Electron beam welding process suitable for encapsulation molding of martensitic steel high-density runner

An electron beam welding and martensitic steel technology, applied in electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of low activation martensitic steel with high density, etc. The shape is beautiful and the effect of improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

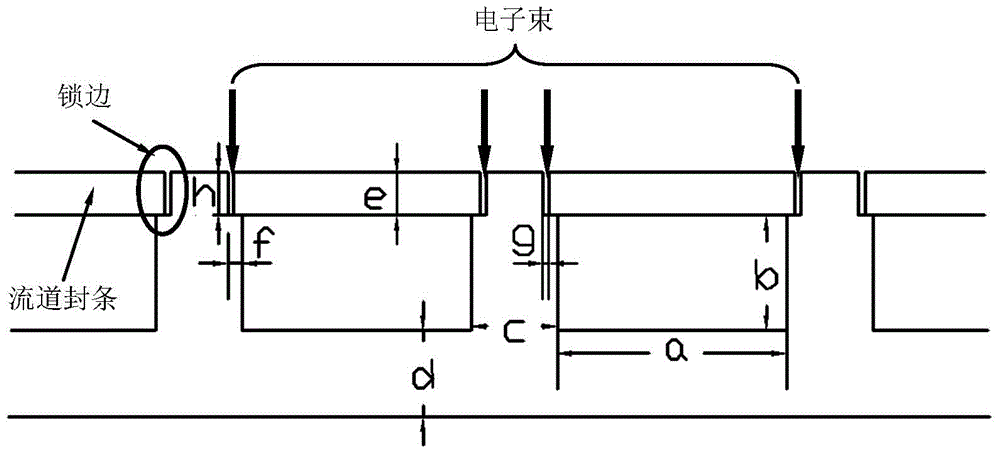

[0030] Example 1, taking the encapsulation and welding of the high-density and narrow-space flow channels of the cooling plate cladding of the fusion reactor China liquid lead-lithium experiment as an example, the cross-section is as follows figure 1 As shown, the structural material is Chinese low-activation martensitic (CLAM) steel;

[0031] (1) if figure 1 As shown, the cross-sectional dimensions of the high-density flow channel of the cooling partition are: width a=8mm, height b=4mm, and flow channel spacing c=3mm. according to figure 1 The dimensions of the flow channel seal and the assembly seam shown are designed as follows: seam depth h=1.2mm, width f=0.3mm, seal thickness e=1.4mm, and assembly gap g less than 0.2mm.

[0032] (2) Parts demagnetization treatment: use a planar AC demagnetizer to demagnetize the parts, the remanence rate of the parts after demagnetization measured by a Gauss meter is less than 3Gs, ultrasonic cleaning and acetone scrubbing.

[0033] (3...

Embodiment 2

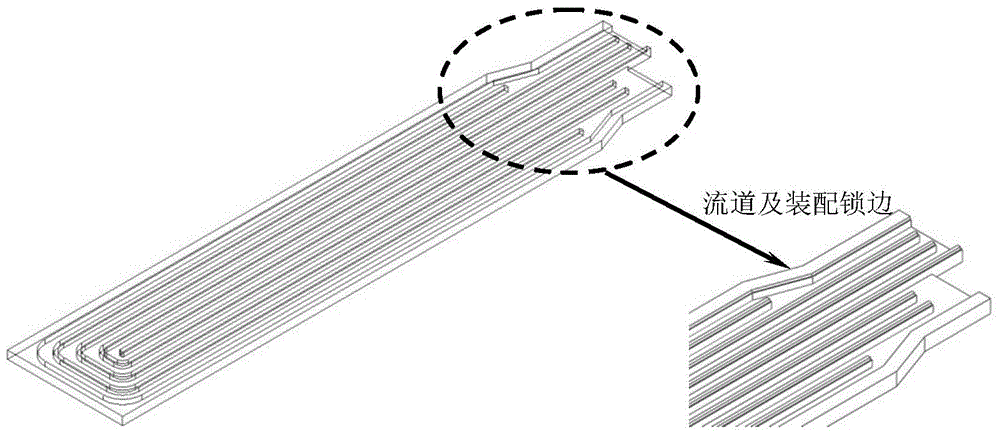

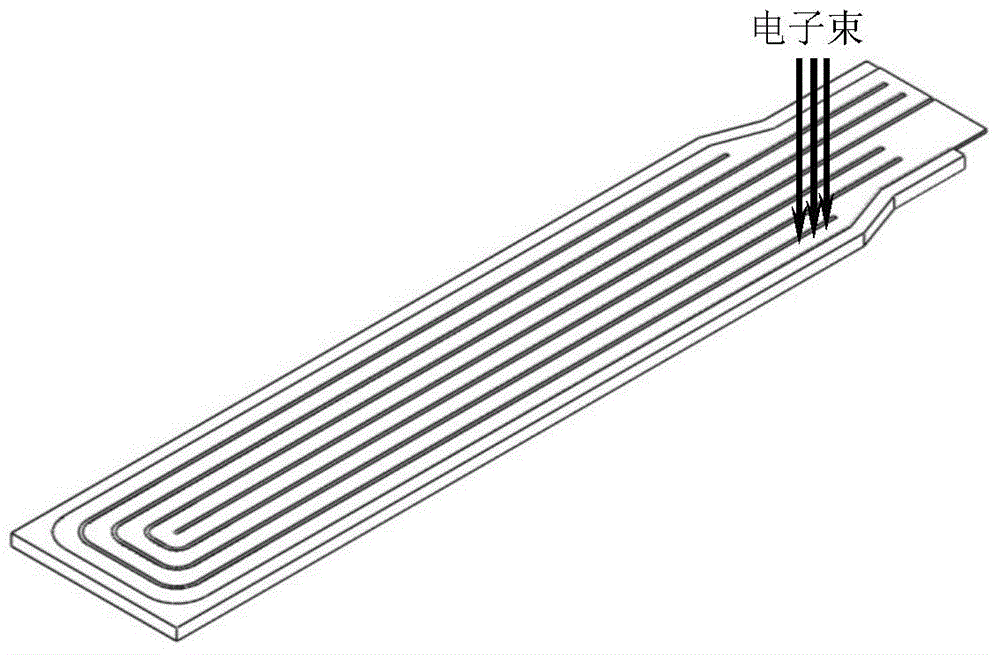

[0037] Example 2, taking the fusion reactor Chinese liquid lead-lithium cladding as an example, the packaging and welding of the radial-polar separator with high density and narrow interval flow channels, the cross-section is as follows figure 2As shown, the structural material is Chinese low-activation martensitic (CLAM) steel, and the preparation steps are as follows:

[0038] (1) Figure 4 It is a radial-polar partition flow channel structure; the cross-sectional dimensions of the flow channel are: width a=9mm, height b=4mm, and flow channel spacing c=3mm. according to figure 1 The dimensions of the flow channel seal and the assembly seam shown are designed as follows: seam depth h=1.4mm, width f=0.3mm, seal thickness e=1.5mm, and assembly gap g less than 0.2mm. The thickness of the substrate is 10mm, and channel steel anti-deformation restraint tooling is used in the process of processing and welding.

[0039] (2) Parts demagnetization treatment: use a planar AC demagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com