Full-hardening withdrawal and straightening roller of withdrawal and straightening machine and heat treatment process

A technology of tension leveling machine and tension leveling roller, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of surface damage, workpiece use effect, etc., to increase thermal shock resistance and wear resistance, The effect of improving efficiency and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

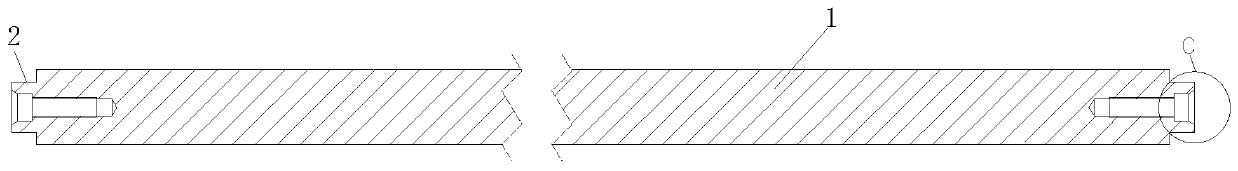

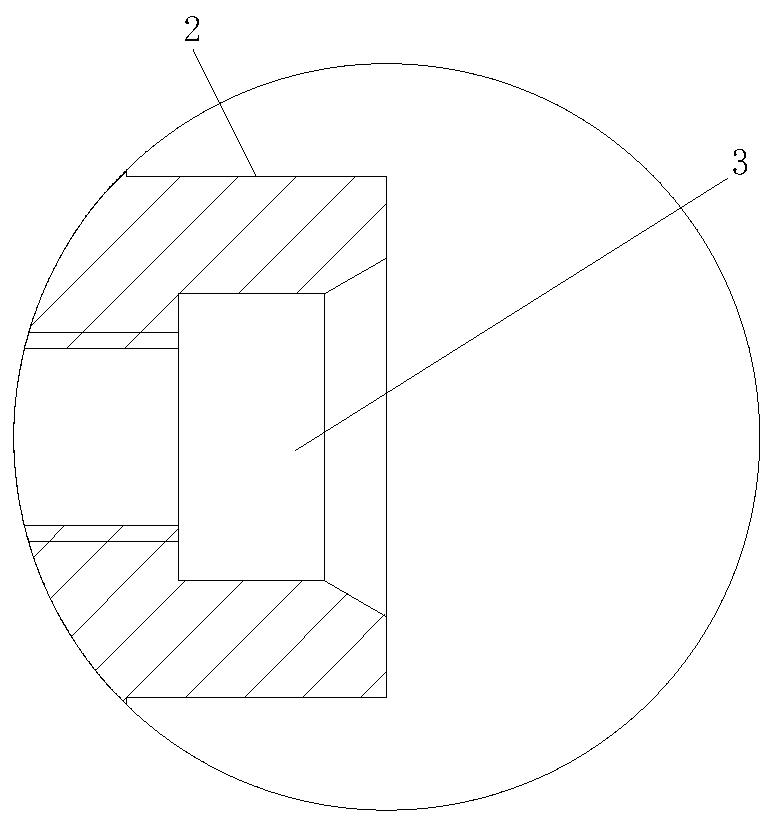

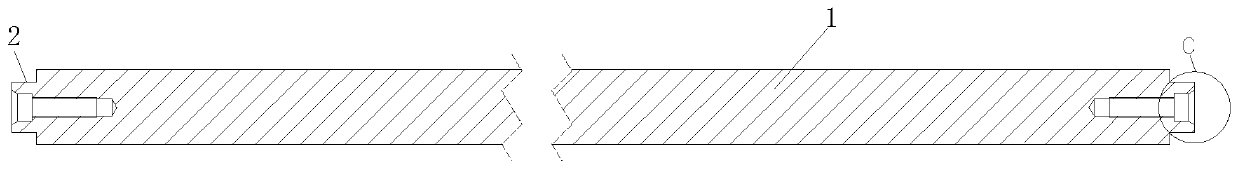

Image

Examples

Embodiment 1

[0033] by An example of the heat treatment process of tensioning and straightening rollers:

[0034] A fully hardened tension leveler tension leveler roll and heat treatment process is characterized in that it comprises the following heat treatment steps:

[0035] S1. The finished forged parts are pre-processed by rough turning. The machining reserve is 8mm. The rough machining is only the hoisting at both ends and the center hole, and then the heat treatment process;

[0036] S2. The workpiece is heat-treated by the segmental preheating method, and preheated in the heating equipment, successively carry out 400°C preheating → 600°C preheating → 800°C preheating, 400°C preheating time is 2.5 hours, 600°C preheating The time is 1.5 hours, and the preheating time at 800°C is 0.75 hours;

[0037] S3, after workpiece preheating finishes, the heating temperature in the heating equipment is raised to 1020 ℃ of temperature and carries out quenching treatment, and quenching treatmen...

Embodiment 2

[0045] by An example of the heat treatment process of tensioning and straightening rollers:

[0046] A fully hardened tension leveler tension leveler roll and heat treatment process is characterized in that it comprises the following heat treatment steps:

[0047] S1. The finished forged parts are pre-processed by rough turning. The machining reserve is 10mm. The rough machining is only the lifting of the two ends and the center hole, and then the heat treatment process;

[0048] S2. The workpiece is heat-treated by segmental preheating method, and preheated in the heating equipment, and the preheating is carried out successively at 400°C→600°C→800°C. The preheating time is 3.5 hours at 400°C and 600°C. The time is 2 hours, and the preheating time at 800°C is 1.5 hours;

[0049] S3, after workpiece preheating finishes, the heating temperature in the heating equipment is raised to 1020 ℃ of temperature and carries out quenching treatment, and the quenching treatment time is 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com