Irradiation-crosslinked low-smoke halogen-free inflaming retarding insulation material for nuclear power station cable and preparation method thereof

A nuclear power plant cable and insulating material technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of insufficient anti-radiation effect, expensive rare earth organic compounds, and great influence on the mechanical properties of inorganic anti-radiation agent materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Preparation method of halogen-free flame-retardant insulating material

[0083] In the present invention, the preparation method of irradiation cross-linked low-smoke halogen-free flame-retardant insulating material for nuclear power plant cables comprises the following steps:

[0084] Mix the flame retardant according to the proportion in a high-speed mixer until the temperature reaches 110°C±5°C, add zinc stearate and stir for 3-6 minutes, discharge and place, and use twin-screw extrusion to granulate with other materials according to the ratio Extrude and granulate by extruder to obtain radiation cross-linkable low-smoke halogen-free flame-retardant insulating material for nuclear power plant cables.

[0085] Preferably, the four temperature sections of the twin-screw granulator used in the extrusion granulation process are: feeding section 115-125°C, conveying section 125-135°C, melting section 135-145°C, head 140- 150°C.

[0086] More preferably, the above-ment...

Embodiment 1

[0101] Each component name and each component parts by weight are as follows:

[0102] EBA 70Kg

[0103] POE 20Kg

[0104] VLDPE 10Kg

[0105] Mg(OH) 2 110Kg

[0106] Melamine 15Kg

[0107] Zinc borate 5Kg

[0108] Compatibilizer (POE-g-MAH) 4Kg

[0109] Naugard 445 1Kg

[0110] Irganox 1010 0.5Kg

[0111] PS802 1.5Kg

[0112] 2-Mercaptobenzimidazole zinc salt (MBZ) 3Kg

[0113] 2,2,4-trimethyl-1,2-dihydroquinoline polymer (RD) 2Kg

[0114] Irganox MD-1024 0.3Kg

[0116] Triallyl isocyanurate (TAIC) 4Kg

[0117] The preparation method of the above invention comprises the following process steps: mixing the flame retardant magnesium hydroxide, melamine, and zinc borate in a high-speed mixer according to the ratio until the temperature reaches 110°C±5°C, adding zinc stearate and stirring After 3 to 6 minutes, the material is discharged and placed, and is extruded and granulated with other materials using a twin-screw granulator (...

Embodiment 2

[0120] Each component name and each component parts by weight are as follows:

[0121] EBA 65Kg

[0122] POE 20Kg

[0123] VLDPE 15Kg

[0124] Mg(OH) 2 95Kg

[0125] Melamine 5Kg

[0126] Zinc borate (ZnB) 10Kg

[0127] Compatibilizer (POE-g-MAH) 2Kg

[0128] Naugard 445 0.5Kg

[0129] Irganox 1010 0.5Kg

[0130] PS802 1Kg

[0131] 2-Mercaptobenzimidazole zinc salt (MBZ) 1Kg

[0132] 2,2,4-trimethyl-1,2-dihydroquinoline polymer (RD) 2Kg

[0133] Irganox MD-1024 0.1Kg

[0134] Zinc stearate 0.2Kg

[0135] Triallyl isocyanurate (TAIC) 2Kg

[0136] The preparation method of above-mentioned cable material is identical with embodiment 1

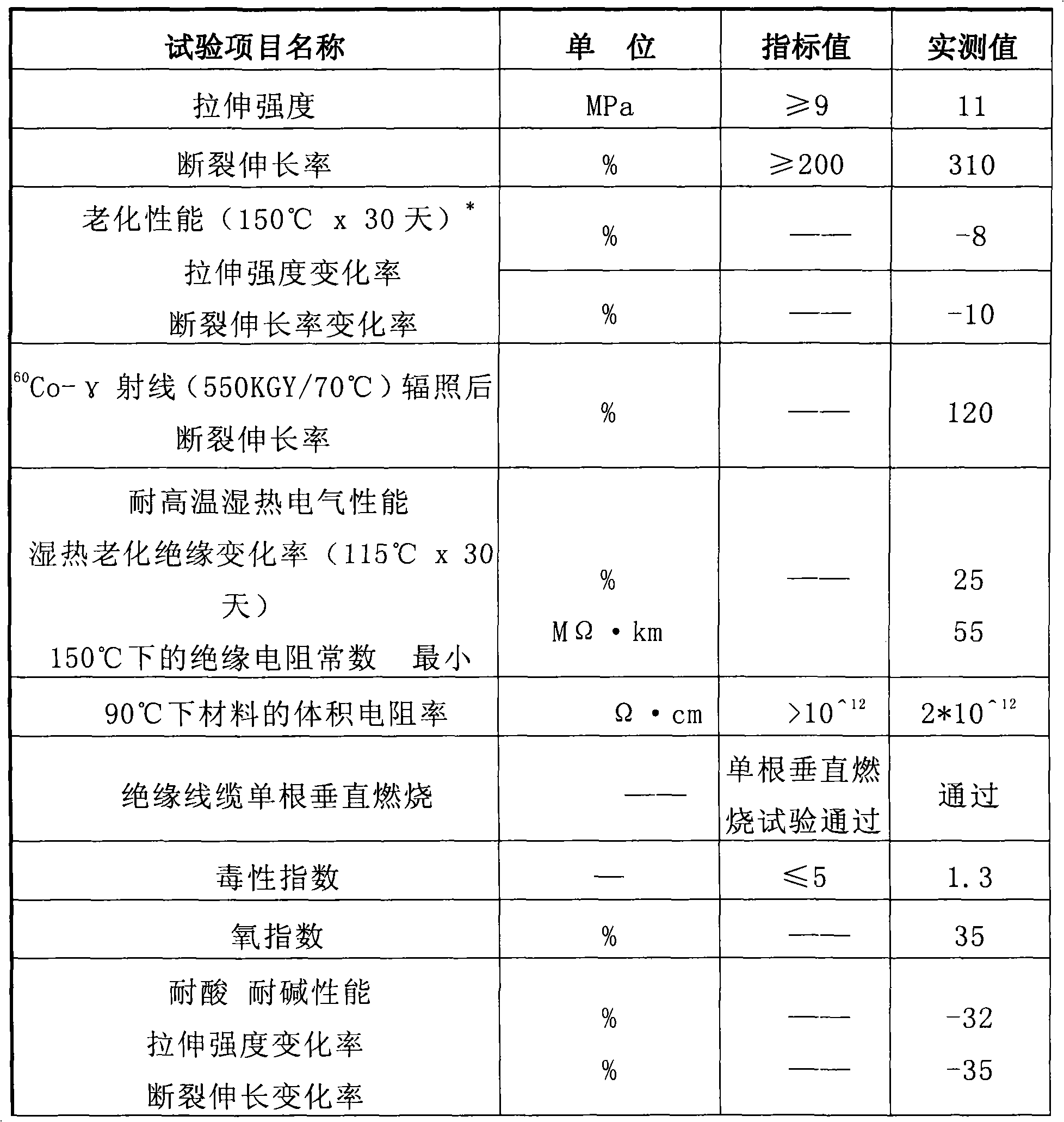

[0137] The product in Example 2 is subjected to a performance detection test, and each performance value is as shown in the performance example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com