Manufacturing method of roll collar material of water cold furnace roller

A manufacturing method and technology of a water-cooled furnace, applied in manufacturing tools, casting equipment, molds, etc., can solve the problems of surface scratches on strip steel products, hindered production of silicon steel, internal slag inclusion, etc., to prevent mesh carbides. The effect of forming, enhancing strength and hardness, and improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with embodiment:

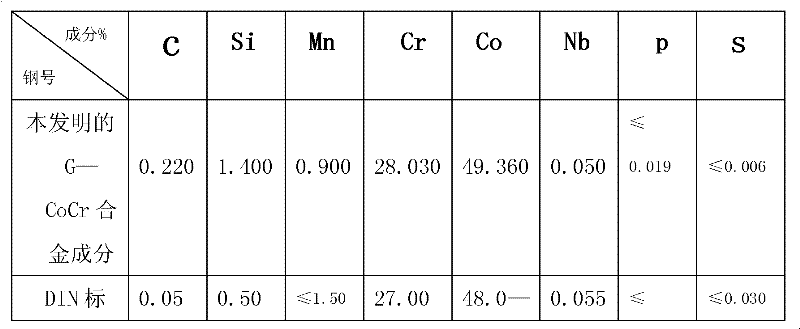

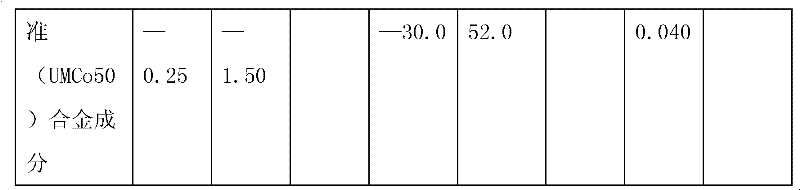

[0011] 1. The present invention is to realize the mass production process requirements of CSP production line silicon steel products. On the basis of analyzing and summarizing CrNi alloy roller ring material composition and DIN standard (UMCo50) alloy composition, it is considered that cobalt element has higher temperature resistance and The advantages of wear resistance, use CoCr alloy material instead of CrNi alloy material to make the roll ring to improve the crystal structure of the material, improve the temperature resistance and high temperature corrosion resistance of the material (see Table 1 for the detailed composition of the CoCr alloy roll ring material).

[0012] Table 1 CoCr alloy roller ring material composition list of the present invention

[0013]

[0014]

[0015] 2. Choose the casting process of G-CoCr roller ring:

[0016] The vacuum smelting-shell casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com