Continuous pressurizing oil-injection quenching device

A technology of quenching device and quenching press, which is applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc., can solve the problems of increasing processing difficulty, large amount of free deformation, and large number of operators, so as to achieve uniform internal stress distribution of the matrix and product The effect of improving flatness and controlling product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

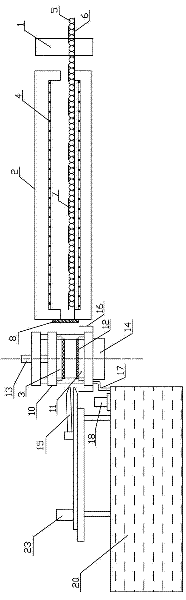

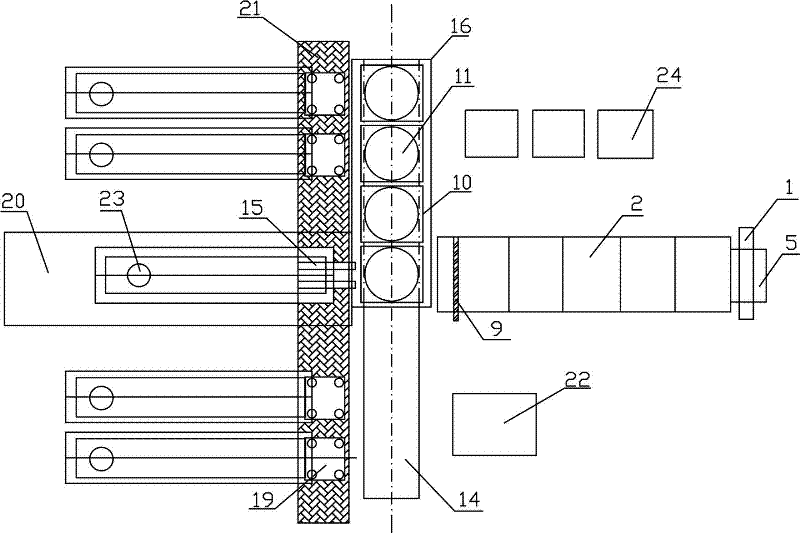

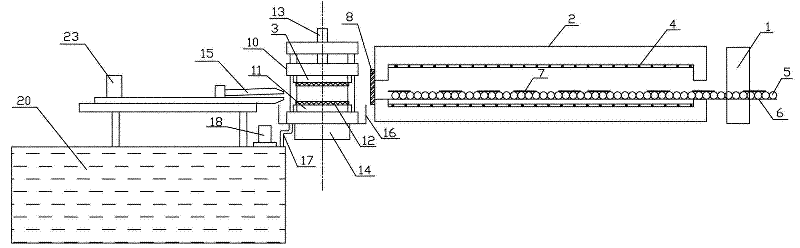

[0018] Such as figure 1 and figure 2 As shown, a continuous pressurized oil injection quenching production device includes an oil tank 20, a heating element 4 is arranged in a roller hearth type continuous heating furnace 2, a feeding device 1 is arranged on one side of the roller hearth type continuous heating furnace 2, and a feeding device 1 is arranged on the other side An oil spray quenching press 10 is arranged on the side, and the oil spray quenching press 10 is placed in the oil tank 16, between the sheet taking manipulator 15 and the roller bottom type continuous heating furnace 2, the oil tank 16 communicates with the oil tank 20 through the oil delivery pipe 17, The retrieving manipulator 19 is located at both sides of the taking sheet manipulator 15 .

[0019] The oil injection quenching press 10 has an upper platen 11 and a lower platen 3, the upper and lower platens have hollow honeycomb fuel injection nozzles 12, the lower platen 3 is fixed, the upper platen 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com