Liquid crystal sealing agent for liquid crystal dropping method and liquid crystal display unit

A liquid crystal sealant and liquid crystal drop technology, applied in the field of photocurable resin compositions, can solve problems such as damage to moisture resistance reliability, liquid crystal contamination, low liquid crystal contamination and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to an Example. In addition, "parts" and "%" herein are based on mass unless otherwise specified.

Synthetic example 1

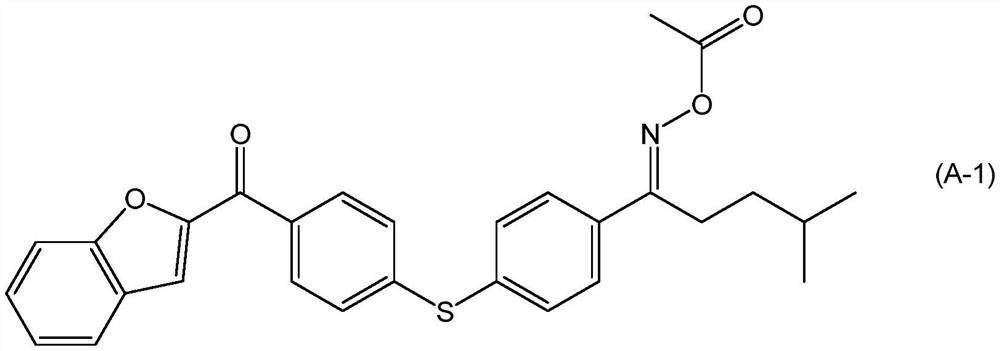

[0107] According to JP 2016-531926 A, a compound represented by the following formula (A-1) was synthesized in the following manner to obtain component (A).

[0108]

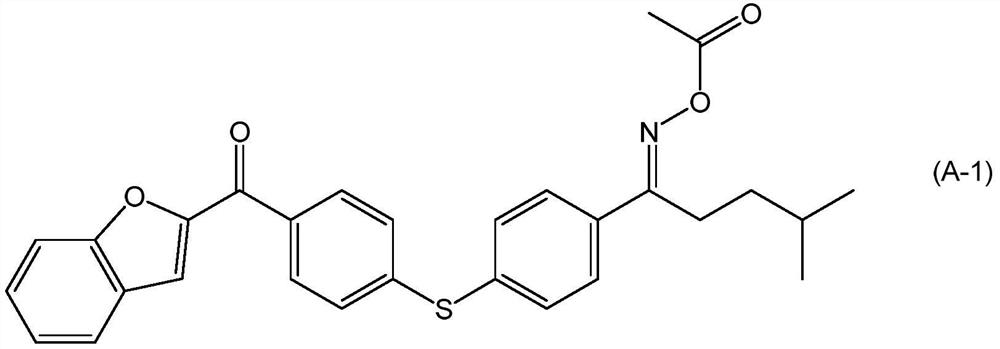

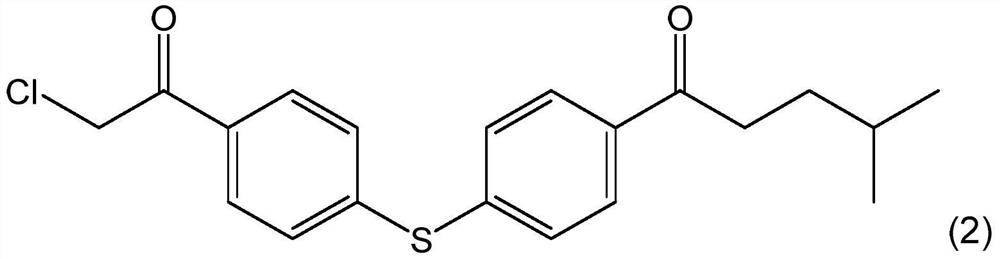

[0109] Diphenyl sulfide was added to aluminum chloride in dichloromethane at 0 °C. Next, chloroacetyl chloride was added at 0°C, and stirred at room temperature for 2 hours to obtain a mixture. Aluminum chloride and 4-methylpentanoyl chloride were added to the mixture at 0° C., and stirred overnight to obtain a reaction mixture. After pouring the reaction mixture into ice water, the organic layer was extracted with dichloromethane. The organic layer was dried over magnesium sulfate and concentrated, and the residue was purified by column chromatography to obtain a compound of the following formula (2) as a white powder.

[0110]

[0111] The compound of the aforementioned formula (2) was added to acetone, potassium carbonate and salicylaldehyde were added, and the mixture was stirred under reflux for 3 h...

Embodiment 1

[0116] [Example 1, Comparative Example 1]

[0117] Mix the two components (B) in the ratio shown in Table 1 below, heat and dissolve the component (A) in Synthesis Example 1 at 90° C., cool to room temperature, and add components (C), (D), (E ), (F), and (H) were stirred, dispersed by a three-roll mill and filtered using a metal mesh (635 mesh) to prepare Examples 1 and 2 of the photocurable resin composition. In addition, Comparative Example 1 was prepared by changing the component (A) using the component (O).

[0118] [Tg(UV+heat hardening)]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com