Preparing technique of hard silk screen abrasion-proof composite material

A composite material and preparation technology, applied in the direction of layered products, etc., can solve the problems that the wear resistance of composite materials cannot be guaranteed, the full filling of molten metal cannot be guaranteed, and the scope of application is limited, achieving small deformation, good plasticity, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: make the wear-resistant composite material of the hard wire mesh of stainless steel wire nitriding treatment and 45 steel

[0037] Manufacturing process of the present invention is carried out according to the following steps:

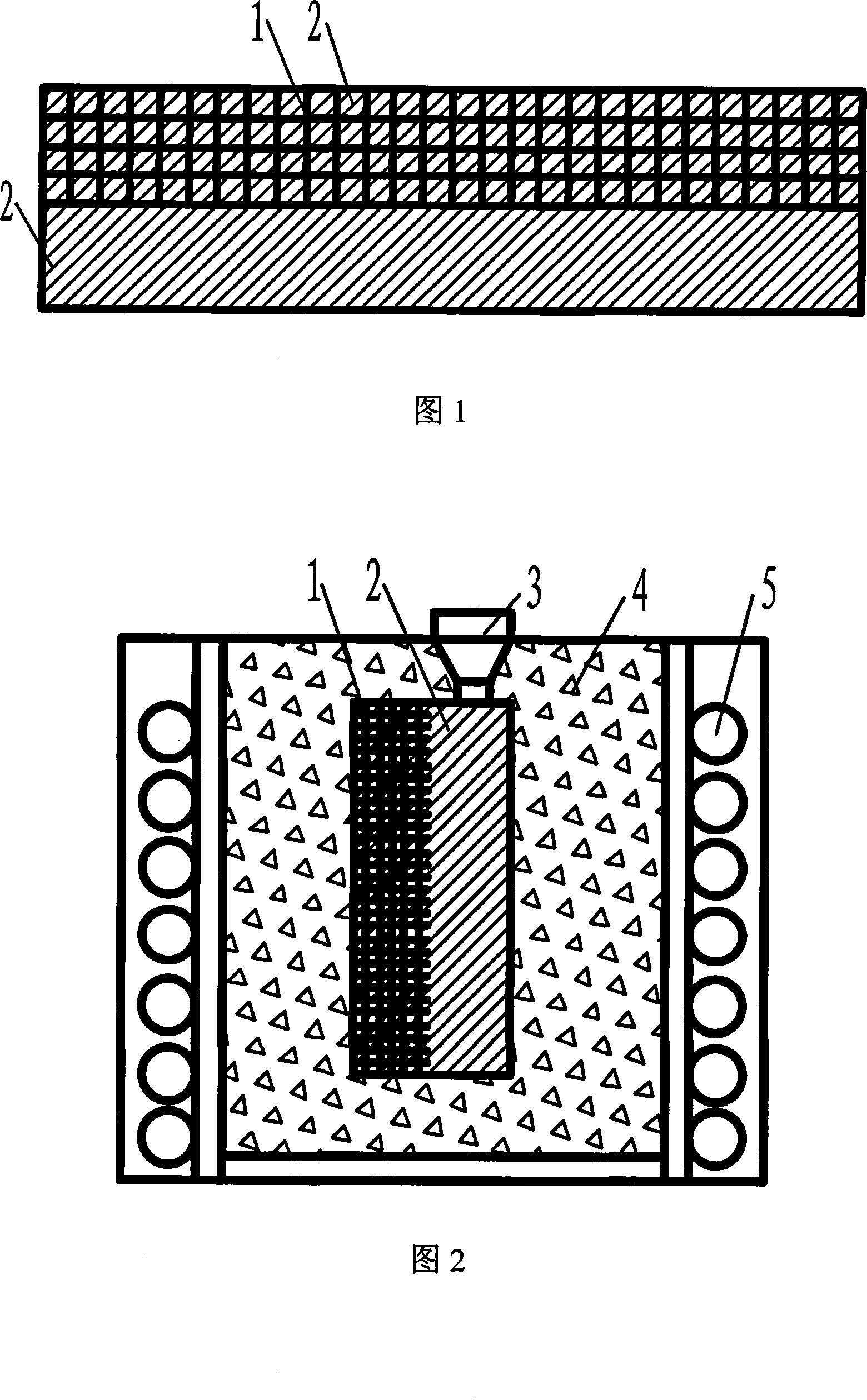

[0038] A, select the 1Cr17 stainless steel wire of 0.1mm diameter for use, weave mesh wire pitch 1mm, weave into net (1) with weaving machine;

[0039] B. According to the structure of the working surface of the workpiece, cut the mesh (1) into a suitable shape, superimpose and fix it according to the volume ratio of 30% of the wear-resistant layer;

[0040] C. Put the prepared forming grid (1) into the plasma equipment, set the temperature at 600°C, power on for plasma nitriding, and take it out after 4 hours;

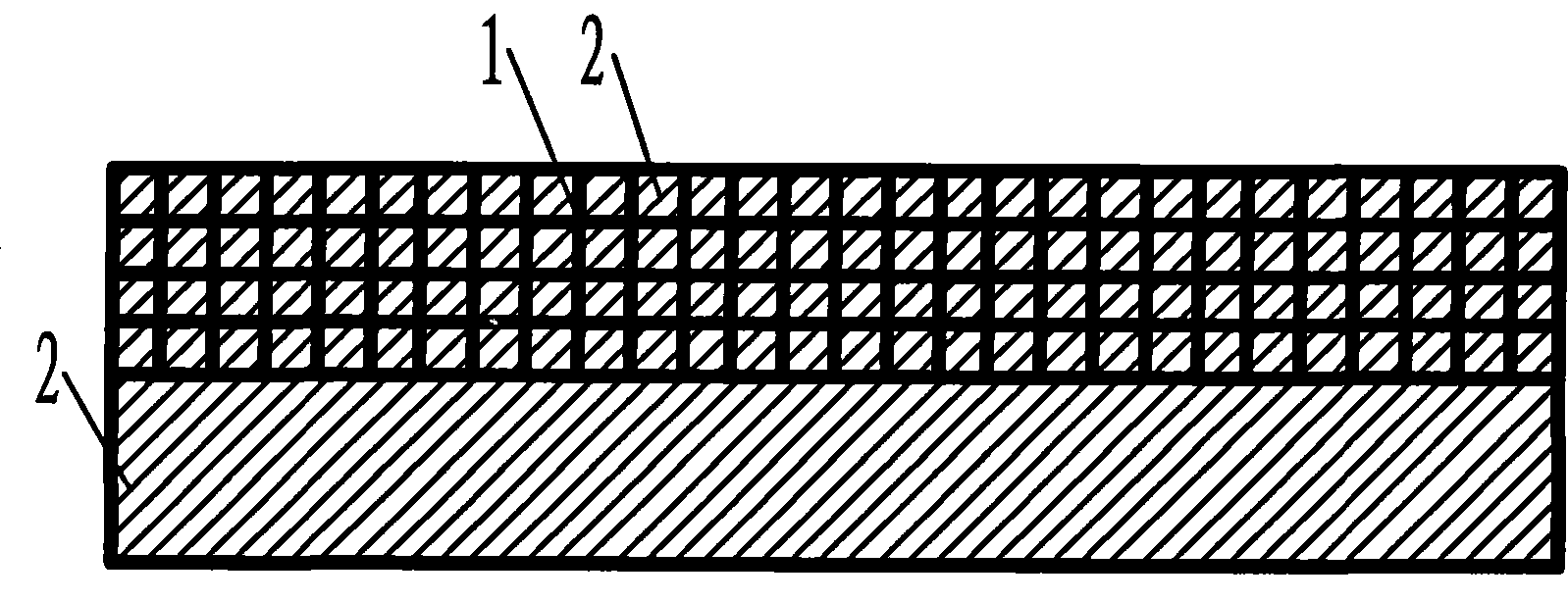

[0041] D. Adopt resin sand, mold according to the casting process, and pre-embed the hard wire mesh (1) in the mold cavity of the sand mold (4) to fix;

[0042] E. Put the sand mold (4) into the medium-frequency inductio...

Embodiment 2

[0047] Embodiment 2: Making the wear-resistant composite material of hard wire mesh and high manganese steel treated by tungsten wire carburizing

[0048] Manufacturing process of the present invention is carried out according to the following steps:

[0049] A. Select tungsten wire with a diameter of 0.2mm, weave the mesh with a distance of 1.5mm, and weave it into a net with a weaving machine (1);

[0050] B. According to the structure of the working surface of the workpiece, the mesh (1) is cut into a suitable shape, superimposed and fixed according to the volume ratio of 40% of the wear-resistant layer;

[0051] C. Put the prepared forming grid (1) into the plasma equipment, set the temperature to 900°C, power on for plasma carburizing, and take it out after 2 hours;

[0052] D. Use sodium silicate sand to shape according to the requirements of the casting process, and pre-embed the hard wire mesh (1) into the cavity of the sand mold (4) to fix it;

[0053] E. Put the sand...

Embodiment 3

[0058] Embodiment 3: making the wear-resistant composite material of hard wire mesh and nodular cast iron treated with titanium wire nitriding

[0059] Manufacturing process of the present invention is carried out according to the following steps:

[0060] A, select the titanium wire of 0.3mm diameter for use, weave net wire pitch 2mm, weave into net with weaving machine (1);

[0061] B. According to the structure of the work surface of the workpiece, the mesh (1) is cut into a suitable shape, superimposed and fixed according to the volume ratio of 45% of the wear-resistant layer;

[0062] C. Put the prepared forming grid (1) into the plasma equipment, set the temperature at 850°C, power on for plasma nitriding, and take it out after 5 hours;

[0063] D. Use resin sand, shape according to the requirements of the casting process, and pre-embed the hard wire mesh (1) into the cavity of the sand mold (4) to fix;

[0064] E. Put the sand mold (4) into the medium frequency induct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com