780MPa-grade cold-rolled hot-dip galvanized dual-phase steel and preparation method thereof

A technology of hot-dip galvanizing and dual-phase steel, applied in hot-dip galvanizing process, coating, metal material coating process, etc., to achieve the effect of reducing fuel consumption, stable chemical composition, and increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

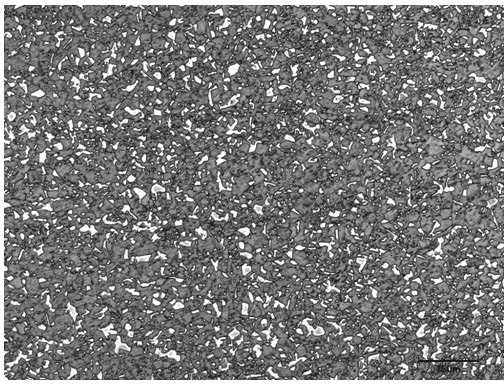

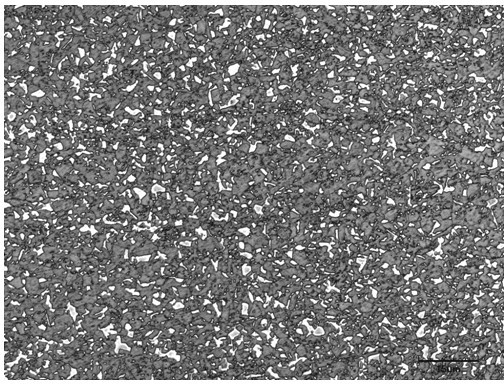

Image

Examples

Embodiment 1

[0048] Example 1, using the production method provided by the present invention to carry out smelting, the weight percentages of the target chemical components at the smelting end point are: C: 0.12%, S: 0.005%, P: 0.008%; the target temperature at the end point of the first furnace during the smelting process It is 1670~1690℃; the target temperature of continuous pouring in the smelting process is 1660~1680℃; Al-Fe is used for deoxidation in the smelting process, and the amount of Al-Fe added is 4kg / t; during the smelting process, adding Slag material, the slag material is added with the steel flow in the early stage of tapping, and 800kg of small-grained lime and 200kg of fluorite are added before the tapping amount of each furnace reaches 1 / 5; after that, Si-Mn is used to adjust Si and micro-carbon Mn-Fe is used to adjust Mn, so that the mass percentage of Mn is 1.9%; the smelting process is in the tapping process, the amount of slag after tapping is ≤80mm, and the tapping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com