Dual-phase high-strength steel welding parameter optimization method

A technology of welding parameters and optimization methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of manpower, financial resources and time waste, high operator requirements, low production efficiency, etc., to achieve The effect of improving quality, reducing the number of tests, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

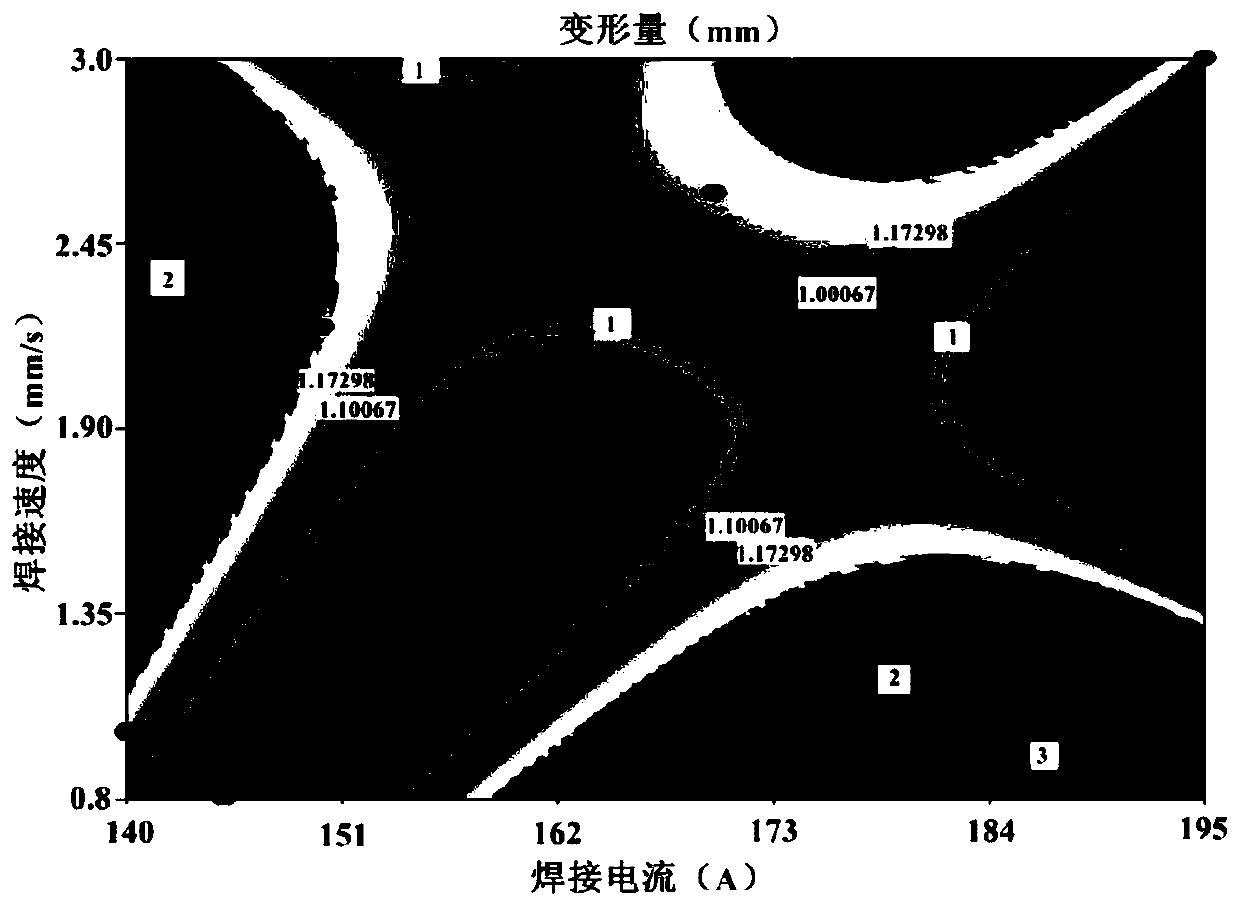

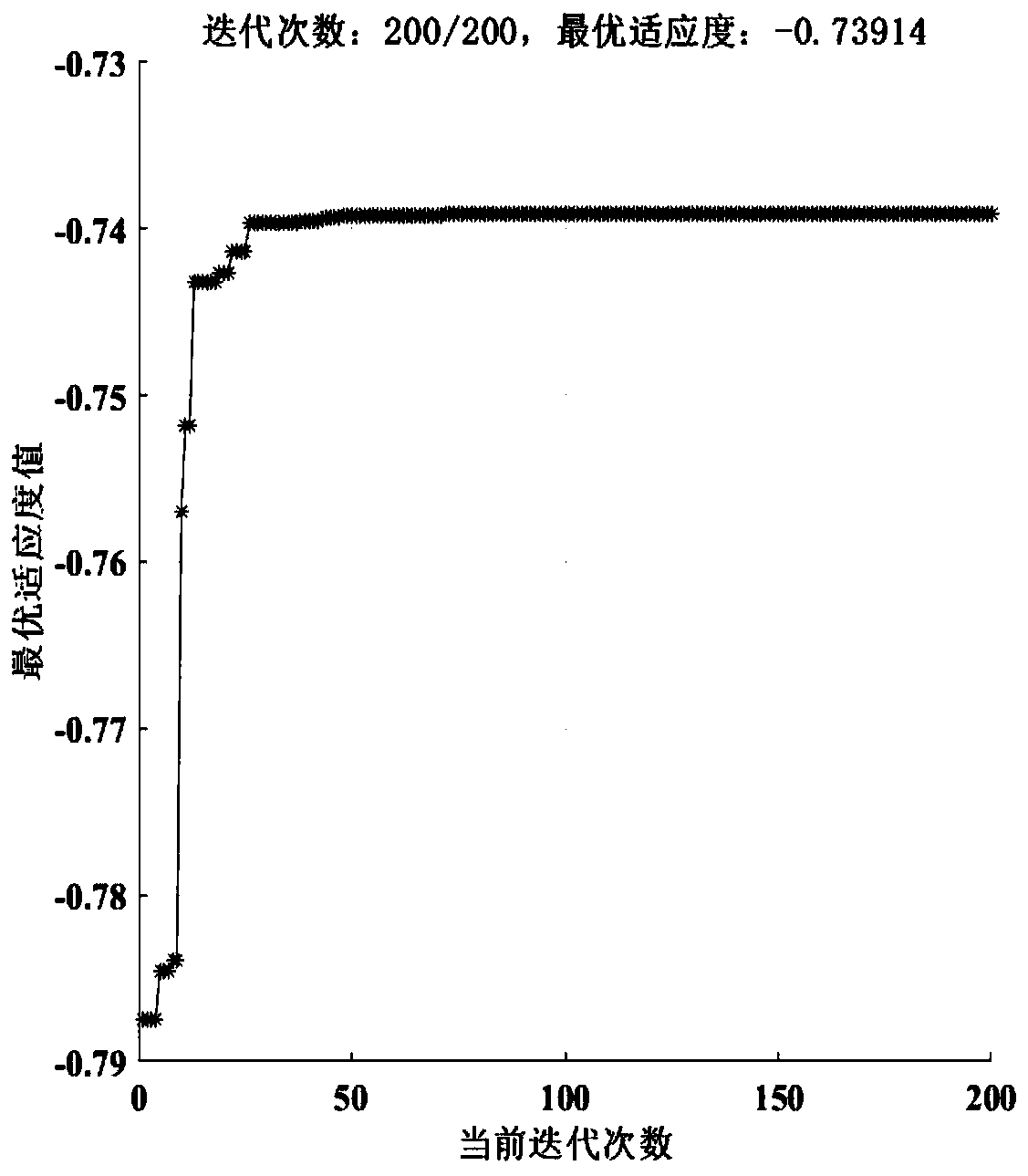

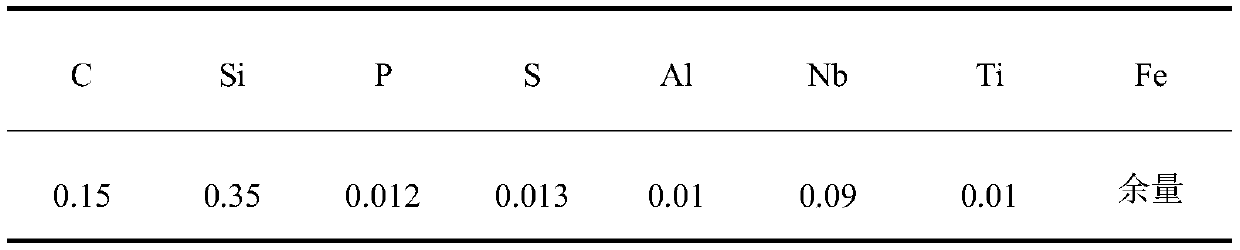

[0024] With the development of mathematical science, more and more studies on combining mathematical agent models with production to optimize product quality have been reported. However, in the field of welding, these methods have not been widely used. The quality of welded joints is directly related to the control of parameters by craftsmen. It is precisely because of the subjectivity of the control of process parameters in welding production that the quality of welded joints is often not optimal, resulting in short product service cycles and potential safety hazards. When using mathematical methods to optimize welding parameters, since the entire optimization process is only realized through a series of algorithms and models, the use of mathematical methods to optimize welding parameters can effectively avoid the influence of human subjectivity in the design process stage , so that the performance of the welded joint is further improved. At the same time, since the establi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com