Making method of glass lubrication pad for steel tube hot extrusion

A glass lubricating and manufacturing method technology, which is applied in the field of hot extrusion lubrication of steel pipes, can solve the problems of difficult forming of glass lubricating pads, etc., and achieve the effects of improving lubricating conditions, simple forming process and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the making of solid cylindrical glass lubricating pad

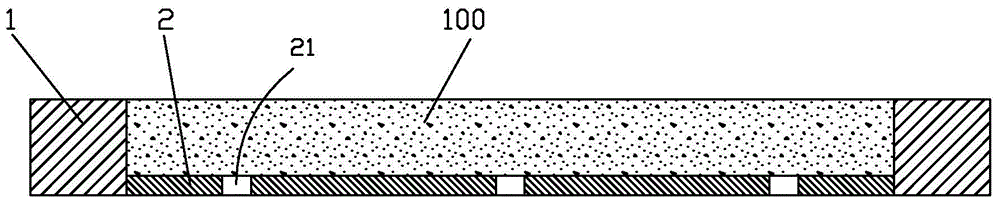

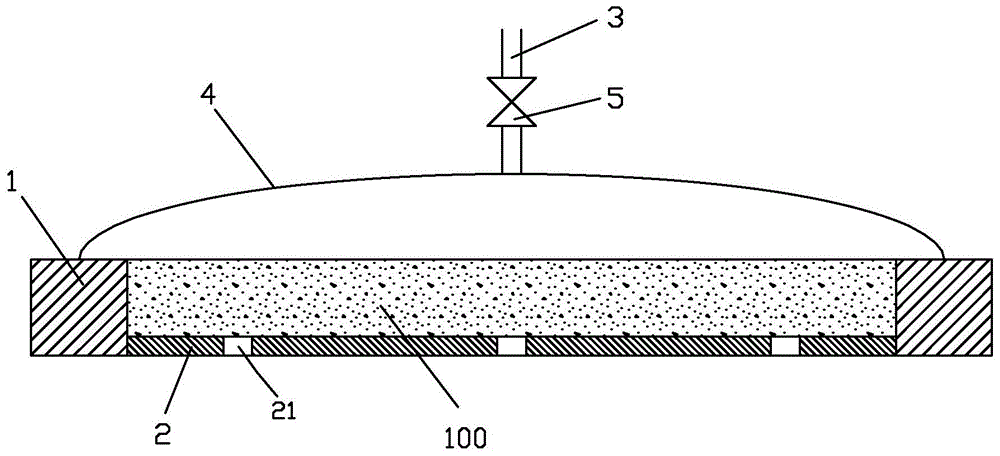

[0039] see figure 1 , figure 2 1 kg of glass powder and 20 g of water glass with a particle size ratio of 38% (20-40 orders), 45% (40-60 orders) and 17% (60-80 orders) were vigorously stirred in a vertical mixer for 5 minutes; Lay air-permeable thin paper on the bottom of the lower mold 2, and evenly open some air holes 21 on the lower mold 2; pour the mixed glass powder into the forming mold formed by the upper and lower molds 1 and 2, and use a scraper to scrape the glass powder The material is evenly filled in the forming mold, and the upper surface is scraped; cover the inflatable cover 4 with a gas pipe 3 on the glass lubricating pad, and open the CO 2 Air supply valve 5, blow air into the mold for 15 seconds; remove the inflatable cover 4; jack up the lower mold 2, and take out the glass lubricating pad 100; it can be used for profile extrusion after subsequent drying. With this method, the ...

example 2

[0040] Example 2: Production of special-shaped glass lubricating pads

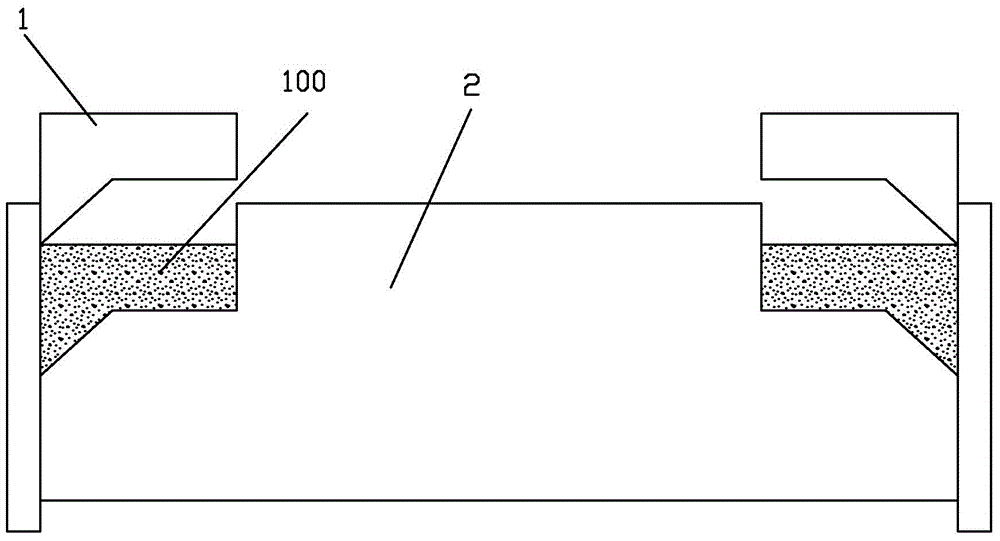

[0041] 1 kg of glass powder with a particle size ratio of 38% (20-40 mesh), 45% (40-60 mesh) and 17% (60-80 mesh) and 20 g of water glass were vigorously stirred in a vertical mixer for 5 minutes. Glass lubricating pad forming mold such as image 3 , 4 shown. Pour the mixed glass powder into the mold, fill the glass powder evenly in the forming mold with a scraper, and scrape the upper surface. Put the upper mold 1' flat into the forming mold, press the upper mold 1' into the mold with a press or manually, so that the glass lubricating pad 100 is formed. Take out the upper mold 1', cover the inflatable cover with air tube on the glass lubricating pad, turn on the CO 2 Air supply valve, blow air into the forming mold for 15 seconds. Remove the inflatable cover. The lower mold 2' is jacked up, and the glass lubricating pad is taken out. It can be used for pipe extrusion after subsequent drying. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com