Copper pipe roller bottom type continuous bright annealing furnace

An annealing furnace and copper tube technology, which is applied in the field of annealing furnaces and copper tube roller hearth continuous bright annealing furnaces, can solve the problems of gas sealing gas consumption, gas pressure fluctuations, etc., and achieve small pressure fluctuations, good gas sealing, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

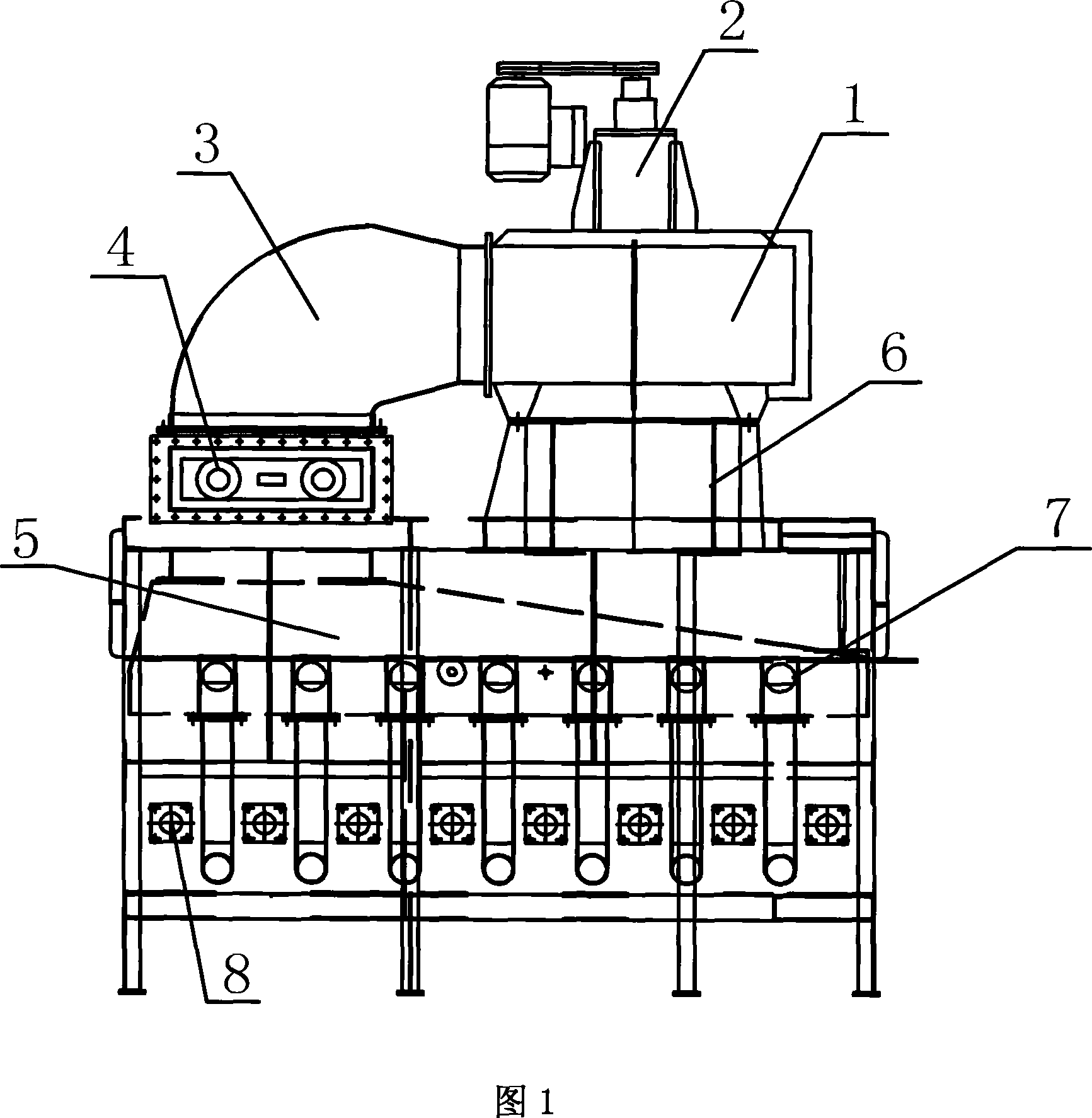

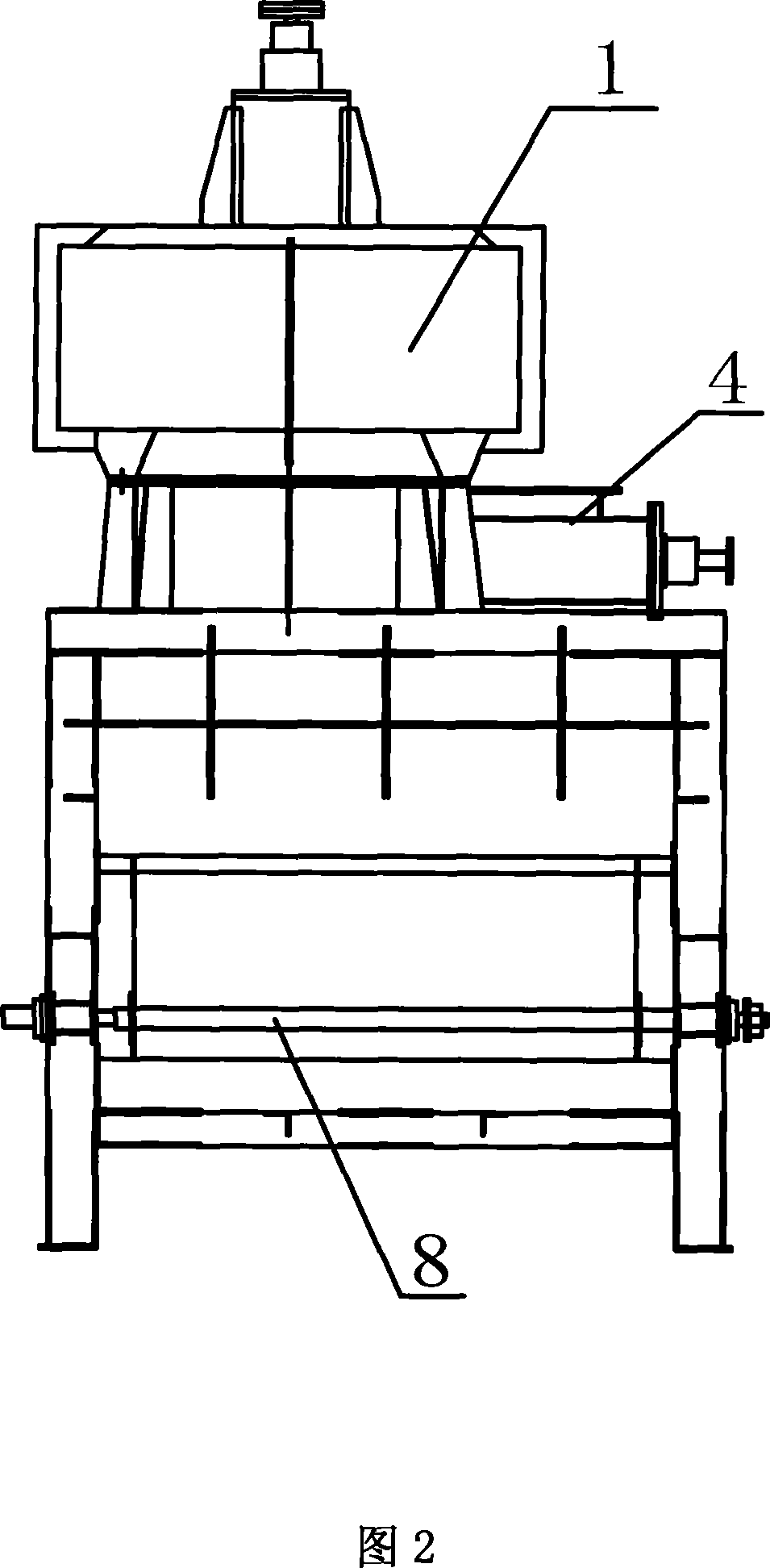

[0018] Copper tube roller hearth continuous bright annealing furnace, including inlet and outlet air lock chamber, inlet and outlet roller table, heating furnace and cooling chamber, the cooling chamber is divided into forced cooling section cooling chamber and heat preservation section cooling chamber, as shown in Figure 1-2 In the forced cooling section cooling chamber shown, the outside of the forced cooling section cooling chamber is provided with a cold pressure tank 1, a centrifugal fan 2, a cold pressure pipe 3, a condenser 4 and a heat exchanger 6, and several The upper and lower gas pipelines 7 for spraying; the inlet of the heat exchanger 6 is connected to the chamber of the cooling chamber of the forced cooling section, the outlet of the heat exchanger 6 is connected with the inlet of the cold pressure tank 1, and the centrifugal fan 2 is installed On the cold pressure groove 1, the outlet of the cold pressure groove 1 is connected with the cold pressure pipe 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com