New energy automobile manufacturing chassis physical performance test system and test method

A new energy vehicle and physical performance technology, applied in the field of new energy vehicle manufacturing chassis physical performance test system, can solve the problems of low vehicle detection efficiency and time-consuming, and achieve the effect of improving physical test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

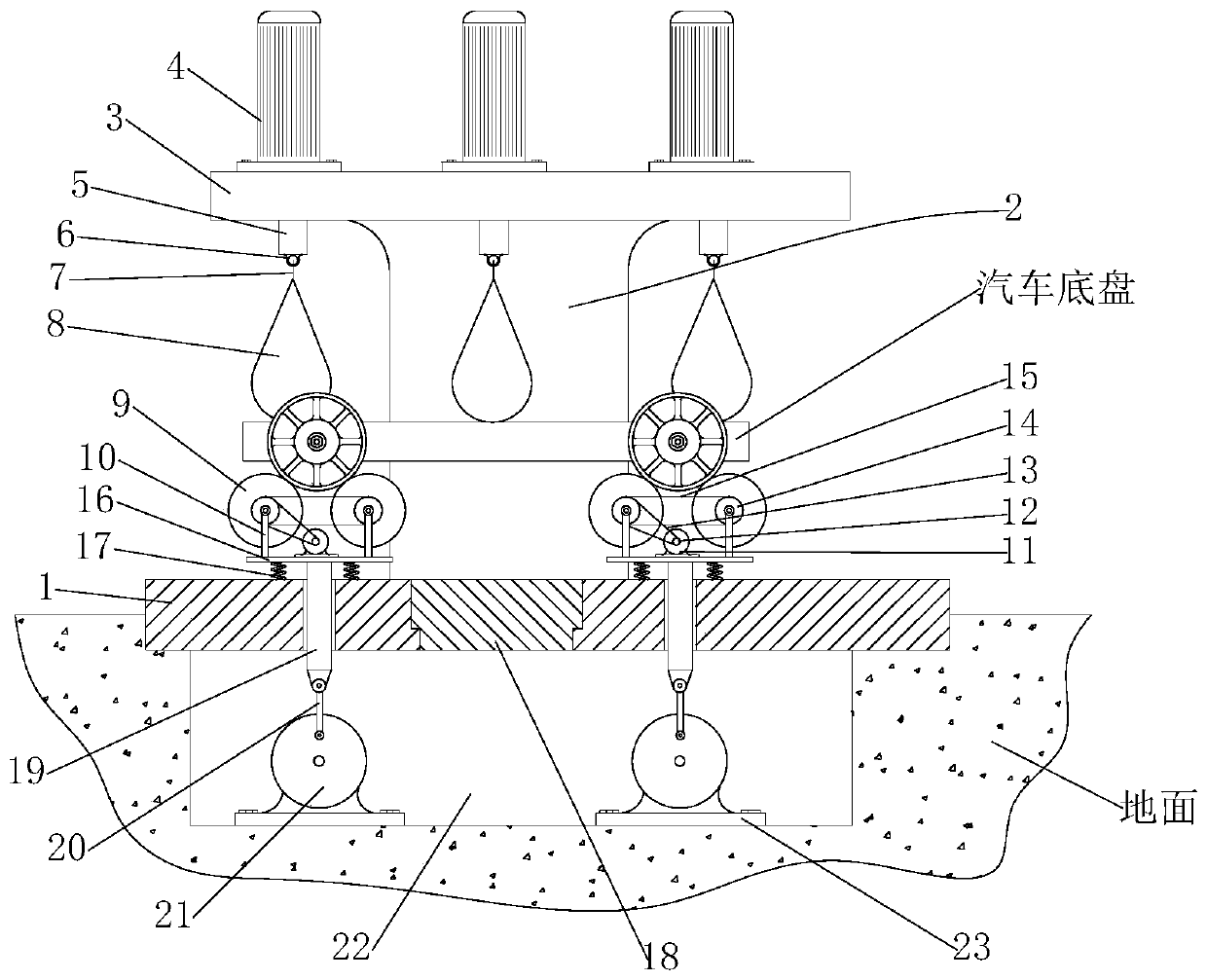

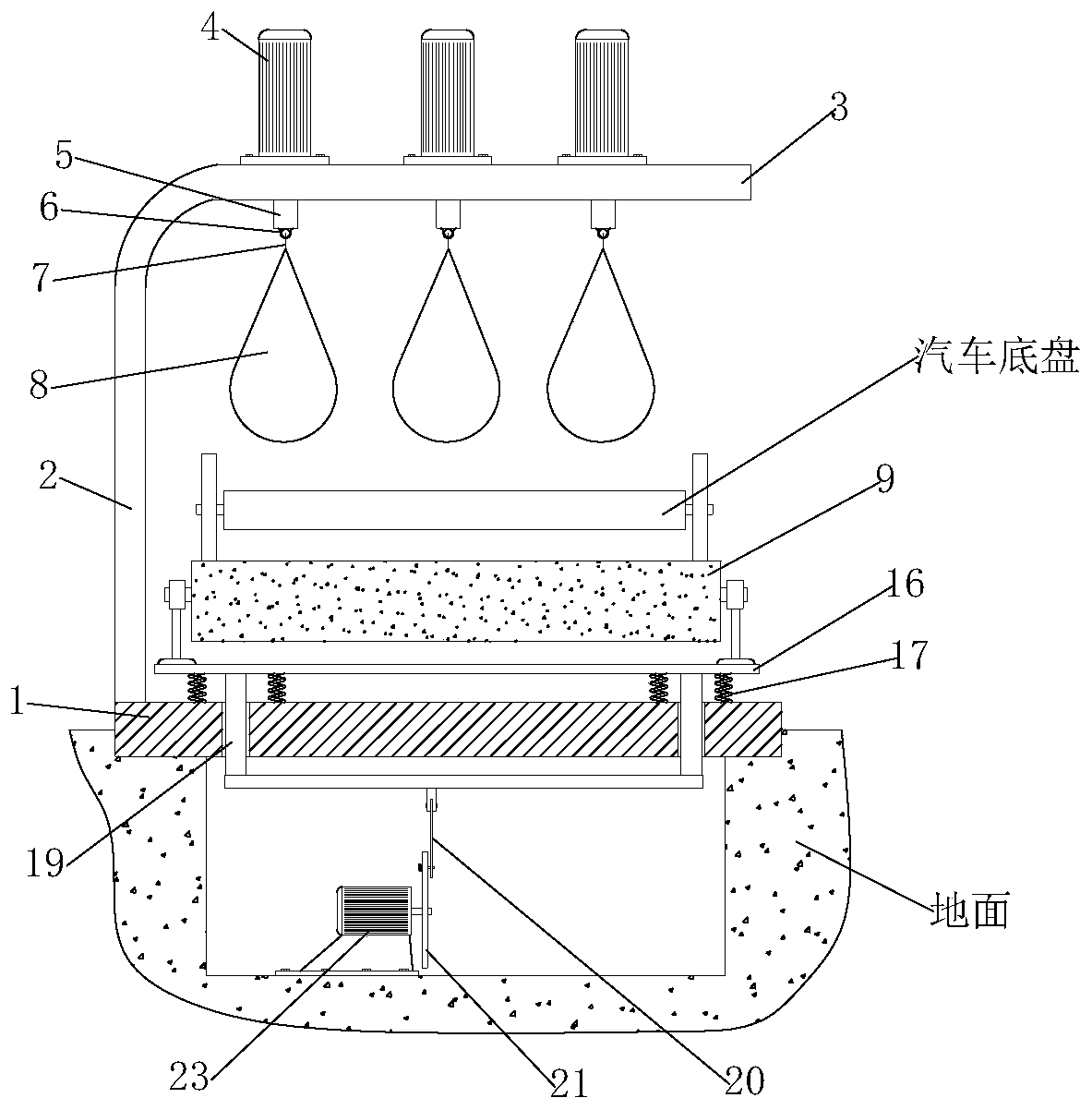

[0037] see Figure 1-6 , which is a schematic diagram of the overall structure of a new energy vehicle manufacturing chassis physical performance testing system and testing method;

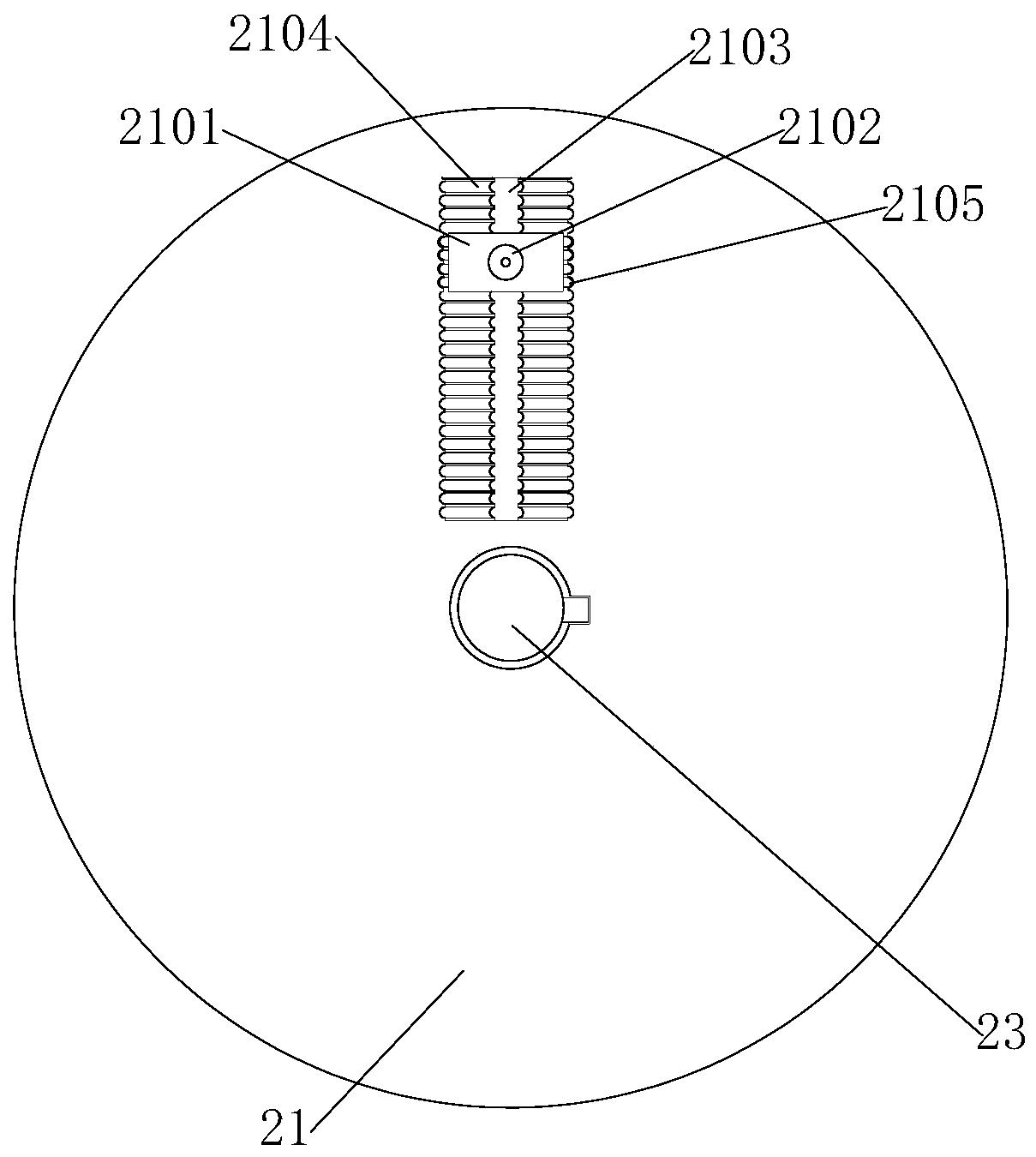

[0038] A new energy vehicle manufacturing chassis physical performance testing system, the new energy vehicle manufacturing chassis physical performance testing system includes a bottom support plate 1 fixedly installed on the ground, the bottom support plate 1 is a square plate structure, and the middle part of the bottom support plate 1 is opened. Through the square mouth, the square mouth of the bottom support plate 1 is equipped with a backing plate 18, the backing plate 18 is a detachable structure, and the backing plate 18 is a detachable device, which is convenient for manually opening the backing plate, manually entering the foundation pit 22, and adjusting the wedge The working position of 2103 improves the ease of operation.

[0039] The top of the bottom support plate 1 is provided wit...

Embodiment 2

[0051] see Figure 1-7 , this embodiment has similarities with the above-mentioned embodiment 1, and the similarities will not be described in this embodiment again, and the specific differences are:

[0052] The present invention also provides a method for testing the physical properties of the chassis of a new energy vehicle. The method for testing the physical properties of the chassis of a new energy vehicle mainly includes the following steps:

[0053] S1. Chassis installation: install the new energy vehicle chassis above the roller 9 on the top of the fixed support plate 16, support the new energy vehicle chassis through the roller 9 and drive the tires of the new energy vehicle chassis to rotate;

[0054] S2. Speed test: Carry out a speed test on the new energy vehicle chassis installed on the drum 9 in step S1, use the first servo motor 11 to drive the tires of the new energy vehicle chassis to rotate on the drum 9, and control the drum through the first servo motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com