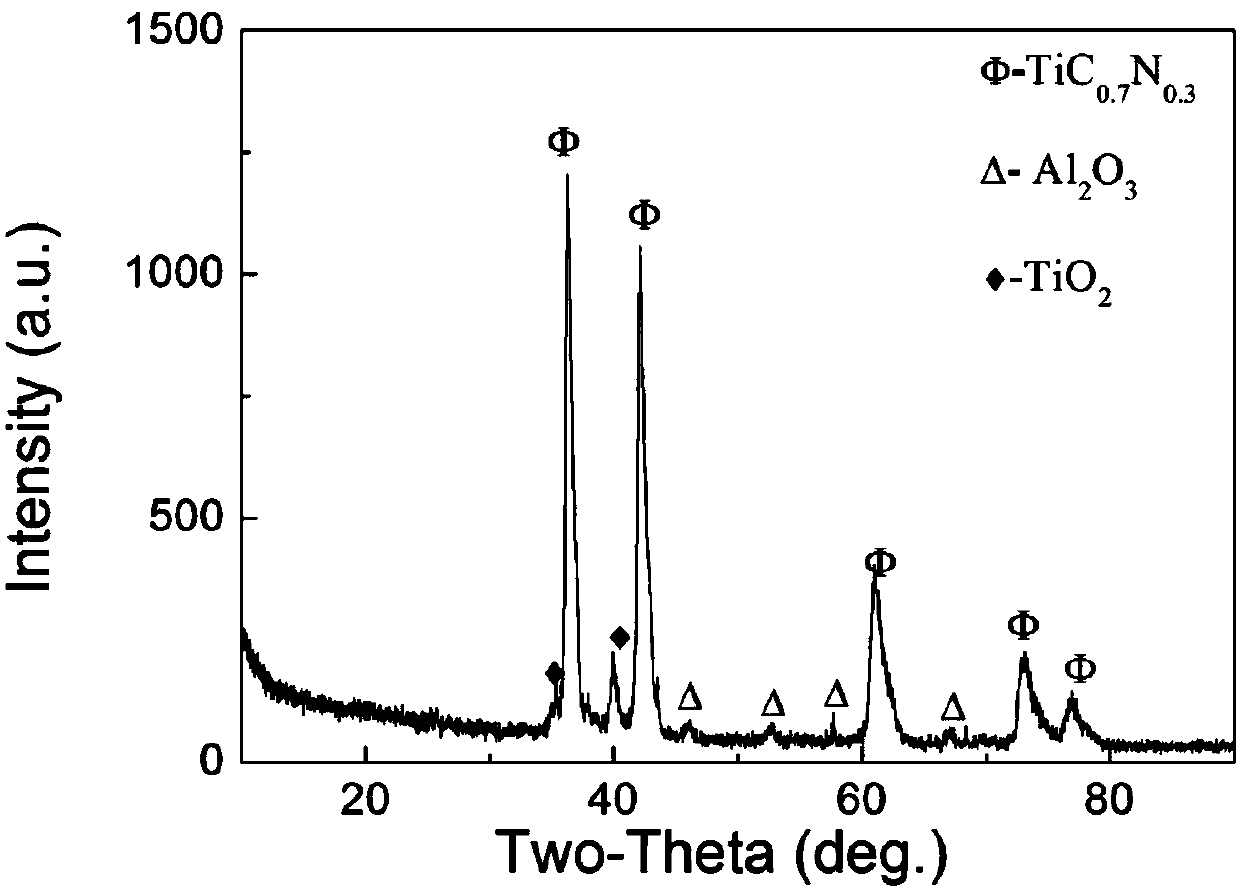

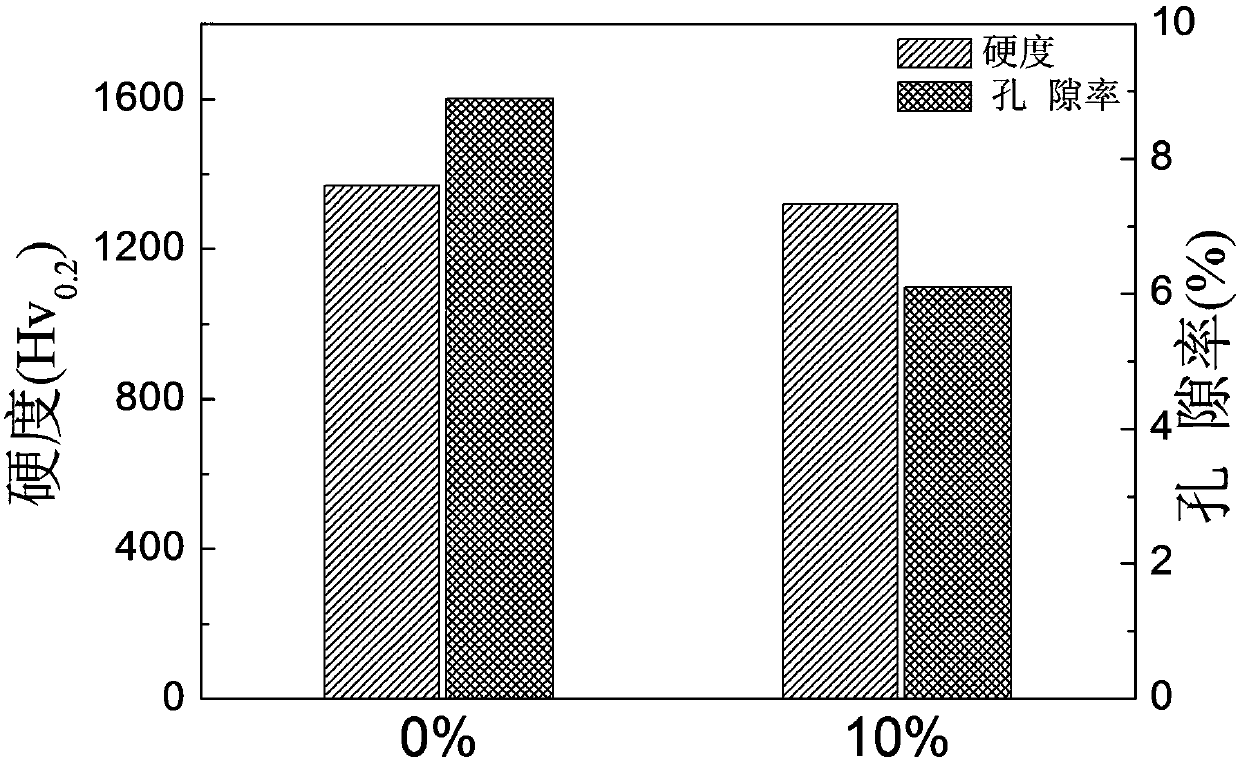

Preparation method for TiCN-Al2O3 ceramic composite coating

ActiveCN107653431AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeWorking environment

The invention provides a preparation method for a TiCN-Al2O3 ceramic composite coating. The method comprises the following steps that 1, a base body sample is subjected to surface roughening treatment; 2, Ti-C composite powder and Al2O3 powder are mechanically stirred and mixed to obtain spray feeding composite powder; 3, the surface of a base body is pre-sprayed with self-melting alloy powder ofNi-10%wtAl to obtain a bonding bottom layer with the thickness 90-120 [mu]m; and 4, the surface of the bonding bottom layer is sprayed with the spray feeding composite powder to obtain the TiCN-Al2O3composite coating with the thickness 300-500 [mu]m. The plasma-sprayed TiCN-Al2O3 ceramic composite coating has excellent performance of high hardness and abrasion and corrosion resistance, is suitable for workpieces under the abrasion and corrosion working environment such as the fields of manufacturing of cars and machinery such as cutters, drill bits and molds, aerospace industry and the like,and has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

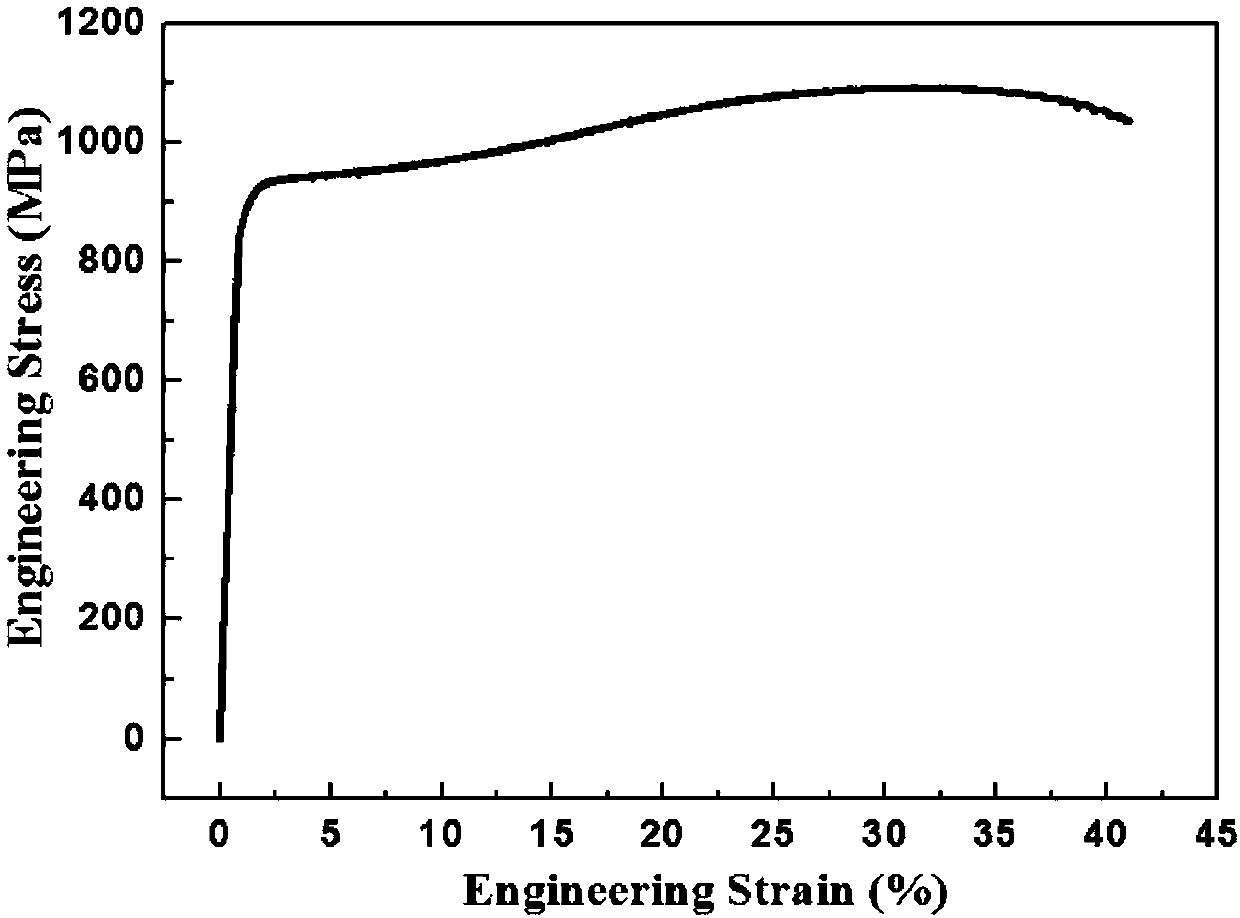

Ultrahigh-strength and ductility low-cost titanium alloy and preparation method and application thereof

The invention relates to ultrahigh-strength and ductility low-cost titanium alloy. The titanium alloy is prepared from Ti, Mo, Cr, Al and Fe, wherein the mass of Ti is more than 75% of the total massof the titanium alloy. The invention further provides a preparation method of the titanium alloy. In order to reduce the total cost of the titanium alloy, preferably, Mo, Cr, Al and Fe elements in thealloy are added in the form of intermediate alloy of Al-Mo, Mo-Fe and Cr-Fe. The ultrahigh-strength and ductility low-cost titanium alloy has ultrahigh strength and ductility, has ideal yield strength, high ductility and good work hardening rate, can be processed into rods, plates, profiles and the like, has the advantage of low use cost and has high application values in the field of aviation, aerospace, marine exploration, shipbuilding and / or automobile making.

Owner:BEIHANG UNIV

Brake pad grinding equipment for new energy automobile manufacturing

ActiveCN113211253APrevent splashImplement basic functionsGrinding machinesGrinding feedersNew energyElectric machinery

The invention relates to grinding equipment, in particular to brake pad grinding equipment for new energy automobile manufacturing, and particularly provides brake pad grinding equipment for new energy automobile manufacturing and capable of achieving manual accurate placement, cooperating with grinding, flexibly controlling the grinding speed and improving the grinding efficiency. The brake pad grinding equipment for new energy automobile manufacturing comprises a bottom plate, supports, a motor and a shaft sleeve; multiple supporting rods are arranged on the bottom plate, and an operation plate is connected among the tops of the supporting rods; the supports are symmetrically arranged on one side of the top of the operation plate; the motor is connected between the tops of the supports, and a spline is arranged on an output shaft of the motor; and the shaft sleeve is arranged on the spline in a sliding manner, and a grinding disc is arranged on the lower portion of the shaft sleeve. The grinding disc is driven to rotate and meanwhile move downwards to grind a brake pad, and the basic functions of the equipment are achieved.

Owner:LUOHE VOCATIONAL TECH COLLEGE

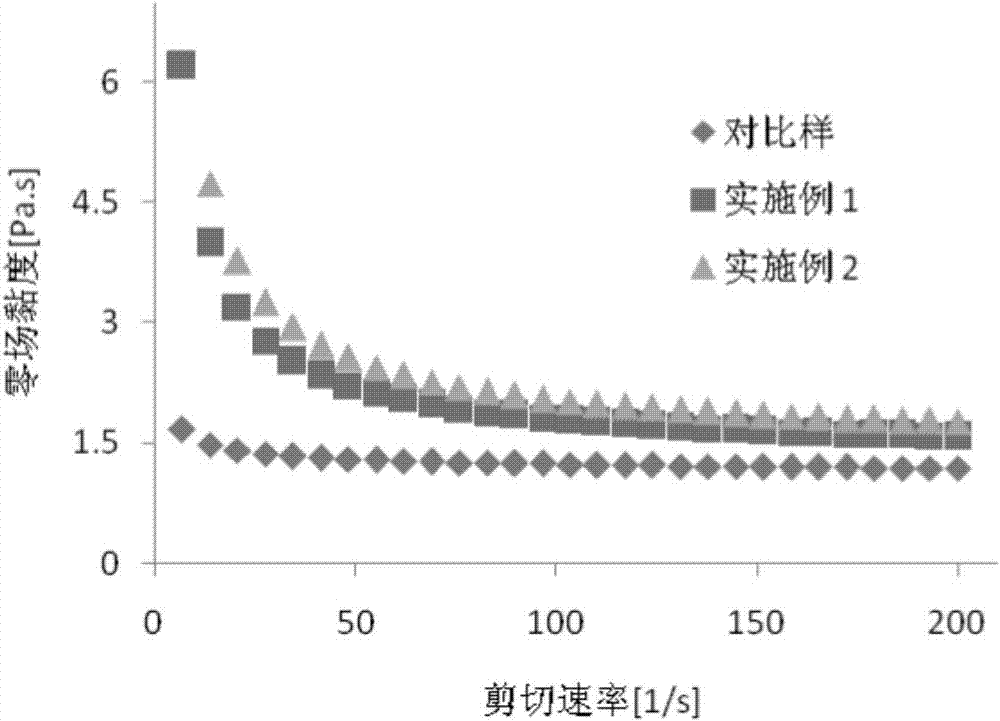

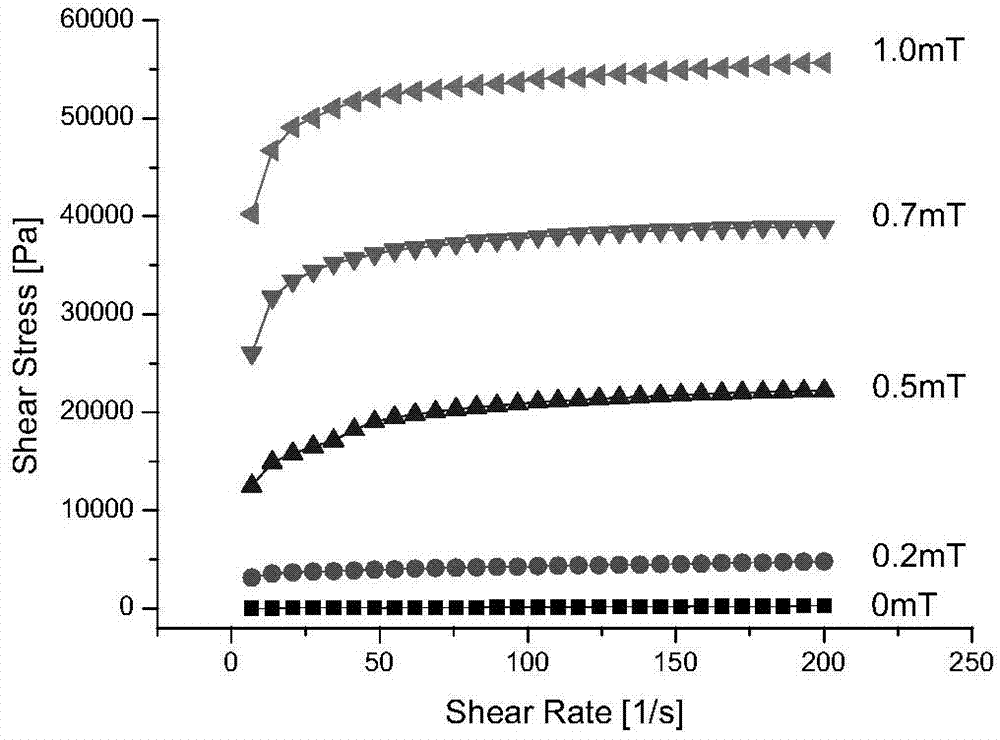

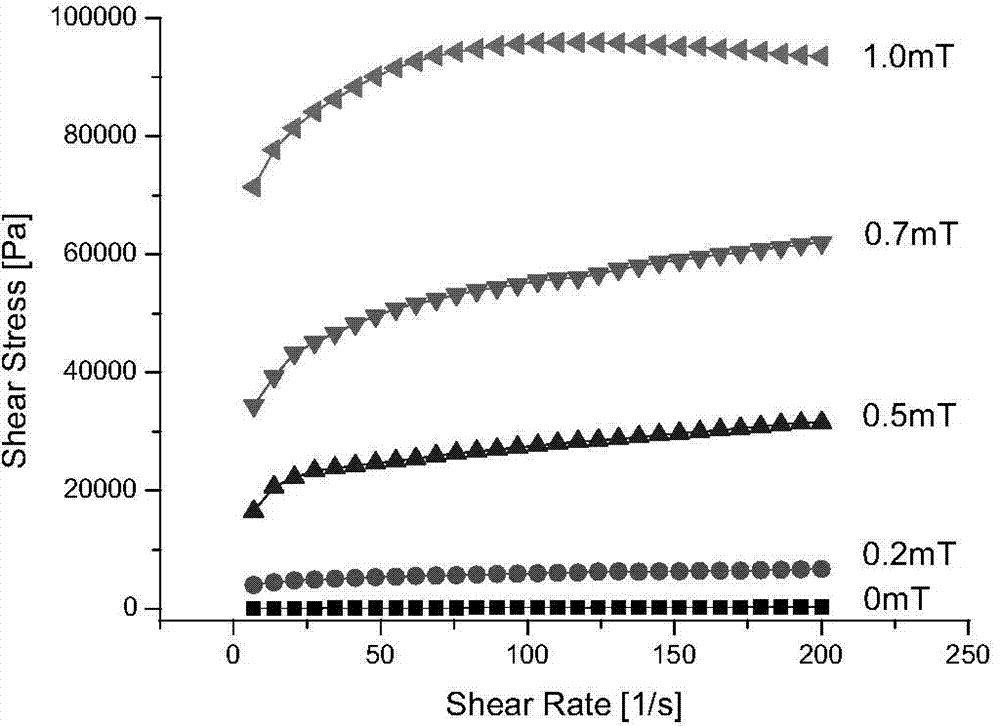

Carbonyl iron powder capable of enhancing magnetorheological effect and magnetorheological fluid prepared from carbonyl iron powder

InactiveCN103525505AHigh yield stressGood settlement stabilityAdditivesMagnetic currentCar manufacturing

The invention discloses carbonyl iron powder capable of enhancing the magnetorheological effect and magnetorheological fluid prepared from the carbonyl iron powder. According to the magnetorheological fluid prepared from the carbonyl iron powder, binary acid is used as the additive, and therefore the yield stress and sedimentation stability of the magnetorheological fluid are effectively improved. The preparing method of the magnetorheological fluid comprises the steps of adding the carbonyl iron powder into the mixed solution of the binary acid and isopropanol, and carrying out ultrasonic dispersion, mechanical milling and vacuum drying to obtain the carbonyl iron powder with the surface treated; adding thixotropic agents and lubricant additives into base oil in sequence to obtain carrier liquid after stirring and mixing; adding the carbonyl iron powder into the carrier liquid, carrying out ultrasonic dispersion and mechanical milling to obtain grinding balls through separation, and then obtaining the magnetorheological which is stable and efficient. The magnetorheological liquid can acquire quite high shear yield stress in a small magnetic field, and therefore the magnetorheological fluid has great application value in the automobile industry, in the measuring technique industry, in the machining industry and in the robot industry.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Axle paint spraying device

InactiveCN112452606AEasy to fixPrevent movementPretreated surfacesCoatingsElectric machineHeater Rod

The invention belongs to the field of automobile manufacturing, and relates to an axle paint spraying device. The axle paint spraying device comprises a base, wherein a shell is fixedly connected to the top of the base, two sliding rails are fixedly connected to the front end wall and the rear end wall in the shell, a hydraulic rod is rotatably connected to a fixing plate, a fixing sleeve is fixedly connected to the other end of the hydraulic rod, and a clamping plate is fixedly connected to the other end of each adjusting screw rod; a driven bevel gear fixedly sleeves the hydraulic rod, a driving bevel gear is fixedly connected to the output end of a second driving motor, four pumps are fixedly connected to the top of the shell, a nozzle fixedly communicates with the output end of each ofthe four pumps, a heating box fixedly communicates with the top of the shell, a ventilation pipe fixedly communicates with the top of the heating box, and an electric heating wire fixedly sleeves a heating rod; and an induced draft fan is fixedly connected to the output end of a third driving motor, and an air cooler is fixedly connected to the top of the shell. The device can fix axles of different sizes, degreasing, rust prevention, cleaning, drying and other treatment can be performed on the axles, and besides, turned-over multi-directional paint spraying can be performed on the axles in the paint spraying process.

Owner:SHANDONG HENGTAI AXLE

Visual discovery tool for automotive manufacturers with network encryption, data conditioning, and prediction engine

ActiveUS20180218420A1Data augmentationImprove the display effectCustomer relationshipDigital data information retrievalAuthorization certificateDisplay device

A visual discovery tool for automotive manufacturing with network encryption, data conditioning, and prediction can include an extraction device configured to receive data records from application-specific file source databases. The tool can further include a vehicle alert database that receives the vehicle records from the plurality of extraction databases. The visual discovery tool can include at least one hardware processor in communication with the extraction device and the vehicle alert database. The tool can be configured to selectively restrict access to an interactive display based on whether a client device receives authorization credentials.

Owner:AUTOALERT

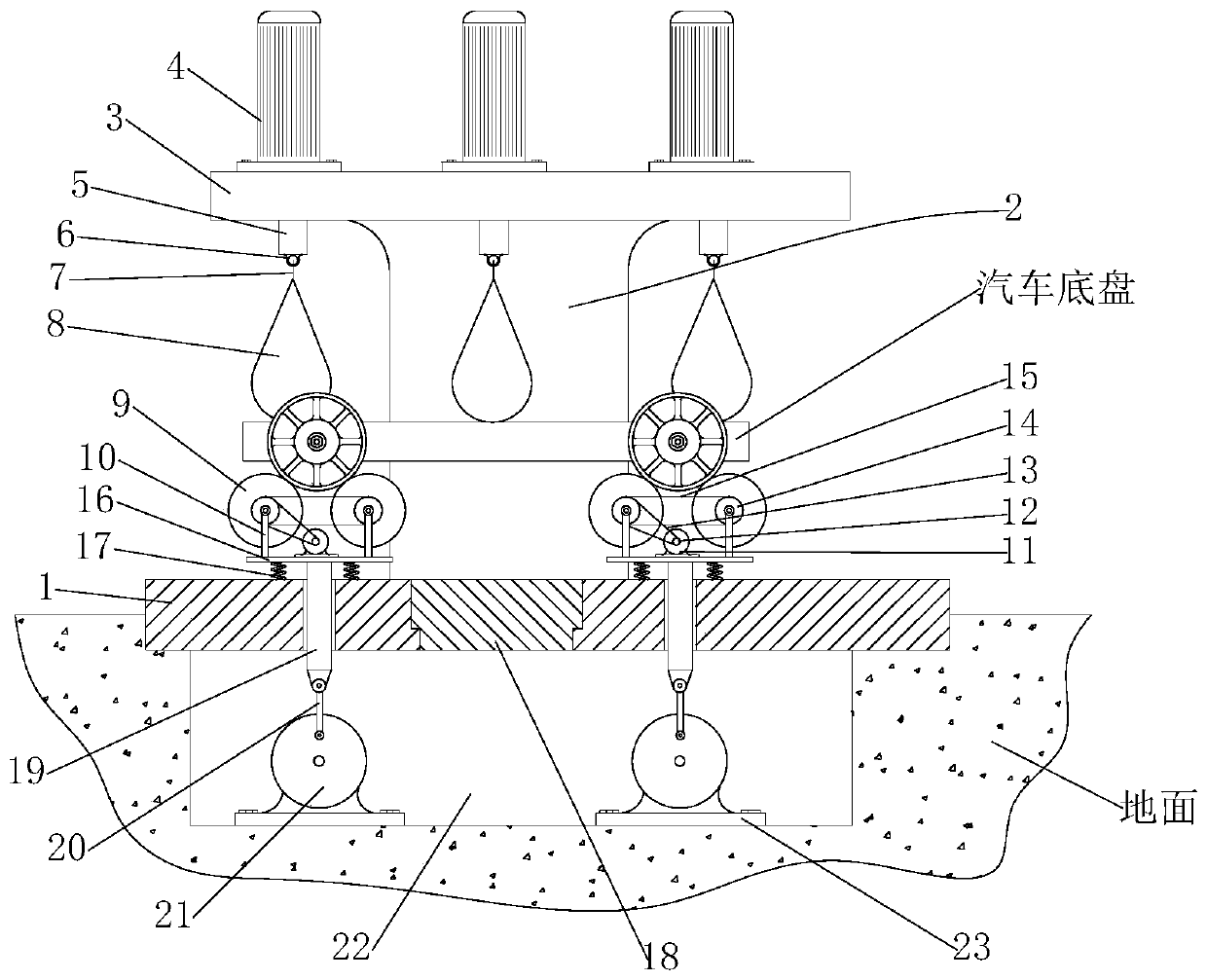

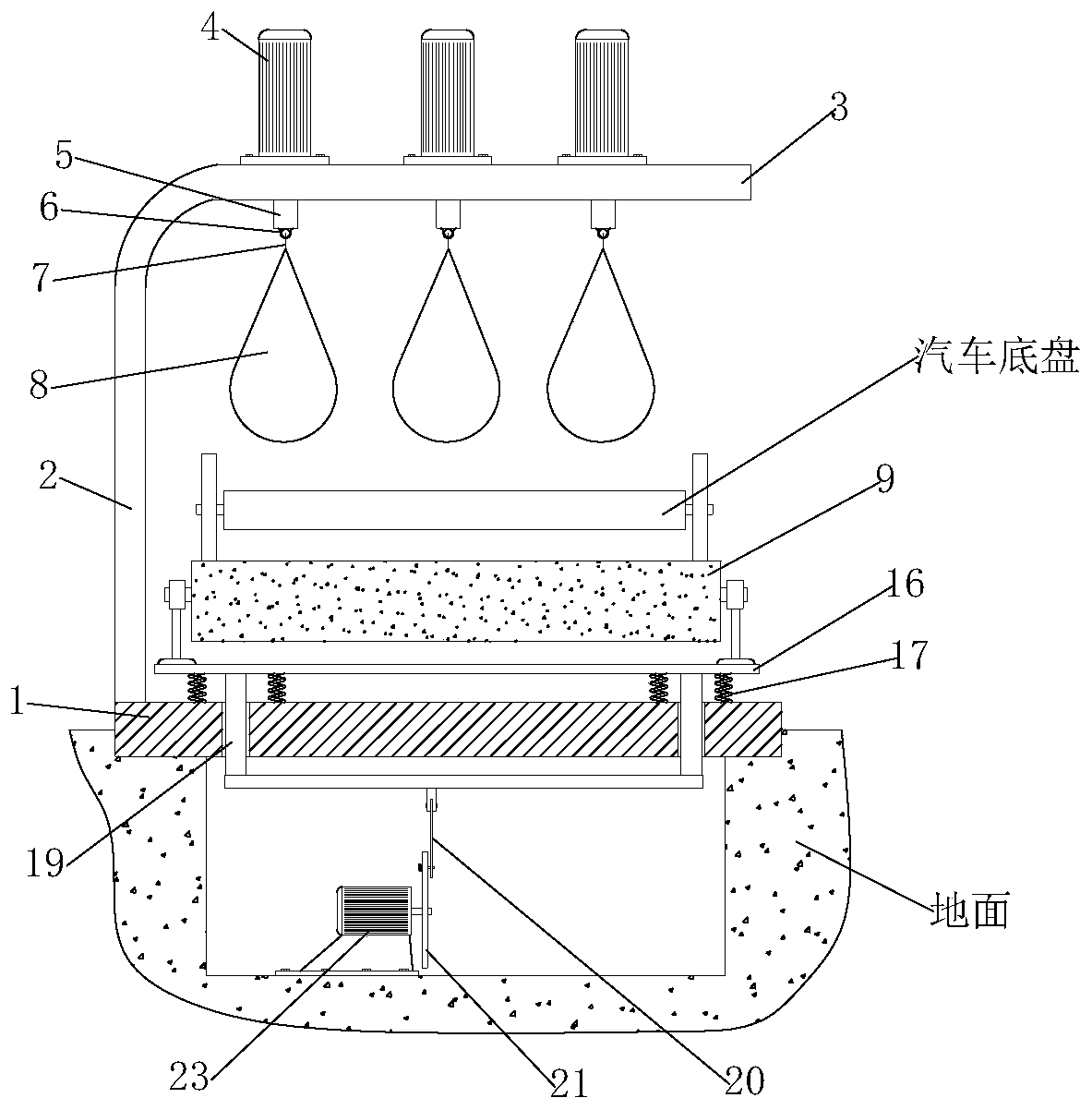

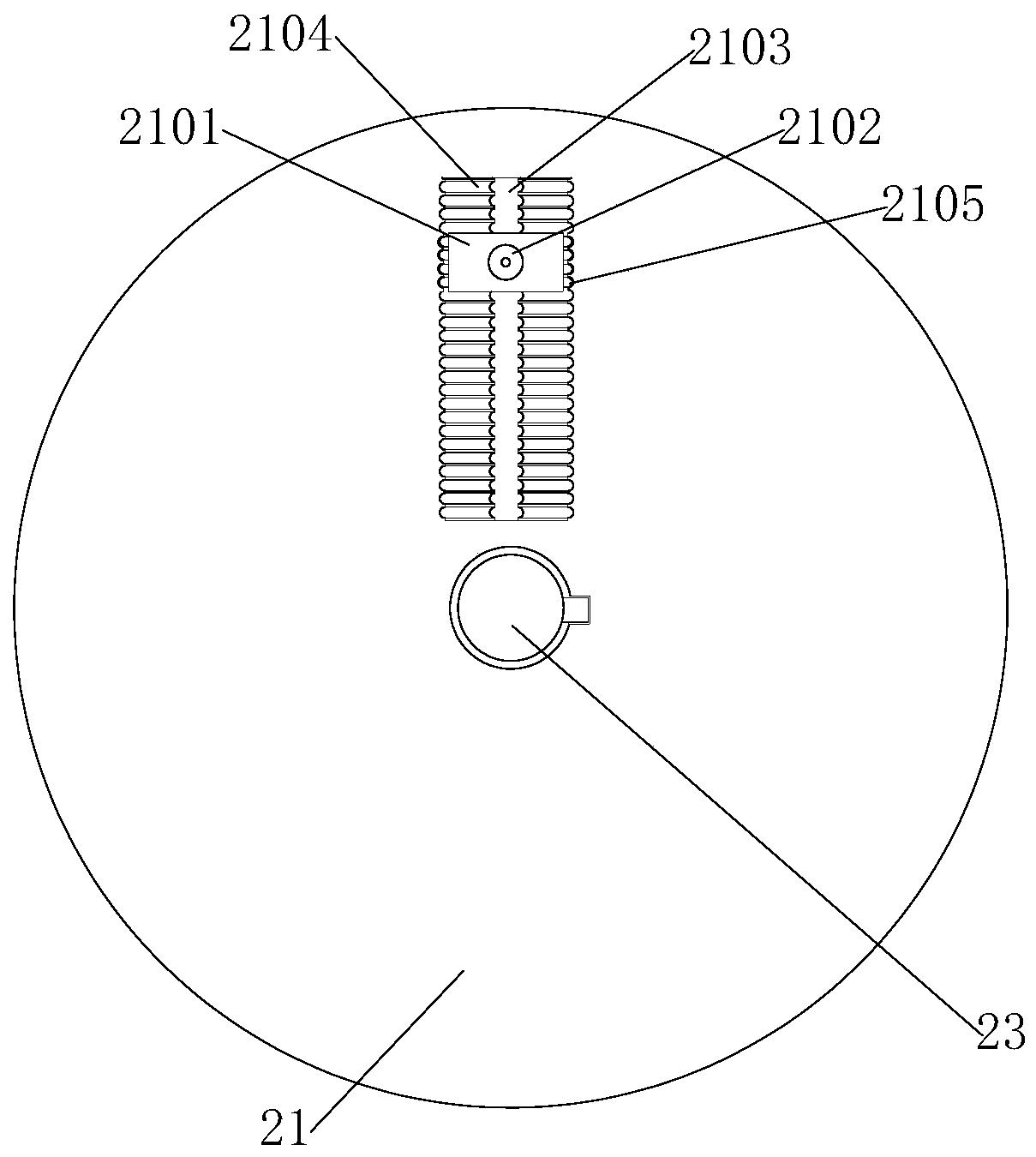

New energy automobile manufacturing chassis physical performance test system and test method

ActiveCN111413106AImprove Physical Testing PerformanceSmooth rotationVehicle tyre testingPhysical performance testPhysical performance testing

The invention discloses a new energy automobile manufacturing chassis physical performance test system and test method and relates to the technical field of automobile production. The new energy automobile manufacturing chassis physical performance test system comprises a bottom support plate fixedly mounted on the ground, a side supporting rib plate vertically fixed to the top end of the bottom supporting plate is arranged at the top end of the bottom supporting plate, a horizontally-fixed top supporting plate is arranged at the top end of the side supporting rib plate, and a plurality of electric push rods fixed at equal intervals are installed at the top end of the top supporting plate. In the system, the side supporting rib plate vertically fixed to the top end of a bottom supporting plate is arranged at the top end of the bottom supporting plate fixedly installed on the ground. The plurality of electric push rods are supported upwards through the side support plates, and each loadbag is independently controlled through the plurality of electric push rods, so that the load test can be performed on any position of the automobile chassis when the load test is performed on the automobile chassis, and the physical test performance of the automobile chassis is improved.

Owner:万高(上海)汽车科技有限公司

Acoustical foam with improved performance

Disclosed is a thermally expandable composition, comprising at least one polymer P, cross-linkable by peroxide, and between 1 wt.-% and 2.5 wt.-%, based on the total weight of the composition, of at least one acrylate A, and between 0.2 wt.-% and 2.5 wt.-%, based on the total weight of the composition, of at least one peroxide, and at least one blowing agent, characterised in that the equivalent ratio of said peroxide to said acrylate A is between 0.01 and 0.5, preferably between 0.13 and 0.41, and the weight ratio of said peroxide to said acrylate A is lower than 0.33 and said polymer P comprises or essentially consists of at least two polymers PI and P2, wherein PI exhibits a melt flow index (MFI) of between 100 and 200 g / 10 min, and P2 exhibits a melt flow index of between 0.1 and 60 g / 10 min, wherein MFI is determined by ASTM D1238. The thermally expandable composition shows excellent properties in terms of expansion stability and minimised buckling and is especially suitable for baffle and / or reinforcement elements, e.g. in automotive manufacturing.

Owner:SIKA TECH AG

Polishing device for new energy automobile manufacturing

InactiveCN112571184AMinimize grinding varianceSolve the problem of inconsistent grinding degreeEdge grinding machinesGrinding drivesNew energyPolishing

The invention relates to the technical field of mechanical polishing, in particular to a polishing device for new energy automobile manufacturing. The polishing device comprises a base and an upper shell, connecting plates are fixedly welded to the two symmetrical outer walls of the base and the upper shell, and a vertically-arranged hydraulic telescopic rod is fixedly installed between the connecting plate on the base and the connecting plate on the upper shell. A closed cavity can be formed between the base and the upper shell, a polishing mechanism is arranged in the closed cavity and comprises a motor fixedly installed in the middle of the top face of the upper shell through a support, the output end of the motor is fixedly connected with a circular shaft, the outer wall of the circular shaft is sleeved with a second cylinder, and a second external spline is fixedly welded to the outer wall of the circular shaft. A second internal spline used in cooperation with the second externalspline is arranged on the inner wall of the second cylinder, and the second external spline is inserted into the second internal spline all the time. The problem that in the prior art, the polishingdegrees of the two faces of a brake disc are inconsistent is solved, the beneficial effect is obvious, and popularization is facilitated.

Owner:容林

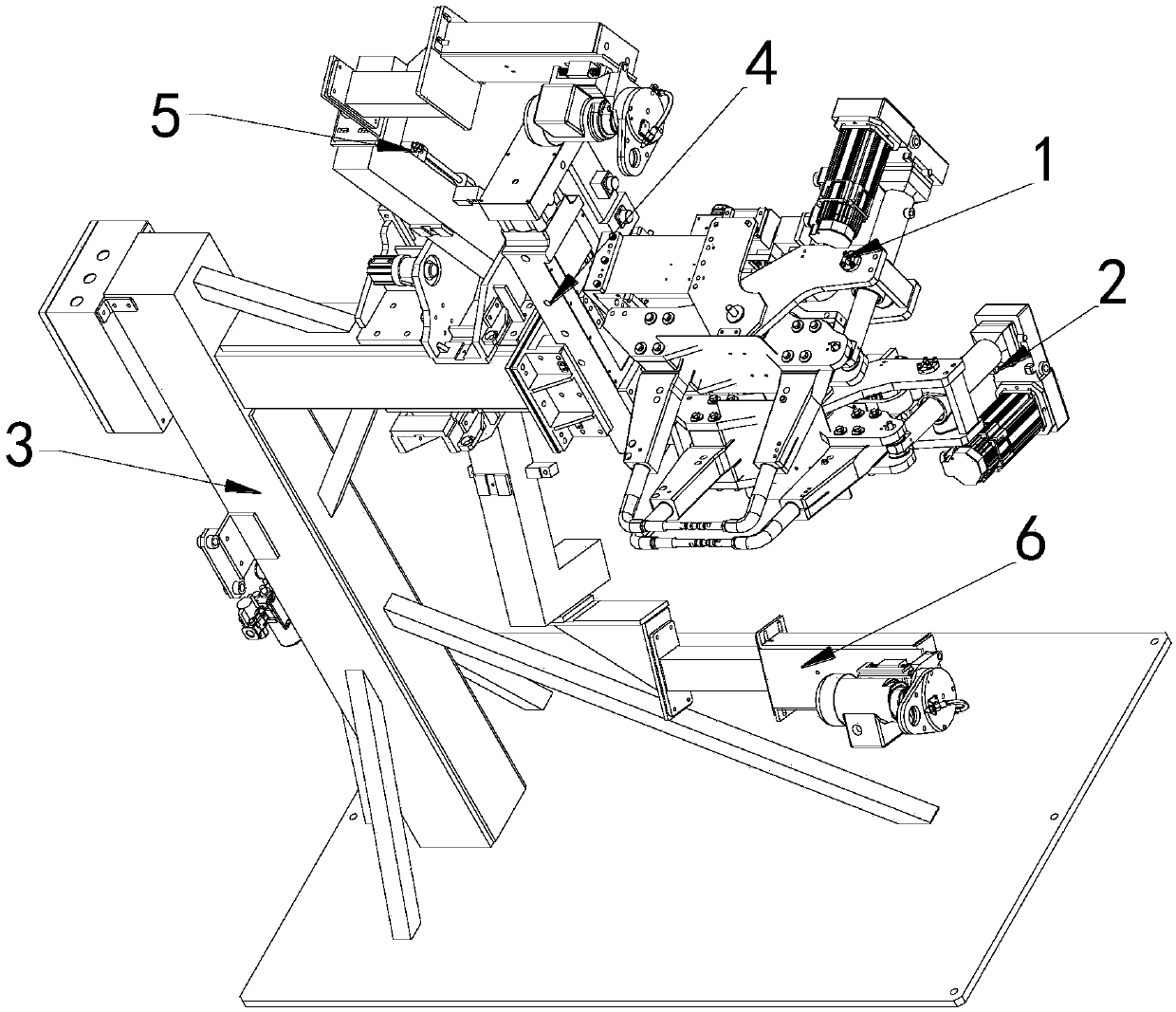

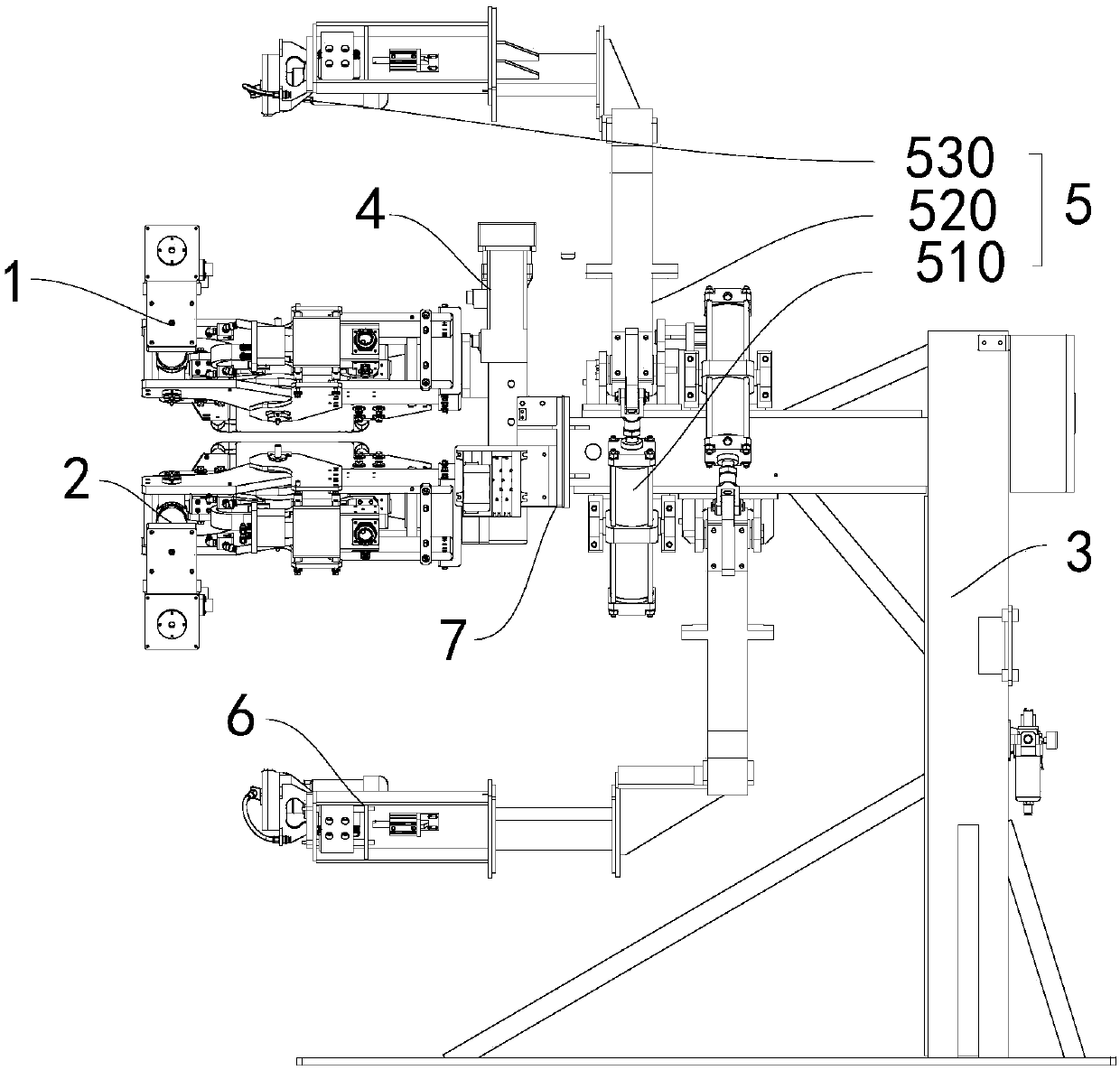

Intelligent double-gun spot welding machine

PendingCN107738029AIncrease profitHigh degree of automationResistance electrode holdersElectrode maintenanceProduction lineAutomotive industry

The invention relates to an intelligent double-gun spot welding machine. The intelligent double-gun spot welding machine comprises a first servo welding gun, a second servo welding gun and a sliding rail unit, wherein the first servo welding gun is arranged on the sliding rail unit; the second servo welding gun is arranged on the sliding rail unit; the first servo welding gun and / or the second servo welding gun is capable of independently moving under the action of the sliding rail unit. The intelligent double-gun spot welding machine has the beneficial effects that two independent servo welding guns are combined into one to design an intelligent double-gun spot welding machine on the premise that the requirements of integrated design on efficiency and spatial arrangement become increasingly higher under the condition that the integrated automation degree of the automobile industry at present becomes increasingly higher; the production efficiency and the production flexibility are improved; the efficiency of the double-gun spot welding machine is higher than the efficiency of two ordinary spot welding machines by 30%; in addition, the space utilization rate and the automation degree of the production line are also improved.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

Design method of system technology for mechanical energy pure electric automobile

PendingCN107161014AReduce manufacturing costImprove securityHybrid vehiclesMagnetic circuit rotating partsPower batteryFlywheel energy storage

The invention discloses a design method of a system technology for a new energy concept pure electric automobile. Relying on available system technologies of a conventional automobile except an engine, as well as the technological bases of a driving motor and a power battery, and based on the innovative thinking of increasing income and reducing expenditure, a multi-stage flywheel energy storage electromechanical system innovation technology which can significantly enhance the efficiency of a driving system, and an innovative application technology for deeply digging the potential of the automobile so as to transform the kinetic energy of the automobile and air resistance into power are invented, and a reliable material foundation is established for improving the endurance capacity of the new energy pure electric automobile. Through the adoption of the system technology for the mechanical energy pure electric automobile, the constraint of bottleneck problems such as short endurance mileage and high manufacturing cost of the pure electric automobile can be broken effectively, and the overall development of a new energy electric automobile manufacturing industry in the world is promoted.

Owner:戚成吉

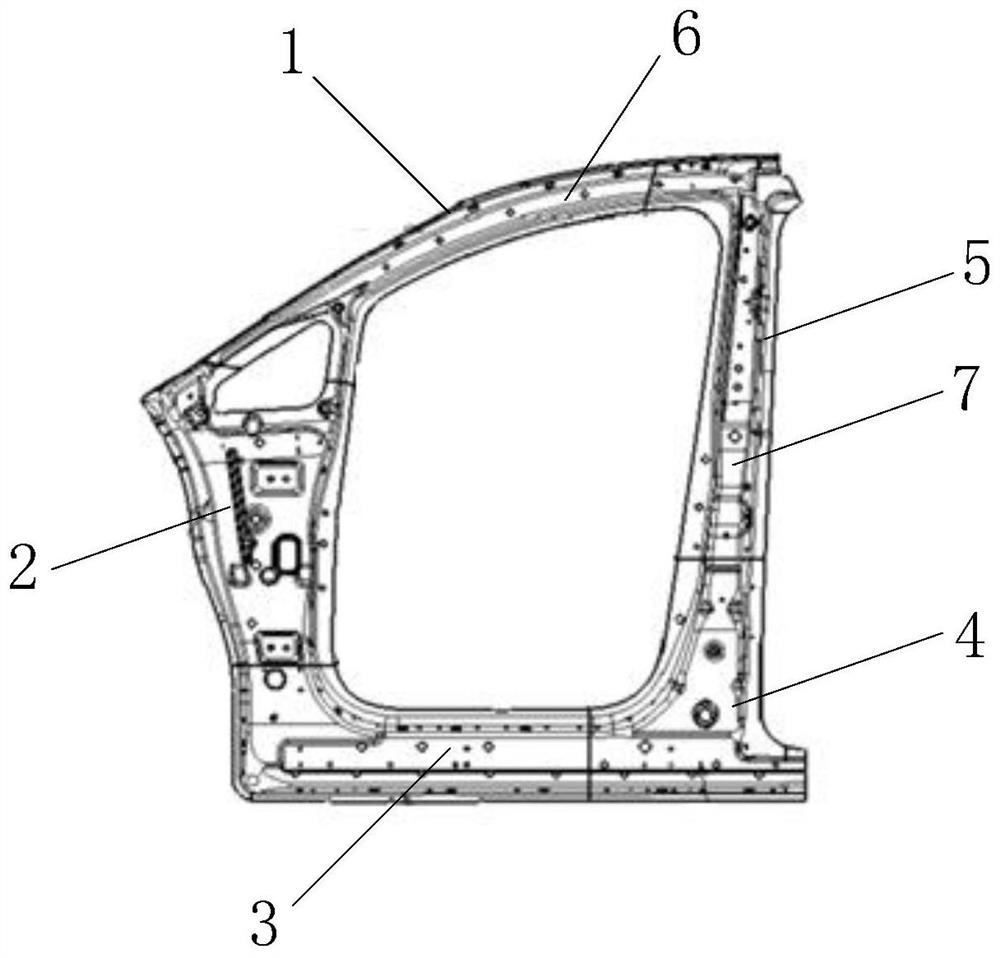

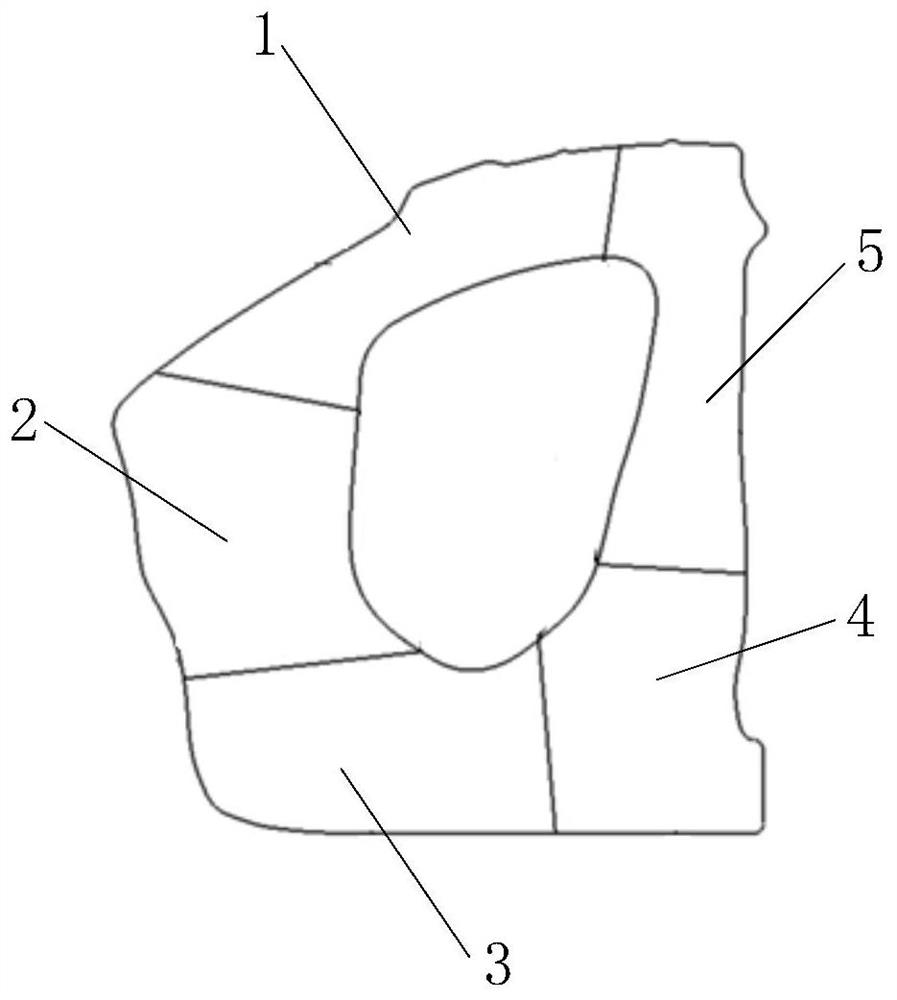

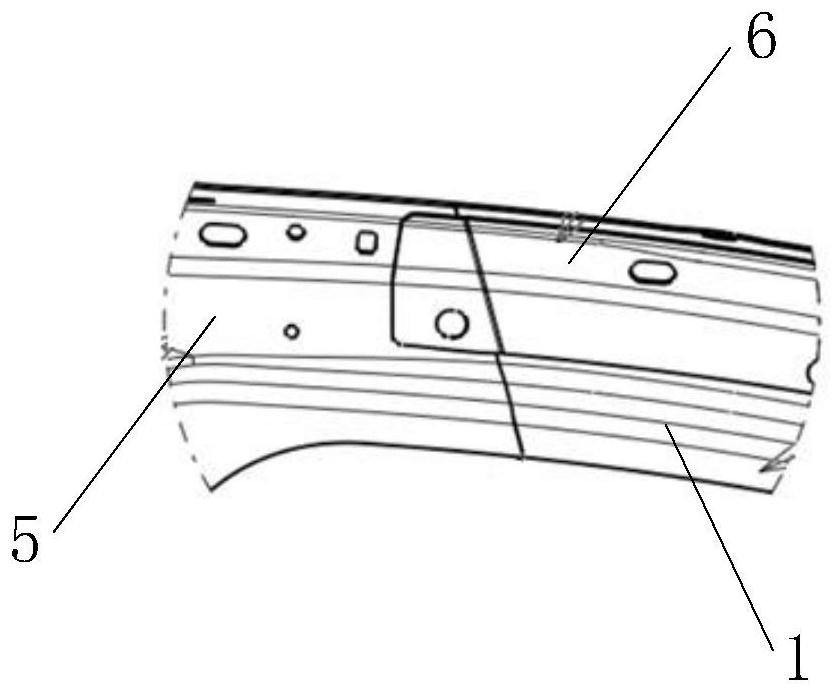

Thermal forming tailored blank laser welding integrated door ring and machining method

PendingCN113276954AGuaranteed thicknessMeet security strength requirementsSuperstructure subunitsLaser beam welding apparatusStructural engineeringSpot welding

The invention discloses a thermal forming tailored blank laser welding integrated door ring and a machining method, and relates to the field of automobile manufacturing. The door ring comprises a top cover edge beam, a column A, a doorsill, a column B lower portion and a column B upper portion, the top cover edge beam, the column A, the doorsill, the column B lower portion and the column B upper portion are sequentially welded through laser, a column A patch plate is arranged on the top cover edge beam, and a column B patch plate is arranged on the column A patch plate. A B column patch plate is arranged on the B column upper part. The A column patch plate is connected with the top cover edge beam in a spot welding mode, and the B column patch plate is connected with the upper portion of the B column in a spot welding mode. According to the method, raw materials are saved. Meanwhile, the thicknesses of all parts can be guaranteed according to the preset thickness requirement through independent stock layout and blanking, the safety strength requirements of different positions of the door ring are met, the safety of an automobile is guaranteed, and the weight of the automobile is reduced.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Predictive maintenance information feedback method and device for automobile manufacturing equipment

PendingCN111931979AImprove the effectiveness of predictive maintenanceEasy to determineForecastingManufacturing computing systemsProduction lineAppliance component

The invention provides a predictive maintenance information feedback method and device for automobile manufacturing equipment. The predictive maintenance information feedback method for the automobilemanufacturing equipment comprises the steps that at least one production area is determined, each production area comprises at least one production line, each production line comprises at least one automobile manufacturing equipment, and each automobile manufacturing equipment comprises at least one equipment assembly; for each production area, predictive maintenance information for the production area is obtained from a predictive maintenance system; the maintenance state information of each production area is respectively displayed; and after a first trigger for any production area is received, the predictive maintenance information obtained for the production area is displayed, and the predictive maintenance information comprises the name of the corresponding maintenance object, the name of the automobile manufacturing equipment to which the predictive maintenance information belongs, the abnormality type and the alarm sending time. According to the scheme, the effect of predictivemaintenance of the automobile manufacturing equipment can be improved.

Owner:SIEMENS FACTORY AUTOMATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com