Super-high strength cold rolled steel and manufacturing method thereof

An ultra-high-strength and manufacturing method technology, applied in the field of ultra-high-strength cold-rolled steel, can solve the problems of poor shape of ultra-high-strength steel plates, excessive tool wear, and increased processing difficulty, so as to improve the shape difference, improve characteristics, Improve the effect of high hardness and difficult machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

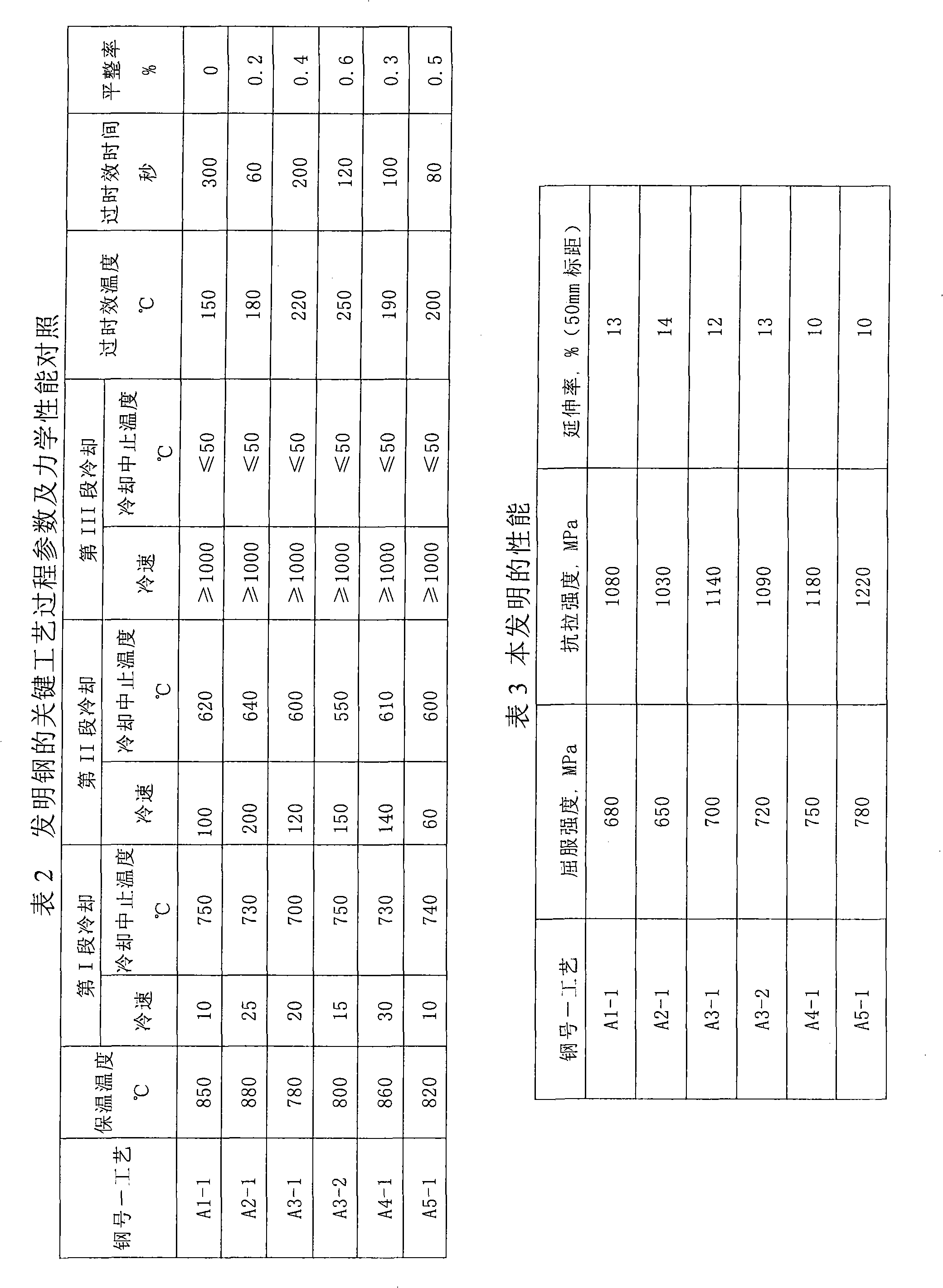

[0047] The present invention is described in more detail below by way of examples.

[0048] Table 1 is the chemical composition of A1~A5 embodiment.

[0049] Table 1 Chemical Composition of Invention Steel, wt%

[0050] steel number

C

Si

mn

Cr

P

S

Al

Se

Bi

N

B

A1

0.12

0.4

2.2

0.2

0.01

0.005

0.01

0.01

0.04

0.0035

0.002

A2

0.08

0.3

2.4

0.25

0.01

0.003

0.04

0

0.05

0.004

0.0025

A3

0.18

0.2

1.4

0.4

0.015

0.004

0.03

0.03

0.03

0.005

0.0025

A4

0.14

0.6

1.8

0.3

0.011

0.003

0.02

0.04

0.02

0.0045

0.0015

A5

0.16

0.5

2

0.1

0.012

0.005

0.05

0.05

0

0.006

0.002

[0051] Test steels A1-A5 having the chemical compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com