Patents

Literature

36results about How to "Fully hardened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

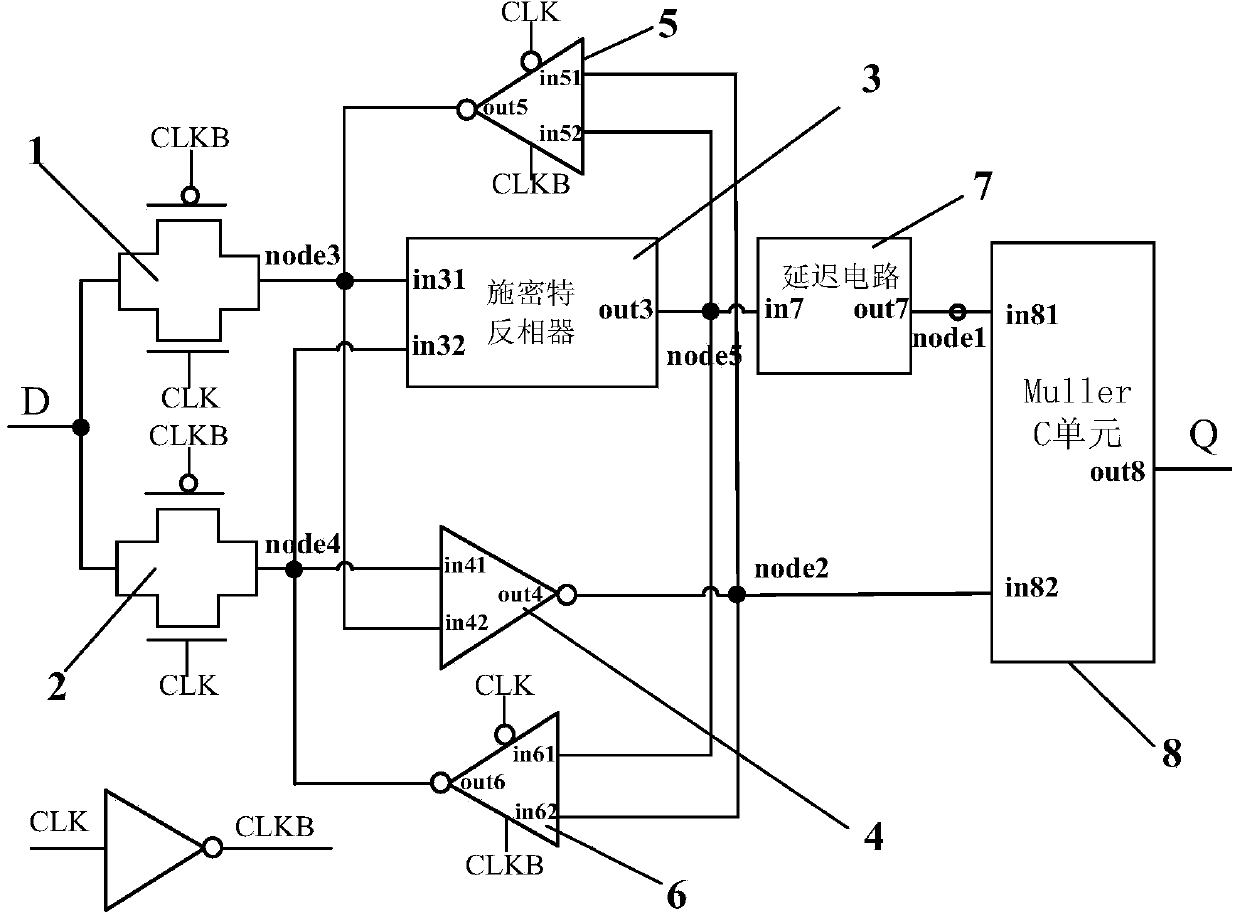

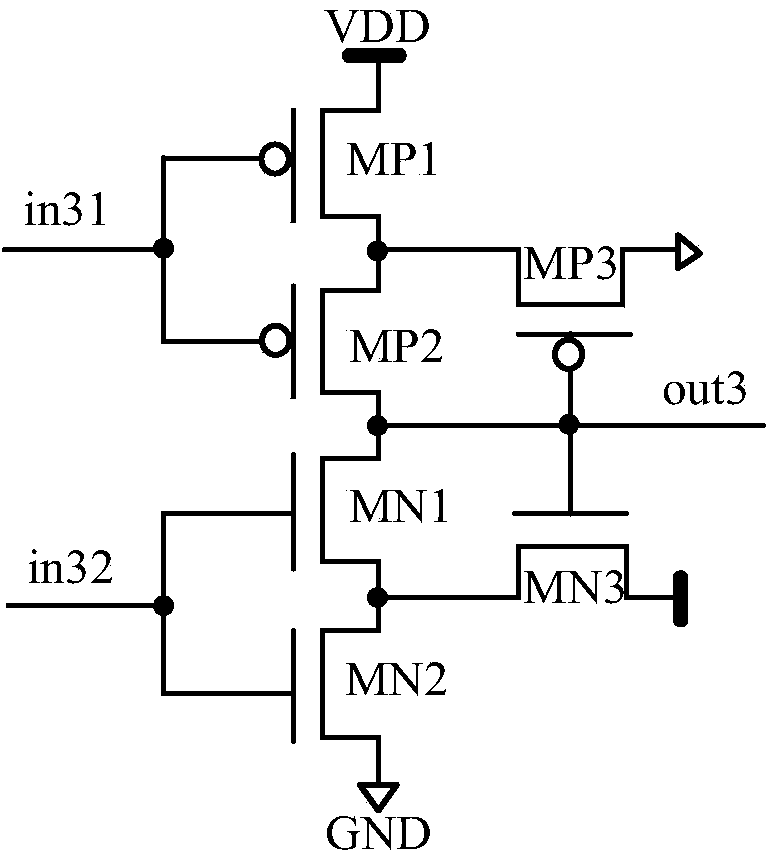

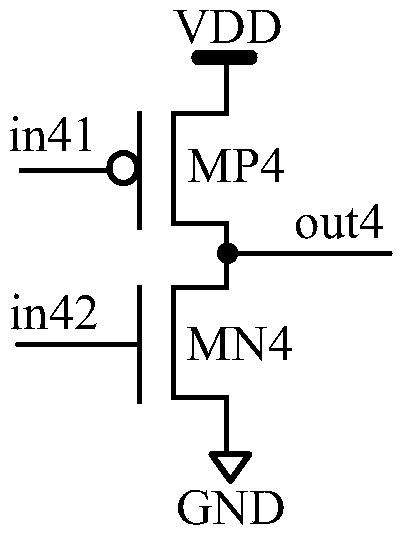

Single event radiation effect resistant reinforced latch circuit

InactiveCN104202037AFully hardenedReduce power consumptionElectric pulse generatorLogic circuitsHysteresisTransmission gate

The invention discloses a single event radiation effect resistant reinforced latch circuit. The single event radiation effect resistant reinforced latch circuit comprises a first transmission gate unit, a second transmission gate unit, a Schmitt inverter, a conventional input separation inverter, a first input separation clock-controlled inverter, a second input separation clock-controlled inverter, a delay circuit and a MullerC unit circuit. When the single event radiation effect resistant reinforced latch circuit operates under a transparent mode, a hysteresis effect of the Schmitt inverter and a delay difference of a latch interior unit are effectively used and SET pulses from a combinational logic unit are shielded through the MullerC unit; when the single event radiation effect resistant reinforced latch circuit operates under a latch mode, any interior node generating SEU due to the irradiation effect can be recovered through states of other nodes through a DIC unit structure having a self-recovery capability and correct output of the latch is guaranteed; accordingly the single event radiation effect resistant reinforced latch circuit has the advantages of effectively eliminating the radiation effect influences and being applicable to a clock gating circuit and small in power consumption and area costs.

Owner:HEFEI UNIV OF TECH

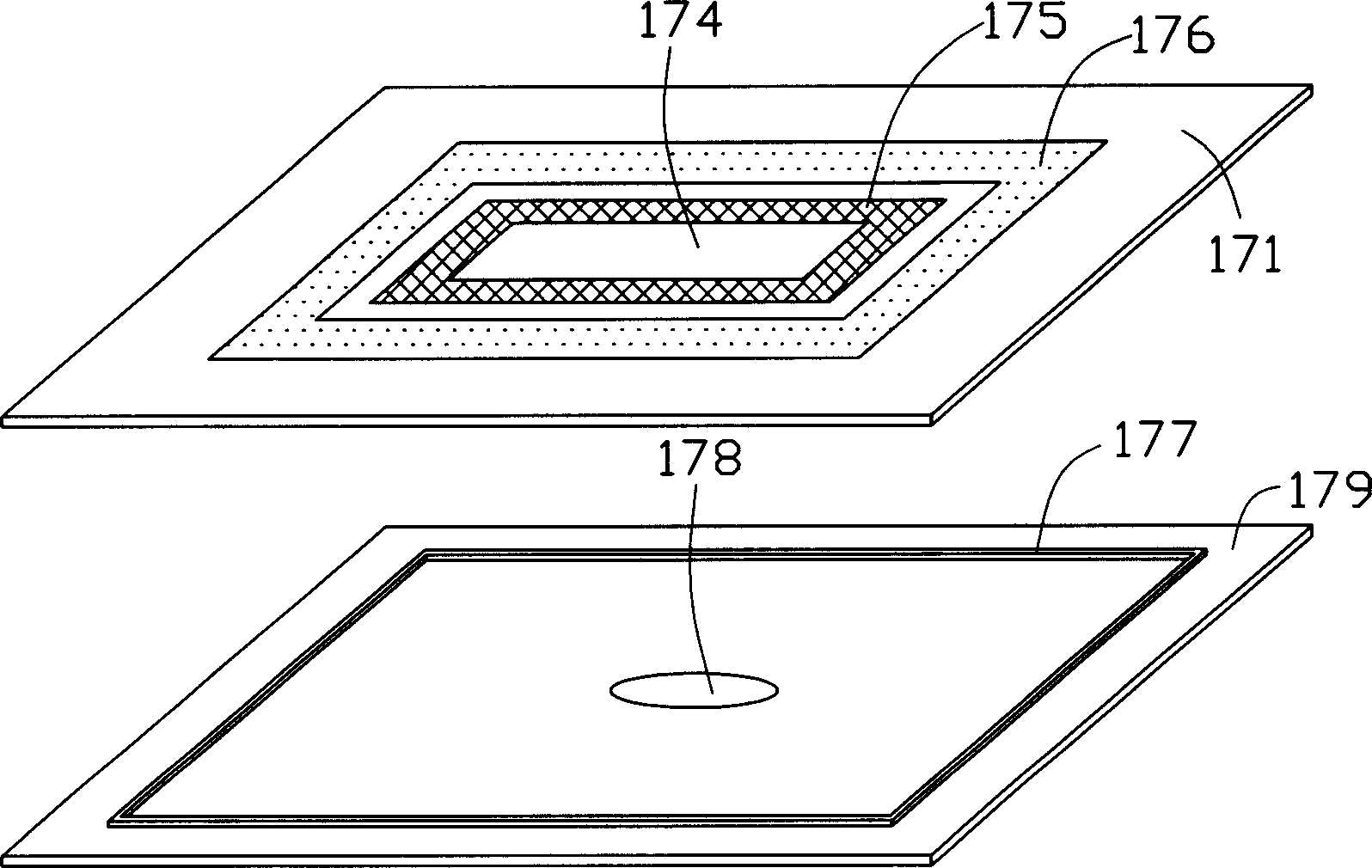

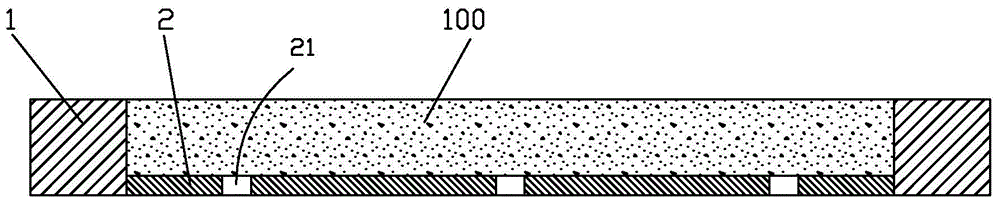

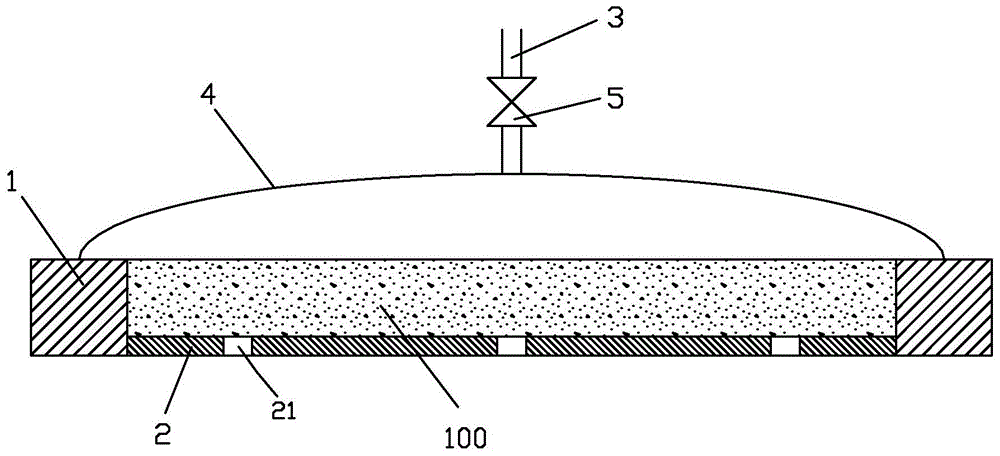

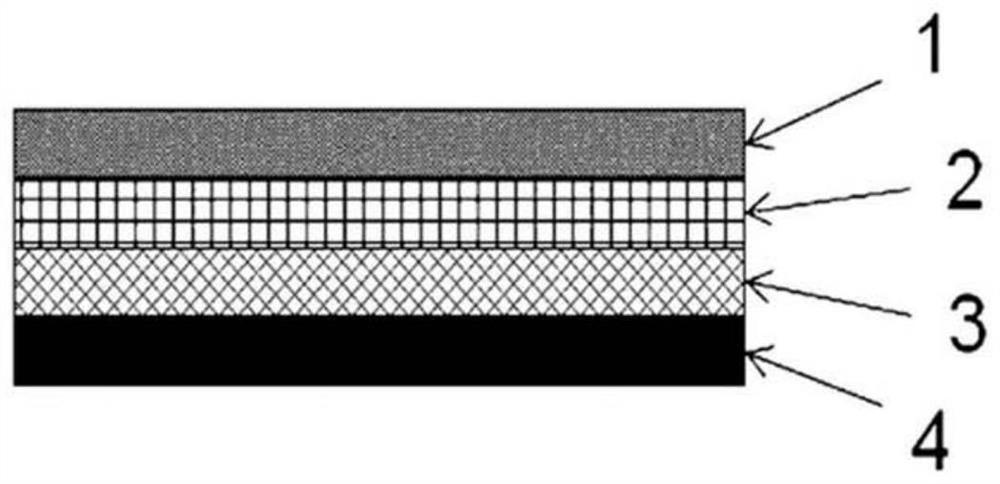

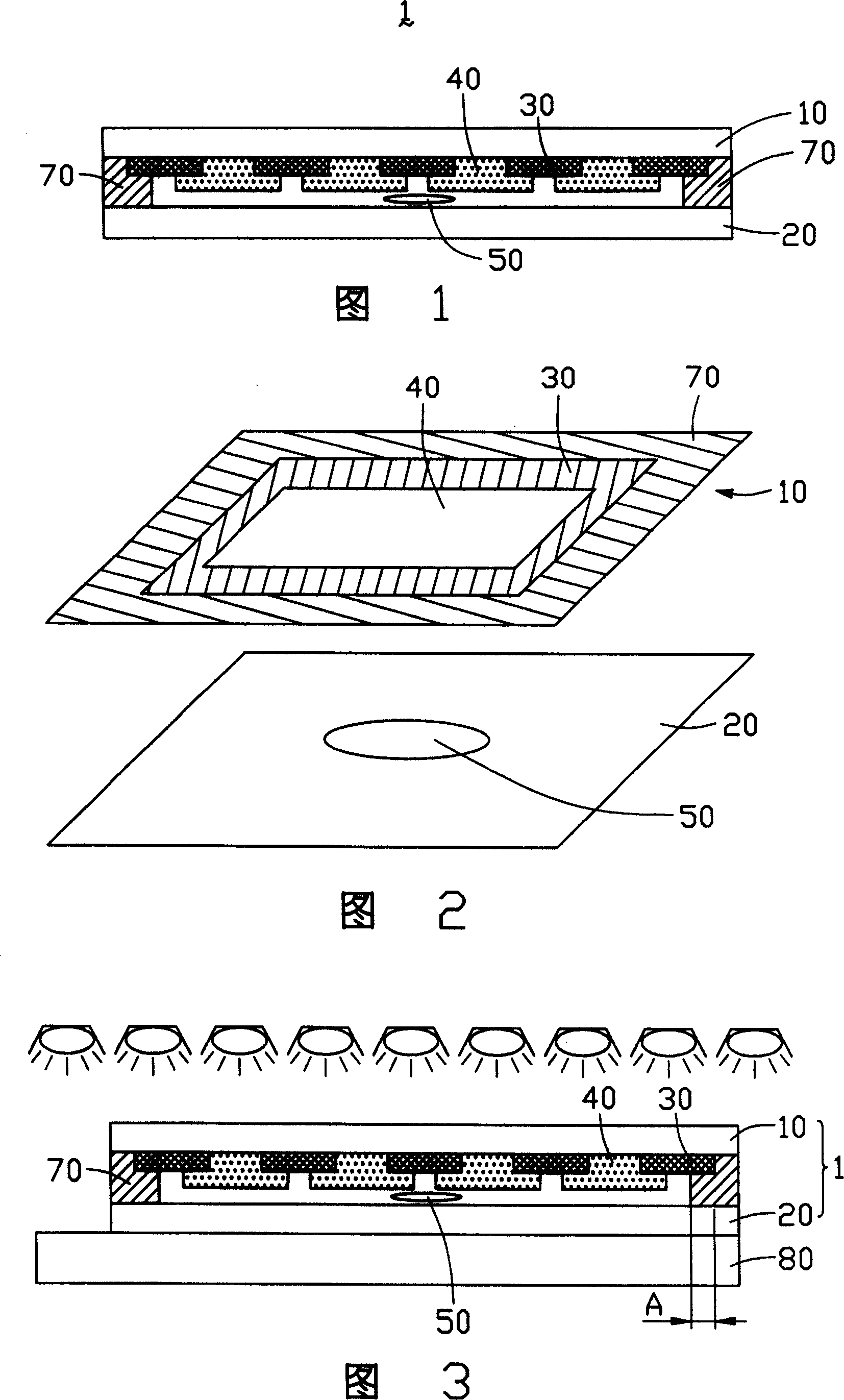

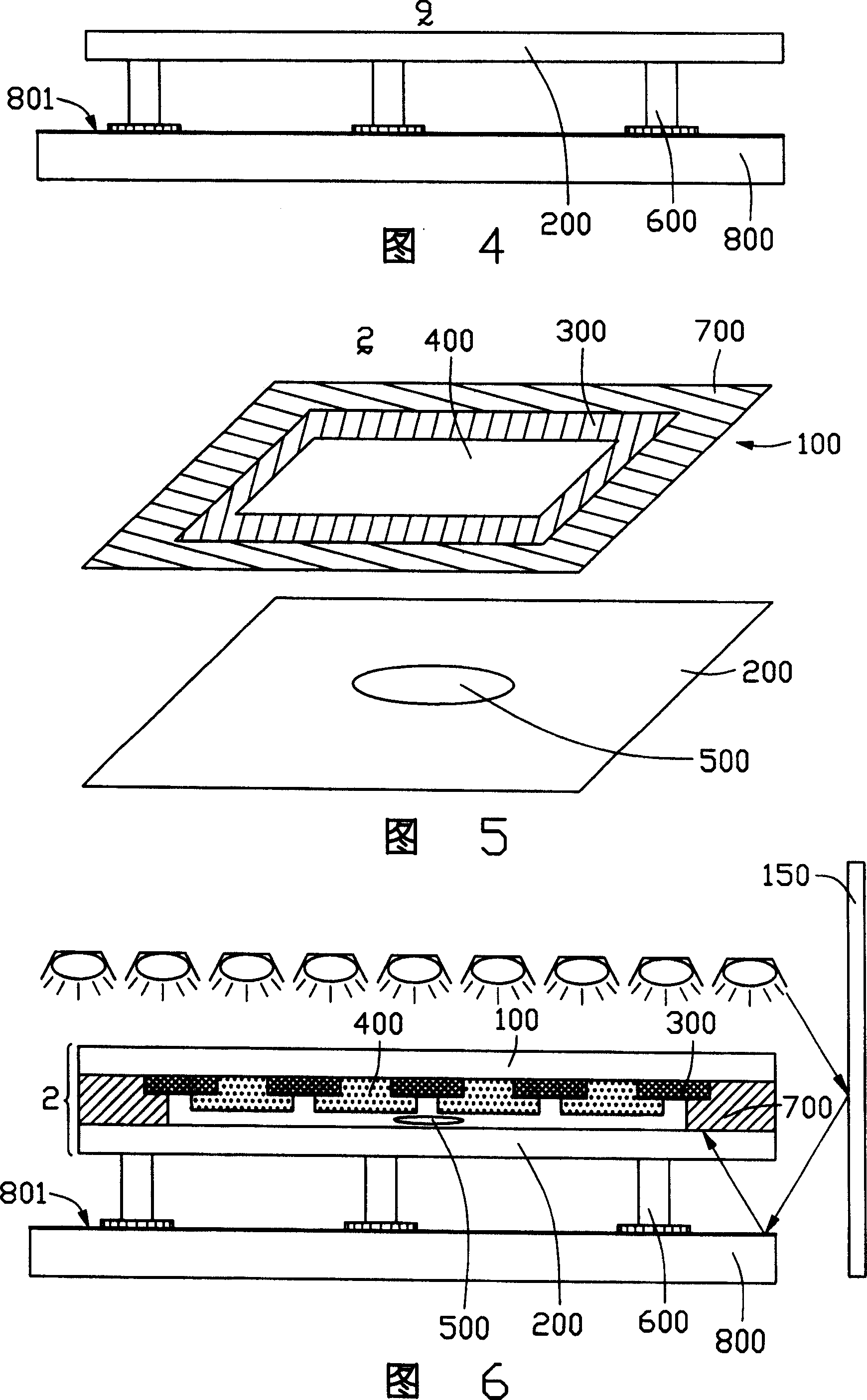

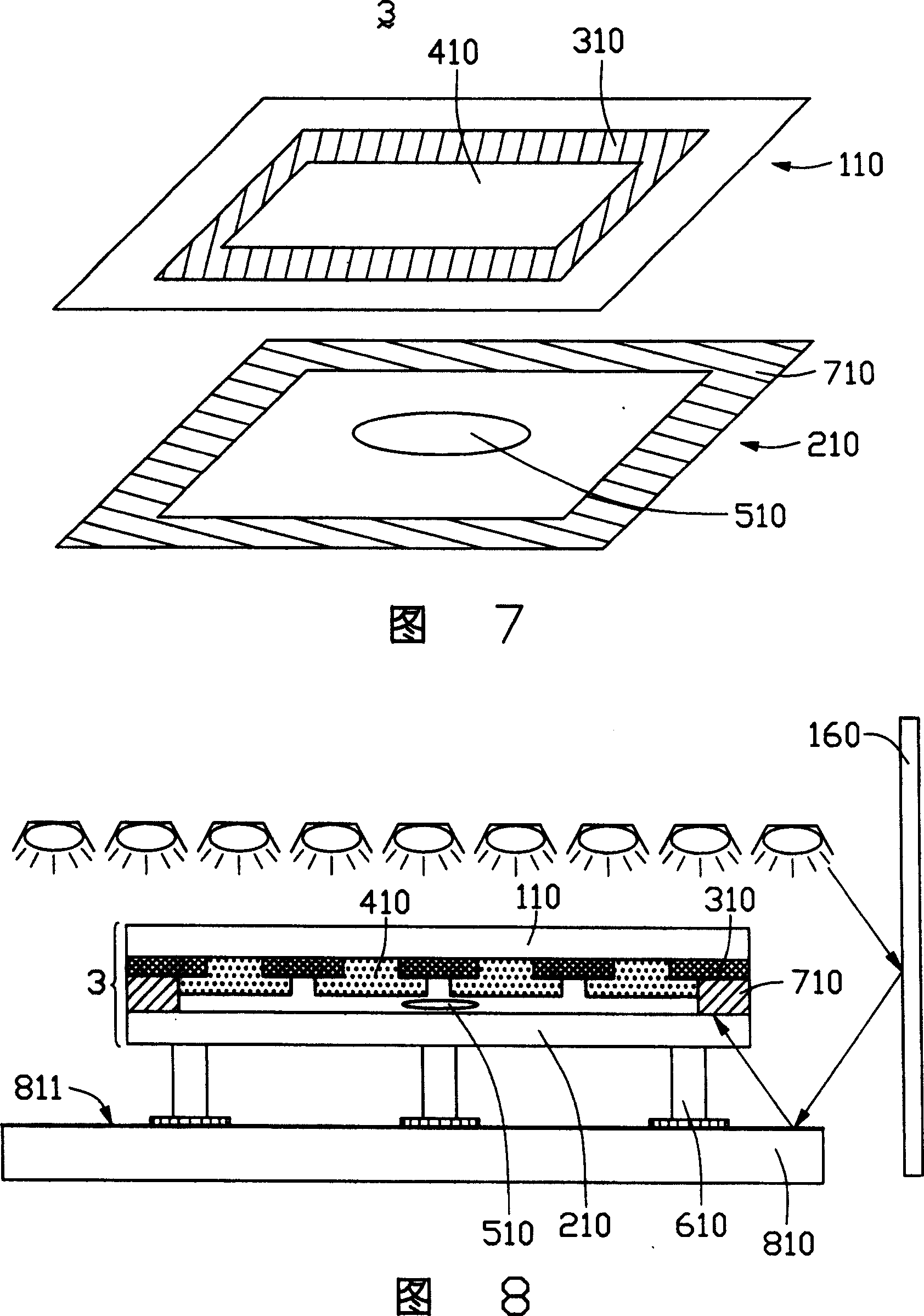

Faceplate of liquid crystal display

InactiveCN1696776AUniform thicknessAvoid light leakageStatic indicating devicesNon-linear opticsLiquid-crystal displayGlue line

A liquid crystal display panel is prepared as setting the first baseplate opposite to the second one and placing liquid crystal layer between said two baseplates, using glue line to bind said two baseplates, dividing each of said two baseplates to be a central portion and peripherical portion, scattering light interval objects in either central portion or peripherical portion of the two baseplates and confirming that its distribution density in central portion line near to glue line is greater than distribution in central portion far from glue line.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

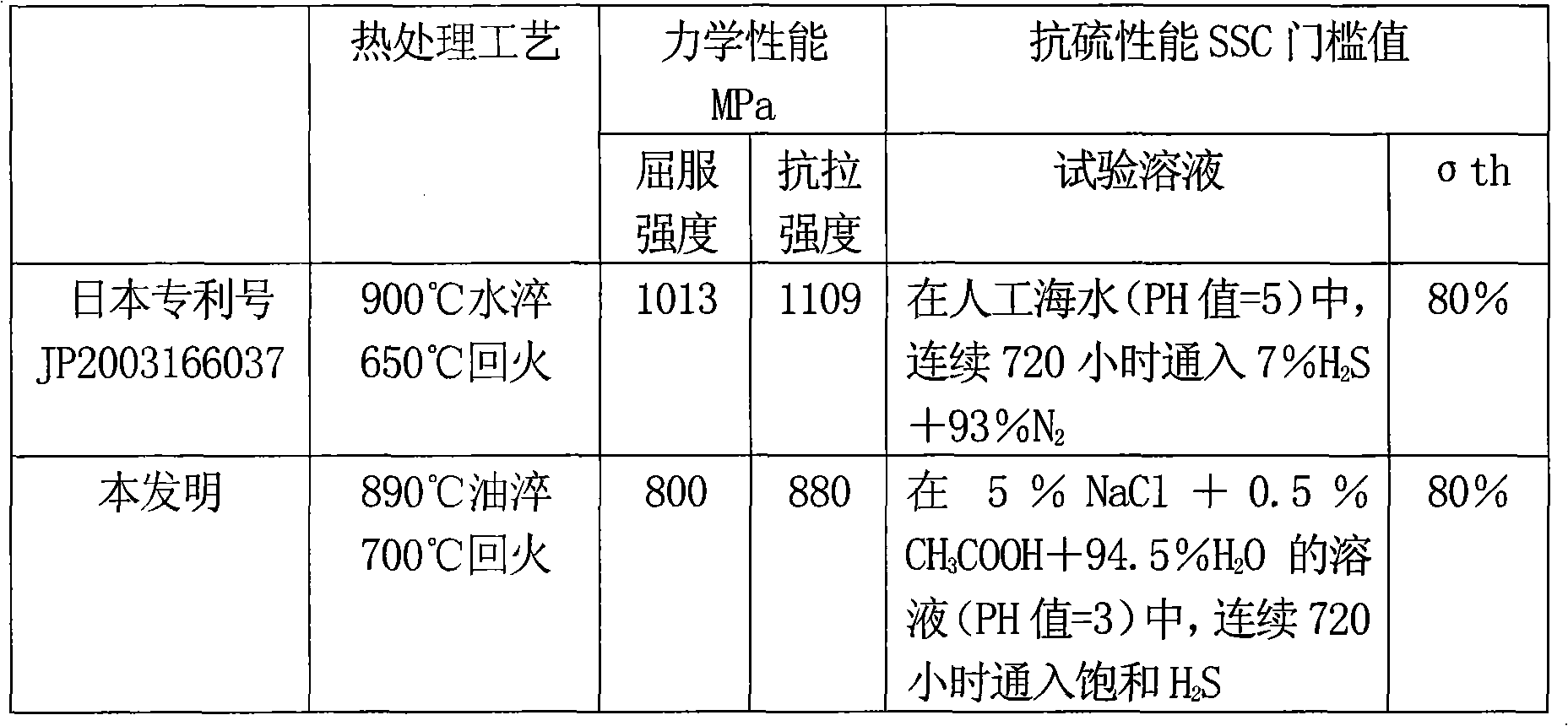

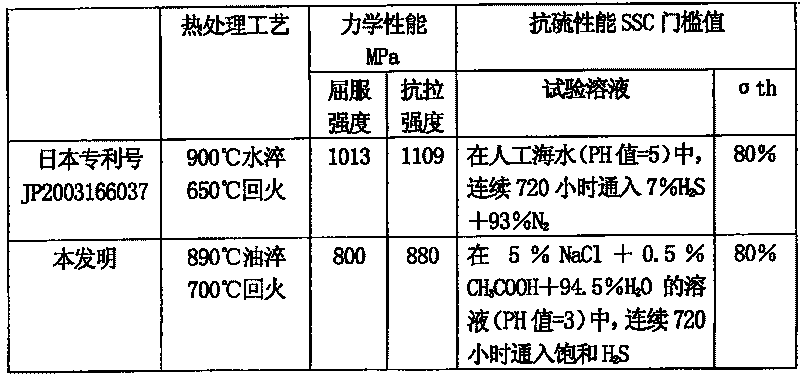

H2S-corrosion-resistant tool joint for petroleum drill pipe and hot treatment method thereof

ActiveCN101275207AImprove hardenabilityGuaranteed full hardeningDrilling rodsFurnace typesHydrogenSulfur

Owner:BAOSHAN IRON & STEEL CO LTD

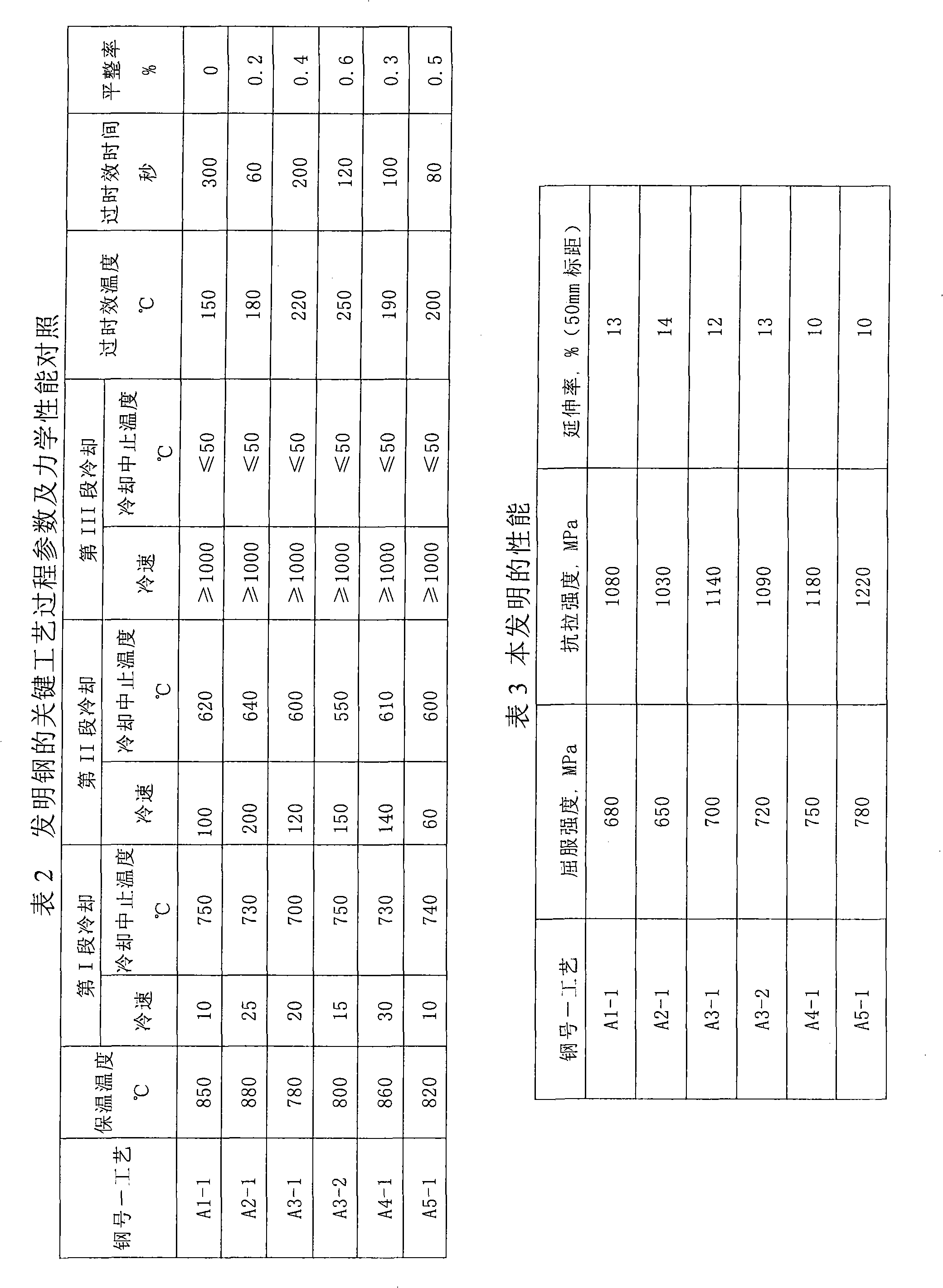

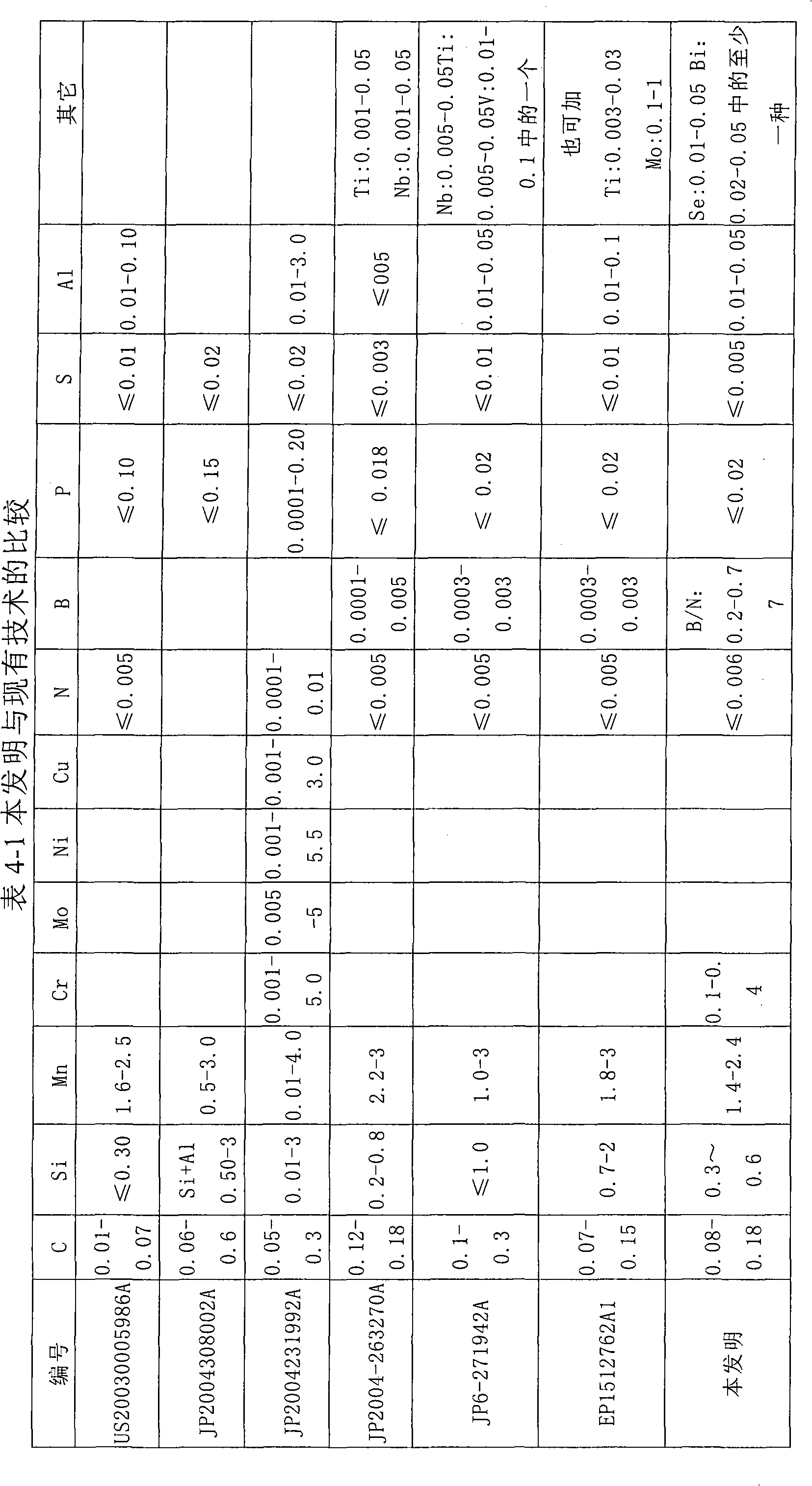

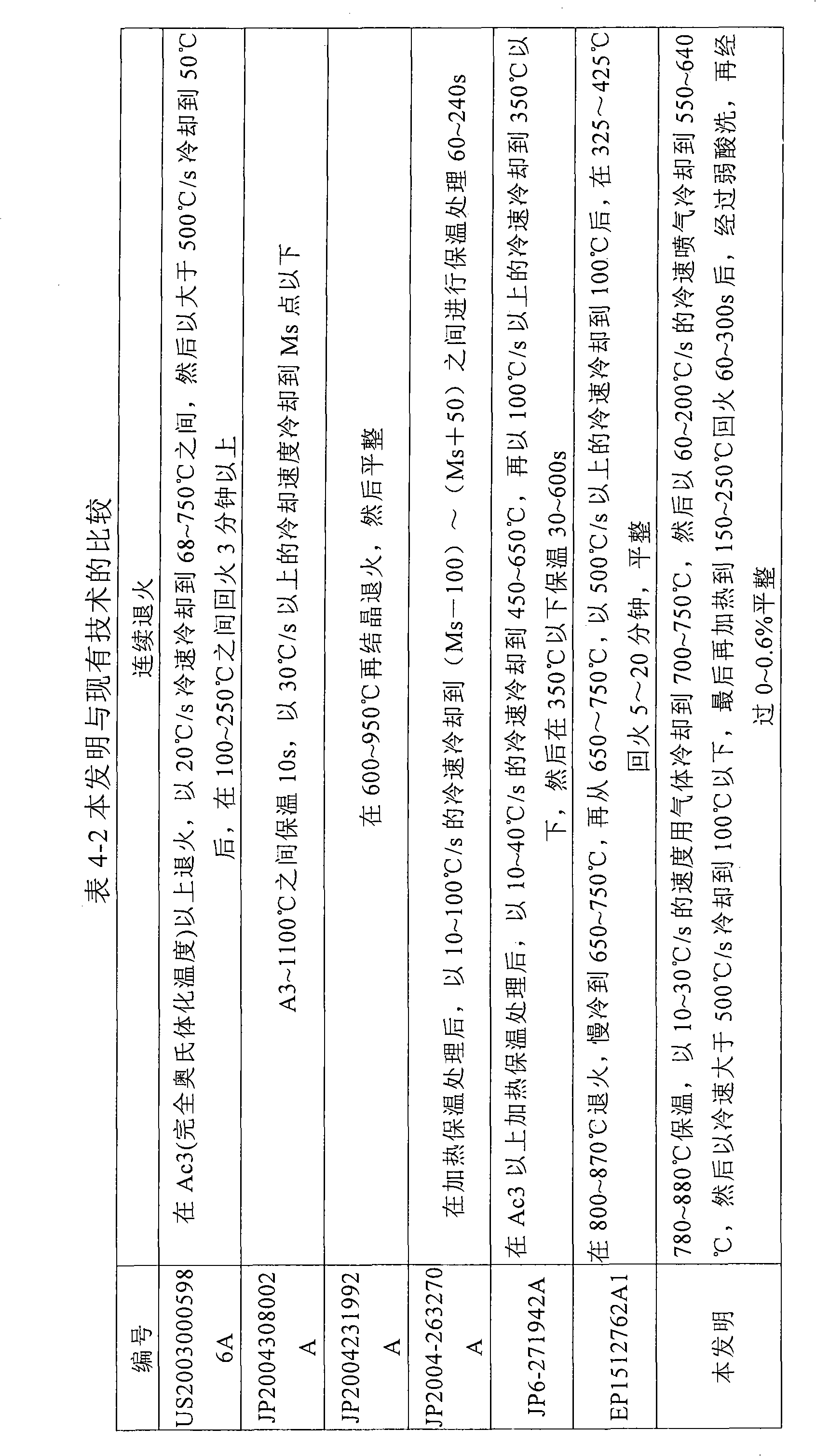

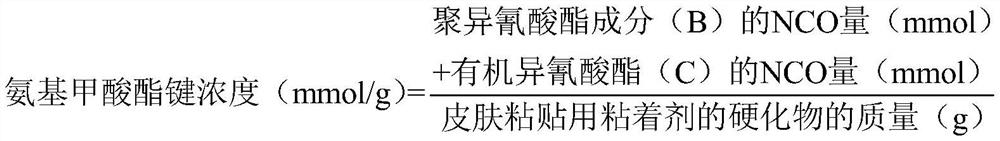

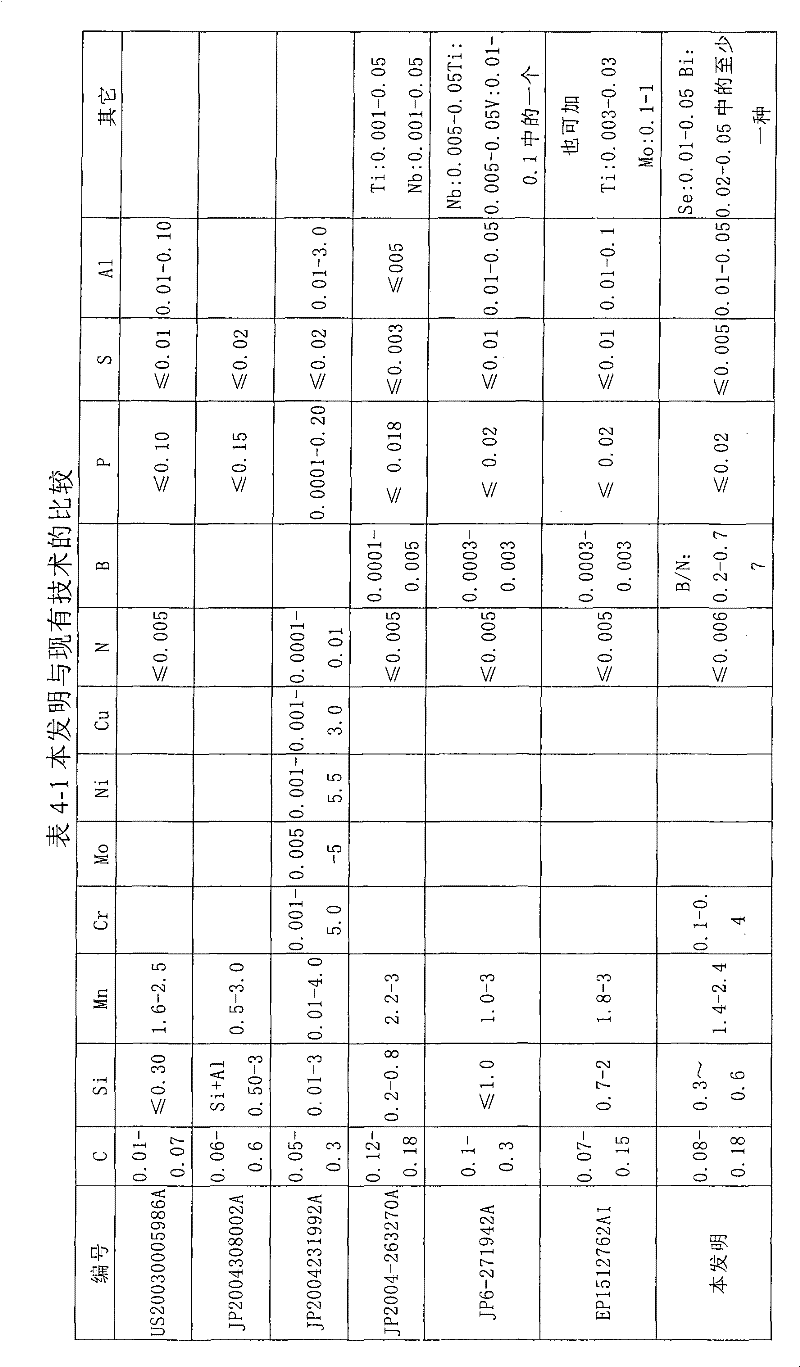

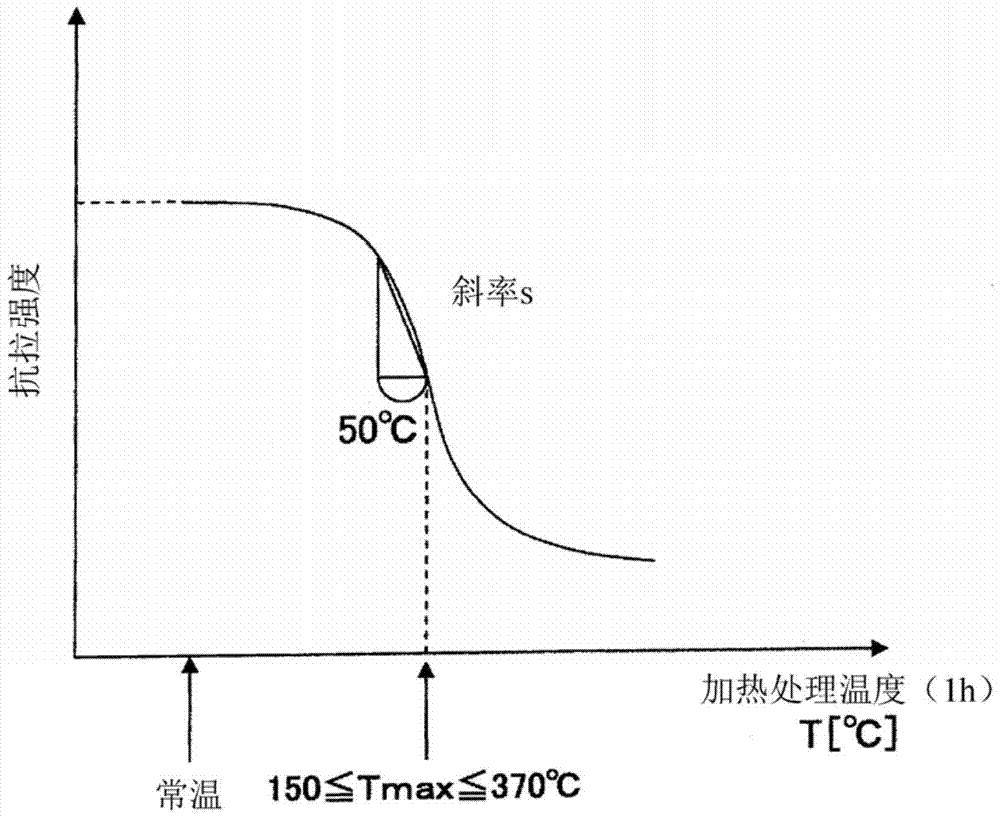

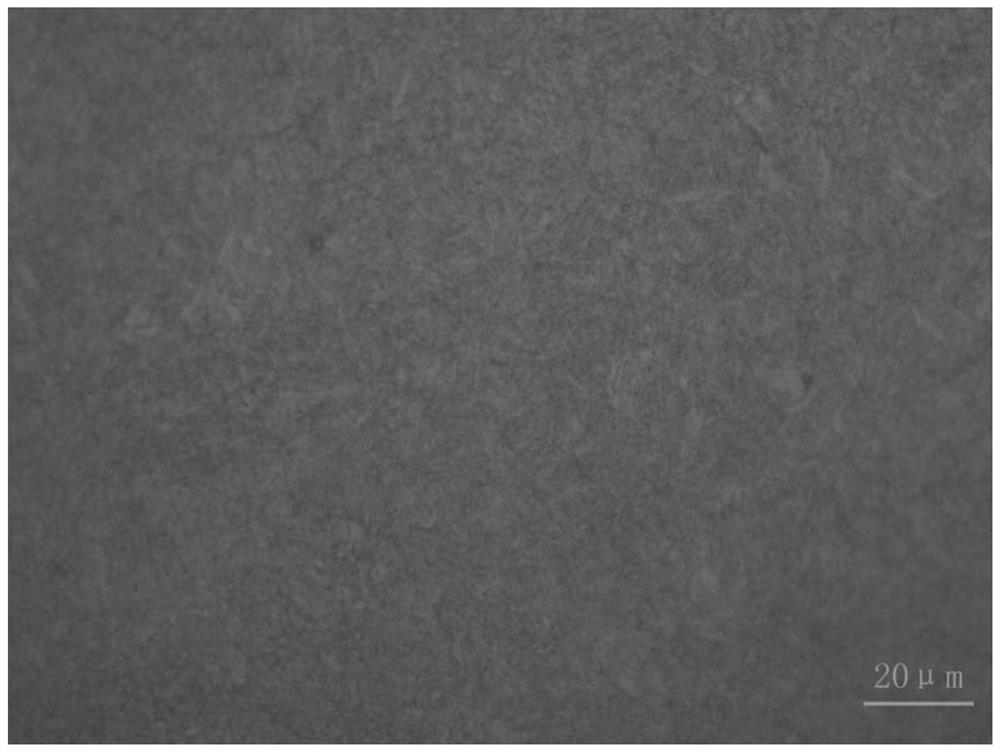

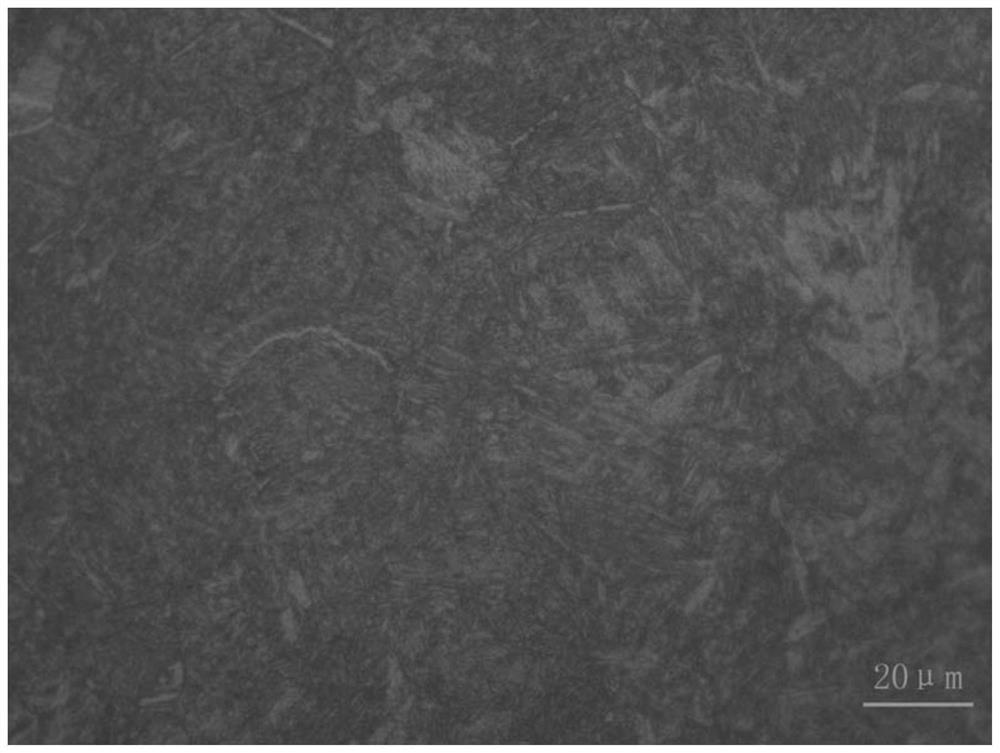

Super-high strength cold rolled steel and manufacturing method thereof

The invention discloses super-high strength cold rolled steel or steel plate, which comprises the following chemical components in percent by weight: 0.08 to 0.18 percent of C, 0.1 to 0.6 percent of Si, 1.4 to 2.4 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, 0.01 to 0.05 percent of A1, less than or equal to 0.006 percent of N, 0.2 to 0.77 percent of B / N and the balance of Fe and inevitable impurities. A manufacturing method for the super-high strength cold rolled steel comprises the following steps: performing hot rolling, wherein the finishing temperature is between 830 and 930 DEG C and the coiling temperature is between 550 and 650 DEG C; performing cold rolling, wherein the rolling reduction is 40 to 70 percent; performing continuous annealing, namely holding the temperature between 780 and 880 DEG C, cooling the steel to be between 700 and 750 DEG C with air at a rate of between 10 and 30 DEG C / s, cooling the steel to be between 550 and 640 DEG C by air blast at the cooling rate of between 60 and 200 DEG C / s, cooling the steel to be below 100 DEG C at the cooling rate greater than 500 DEG C / s and heating the steel to be between 150 and 250 DEG C to perform tempering for 60 to 300s; washing the steel with weak acid; and levelling the steel by 0 to 0.6 percent. Thus the obtained super-high strength band steel or steel plate with high processability can be applied to structures or enhanced parts for automobile manufacturing.

Owner:BAOSHAN IRON & STEEL CO LTD

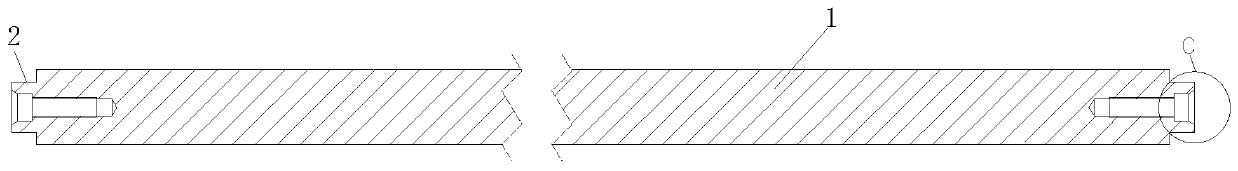

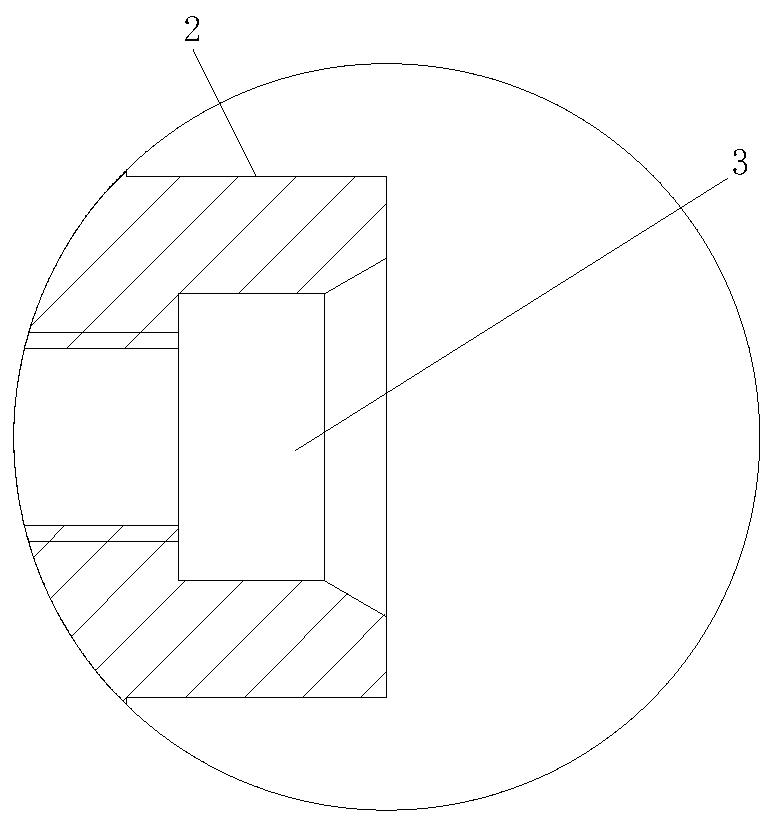

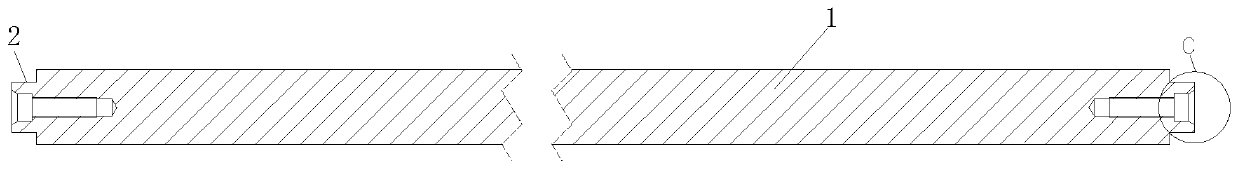

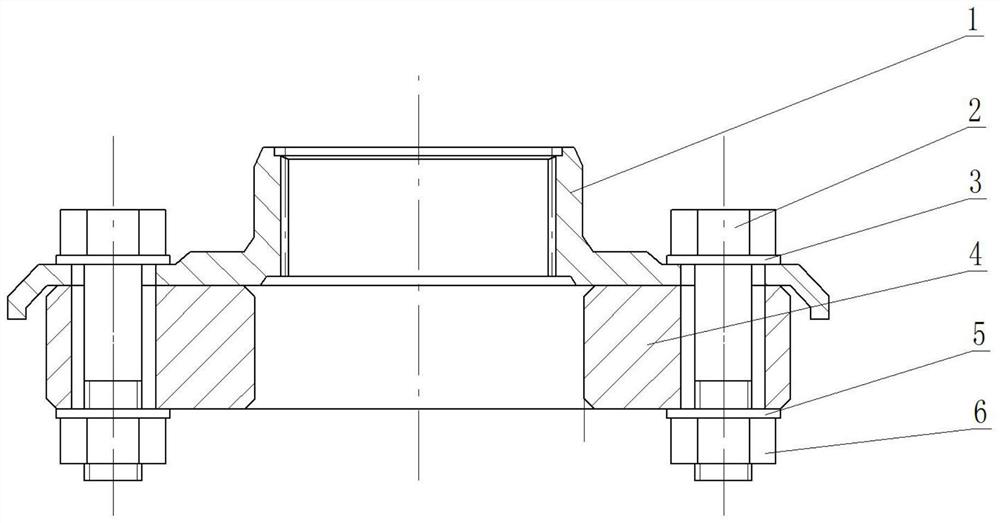

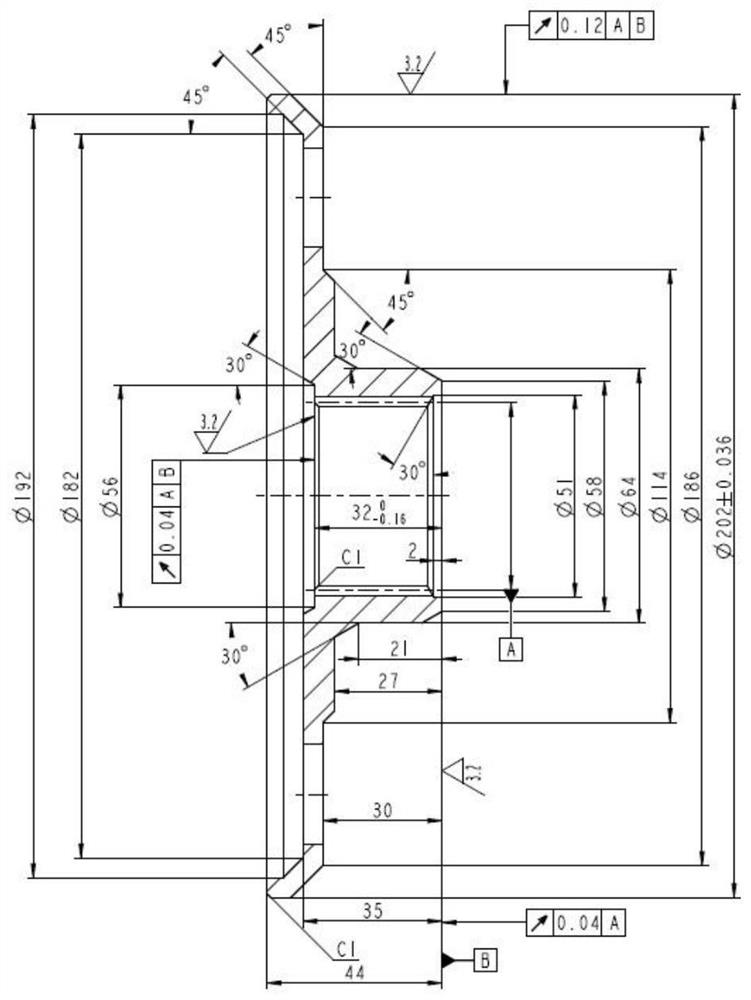

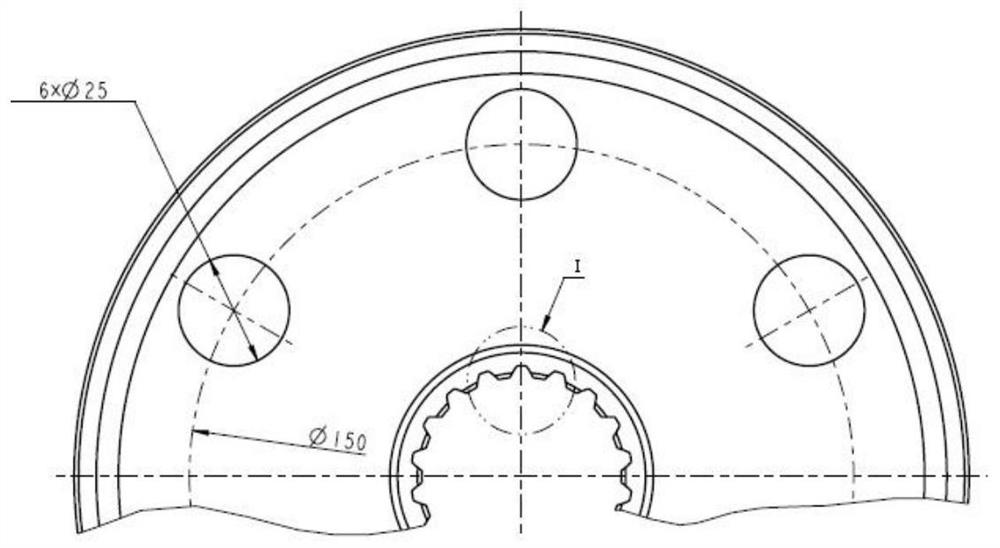

Full-hardening withdrawal and straightening roller of withdrawal and straightening machine and heat treatment process

PendingCN111136127AFully hardenedLess bendingFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to the technical field of withdrawal and straightening roller heat treatment, and discloses a full-hardening withdrawal and straightening roller of a withdrawal and straighteningmachine and a heat treatment process. The full-hardening withdrawal and straightening roller comprises a roller body, the two ends of the roller body are both connecting ends, and the end surfaces ofthe two connecting ends are both provided with positioning counter bores. According to the full-hardening withdrawal and straightening roller of the withdrawal and straightening machine and the heattreatment process, the purpose of preheating is to reduce the temperature difference of a workpiece in all stages, the purpose of heat preservation in each temperature stage is to enable the temperature inside and outside the workpiece to reach the set temperature and then move upwards, bending and deformation of the workpiece during rapid heating and quenching are effectively reduced, the quenching heat treatment time of the inner and outer metal structures of the workpiece at the quenching temperature is shortened, the heat treatment efficiency is effectively improved, and residual austenitic iron is converted into bast-field loose iron, so that on one hand, the hardness of the workpiece can be improved, and on the other hand, deformation of the workpiece caused by temperature rise during use can be reduced; and local tempering connecting ends are adopted, breakage during use is avoided, and the stability of the workpiece during use is guaranteed.

Owner:WUXI YIBAO MACHINERY EQUIP CO LTD

Electroslag ignition agent and preparation method thereof

InactiveCN104726721AGood arc starting effectReduce manufacturing costCarrying capacityGraphite electrode

The invention discloses an electroslag ignition agent and a preparation method thereof. The electroslag ignition agent is used for igniting and remelting slag material in an electroslag remelting technology to establish electroslag. The ignition agent comprises the following raw material components in percentage by weight: 25-35% of fluorite powder, 2-12% of silica powder, 30-40% of graphite electrode powder, 1-11% of quicklime powder and 18-28% of water glass. The preparation method comprises the following process steps: preparing mixed dry powder: uniformly mixing the raw materials according to the content in percentage by weight of each raw material and the carrying capacity of a mold to obtain the mixed dry powder; mixing with sludge, loading into the mold, adding the water glass into the mixed dry powder, stirring till no dry powder exists, loading a mixture which is uniformly stirred into the mold, tamping and compacting; blowing gas, demolding, blowing CO2 into the mold, and demolding after stopping gas blowing to obtain an ignition agent block; and drying at low temperature. The ignition agent disclosed by the invention has a good arc starting effect in the using process and can avoid a titanium-increasing effect, and high-temperature smelting is not required in the manufacturing process of the ignition agent.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Production method for making bricks from building waste

The invention provides a production method for making bricks from building waste. The building waste can be recovered effectively and made into bricks by means of the method, so that resource utilization of the building waste is achieved, and environmental pollution caused by stacking or landfill of the building waste is avoided. The process comprises the following steps: A, pre-treatment: firstly, reducing the building waste to 0.5m; B, charging; C, primary crushing: carrying out primary crushing through a jaw crusher; D, deironing; E, secondary crushing: conveying a material without iron toan impact crusher to be crushed secondarily; F, screening: screening the secondarily crushed material to different specifications through a vibrating screen; G, preparing brick-making raw materials: proportioning the screened regenerated fine aggregate in a proportion as follows: 65% of mud powder, 15% of cement and 20% of regenerated aggregate; H, brick making: conveying the uniformly stirred rawmaterial to a hopper of a brake maker; and I, maintaining: transferring ecological bricks produced in the brick maker to a maintaining region to be maintained.

Owner:鸿翔环境科技股份有限公司

Colored inorganic exterior wall coating and production process thereof

The invention discloses a colored inorganic exterior wall coating which comprises 30-50% of white cement, 40-60% of calcium carbonate powder, 5-20% of iron oxide pigment, 1-5% of hydroxypropyl methyl cellulose and 5-10% of ammonium bicarbonate; and the production process is as follows: adding the raw materials into a stirring kettle according to the proportion, stirring, uniformly mixing and packaging to get the product. The exterior wall coating has the advantages of good stability, simple process, low cost and broad market space.

Owner:GUIZHOU ZHUOSHENG FENGYE ENVIRONMENTAL PROTECTIONNEW MATERIAL DEV

Thermal processing method for H2S-corrosion-resistant tool joint for petroleum drill pipe

ActiveCN101275207BImprove hardenabilityGuaranteed full hardeningDrilling rodsFurnace typesHydrogenPetroleum

Owner:BAOSHAN IRON & STEEL CO LTD

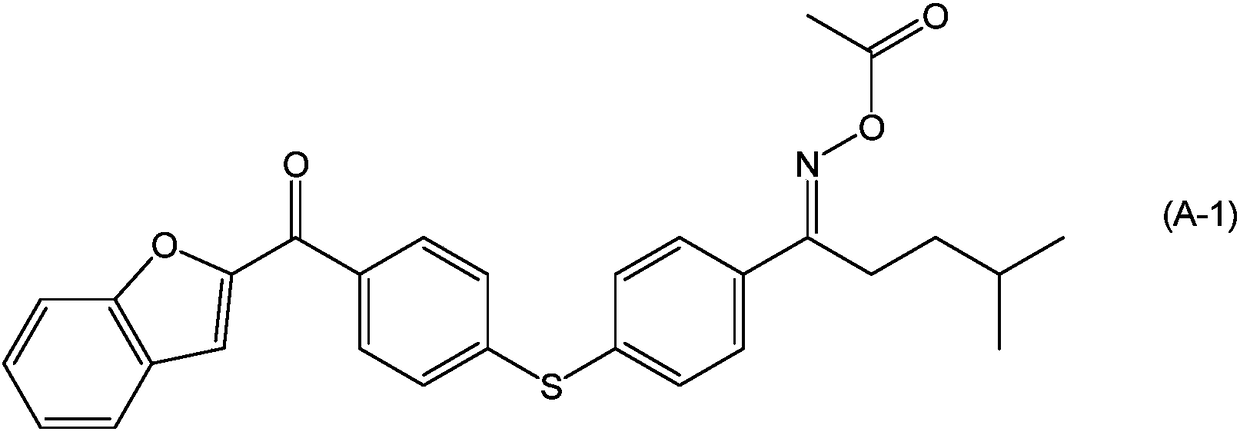

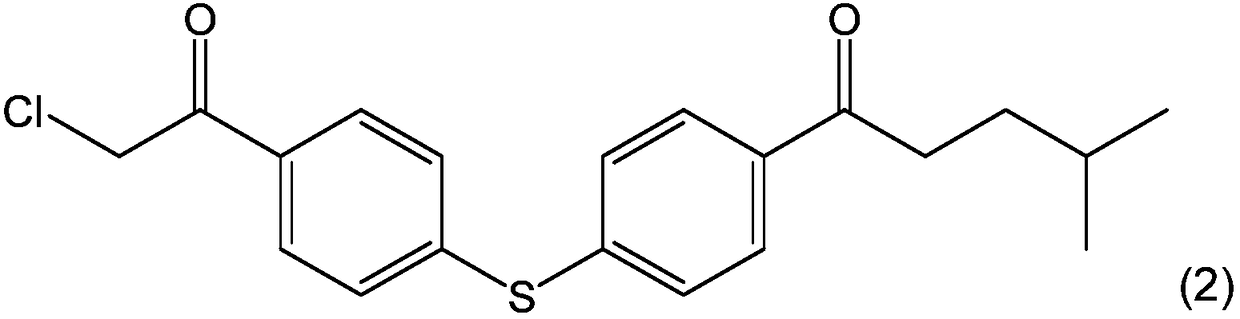

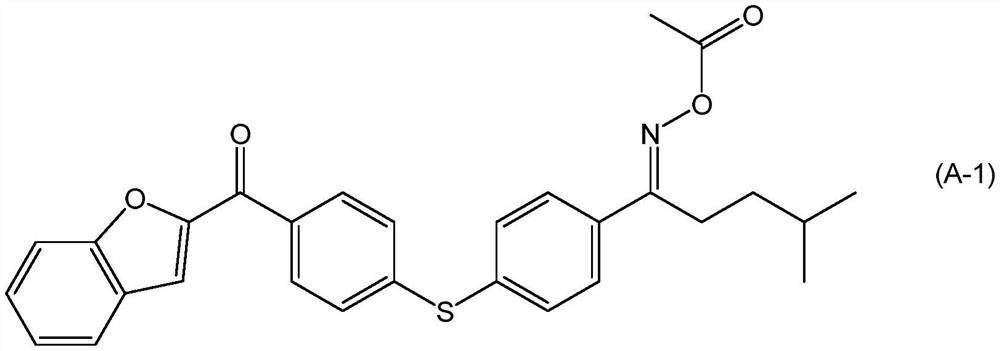

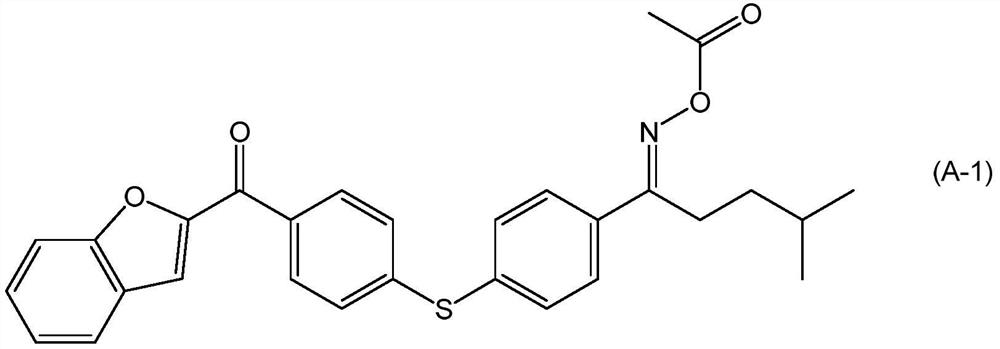

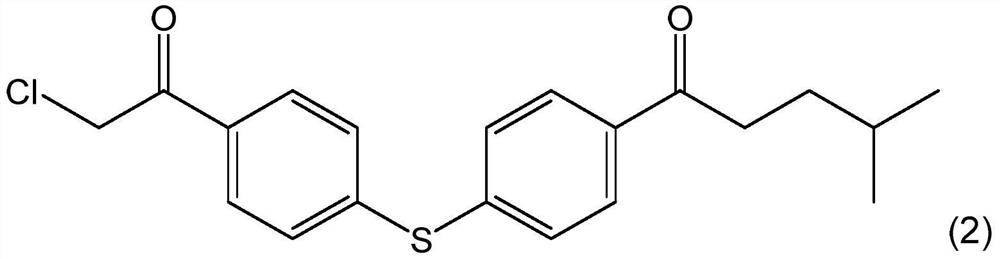

Photo-hardening resin composition, sealing agent, electronic component and liquid crystal display unit

ActiveCN108239508AFully hardenedNon-macromolecular adhesive additivesOther chemical processesLiquid-crystal displayLight irradiation

The invention relates to a resin composition hardened through light irradiation of ultraviolet rays or visible lights, and proposes a resin composition which is highly sensitive to light and can be fully hardened even through a low-energy light. The solution of the invention is to provide a photo-hardening resin composition including components: (A) an oxime compound having a furan structure in molecules and (B) a hardening compound.

Owner:NIPPON KAYAKU CO LTD

A Platinum Hardening Process

The invention relates to the technical field of platinum, and in particular relates to a platinum hardening process which comprises steps of baking mixture powder consisting of platinum, sodium chloride, ammonium bifluoride and silicon carbide, and subsequently boiling in water. By adopting the process, the hardness of platinum can be remarkably improved, and the Vickers hardness of platinum is increased to 175 from 54 before process. In the baking process, a container is shaken and oscillated at intervals, so that the surface of platinum comes into full contact with the powder, the surface of platinum can be sufficiently hardened, and the hardening effect is better.

Owner:SHENZHEN EDL JEWELRY

Molding sand preparation method for casting 350-kilometer axle boxes

ActiveCN109465391AReduce pollutionIncreased preparation rateFoundry mouldsFoundry coresCouplingPolyresin

The invention relates to a molding sand preparation method for casting 350-kilometer axle boxes, and belongs to the technical field of casting axle boxes of railways. The molding sand preparation method includes the steps that firstly, the proportioning of molding sand is quartz sand of 100% by mass, binder and inorganic hardener; the binder is composed of phenolic resin and powder coupling agents, wherein the amount of phenolic resin is 1.6-2.5% of the quartz sand by mass and the amount of powder coupling agents is 10-50% of the quartz sand by mass; secondly, the sand is subjected to mixing;thirdly, air holes are formed; fourthly, a blowing hardening process is carried out; and fifthly, molding is carried out. A developed two-component carbon dioxide hardening resin is used as a raw material; a carbon dioxide hardening process is adopted to prepare the molding sand for casting 350-kilometer axle boxes of American railways, and according to the preparation method, the efficiency is high, the raw materials can be reused, and the cost is greatly reduced.

Owner:QINGDAO LIANSHAN CASTING

Resin cooling device

PendingCN107186934AHigh tensile strengthImprove cooling effectCoatingsProcess engineeringComposite material

The invention discloses a resin cooling device. The resin cooling device comprises a reactor, wherein the bottom of the reactor is connected with a discharging tube through a tube; a bottom valve is arranged on the tube; a plurality of discharging holes are uniformly formed in the bottom of the discharging tube; a conveying belt is arranged under the discharging tube; and fans and water towers are arranged on two sides of the conveying belt. Compared with the prior art, the resin cooling device has the characteristics that softened resin flows out through the discharging holes, and regularly drops on the conveying belt, the effects of full cooling and hardening are achieved by air cooling and water cooling on the conveying belt, the resin is packed directly, the efficiency is higher than the efficiency of a traditional mode of directly discharging the resin and then pulverizing the resin, the labor is saved, the obtained strip-shaped resin is applied to the casting industry, and can be directly mixed with sand uniformly, and therefore, the tensile strength of precoated sand is improved.

Owner:WUXI YINXING PLASTIC IND TECH

Platinum hardening process

The invention relates to the technical field of platinum, and in particular relates to a platinum hardening process which comprises steps of baking mixture powder consisting of platinum, sodium chloride, ammonium bifluoride and silicon carbide, and subsequently boiling in water. By adopting the process, the hardness of platinum can be remarkably improved, and the Vickers hardness of platinum is increased to 175 from 54 before process. In the baking process, a container is shaken and oscillated at intervals, so that the surface of platinum comes into full contact with the powder, the surface of platinum can be sufficiently hardened, and the hardening effect is better.

Owner:SHENZHEN EDL JEWELRY

Making method of glass lubrication pad for steel tube hot extrusion

A making method of a glass lubrication pad for steel tube hot extrusion comprises the following steps: a) glass powder comprises 30 to 50% of glass powder with the particle size of 20-40 mesh, 30 to 50% of glass powder with the particle size of 40 to 60 mesh and 10 to 30% of glass powder with the particle size of 60 to 80 mesh; 2) sodium silicate is used as a binder for molding of the glass powder, and the weight ratio of the glass powder to the sodium silicate is 100:1-3; 3) a mixture of the glass powder and the sodium silicate is put into a molding mold for molding, when in molding, the molding pressure is 0 or not more than 100kPa; and 4) CO2 is charged into a mold cavity, so that the CO2 is infiltrated into the mixture, the gas flow per liter of the mixture of the glass powder is 0.1-5L / min, and the gas charging time is 10 to 100 seconds. Through the making method, the glass lubrication pad can be reinforced in the molding mold in the making process, and has certain strength, so that the glass lubrication pad is not easy to break in a moving process, and the problem of difficult molding of the glass lubrication pad with a local complex structure can be also solved.

Owner:宝武特种冶金有限公司

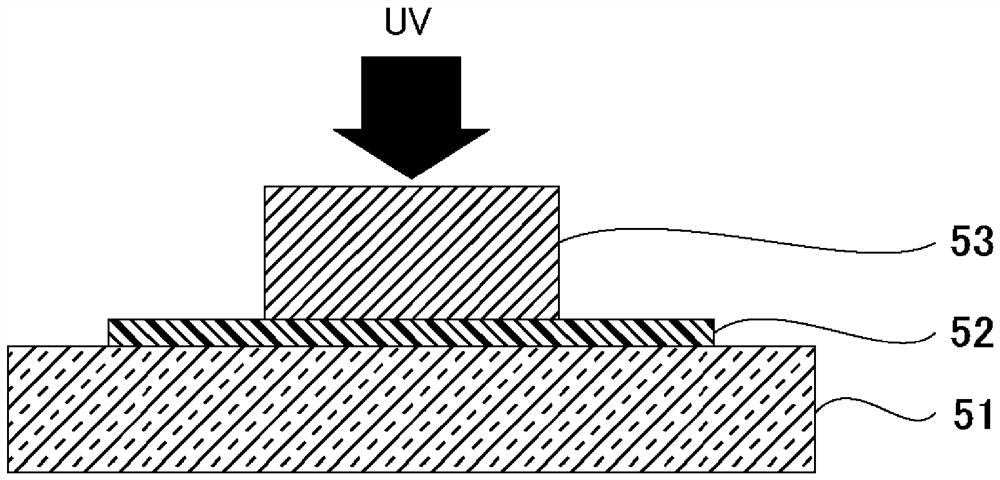

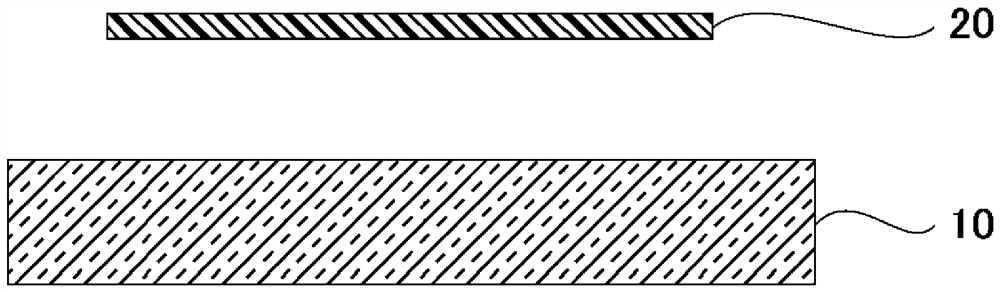

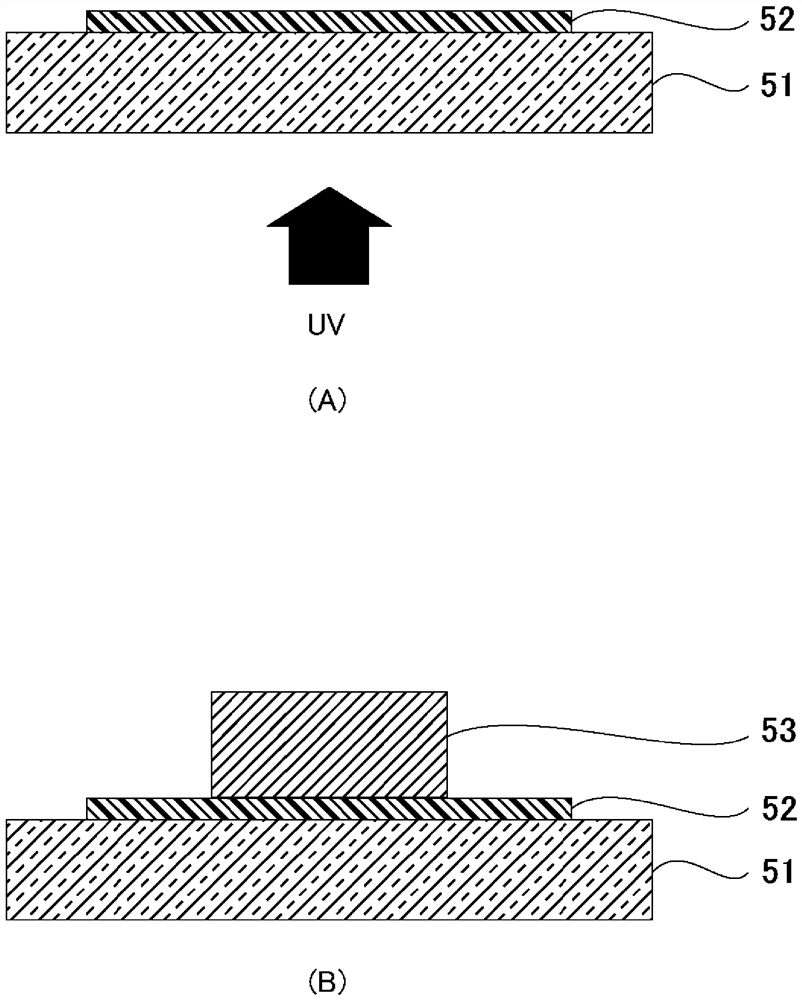

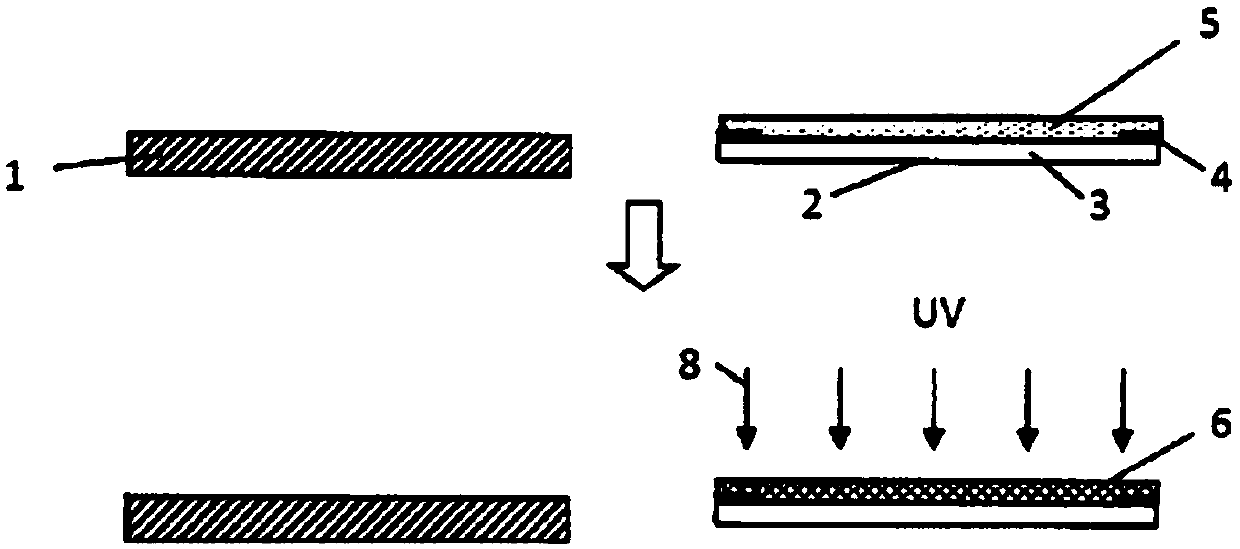

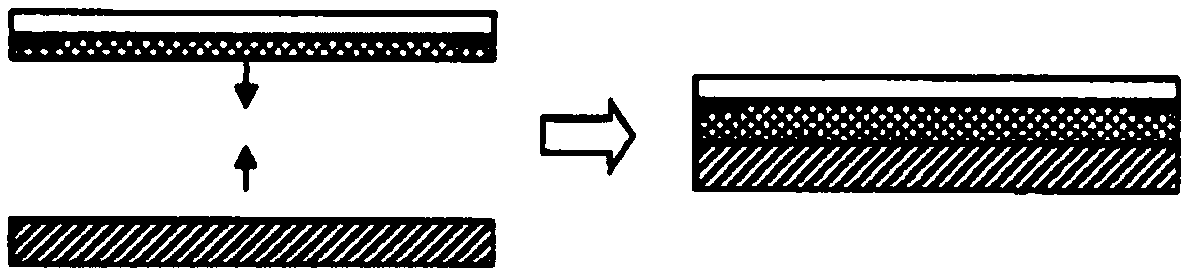

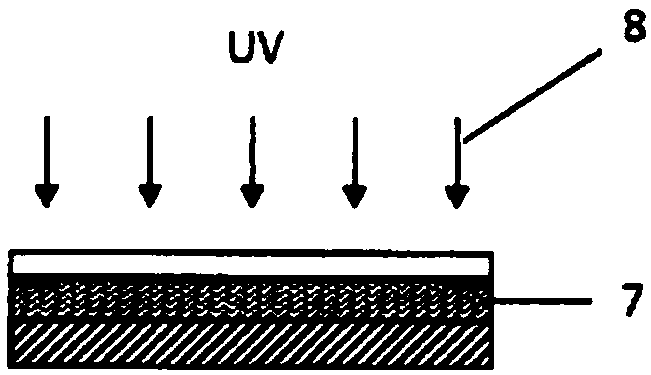

Manufacturing method of bonded structure and anisotropic conductive adhesive film

ActiveCN105375232BFully hardenedIncrease the on-resistanceLine/current collector detailsElectrically conductive adhesive connectionsAnisotropic conductive filmPolymer science

The invention provides a method for manufacturing a connection structure and an anisotropic conductive adhesive film. The method comprises the following steps: light irradiation: irradiating UV rays on an anisotropic conductive film (20), wherein polymeric compounds and photopolymerization are in different parts of the anisotropic conductive film (20); hot pressure welding: subjecting first circuit part and second circuit part to hot pressure welding under the protection of the anisotropic conductive film (20). Because the hot pressure welding is carried out under the state that the photopolymerization initiator in the anisotropic conductive film is activated, the parts on which circuit is distributed can be fully cured, and thus excellent turn-on resistance can be obtained. Moreover, because the polymeric compounds and photopolymerization initiator are in different parts of the anisotropic conductive film, the hardening reactions are inhibited when the anisotropic conductive film is irradiated by UV rays, and the insufficient pressing due to early hardening is avoided.

Owner:DEXERIALS CORP

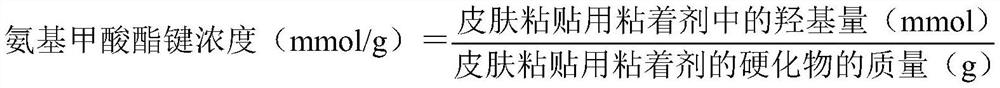

Adhesive for skin application, hardened product, and adhesive tape for skin application

PendingCN114698371AExcellent productivityExcellent skin adhesionPolyureas/polyurethane adhesivesOrganic non-active ingredientsIsocyanateChemistry

An embodiment of the present invention relates to an adhesive for skin application, which contains a polyurethane polyol (P) and an organic isocyanate (C), and wherein the polyurethane polyol (P) is a reaction product of a polyol component (A) containing a polyether polyol (a1) and a polyisocyanate component (B), has a hydroxyl number of 2.0-45 KOHmg / g, has a weight average molecular weight of 25,000-300,000, and has a hydroxyl number of 1-5 KOHmg / g. The molecular terminal of the polyether polyol (a1) is a hydroxyl group, the content of primary hydroxyl groups in the hydroxyl group is 40 mol% or more, and the average number of hydroxyl groups is 2 or more.

Owner:TOYO INK SC HOLD CO LTD +1

Super-high strength cold rolled steel and manufacturing method thereof

The invention discloses super-high strength cold rolled steel or steel plate, which comprises the following chemical components in percent by weight: 0.08 to 0.18 percent of C, 0.1 to 0.6 percent of Si, 1.4 to 2.4 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, 0.01 to 0.05 percent of A1, less than or equal to 0.006 percent of N, 0.2 to 0.77 percent of B / N and the balance of Fe and inevitable impurities. A manufacturing method for the super-high strength cold rolled steel comprises the following steps: performing hot rolling, wherein the finishing temperature is between 830 and 930 DEG C and the coiling temperature is between 550 and 650 DEG C; performing cold rolling, wherein the rolling reduction is 40 to 70 percent; performing continuous annealing, namely holding the temperature between 780 and 880 DEG C, cooling the steel to be between 700 and 750 DEG C with air at a rate of between 10 and 30 DEG C / s, cooling the steel to be between 550 and 640 DEG C by air blast at the cooling rate of between 60 and 200 DEG C / s, cooling the steel to be below 100 DEG C at the cooling rate greater than 500 DEG C / s and heating the steel to be between 150 and 250 DEG C to perform tempering for 60 to 300s; washing the steel with weak acid; and levelling the steel by 0 to 0.6 percent. Thus the obtained super-high strength band steel or steel plate with high processability can be applied to structures or enhanced parts for automobile manufacturing.

Owner:BAOSHAN IRON & STEEL CO LTD

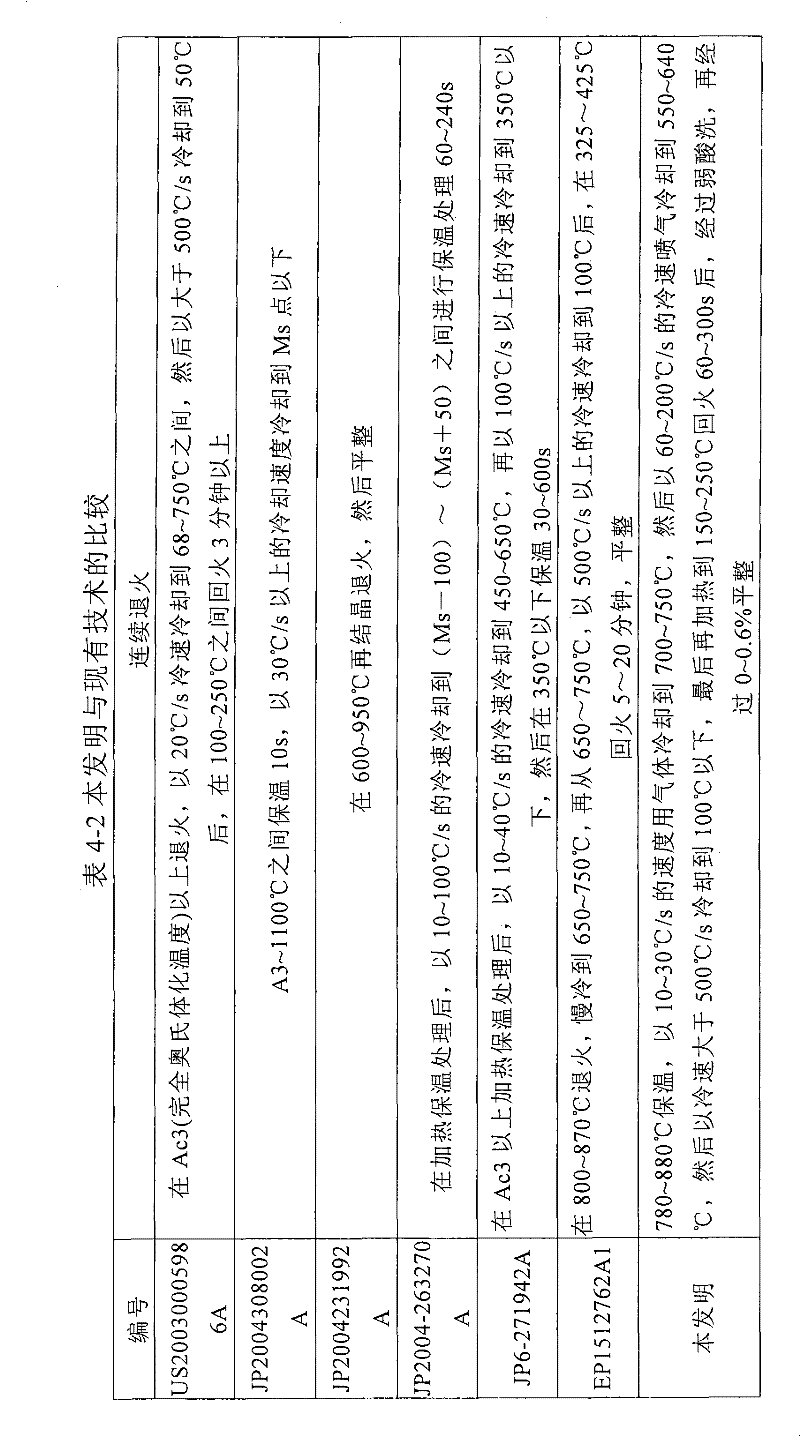

Copper foil for wiring board

ActiveCN105492660BFully hardenedImprove bending performancePrinted circuit aspectsConductive materialCopper foilAlloy

Provided is a copper foil which is a thin foil of no more than 18m in thickness that is required for a copper foil for a printed wiring board such as a flexible copper clad laminate (FCCL) or a flexible printed circuit board (FPC), for which foil breakage or wrinkling does not occur when using roll-to-roll conveyance, which is sufficiently softened after heat treatment at a polyimide curing temperature, and which demonstrates high bendability and flexibility. The copper foil for a printed wiring board, the copper foil being copper or an alloy of copper and having a thickness of no more than 18m, is characterized by the following: a temperature Tmax, at which a gradient (S) of tensile strength represented by formula (1) becomes largest, is 150°C-370°C in a range of no more than 400°C; in such a case, a gradient (Smax) is at least 0.8; and the tensile strength after heat treatment for one hour at Tmax is 80% or less of normal strength. Formula (1): S=(Ts(T-50)-Ts(T)) / 50 Here, Ts(T) is the tensile strength after heat treatment for one hour at T°C.

Owner:FURUKAWA ELECTRIC CO LTD

High-strength drilling rod for petroleum and method for making same

A high strength oil drilling rod, the constituent is (mass ratio): C 0.20 to 0.30 percent, Si 0.1 to 0.5 percent, Mn 0.7 to 1.5 percent, Cr 0.7 to 1.5 percent, Mo 0.1 to 0.4 percent, and the rest being Fe and inescapable impurity. The method for preparation includes: thickening the end of the related steel pipe to prepare the body-pipe of upset drilling rod; heating the whole steel pipe and cooling, lying on a rotating quenching stand, spraying water by axial-flow inside surface and spraying water by laminar flow outside surface when the steel pipe is rotating; by controlling the various amount of outer water delivered to the thickening end of the steel pipe and the body-pipe, or by decreasing the amount of outer water delivered to the body-pipe, or increasing the amount of outer water delivered to the thickening end of the steel pipe, makes the thickness-different pipe and the thickening end have the same cooling rate and the same quenching structure, and also have the same dynamic behavior after quenching.

Owner:BAOSHAN IRON & STEEL CO LTD

Integral hot working sizing tool for disc parts

PendingCN113817909AGuaranteed deformationImprove deformationShaping toolsFurnace typesTemperingEconomic benefits

The invention discloses an integral hot working sizing tool for disc parts. The integral hot working sizing tool for the disc parts comprises a disc part, a bolt, a gasket, a pressing body and a nut, wherein the disc part is arranged on the pressing body and is pressed and corrected through the bolt, the gasket and the nut; a plurality of oil grooves are formed in one side face of the pressing body; and a conical face is arranged on the other side face of the pressing body. According to the integral hot working sizing tool for the disc parts provided by the invention, heat treatment deformation of the disc parts can be effectively controlled, synchronous heat correction is conducted in the tempering process of heat treatment, the problem that the parts are greatly deformed under the action of heat stress and structural stress in the heat treatment process is solved, and the deformation of the parts is controlled within the range of finish machining and reserved grinding amount, so that the processing quality of heat treatment is ensured, and economic benefits are created for factories.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

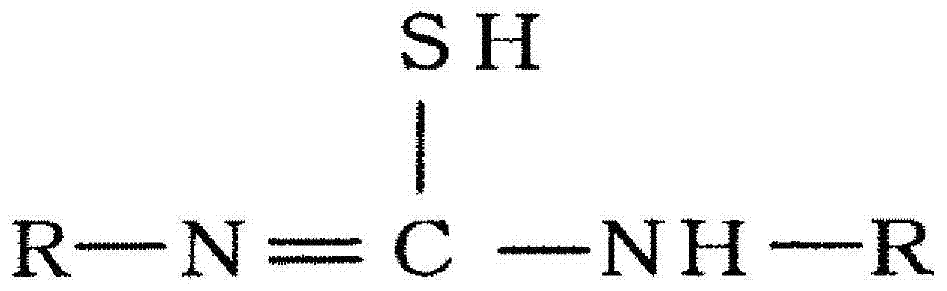

Adhesive for display, optical member, touch control panel, liquid crystal sealing agent or packaging agent and liquid crystal display unit

InactiveCN109609070AFully hardenedNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveDisplay device

The present invention relates to an adhesive for a display and an optical member. The present invention provides an adhesive for a display which has high sensitivity to light, is sufficiently hardenedby low-energy light, and has high hardenability in a portion that is not sufficiently illuminated. The binder for a display of the present invention contains the component (A): a photopolymerizationinitiator represented by the following formula (1); and the component (B): a binder for a display of a photopolymerizable compound; in the formula (1), X a residue obtained by removing n hydrogen atoms from a saturated hydrocarbon having a ring structure, or a substituent represented by the following formula (1-1); when X is a residue obtained by removing n hydrogen atoms from a saturated hydrocarbon having a ring structure; When n represents an integer of 1 to 6, and X is a substituent represented by the formula (1-1), n represents 1. R1 to R7 represent a predetermined substituent; in the formula (1-1), R8 represents an alkylene group or an arylene group; R9 represents a hydrogen atom or an alkyl group having 1 to 4 carbon atoms; and Y represents an oxygen atom or a sulfur atom.

Owner:NIPPON KAYAKU CO LTD

Production method of round steel for high-strength bolt capable of resisting impact at -40 DEG C

PendingCN114015832AImprove hardenabilityImprove toughnessProcess efficiency improvementElectric furnaceHeating furnaceContinuous caster

A production method of round steel for a 10.9-grade high-strength bolt capable of resisting impact at -40 DEG C comprises the following steps: (1) smelting molten iron and scrap steel, which are adopted as raw materials, by using an ultrahigh-power eccentric bottom type electric furnace; (2) refining the materials through an LF refining furnace; (3) degassing through a VD vacuum furnace, and feeding in a cored wire and B iron; (4) performing continuous casting treatment through an arc-shaped continuous casting machine; (5) heating steel billets by a walking beam furnace; (6) rolling steel; (7) controlling cooling; (8) slowly cooling; and (9) performing heat treatment. Compared with 42CrMoA, the production cost can be reduced by 330 yuan / ton at least when the steel for the wind power bolt with the diameter being smaller than or equal to 30 mm is produced.

Owner:山东寿光巨能特钢有限公司

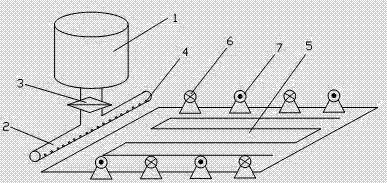

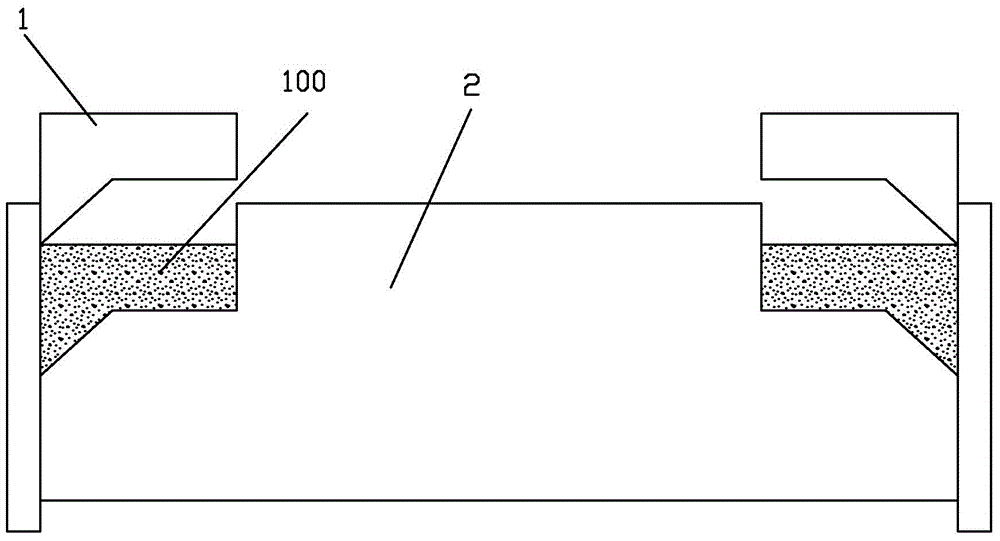

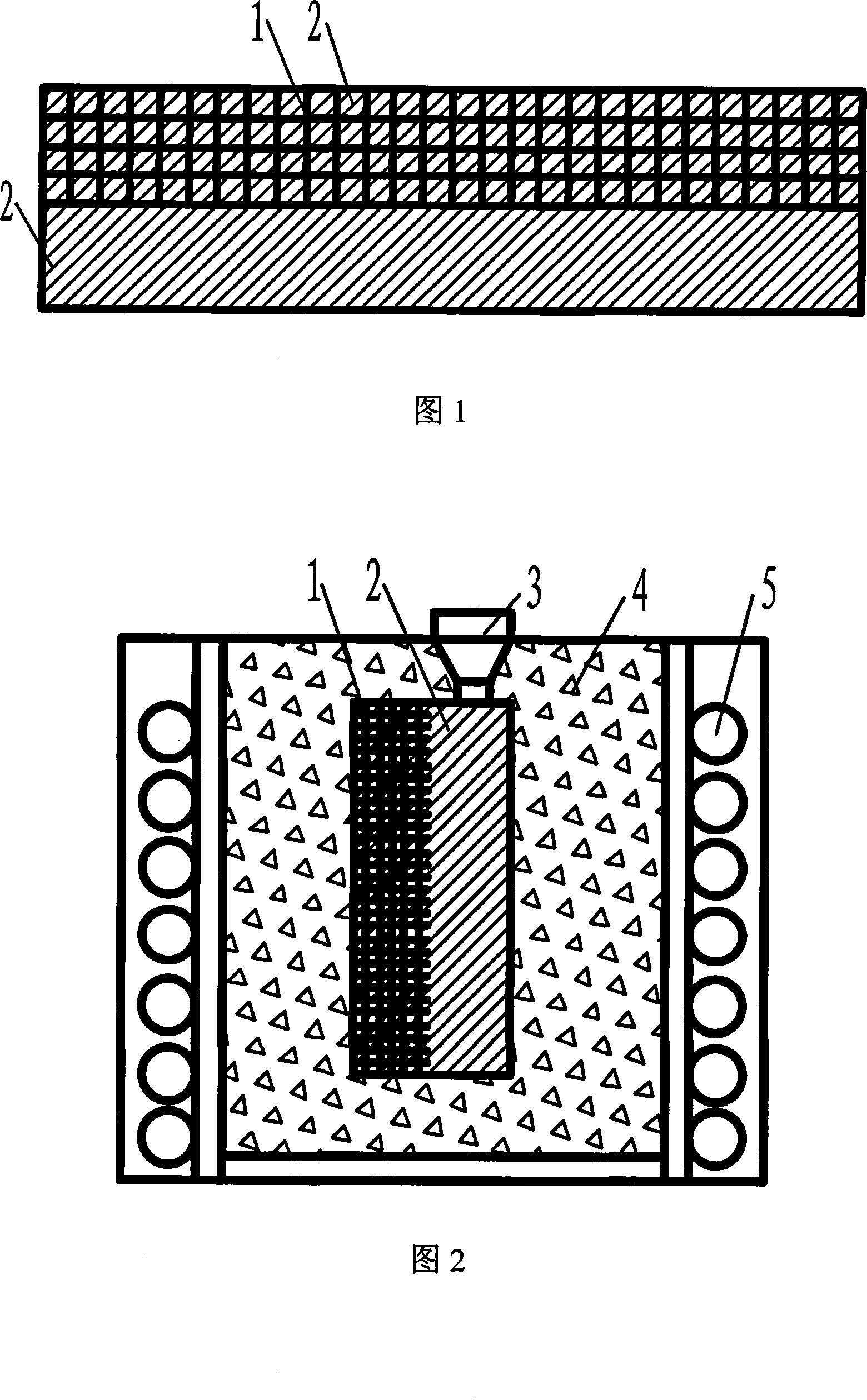

Apparatus and method of frame glue solidification and liquid crystal panel manufacturing method

ActiveCN100363824CWill not polluteFully hardenedStatic indicating devicesNon-linear opticsEngineeringLiquid crystal

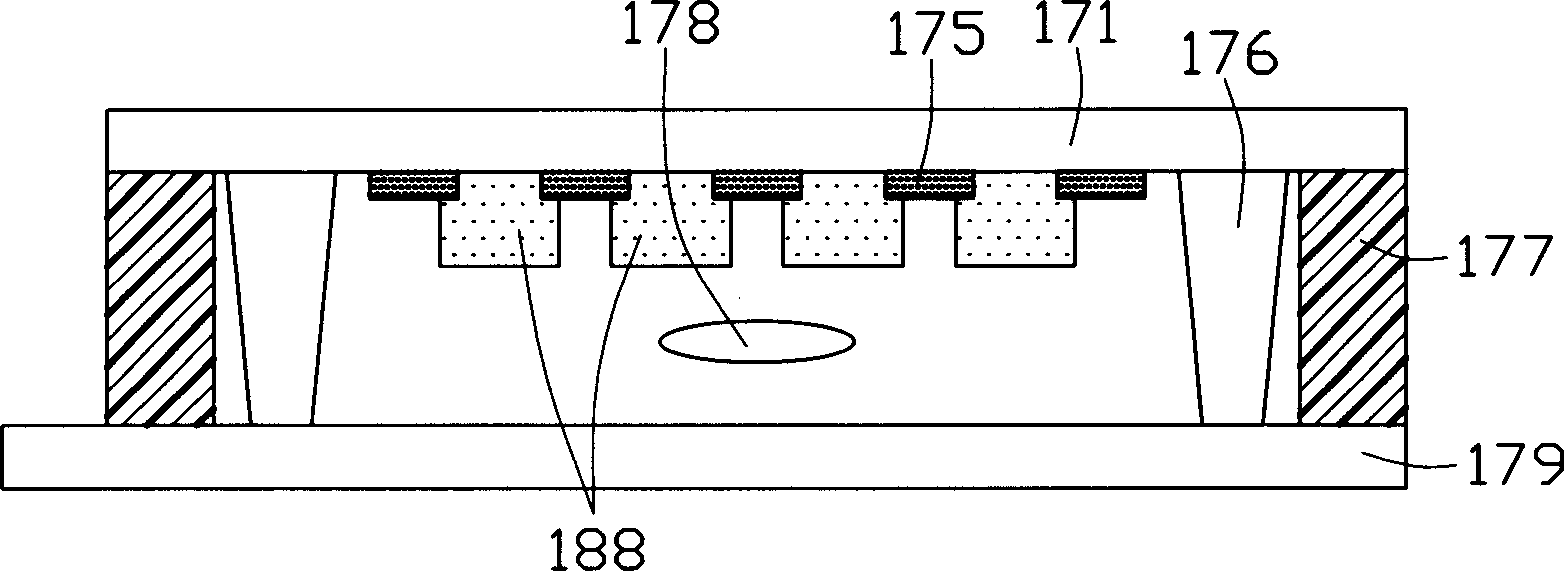

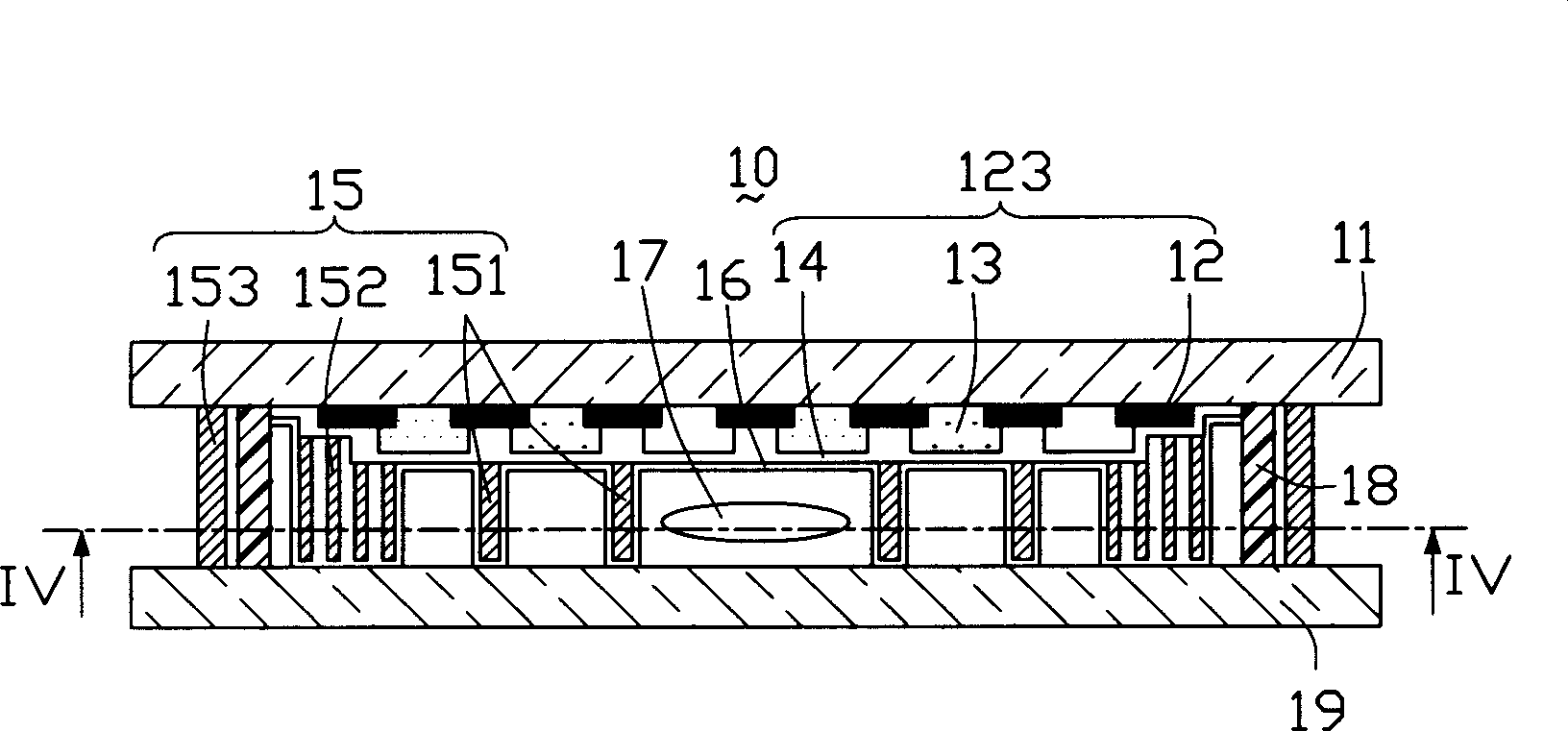

The invention discloses a glue-welding device used in liquid crystal plate. It comprises an operating platform, which has a light reflecting side. The welding device also comprises many supporting feet, which are positioned on one side of reflecting side of the operating platform. The glue-welding device is used in the glue welding art of liquid crystal plate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

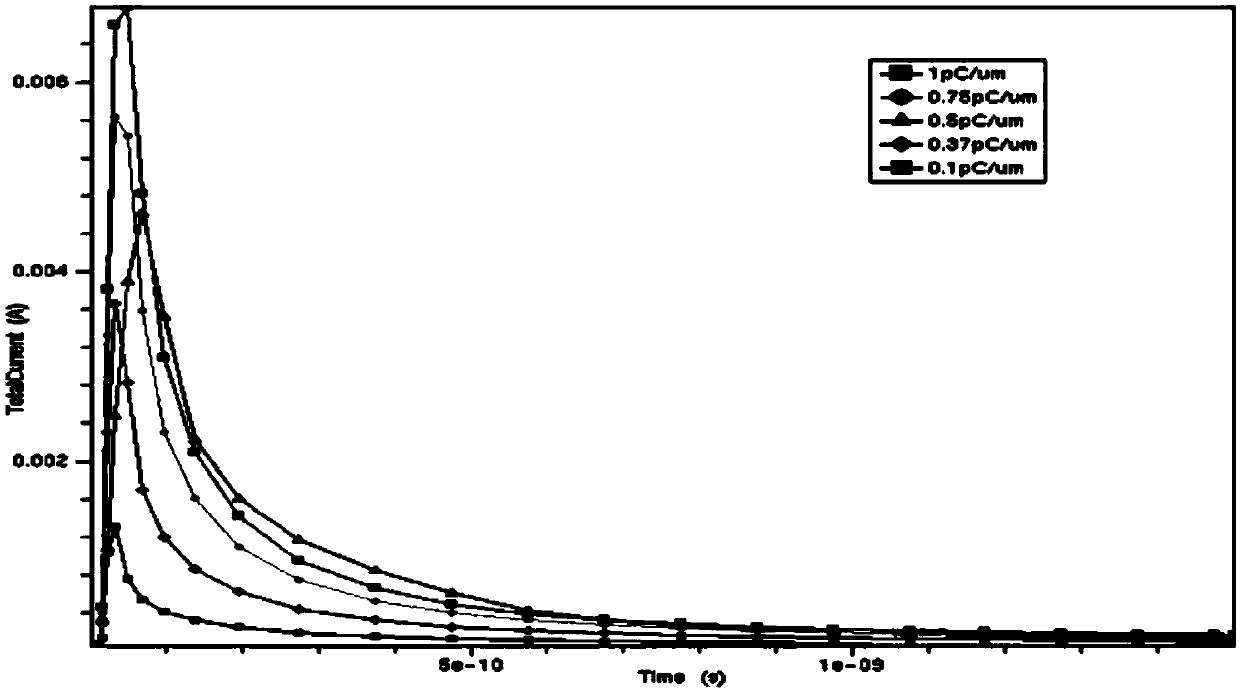

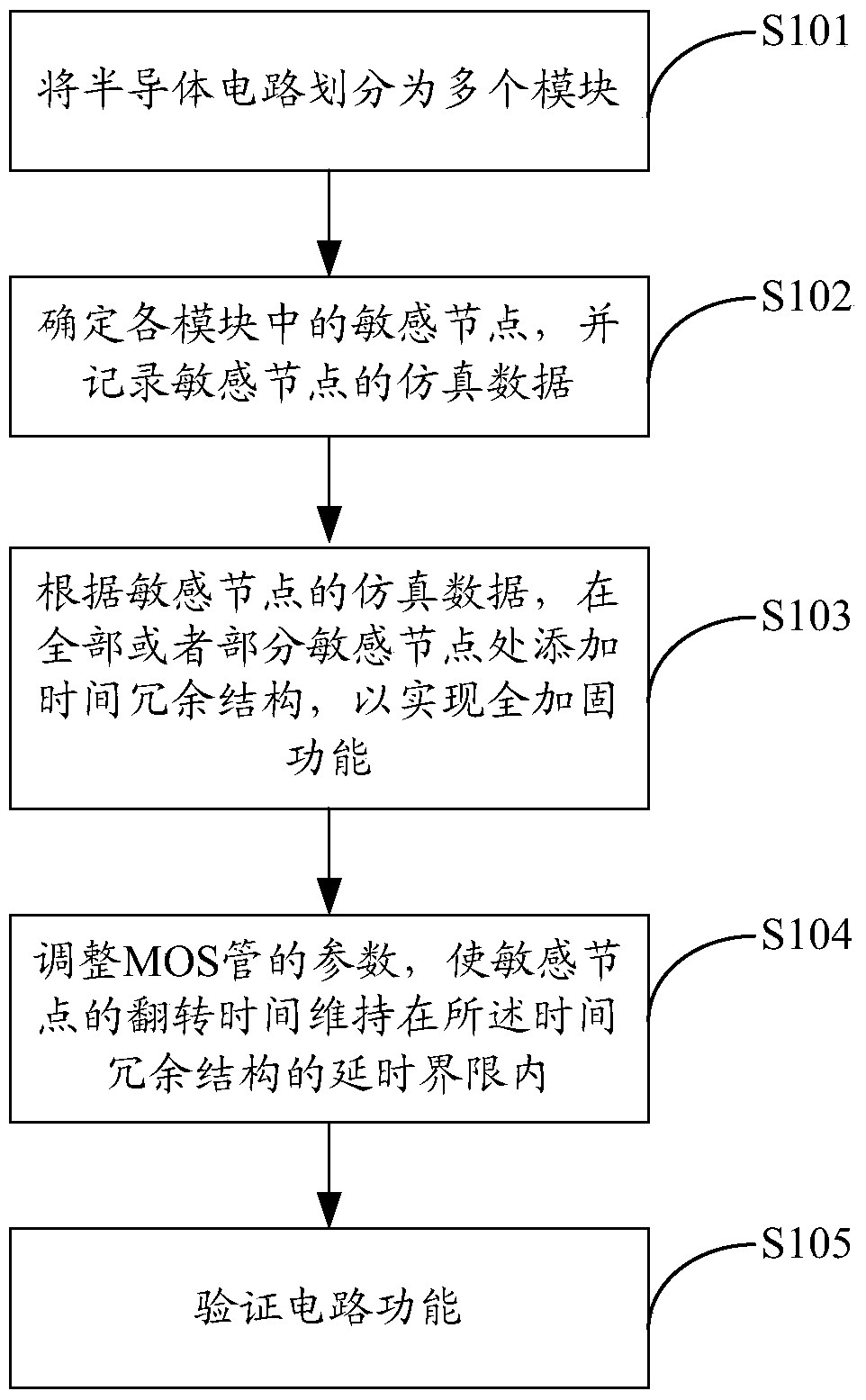

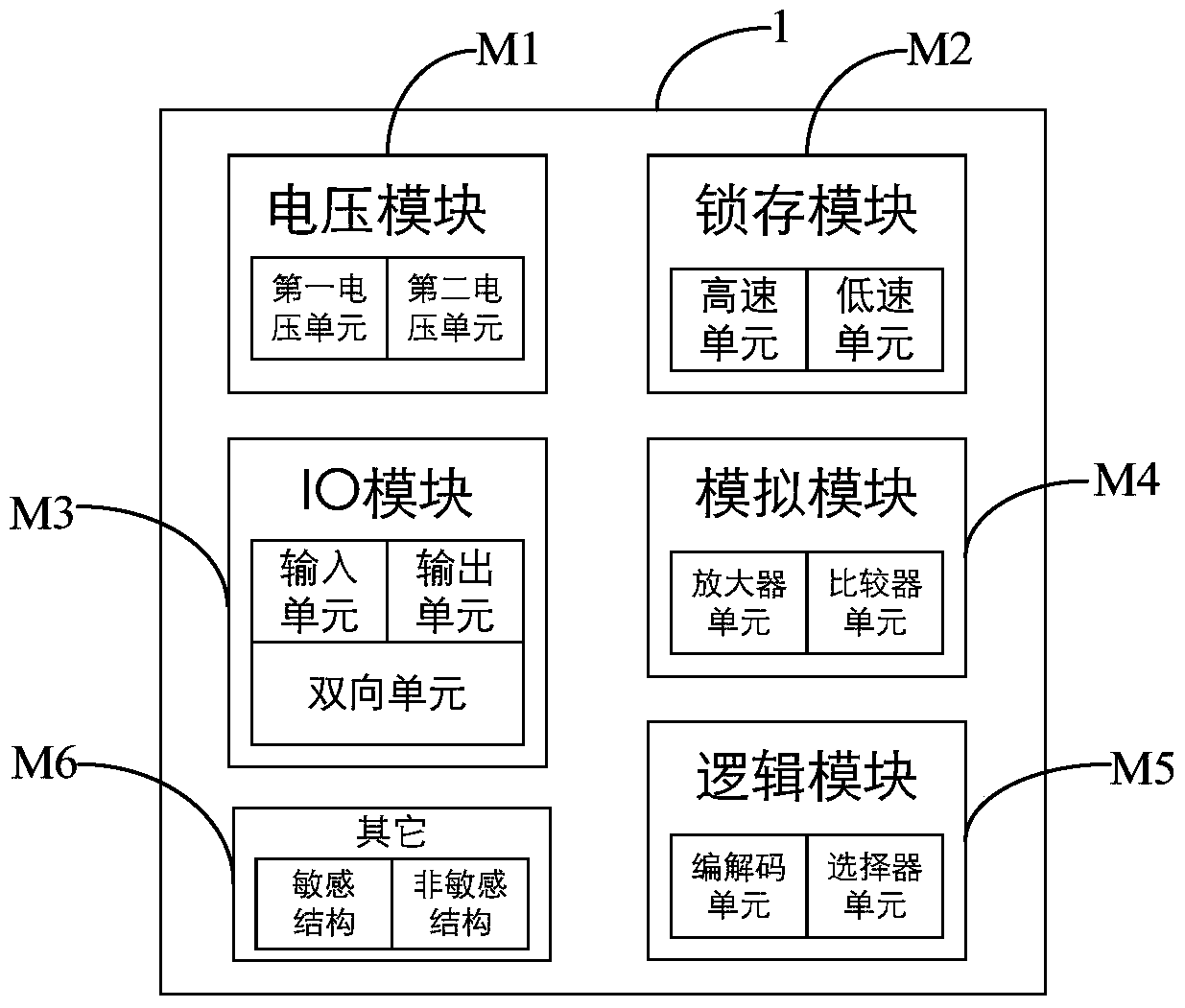

A full reinforcement method and system for anti-single event flipping of semiconductor circuits

ActiveCN104731993BGuaranteed reinforcement effectReduce areaSpecial data processing applicationsLogic circuitsReverse timeComputer module

The present invention is applicable to the field of semiconductors, and provides a method and system for fully strengthening semiconductor circuits against single event flipping. The method includes: dividing the semiconductor circuit into multiple modules; determining sensitive nodes in each module, and recording the sensitive The simulation data of the node; according to the simulation data of the sensitive node, add a time redundancy structure at all or part of the sensitive node to realize the full reinforcement function; adjust the parameters of the MOS tube to maintain the flipping time of the sensitive node Within the delay bounds of the time redundancy structure; verifying circuit functionality. In the present invention, the circuit is divided into blocks before simulation, and the sensitive nodes in each module are respectively determined, so as to add a time redundant structure to the sensitive nodes, realize the full reinforcement function, and further enhance the reinforcement effect by adjusting the parameters of the MOS tube , to achieve the design standard of full reinforcement, simple operation, small increase in circuit area, and low increase in power consumption.

Owner:SHENZHEN STATE MICROELECTRONICS CO LTD

Zirconium-plated carbonized high-strength heat-dissipation rail cutting grinding wheel formula and process

InactiveCN112157602AHigh bonding strengthImprove self-sharpeningAbrasion apparatusGrinding devicesCarbon blackSafety coefficient

The invention relates to the technical field of rail cutting, and discloses a zirconium-plated carbonized high-strength heat-dissipation rail cutting grinding wheel formula and process. The grinding wheel formula mainly comprises the following components in percentage by weight: 39.22% of zirconium-plated white corundum, 19.61% of calcined corundum, 19.61% of brown fused alumina, 2.35% of iron sulfide, 4.71% of cryolite, 21.57% of KEP, 0.39% of carbon black and 12.55% of resin. According to the problems, such as machine requirements of a high rotating speed, high power and large stress in theworking process of the grinding wheel, and high safety coefficient requirements on the grinding wheel, of an existing rail cutting grinding wheel, the formula is provided.

Owner:金华市国泰砂轮研磨有限公司

Liquid crystal sealing agent for liquid crystal dropping method and liquid crystal display unit

ActiveCN108239508BFully hardenedNon-macromolecular adhesive additivesOther chemical processesFuranLiquid-crystal display

The present invention relates to a resin composition that can be cured by irradiation of ultraviolet light or visible light, and proposes a resin composition that is highly sensitive to light and can be fully cured even by low-energy light. The solution means of this invention is providing the photocurable resin composition containing the oxime compound which has a furan structure in a molecule|numerator of a component (A), and a curable compound of a component (B).

Owner:NIPPON KAYAKU CO LTD

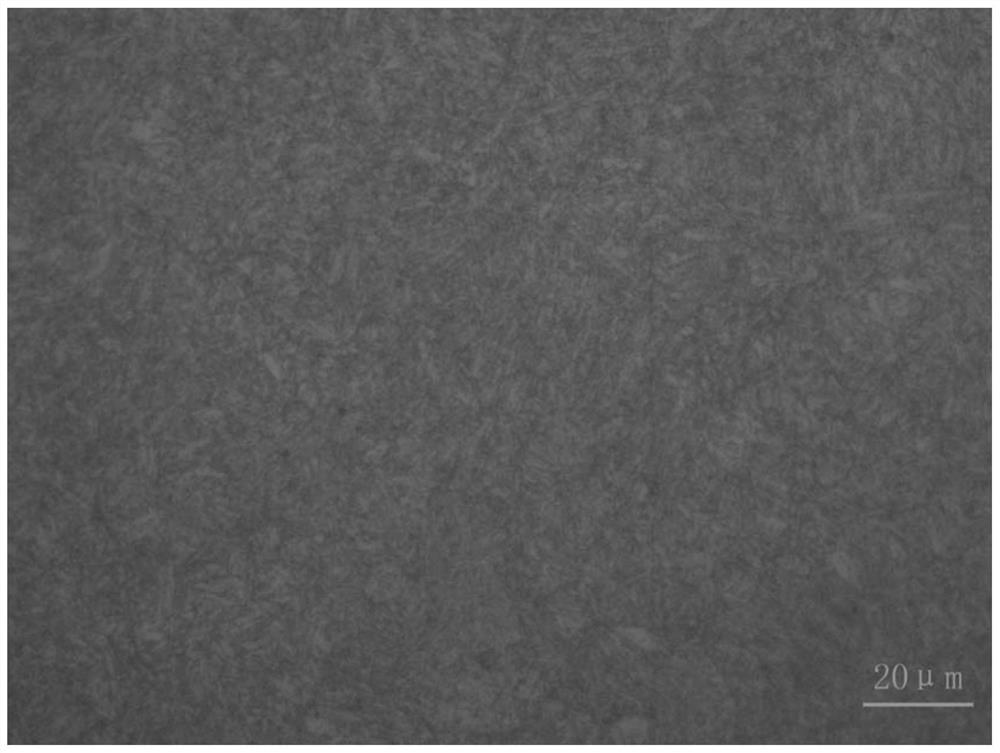

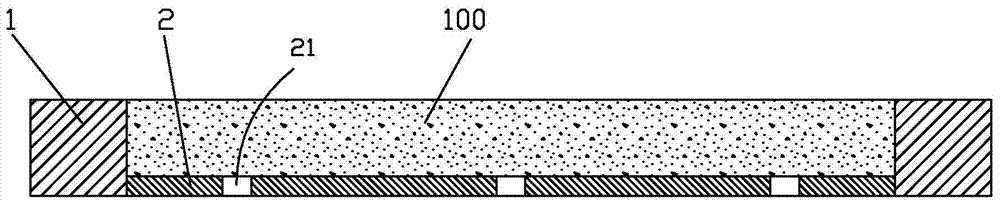

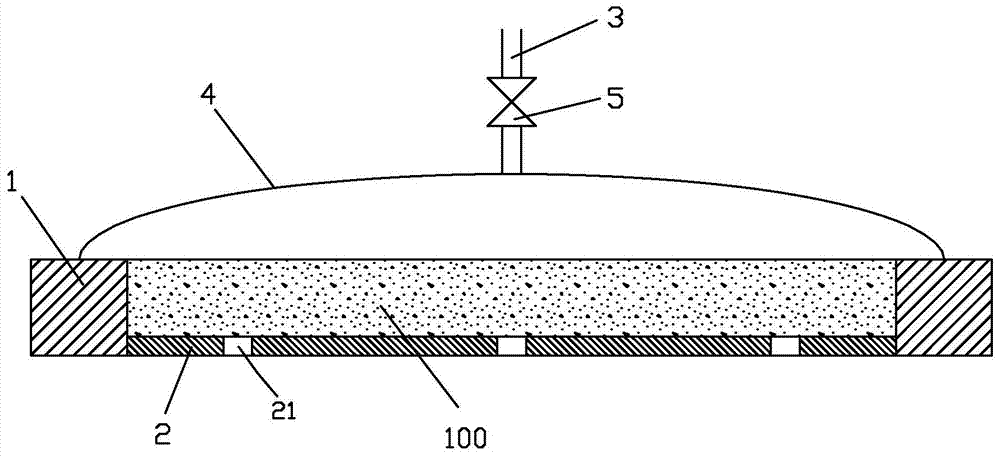

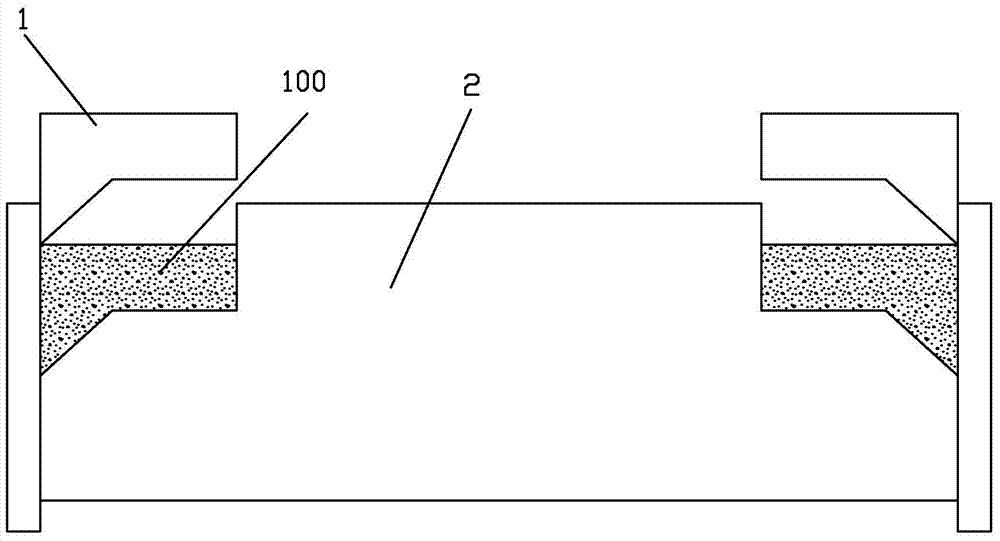

Preparing technique of hard silk screen abrasion-proof composite material

The invention discloses a hard wire mesh wearproof composite material, which is formed by compounding a plasma nitrided or carbonized wire gauze (1) and matrix metal (2). The invention also discloses a process to prepare the hard wire mesh wearproof composite material. When the process is used to prepare the wearproof composite material, the material can be carburized or nitrided at quite low temperature; the composite material is prepared quickly; the carburized or nitrided layer is uniform. In addition, the wire gauze can be fully infiltrated and filled with the matrix metal; the wire gauze and the matrix metal can be compounded reliably under the state of thermal insulation with high performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

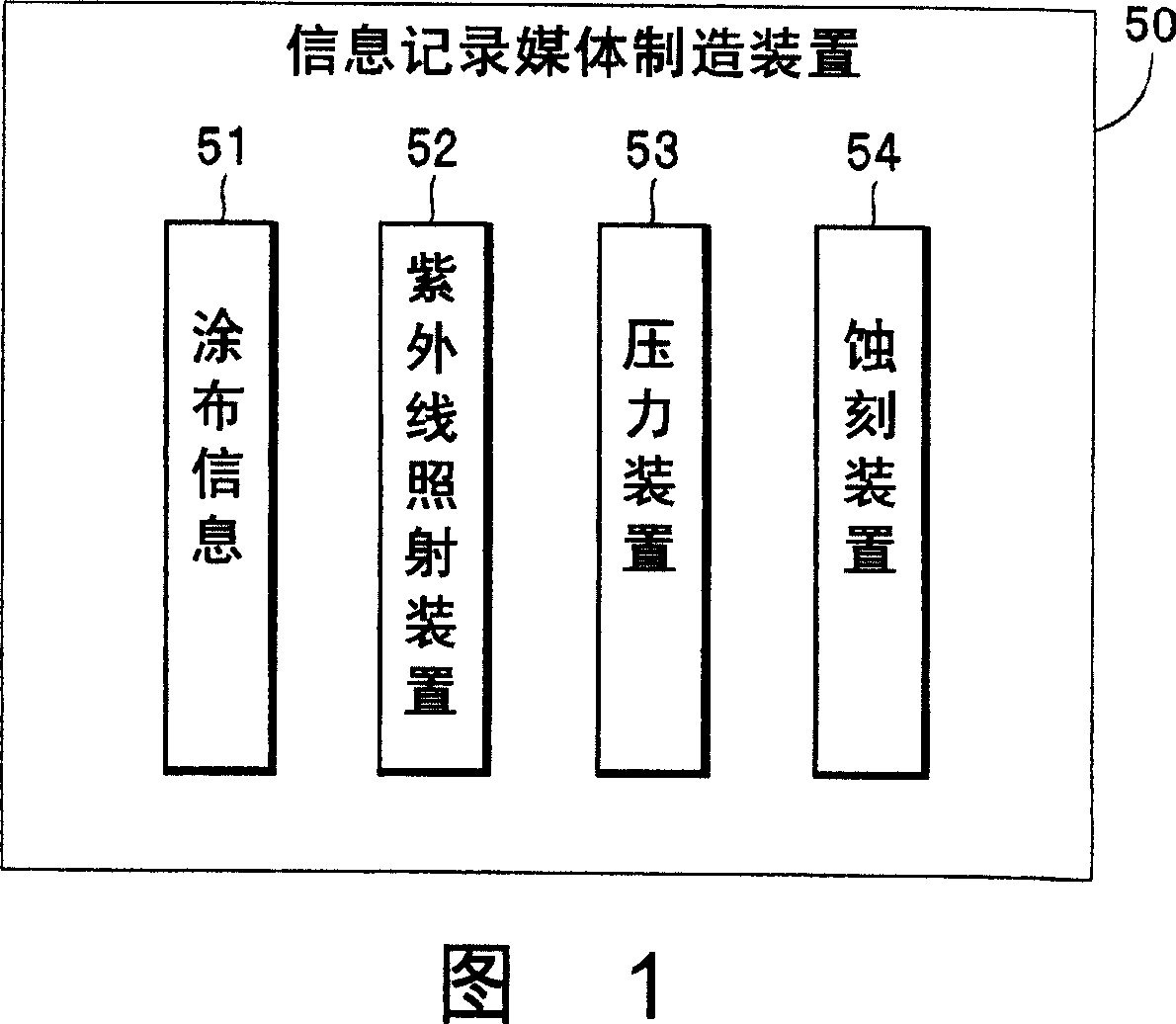

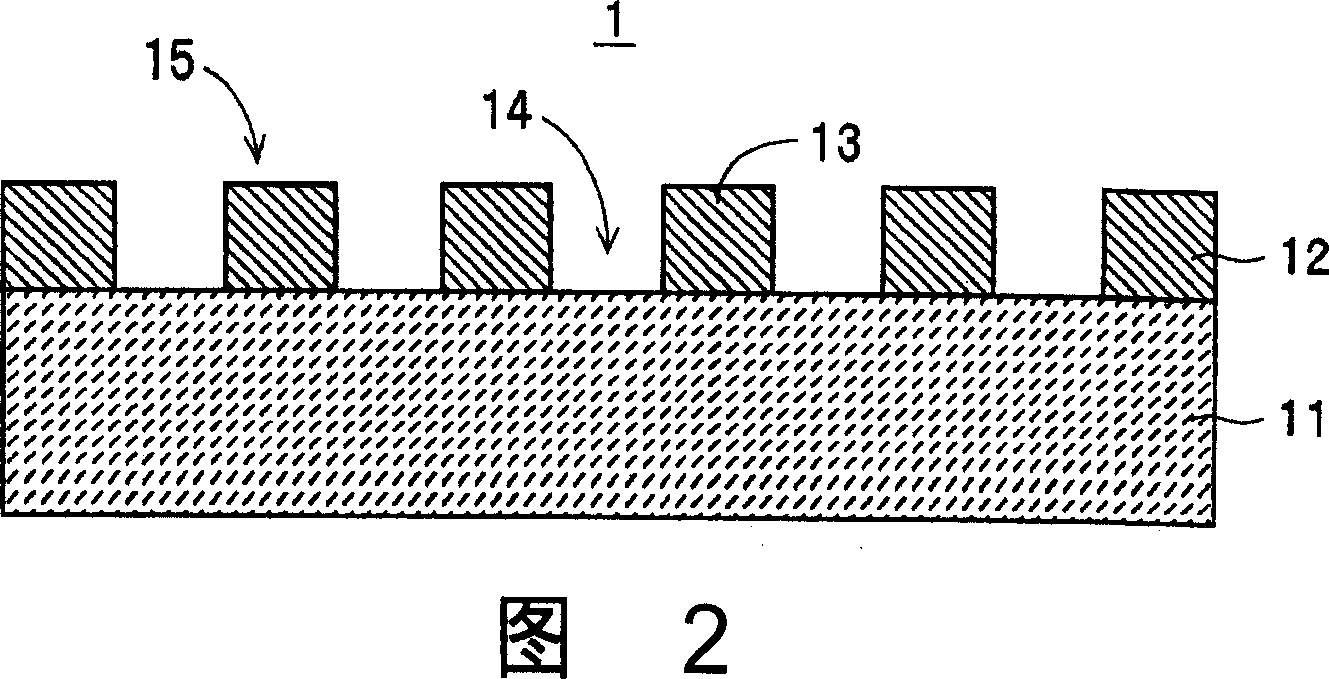

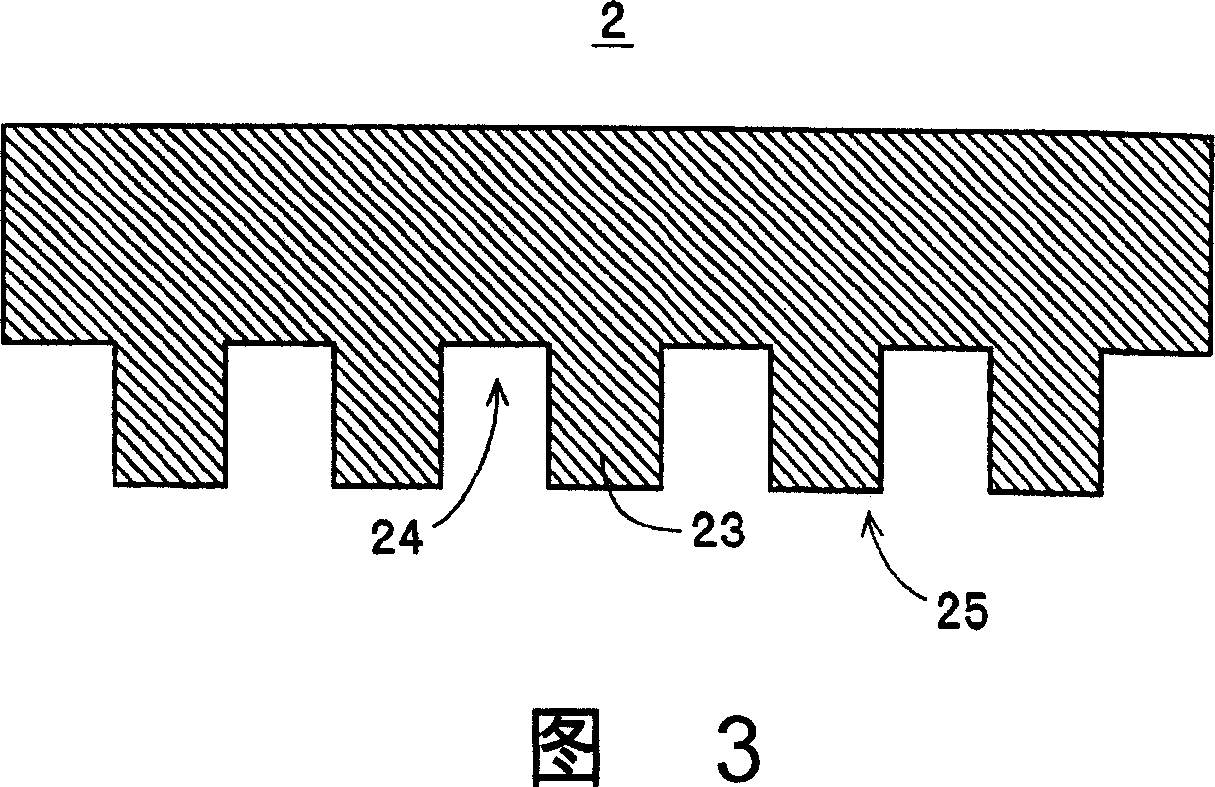

Mask forming method and information recording medium manufacturing method

InactiveCN1928994AShorten the timePrevent collapseRecord carriersNanoinformaticsUltravioletEngineering

Owner:TDK CORPARATION

Manufacturing method of glass lubricating pad for hot extrusion of steel pipe

A method for making a glass lubricating pad for hot extrusion of steel pipes, comprising the following steps: 1) The particle size of glass powder is: 20-40 mesh, 30-50%; 40-60 mesh, 30-50%; 60-80 mesh, 10-30%; 2) Water glass is used as the binder for glass powder molding, and the weight ratio of glass powder to water glass is 100:1-3; 3) The mixture of glass powder and water glass is put into a molding mold for molding , no pressure is used during molding or a molding pressure of no more than 100kPa is used; 4) CO2 is filled into the cavity of the molding mold to infiltrate CO2 into the mixture, and the gas flow rate of the mixture of glass powder and water glass per liter is 0.1~5L / min , The inflation time is 10-100 seconds. The method of the invention can strengthen the glass lubricating pad in the forming mold during the production process to have a certain strength, so that the glass lubricating pad is not easily broken during the moving process, and can also solve the problem that the glass lubricating pad with a partially complex structure is difficult to form.

Owner:宝武特种冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com