Heat treatment method for normalizing type nuclear power pressure vessel equipment bearing steel plate

A heat treatment method and normalizing heat treatment technology, applied in the field of metallurgy, to achieve the effect of reasonable matching, excellent comprehensive performance and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

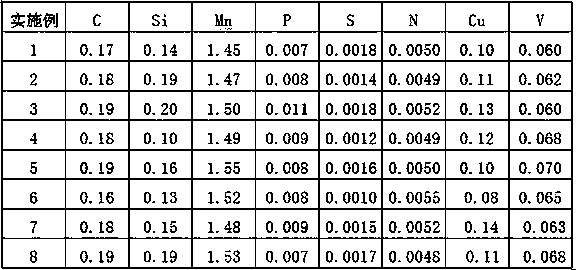

[0016] The thickness of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment is 120 mm, and the width is 3800 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0017] The heat treatment method of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment includes normalizing heat treatment and cooling process, and the specific process steps are as follows:

[0018] (1) Normalizing heat treatment process: a roller hearth heat treatment furnace heated by radiant tubes, nitrogen protection throughout the whole process, a reasonable and strict control of the ratio of oxygen and nitrogen in the furnace to 0.5 / 20000, the normalizing holding temperature is 907°C, and the total heating time 120min;

[0019] (2) Cooling process: the steel plate is accelerated to water cooling when it comes out of the furnace, adopts laminar flow cooling, ...

Embodiment 2

[0022] The thickness of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment is 100 mm, and the width is 3700 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0023] The heat treatment method of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment includes normalizing heat treatment and cooling process, and the specific process steps are as follows:

[0024] (1) Normalizing heat treatment process: a roller hearth heat treatment furnace heated by radiant tubes, nitrogen protection throughout the whole process, a reasonable and strict control of the ratio of oxygen and nitrogen in the furnace to 0.8 / 20000, the normalizing holding temperature is 909°C, and the total heating time 100min;

[0025] (2) Cooling process: the steel plate is accelerated water cooling when it comes out of the furnace, adopts laminar flow cooling, the...

Embodiment 3

[0028] The thickness of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment is 80 mm, and the width is 3650 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0029] The heat treatment method of the steel plate used for supporting the normalized nuclear power pressure vessel equipment in this embodiment includes normalizing heat treatment and cooling process, and the specific process steps are as follows:

[0030] (1) Normalizing heat treatment process: a roller hearth heat treatment furnace heated by radiant tubes, nitrogen protection throughout the whole process, a reasonable and strict control of the ratio of oxygen and nitrogen in the furnace to 0.6 / 20000, the normalizing holding temperature is 925°C, and the total heating time 85 minutes;

[0031] (2) Cooling process: the steel plate is accelerated water cooling when it comes out of the furnace, adopts laminar flow cooling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com