Semi-automatic tool for intelligent welding of connection section of belt A type coal feeder

A semi-automatic, connecting section technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of position tolerance, scribing, inconvenient handling, and large connecting section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

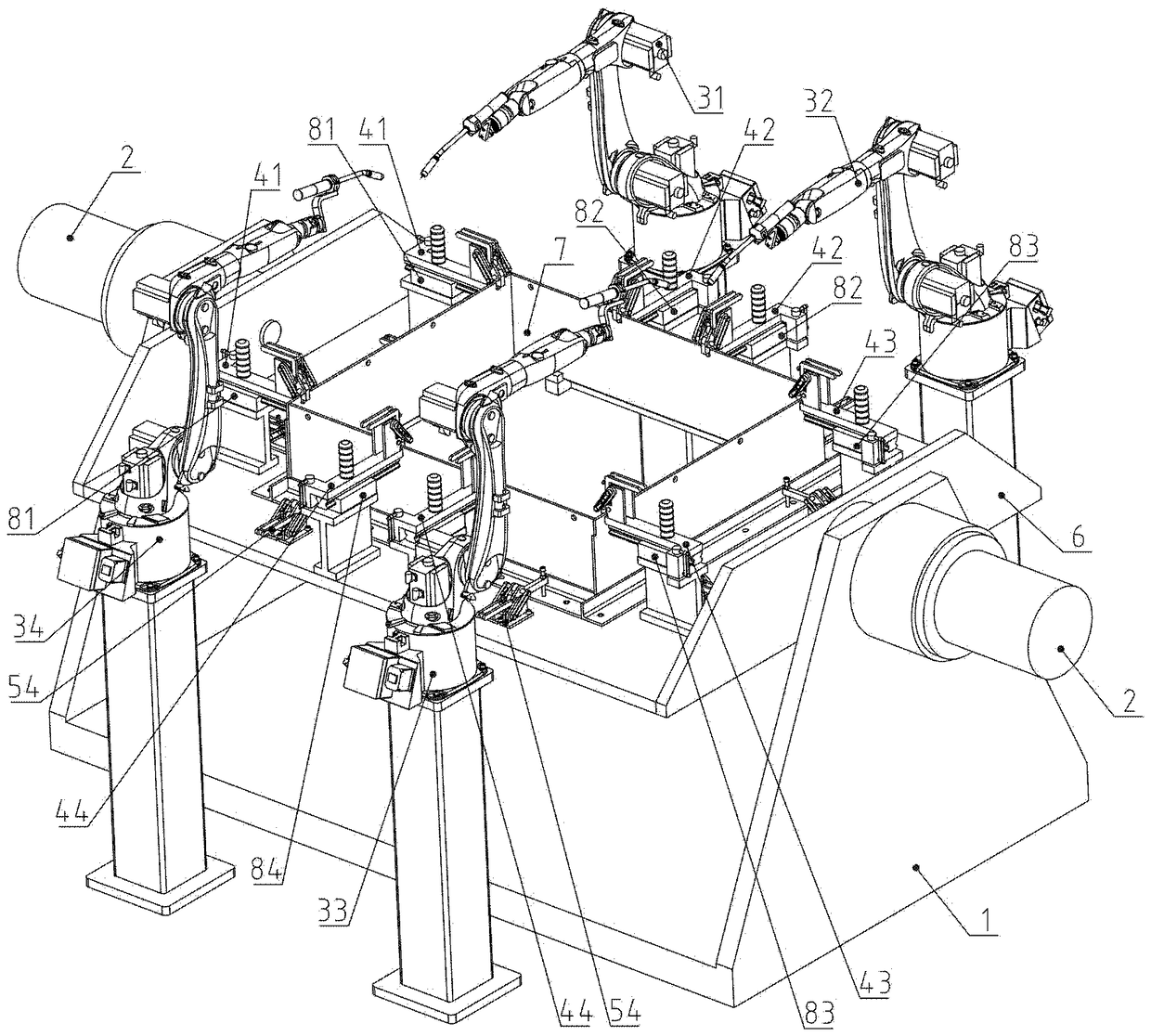

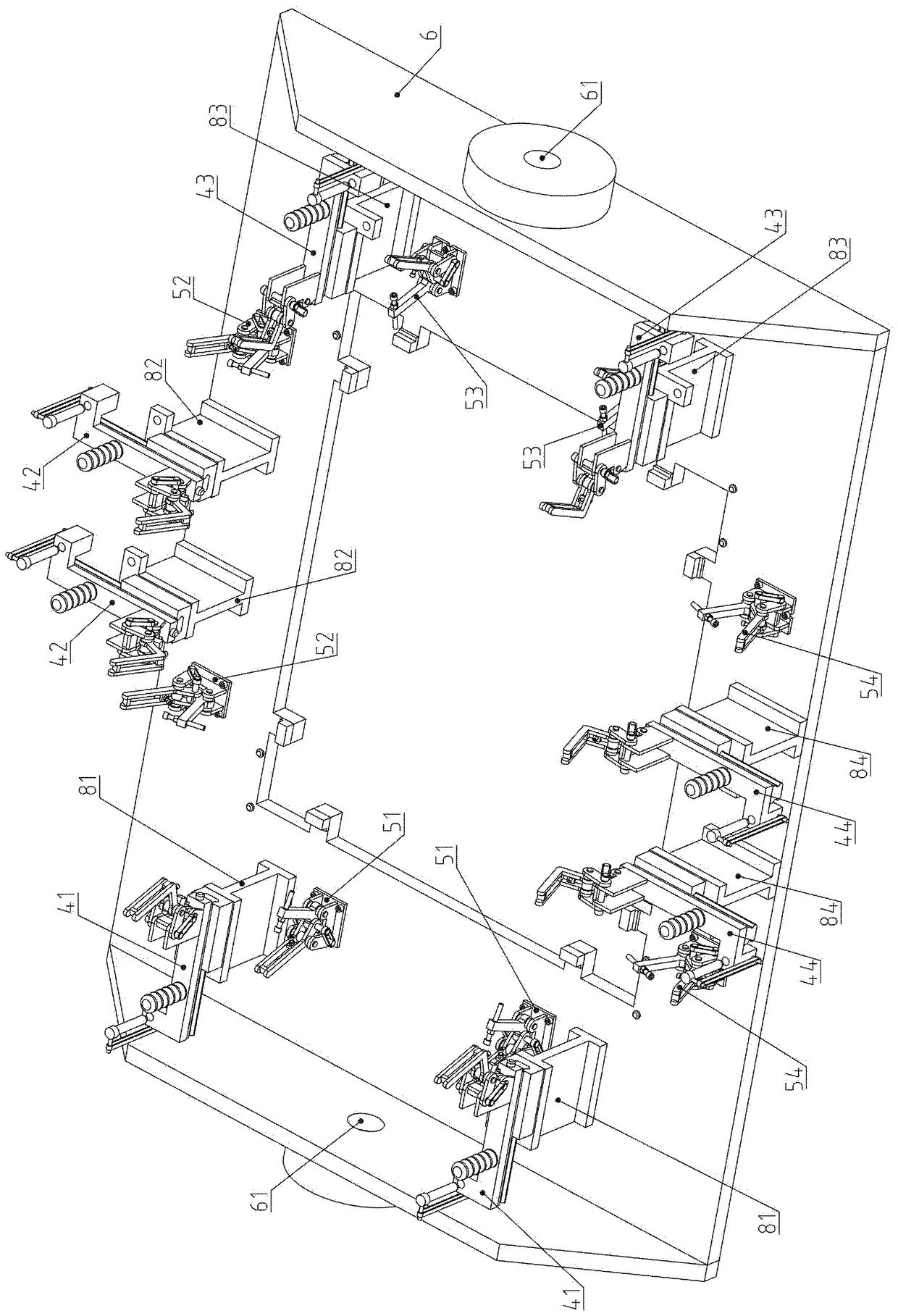

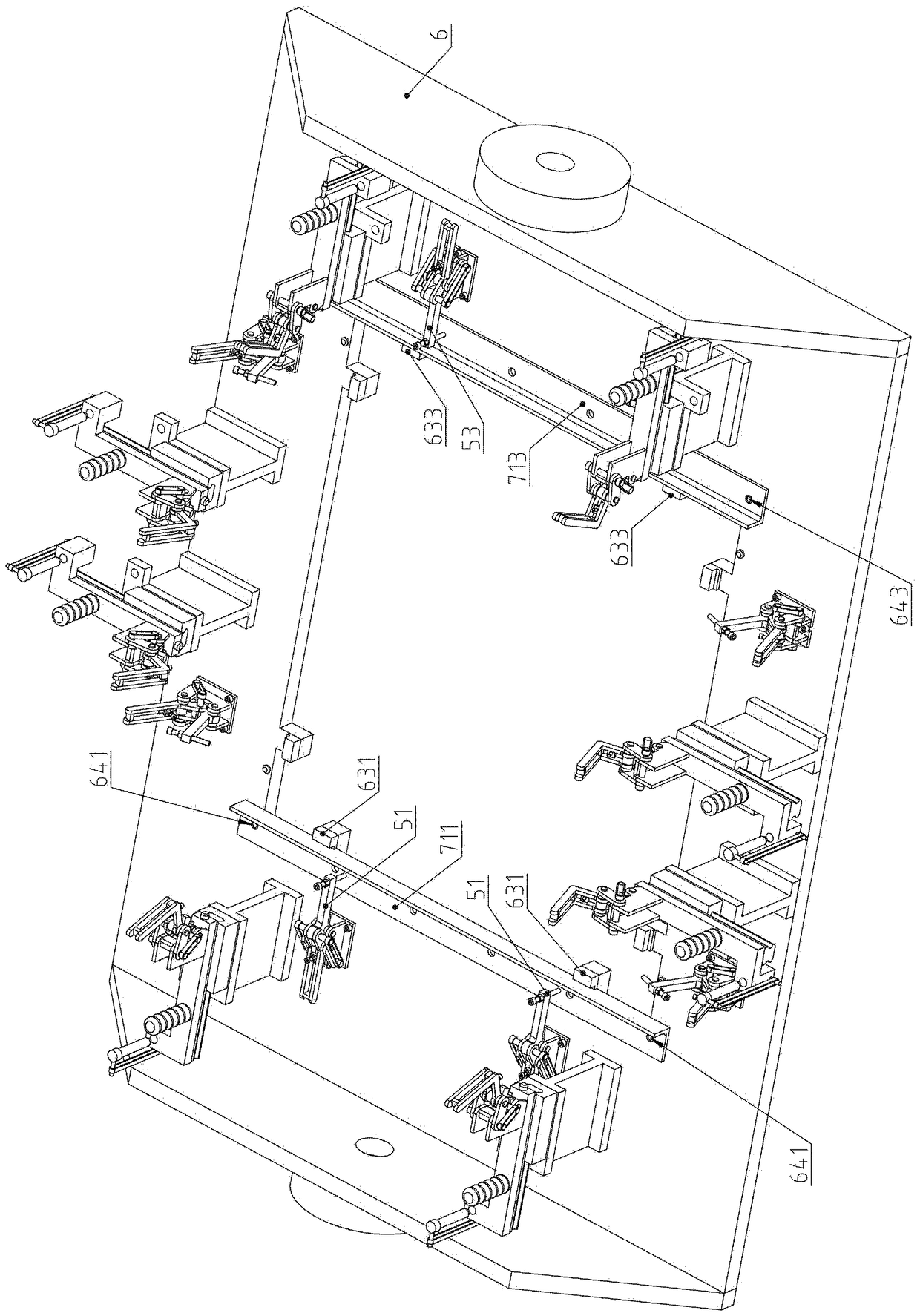

[0048] Example: see Figure 1 to Figure 20 .

[0049] An intelligent welding semi-automatic tool for the joint section of a belt coal machine, including four welding robots and semi-automatic tool;

[0050] The four welding robots are welding robot one 31, welding robot two 32, welding robot three 33 and welding robot four 34, wherein welding robot one 31 and welding robot two 32 are fixed on the front of the semi-automatic tooling, welding robot three 33 and welding robot Four 34 are fixed on the rear of the semi-automatic tooling, welding robot one 31 is on the left side of welding robot two 32, and welding robot three 33 is on the left side of welding robot four 34;

[0051]The semi-automatic tooling includes a tooling bracket 1, a combination of a servo motor and a reducer 2, and an overturning assembly; the overturning assembly includes a turntable assembly 6, a positioning assembly, a fast clamp and a base assembly; the turntable assembly 6 includes a rectangular horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com