Apparatus and method of frame glue solidification and liquid crystal panel manufacturing method

A liquid crystal panel and curing device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of easy contamination of the liquid crystal by the sealant of the encapsulated panel, poor panel display characteristics, etc., and achieve the goal of improving production yield and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

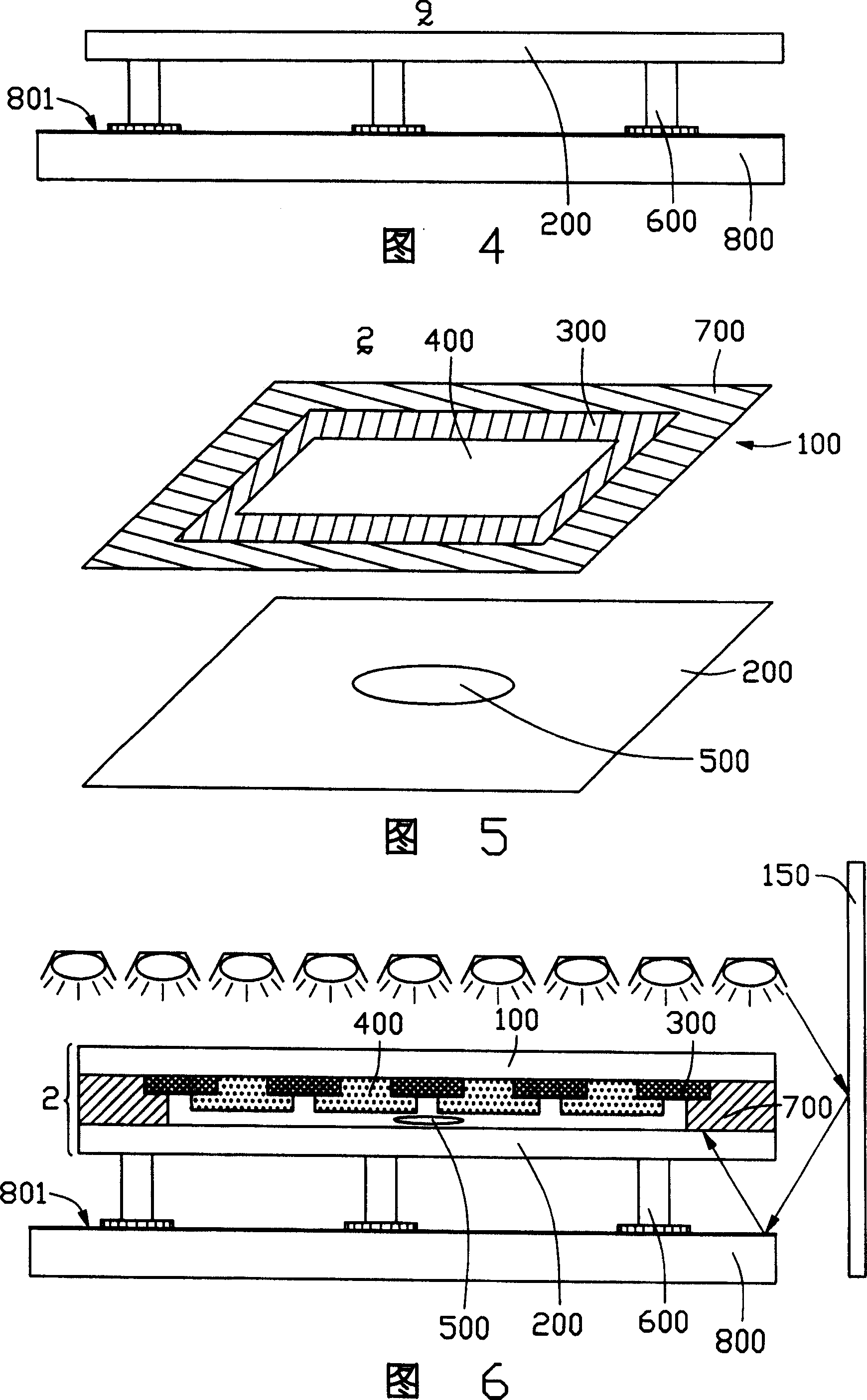

[0024] Please refer to FIG. 4, which is a sealant curing device used in the liquid crystal panel manufacturing process of the present invention. The sealant curing device 9 includes an operating platform 800, and the second substrate 200 of the liquid crystal panel is located on the operating platform 800. There are a plurality of supporting feet 600 between the operation platform 800 and the second substrate 200 of the liquid crystal panel. An adjustment device (not shown) adjusts the height of the plurality of supporting feet 600. For heightening, the operating platform 800 has a reflective surface 801 adjacent to the supporting feet 600, and a reflective device 150 (see FIG. 6 ) is provided on the outer side of the operating platform 800 and the second substrate 200 for reflecting ultraviolet light.

[0025] During the manufacturing process of the liquid crystal panel, the supporting feet 600 allow the ultraviolet light to fully irradiate the frame glue during the process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com