Patents

Literature

136results about How to "Small amount of welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

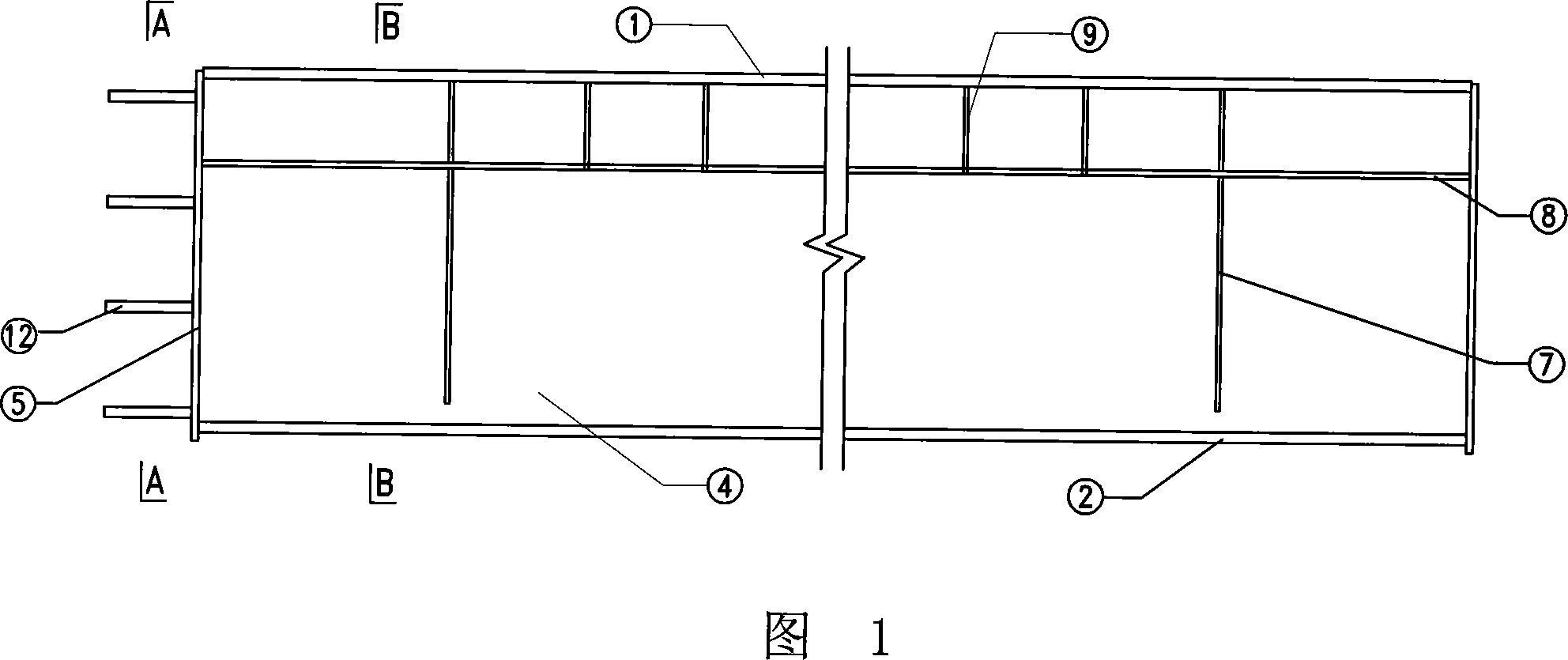

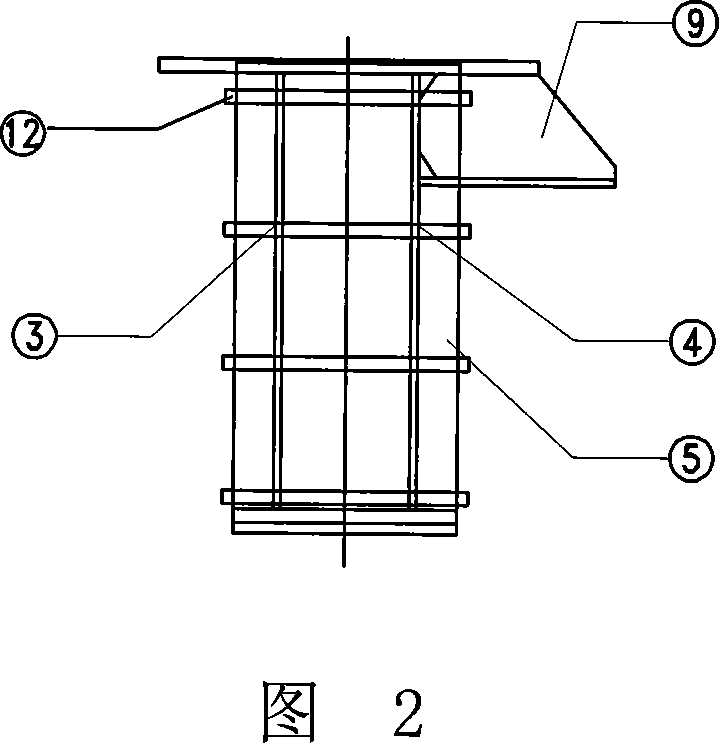

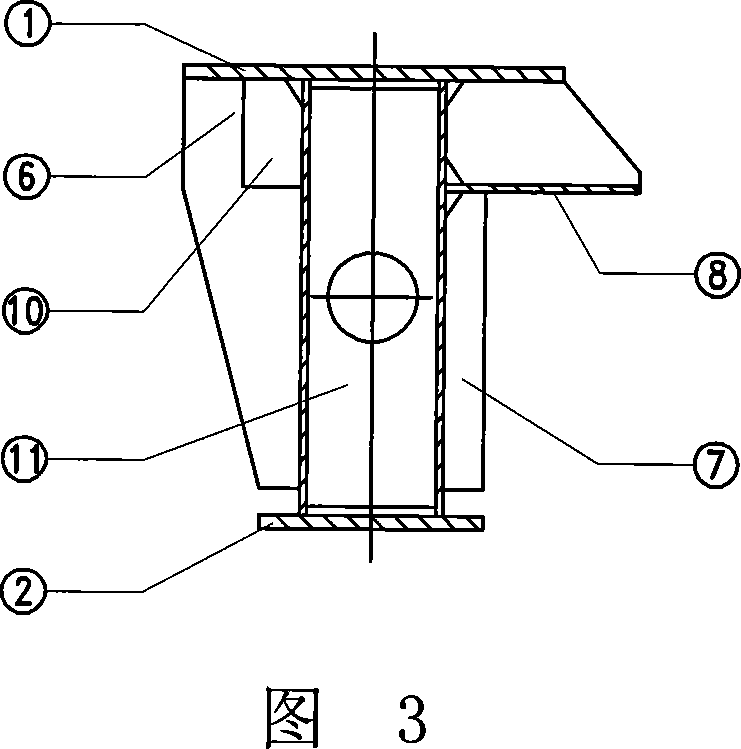

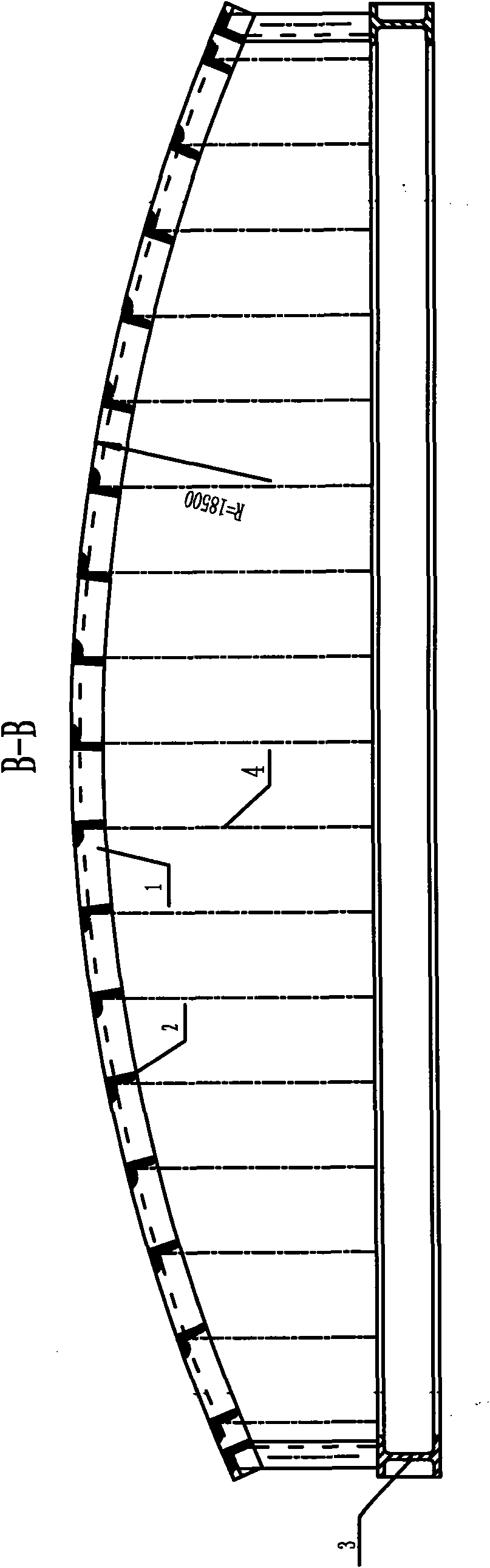

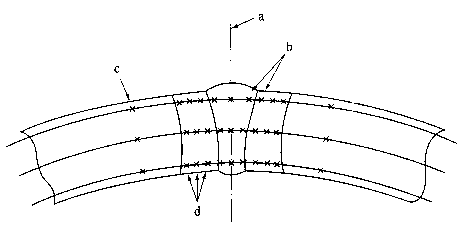

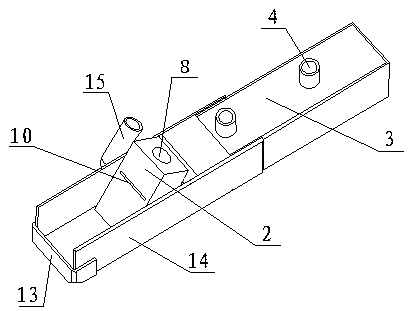

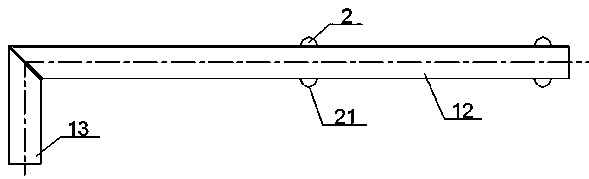

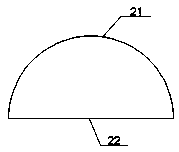

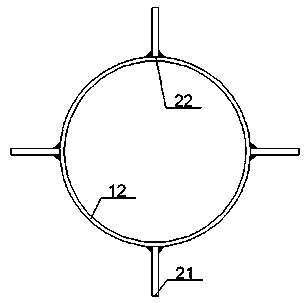

Method for assembling and welding cased crane-beam in circular rail of nuclear-power station

ActiveCN101074085ASmall amount of welding deformationGuarantee welding qualityArc welding apparatusRunwaysPower stationNuclear power

The invention is concerned with an assembled and seal method of box crane beam with ring type orbit using for nuclear power plant, belonging to the establishment construction technology field of nuclear power plant. It relates to rectification of stuff, sealing inner and outside webs and clapboard, sealing upper and down wing edge and the inner and outside webs, sealing stiffened panel, sealing end plate and the rectify after seal. Assemble and seal the web and inner muscle plate to a type of H to reduce the distortion and keep the seal quality, while the temporary backboard controls the final seal distortion when sealing the end plate. It will control the distortion effectively to reach the demand of the first level of nuclear quality and nuclear safety through easy adjustment of circle crane beam after sealed with steady quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

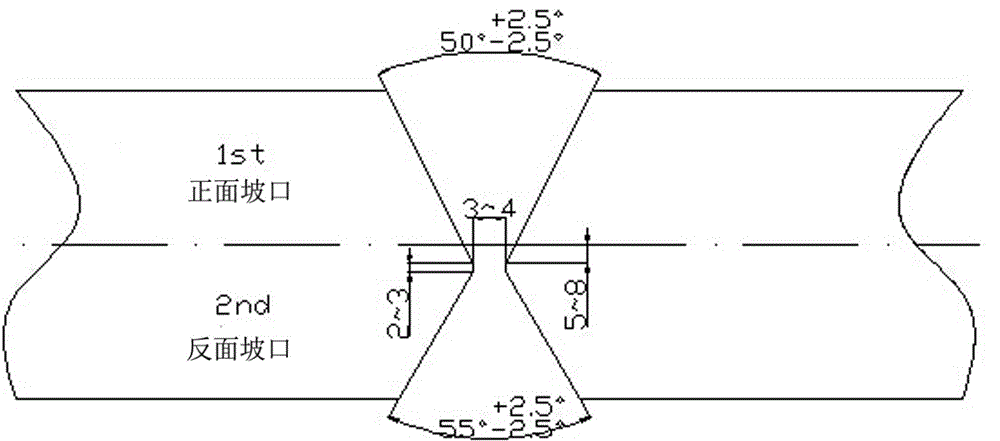

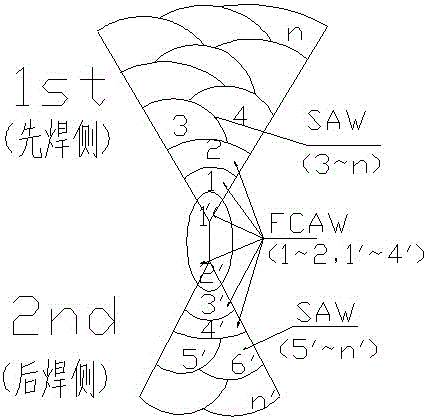

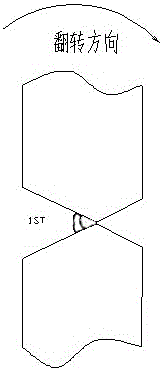

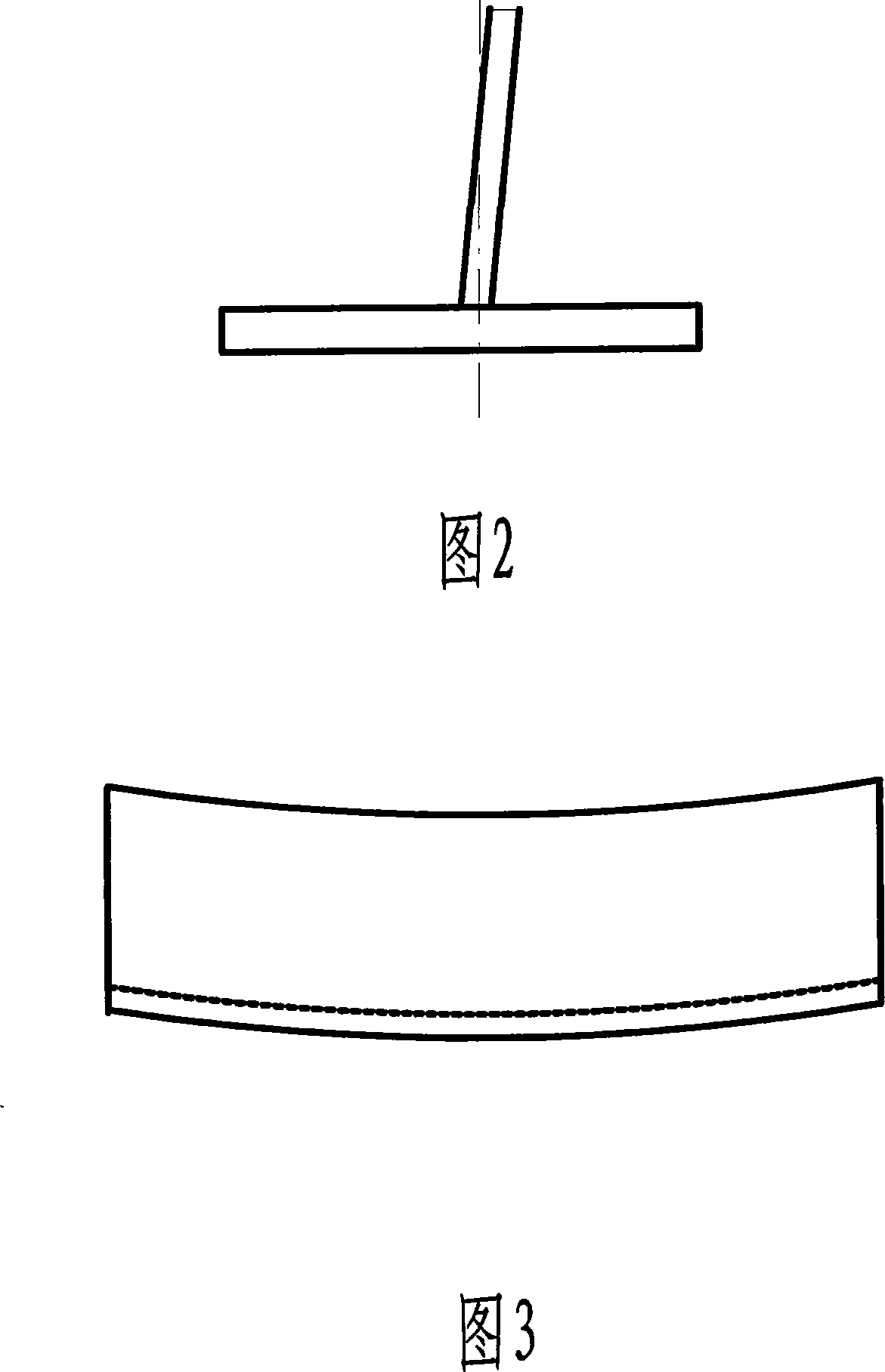

Extra-thick sheet submerged-arc welding technique

ActiveCN105057856ASmall amount of welding deformationReduce turning timesArc welding apparatusWelding/soldering/cutting articlesThick plateWelding residual stress

The present invention discloses an extra-thick sheet submerged-arc welding technique. The technique comprises the following technological parameters and steps: 1) connector preparation: X-type beveled edges are adopted by extra-thick sheets; 2) preheating: first heating a back side of an extra-thick sheet and then a front side of the extra-thick sheet, a preheating temperature being 150 DEG C to 160 DEG C, and a heating rate being not higher than 105 DEG / h; 3) backing welding: after preheating, using flux-cored wire gas shield welding for backing welding for two paths to form two layers, and using submerged-arc welding to fill at least two paths to form one layer, maintaining interlayer temperature to be not higher than 230 DEG C; 4) turning over after an inter-welding deformation is not larger than 6-8 mm; 5) backside welding: after carbon gouging and back chipping, backing welding according to the step 3) after the extra-thick sheet reaches a preheating requirement according to the preheating method described in the step 2); 6) stress relief treatment; and 7) carrying out post heating treatment at 200 DEG C / 2h after the welding, then slowly cooling the extra-thick sheet to be at the room temperature. With adoption of the technique provided by the present invention, rooting welding deformation is reduced, welding residual stress for subsequently filling a cover face is also reduced, and thus turn-over times in welding of the extra-thick sheet are reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

Metal inert gas (MIG) welding method of aluminum alloy thin plate for high speed train

InactiveCN103537784AReduce processIncrease productivityArc welding apparatusVehicle componentsSurface oxidationThin slab

The invention discloses a metal inert gas (MIG) welding method of an aluminum alloy thin plate for a high speed train. The method is characterized in that an ER5356 welding wire and 99.9% argon protective gas are selected to conduct single pass welding. The method includes the following steps: 1) surface machining of a workpiece to be welded; 2) MIG welding; 3) welding gap defect checking. The step 1) includes that the workpiece to be welded is not preheated, an organic solvent is directly adopted to remove grease dirt and dust on the surface of the workpiece to be welded, and a mechanical method is adopted to remove an oxidation film on the surface of the workpiece in a washing mode. The step 2) includes that weld heat input is controlled between 4.0KJ / cm and 5.0KJ / cm during MIG welding, and environment humidity is controlled to be smaller than or equal to 70%. The step 3) includes that pore defects of a welded workpiece are removed through a steel wire brush or an air chipper. The method has the advantage that thin plate aluminum alloy welding connector pore welding hot crack number can be greatly reduced, welding gap forming is good, welding deformation is small, welding connector strength is higher, the MIG welding quality of the aluminum alloy thin plate for the high speed train is effectively improved, and welding quality stability is ensured.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

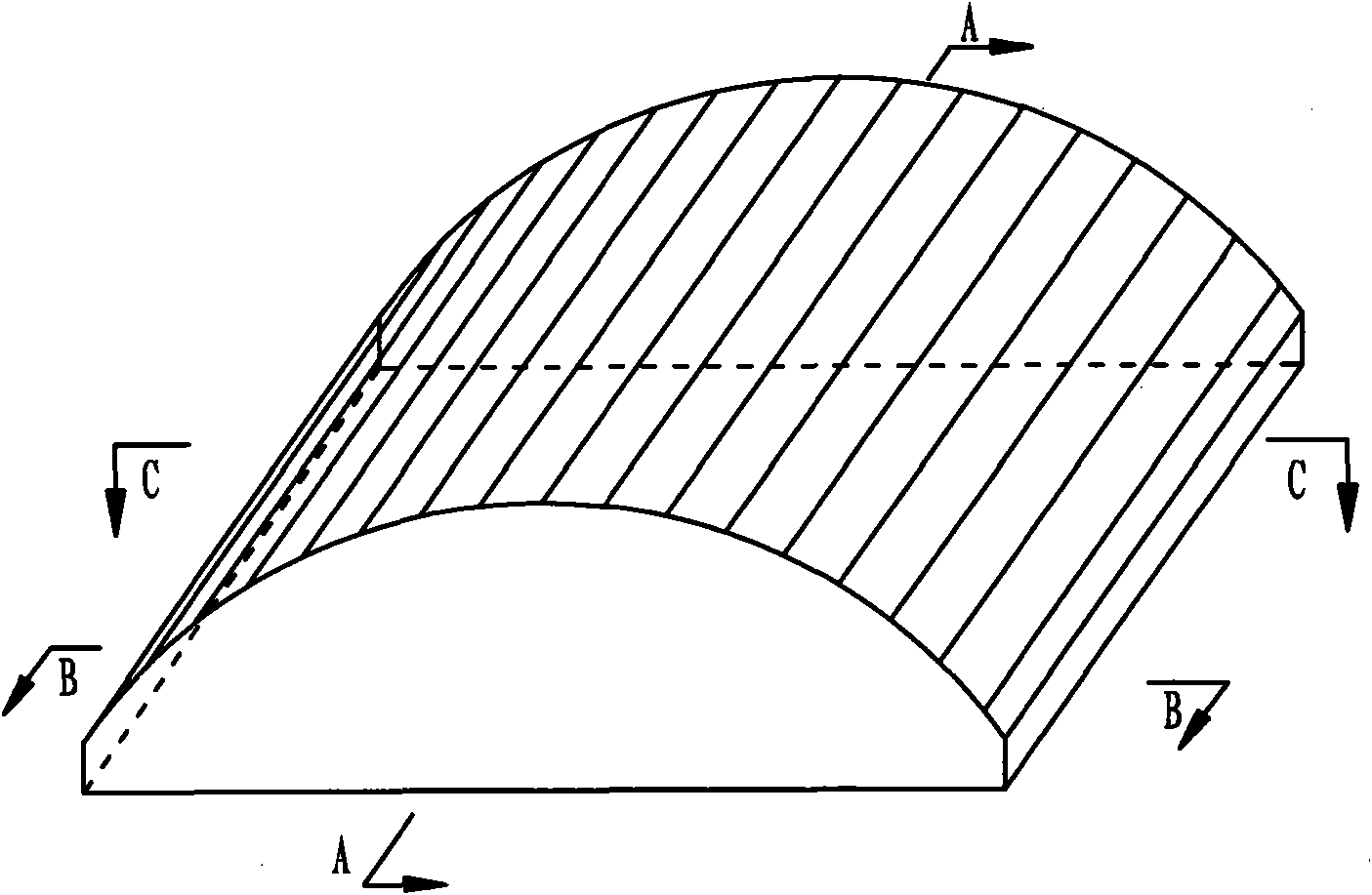

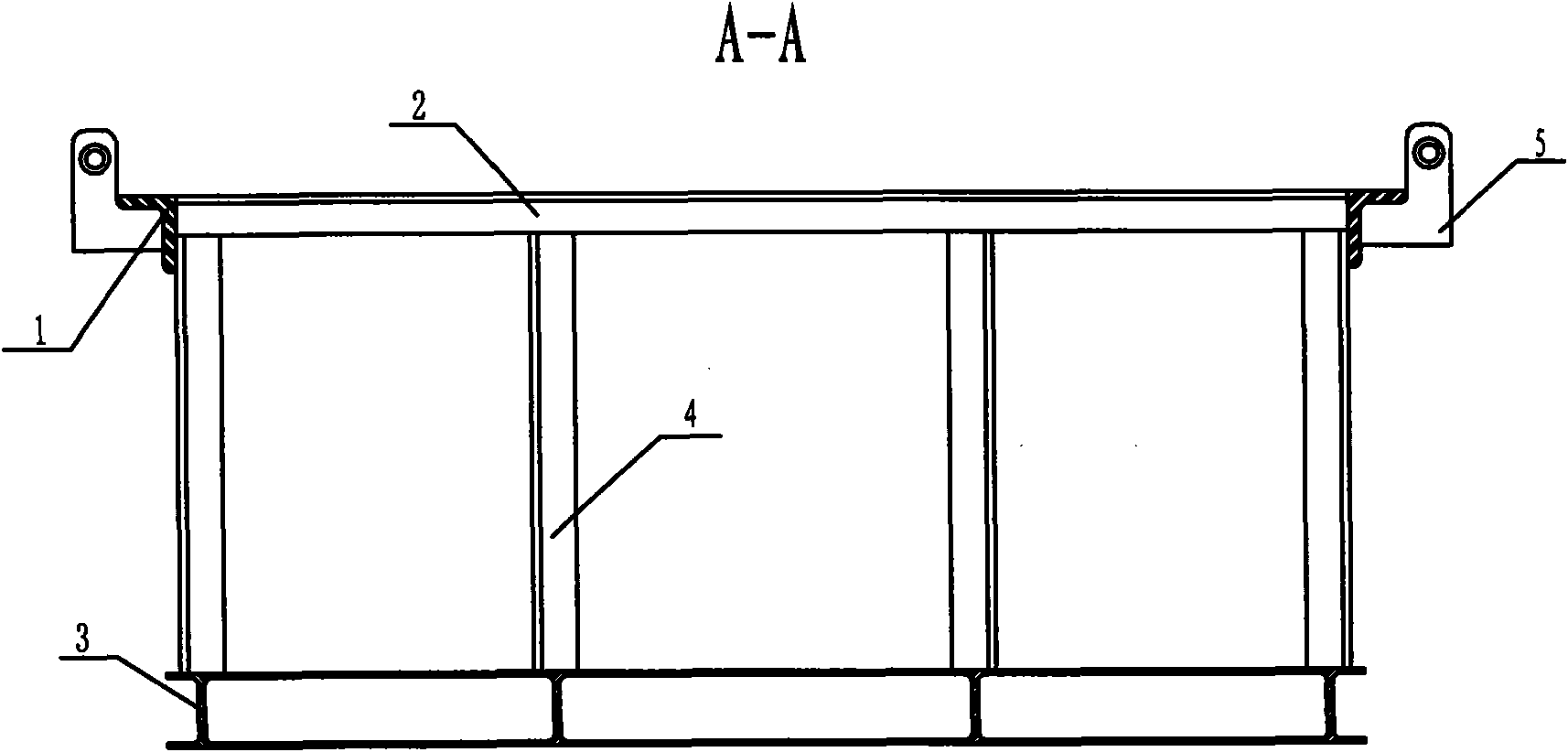

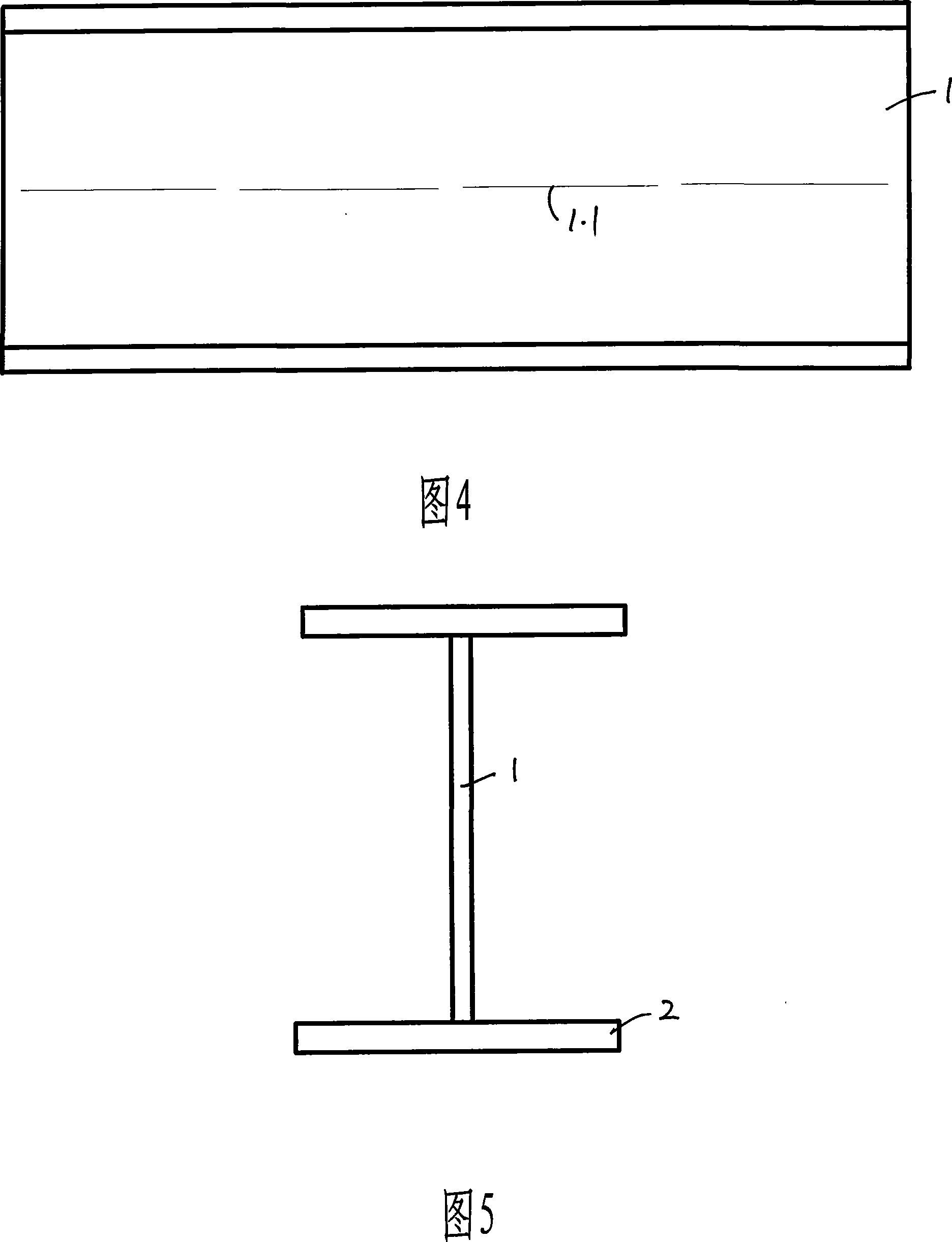

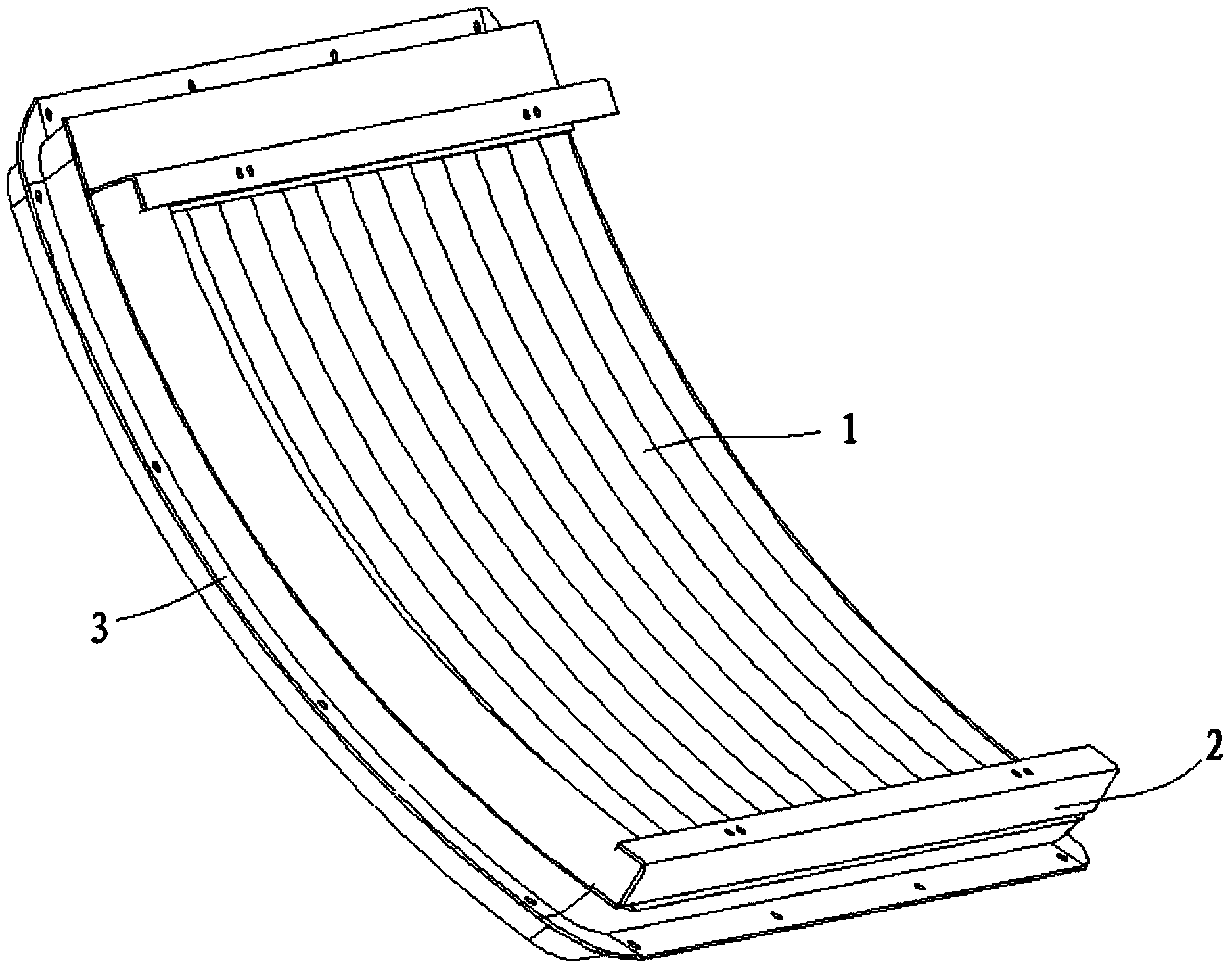

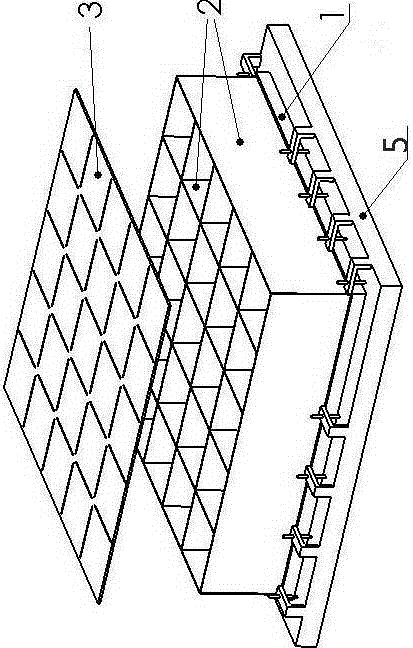

Preparation method of steel lining prefabricated moulding bed in nuclear power station

ActiveCN101913068AEnsure stabilitySmall amount of welding deformationBlock structureNuclear power plant

The invention relates to a preparation method of a prefabricated moulding bed, which is widely applied to steel lining prefabrication construction in a nuclear power station particularly and belongs to the technical field of construction of the nuclear power station. The preparation method comprises the following steps of, firstly, welding base H-shaped steel into a meshy block structure; welding an upright post on the meshy block structure; respectively welding longitudinal arc angle steel with a longitudinal upright post support, and welding traverse bus angle steel with a traverse upright post support respectively; and connecting the two upright post supports mutually to form a support structure. The process can effectively decrease the integral welding deflection, and is favorable for guaranteeing the integral stability of a construction member. The moulding bed structure prepared according to the steps can completely achieve the prefabricating precision of a nuclear island steel lining, meet the strict requirements on the level 1 nuclear quality and the nuclear safety, and guarantee the stability of production quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

MIG (metal inert-gas) welding method for aluminum alloy thick plates in high-speed trains

InactiveCN103521900AEnsure the stability of welding qualityImprove welding qualityArc welding apparatusWelding/cutting media/materialsSurface oxidationWelding defect

The invention discloses an MIG (metal inert-gas) welding method for aluminum alloy thick plates in high-speed trains. The method using ER5356 welding wires and 99.9% protective argon gas for multiple welding includes the steps: 1, preheating a work piece before welding at the temperature of 70-90 DEG C; 2, treating the surface of the work piece to be welded, removing oil stain and dust on the surface of the work piece to be welded with organic solvent, and clearing surface oxide film from the work piece to be welded by mechanical means; 3, controlling welding wire energy to range from 7.0KJ / cm to 9.0KJ / cm, ambient humidity to be not larger than 70%, and interlayer temperature to be between 70 DEG C and 90 DEG C; 4, checking the weld defect, checking the weld after each single welding, removing checked weld pores with wire brushes or air chippers, and performing next welding then. The method has the advantages that welds form well, welding deformation is little, welded joints are high in strength, MIG welding quality of the aluminum alloy thick plates in high-speed trains is improved effectively, and welding quality stability is guaranteed.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Semi-automatic tool for intelligent welding of connection section of belt A type coal feeder

ActiveCN108581283AEasy to carryEasy to operateWelding/cutting auxillary devicesOther manufacturing equipments/toolsSemi automaticEngineering

The invention belongs to the technical field of mechanical coal manufacturing equipment and relates to a semi-automatic tool for intelligent welding of a connection section of a belt A type coal feeder. Lower mounting holes in the two ends of angle steel are matched with two positioning pins; pressing quick pincers are used for pressing the angle steel; a steel plate is placed on a raising surfaceof a positioning block; a first side surface clings to a positioning surface of the positioning block; a second side surface clings to a positioning surface of the steel plate and an upright side ofthe angle steel; vertical plate positioning pins are correspondingly inserted into two upper mounting holes in the two ends; and wrenching quick pincers are used for wrenching the first side surface.According to the semi-automatic tool provided by the invention, a small work piece is firstly drilled before welding, the specification of drilling equipment is reduced, fund occupation quantity is reduced, and the small work piece is convenient to transfer and operate; precise positioning is realized; the location degree tolerance of a finished fixing hole is guaranteed by virtue of the precisionof the tool; the welding deformation degree can be reduced as far as possible by virtue of symmetric welding; the workload of a worker is greatly reduced; the dependence on skills of the worker is reduced; and the labor cost is lowered.

Owner:新昌县北联建筑工程有限公司

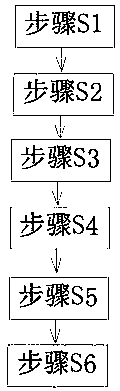

A railway vehicle chassis floor welding process

ActiveCN106607638ASmall amount of welding deformationReduce welding distortionWelding/cutting auxillary devicesArc welding apparatusWelding processChassis

The invention relates to a railway vehicle chassis floor welding process which comprises the steps of: firstly, cleaning section bars for a chassis floor; secondly, locating the section bars for the chassis floor: successively locating a second side beam, the floor section bars and a first side beam, and adjusting the gaps between the section bars to make the gaps uniform; thirdly, installing a run-on plate and a run-off plate; fourthly, performing tack welding, wherein the length of tack welds is kept to be 80-100mm, and in the length direction, the spacing distance between adjacent tack welds is 1000-2500mm; fifthly, performing reserve automatic welding: setting the welding parameters of an IGM automatic welding robot reasonably, and using double guns to perform welding crosswise according to the order of firstly welding the first weld and the fourth weld, secondly welding the second weld and the fifth weld and thirdly welding the third weld and the sixth weld; sixthly, performing overall turning: turning the chassis floor wholly; seventhly, performing frontal welding on the chassis floor: completing frontal automatic welding according to the fifth step; eighthly, performing overall adjustment on the chassis floor.

Owner:丛林铝业科技(山东)有限责任公司 +1

Spiral seam submerged-arc welded pipe butt joint process

ActiveCN103008999ASimple designIncrease automatic submerged arc weldingArc welding apparatusSlag (welding)Butt joint

The invention discloses a spiral seam submerged-arc welded pipe butt joint process and relates to the technical field of a spiral seam submerged-arc welded pipe. The process comprises the processing procedures of pipe end rounding, pipe end chamfering, steel pipe butt joint, prewelding, inner welding, outer welding, repair welding and circular seam nondestructive inspection. Compared with the traditional manual welding single-side welding double-sided forming process, the spiral seam submerged-arc welded pipe butt joint process has the advantages that the problems of welding quality stability influence and the like caused by great probability generation of defects such as air holes, slag clamping and cracks in the welding seam of the manual welding are solved, the butt joint quality and the efficiency of a steel pipe are greatly improved, the material consumption and the production cost can be greatly reduced, the field construction operation is convenient, and the batch production capability for producing butt joint pipes meeting API5L and relevant standard requirements is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Electronic beam welding method of sealing thin-wall aluminium alloy frame

ActiveCN102500905ASmall amount of welding deformationReduce machining timeElectron beam welding apparatusAluminium alloyRobot welding

The invention relates to an electronic beam welding method of a sealing thin-wall aluminium alloy frame, which comprises the following steps that: a, before a cover board and the upper opening of a cavity are welded, a circular table is firstly added around the opening of the cavity, and the cover board is assembled in the circuit table in an interference fit way; b, during welding, welding parameters are adjusted, then, positioned welding of positioned welding points is carried out along the interval of 5-10mm of a welding seam, during the positioned welding, the mode of firstly temporarily welding shot welding seams and then temporarily welding long welding seams is taken as a principle; and c, during electronic beam welding, a circle of welding is carried out clockwise or anticlockwise along the welding seams from the positioned welding points of a short side, and scanning welding is added in the electronic beam welding parameters, the welding seams which are subject to butt welding are subject to secondary modified welding so as to reduce welding defects. The invention has the beneficial effects that the purposes of reducing welding deformation quantity and shortening following mechanical processing time are realized; and by carrying out modified welding to the welding area, the quality of the welding seams is improved, the intergranular structure of the heat influence area is improved, the skeleton strength of the sealing thin-wall aluminium alloy frame is ensured, and the production efficiency is greatly improved.

Owner:ZHENGZHOU AIRCRAFT EQUIP +1

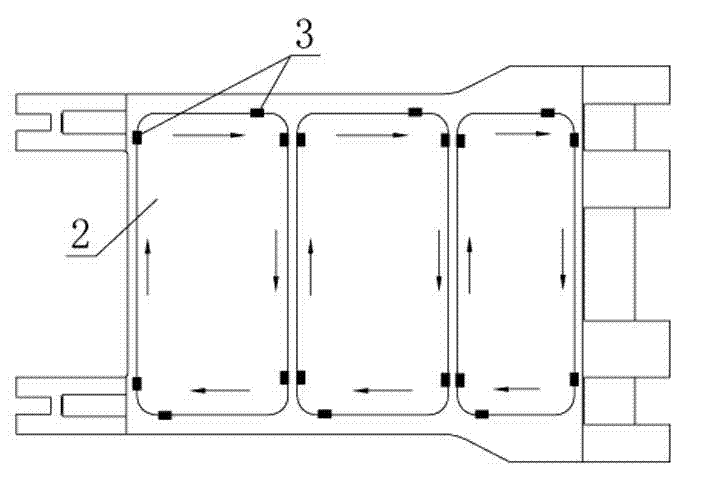

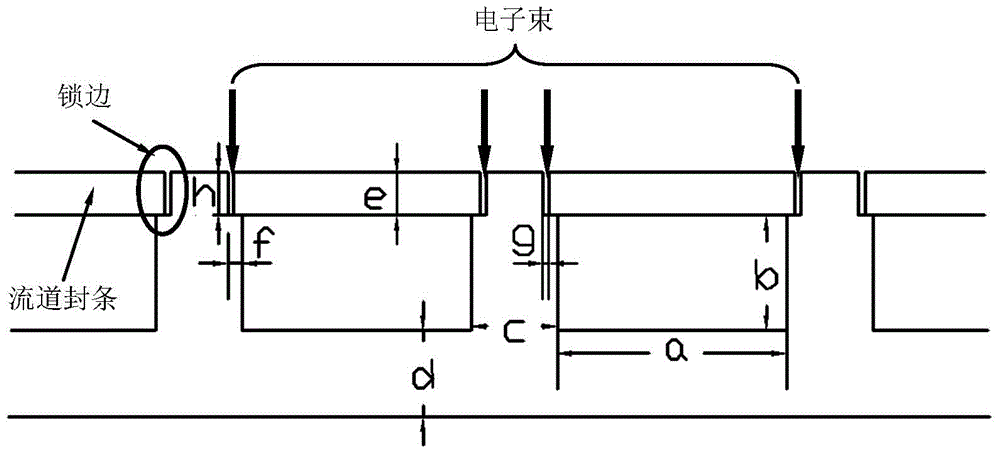

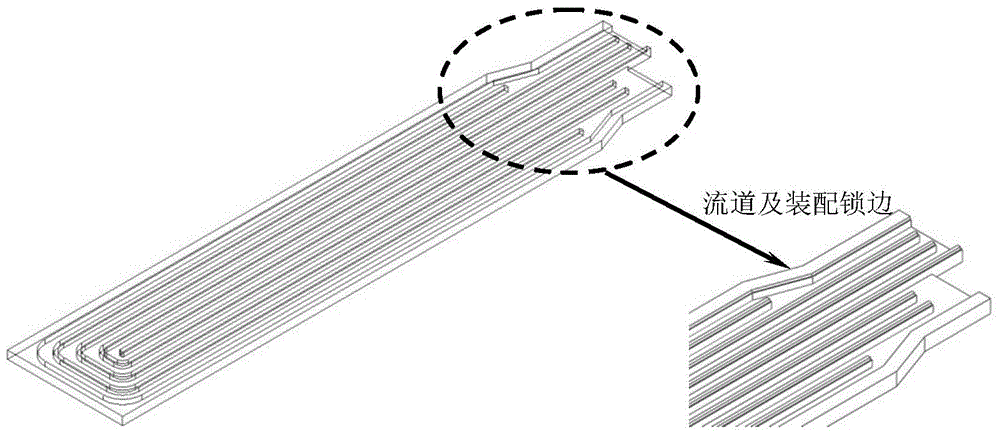

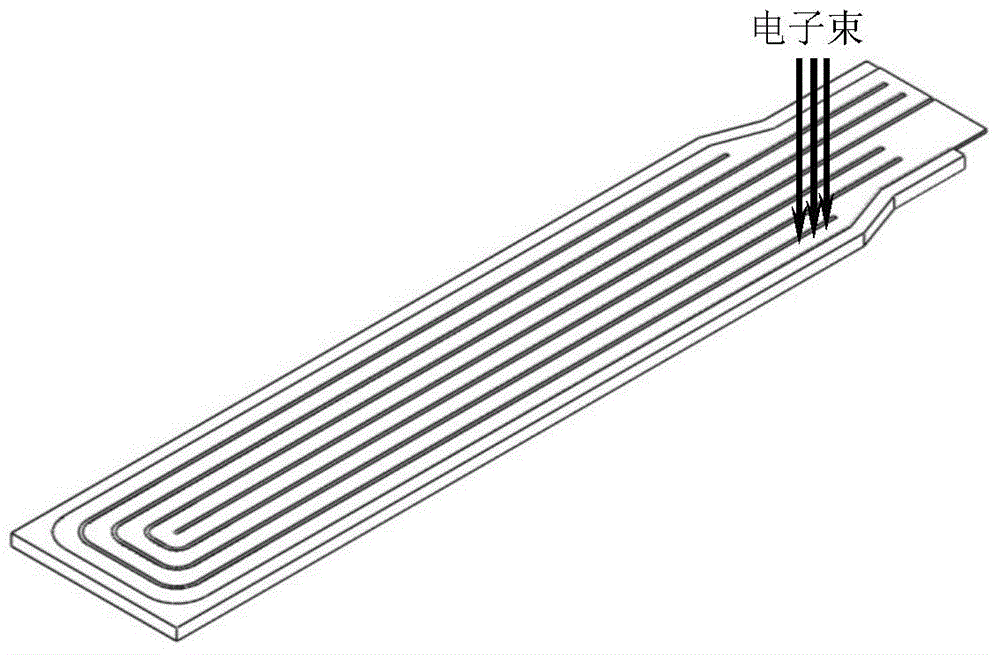

Electron beam welding process suitable for encapsulation molding of martensitic steel high-density runner

ActiveCN104400203AImprove performanceLarge amount of deformationElectron beam welding apparatusWelding/soldering/cutting articlesHigh densityBiological activation

The invention discloses an electron beam welding process suitable for encapsulation molding of a martensitic steel high-density runner. The process comprises such steps as size design of a runner seal and an assembly lockrand, demagnetization and cleaning of parts, weld preheating, electron beam welding of the seal, excess weld metal processing of the seal and annealing heat treatment. The electron beam welding process suitable for encapsulation molding of a cooling part runner of the martensitic steel high-density runner has such advantages as good runner molding, no such defects as air holes and cold / hot cracks and small welding deformation, solves the problems of easy cracking of an encapsulation welding line and big welding deformation of the martensitic steel high-density runner, and can be suitable for encapsulation molding of low-activation martensitic steel high-density and narrow-gap runners.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

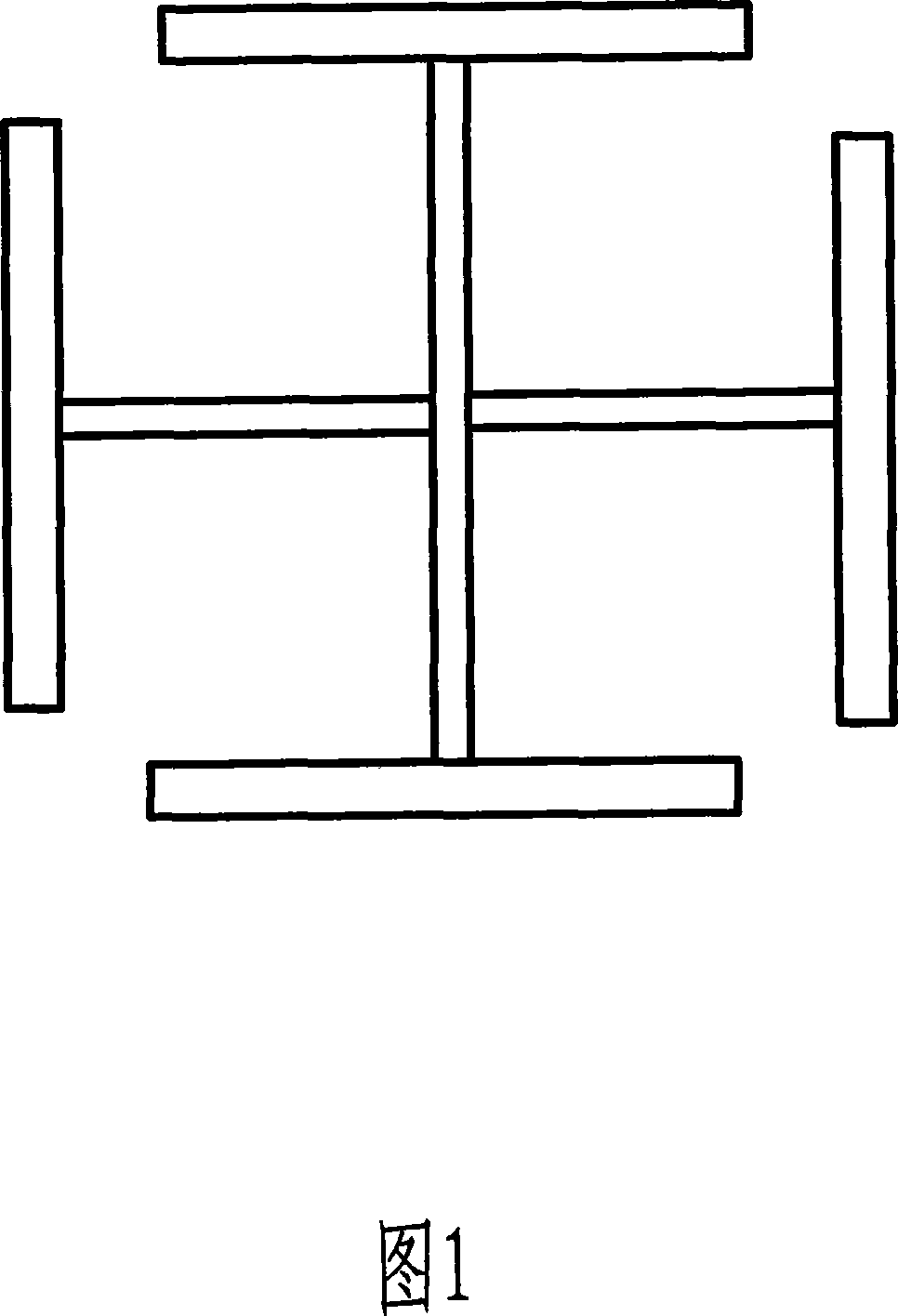

Method for preparing plate-patched cross-column

InactiveCN101122160AParallel goodGood perpendicularity to the webStrutsPillarsEngineeringImproved method

The invention relates to an improved method of making a steel structure plate assembly crisscrossed post, which is characterized in that the single components are made by first assembling and welding two H-shaped bars, and then cutting one of the two H-shaped bars into two same T shapes along the center of a web plate; during assembly, welding and shaping, the two same T shapes cut are welded and fixed in the H-shaped bar web plate through diagonal alternation and circulation. The method of the invention changes the ordinary practice of the prior art by first making two H-shaped bars and then cutting one of the H-shaped bars; in this way, two faces of the T-shaped are in parallel and are well vertical to the web plate, so as to reduce the welding deformation of transverse plates and vertical plates and effectively ensure the verticality between wing plates and the web plate, straightness and torsion resistance of the assembly bars. And upon final assembly and welding, through diagonal alternation and circulation welding, the assembly deformation is reduced and 100 percent hole correction can be achieved basically without need of extra calibration, which greatly improve the on-site assembly production efficiency.

Owner:江苏美凯龙钢业有限公司

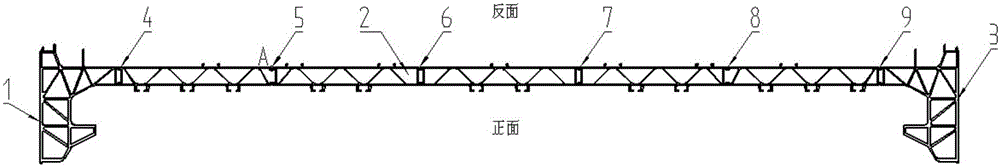

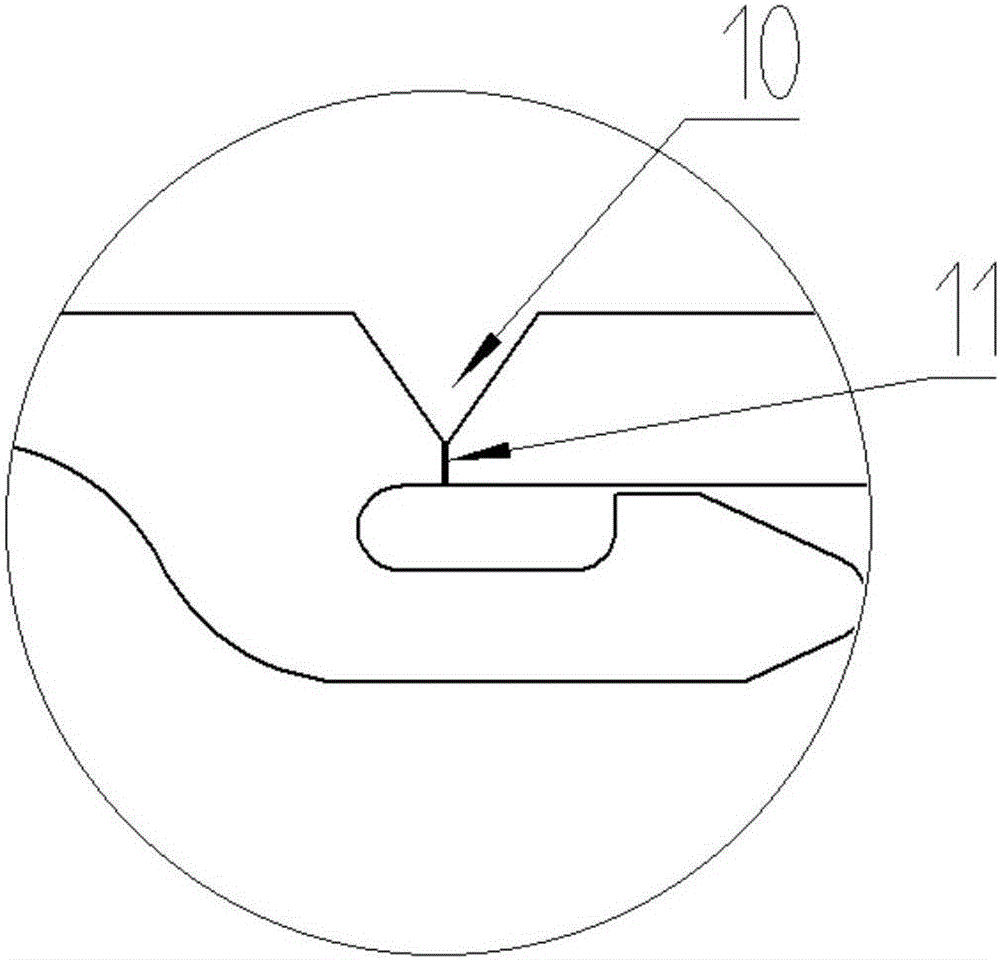

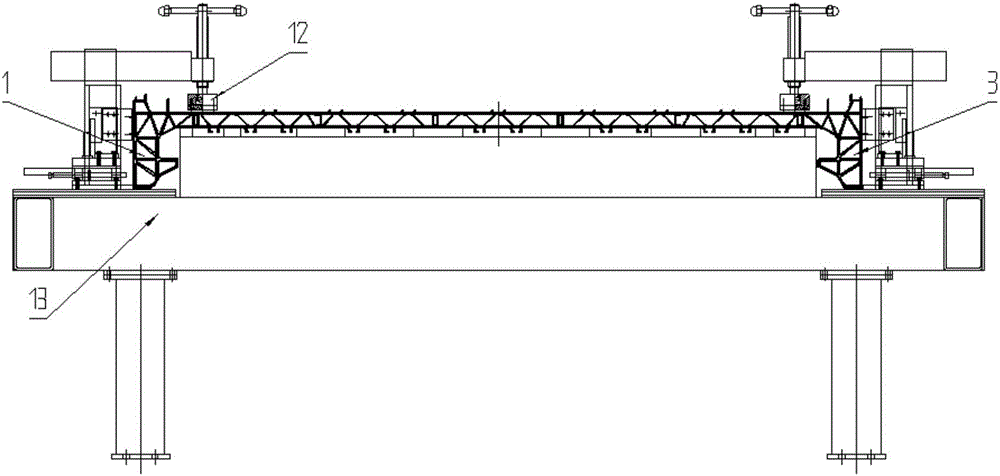

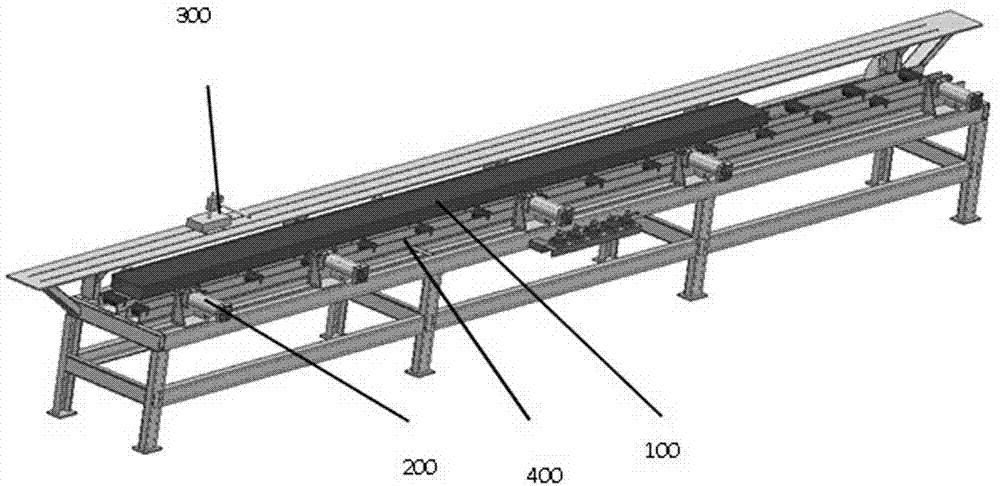

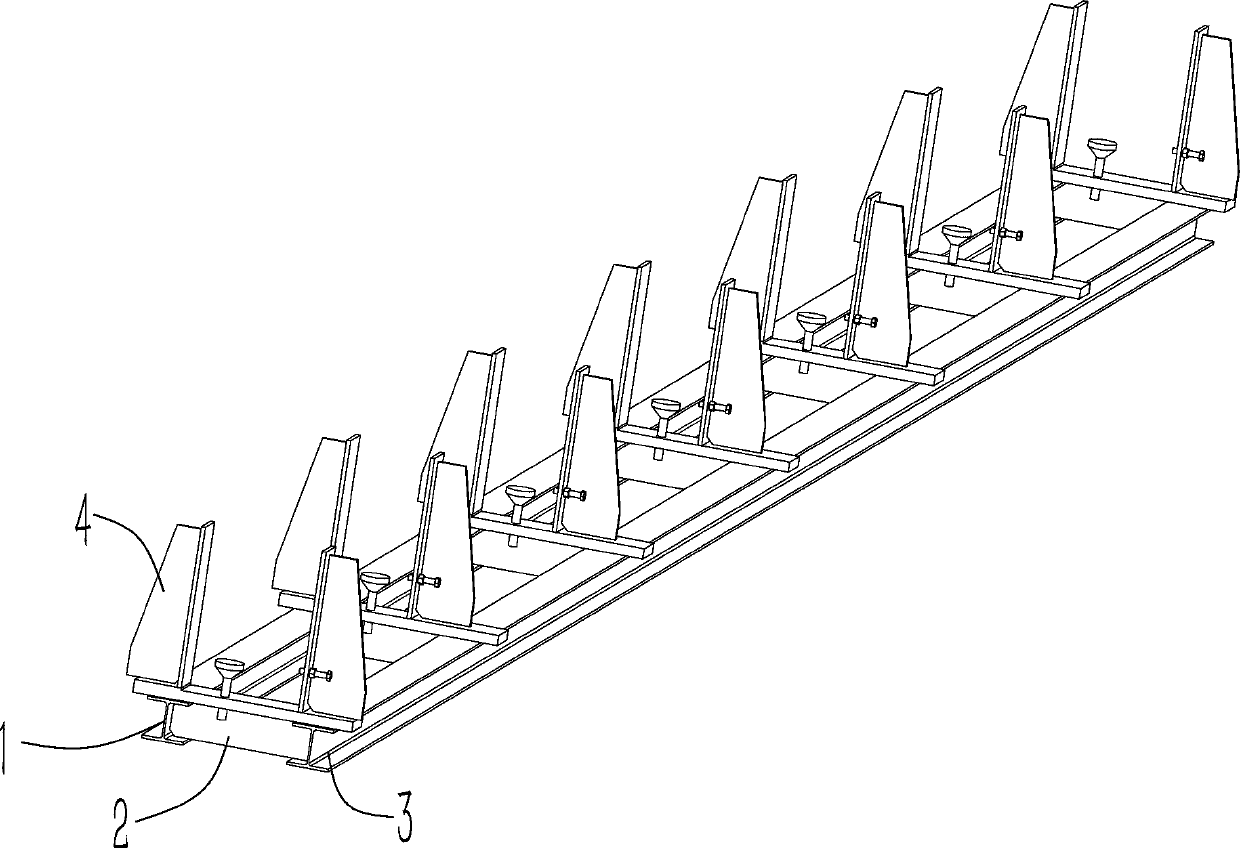

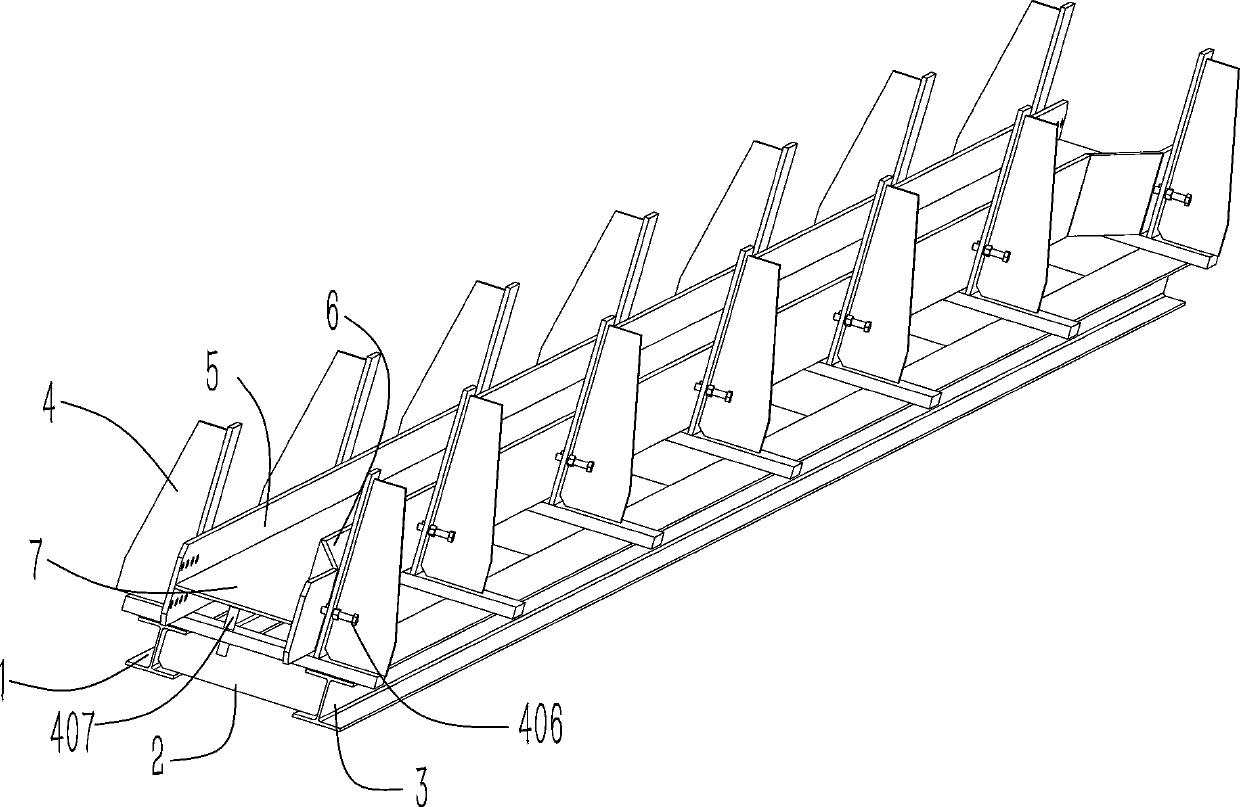

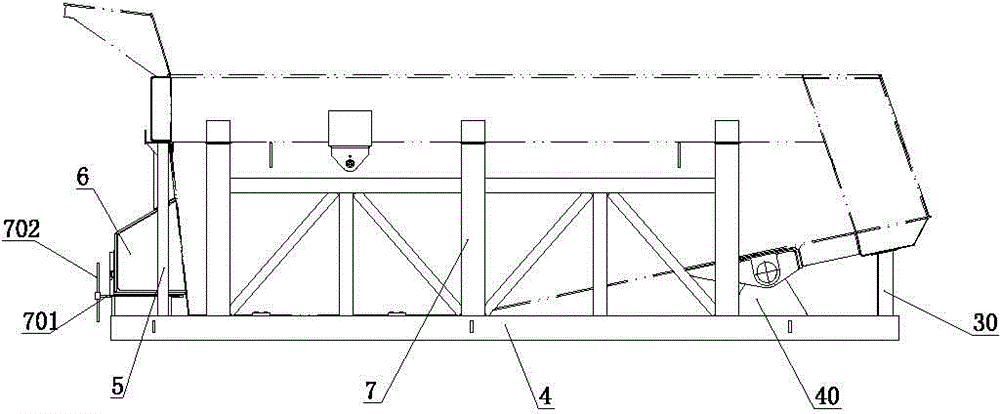

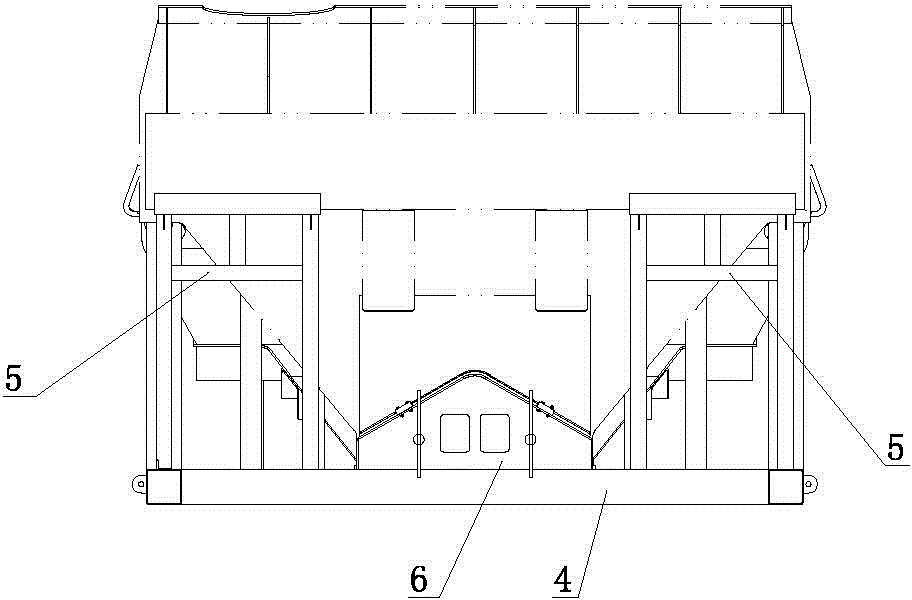

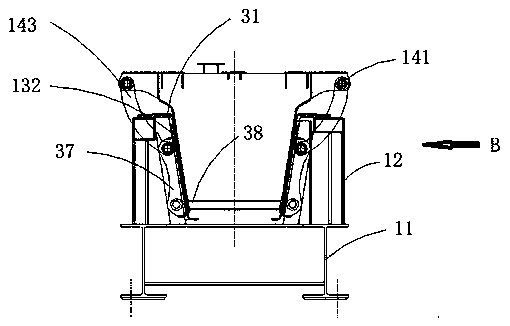

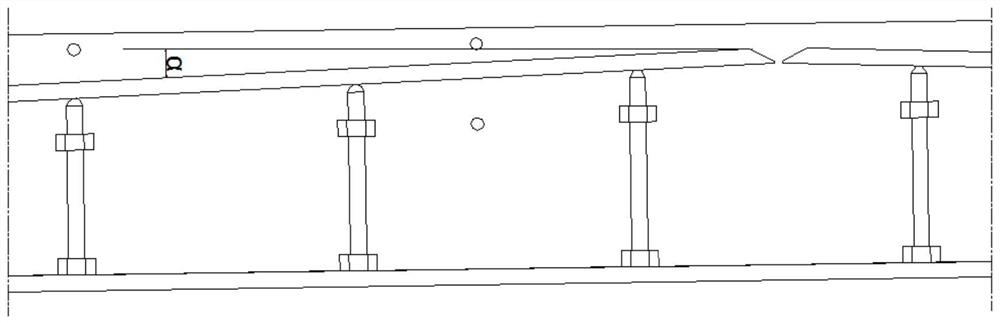

Large box beam welding platform and welding method

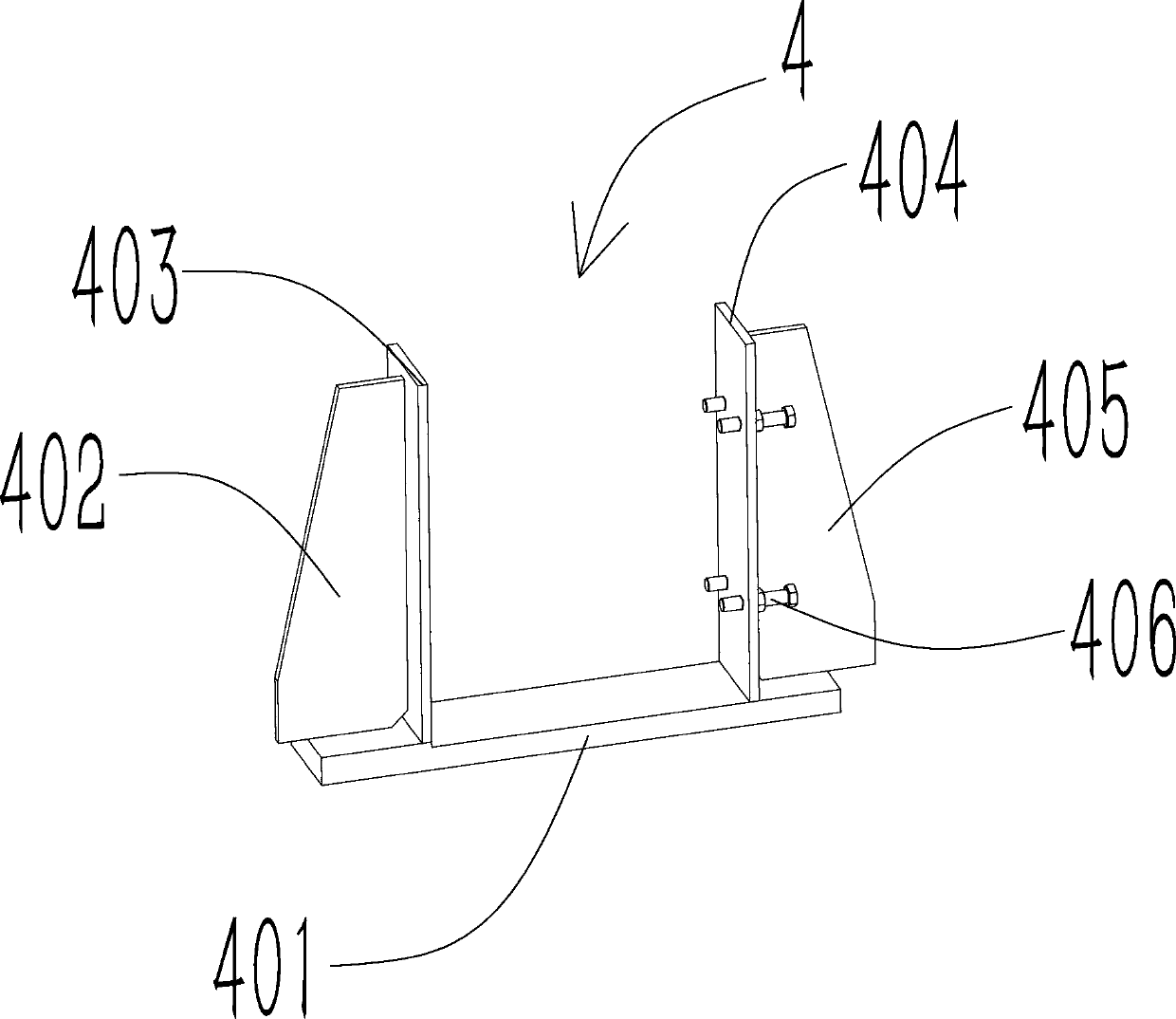

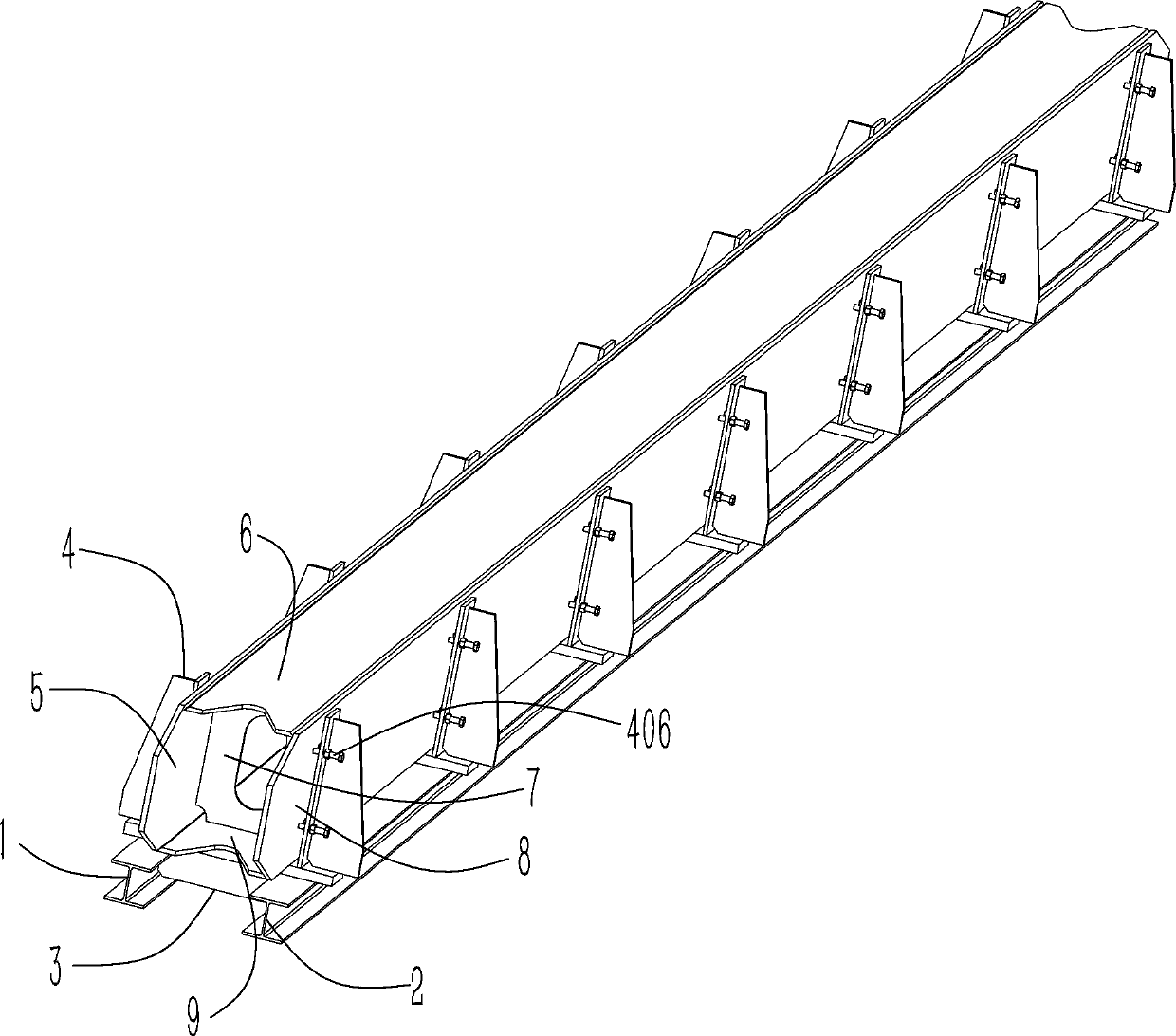

PendingCN110900081AGuaranteed stabilityGuaranteed verticalityWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding deformation

The invention provides a large box beam welding platform and a welding method. The large box beam welding platform comprises first I-shaped steel and second I-shaped steel which are placed in parallel, wherein a plurality of connecting plates are arranged between the first I-shaped steel and the second I-shaped steel; the first I-shaped steel and the second I-shaped steel are connected through theplurality of connecting plates; positioning devices are arranged above the connecting plates; a large box beam is placed in the positioning devices and is fixed through bolts; the plurality of positioning devices are uniformly arranged on the basis of the two I-shaped steel, so that the positioning devices are ensured to be positioned on the same horizontal plane; a first vertical plate and a second vertical plate in each positioning device are perpendicular to a transverse plate, so that the stability and the connectivity during welding are ensured; the large box beam is placed on the platform, so that the perpendicularity and the parallelism between the plates during welding can be ensured; the locking and the fixing are firm, the welding deformation is small, the tool positioning and clamping are achieved, and the size is welded in place in one step; and the flatness and the straightness of the welded beam are qualified in one-time acceptance, so that the large box beam welding platform is suitable for popularization and use.

Owner:YICHANG JIANGXIA MARINE MACHINERY

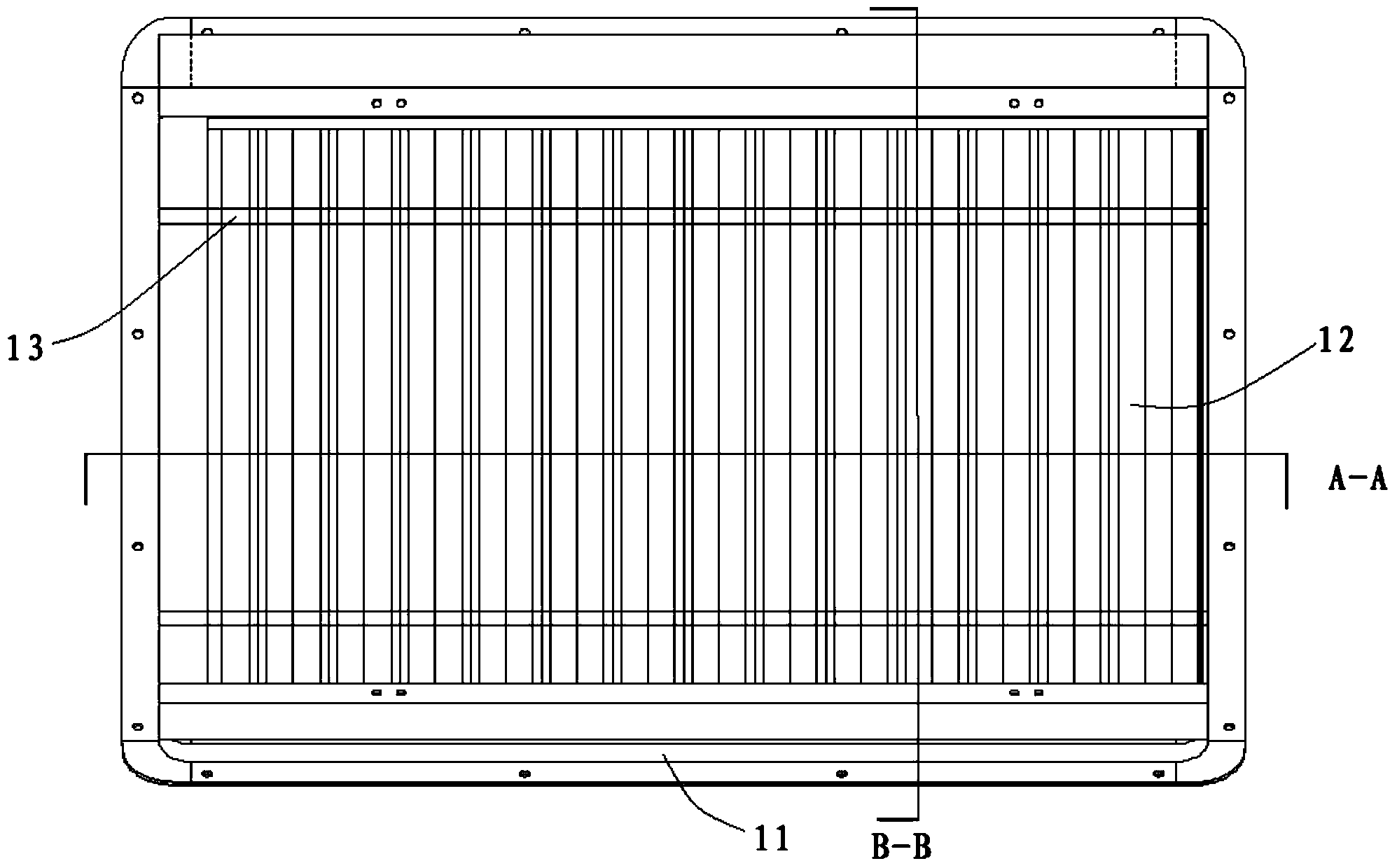

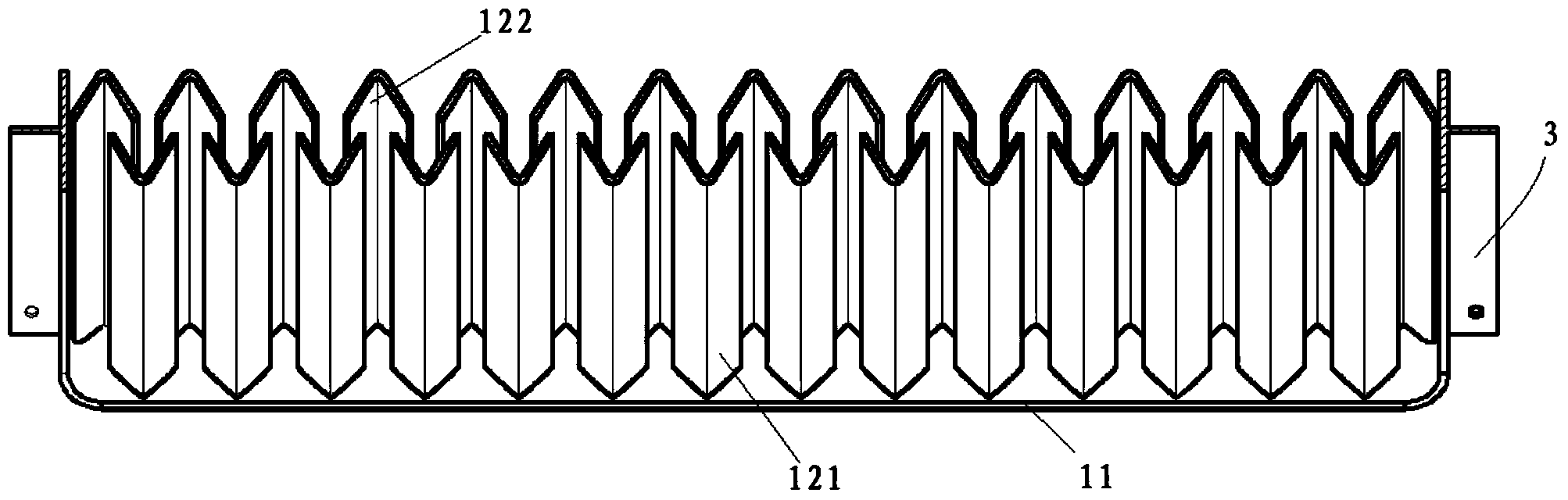

Aluminum alloy grating and welding process thereof

ActiveCN103978945ASmall amount of welding deformationLow costWelding/cutting auxillary devicesArc welding apparatusSpot weldingWelding deformation

The invention discloses an aluminum alloy grating which comprises a grating body and a filter frame. The grating body comprises a frame and multiple V-shaped strips. The multiple V-shaped strips are parallel to one another and comprise the upper V-shaped strips and the lower V-shaped strips. Notches of the upper V-shaped strips are opposite to notches of the lower V-shaped strips. The two ends of each upper V-shaped strip and the two ends of each lower V-shaped strip are fixed to the inner wall of the frame in a welding mode. The filter frame is fixed to the side wall of the frame in a welding mode. Reinforcing ribs are arranged between the upper V-shaped strips and the lower V-shaped strips in the direction perpendicular to the V-shaped strips. The reinforcing ribs are connected with the notches of the upper V-shaped strips and the notches of the lower V-shaped strips respectively in a spot welding mode. The two ends of each reinforcing rib are fixed to the inner wall of the frame in a welding mode. The invention further discloses a method for welding the aluminum alloy grating. According to the process for welding the aluminum alloy grating, by means of adjusting welding process steps and welding process parameters, the welding deformation can be lowered substantially, the rate of finished products is increased, cost is lowered, and production efficiency is improved.

Owner:忠旺(辽阳)铝模板制造有限公司

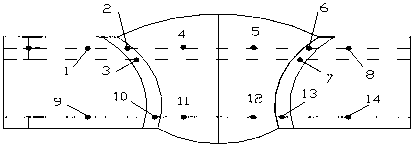

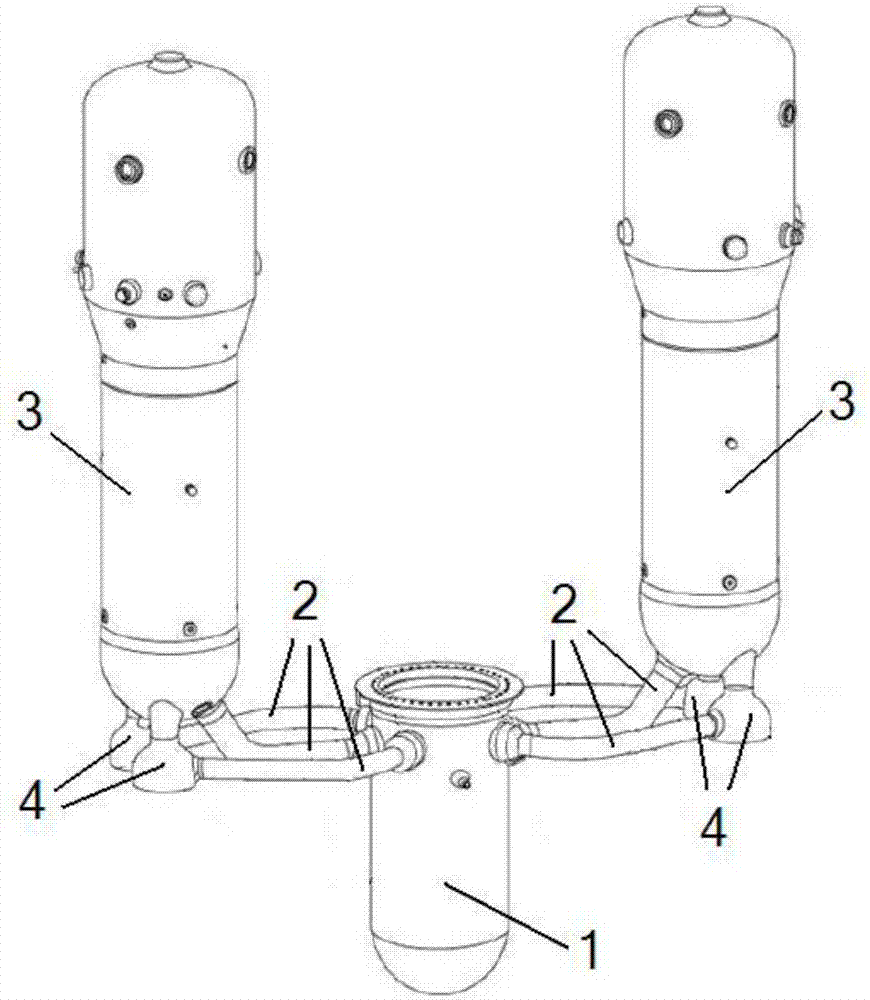

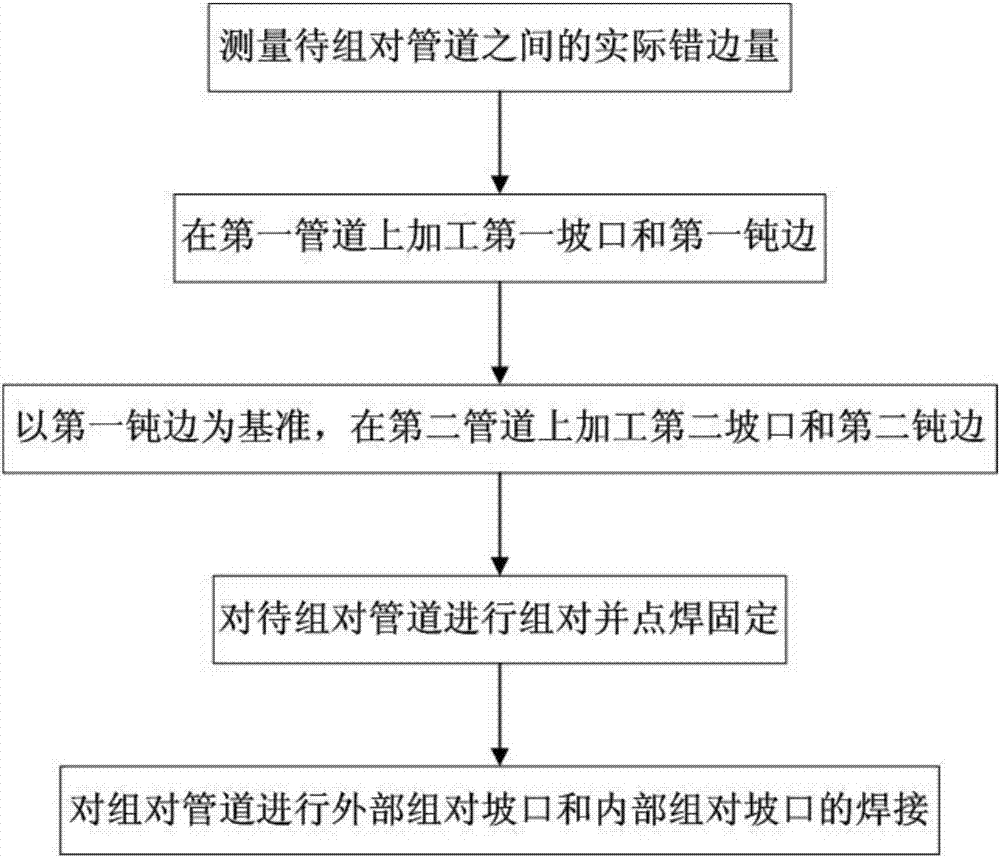

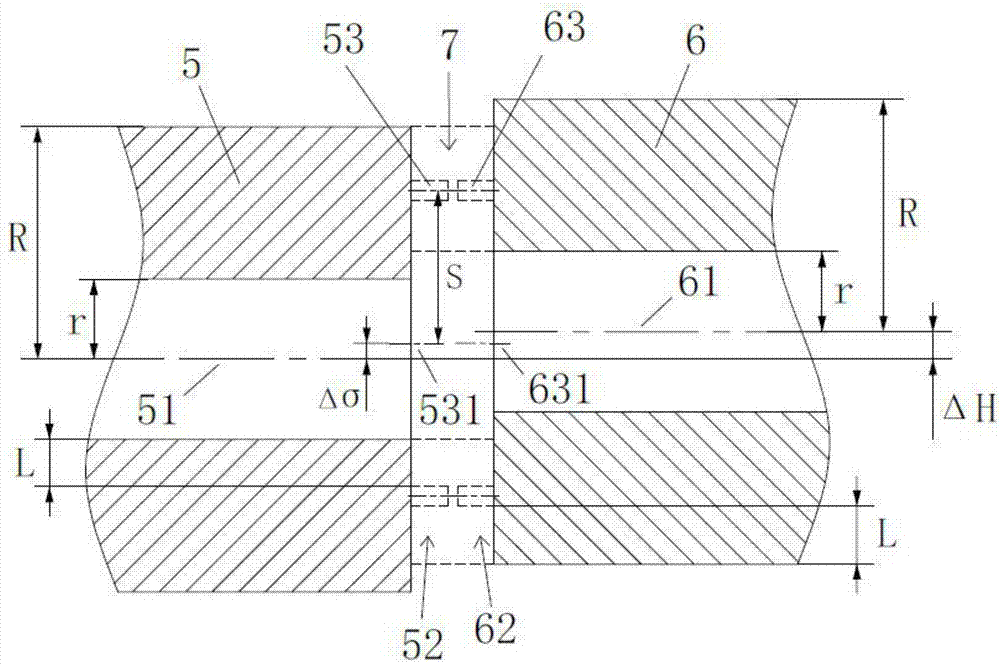

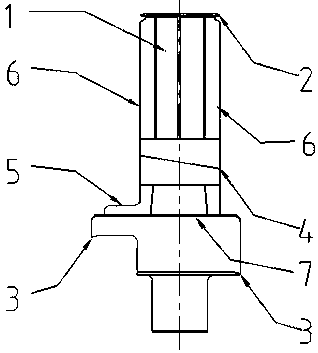

Pipeline assembly welding method

ActiveCN106862785AFast and accurate pairing operationIncrease the misalignment marginWelding/cutting auxillary devicesAuxillary welding devicesSimulationSpot welding

The invention belongs to the field of pipeline construction. In order to solve the problems that in the prior art, a method of expanding the pipeline inner diameter size or using an assembly tool is adopted to carry out assembly welding operation on pipelines with the large alignment tolerance, and the potential safety hazard exists in the use of the pipelines, the brand-new pipeline assembly welding method is provided. The method comprises following steps: firstly, the actual alignment tolerance between assembled pipelines is measured; secondly, a first groove and a first blunted edge are machined on the first pipeline; thirdly, a second groove and a second blunted edge are machined on the second pipeline; fourthly, the assembled pipelines are subject to assembly and spot welding fixing; fifthly, the assembled pipelines are subject to welding of outer assembled grooves and inner assembled grooves. Therefore, according to the actual alignment tolerance between the assembled pipelines, the size and the position of the blunted edges are adjusted, the sizes and the positions of the assembled blunted edges between the assembled pipelines are kept consistent, and therefore rapid and accurate assembling between the assembled pipelines can be achieved.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

Welding device for longitudinal beam of underframe of carriage of dumper truck

InactiveCN103753036ASmall amount of welding deformationBeautiful weldWelding/cutting auxillary devicesAuxillary welding devicesTruckWeld line

A welding device for a longitudinal beam of an underframe of a carriage of a dumper truck is used for changing the welding mode of the longitudinal beam of the underframe of the carriage. The welding device of the longitudinal beam of the underframe of the carriage of the dumper truck comprises an air cylinder used to tightly clamp the longitudinal beam of the underframe, a welding tractor used to weld a welding line on the longitudinal beam of the underframe, and an electric device to control the moving of the welding tractor, wherein the electric device is used to protect the welding tractor to automatically move and weld. According to this arrangement, the welding mode is changed; therefore, the deformation of the welding is small, the welding line is beautiful, and the welding efficiency is improved.

Owner:LIUZHOU CHENGLONG SPECIAL PURPOSE VEHICLE CO LTD

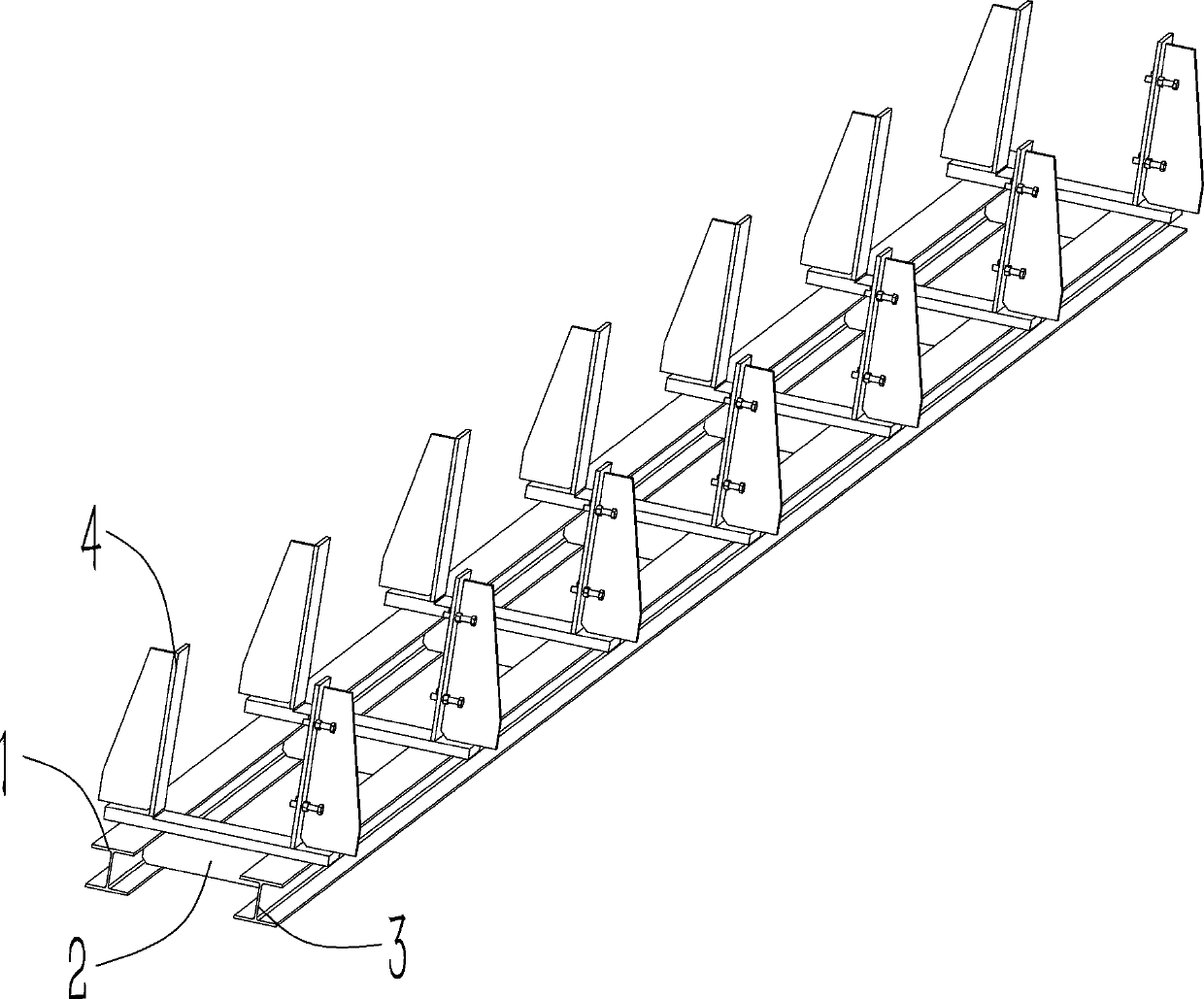

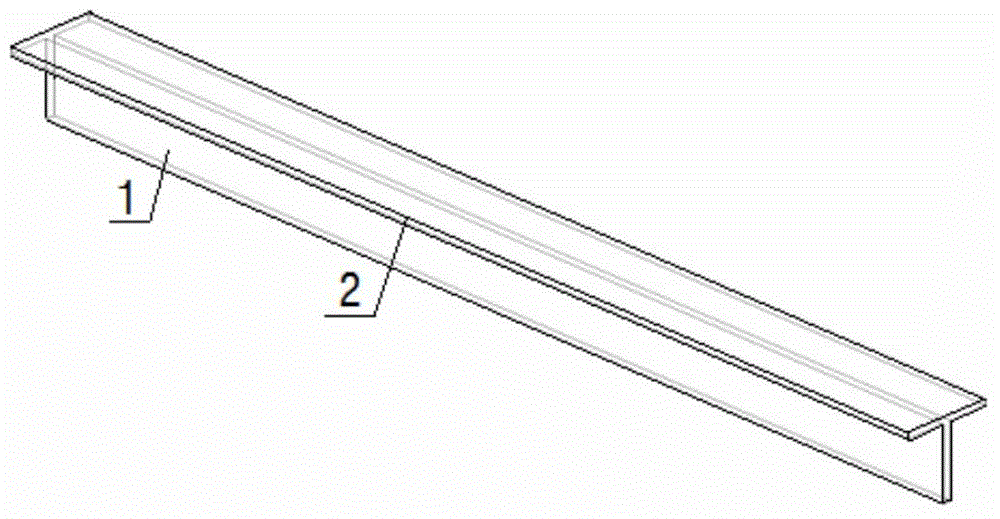

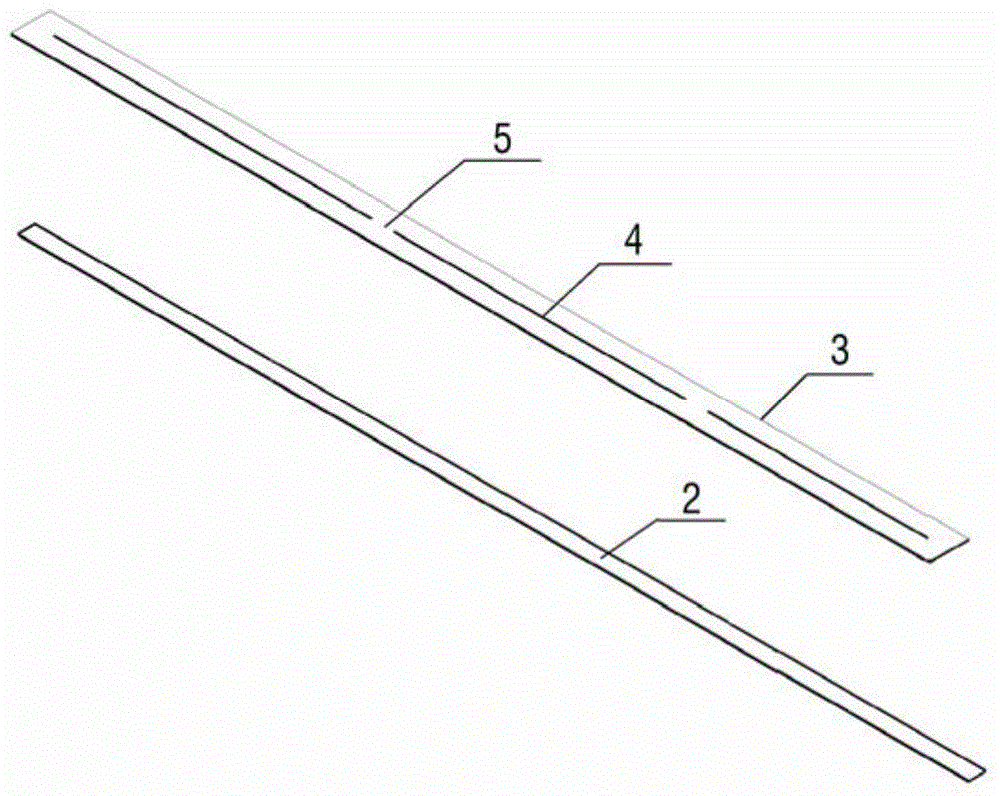

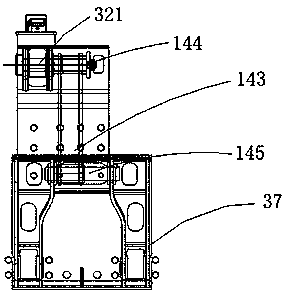

Large I-shaped beam welding platform and welding method

PendingCN110900082AGuaranteed stabilityGuaranteed verticalityWelding/cutting auxillary devicesArc welding apparatusShaped beamStructural engineering

The invention provides a large I-shaped beam welding platform and a welding method. The large I-shaped beam welding platform comprises first I-shaped steel and second I-shaped steel which are placed in parallel; multiple connecting plates are arranged between the first I-shaped steel and the second I-shaped steel; the first I-shaped steel and the second I-shaped steel are connected through the multiple connecting plates; positioning devices are arranged on the connecting plates respectively; a large I-shaped beam profile is placed in the positioning devices, the end surface of the large I-shaped beam profile is supported by cushion blocks, and the side surfaces of the large I-shaped beam profile are locked and fixed by bolts; all the positioning devices are ensured to be in one horizontalplane, a first vertical plate and a second vertical plate in each positioning device are perpendicular to a transverse plate, and the bolt on the second vertical plate are used for locking the right side plate of the large I-shaped beam; and by placing the large I-shaped beam on the platform, the perpendicularity and the parallelism between two plates during welding can be ensured, locking and fixing are firm, the welding deformation quantity is small, tool positioning and clamping are achieved, and mounting and welding in size are achieved into place with one step.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Frame-type car body rear compartment structure and welding method

ActiveCN109501867AControl welding deformationGuarantee welding qualityWelding/cutting auxillary devicesSuperstructure subunitsEngineeringWeld seam

The invention relates to a frame-type car body rear compartment structure and a welding method. The structure comprises a first side assembly at the rear portion of a car body, a second side assemblyat the rear portion of the car body, a first cross beam assembly at the rear portion, a second cross beam assembly at the rear portion, a battery box frame fixing assisting beam, a storage battery cross beam and a process beam, wherein the process beam is mounted between the bottom of the first side assembly at the rear portion of the car body and the bottom of the second side assembly at the rearportion of the car body. According to the structure and the welding method, the welding quality of a rear compartment of the car body and a welding process for welding deformation can be effectivelycontrolled, the repair quantity and size adjustment of welding seams are reduced, the welding seam quality and structural size of the rear compartment of the car body are ensured, the production efficiency is improved, and the qualification rate of products is increased.

Owner:CH AUTO TECH CORP CO LTD

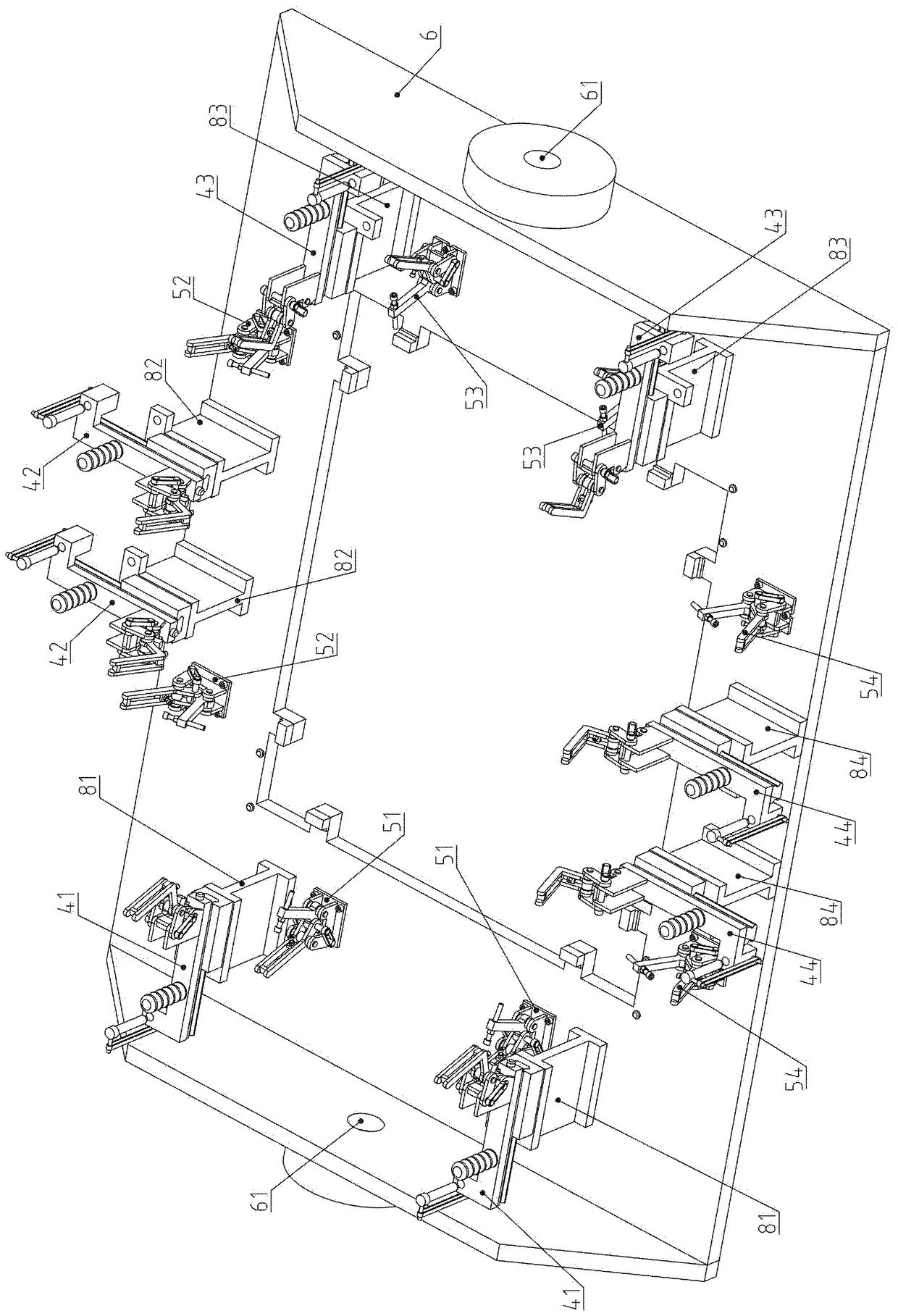

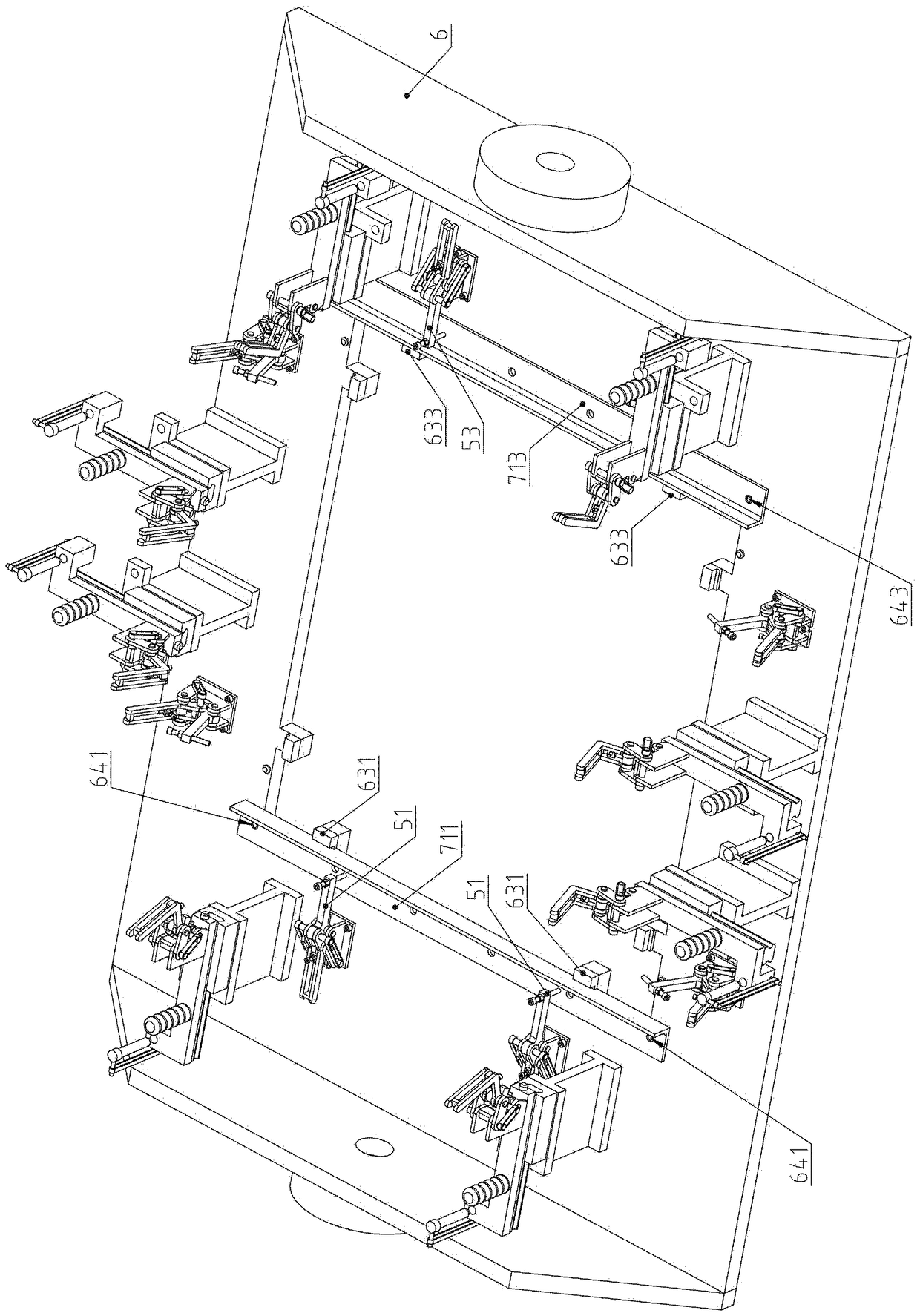

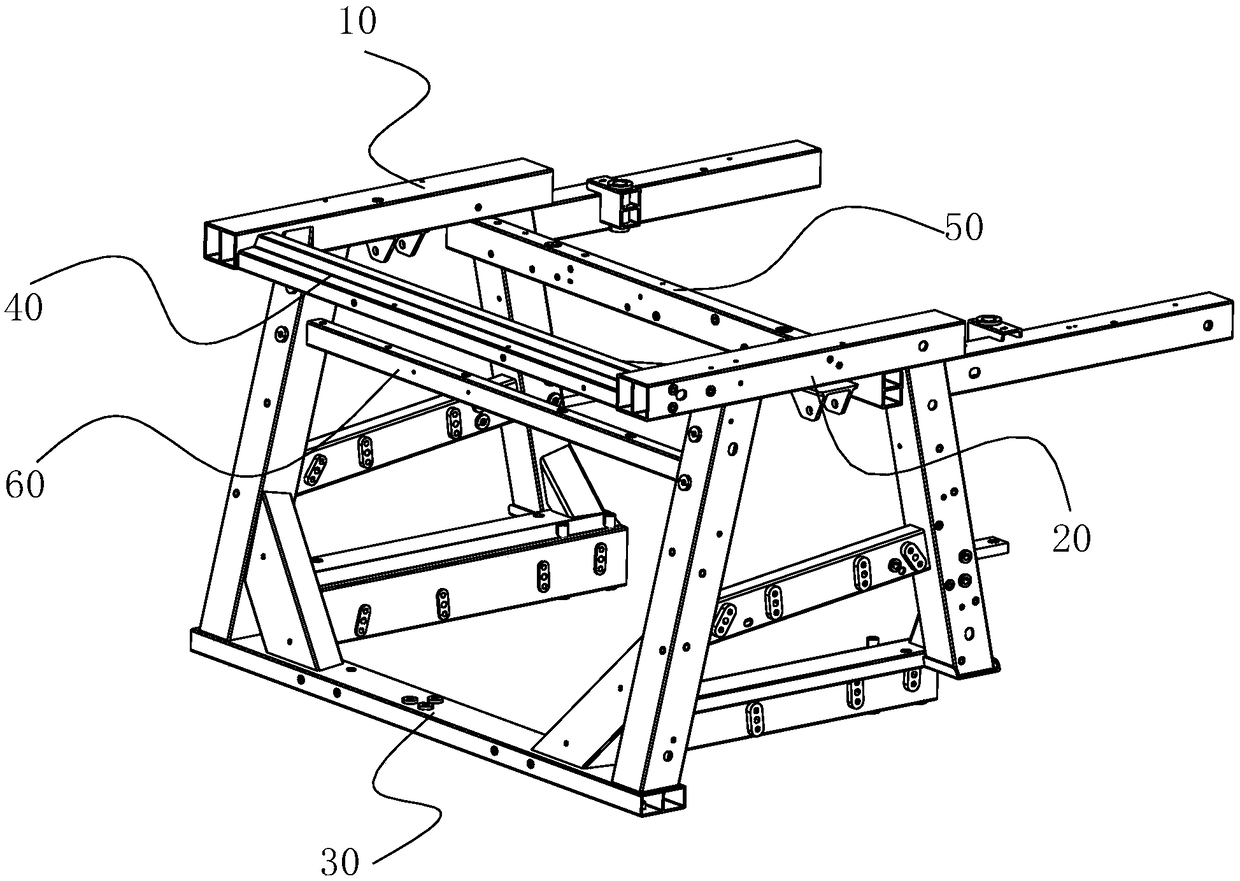

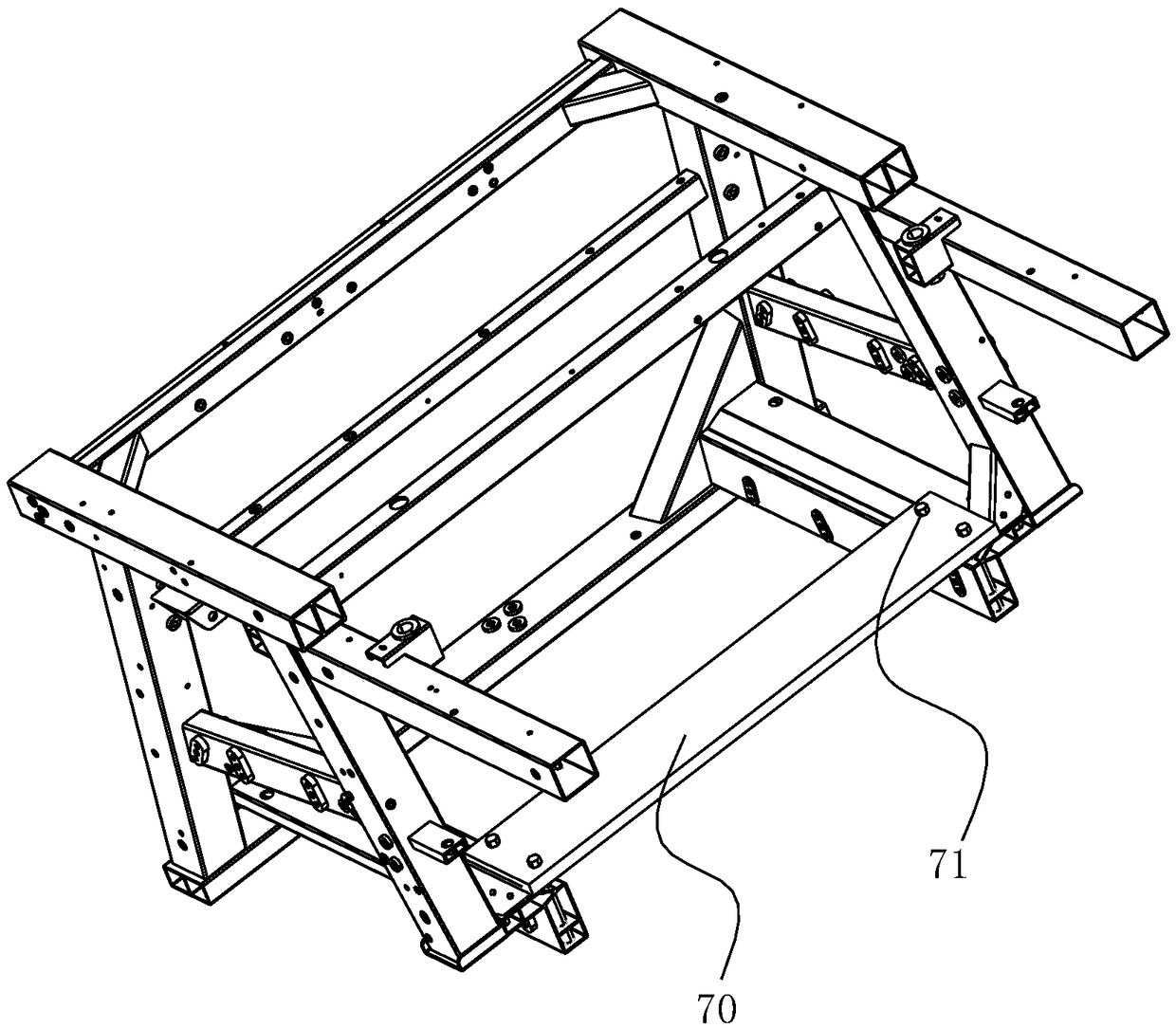

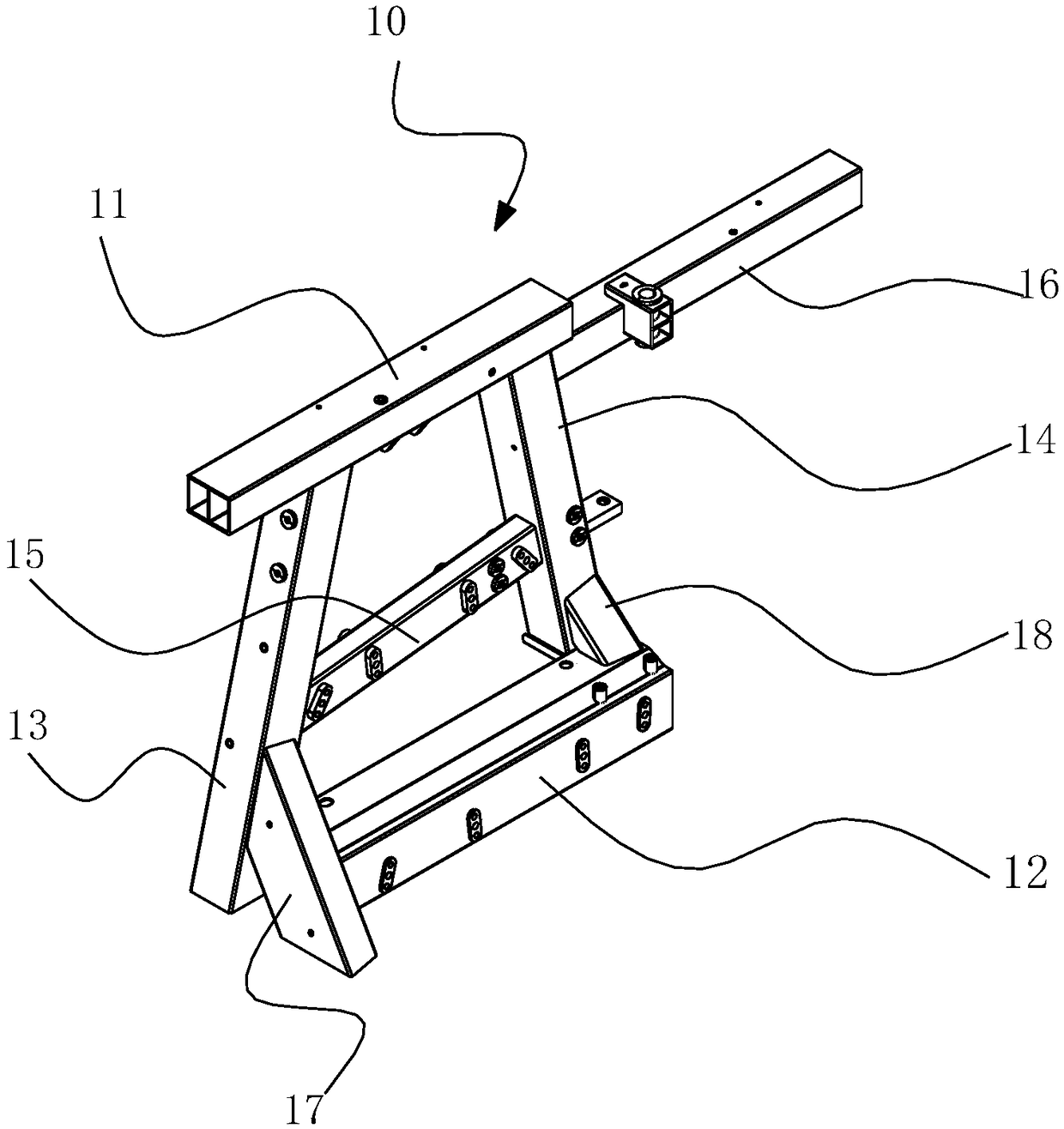

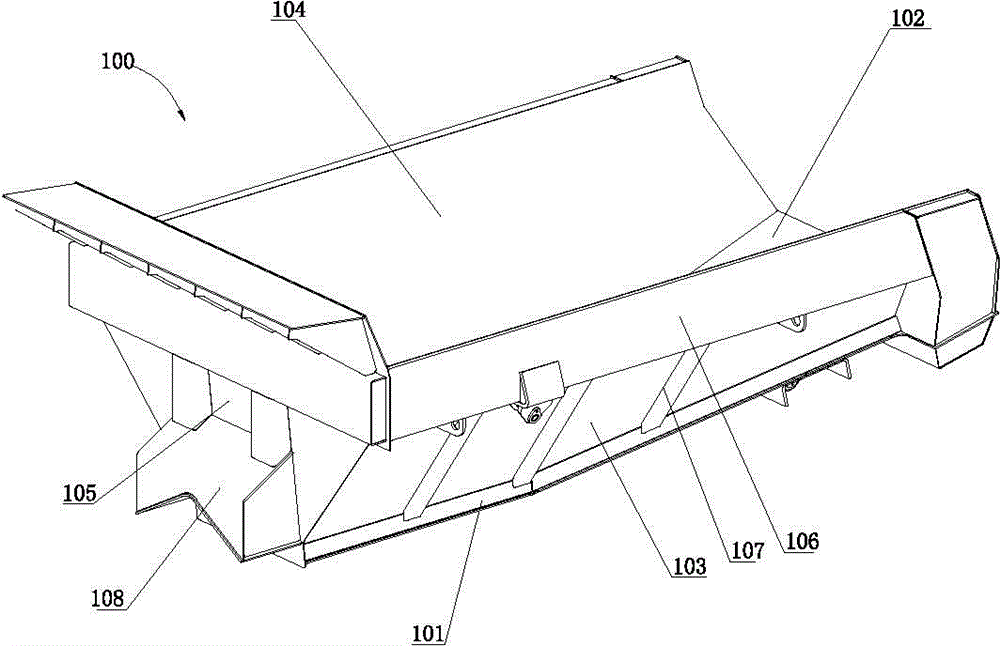

Welding assembly tool and method for electric wheel dumper cargo tank

ActiveCN104625531AEasy to disassembleHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding assembly tool and method for an electric wheel dumper cargo tank. The welding assembly tool comprises a cargo tank front plate welding assembly welding tool and a cargo tank assembly tool. The cargo tank front plate welding assembly welding tool comprises a saddle positioning base, first front plate supporting base sets, second front plate supporting bases, first pressing blocks, a fixed pressing block and a movable pressing block. The cargo tank assembly tool comprises bases, front plate welding assembly positioning frames, a saddle positioning frame, a left side plate positioning frame, a left side plate inclined supporting frame, a right side plate positioning frame, a right side plate inclined supporting frame, rear wane supporting frames, hinged bases, a saddle pressing block and bottom plate pressing blocks. The welding assembly method for the cargo tank includes the steps that a cargo tank front plate welding assembly is welded; the cargo tank is assembled. According to the structure and the method, before welding, all parts of the cargo tank can be accurately positioned, and the cargo tank can be prevented from deforming severely in the welding process.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

Method for manufacturing steel structure bridge T-shaped longitudinal rib braces

The invention relates to a method for manufacturing steel structure bridge T-shaped longitudinal rib braces. The method includes the steps that lofting is conducted on the T-shaped longitudinal rib braces according to the design of a steel structure bridge, the size of a T-shaped longitudinal rib brace web and the size of wing plates are determined, a numerical control plasma cutting machine is used for blanking a workpiece web and wing plates of a formed H-shaped component according to the design that the H-shaped component is formed by manufacturing the two symmetric T-shaped longitudinal rib braces, the length and the width of the wing plates of the H-shaped component are equal to those of the T-shaped longitudinal rib brace web, the width of the web is the sum of two times the width of the T-shaped longitudinal rib brace web and the width of a cutting seam, and lock point cutting is conducted on the longitudinal center line of the web. H-shaped components are assembled through an assembling machine, and the multiple H-shaped components are arranged on a reverse deformation jig frame to be welded. A flange correction machine is used for correcting the H-shaped components, and finally a lock point of each web is cut so that the two T-shaped longitudinal rib braces can be obtained. According to the method for manufacturing the steel structure bridge T-shaped longitudinal rib braces, the T-shaped longitudinal rib braces are manufactured in a mechanical and batched mode, the production efficiency is improved, the manufacturing precision and quality are ensured, and the promotional value is achieved.

Owner:HAIOD HEAVY ENG TECH

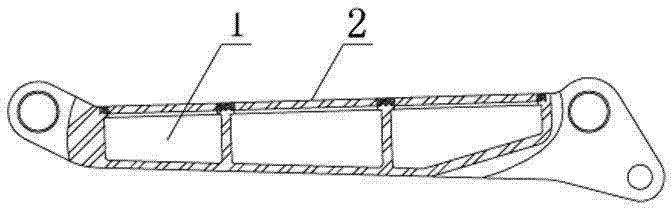

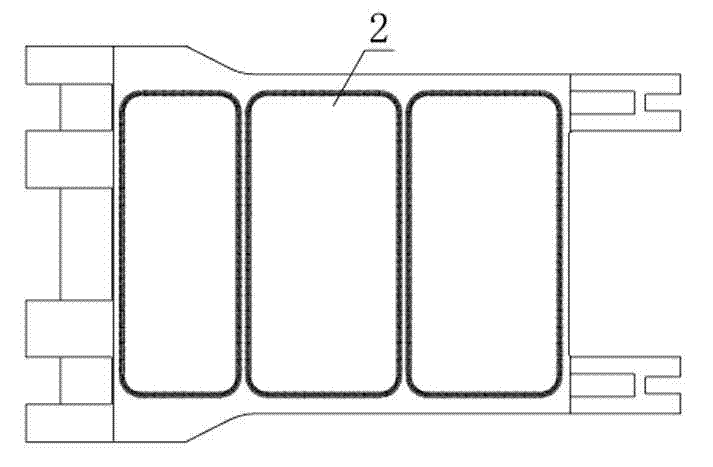

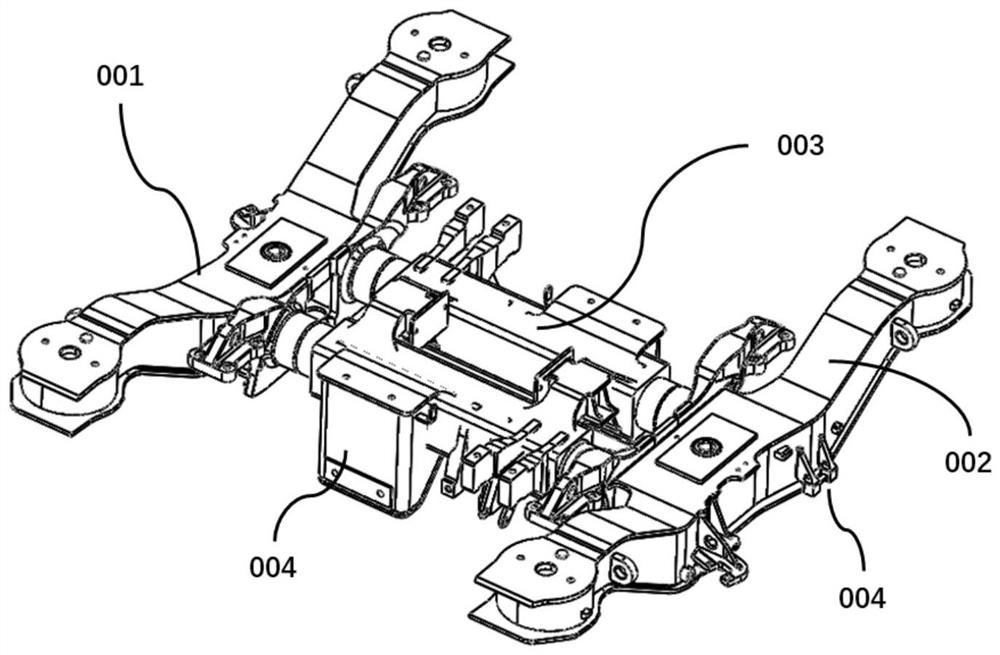

Hydraulic support top beam tailor-welding tool

ActiveCN108907575AImprove consistencyControl position sizeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention belongs to the technical field of hydraulic support welding, and particularly relates to a hydraulic support top beam tailor-welding tool. The hydraulic support top beam tailor-welding tool comprises a rectangular welding platform, a locking and positioning device which is located on the front portion of the rectangular welding platform and used for fixing rib plates arranged on thehead of a hydraulic support top beam and a shaft positioning device which is located on the back portion of the rectangular welding platform and used for fixing the tails of hydraulic support top beamparts; the hydraulic support top beam tailor-welding tool further comprises a side positioning device located on the right side of the rectangular welding platform and a side jacking device located on the left side of the rectangular welding platform; and the middle of the rectangular welding platform is provided with a jacking, hoisting and positioning device used for eliminating a gap formed between a hydraulic support main rib plate and a top beam top plate. The hydraulic support top beam tailor-welding tool has the advantages that the tailor-welding efficiency is high, the part positioning size precision is high, the finished product size consistency and the interchangeability are high, and tolerance and gap control is precise.

Owner:河南德佰特机电设备制造有限公司

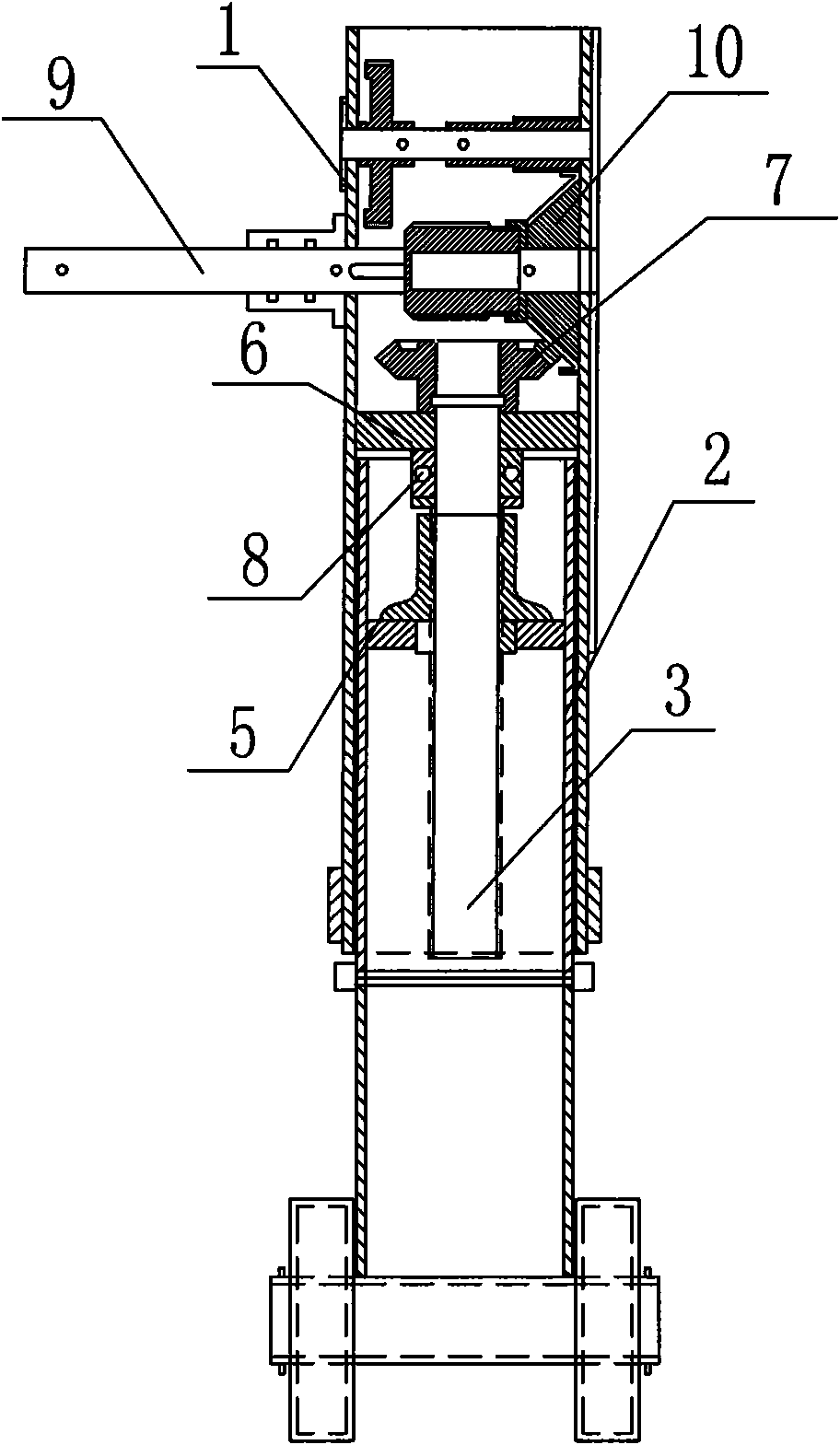

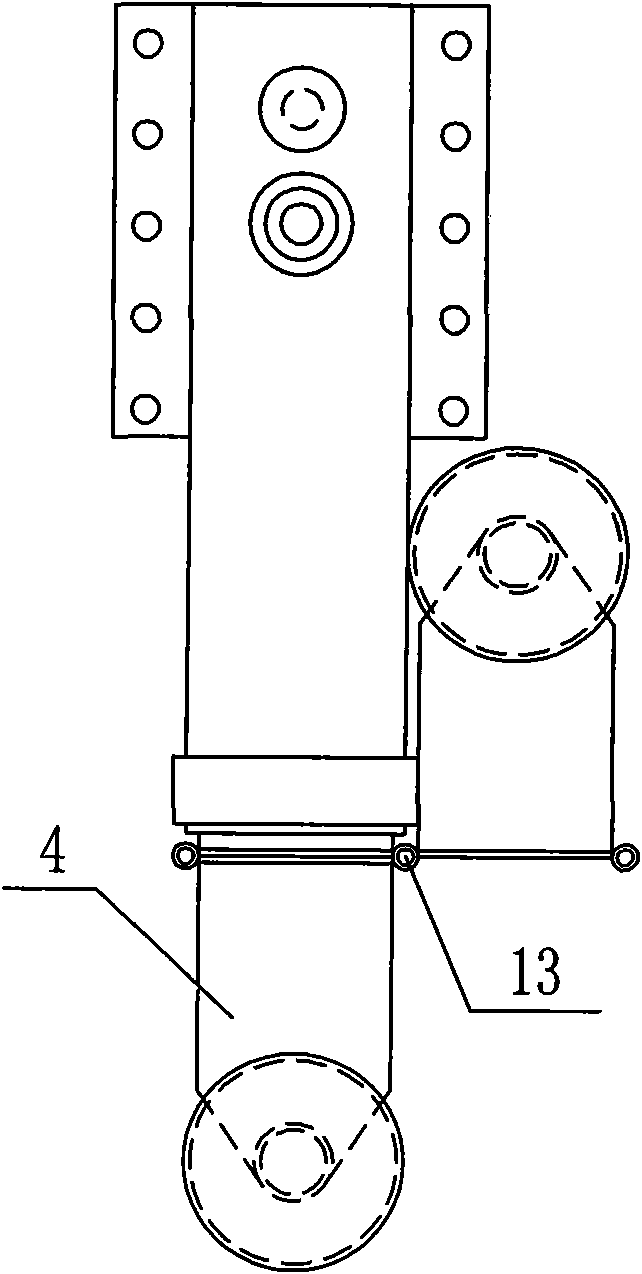

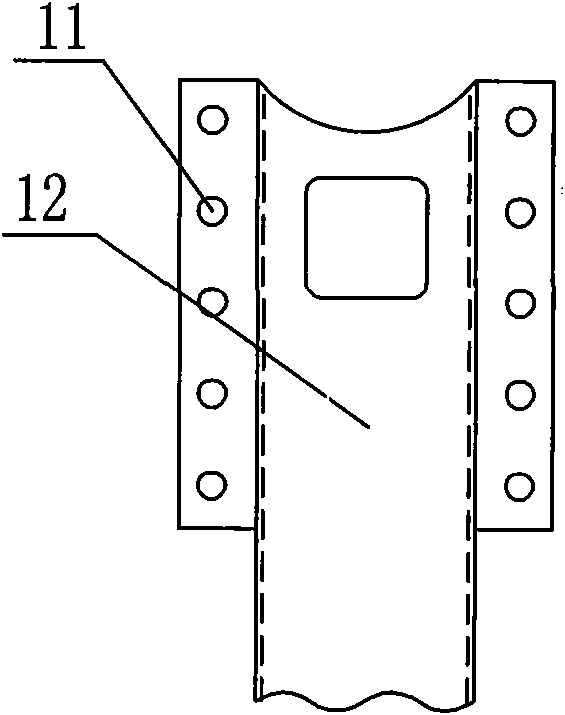

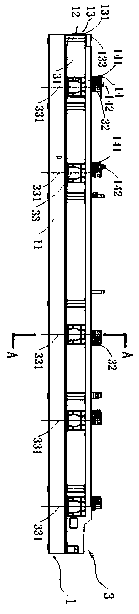

Lifting semitrailer outrigger

InactiveCN101837770ASimplify scaling rangeEasy to foldVehicle fittings for liftingHigh intensityEngineering

The invention discloses a lifting semitrailer outrigger, comprising an outer leg, lifting inner leg sheathed inside the outer leg, and a screw connecting the outer leg with the lifting inner leg, wherein a folding support leg is connected at the lower end of the lifting inner leg, and a wheel structure is arranged at the lower end of the folding support leg; the screw is respectively connected with a guide screw fixed at the inner side of the lifting inner leg and a bearing block fixed at the inner side of the outer leg; fixed nuts are connected at the top end of the screw and the upper end of the bearing block, a plane pressure bearing is connected at the lower end of the bearing block, and the inner side of the plane pressure bearing is connected with the screw; the outer leg is equipped with a screw rod, and a spiral bearing is connected inside the outer leg and the back end of the screw rod; and the outer side of the spiral bearing is clamped with the outer sides of the tops of the fixed nuts. The lifting semitrailer outrigger has the advantages of compact structure, low cost, small welding deformation, convenient manufacture and assembly, high precision, great lifting force, portability and flexibility, foldable folding support leg and convenient operation. And high- strength mill ball-resistant nodular iron nuts are used.

Owner:QINGDAO JIXIANGRONG MACHINERY

Large car frame welding location tyre and large car frame welding technological method

ActiveCN109794725AMeet the design requirementsHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to a large car frame welding location tyre and a large car frame welding technological method. The location tyre comprises a basic welding tyre I and a location and detection tyre II; the basic welding tyre I comprises a base I and a location bracket I; the location bracket I is located on the base I; a longitudinal beam location assembly is arranged on the location bracket I; the longitudinal beam location assembly comprises a longitudinal beam front location plate which is arranged at the end of the location bracket I, and further comprises a longitudinal beam side location plate which is obliquely arranged; a transverse beam location assembly is further arranged on the location bracket I; the transverse beam location assembly comprises a transverse beam shaft location component and a transverse beam longitudinal location component; and the transverse beam shaft location component is a supporting shaft seat which is in fit with a movable connecting shaft. Combined welding of a large car frame is completed with the adoption of a mode that two location tyres are combined, and the large car frame welding location tyre and the large car frame welding technological method have the advantages of high location accuracy and high welding speed; and welding work is completed in a tyre mould, so that welding deformation is reduced effectively, and the welding accuracy is improved.

Owner:SHANDONG HONGKANG MACHINERY MFG

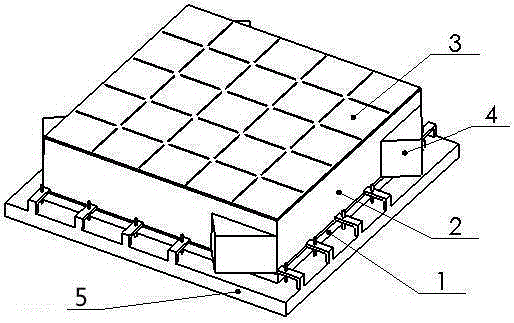

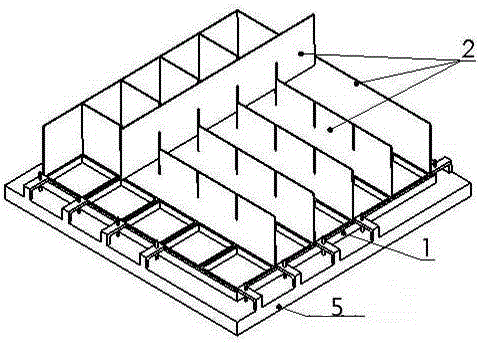

Manufacturing process for aluminum alloy vibrating platform

ActiveCN105252214AReduce in quantitySolve assembly problemsWelding accessoriesFillet weldEngineering

The invention relates to a manufacturing process for an aluminum alloy vibrating platform. The manufacturing process comprises the following steps that firstly, a panel is placed on a welding platform; secondly, rib plates are installed in positioning grooves in the panel, electric welding positioning is conducted on fillet weld joints between the rib plates and the panel, and then electric welding positioning is conducted on fillet weld joints between the rib plates; thirdly, the fillet weld joints between the rib plates and the panel and the fillet weld joints between the rib plates are welded in sequence through a metal inertia gas welding method; fourthly, plug welding grooves in a base plate are aligned with the rib plates in position, electric welding positioning is conducted, and then plug weld joints in the base plate are welded; fifthly, side pile feet are welded on the vibrating platform; and sixthly, the welded vibrating platform and the welding platform are subjected to stress relief annealing together. By machining the positioning grooves in the panel, the assembly problem is solved; the assembly accuracy is guaranteed to the greatest extent through the mutual embedding structure of the rib plates, and the welding deformation amount is reduced; by means of stress relief annealing, the welding stress is eliminated, and the product quality is guaranteed.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

LNG transport ship rudder sleeve installation method

The invention relates to an LNG transport ship rudder sleeve installation method. The method features that a rudder nacelle is hoisted integrally with a rudder sleeve, and the rudder sleeve is reduceby space restriction and is easier to hoist. Installation of positioning rudder sleeve on the ship bench eliminates positioning of the rudder centerline on the segments and avoids secondary positioning and inspection; By fixing the rudder sleeve in the rudder engine room and overlaying the groove in the rudder engine room, the workload caused by the accumulated deviation of the rudder sleeve in the rudder engine room can be reduced, the work at height can be reduced, and the construction environment can be improved. As that assembly gap between the surfacing groove and the weld seam is not more than 2mm and the joint misalignment is adjusted by the fire work industry, As that saw-tooth shape horse plate is adopted for reinforce and positioning, and the welding sequence is adopted, the welding fil amount can be reduced, the welding heat input can be reduced, the welding deformation can be reduced, the installation efficiency and the installation precision can be improved, and the machining time and the cost can be reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

Laser welding multifunctional negative pressure gas protection device and method

PendingCN108581193APremium Laser WeldingLower the altitudeLaser beam welding apparatusSolid structureEngineering

The invention discloses a laser welding multifunctional negative pressure gas protection device and method. During small-batch multi-variety laser welding, the problems that production efficiency is seriously affected since tools are repeatedly replaced, air holes are likely to be produced, forming is not uniform, and fusion depth loss is serious in the welding process are prominent. The device comprises a negative pressure fence (1), an isolation separation bin (2) is installed in the negative pressure fence, the rear side of the isolation separation bin is provided with a tail drag cover (3), two air inlet pipes (4) are installed above the tail drag cover, one side of the negative pressure fence is provided with a direct protection channel air inlet pipe (15), the isolation separation bin is of a square cylindrical solid structure in the appearance and forms an angle of 20-50 degrees with the vertical direction, a compressed air injection air chamber (8), a gradual transition structure (9) and a straight air outlet (10) are sequentially arranged above the interior of the isolation separation bin, and a direct conveying type gas protection channel (11) is arranged below the interior of the isolation separation bin and communicates with a separation bin air inlet hole (12). The device is used for laser welding multifunctional negative pressure gas protection.

Owner:HARBIN WELDING INST LTD

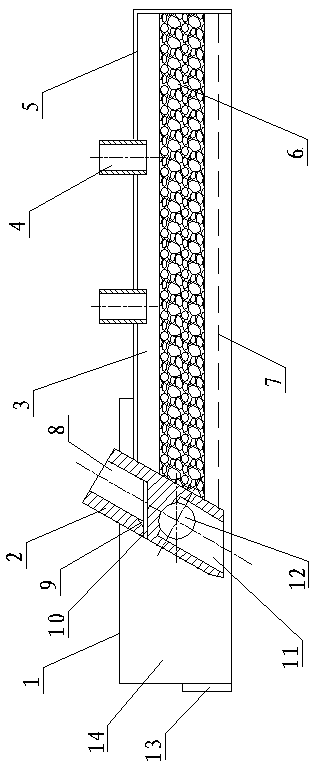

Manufacturing process of smoke waste heat exchanger for radiant tube burner

InactiveCN104191069AImprove cohesionNo hindranceArc welding apparatusHeat exchange apparatusEngineeringGuide tube

A manufacturing process of a smoke waste heat exchanger for a radiant tube burner sequentially comprises the steps of assembling of an external air guide tube and an air inlet tube, assembling of a sealing head and an external fin heat exchange tube, assembling of the external fin heat exchange tube, the external air guide tube, the air inlet tube and a jacketed tube, assembling of a special flange, a smoke guide tube and a blocking plate, assembling of an air inlet flange and a reinforcing tube, assembling of a heat exchange ring, an air jet flow tube, a bending tube and a middle guide tube, assembling of the smoke guide tube, a smoke outlet flange and a smoke outlet tube, and assembling of a flow baffle and lifting lugs. The steps are bridged well, and are proper, the production efficiency is improved, meanwhile, the welding process is flexible and changeable, the welding deformation amount is small, and the welding line quality is greatly improved. According to the manufacturing process, the welding quality is good, and the production efficiency is higher.

Owner:武汉宇宙科技有限公司

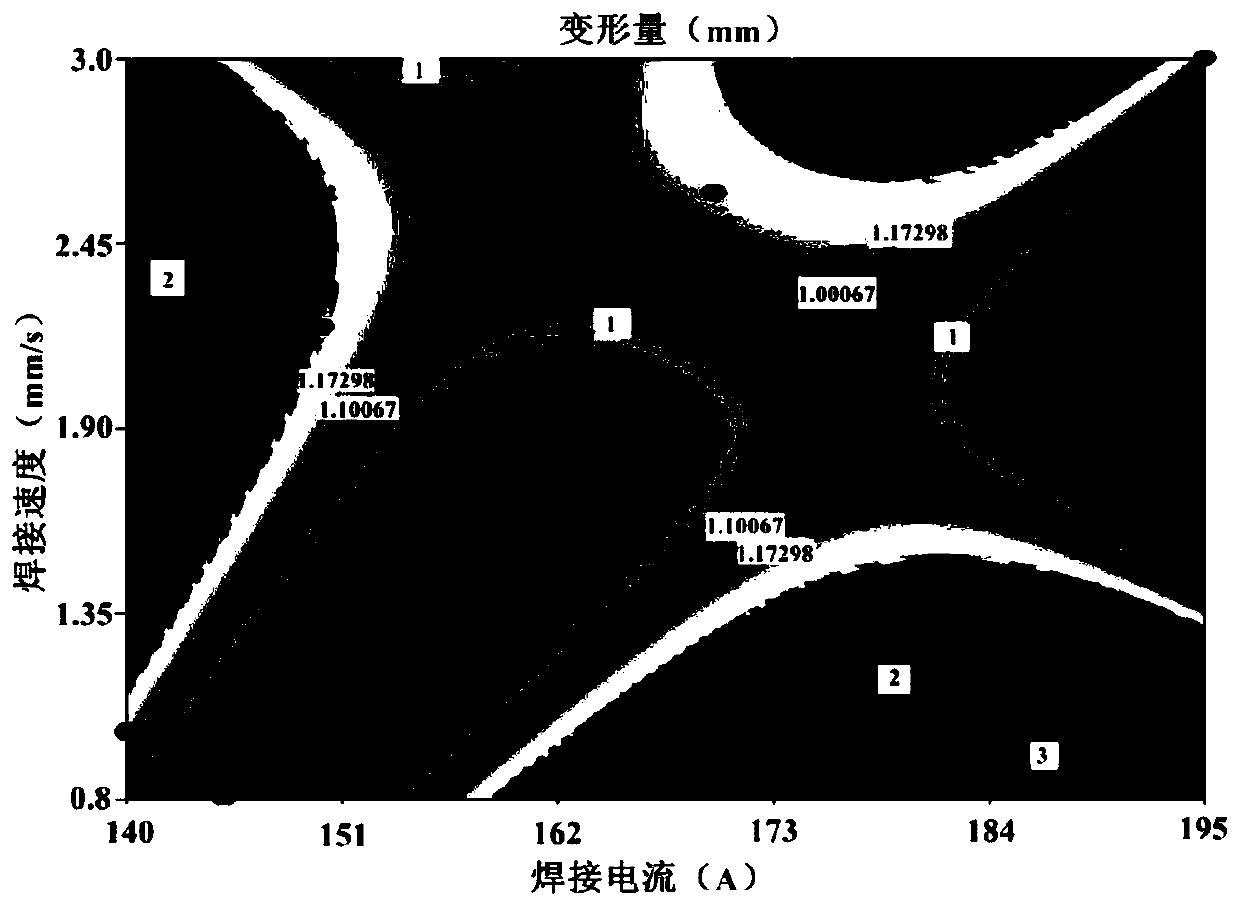

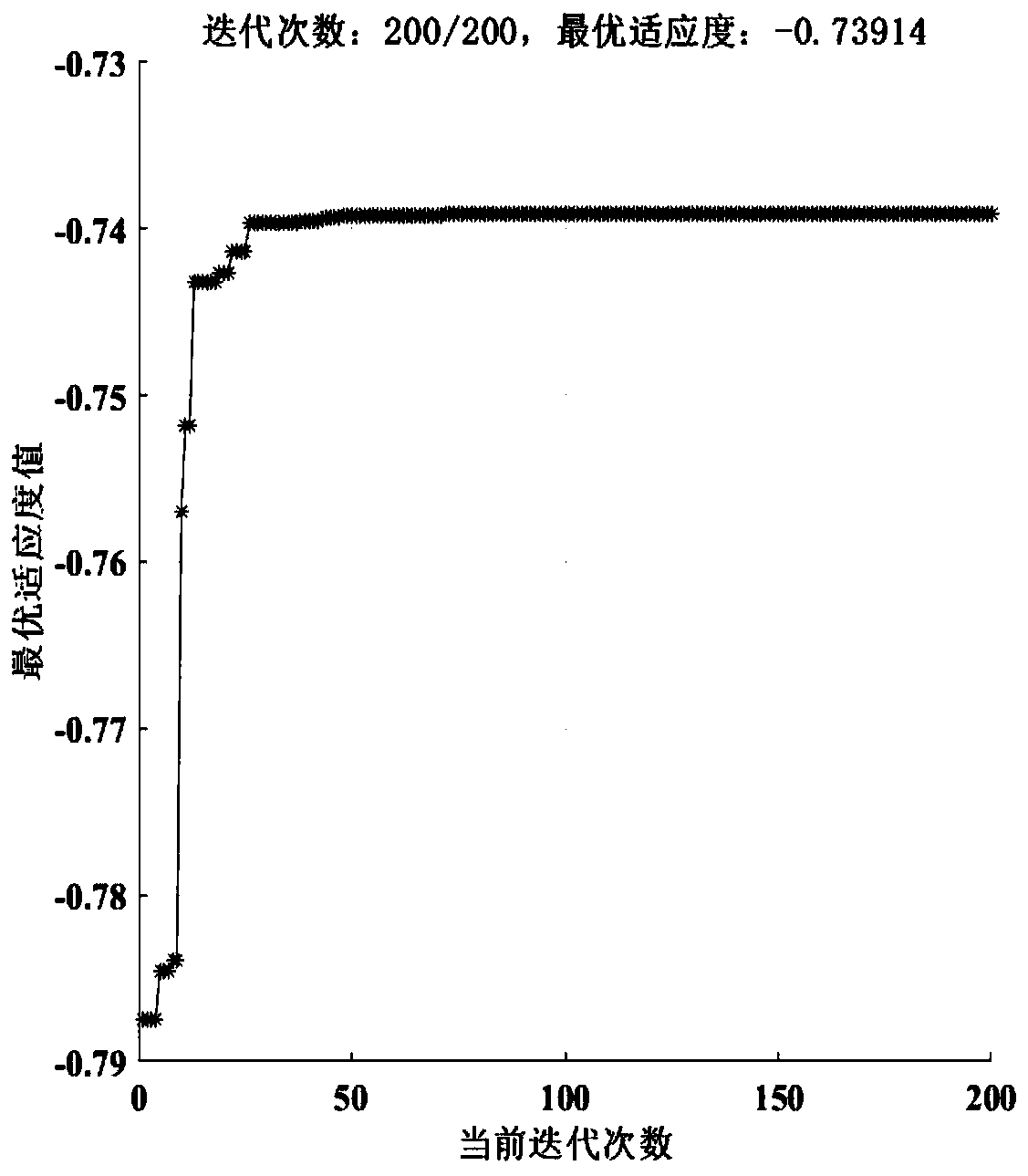

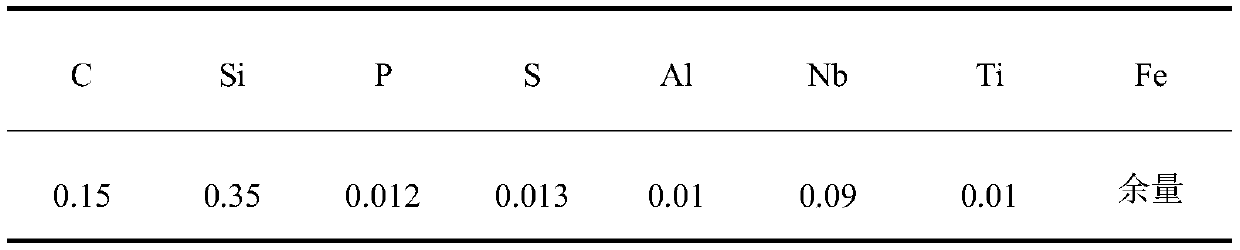

Dual-phase high-strength steel welding parameter optimization method

ActiveCN110614416AQuality improvementGood welding deformationArc welding apparatusWelding/soldering/cutting articlesDesign cycleQuantum genetic algorithm

The invention discloses a dual-phase high-strength steel welding parameter optimization method. A method of combining a response surface method (RSM) with a quantum genetic algorithm (QGA) is utilizedfor optimizing TIG double-sided welding process parameters of double-phase high-strength steel with an I-shaped groove, and the method particularly comprises the steps of determining a welding material and initial process parameters, performing welding and measuring the deformation amount after welding, establishing a response surface model, obtaining optimal parameters by using the QGA to solvea response surface model, verifying the optimal process parameters and the like. A reliable response surface model can be established by using a limited number of tests to replace a large number of tests, so that the purpose of predicting the welding quality through welding parameters is achieved; double-sided TIG welding of dual-phase high-strength steel such as DP590 and DP780 with the I-shapedgrooves is conducted, the design cycle can be greatly shortened, the welding deformation amount can be reduced, and not only can the production efficiency be improved, but also the quality of weldingproducts can be improved.

Owner:XUZHOU NORMAL UNIVERSITY

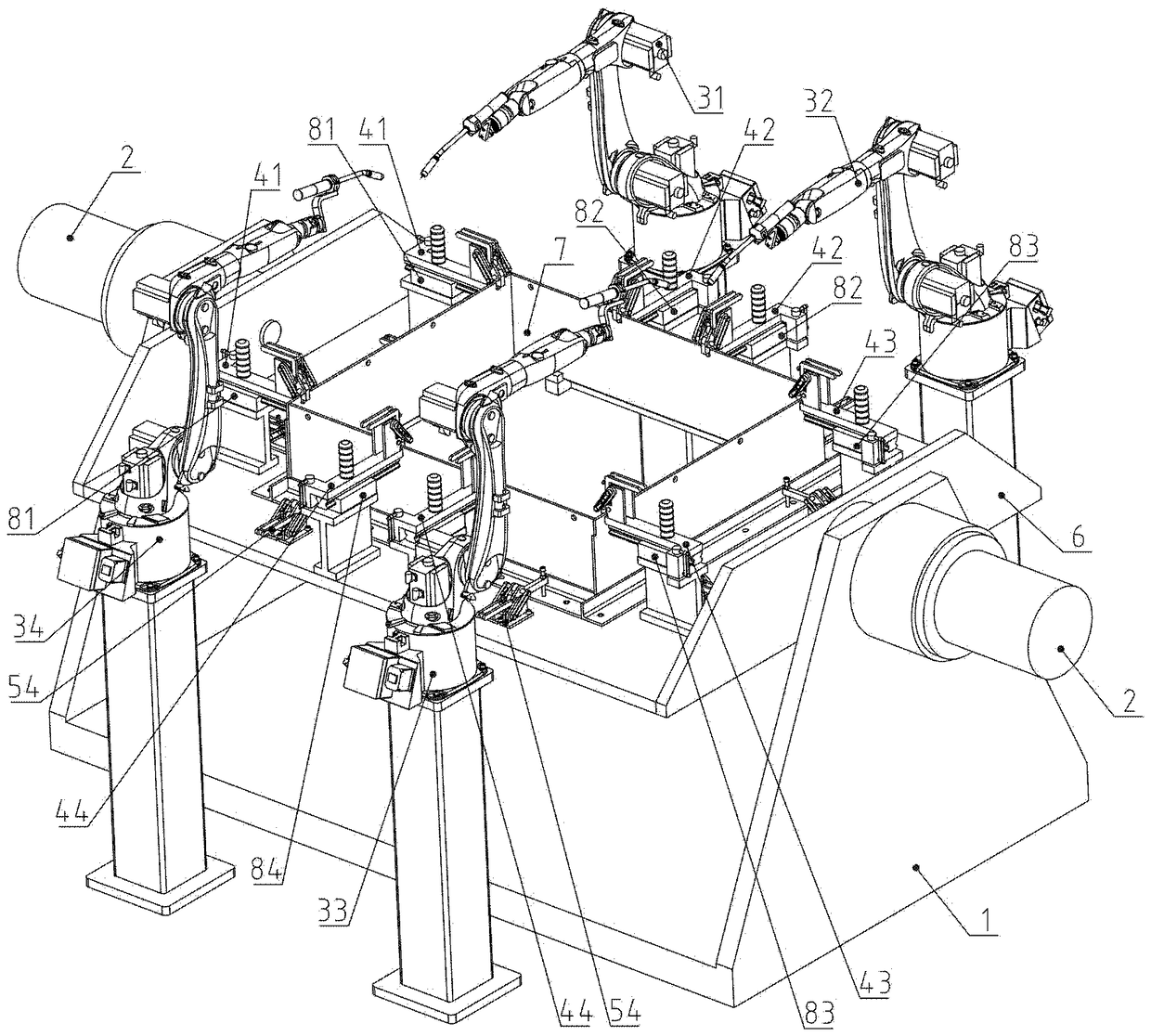

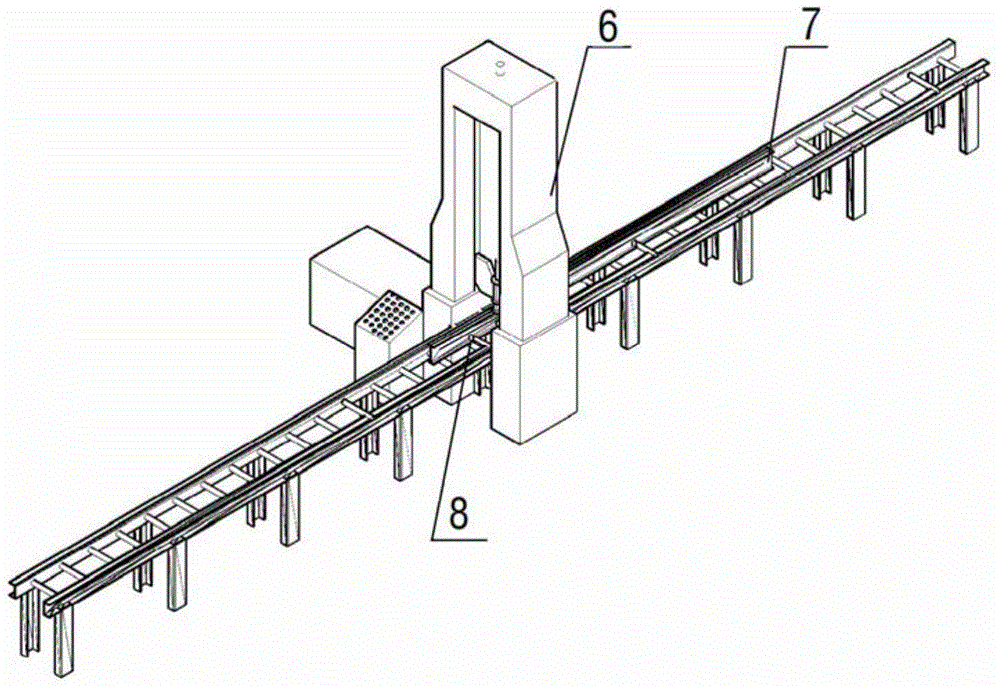

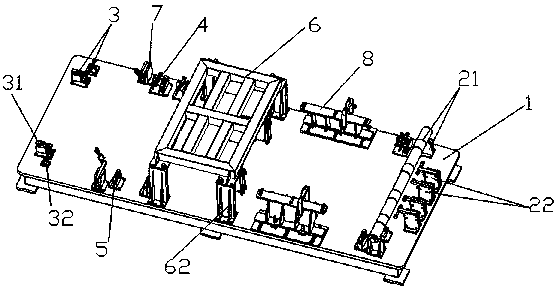

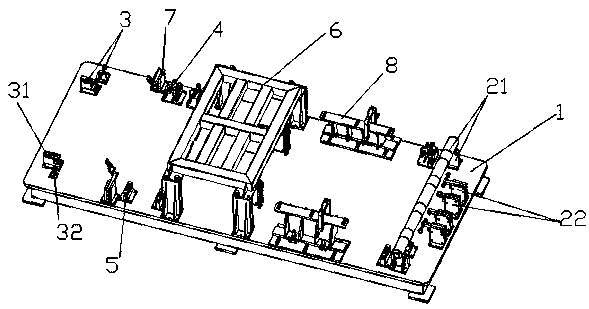

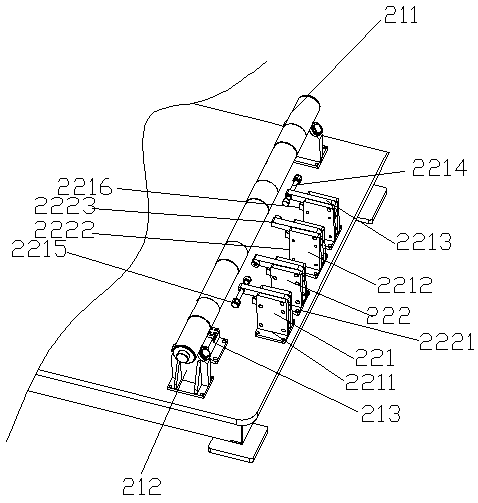

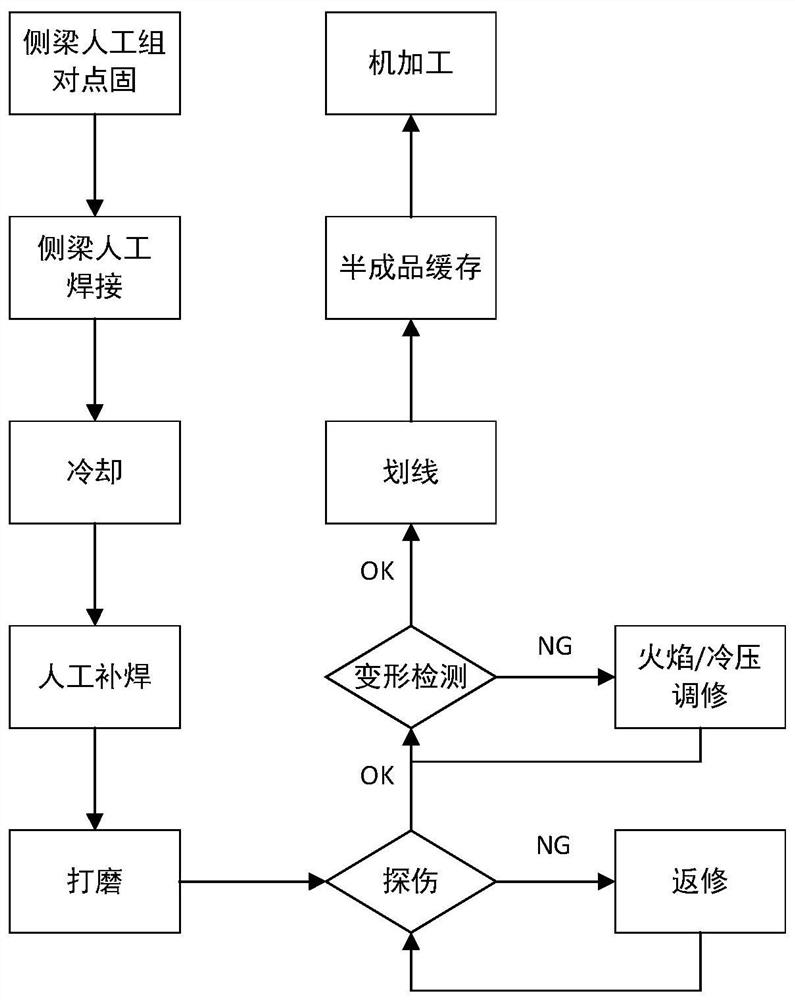

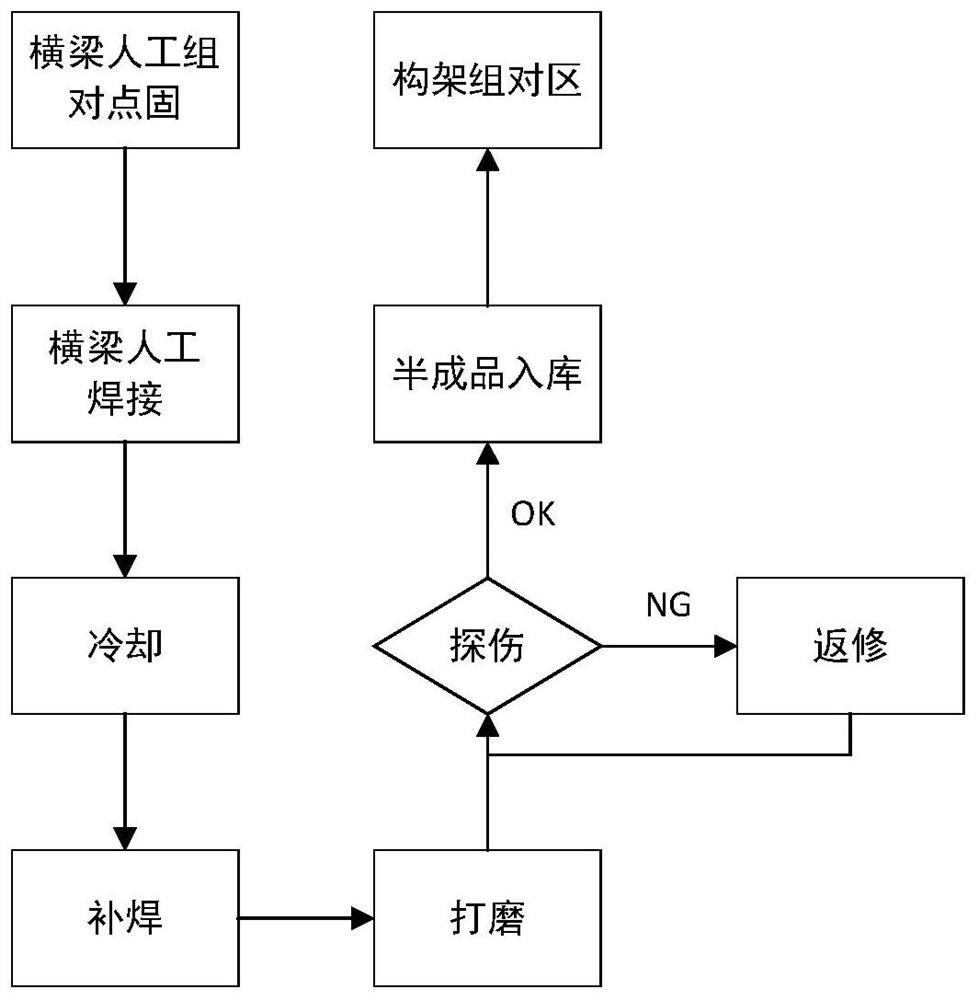

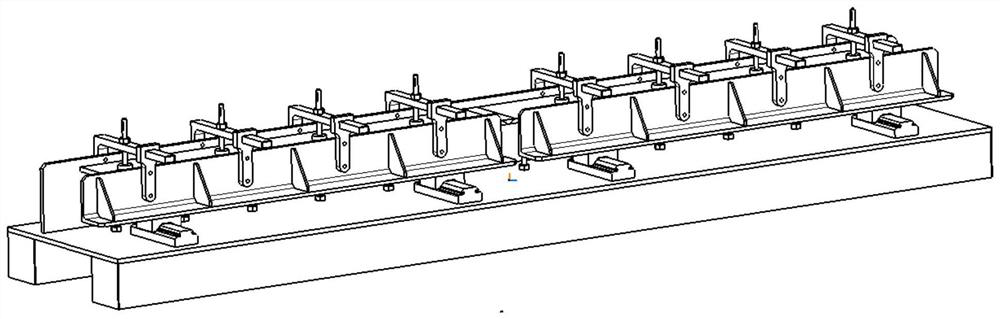

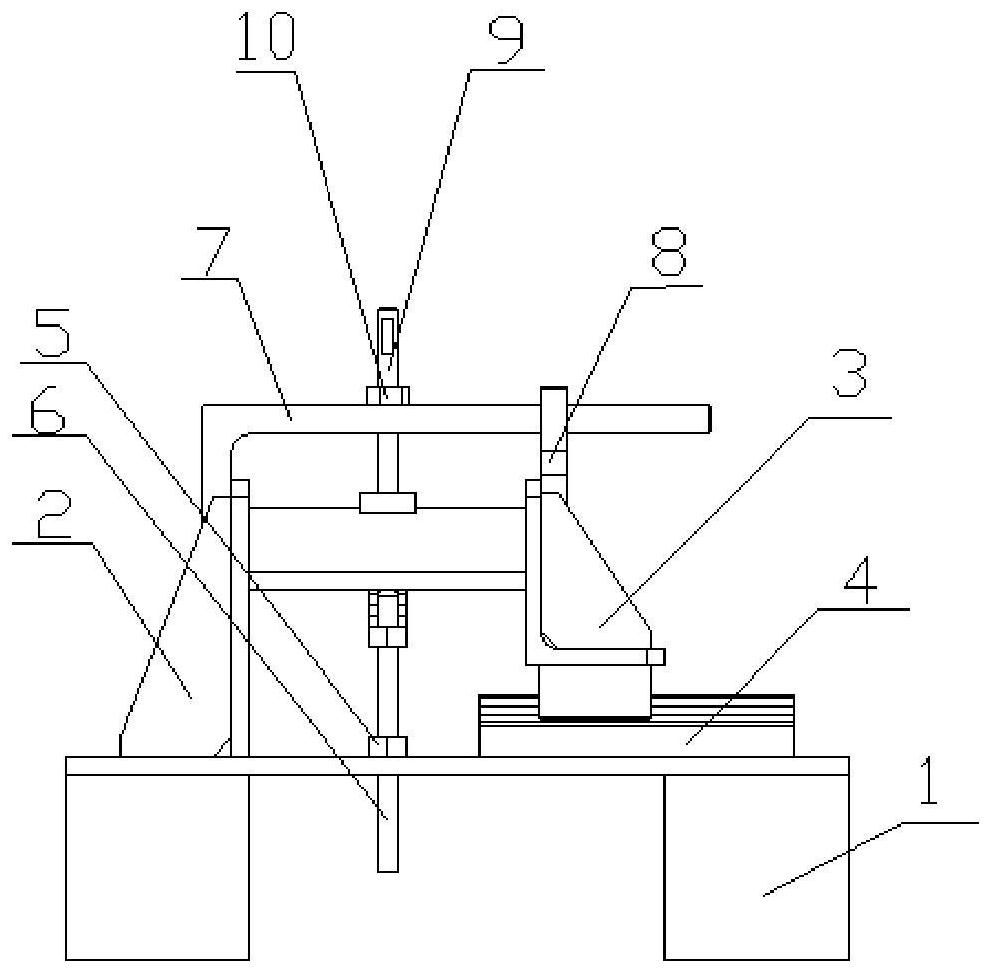

Rail transit box girder framework welding process and lean production layout method thereof

ActiveCN111993053ASmooth and safe transportation pathEasy accessOther manufacturing equipments/toolsWelding apparatusWeld seamBox girder

Owner:武汉中车电牵科技有限公司

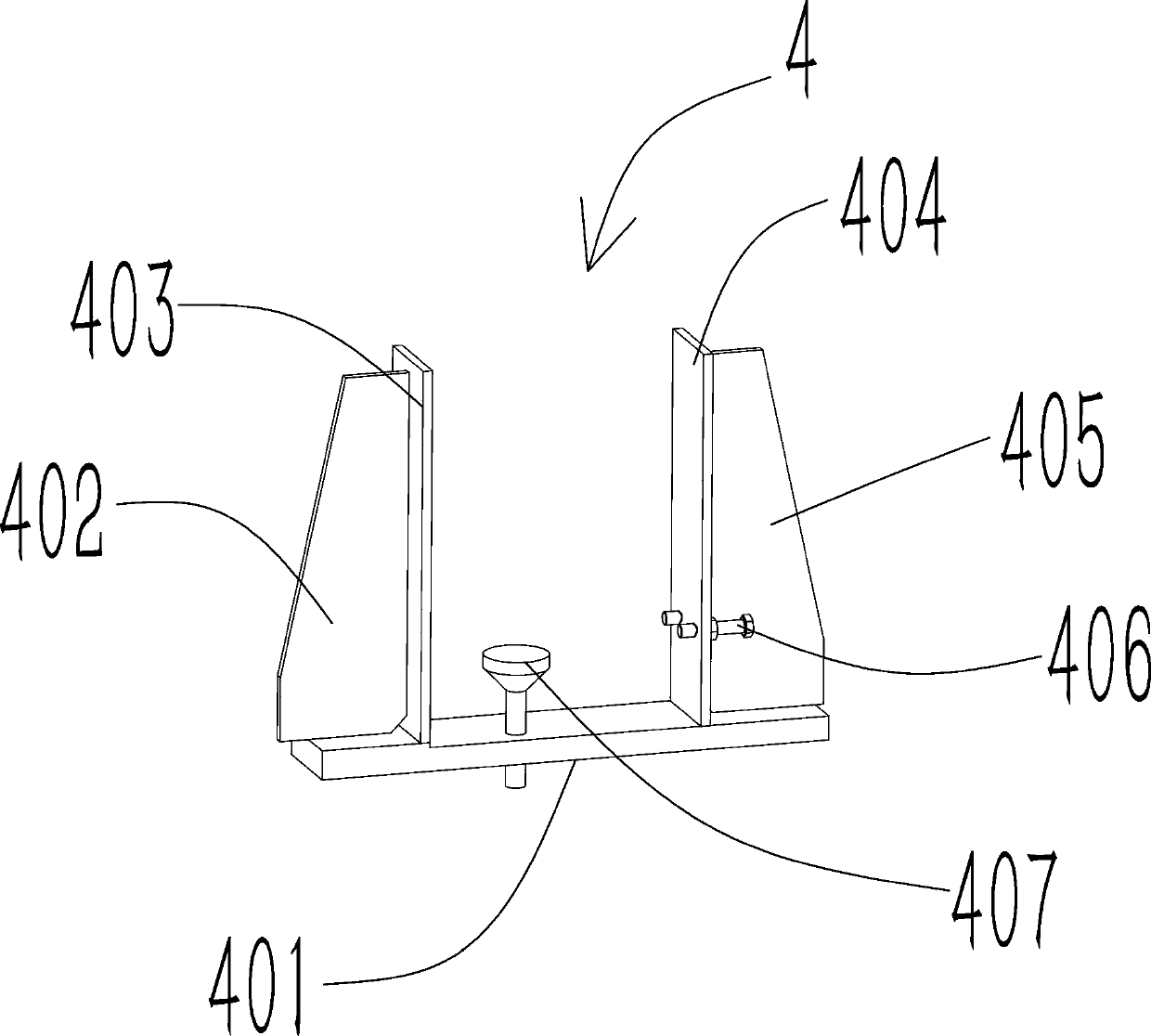

Slender part welding deformation control method

InactiveCN112518194AAnti-distortionSmall amount of welding deformationWelding/cutting auxillary devicesAuxillary welding devicesElement analysisStructural engineering

The invention discloses a slender part welding deformation control method. Deformation pre-judgment is carried out through finite element analysis before welding, reverse deformation control is adopted, welding reverse deformation control is carried out through a flexible welding device during welding, and welding deformation is reduced through a method that flexible shape preserving devices control deformation after welding. The flexible welding device comprises a base, a fixed baffle, a movable baffle, a screw, a nut and a sliding guide rail. Each flexible shape preserving device comprises an L-shaped clamping plate, a supporting plate, a shape preserving ejector rod, and a shape preserving nut. According to the slender part welding deformation control method, by means of the flexible welding device, the welding of slender parts is achieved easily and effectively, the production key point is broken through, welding and welding shape preserving processing are achieved through the flexible welding device and the multiple flexible shape preserving devices, the working efficiency is improved, the cost is saved, and the quality is guaranteed.

Owner:XIAN AIRCRAFT IND GROUP

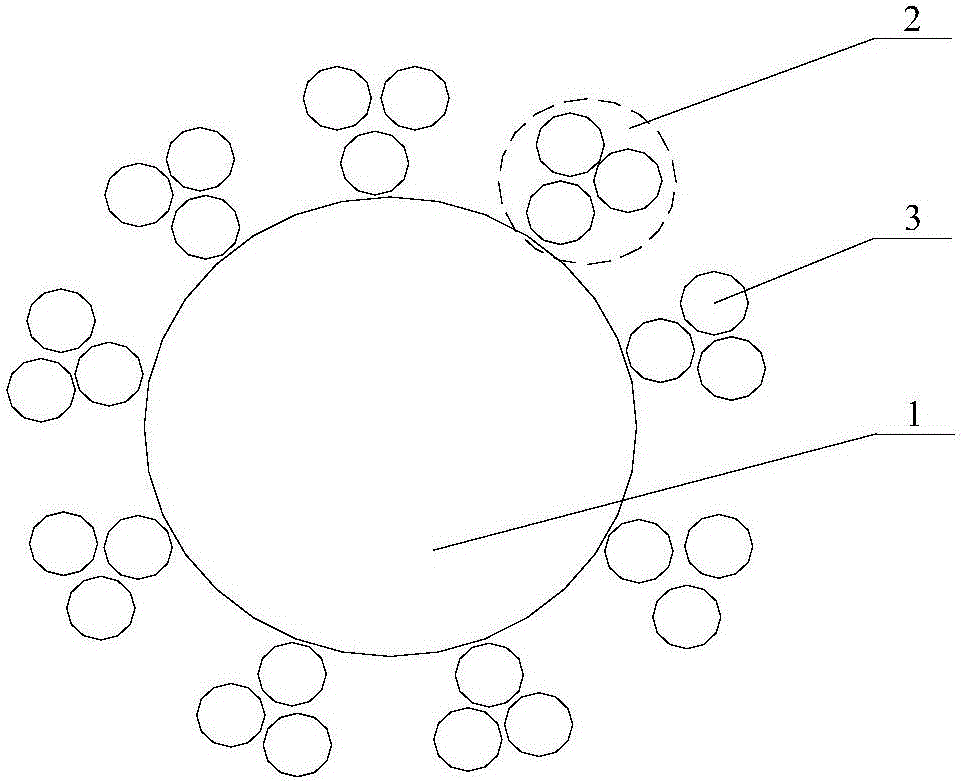

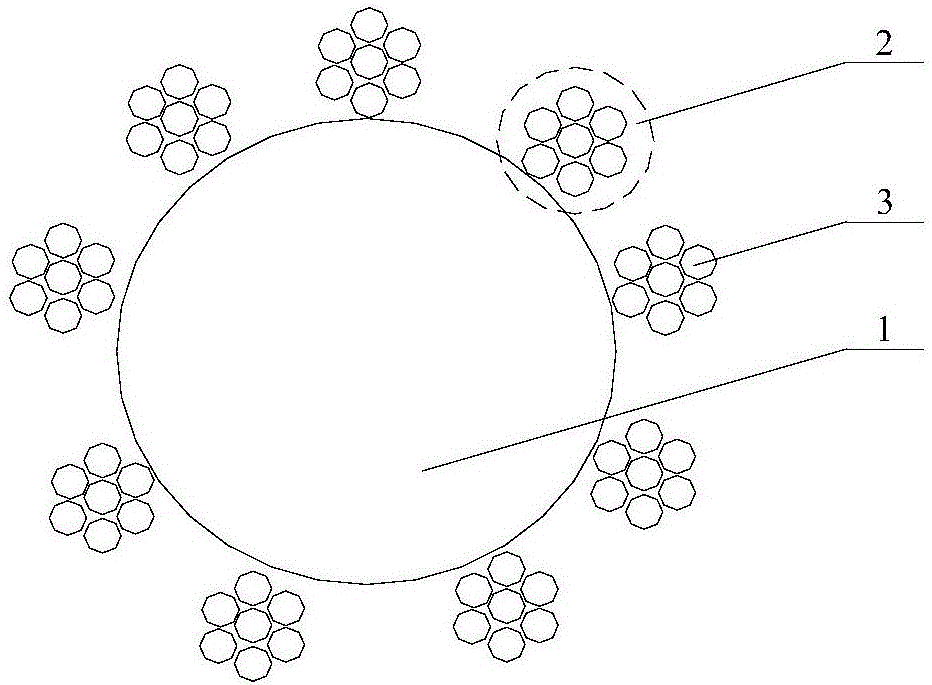

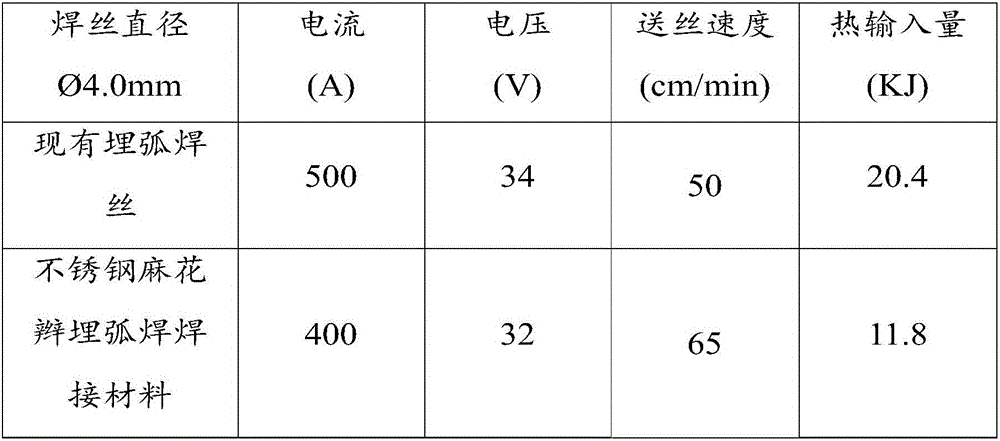

Stainless steel braid welding material and manufacturing method thereof

InactiveCN106238950AFast meltingLow heat inputWelding/cutting media/materialsSoldering mediaHeat-affected zoneMetallurgy

The invention discloses a stainless steel braid welding material and a manufacturing method thereof, and relates to the technical field of welding. The stainless steel braid welding material comprises a core wire and multiple strands of steel wire bundles. The whole core wire is in a round strip shape. The steel wire bundles wrap the outer surface of the core wire in the axis direction and are stranded and formed along the circumference of the core wire. Each strand of steel wire bundles is formed by stranding multiple thin wires. According to the stainless steel braid welding material and the manufacturing method, the stainless steel braid welding material which is adopted is high in melting speed, does not need large welding current, lowers the electrical energy consumption and is low in heat input amount, small in adverse effect on base metal thermal effect areas, small in welding deformation amount, good in stability during wire feeding, high in welding efficiency, good in quality and attractive in molding.

Owner:WUHAN RUNZHIDA PETROCHEM EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com