Manufacturing process for aluminum alloy vibrating platform

A vibration platform and manufacturing process technology, applied in manufacturing tools, metal processing equipment, arc welding equipment, etc., to achieve the effect of eliminating welding stress, ensuring size, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

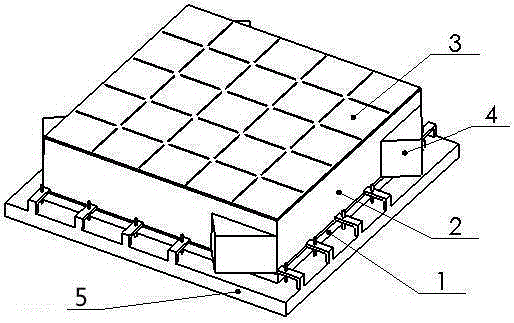

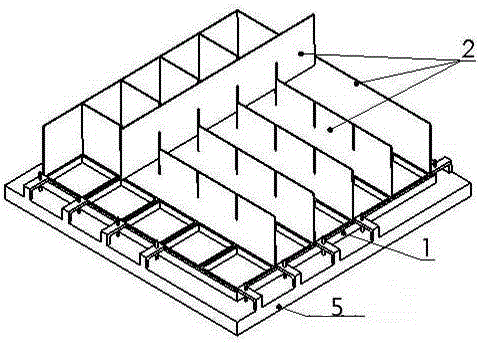

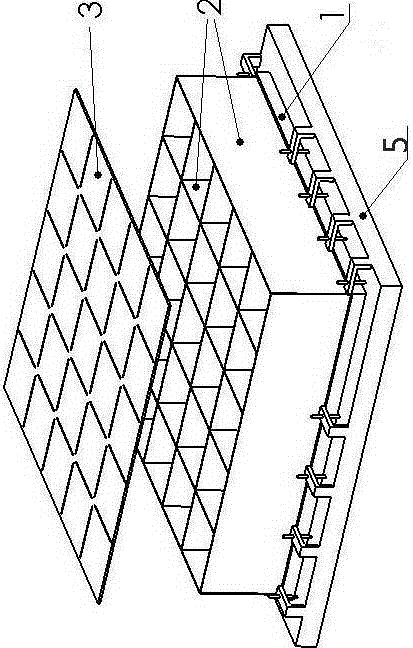

[0027] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0028] Such as figure 1 , figure 2 , image 3 As shown, the aluminum alloy vibration platform is mainly composed of panels, ribs, bottom plates and side pile feet, which are manufactured by optimizing the structural design and using the method of MIG shielded welding.

[0029] The grade of the aluminum alloy material is 5A06-H112. There is a lightening groove on the panel, and a positioning groove with a depth of 2mm is processed on the rib of the panel, and the length and width match the rib plate. All fillet welds are used, there are plug welding grooves on the bottom plate, the connection between the bottom plate and the rib plate is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com