Resin cooling device

A technology of cooling device and resin, which is applied in the direction of coating, etc., to achieve the effects of labor saving, tensile strength improvement and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

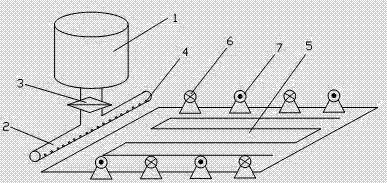

[0008] Such as figure 1 The shown resin cooling device includes a reaction kettle 1, the bottom of the reaction kettle 1 is connected to the discharge pipe 2 through a pipeline, the pipeline is provided with a bottom valve 3, and a number of discharge holes 4 are evenly opened at the bottom of the discharge pipe 2, and the discharge pipe 2 is uniformly opened. A conveyor belt 5 is provided directly below the pipe 2, and fans 6 and water towers 7 are arranged on both sides of the conveyor belt 5, and the fans 6 and water towers 7 are alternately arranged on both sides of the conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com