Patents

Literature

105 results about "Bottom type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In type theory, a theory within mathematical logic, the bottom type is the type that has no values. It is also called the zero or empty type, and is sometimes denoted with falsum (⊥). A function whose return type is bottom cannot return any value, not even the zero size unit type. Therefore a function whose return type is the bottom type cannot return. In the Curry–Howard correspondence, the bottom type corresponds to falsity.

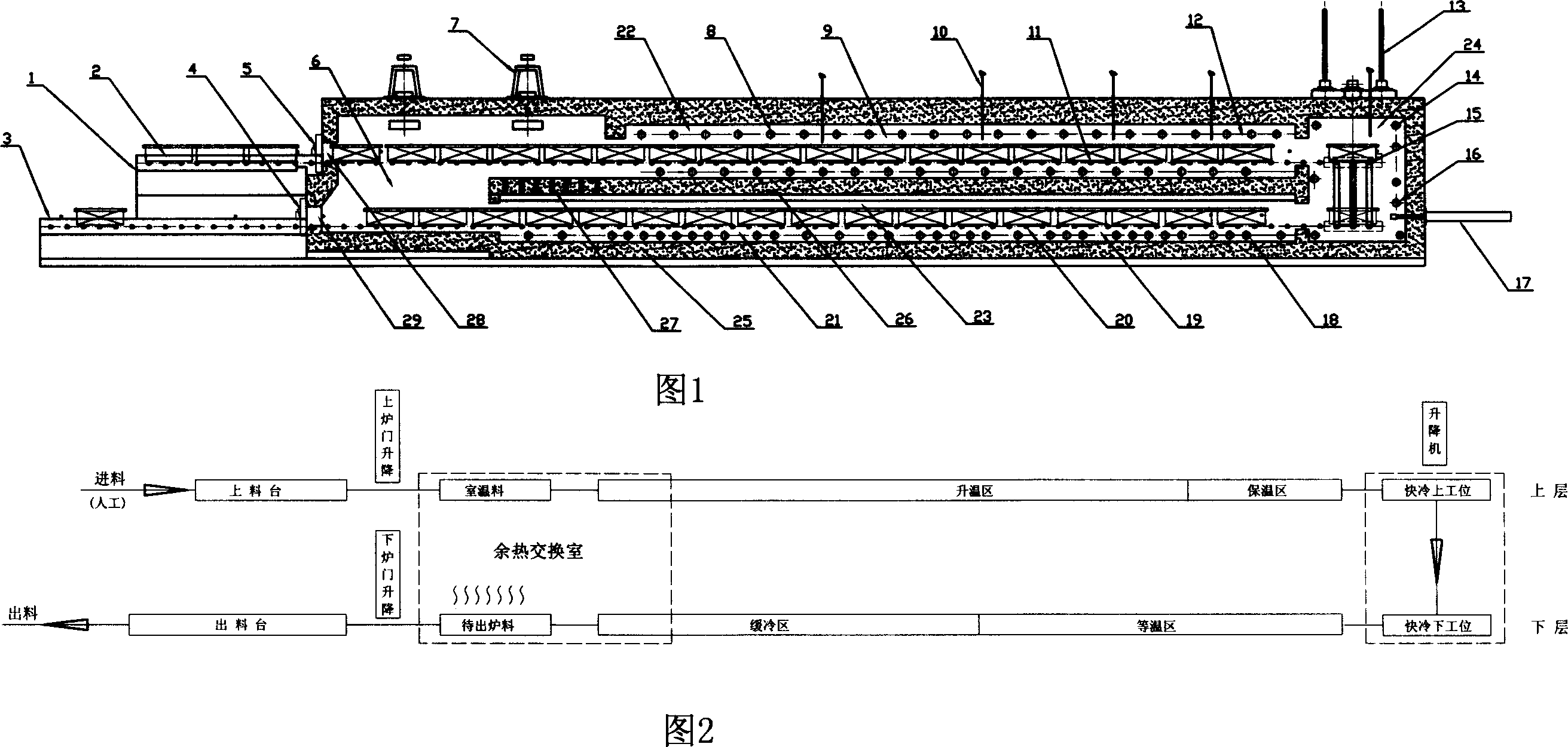

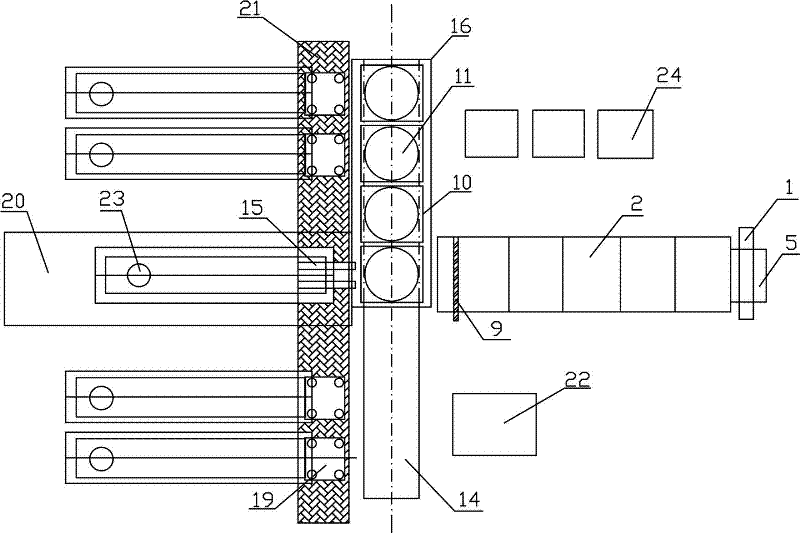

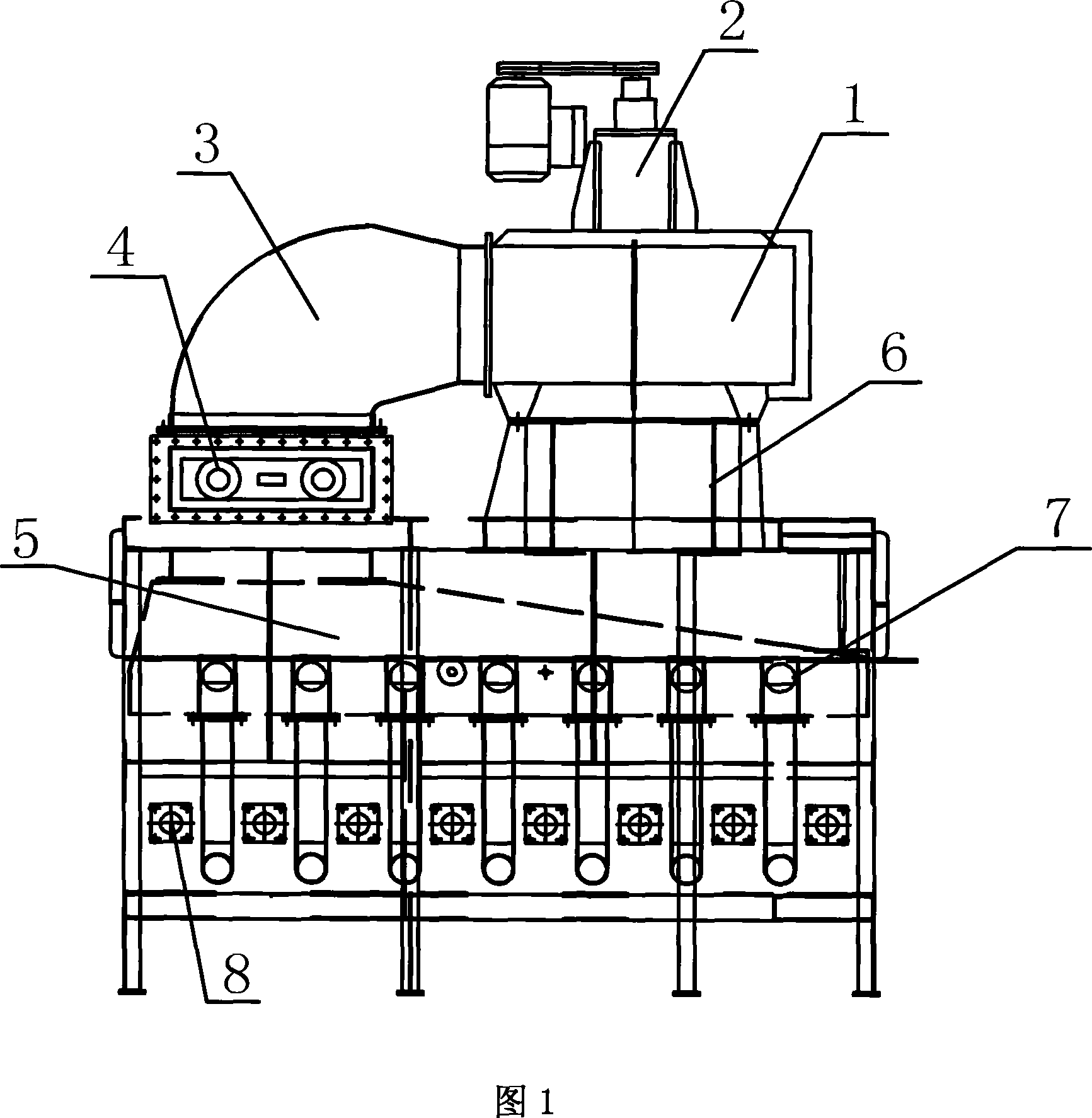

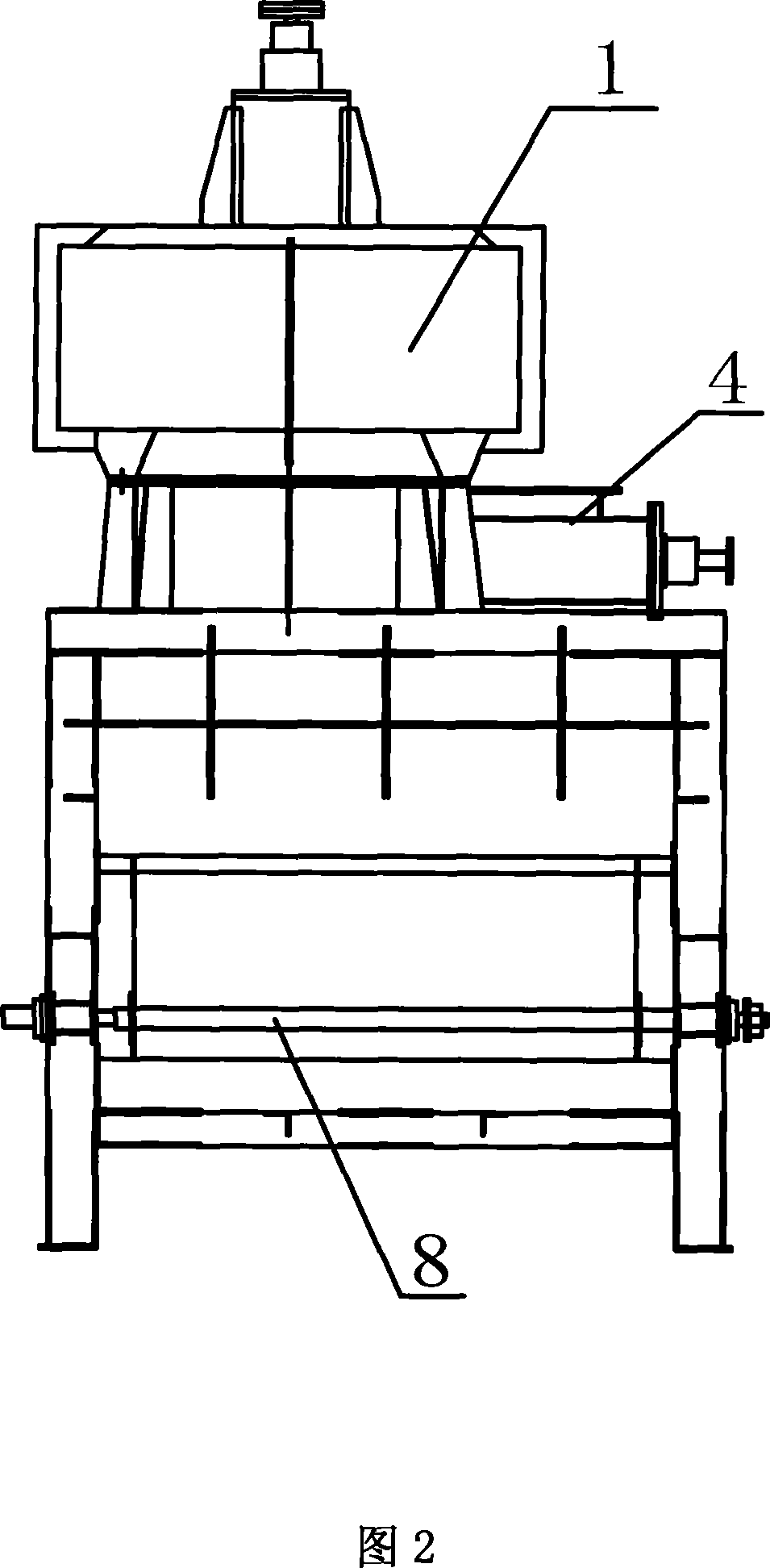

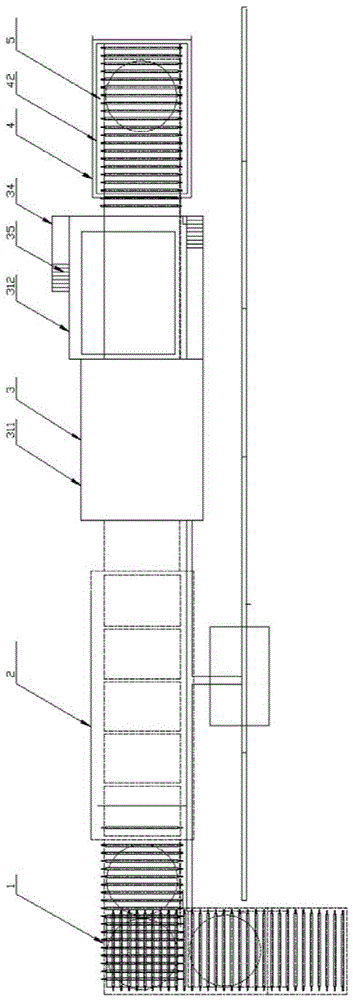

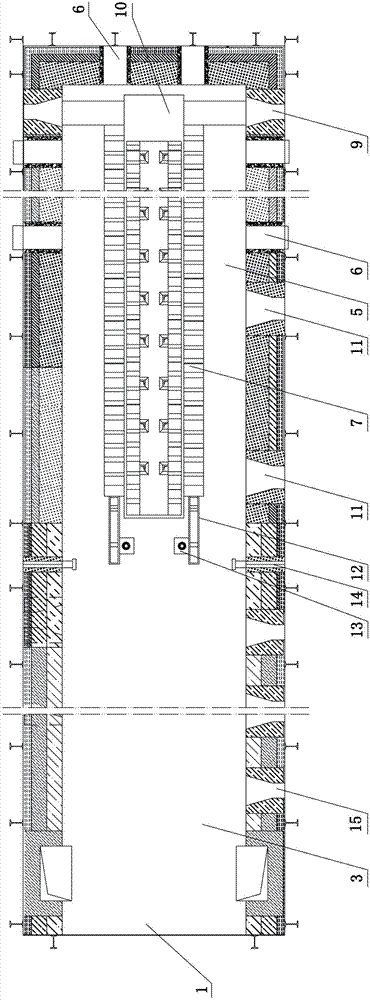

Double layer roller bottom type continuous spheroidizing annealing furnace

ActiveCN1908203AGood for healthEasy and reliable annealing transferFurnace typesHeat treatment furnacesCooling chamberHearth

the invention discloses a double-layer roll-bottom continuous-balling annealing furnace, which contains furnace, wherein the hearth consists of upper hearth and lower hearth, whose inlet and outlet are set on one end of furnace; the residual heat exchanging chamber is set near the furnace; the sealing rapid-cooling chamber is set in the furnace far away from inlet and outlet, which interconnects upper and lower furnaces; the upper driving roll is set on the upper furnace; the lower driving roll is set in the lower furnace; the elevator and pushing rod are set in the sealing rapid-cooling chamber; the upper heater and heat coupler are set in the upper furnace and lower heater is set in the lower furnace.

Owner:杭州骏马轴承有限公司

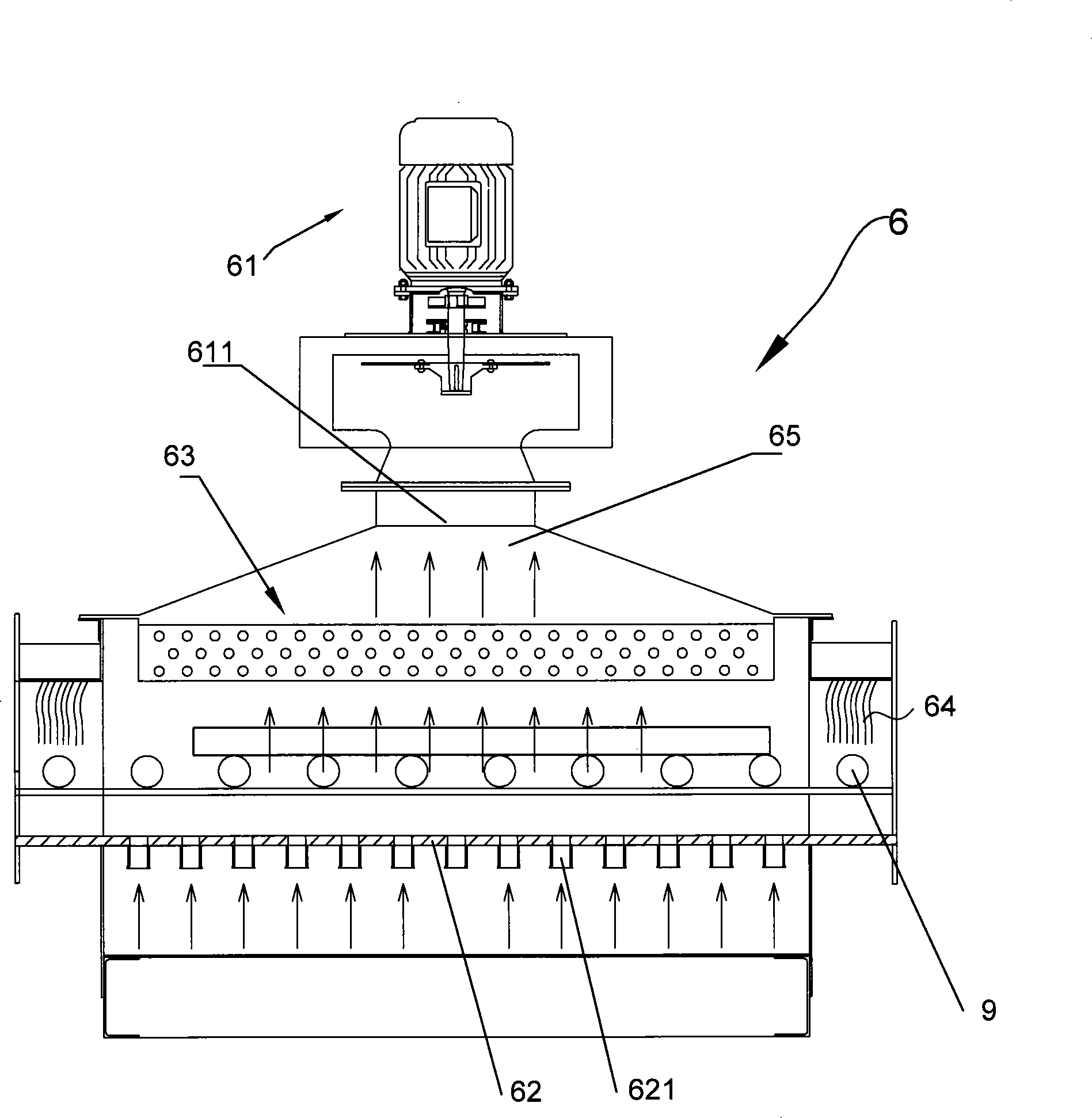

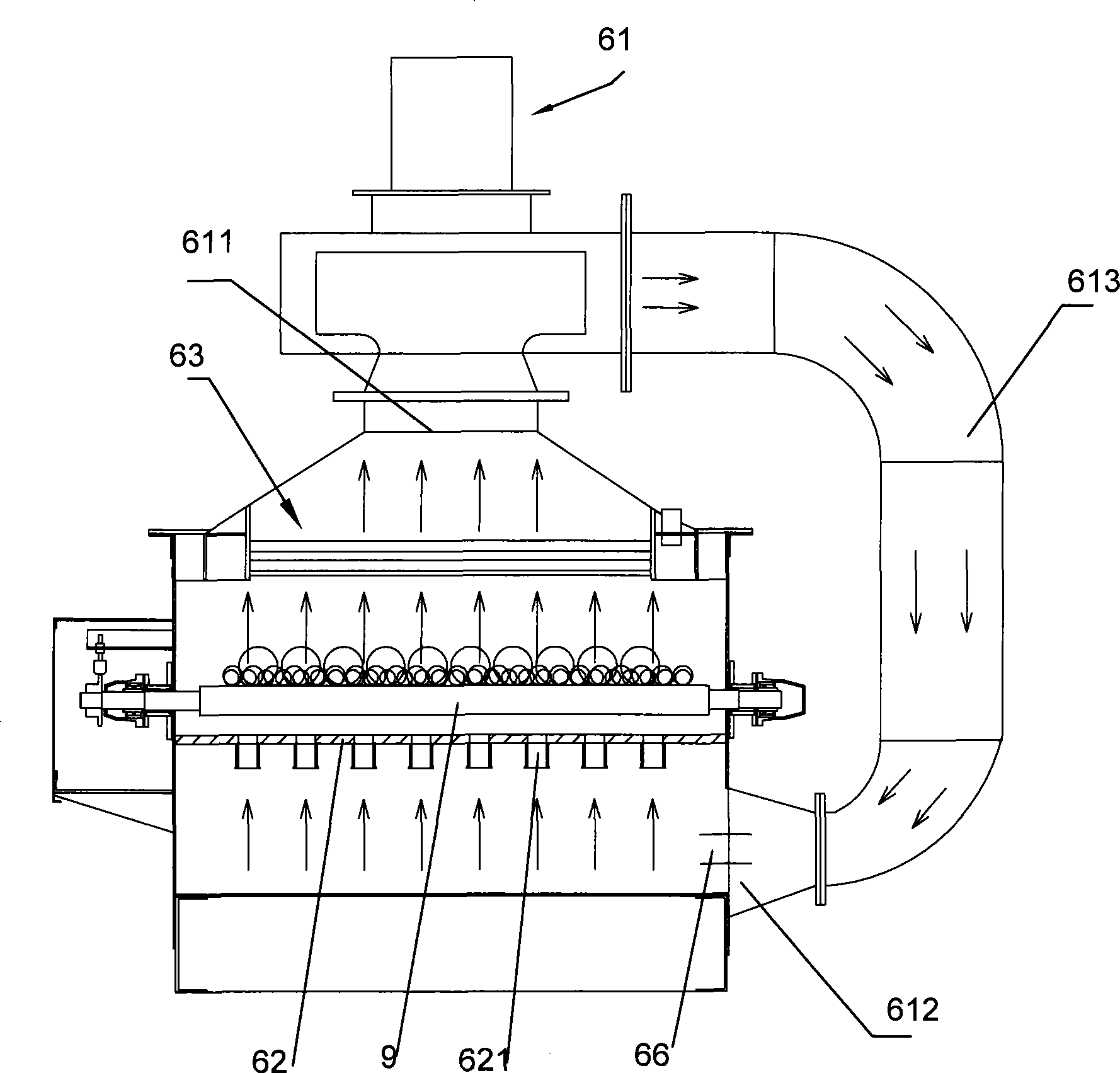

Low stove pressure convection continuous roller bottom type annealing furnace and annealing technique

The invention relates to a low furnace pressure convective continuous roller hearth type annealing furnace, which comprises a charging magazine, a heating chamber, a strong cooling chamber and a roller way driving system, wherein an internal circulation draught fan and a plurality of heating elements are arranged in the heating chamber, both an air inlet and an air outlet of the internal circulation draught fan are located in a furnace body of the heating chamber, the air inlet is vertical to the plane of a roller way, the air outlet is parallel to the plane of the roller way, an external circulation draught fan, a heat exchanger and a baffle plate are arranged in the strong cooling chamber, the baffle plate is located in the middle portion of the furnace body of the strong cooling chamber, the roller way is located between the heat exchanger and the baffle plate, an upper opening and a lower opening are respectively opened on the top and the bottom of the furnace body of the strong cooling chamber, the air inlet of the external circulation draught fan is communicated with the upper opening, the air outlet of the external circulation draught fan is connected with the lower opening through a connecting pipe which is arranged outside the strong cooling chamber, the complex number of nozzles are evenly distributed on the baffle plate, and the upper portion and the lower portion of the furnace body of the strong cooling chamber are communicated only through a complex number of nozzles. The annealing furnace of the invention has the advantages of even heating, rapid cooling, high efficiency and the like.

Owner:SUZHOU ZHONGMENZI IND FURNACE TECH CO LTD

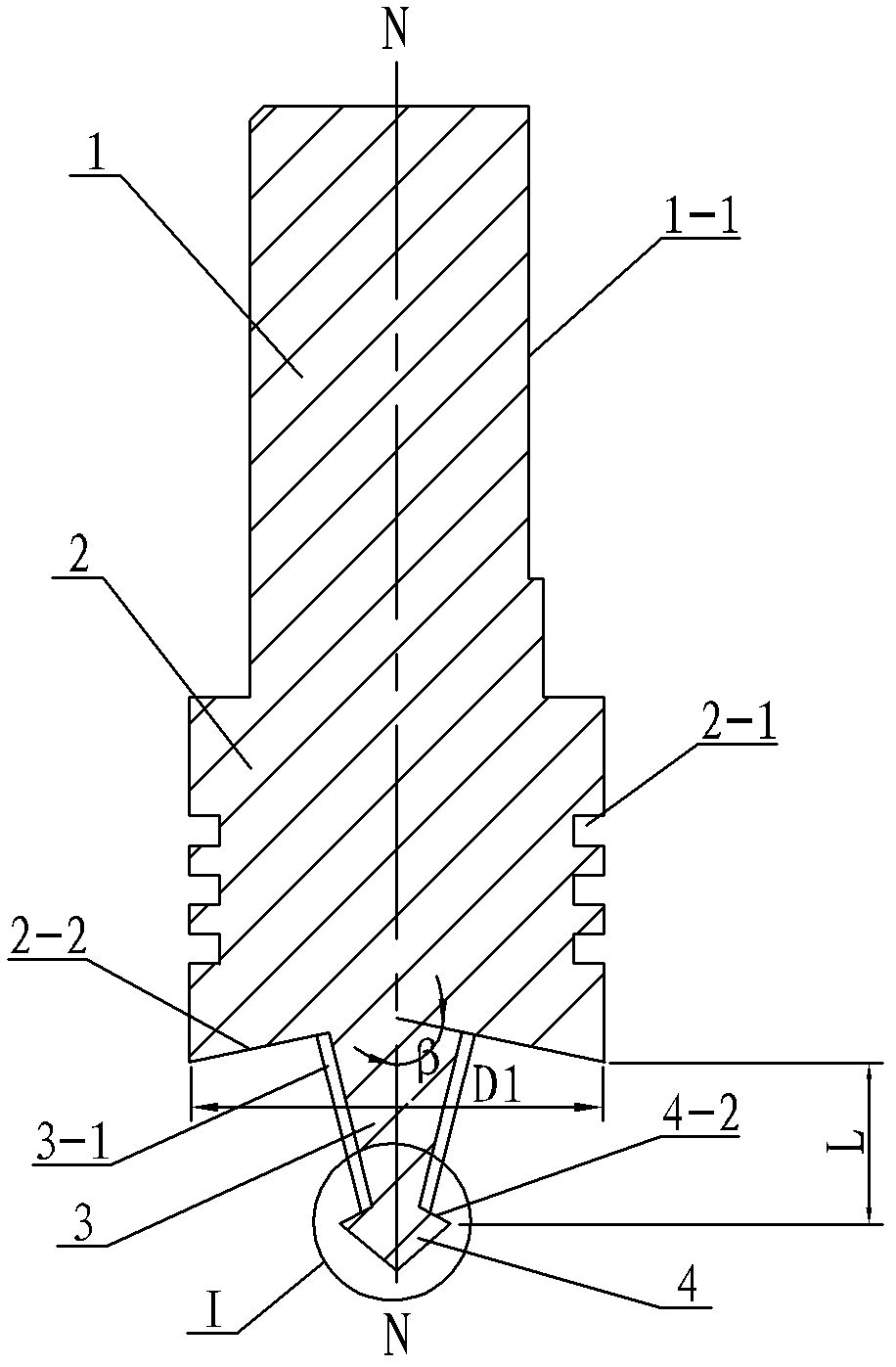

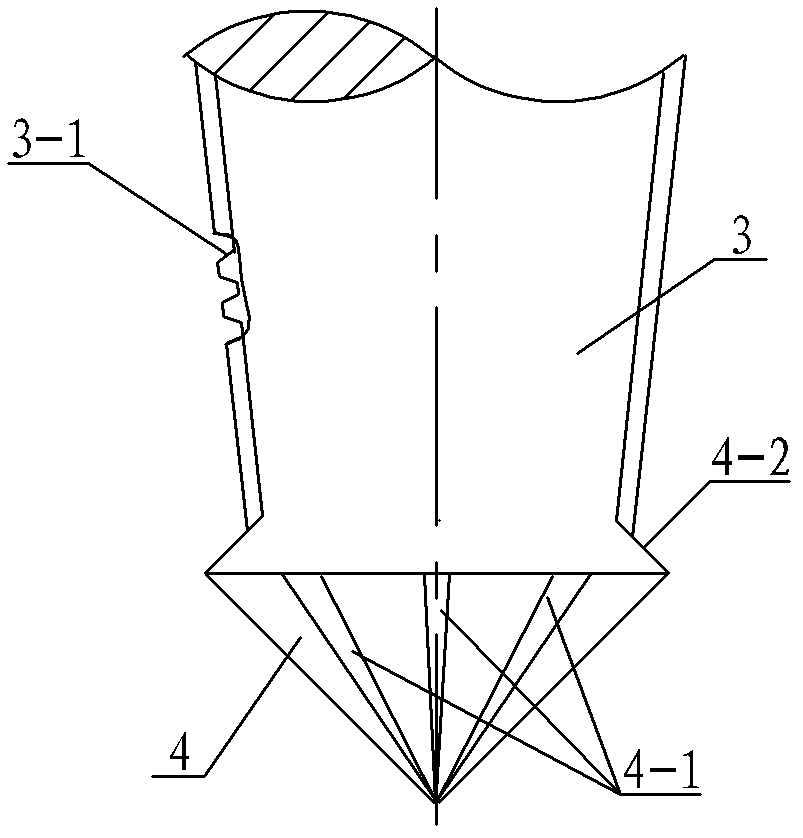

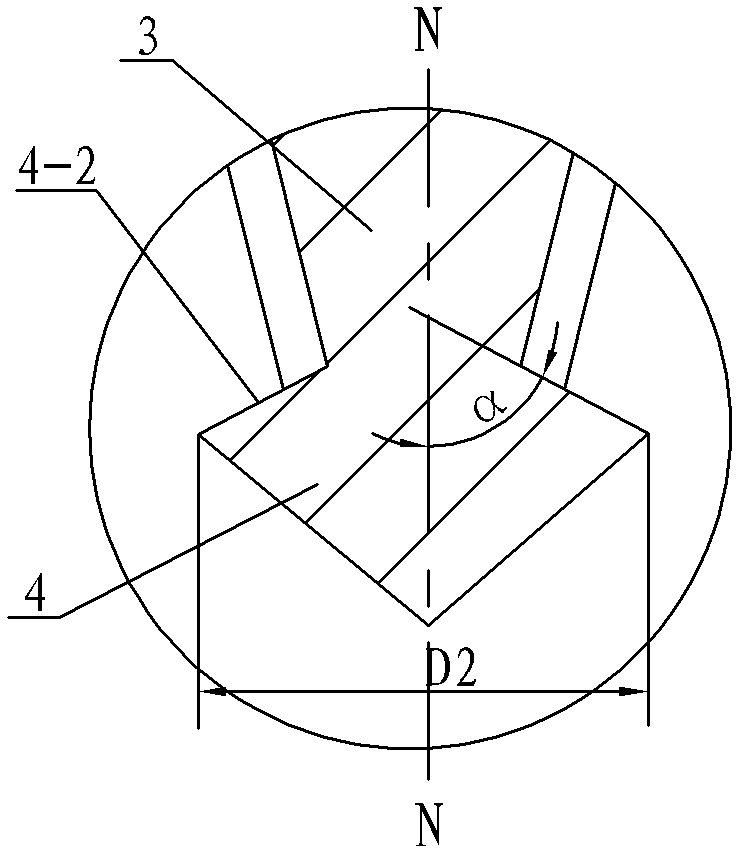

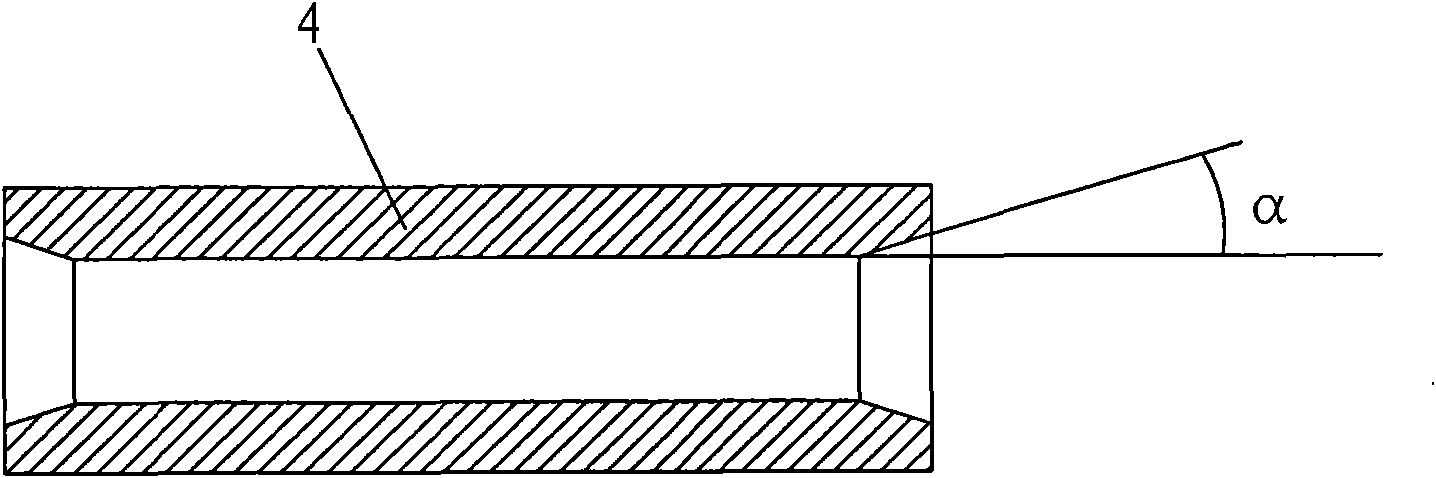

Soldering set for agitating friction welding with adjustable inclined angle and concave-top and convex-bottom type shaft shoulder and method thereof

ActiveCN102581475AImprove adaptabilityEasy to shapeNon-electric welding apparatusFriction weldingSoldering

The invention discloses a soldering set for agitating friction welding with an adjustable inclined angle and a concave-top and convex-bottom type shaft shoulder and a method thereof, relating to a soldering set for agitating friction welding and a method thereof. With the invention, the problems that a leading-in hole and a leading-out hole are required to be pre-fabricated in the conventional dual-shaft shoulder self-held agitating friction welding, and the thermal input amount in the agitating friction welding process is too large to cause decreased joint performance are solved. The soldering set comprises an upper cylinder, a lower cylinder, a main agitating needle, an auxiliary agitating needle which are orderly arranged from top to bottom and fabricated into one piece, the lower end face of the lower cylinder is a concave shaft shoulder face, and the upper end face of the auxiliary agitating needle is a convex shaft shoulder face. The method comprises the following steps of determining size of the auxiliary agitating needle; determining a lower included angle between the convex shaft shoulder face and the soldering set central axis; determining use length of an agitating body; determining an upper included angle between the concave shaft shoulder face and the soldering set central axis; adjusting the inclined angle of soldering set; and carrying out the agitating frictionwelding of a hollow unbraced structure. The invention is used for soldering the hollow unbraced structure.

Owner:安徽万宇机械设备科技有限公司

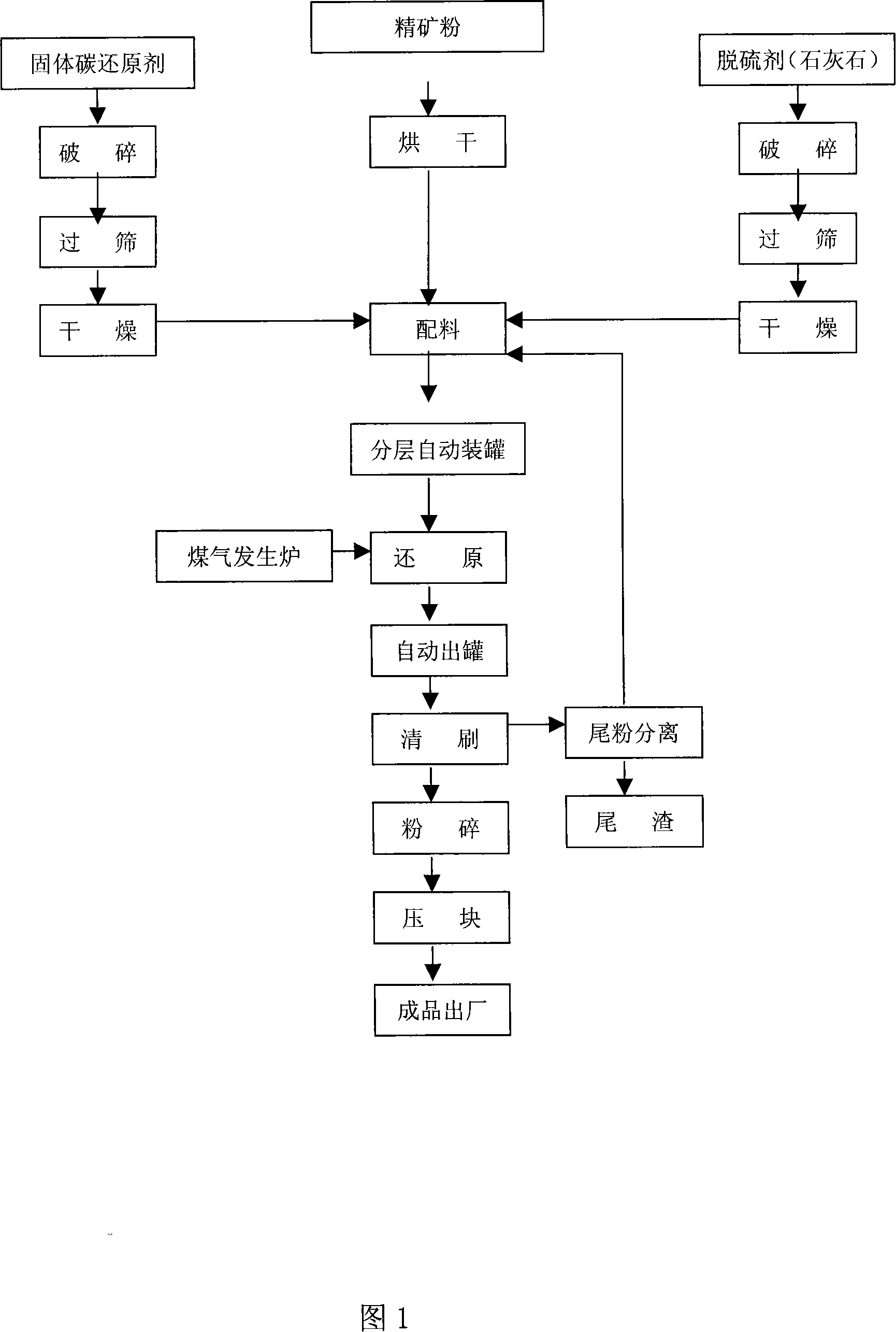

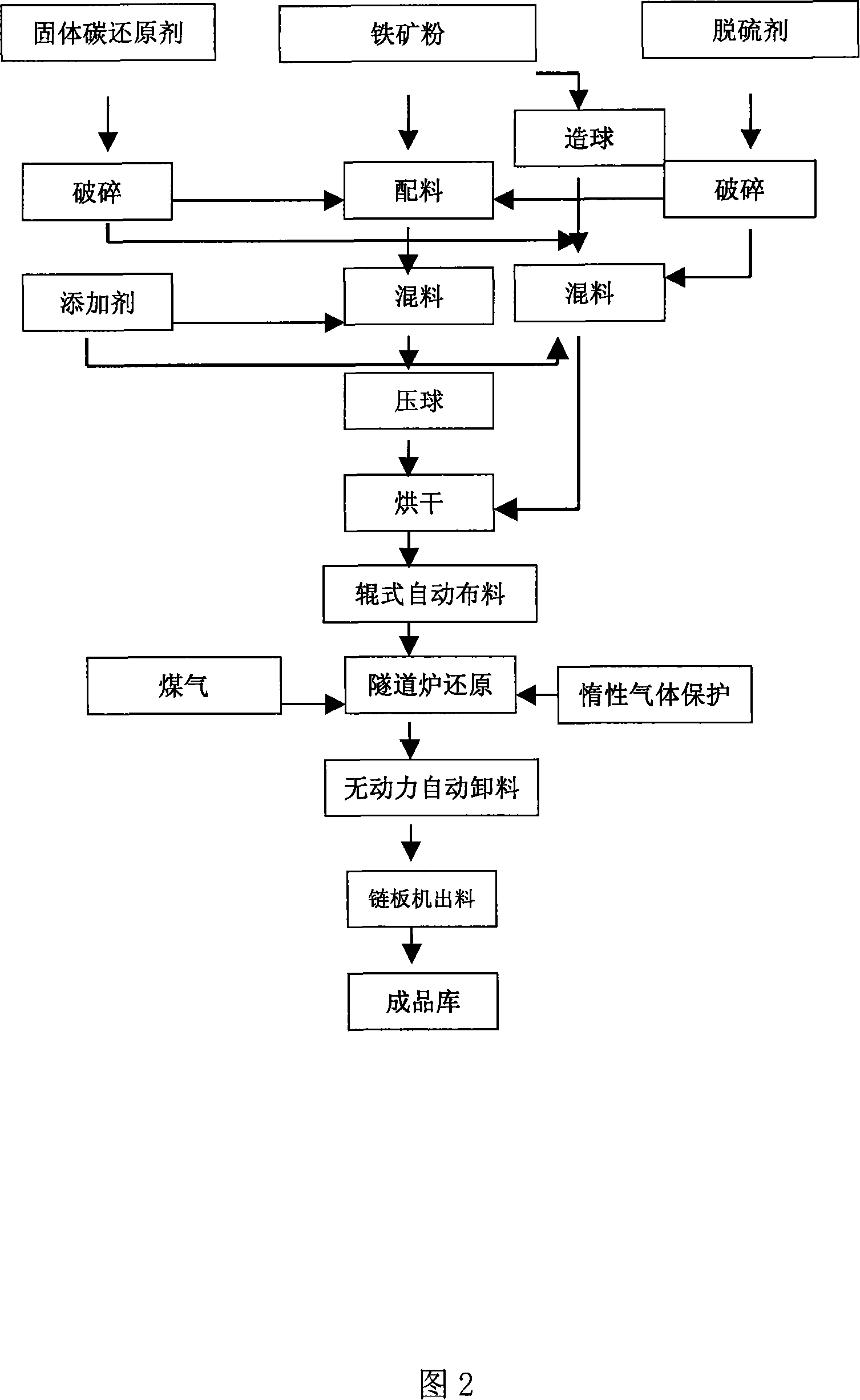

Technique for directly reducing iron by using tunnel vehicle bottom type fast reducing furnace

The present invention relates to fast reduction of directly reduced iron, and is especially the production process of fast reducing iron oxide in a fast no-tank reducing furnace in the bottom of a tunnel bogie to replace traditional externally heated reaction tank in a tunnel kiln. The present invention features that pressed and dried pellets are spread on bogie of the no-tank reducing furnace, rather than inside a reaction tank, for heating reduction reaction. The present invention has the direct action of the high temperature reducing atmosphere onto the iron oxide pellets in great contact area, fast reaction speed, high quality of reduced iron, greatly raised output, greatly reduced power consumption and greatly lowered production cost.

Owner:TANGSHAN OUTSTANDING SCI & TECH

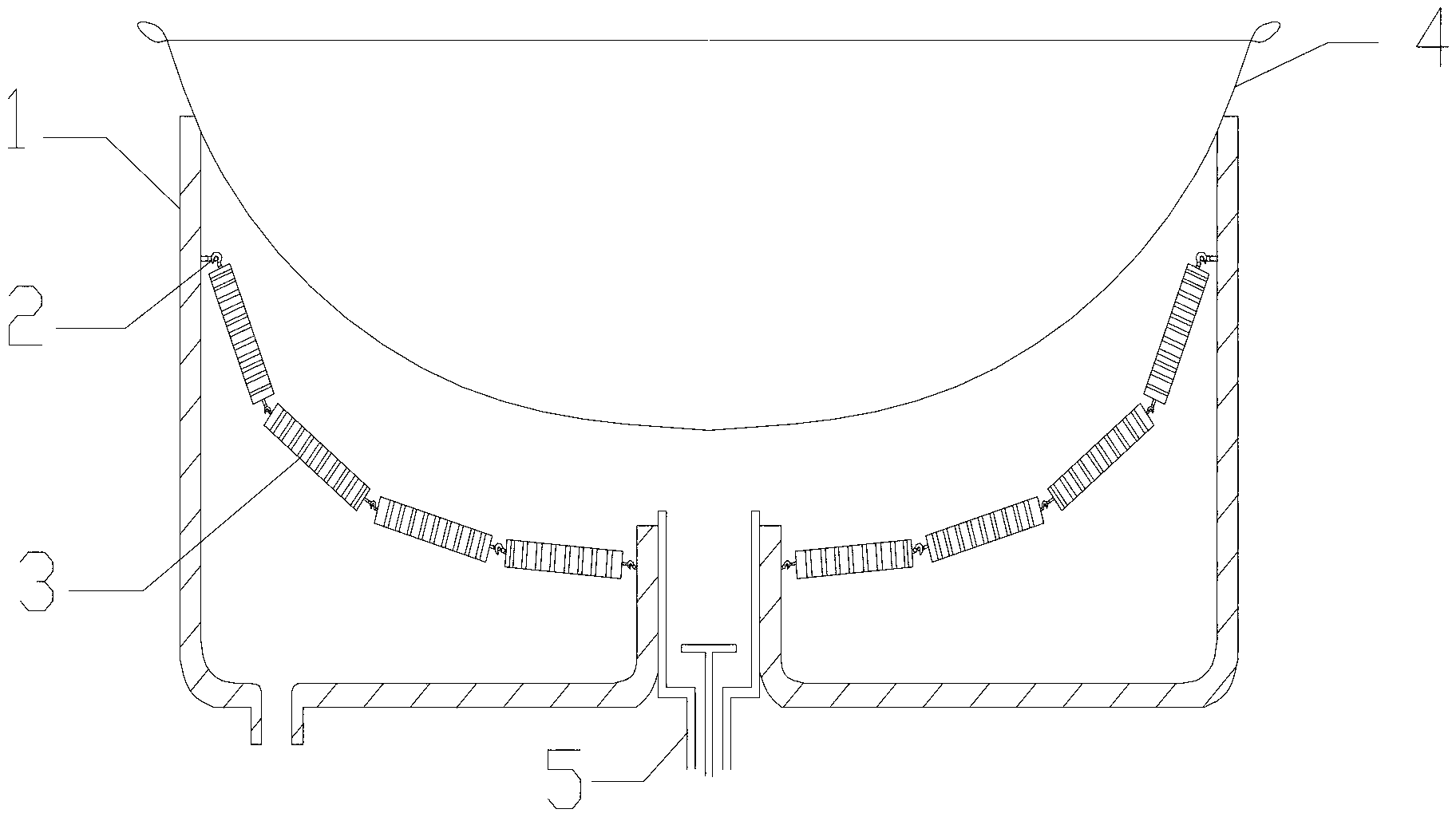

Solar heat collecting device

InactiveCN102563908AReduce loadReduce power consumptionSolar heating energySolar heat devicesHeliostatEngineering

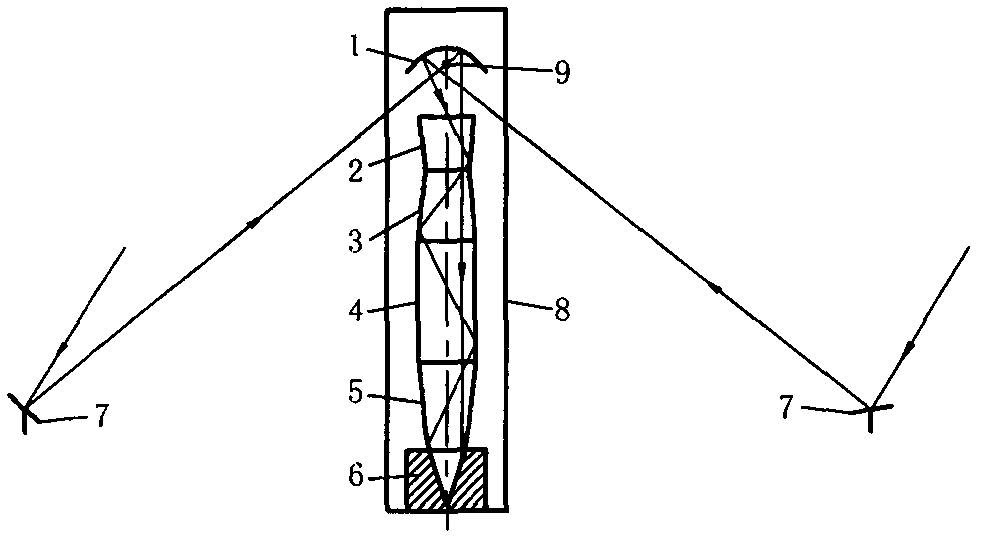

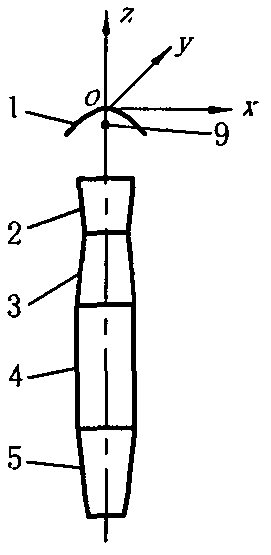

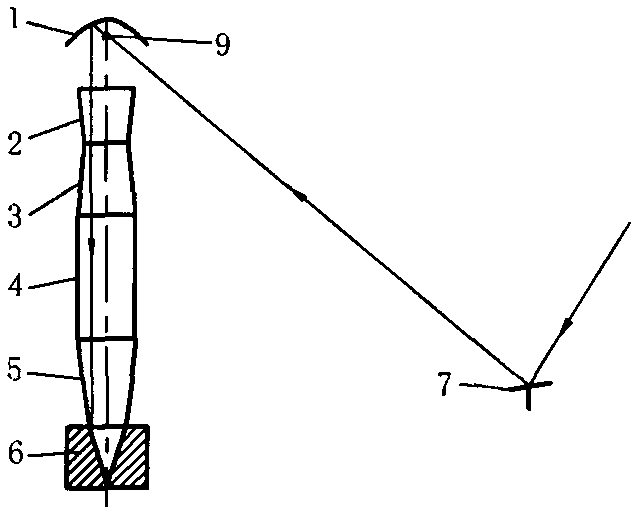

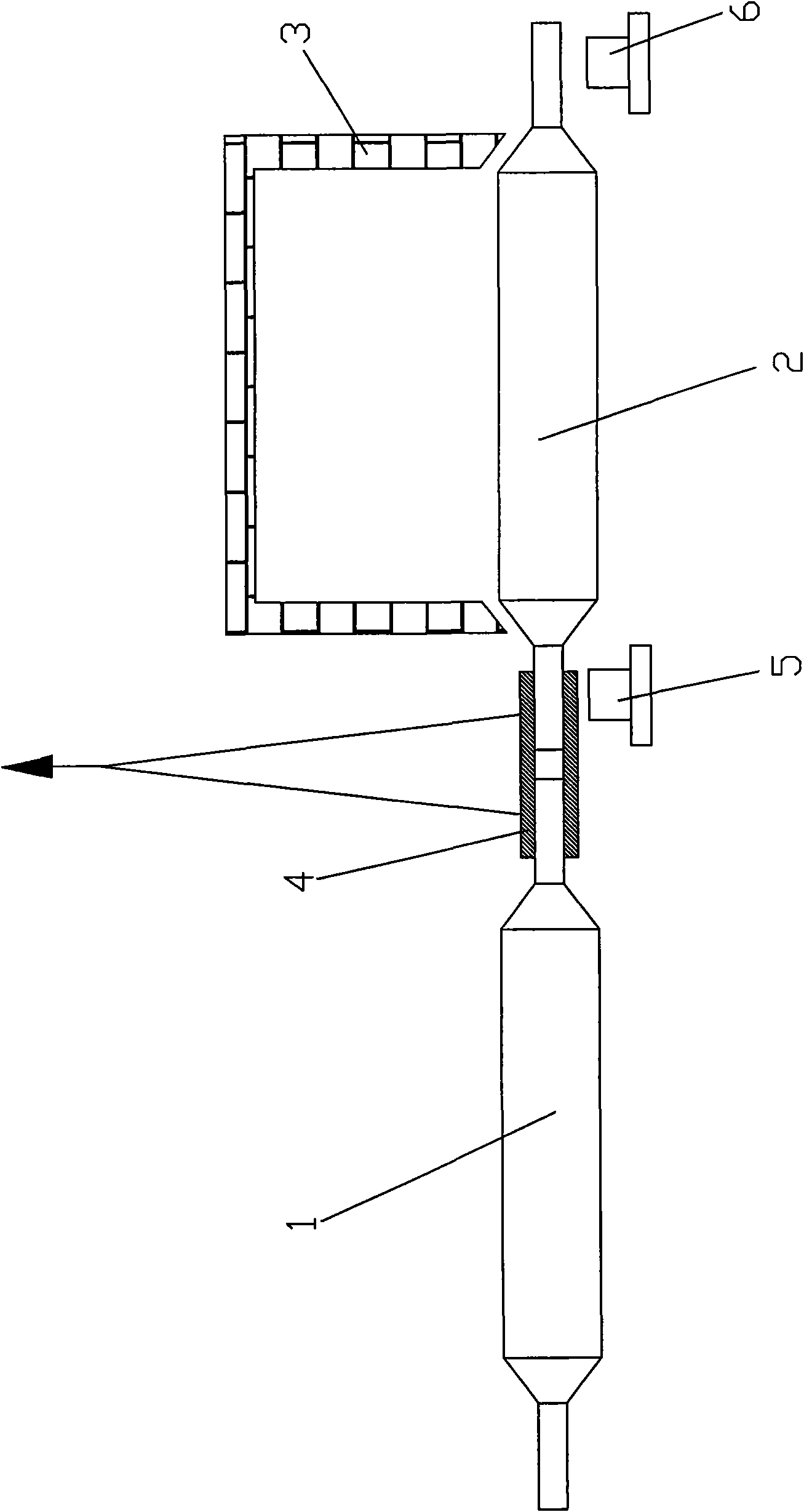

The invention discloses a reflecting-tower-bottom type solar focusing high-temperature heat collecting device, which consists of a plurality of heliostats, a reflecting tower, a rotary parabolic mirror, a conical mirror, an inverted compound parabolic mirror, a cylindrical mirror, a compound parabolic mirror and a sunlight receiver, wherein the rotary parabolic mirror, the conical mirror, the inverted compound parabolic mirror, the cylindrical mirror, the compound parabolic mirror and the sunlight receiver are arranged on a reflecting tower in sequence from top to bottom. The sunlight is focused and reflected to the tower top of the reflecting tower by the plurality of heliostats, and then is reflected again on the sunlight receiver of the tower bottom from the tower top by the rotary parabolic mirror, the conical mirror, the inverted compound parabolic mirror, the cylindrical mirror and the compound parabolic mirror so as to realize heat collection, heat storage and heat exchange at the tower bottom. The reflecting-tower-bottom type solar focusing high-temperature heat collecting device has the advantages that the load of a tower body, the power consumption and the heat loss can be reduced, the process can be simplified, and high-temperature heat storage can be convenient. The reflecting-tower-bottom type solar focusing high-temperature heat collecting device is applicable to occasions such as solar thermal power generation and high-temperature heating.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

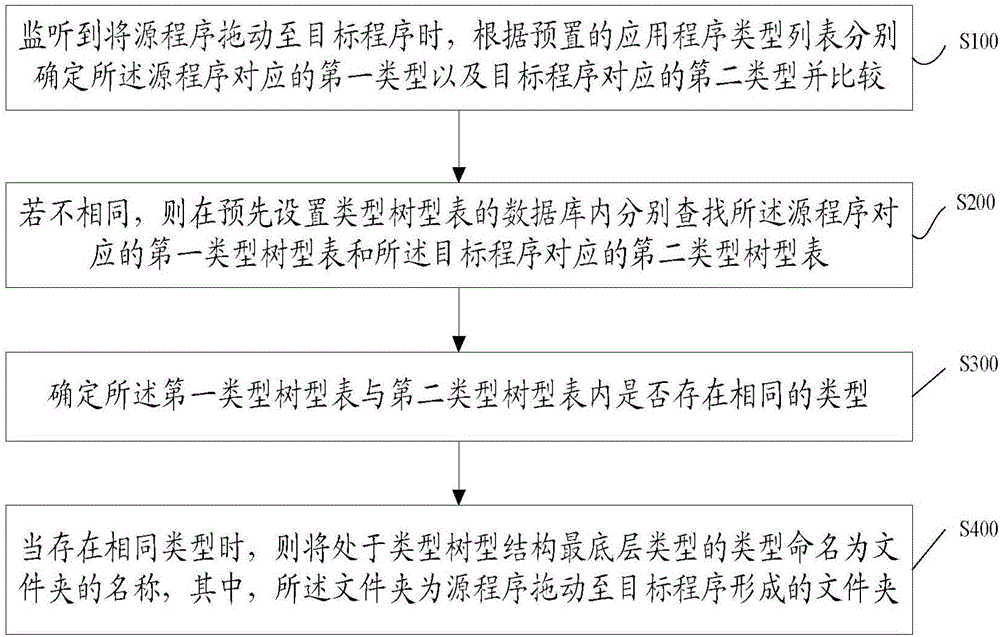

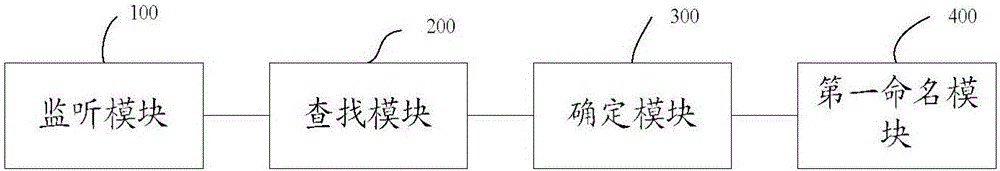

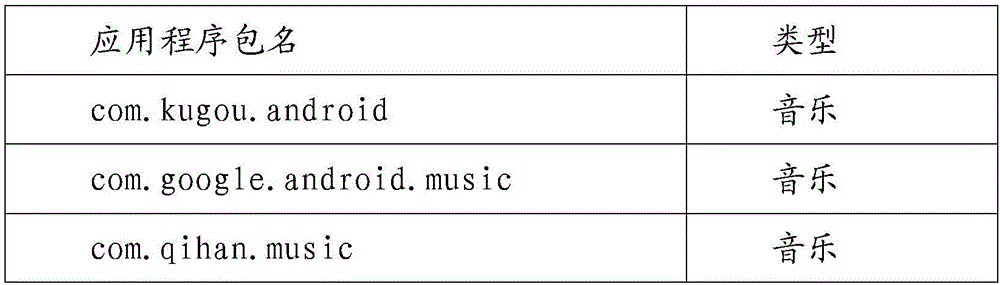

Name method and system of desktop folder

ActiveCN106649633AEasy to findEasy to useFile/folder operationsSpecial data processing applicationsTheoretical computer scienceBottom type

The invention discloses a name method and a system of a desktop folder. The name method of the desktop folder comprises that when monitoring a source program is going to be dragged to a target program, according to a predetermined list with some application program types, the corresponding first type and the second type of the source program and the target program and the corresponding first type tree table and the second type tree table of the source program and the target program are determined respectively; whether the first type tree table and the second type tree table exist some same types or not is determined; If the first type tree table and the second type tree table exist the same types, a type of the bottom type of the type tree structure is named the name of the folder. The name method and the system of the desktop folder have the advantages that users can search conveniently because the folder accurately reflects the containing application program thereof by acquiring the first type and the second type of the source program and the target program respectively and naming the folder according to the dynamic state of the first type and the second type, so that the usage of the name method and system of a desktop folder is convenient.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

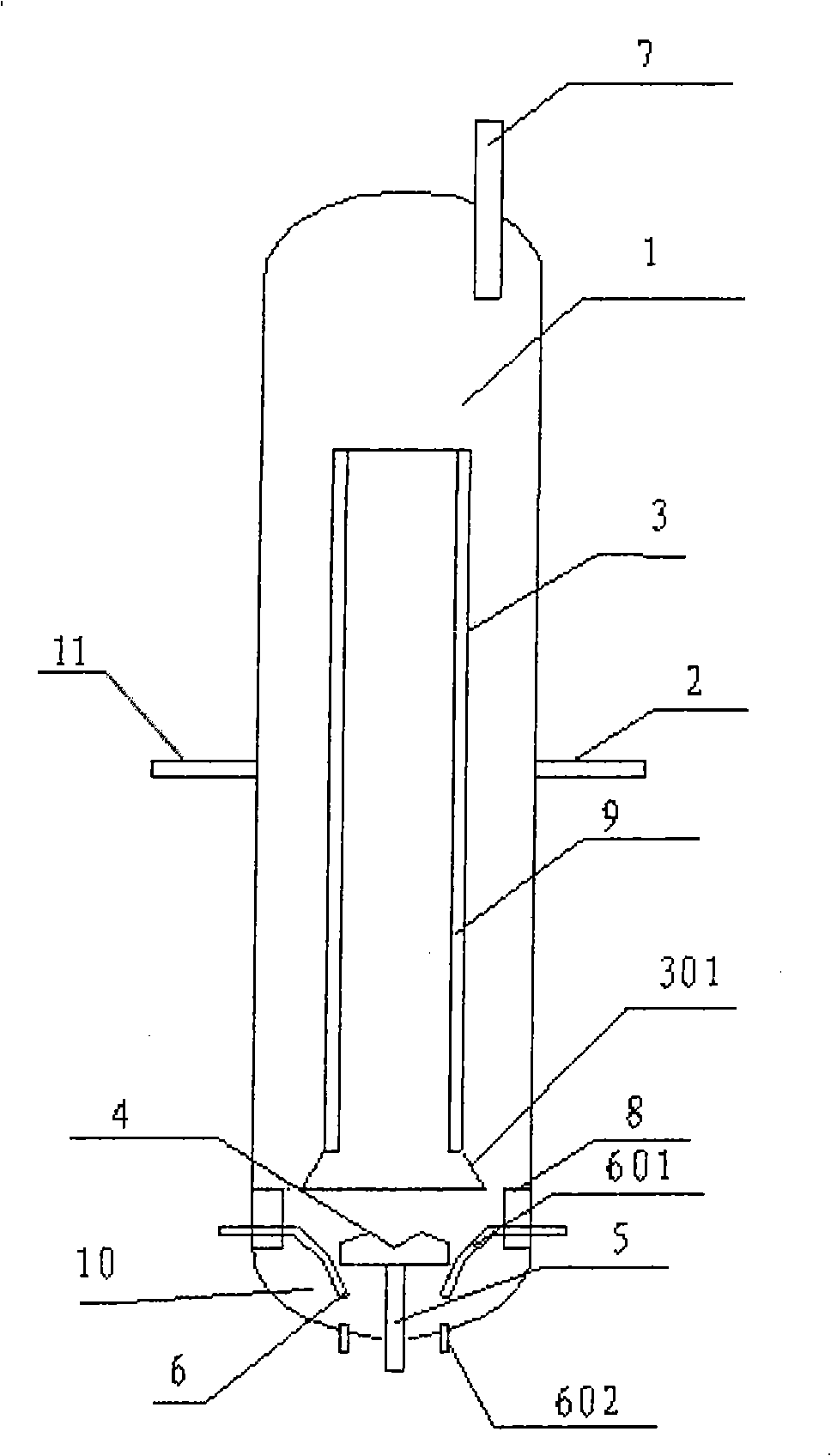

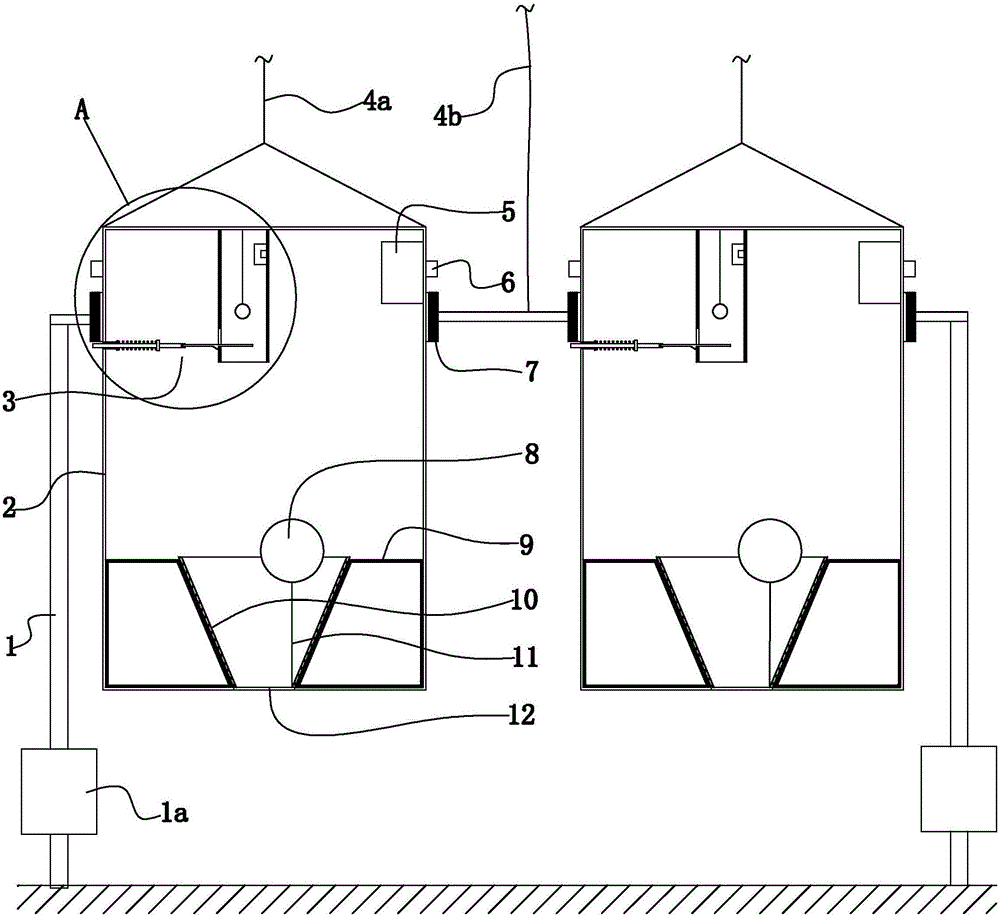

Stirring/flow-guiding multi-phase reactor

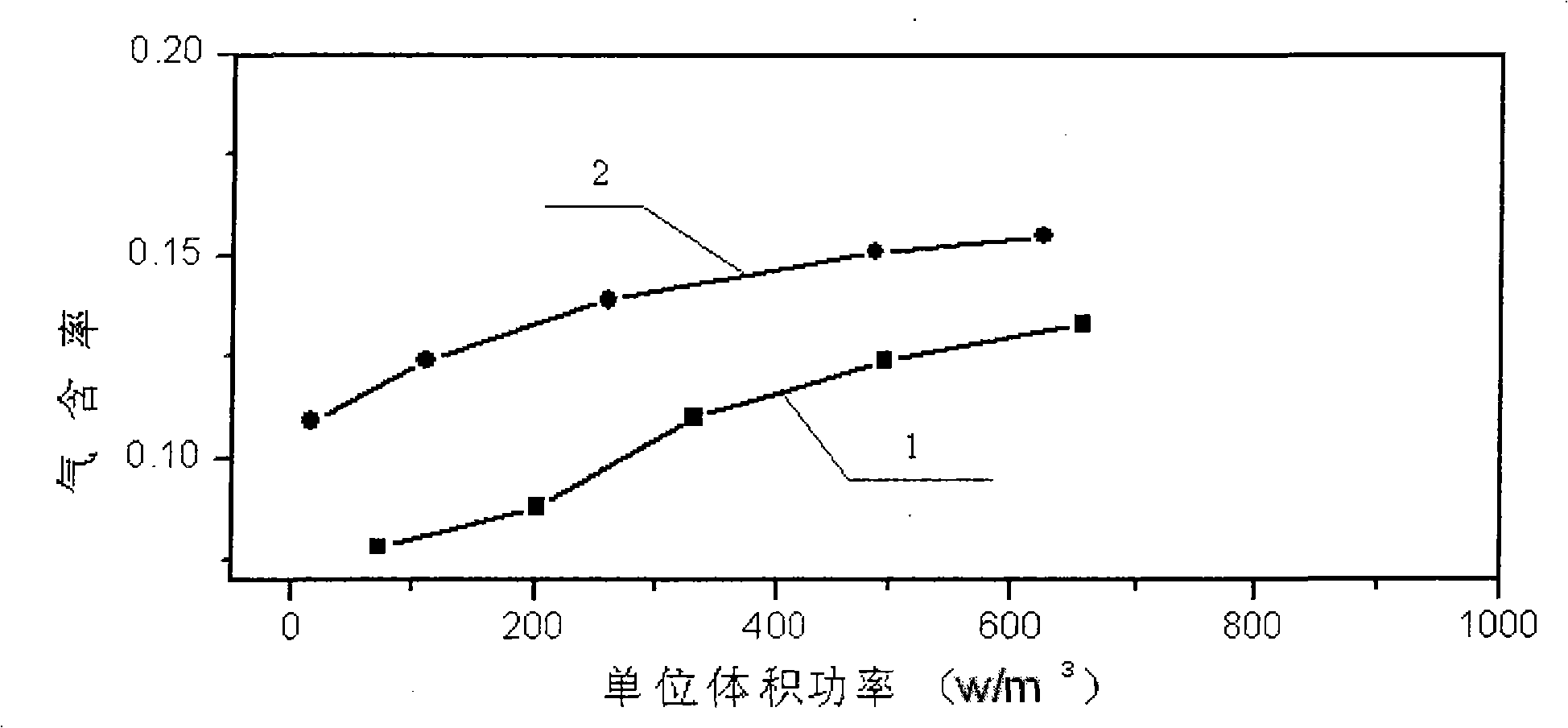

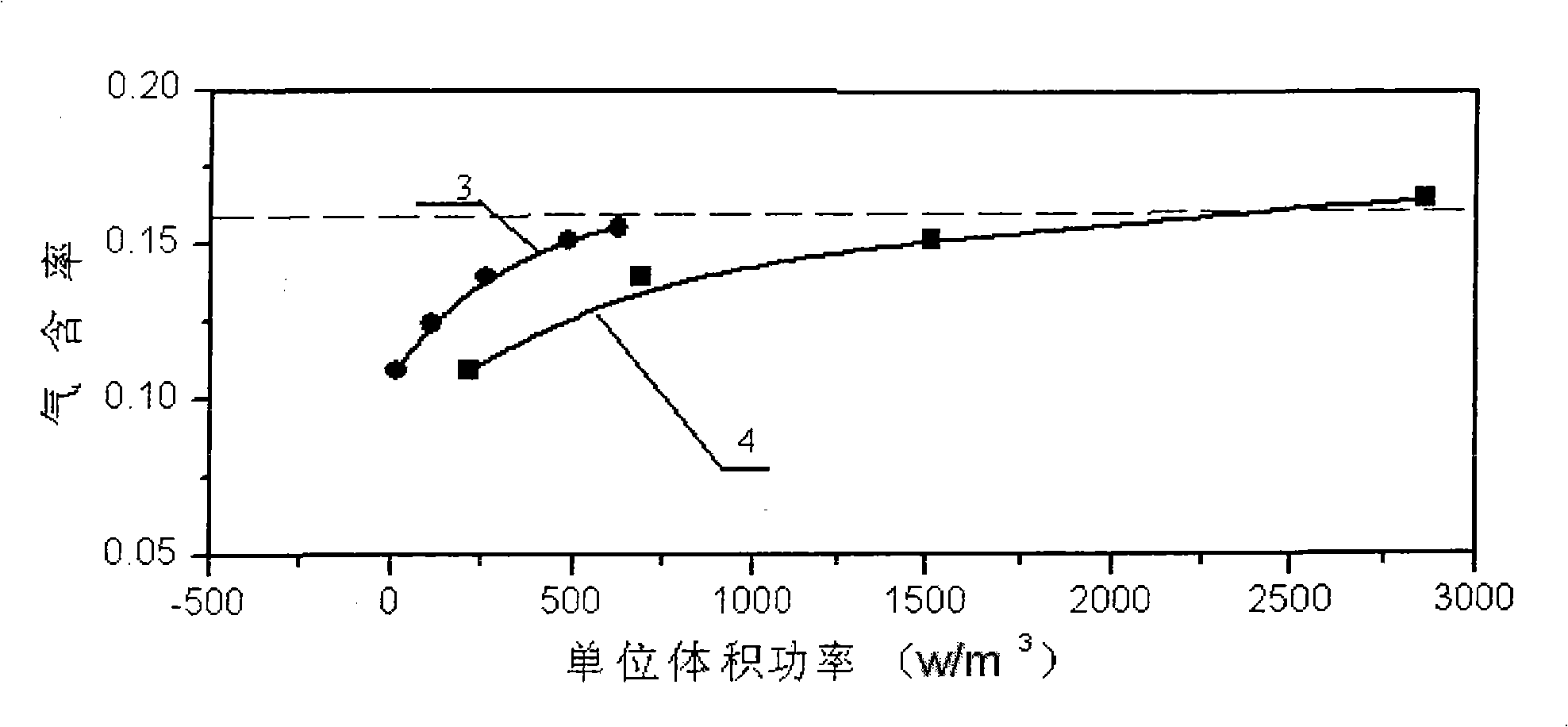

InactiveCN101293195ARaise the stirring shaftEasy to operateRotary stirring mixersChemical/physical/physico-chemical stationary reactorsBiochemical engineeringBlend time

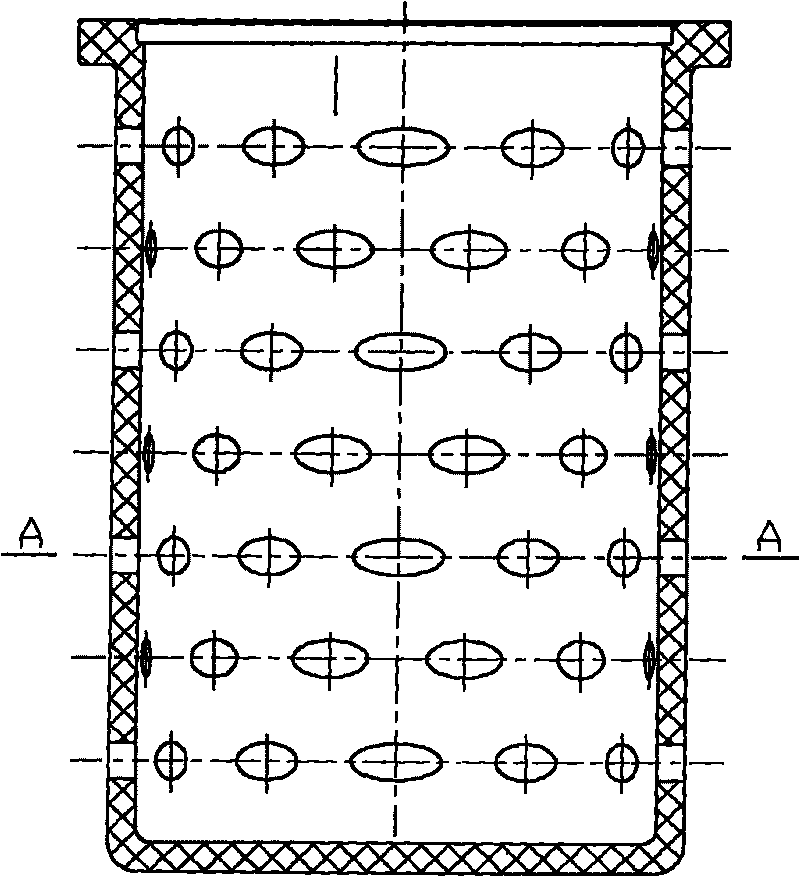

The present invention provides a stirring / guide multi-phase reactor, comprising a cylindrical sealed shell, a guide cylinder, a stirring device, air inlet device and an air outlet device; wherein, the cylindrical sealed shell is provided with a material inlet and outlet device; the lower part inside the shell is provided with the guide cylinder with an external diameter smaller than the internal diameter of the shell, a clearance is left between the guide cylinder and the shell bottom; the stirring device is arranged in the clearance between the guide cylinder and the shell bottom and comprises a stirring shaft and a blade fixed on the stirring shaft; the stirring shaft passes through the shell bottom and extends out of the shell; the air inlet device is arranged on the shell bottom and / or a lateral wall and the air outlet of the air inlet device is arranged below the blade; the air outlet device is arranged on the shell top. The stirring / guide multi-phase reactor provided by the present invention, which adopts the combination of the bottom-type stirring device and the guide cylinder, only needs comparatively low energy consumption to reach and even surpass the air rate the multi-layer or single-layer stirring reactor requires a plurality of times of energy consumption. Due to short mixing period and high effective energy utilization, the reactor is suitable for various industrial processes.

Owner:SINOPEC OILFIELD SERVICE CORPORATION +1

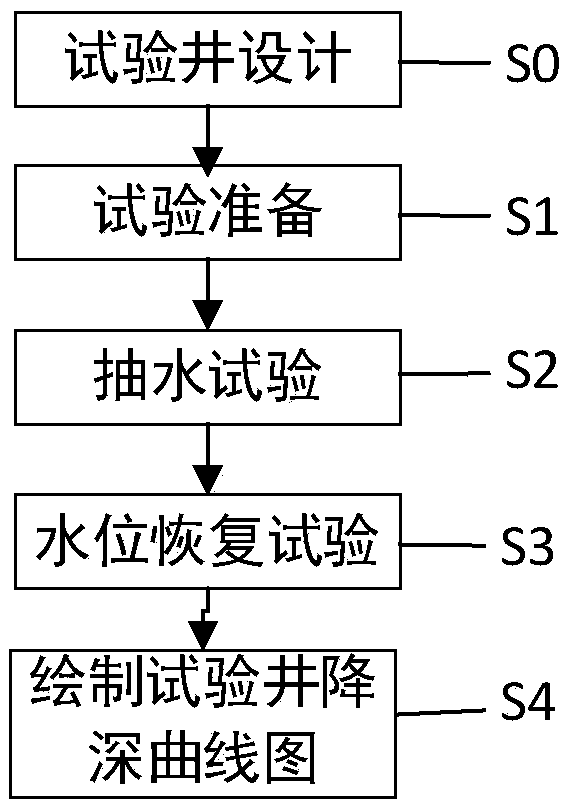

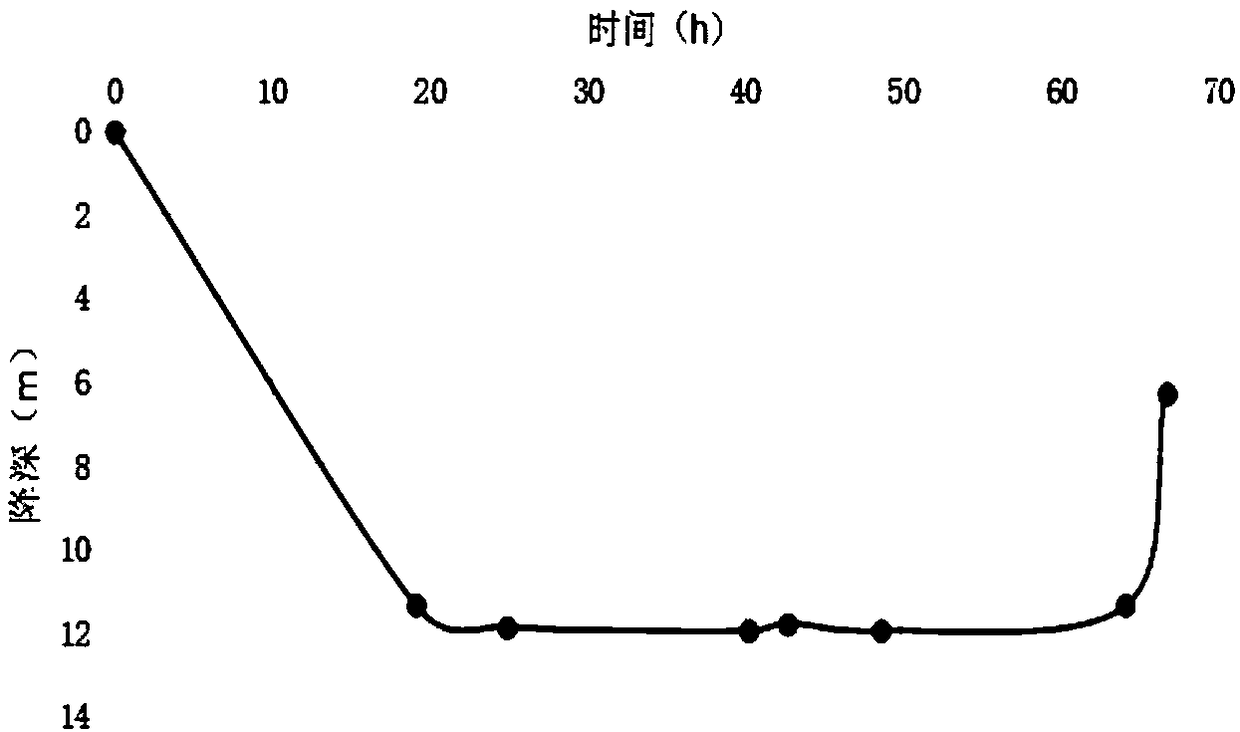

Water pumping communicating test method for drop-bottom-type water-stopping curtain

ActiveCN108867716AAccurate Hydrogeological ParametersPredicting the effects of subsidenceFoundation testingEngineeringWater level

The invention provides a water pumping communicating test method for a drop-bottom-type water-stopping curtain. The water pumping communicating test method is realized by the drop-bottom-type water-stopping curtain at the boundary of a foundation pit, the foundation pit and a plurality of test well sets, wherein each test well set is composed of a water pumping well in the foundation pit, and a plurality of observation wells arranged inside and outside the foundation pit correspondingly. According to the test method, an on-site water pumping communicating test is conducted at the earlier stage, the variation law of the water levels inside and outside the pit is monitored, and test data are collected; at the later stage of the test, by analyzing the variation law of the water levels of thetest wells inside and outside the foundation pit, the seepage isolating effect of the drop-bottom-type water-stopping curtain can be effectively evaluated, the influence on peripheral ground settlement after foundation pit dewatering is predicted, the strong basis is provided for later-stage dewatering optimal design, and the safety guarantee is provided for excavation construction of the foundation pit.

Owner:武汉丰达地质工程有限公司

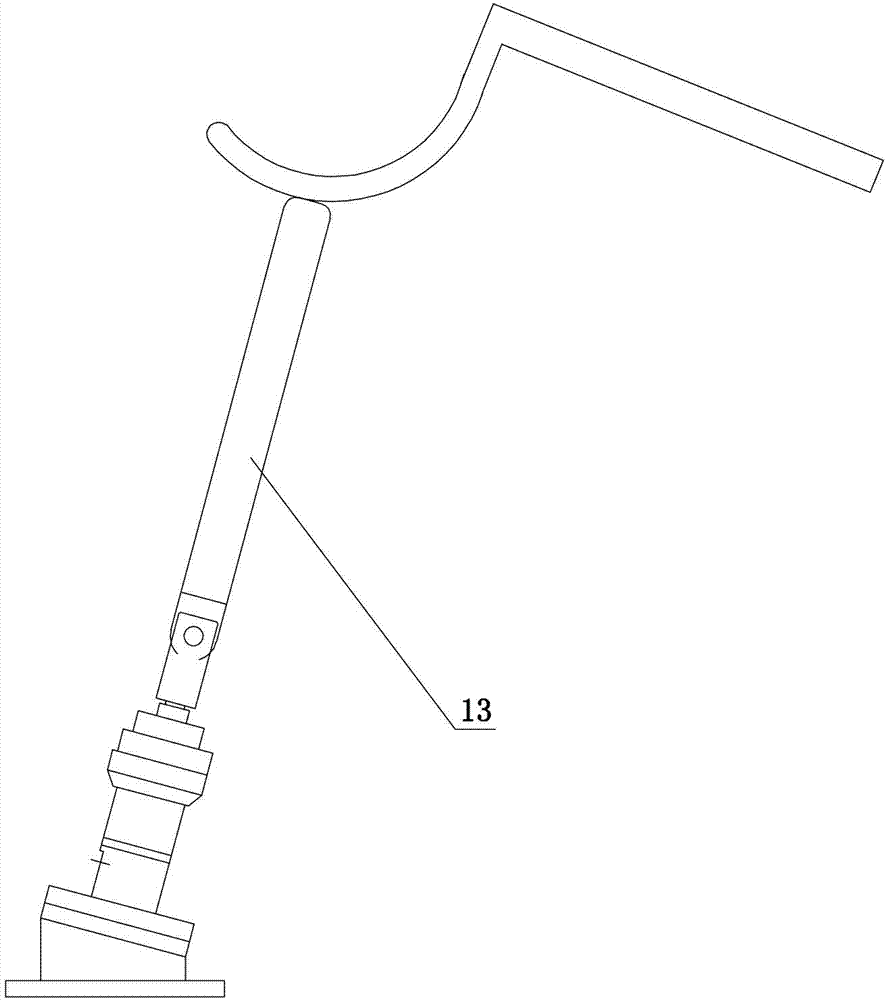

Roller-bottom type normalizing furnace bottom-roller changing method

InactiveCN101575665AReduce replacement timeEasy to operateFurnace typesHeat treatment furnacesMaterial resourcesEngineering

The invention discloses a roller-bottom type normalizing furnace bottom-roller changing method, which adopts a method of coaxially arranging new and old bottom rollers of a furnace, maintaining balance to hoist and rotating by 180 degrees for transposition; the method is simple and convenient to be operate, directly rotates the new bottom roller of the furnace to the position of the bottom roller of the furnace needed to be changed, and does not need to dismount the body of the furnace; therefore, the roller-bottom type normalizing furnace bottom-roller changing method can implement changing under the situation of maintaining the temperature inside the furnace and does not need to raise the temperature again, thus being capable of saving the product cost and improving the production efficiency. As the complex hoisting out and hoisting in processes are not needed, the changing time for the bottom roller of the furnace can be greatly shortened, which only needs about 6 hours, thereby being capable of ensuring the normal running of production to the largest extent, saving the manpower and material resources for changing the bottom roller of the furnace and improving the working efficiency for changing the roller.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

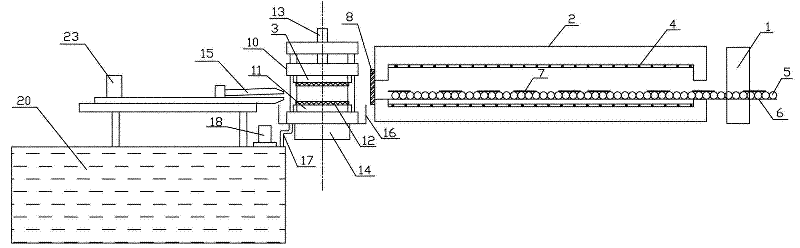

Continuous pressurizing oil-injection quenching device

InactiveCN102242245AIncrease productivityHigh degree of automationQuenching devicesAutomatic controlControl system

The invention provides a continuous pressurizing oil-injection quenching device, belonging to the field of thermal treatment devices. The continuous pressurizing oil-injection quenching device is mainly used for pressurizing quenching treatment of a saw web substrate. The continuous pressurizing oil-injection quenching device mainly comprises a feeding device, a roller bottom type continuous heating furnace, a saw web taking mechanical arm, an oil-injection quenching press, a discharging mechanical arm, a material discharging transference net belt, an oil groove and the like, wherein the heating furnace is used for heating and insulating the saw web body so as to meet the quenching requirement; and the saw web taking mechanical arm feeds the saw web substrate which reaches the quenching requirement to the oil-injection quenching press for pressing and oil-injection quenching, wherein a quenching medium is delivered to the quenching press and then circularly flows back to the oil groove. The device provided by the invention has the advantages of high production efficiency, even product hardness, less deformation amount, high automation control degree, low energy consumption, good work environment and the like, is beneficial to work piece quality control and is simple to operate; the product after thermal treatment has even hardness and less deformation amount, can be matched with a control system, and a full-automatic control process of thermal treatment processes such as feeding, heating, planishing, quenching, discharging, transferring work pieces and the like can be achieved.

Owner:HEIXUANFENG SAW IND

Sinking-to-bottom type shrimp catcher

The invention discloses a sinking-to-bottom type shrimp catcher, and aims at providing the sinking-to-bottom type shrimp catcher which is small in yield, convenient to operate and capable of automatically floating up and automatically conducting sampling after catching shrimps. The sinking-to-bottom type shrimp catcher comprises a supporting frame and a plurality of automatic floating-up catcher bodies arranged on the supporting frame. Each automatic floating-up catcher body comprises a vertical limiting sleeve arranged on the supporting frame, a mesh-shaped shrimp catching cylinder inserted in the vertical limiting sleeve, a floating ball and an automatic releasing device arranged on the mesh-shaped shrimp catching cylinder, wherein an upper limiting block is arranged at the position, above the vertical limiting sleeve, of the upper portion of the outer side face of the mesh-shaped shrimp catching cylinder, an inverted conical limiting sleeve with the section area gradually increased from bottom to top is arranged in the middle of the inner bottom face of the mesh-shaped shrimp catching cylinder, the upper end and the lower end of the inverted conical limiting sleeve are provided openings, a shrimp inlet corresponding to the lower end opening of the inverted conical limiting sleeve is formed in the middle of the bottom face of the mesh-shaped shrimp catching cylinder, and a buoyancy device capable of making the mesh-shaped shrimp catching cylinder float up is arranged in the mesh-shaped shrimp catching cylinder.

Owner:南陵县工业投资有限公司

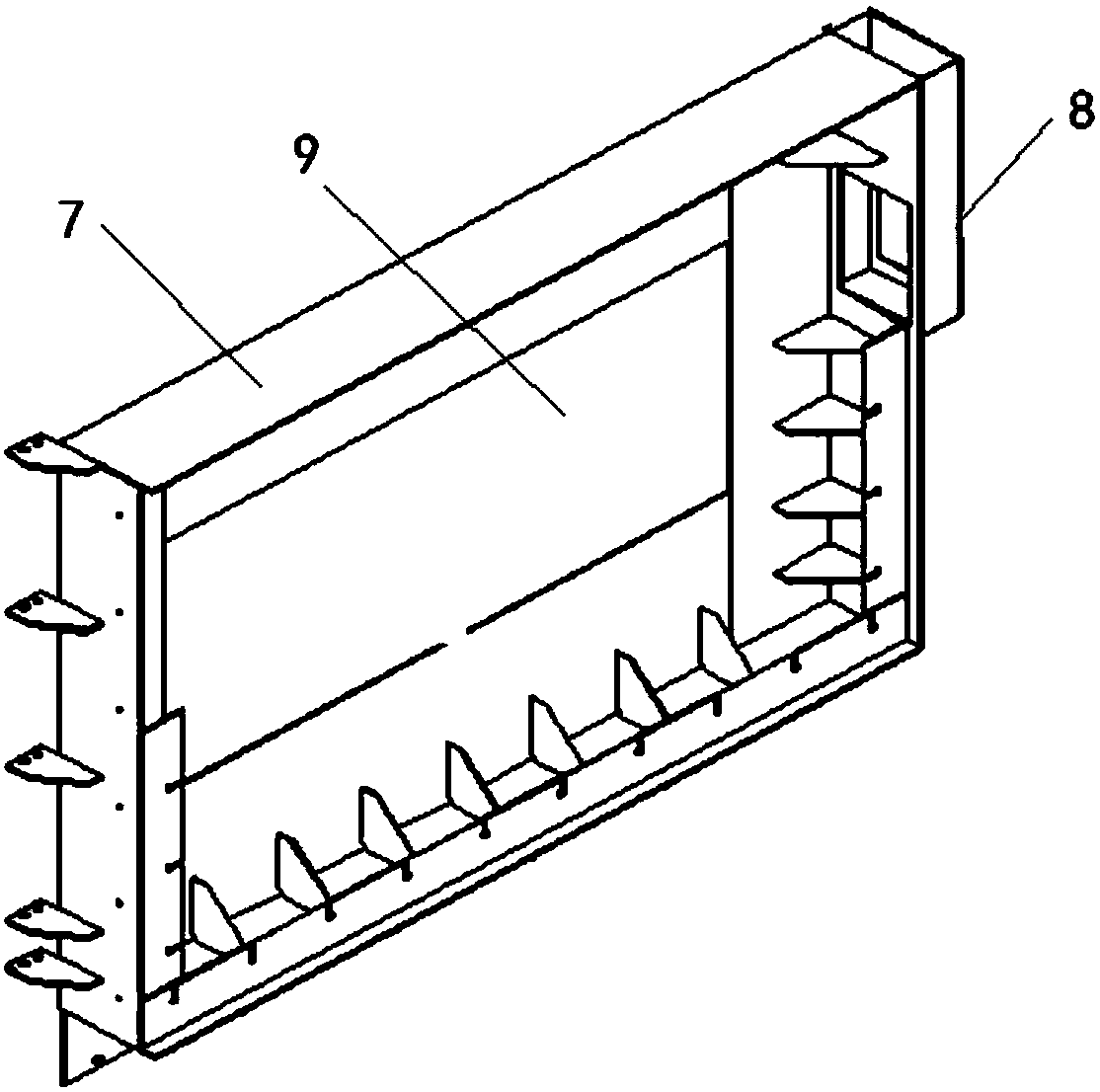

Copper pipe roller bottom type continuous bright annealing furnace

The invention relates to a continuously bright annealing furnace with copper pipe roller hearth type which includes an inlet and an outlet air locking chambers, a feeding and an unloading roller, a heating furnace and a cooling chamber; a fan, a cold pressing groove, a cold pressing pipe and a heat exchanger are arranged out of the cooling chamber at the severe cold section, while a plurality of gas pipes opposite spraying up and down are arranged in the cooling chamber; the inlet of the heat exchanger is connected to a cavity chamber of the cooling chamber of the severe cold section, while the outlet of the heat exchanger is connected with the inlet of the cold pressing groove; the fan is mounted on the cold pressing groove; the outlet of the cold pressing groove is connected with the cold pressing pipe; the outlet of the cold pressing pipe is connected with a cold pressing guide groove; the cold pressing guide groove is connected with the gas pipes opposite spraying up and down; a plurality of upper spray nozzles are spreaded on the upper horizontal section of each gas pipe, and a plurality of lower spray nozzles are spreaded on the lower horizontal section of each gas pipe; the nozzle mouths of the upper and the nozzle mouths of the lower spray are arranged oppositely. The annealing furnace of the invention has fast cooling speed and high evenness, is applicable in the continuous annealing technology treatment of a large number of copper pipes with different length, diameter and wall thickness.

Owner:苏州工业园区华福科技有限公司

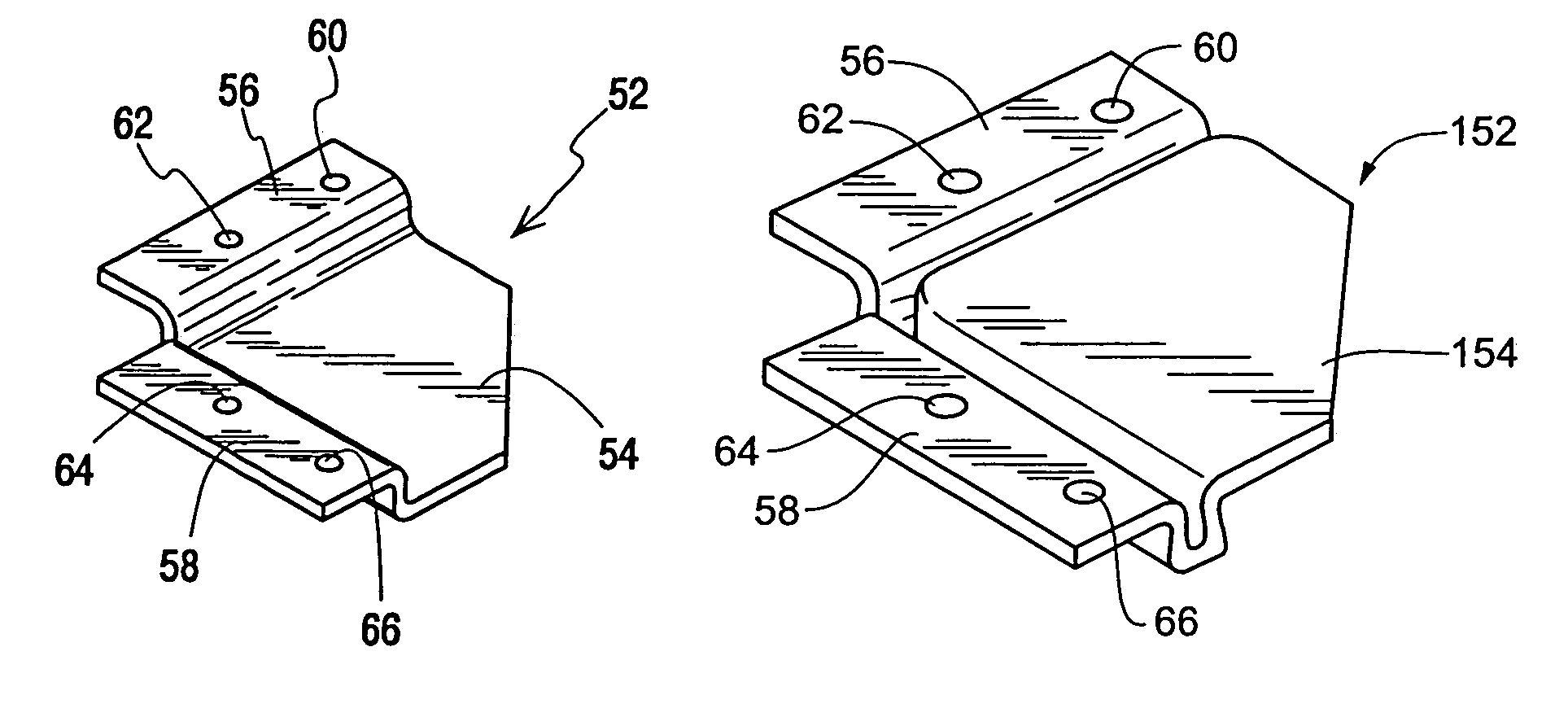

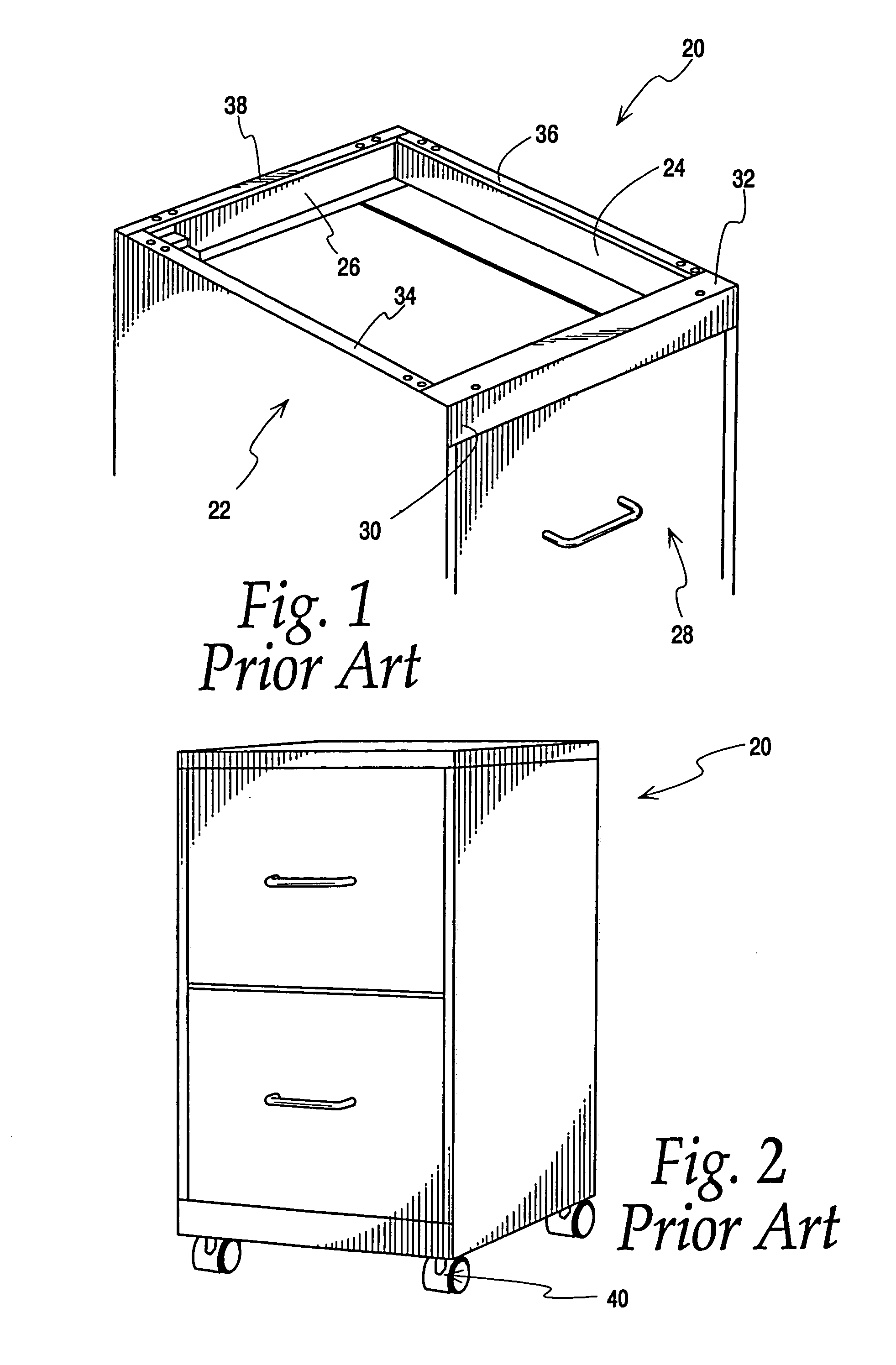

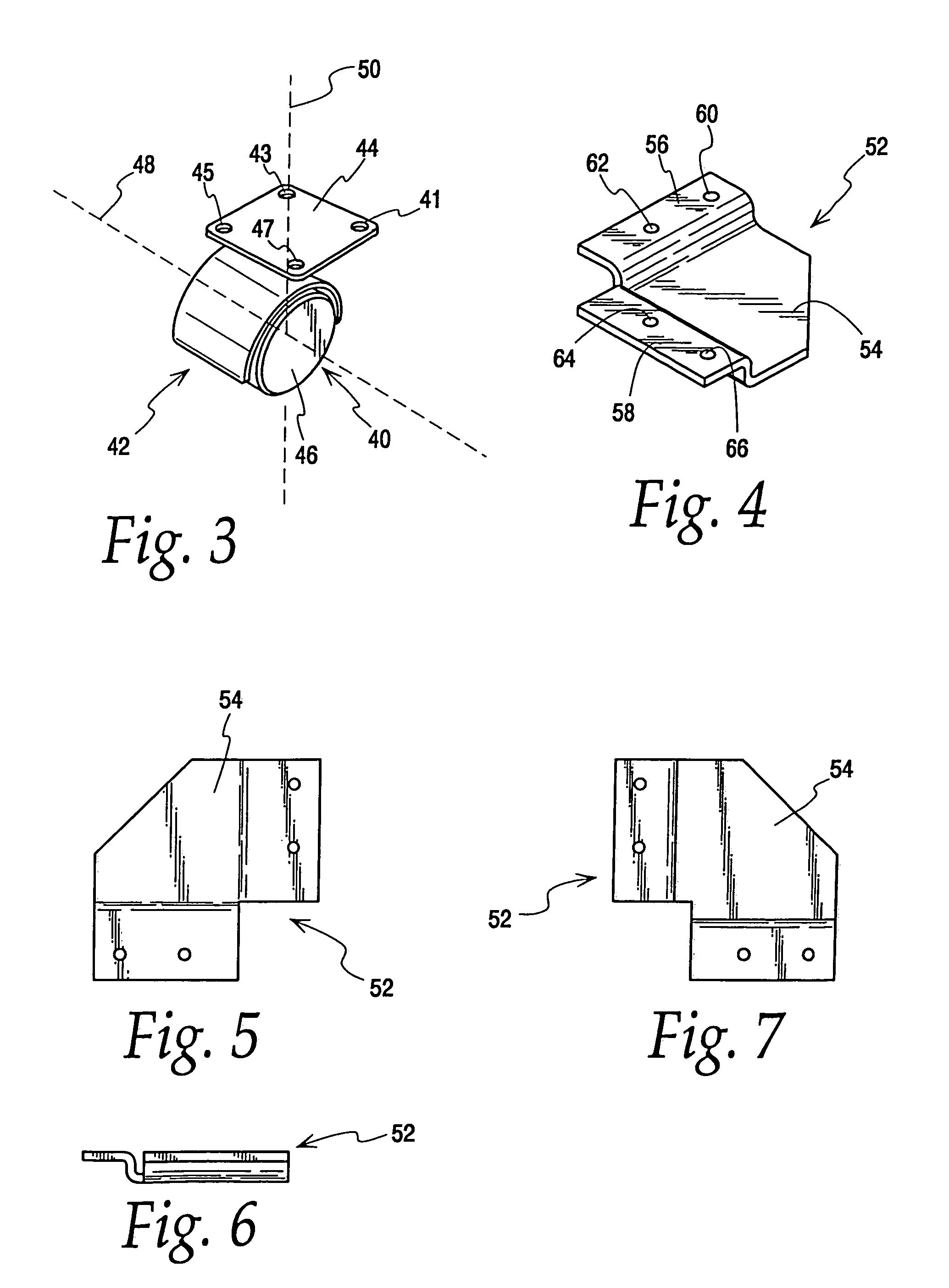

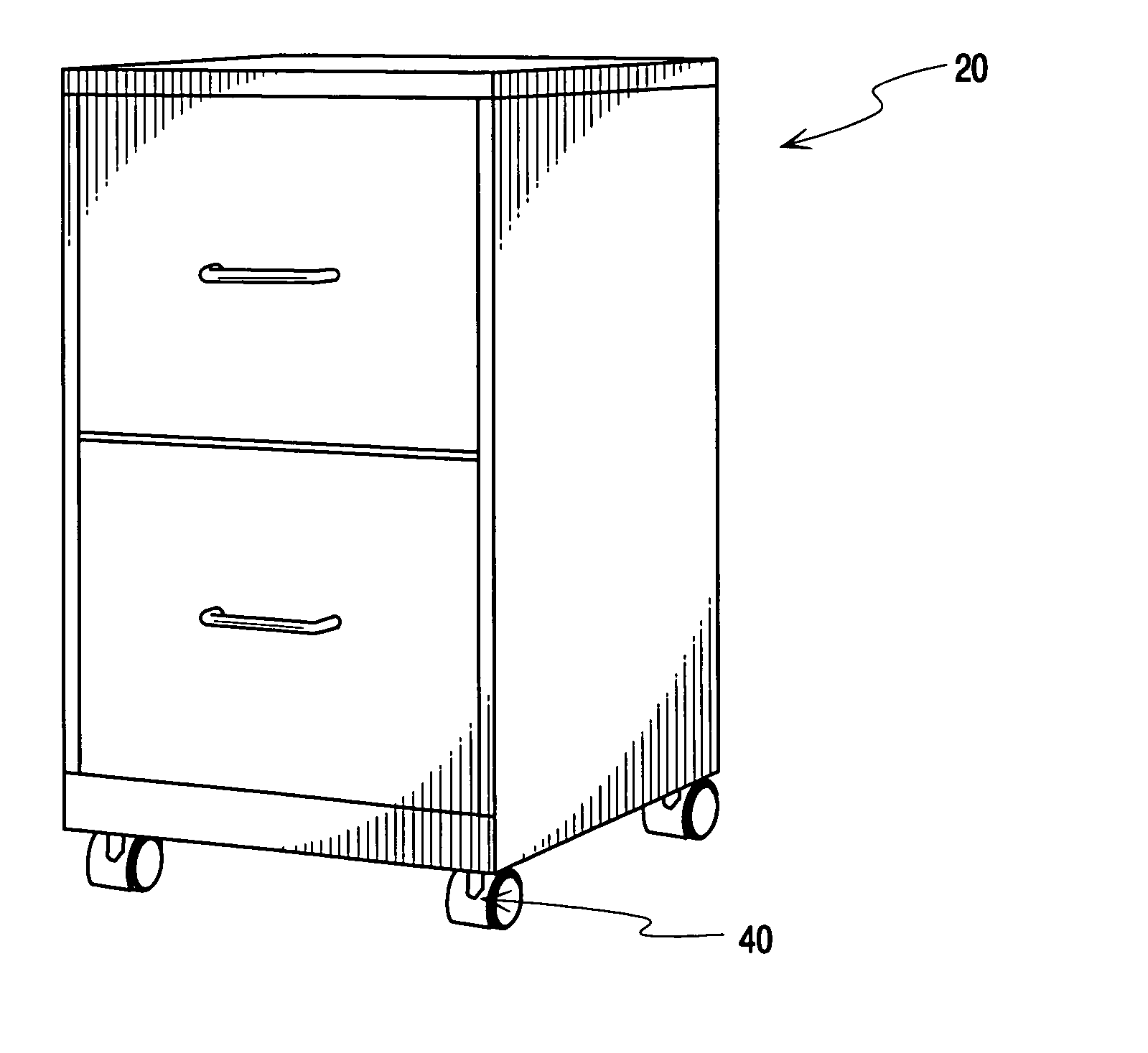

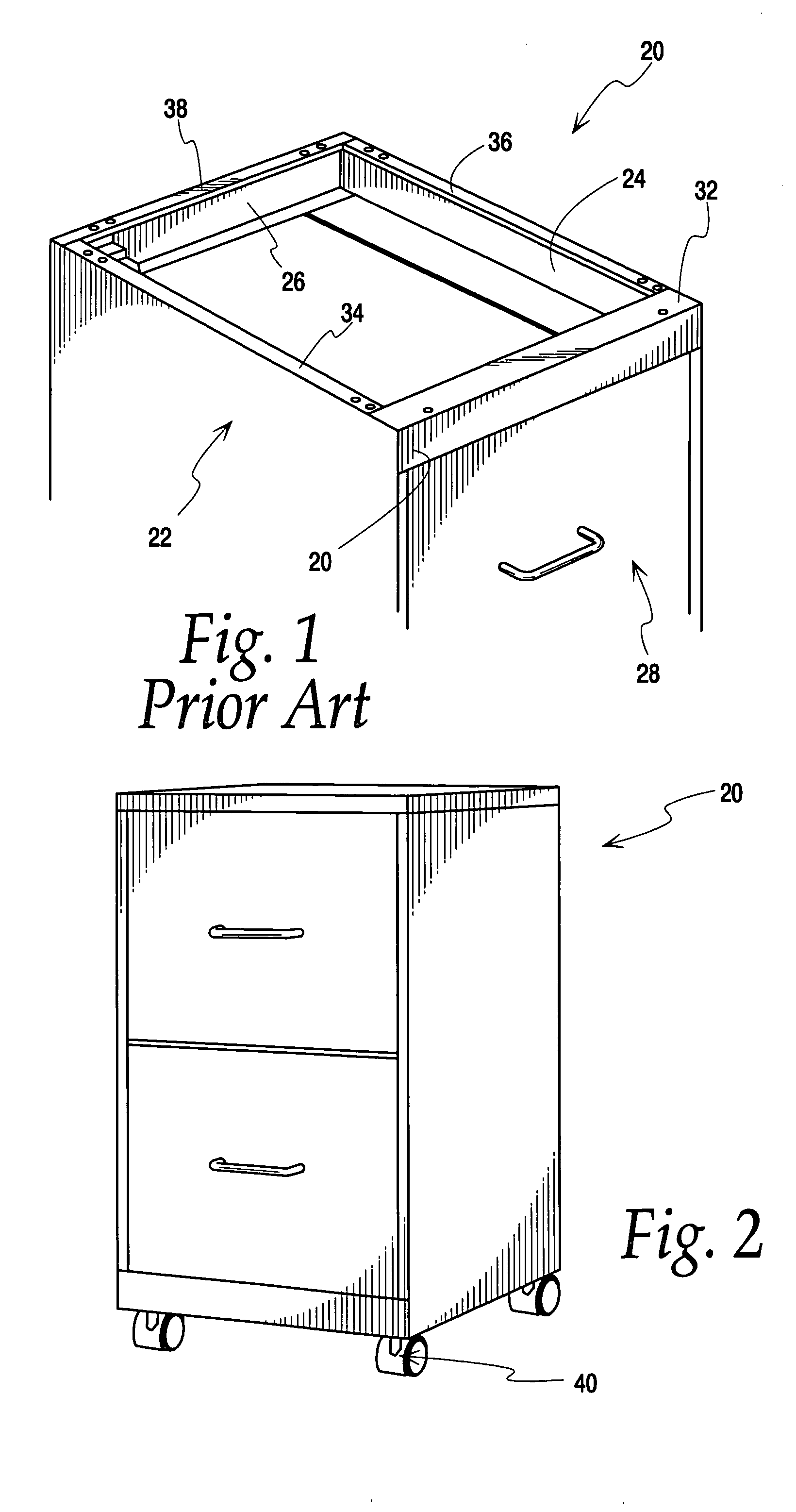

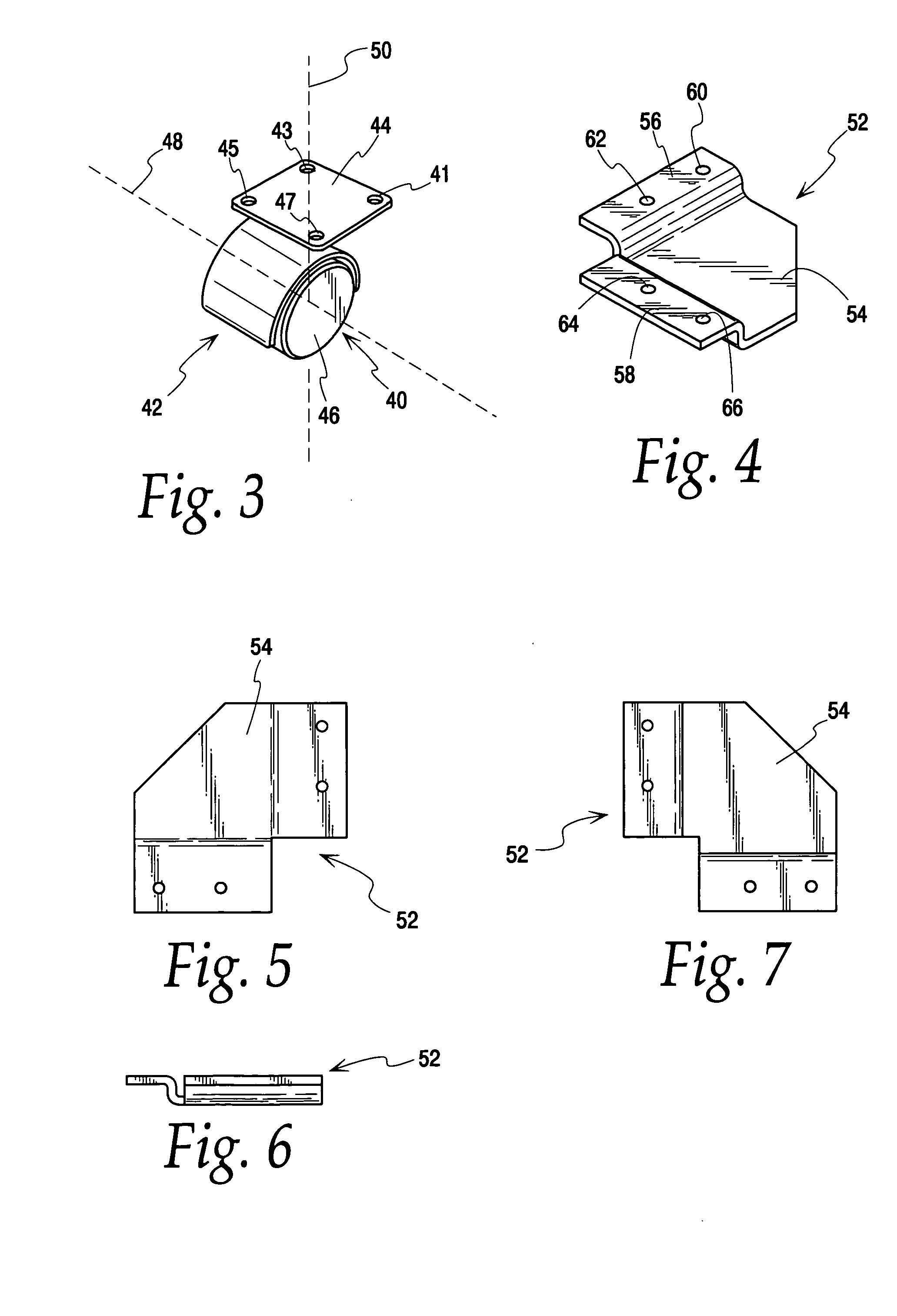

Bracket for open bottom type cabinet

A bracket is disclosed for use in open bottom type cabinets, such as file cabinets, which enables caster assemblies and the like to be secured thereto. The bracket is configured to be secured in the corners of an open bottom cabinet. In accordance with the present invention, the bracket provides stiffening of the cabinet as well as a secure surface for securing caster assemblies thereto. The brackets are simply mounted to the corners of the cabinet utilizing, for example, a pair of fasteners.

Owner:HIRSH INDS

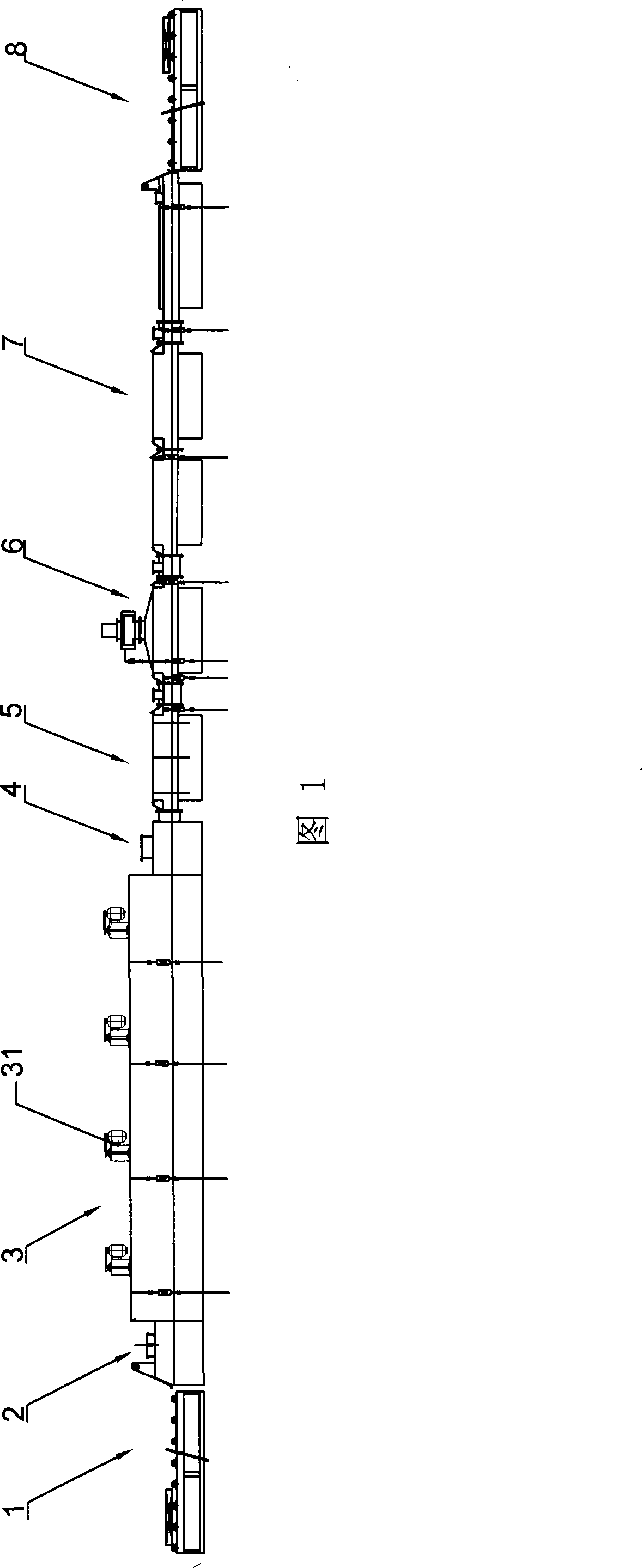

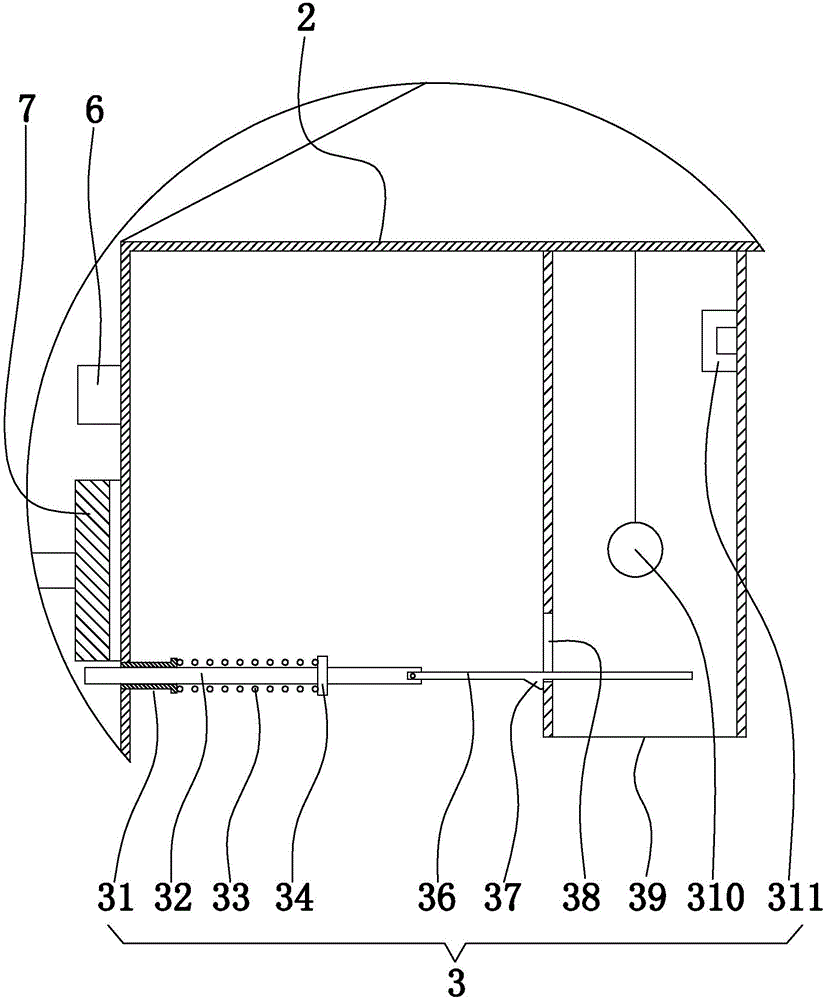

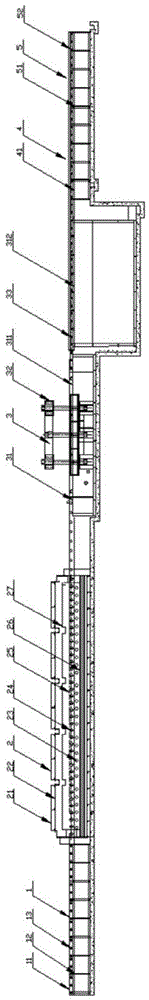

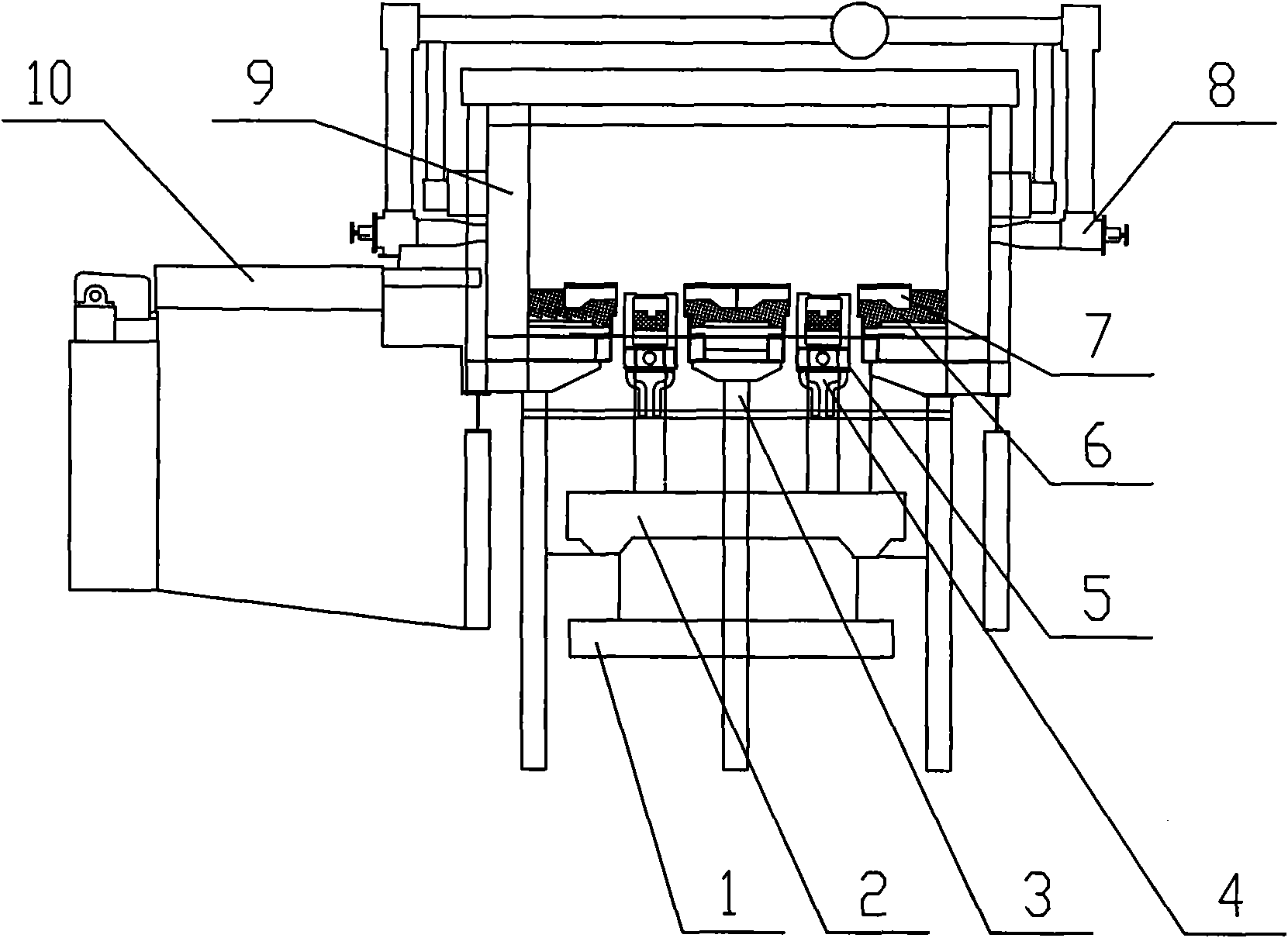

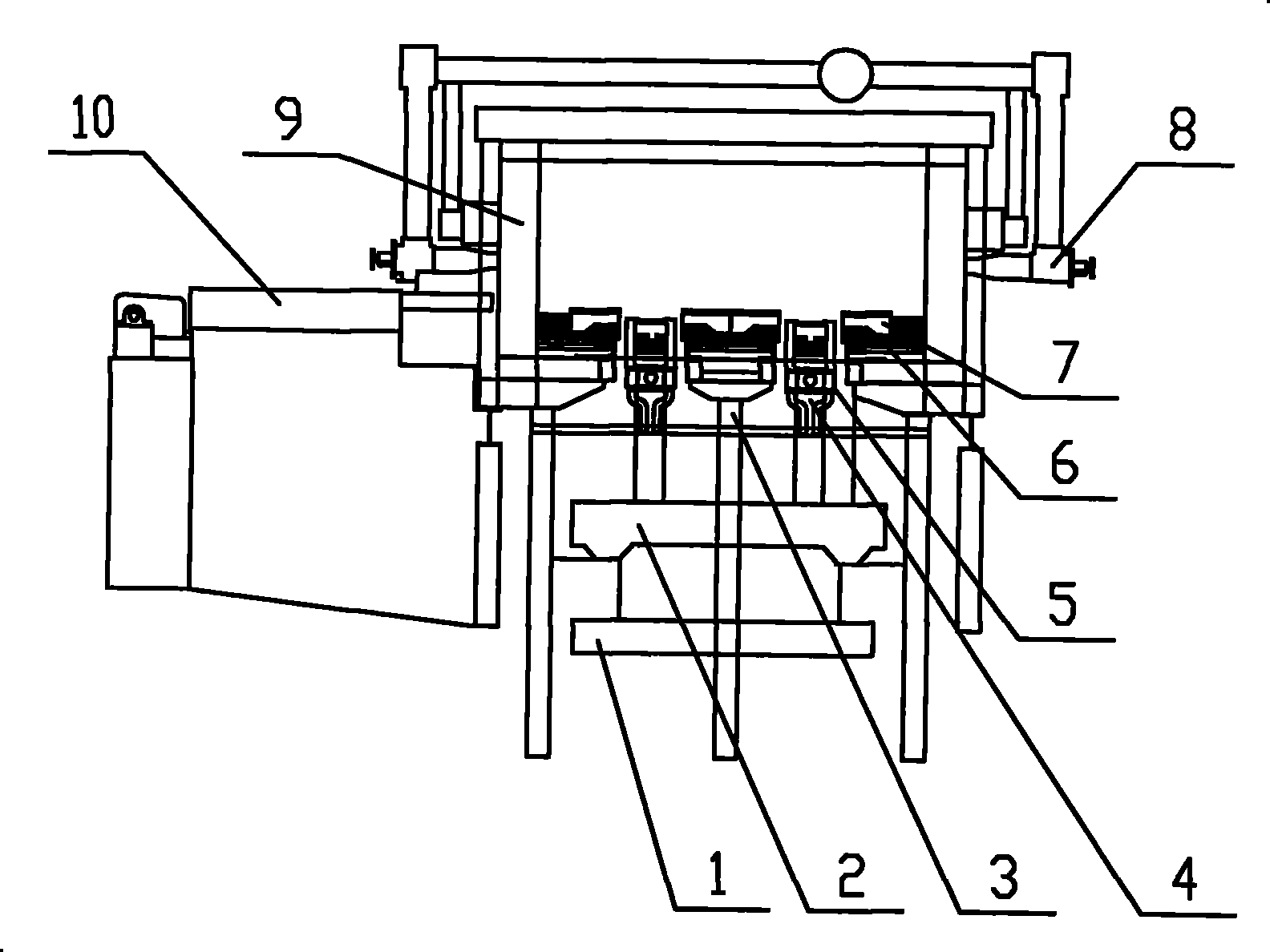

Roller bottom type saw web quenching line

The invention discloses a roller bottom type saw web quenching line. The quenching line comprises a feeding table, a heating furnace, an automatic quenching flattening system, a discharged material cleaning tank and a discharging table which are connected in sequence. The heating furnace is mainly composed of a furnace shell, a furnace lining, a radiant tube electric heating element, transmission carrier rollers, a delivery mechanism, a protective atmosphere pipeline system and a homogenizing fan, wherein the transmission carrier rollers are arranged in the furnace shell and used for supporting and delivering workpieces, and the transmission carrier rollers are leveled horizontally to be located on the same horizontal plane. The automatic quenching flattening system is mainly composed of an oil groove, a press, a deoiling rubber roller device and an external auxiliary oil tank, wherein the oil groove comprises a main oil groove part and an auxiliary oil groove part, the main oil groove part and the auxiliary oil groove part are provided with two filter screens, and the press comprises an upper pressure plate and a lower pressure plate. The discharged material cleaning tank is a cuboid cleaning water tank formed by tight welding of sheet steel and sectional steel, and a sprinkling pipe is arranged on top of the cleaning water tank. According to the production line, interval continuous operation is adopted from feeding to discharging, equipment maintenance is convenient and safe, heating transmission and quenching flattening are conducted in different stages, and production efficiency is improved.

Owner:QUANZHOU HAIENDE ELECTROMECHANICAL TECH DEV

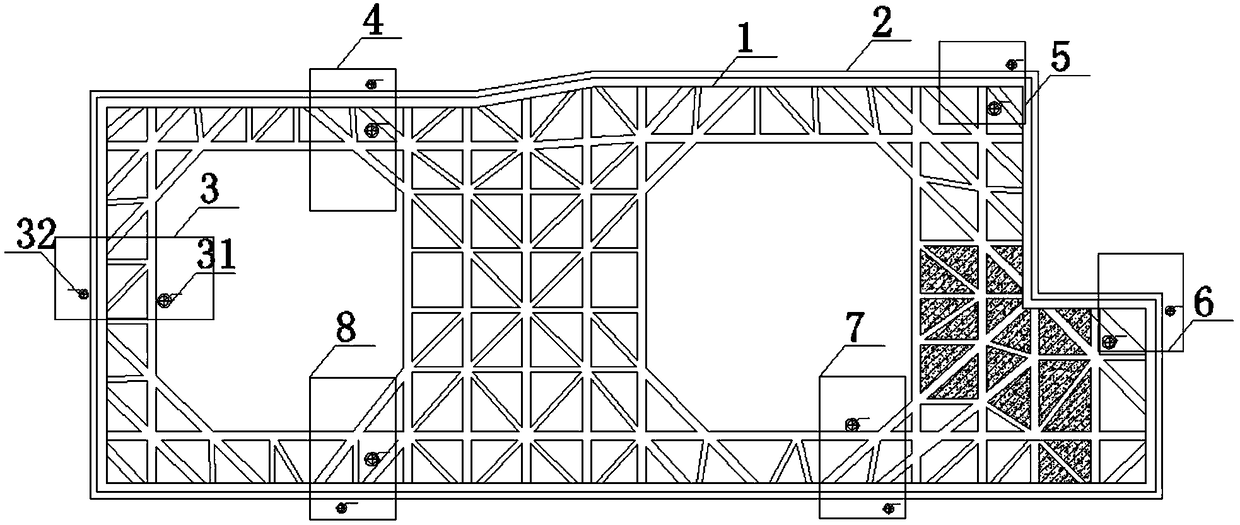

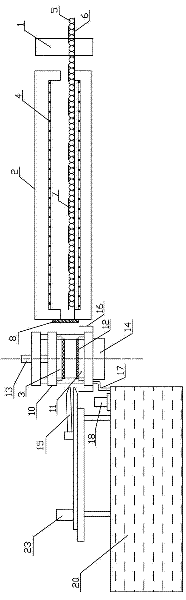

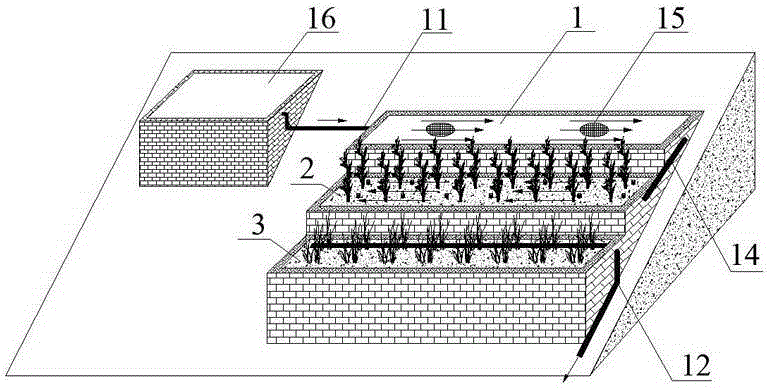

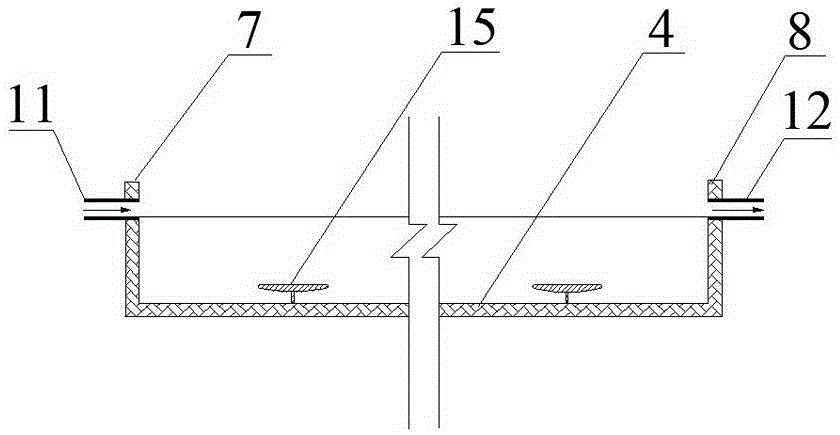

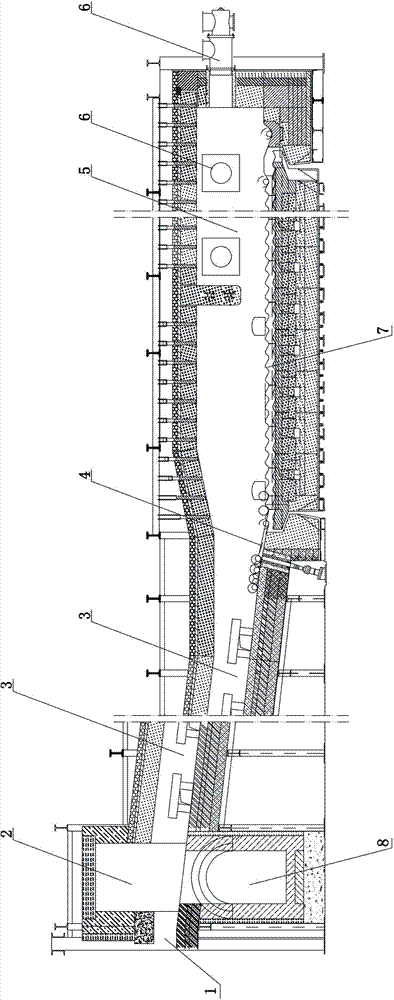

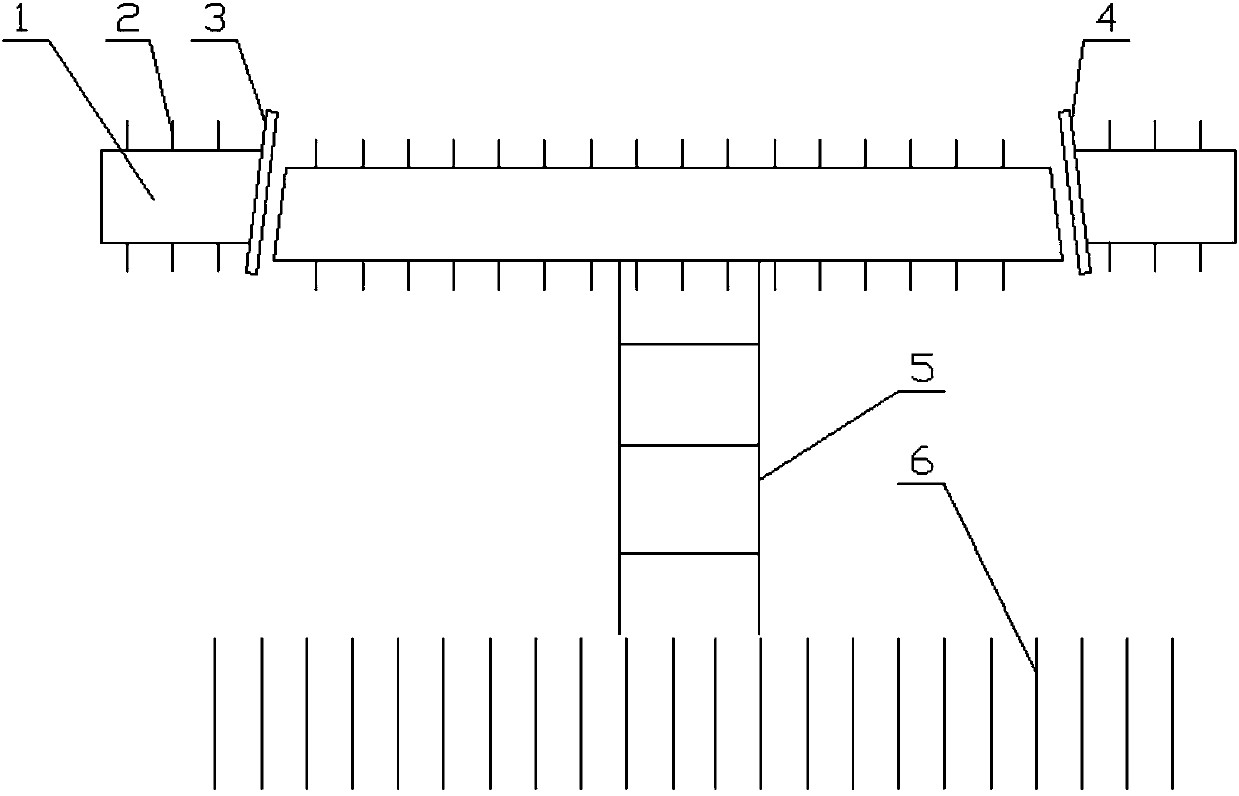

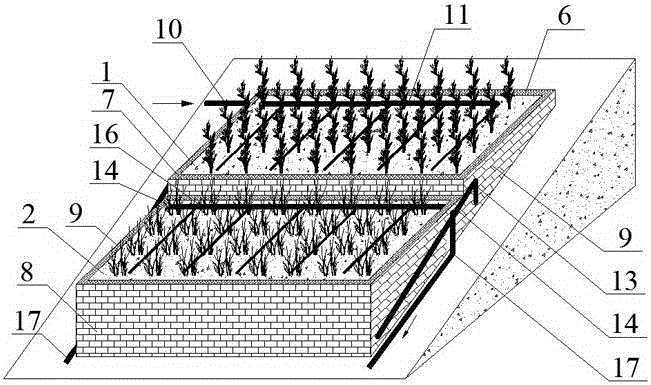

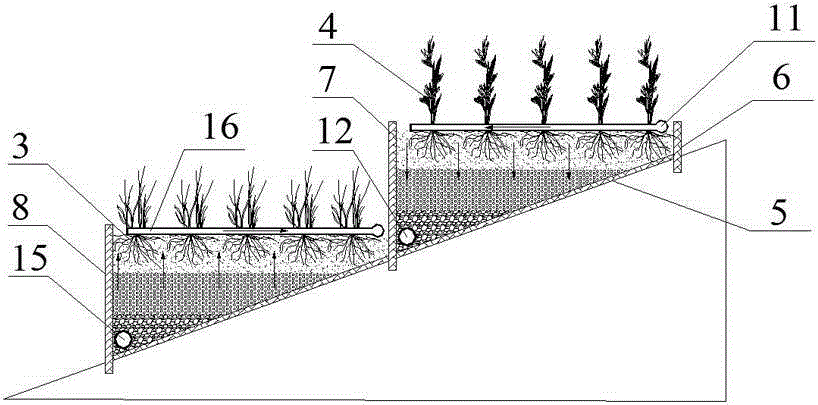

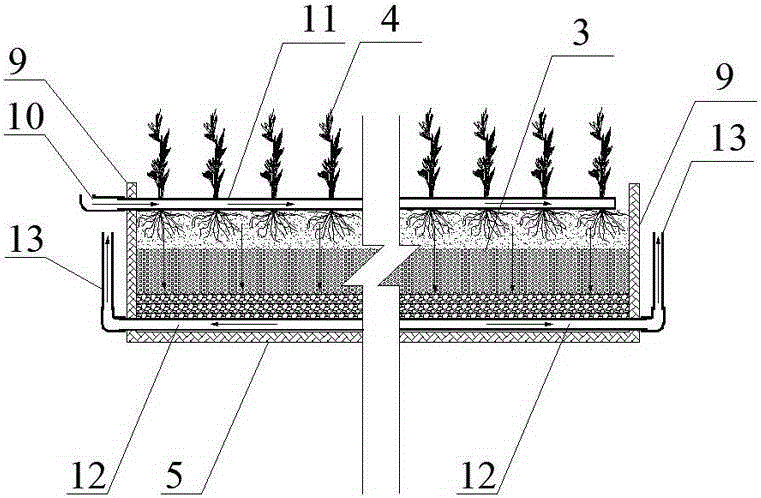

Sloping bottom type subsurface flow constructed wetland combined system

InactiveCN105217893ASimple structureEasy constructionMultistage water/sewage treatmentConstructed wetlandTherapeutic effect

The invention discloses a sloping bottom type subsurface flow constructed wetland combined system, and relates to a sloping bottom type subsurface flow constructed wetland combined system applicable to slope topography. The sloping bottom type subsurface flow constructed wetland combined system is mainly used to solve the problems that a conventional constructed wetland technology is difficult to be applied to the slope topography, or a purification space is idle, a treatment effect is bad, the construction cost is high, the cost-efficiency ratio is low and the like when the conventional constructed wetland technology is applied to the slope topography. The constructed wetland combined system is formed by connecting at least three-stage pool body units which are distributed in a stepped manner from top to bottom according to the slope gradient in series, the pool bottom of the pool body units is a slope surface, and the pool body units are sequentially an aeration pool unit, a horizontal flow constructed wetland unit and an up-flow constructed wetland unit from top to bottom. The sloping bottom type subsurface flow constructed wetland combined system brakes through the limitation to the application of constructed wetlands caused by the slope topography, is good in treatment effect, simple in structure, simple and convenient to construct and low in cost, expands the application range of the constructed wetlands, and can be widely applied to treatment of various types of sewage in slope regions such as mountain lands, hills and water body banks.

Owner:CAS WEE ECO ENG TECH

Sloping bottom step comprehensive heating furnace

ActiveCN102888507AReduce the number of peopleReduce labor intensityFurnace typesHeat treatment furnacesElectricityWorking environment

The invention relates to a heat treatment device of round steel, in particular a sloping bottom step comprehensive heating furnace, which comprises a preheating zone, a heating zone and a soaking zone, and is characterized in that the preheating zone adopts a sloping bottom type heating furnace structure, the heating zone and the soaking zone adopt a step heating furnace structure, the lower end of the sloping bottom type heating furnace are integrally docked with the front end of the step heating furnace, a blank alignment device and a material stop substep device are arranged on a combination place of hearths of the sloping bottom type heating furnace and the step heating furnace, the material stop substep device comprises two 7-shaped material stop connecting plates which are arranged at an interval in parallel, a left ejection oil cylinder and a right ejection oil cylinder are respectively close to the heads of the two material stop connecting plates, and arc-shaped material supporting plates are arranged on the heads of pistons of the ejection oil cylinders. According to the invention, the advantages of the sloping bottom type heating furnace and the step type heating furnace are combined, the performance of the heating furnace is improved, the working environment of a production workshop is improved, and consumption of labor, gas, water and electricity is reduced as much as possible.

Owner:湖北中冶窑炉有限公司

Stepping-bottom-type heating furnace

InactiveCN101806540AHigh section flexural modulusIncrease productivityCharge manipulationFurnace typesCombustion systemRefractory

The invention relates to a stepping-bottom-type heating furnace, in particular to the improvement of a fixed bottom and a movable bottom of the stepping-bottom-type heating furnace. The furnace bottom has high bearing capacity, easy maintenance of refractory and reliable water-cooling structure. The stepping-bottom-type heating furnace comprises a furnace body, a combustion system, the fixed bottom, the movable bottom, a translation frame, a lifting frame and a loading steel discharger, wherein the fixed bottom and the movable bottom are provided with precast blocks used for bearing and locating a heated workpiece. A bearing frame of the fixed bottom and the movable bottom respectively adopts a rectangular square tube as main component, and the rectangular square tube has higher cross section bending-resistant modulus, is seamless steel tube without a weld joint so as to be difficultly deformed, and has no leakage weak link when being filled with water; as the fixed bottom and the movable bottom are provided with the precast blocks, unshaped refractory is prefabricated into a special solid shape, the working efficiency is improved in the manufacturing, installing and using process, the construction period of the furnace is shortened, the service life of the furnace is prolonged, the single precast block can be rapidly replaced without roasting oven when being damaged, and the production efficiency of the furnace is improved.

Owner:YANGZHOU METALLURGICAL MACHINERY

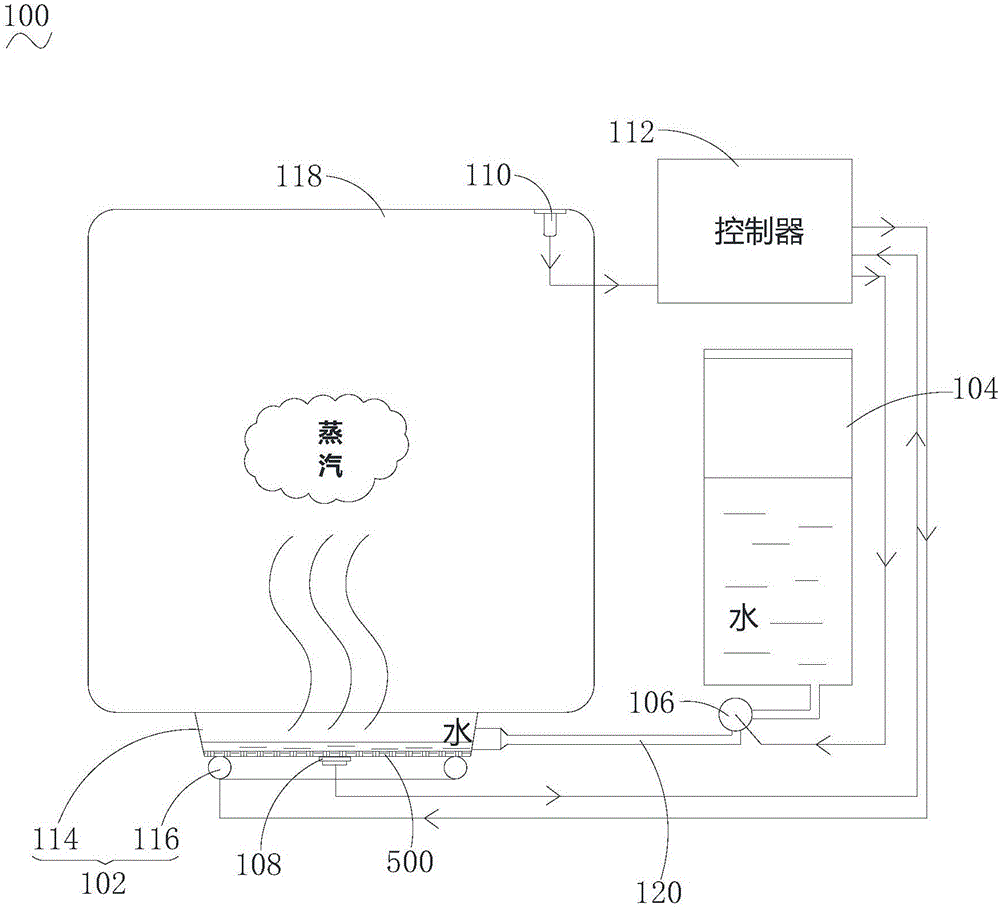

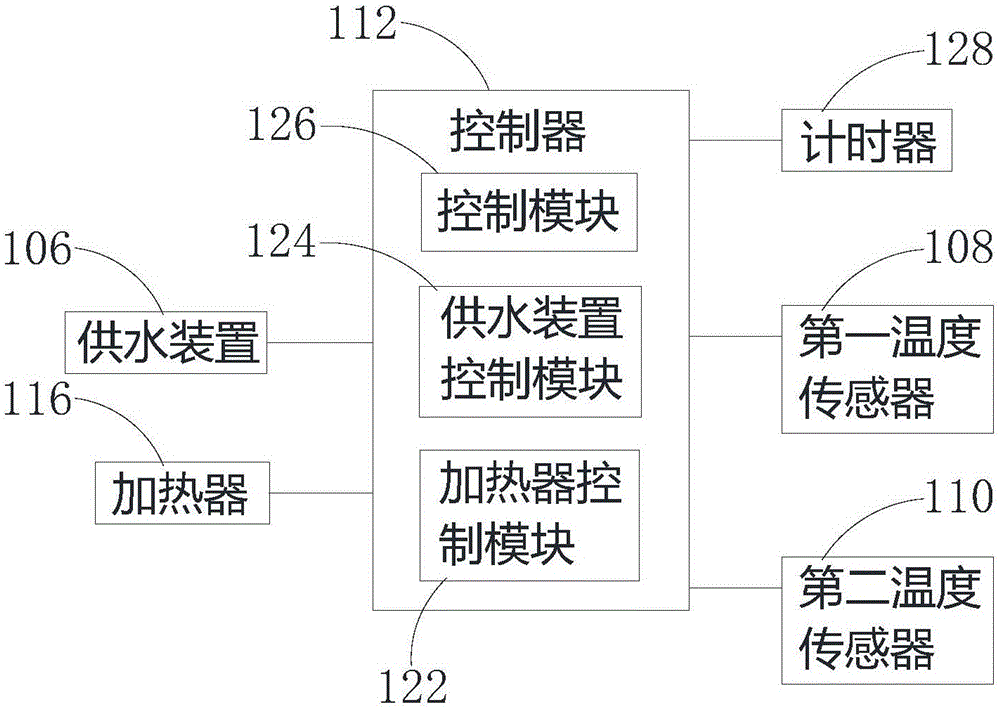

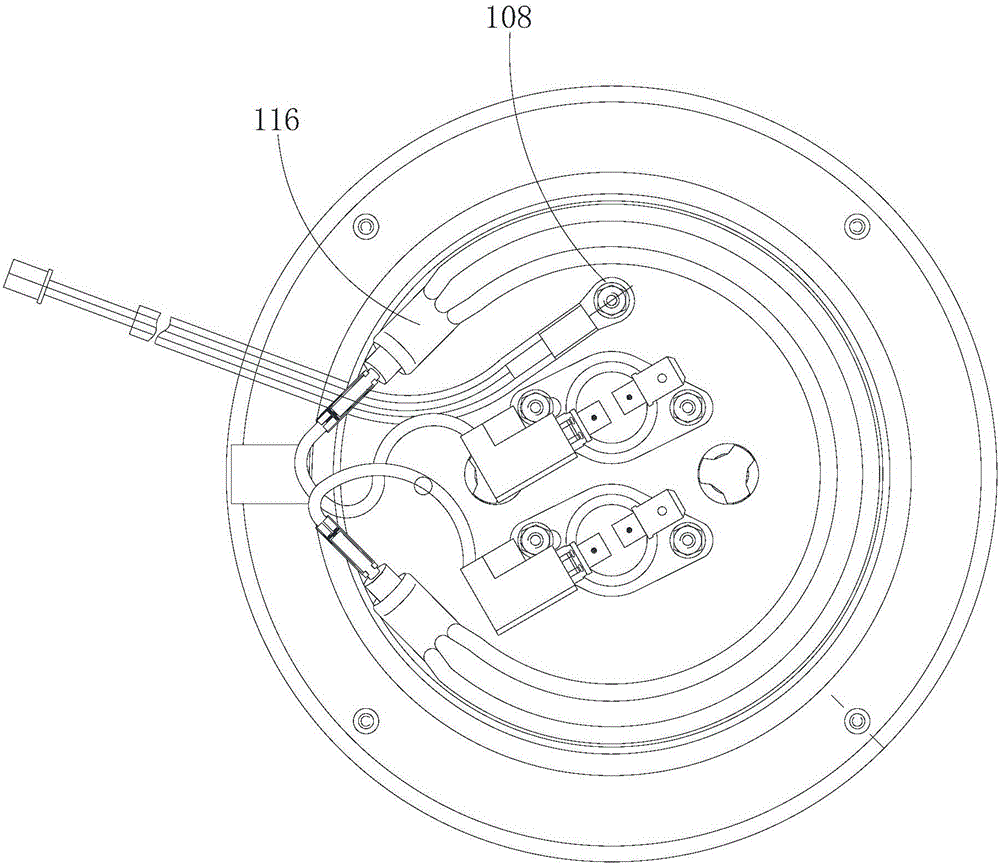

Bottom type steam generation device and control method thereof

ActiveCN105042550ASteam generation heating methodsBoiler indication operationsEngineeringSteam generation

The invention discloses a bottom type steam generation device. The bottom type steam generation device comprises a steam generator, a first temperature sensor and a controller. The steam generator comprises a water container and a heater connected with the water container. The heater is used for heating the water container. The first temperature sensor is used for detecting the temperature of the water container. The controller is used for turning on the heater, so that the water container is heated, and the controller is also used for acquiring the temperature of the water container. The controller is used for judging whether the temperature of the water container is larger than a set temperature or not, and if yes, the controller is used for turning off the heater. According to the bottom type steam generation device, whether the temperature of the water container is larger than the set temperature or not is judged by the temperature sensor so that whether water scale exists in the water container or not can be judged, if yes, the heater is turned off by the controller, and then the water container can be prevented from being damaged. The invention further discloses a control method of the bottom type steam generation device.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

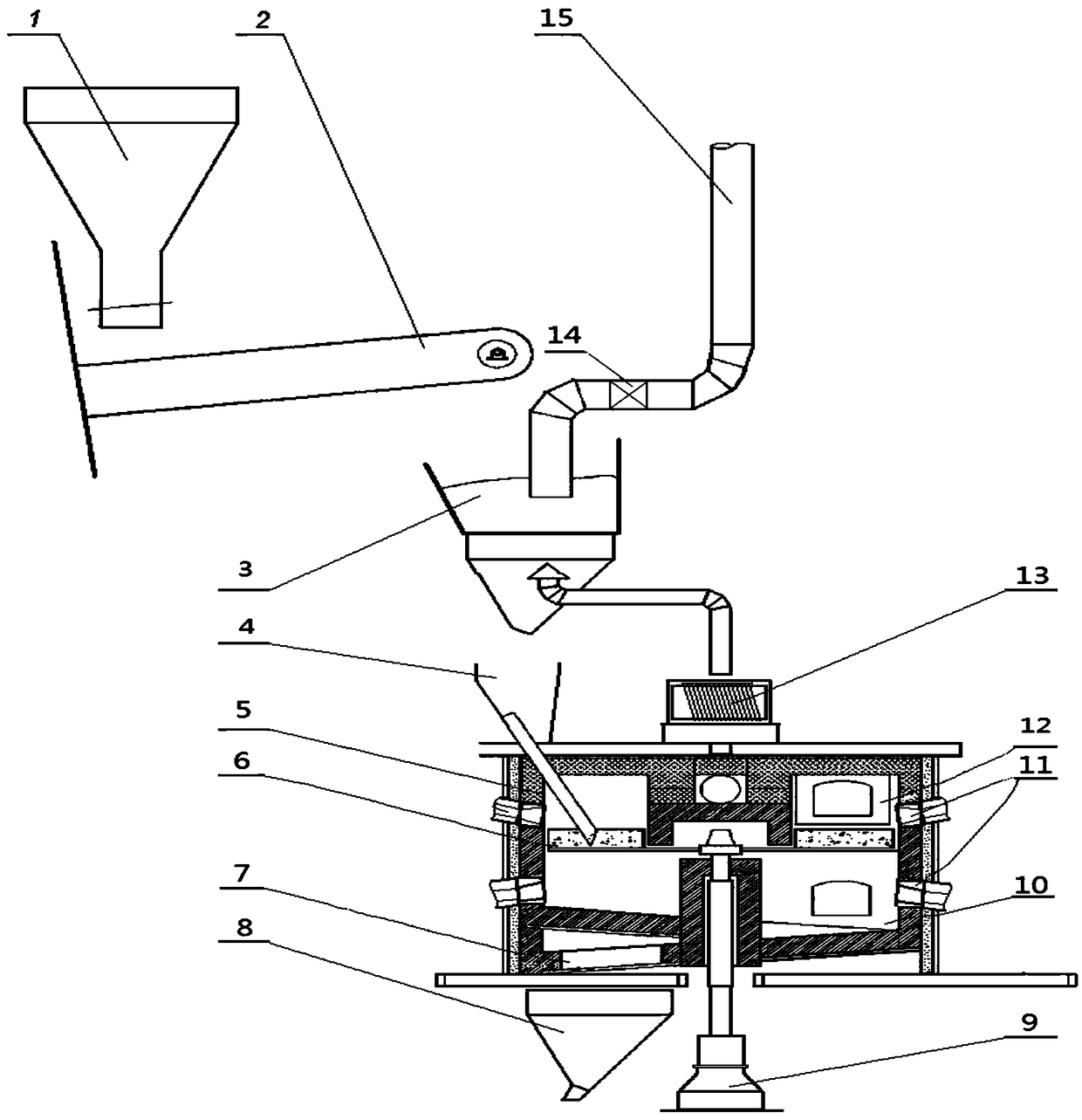

System for baking alloy materials processed by rotary cloth revolving furnace and operation method of system

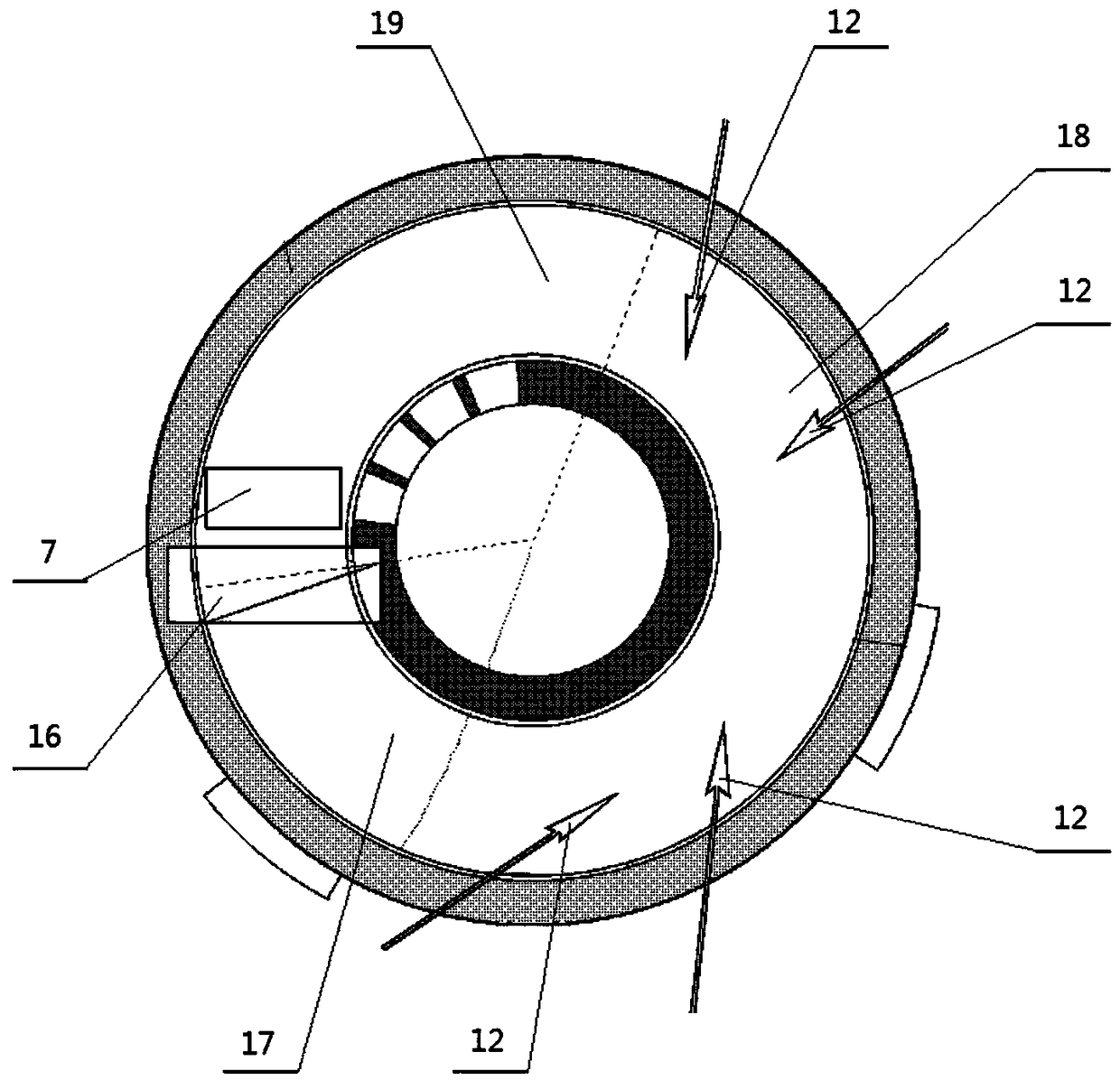

The invention relates to an alloy material furnace and particularly relates to a system for baking an alloy materials processed by a rotary cloth revolving furnace and an operation method of the system. The system comprises a loading device, a baking furnace, combustors, an air heat exchanger, a discharging tank and a smoke exhausting device, wherein the loading device comprises a charging tank, aconveying belt, a primary preheating bin and a chute type material distributor; the baking furnace is of an annular rotation bottom type and is used for heating an upper cavity and a lower cavity, and an annular chamber is internally divided into a preheating section, a heating section and uniform heating section; the combustors are mounted in the upper cavity and the lower cavity of the baking furnace, the combustor in the upper cavity is used for tangentially heating downwards, and the combustor in the lower cavity is used for tangentially heating upwards; the air heat exchanger and the chute type material distributor are mounted above the baking furnace, and the smoke exhausting device is connected with air heat exchanger, penetrates through the primary preheating bin and stretches outof the upper end of the primary preheating bin; and the discharging tank is arranged below the baking furnace. The alloy materials are uniformly distributed and heated, so that the heating effect isgood; the utilization rate of energy sources is high, the energy sources are saved, and the environmental protection is promoted; and the alloy material furnace is compact in structure and occupies asmall area.

Owner:ANGANG STEEL CO LTD

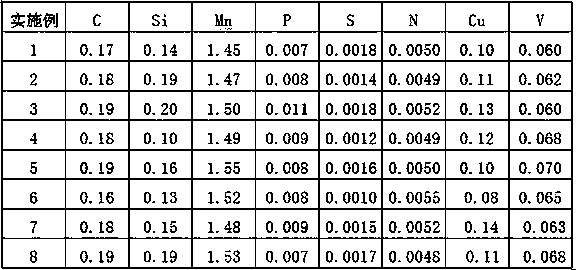

Heat treatment method for performance uniformity of whole plate surface of 550 MPa grade steel plate

The invention discloses a heat treatment method for the performance uniformity of the whole plate surface of a 550 MPa grade steel plate. According to the heat treatment method, secondary quenching and tempering process heat treatment are adopted by a car bottom type heating furnace, and the heat treatment method comprises heating, primary quenching, secondary quenching and tempering processes. The heat treatment method solves the problem that the large-thickness large-single-weight steel plates cannot be normalized and quickly cooled in a roller type quenching furnace and the problem of the performance uniformity of the whole plate surface during heat treatment in the car bottom type heating furnace. A steel plate obtained after heat treatment has the characteristics that the steel platehas good mechanical properties, 1 / 4 thickness and 1 / 2 thickness positions of the steel plate are large in -20 DEG C impact energy and Z-direction section shrinkage rate, and the steel plate has a goodsingle bainite structure, excellent comprehensive performance and excellent welding performance. Meanwhile, the problem of the performance uniformity of the whole plate surface of the steel plate iseffectively improved, and the produced large-thickness large-single-weight 550 MPa grade steel plate has stable quality. The heat treatment method is especially suitable for the heat treatment processof the large-thickness large-single-weight 550 MPa grade steel plate.

Owner:WUYANG IRON & STEEL

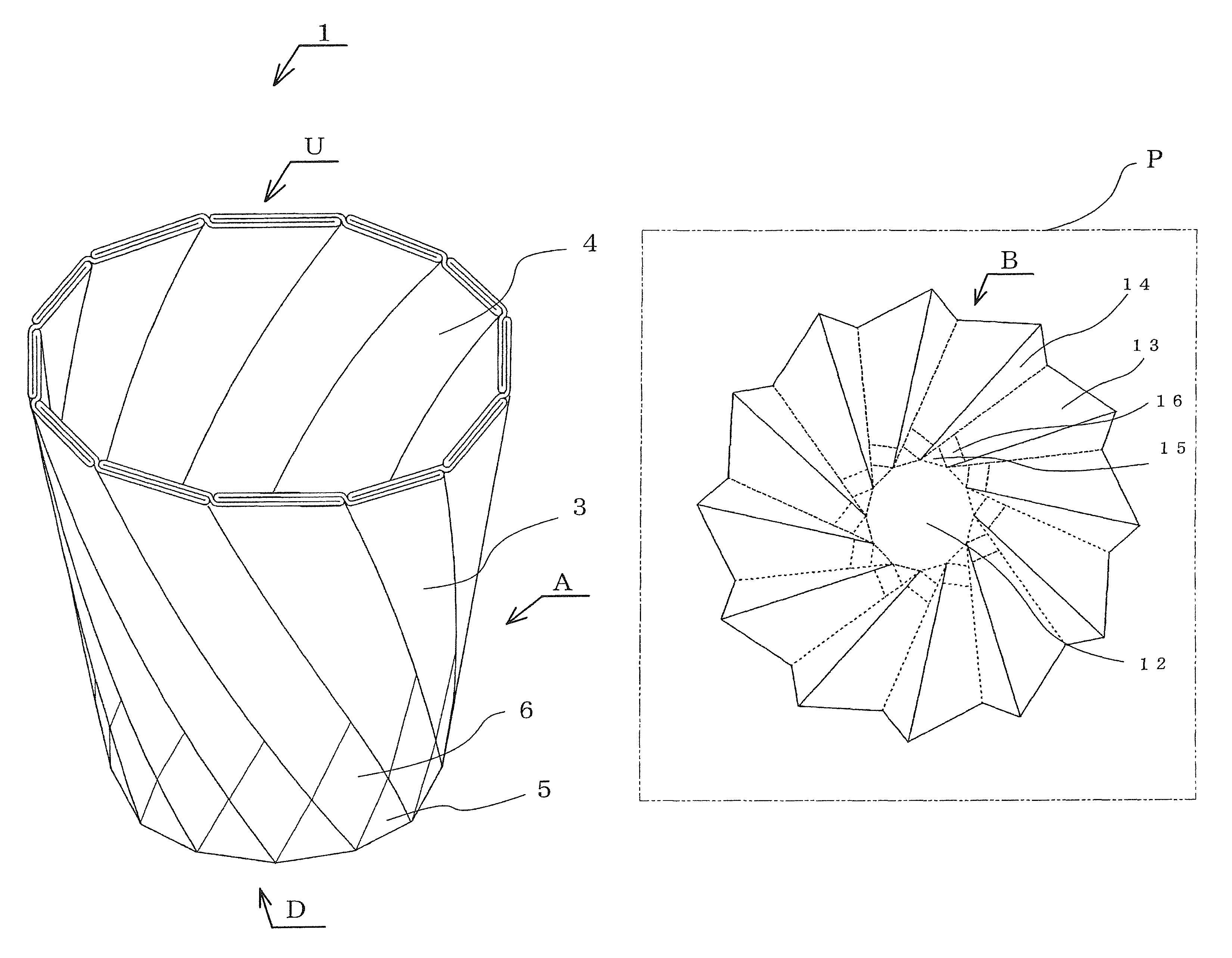

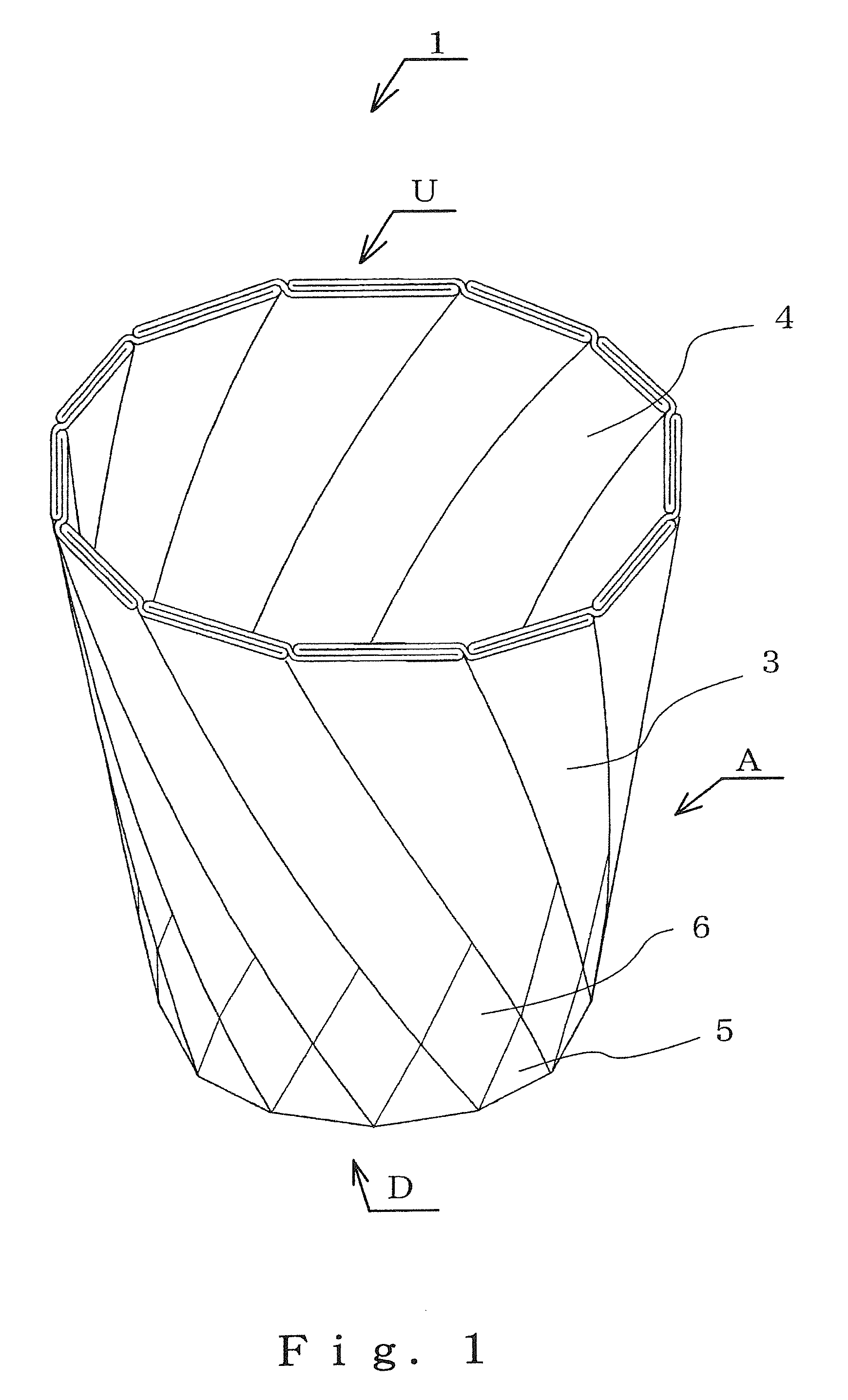

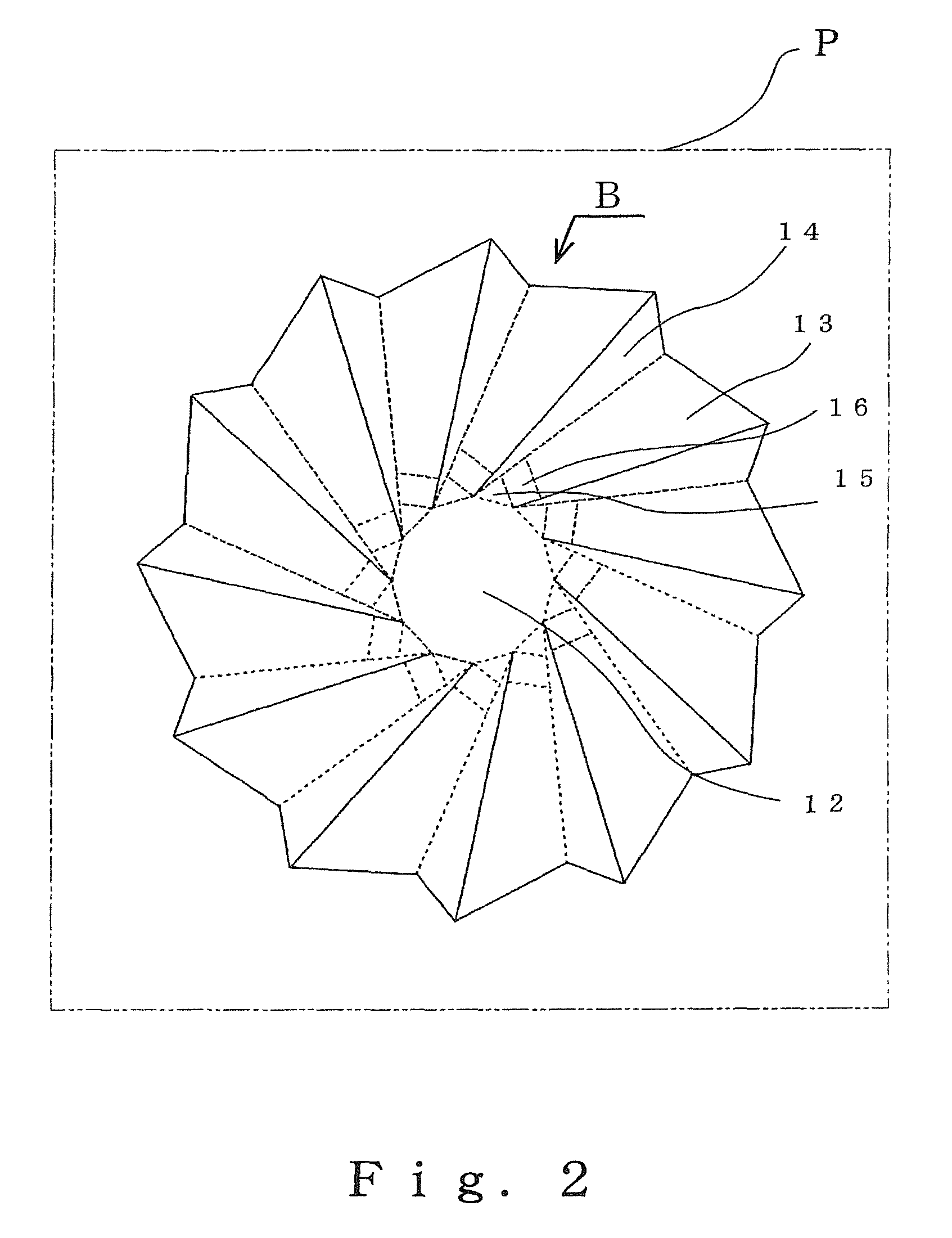

Container usable as a deep bottom and shallow bottom type container, and manufacturing method thereof

InactiveUS9045246B2Avoid deformationBoxes/cartons making machineryBox making operationsMechanical engineeringDistortion

To provide a container usable as a deep bottom- and shallow bottom-type container by changing between deep bottom- and shallow bottom-type container configurations by folding along prescribed ruled lines, forming a protruding part on the circumferential wall surface and forming undistorted smooth surfaces; and to provide a manufacturing method thereof. This container usable as a deep bottom- and shallow bottom-type container in which a deep bottom-type container configuration can be changed into a shallow bottom-type container configuration, wherein said deep-bottom type container is obtained by folding, along prescribed ruled lines, a single blank having a part with prescribed ruled lines and corresponding to the bottom surface, a part sectioned into compact triangles and quadrilaterals and corresponding to a partition surface, and a part corresponding to an inner folded surface, and said deep-bottom type container comprises a protruding part formed without distortion on the circumferential wall surface; and a manufacturing method thereof.

Owner:GREENPACKS +1

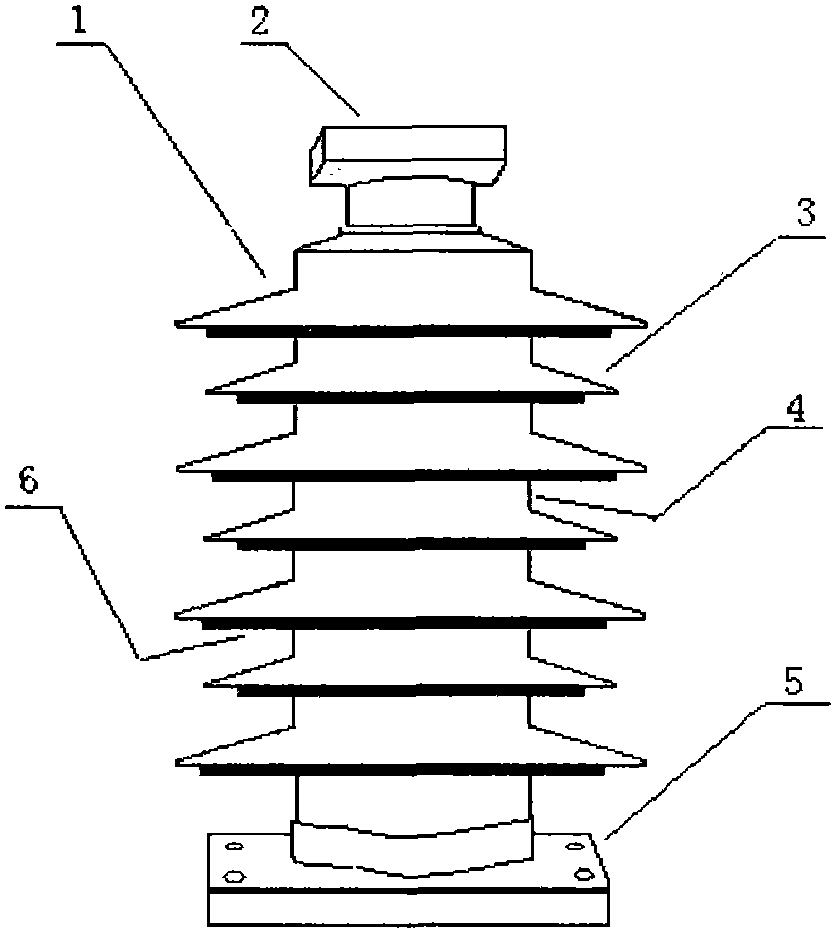

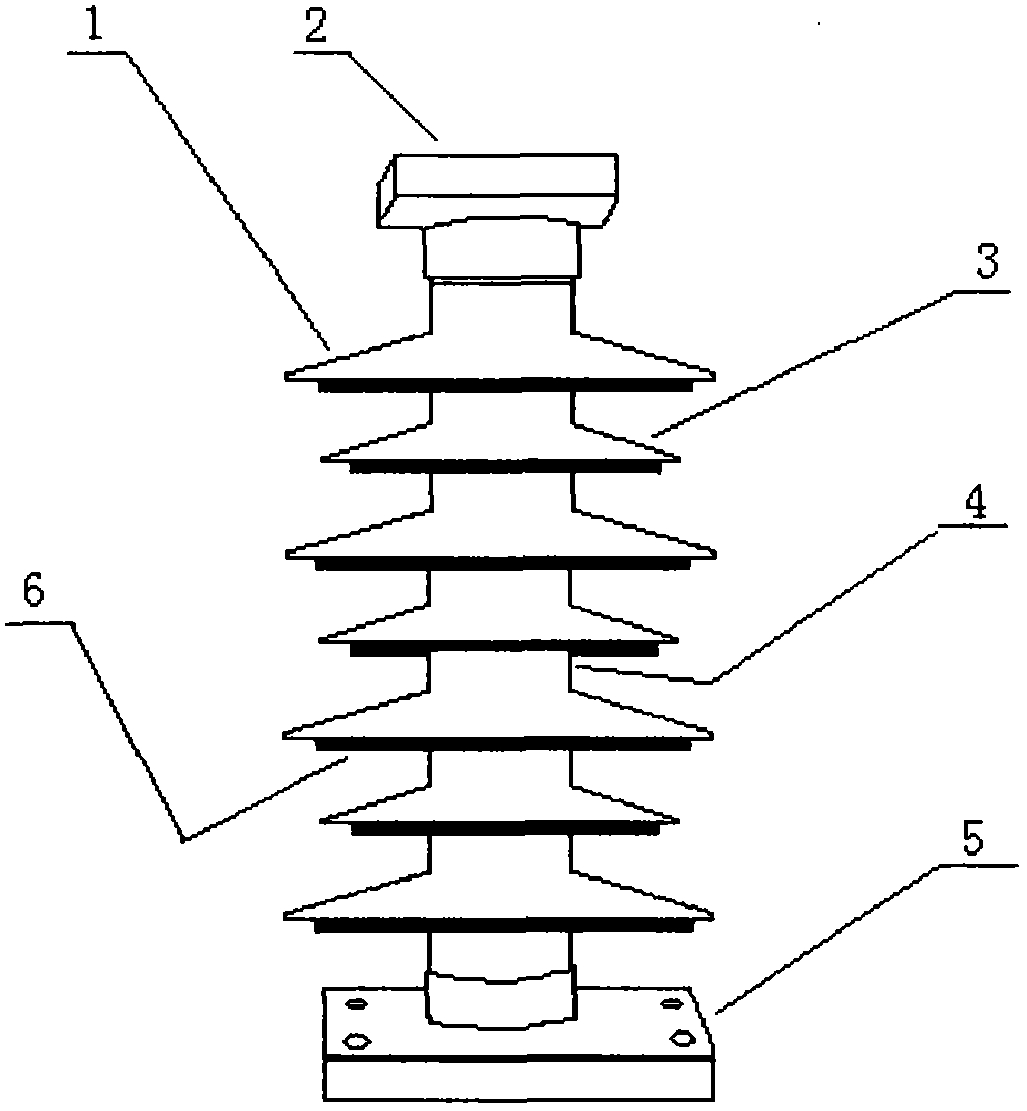

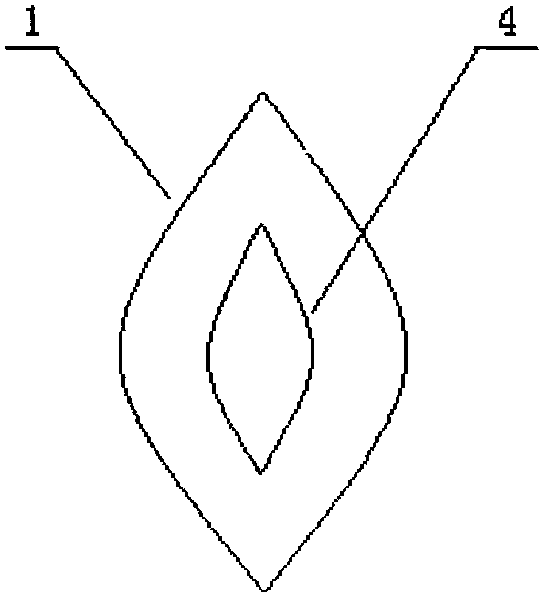

Boat-bottom-type top face rhombus supporting pillar insulator string

The invention relates to a boat-bottom-type top face rhombus supporting pillar insulator string of the roof of an electric locomotive. The boat-bottom-type top face rhombus supporting pillar insulator string is composed of a boat-bottom-type top face insulator sheet (1), a top armor clamp (2), a small umbrella skirt insulator sheet (3), a rhombus supporting pillar (4), an underframe fastening base (5) and an umbrella skirt inner side frost stopping pad (6). The boat-bottom-type top face rhombus supporting pillar insulator string is installed on the roof of the electric locomotive, the left side and the right side are provided with the boat-bottom-type top face insulator sheet (1) and the acute corner of the rhombus supporting pillar (4) respectively, when the electric locomotive runs in the heavy fog weather, the rhombus acute corner of the rhombus supporting pillar (4) guides collided supercooled water drop fog, ice crystal fog and the like in the running direction to the two sides of the rhombus supporting pillar (4), the ice crystal fog is prevented from being gathered on the rhombus supporting pillar (4) to form frost-shaped ice, and fog flicking faults caused by formation of conductive layers on the surface of the insulator string are prevented. The umbrella skirt inner side frost stopping pad (6) rich in grease has the hydrophobic character, dirty fog water drops can be prevented from being coagulated on the surface of the umbrella skirt inner side frost stopping pad (6), the inner sides of umbrella skirts of the supporting pillar insulator string are kept in the drying state, and the fog flicking faults caused by the formation of the conductive layers on the surface of the insulator string are prevented.

Owner:杜明义

Heat treatment method for normalizing type nuclear power pressure vessel equipment bearing steel plate

InactiveCN110117705ASolve the problem of nodulation on the roll surfaceReasonable matching of strength and toughnessFurnace typesHeat treatment furnacesNuclear powerOxygen

The invention discloses a heat treatment method for a normalizing type nuclear power pressure vessel equipment bearing steel plate. The procedures of normalizing heat treatment and cooling are included. A radiation pipe heated roller bottom type heat treatment furnace is adopted, nitrogen protection is adopted in the whole process, and the proportion of oxygen and nitrogen in the furnace is reasonably and strictly controlled to be lower than 1 / 20000; through optimization adjustment of the normalizing heat preservation temperature, the total heating time and the cooling red return temperature,steel plate toughness matching is reasonable, the comprehensive performance is excellent, a uniform and refined bainite + ferrite structure is obtained in the through-thickness direction, the grain size is at the level from 8.5-9.5, the steel plate yield strength is larger than or equal to 355 MPa, the tensile strength is 510-680 MPa, ductility A50 is larger than or equal to 20%, the lamellar tearing resisting performance value is larger than or equal to 45%, the 0 DEG C low temperature impact toughness average value is larger than or equal to 220 J, the lateral swell increment is larger thanor equal to 1.55 mm, and roughness is smaller than or equal to 6.3 microns. The characteristics that the production procedure is simple, the product quality is stable, and batched production can be achieved are achieved.

Owner:WUYANG IRON & STEEL

Roller bottom type tunnel heating furnace

The invention relates to a roller bottom type tunnel heating furnace. The furnace comprises a furnace body, a plurality of burners and a sealing device, a first automatic flame cutting gun and a second automatic flame cutting gun, the furnace body comprises a furnace top, a furnace bottom roller and two side furnace walls, the plurality of burners are arranged on the inner wall of the furnace wallat intervals; the sealing device is arranged in the furnace body; a cutting gun furnace door is arranged at one side end of the sealing device, and the first automatic flame cutting gun correspondingto the cutting gun furnace door is arranged outside the furnace wall; the first automatic flame cutting gun is obliquely arranged relative to the longitudinal section of the furnace body; the secondautomatic flame cutting gun is arranged at the outlet position of the furnace body; and the second automatic flame cutting gun is obliquely arranged relative to the longitudinal section of the furnacebody, and the inclination direction of the second automatic flame cutting gun is opposite to the inclination direction of the first automatic flame cutting gun. The roller bottom type tunnel heatingfurnace can obviously shorten the length of the heating furnace on the premise of ensuring the heating effect, so that the deviation probability of casting blanks in the furnace can be greatly reduced, and the equipment cost can be remarkably reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Air distributor for floatation machine

The invention discloses an air distributor for a floatation machine. The air distributor has a cylindrical structure of which the edge of the upper end is provided with a lug boss; the sidewall of the cylindrical air distributor is provided with a plurality of sidewall holes; and the shape of each sidewall hole is circular, elliptic or semi-circular. The air distributor is designed into a through type or a bottomed type cylindrical structure, and the sidewall and / or the underside of the cylindrical structure are / is provided with the holes, so that the air distributor can reasonably distribute the charged air among impeller stators and optimize the mineralizing effect. The air distributor has the advantages of simple structure, convenient installation and high efficiency and is widely applicable to floatation equipment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Bracket for open bottom type cabinet

A bracket is disclosed for use in open bottom type cabinets, such as file cabinets, which enables caster assemblies and the like to be secured thereto. The bracket is configured to be secured in the corners of an open bottom cabinet. In accordance with the present invention, the bracket provides stiffening of the cabinet as well as a secure surface for securing caster assemblies thereto. The brackets are simply mounted to the corners of the cabinet utilizing, for example, a pair of fasteners.

Owner:HIRSH INDS

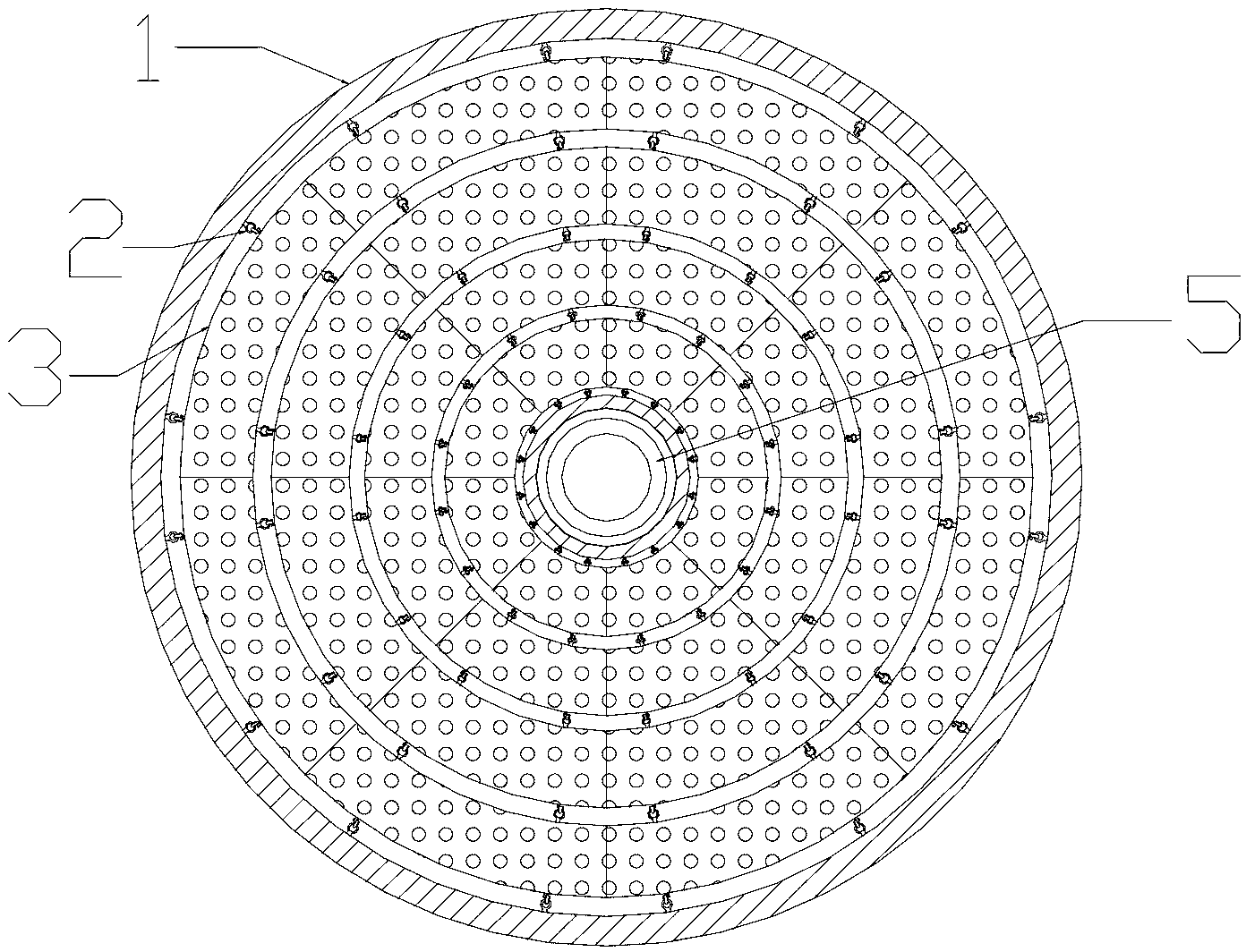

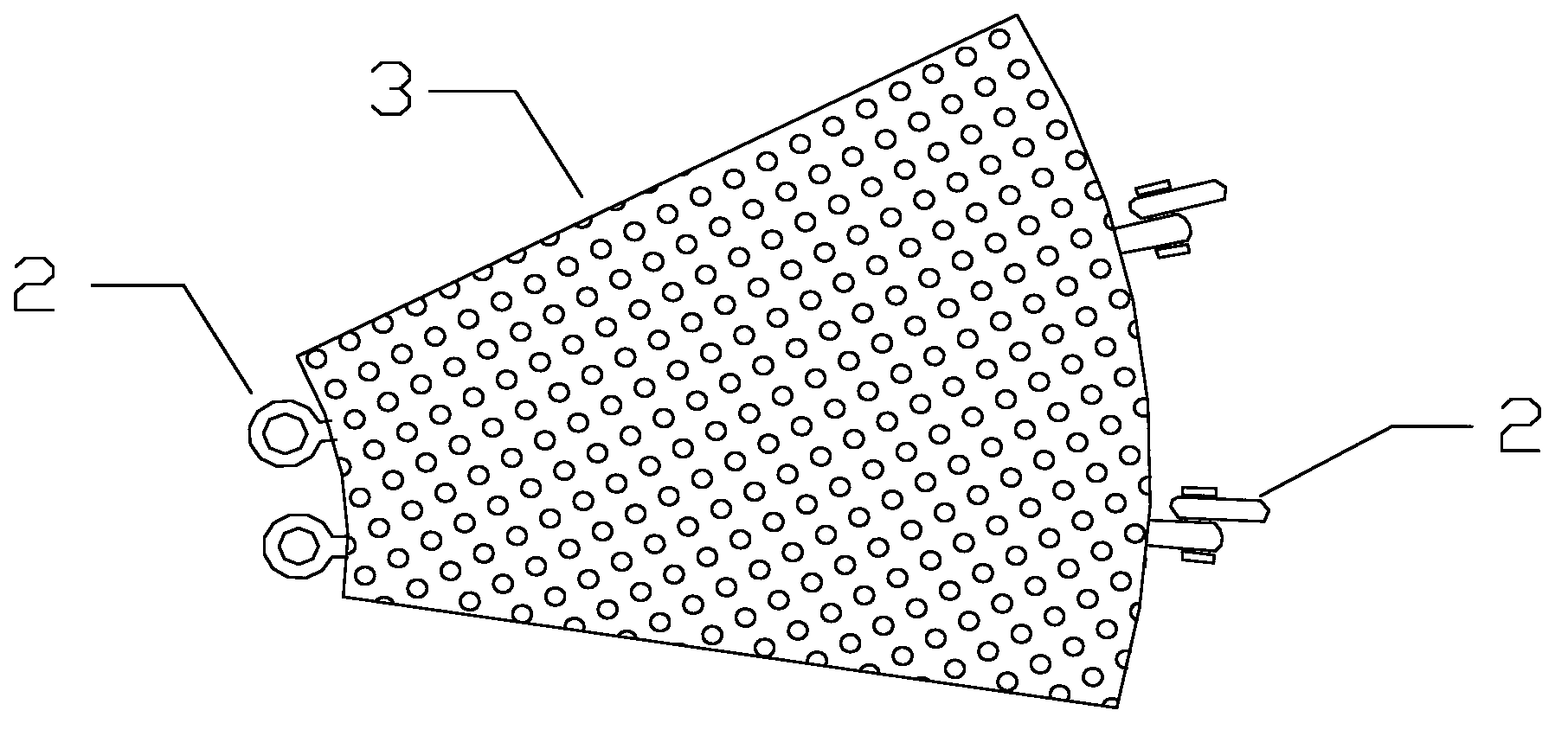

Unit connection and arbitrary combination type Chinese dinner gas stove energy collecting device

The invention discloses a unit connection and arbitrary combination type Chinese dinner gas stove energy collecting device comprising a hearth, connectors, unit energy collecting plates, an iron boiler and a gas stove head, wherein the side wall of the hearth is provided with the connector; the unit energy collecting plates are sector-shaped plates; two circular arc sections of the sector-shaped plates are respectively provided with connectors; the plurality of sector-shaped plates are mutually connected or connected with the connector on the side wall of the hearth to form a boiler bottom type energy collecting surface; each unit energy collecting plate is made of cordierite radiation ceramic; air holes are formed in the unit energy collecting plates; the diameter of the holes is 1.2-1.8mm and the distance between the holes is 1.6-2.1mm; and one surface, facing the bottom of the hearth, of each unit energy collecting plate, is coated with a VK-TC03 type low-radiation-rate coating. The unit connection and arbitrary combination type Chinese dinner gas stove energy collecting device disclosed by the invention is applicable to Chinese dinner gas stoves with different sizes; the unit energy collecting plates can reflect one part of heat radiation which is not used and absorb a large part of heat in hot waste gas to generate heat radiation again; and the heat radiation is used for heating the iron boiler for the second time so that the heat utilization rate of the Chinese dinner gas stove is improved.

Owner:SOUTH CHINA UNIV OF TECH

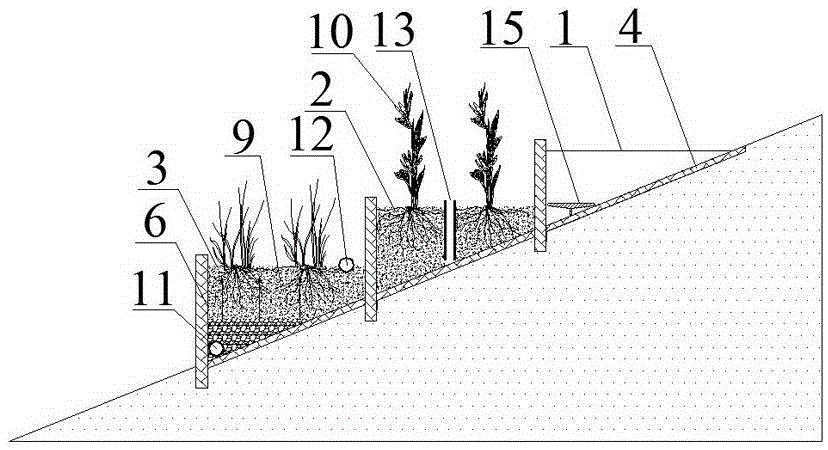

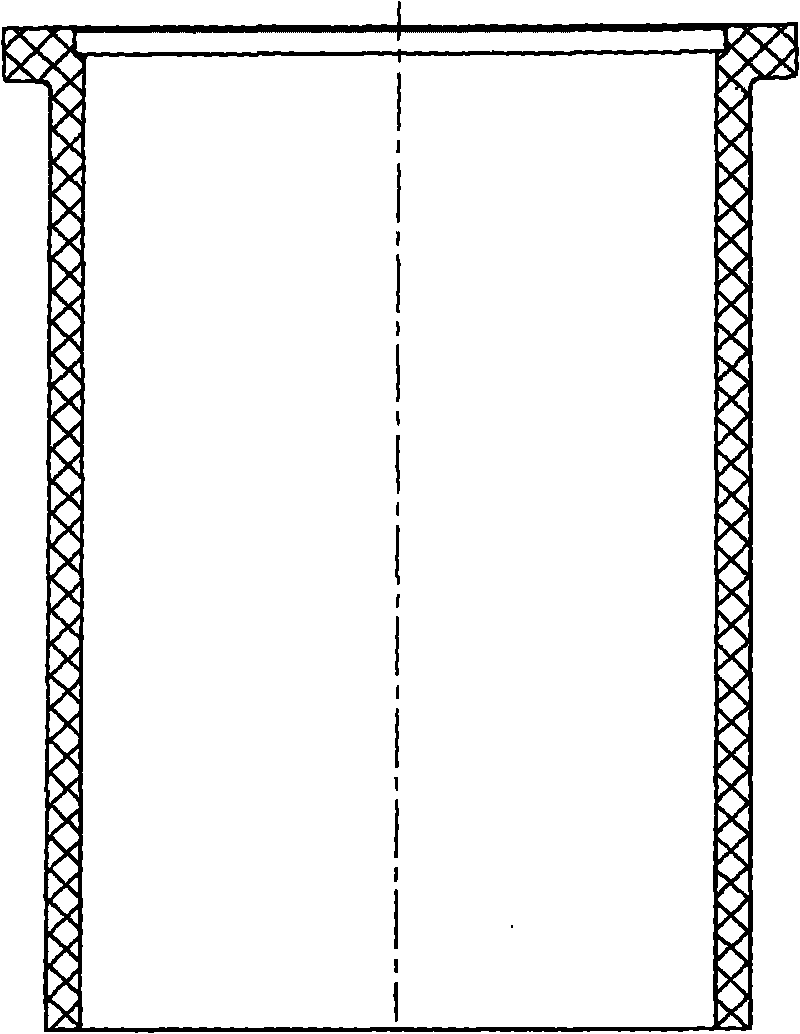

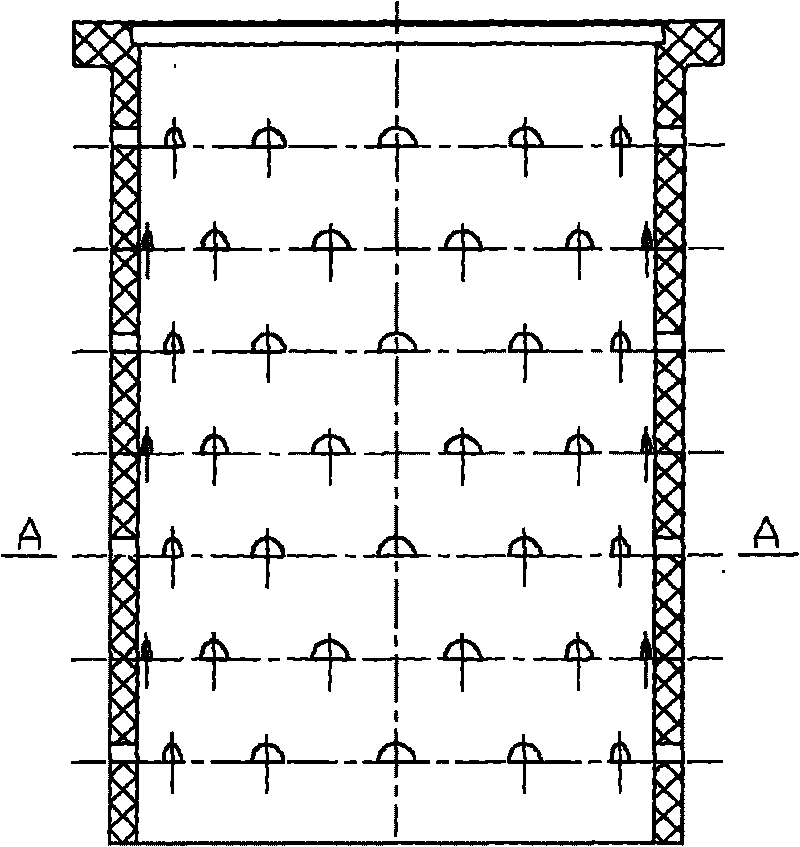

Sloping bottom type integrated vertical-flow constructed wetland system

ActiveCN105198092ASolve the problem that it is impossible to build vertical flow constructed wetlandsSimple structureSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandTreatment effect

The invention discloses a sloping bottom type integrated vertical-flow constructed wetland system, relates to a sloping bottom type integrated vertical-flow constructed wetland system applicable to slope topographies and mainly solves the problems that existing integrated vertical-flow constructed wetland technologies can hardly be applicable to the slope topographies, or land is required to be excavated and leveled, construction costs are high and the construction difficulty is high when the technologies are applied to the slope topographies. The constructed wetland system is a two-stage wetland unit of a frame-structure pool formed through step-shaped adjacent distribution of an upper-stage wetland unit and a lower-stage wetland unit, wherein the bottom of the frame-structure pool is a slope surface, the upper-stage wetland unit is a downstream constructed wetland unit, and the lower-stage wetland unit is an upstream constructed wetland unit; matrixes are arranged in the frame-structure pool, and plants are planted in the matrixes. The system has the good treatment effect, adopts the simple structure and is convenient to construct, low in cost and capable of being widely applied to all kinds of sewage treatment of slope areas such as mountains, hills, water banks and the like.

Owner:襄阳市大学科技园发展有限公司

Sloping-bottom type seed germination box

InactiveCN104770107AImprove water absorptionImprove water holding capacityGerminating apparatusEngineeringGermination

The invention discloses a sloping-bottom type seed germination box which is composed of a transparent box body, a transparent box cover, supporting feet, an air hole and an overflow hole. The supporting feet are located on the lower surface of the box bottom and put up one end of the box body to make the bottom face of the seed germination box have an included angle to the horizontal plane; the overflow hole is formed in the lower portion of the box wall at the low end of the box body and has a certain distance from the box bottom, and the box wall and the box bottom which are below the height of the overflow hole together form a reservoir in the seed germination box; the air hole is formed in the box cover. The sloping-bottom type seed germination box is simple in structure and convenient to use. Seed germination experiments are conducted by using the sloping-bottom type seed germination box, times of adding water can be reduced, germinating beds can be kept in a moist state all the time, influence on the seed germination due to too much water or too little water can be prevented, directional growth of seed roots can be achieved, and determination can be conducted on characters such as root length conveniently.

Owner:ANHUI SCI & TECH UNIV

Manufacturing method of roll collar material of water cold furnace roller

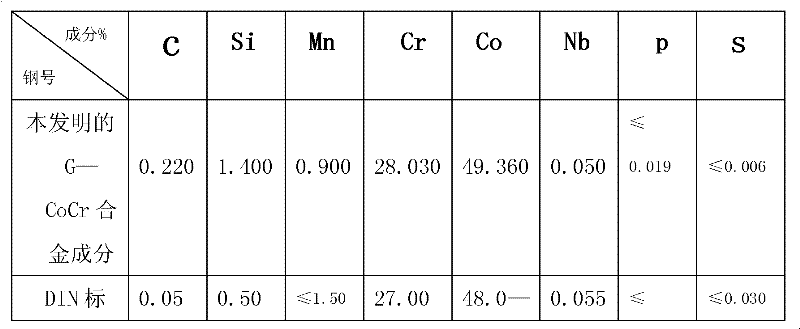

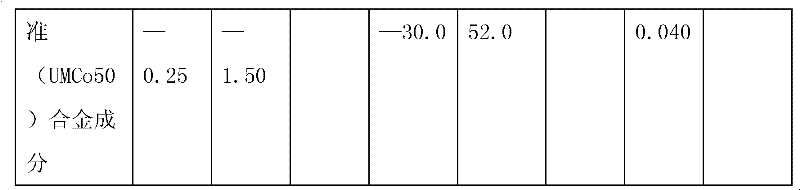

The invention provides a manufacturing method of a roll collar material of a water cold furnace roller, belonging to the technical field of steel rolling. The roll collar material of the water cold furnace roller is manufactured from a CoCr alloy material by adopting a vacuum melting process combined with a vacuum paraffin casting mould process, wherein the CoCr alloy material comprises the following components by weight percent: 0.220% of C, 1.400% of Si, 0.900% of Mn, 28.030% of Cr, 49.360% of Co, 0.050% of Nb, less than or equal to 0.019% of P, less than or equal to 0.06% of S and the balance of Fe. when the CoCr alloy material roll collar and the casting process thereof provided by the invention are used in a roll bottom type soaking pit furnace, the precipitation of carbides is effectively inhibited and delayed, the formation of net-shaped carbides is prevented, the strength and hardness of the roller collar are enhanced, the temperature resisting, and abrasion resisting and creep resisting properties of the roll collar are improved and the roll collar dose not generate steel-adhering and nodulation phenomena when hot blank is transmitted by silicon steel.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com