Load economical allocation control method based on flow balance

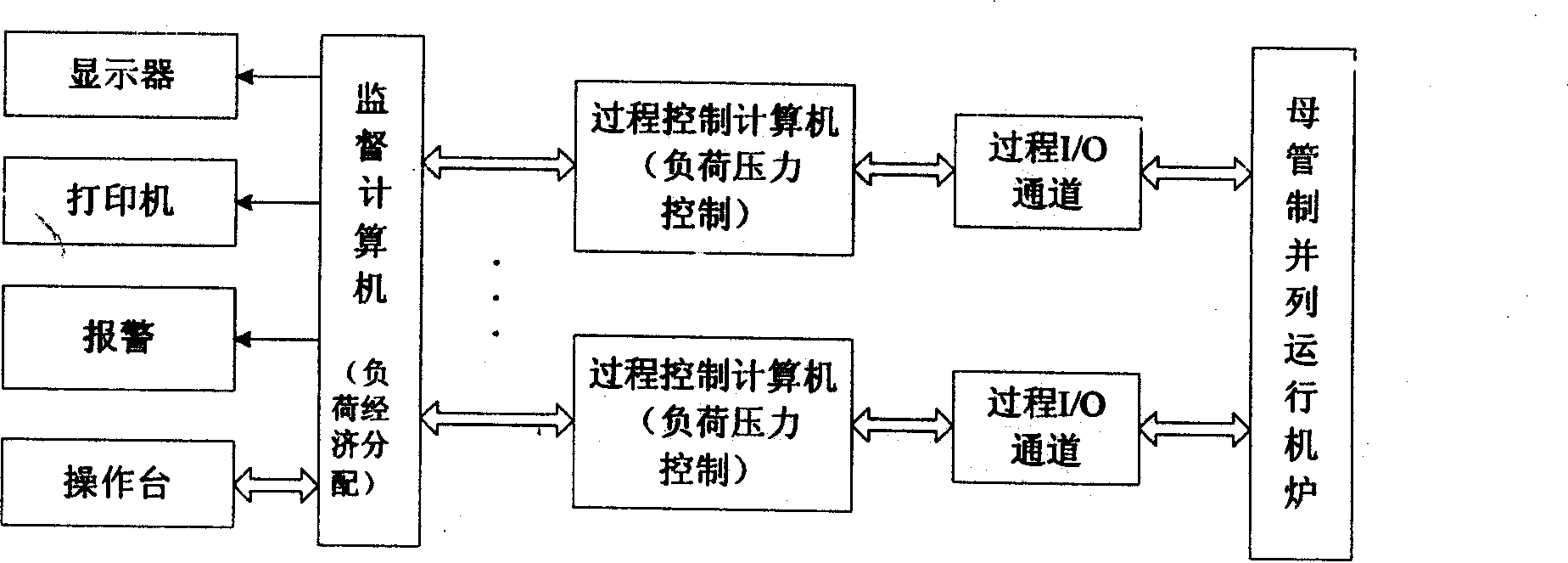

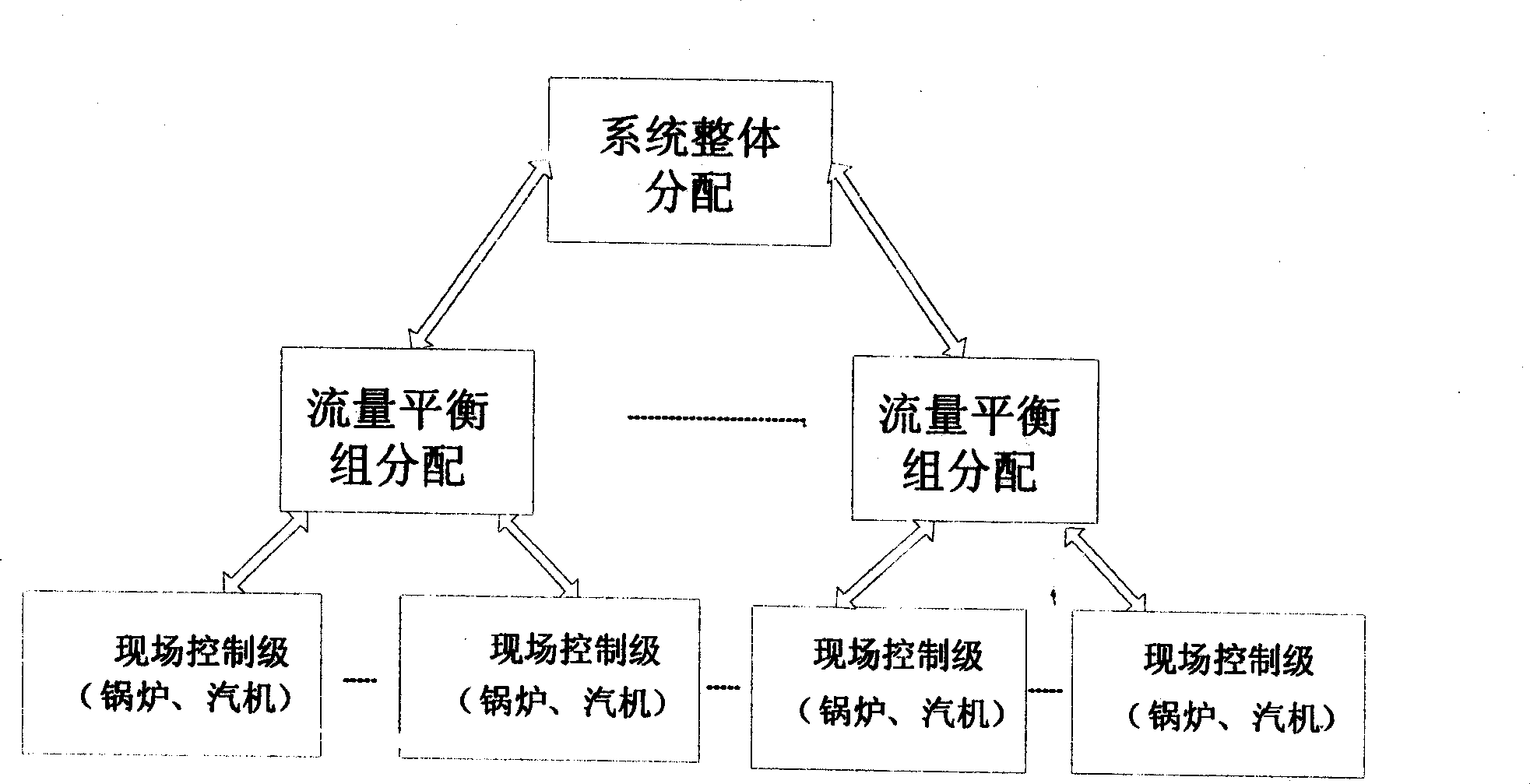

A technology of load economical distribution and flow balance, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as the inability to guarantee the balance of supply and demand of local flow in the main pipe, difficult pressure in the main pipe, and increased fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

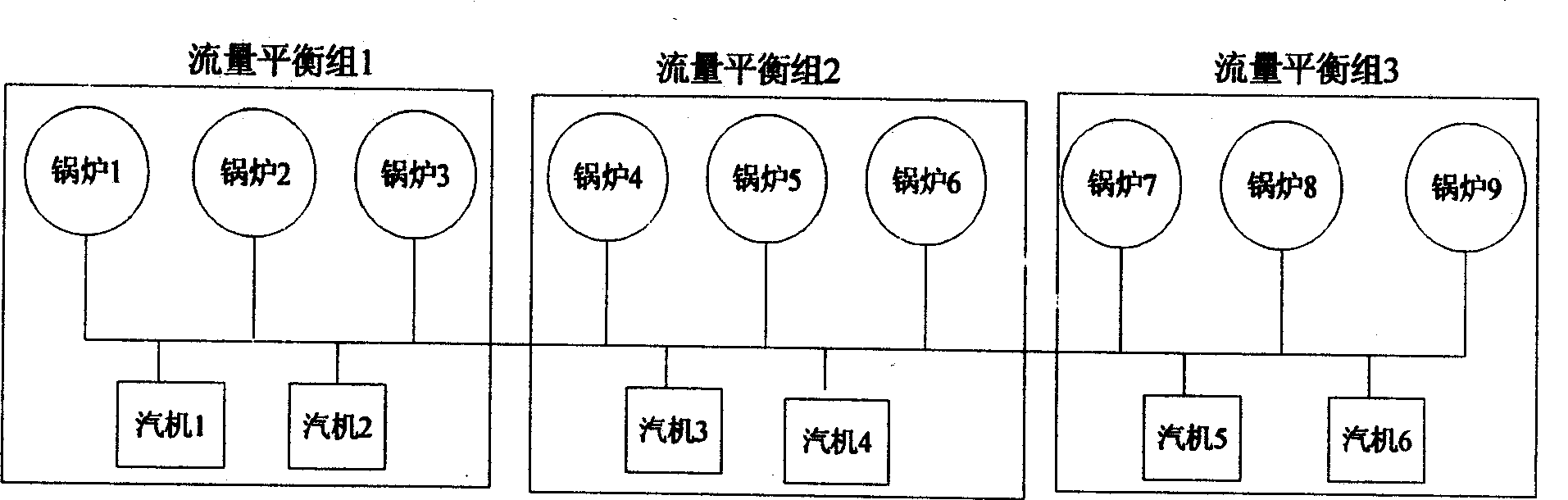

[0197] There are nine furnaces and six machines operating in parallel in the main pipe system of a thermal power plant in a petrochemical company. The boiler is a HG-220 / 100-10 pulverized coal boiler with a rated steam production of 220t / h (61.1kg / s), and the numbers are B1-B9 respectively; the rated steam consumption of the steam turbine is 220t / h (61.1kg / s ), numbered T1-T6. The coal consumption characteristic curve of the boiler is fitted by a quadratic polynomial, and the steam consumption characteristic of the steam turbine is approximately a straight line. The parameters are shown in Table 2 and Table 3 below.

[0198] Table 1 Traffic balancing group

[0199] balance group 1 B1 T1 B2 T2 B3 balance group 2 B4 T3 B5 T4 B6 balance group 3 B7 T5 B8 T6 B9

[0200] Table 2 Boiler coal consumption characteristic curve coefficient (steam flow unit is t / h, coal consumption unit is t / h)

[0201] boiler number a 0 a 1 a 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com