Electronic beam welding method of sealing thin-wall aluminium alloy frame

A technology of electron beam welding and aluminum alloy frame, applied in the field of aluminum alloy welding, can solve the problems of difficult control of welding quality, difficult to improve product quality, large deformation of welding seam, etc., so as to shorten machining time, improve production efficiency, improve The effect of intergranular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

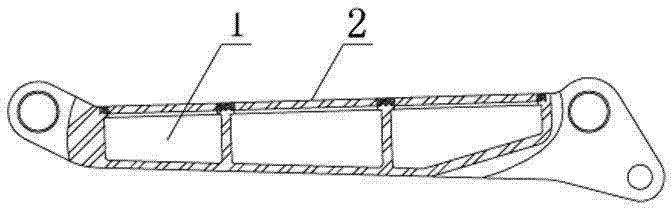

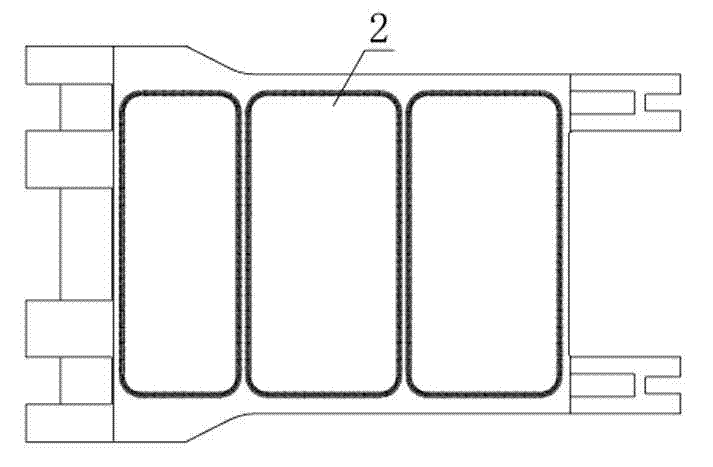

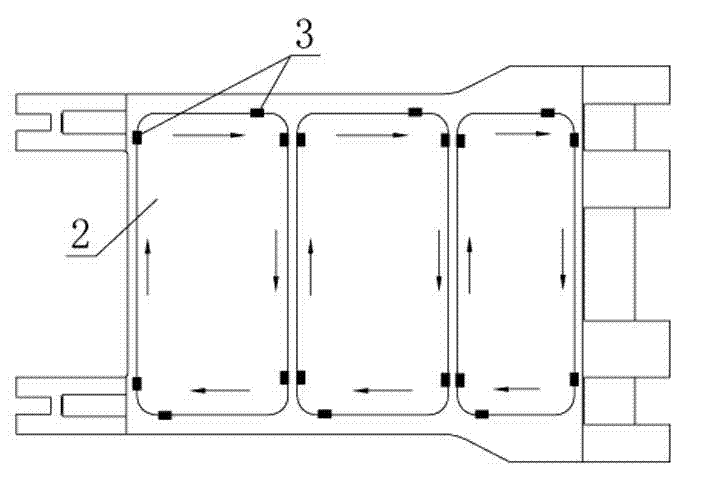

[0014] Such as figure 1 , 2 , 3, the closed thin-walled aluminum alloy frame is made of an upper opening cavity 1 made of aluminum alloy material, and a cover plate 2 fastened on the opening of the cavity 1; the cavity 1 and the cover plate The material of 2 is hard aluminum alloy 2A12, the thickness of the cover plate 2 is 3.5mm, the wall thickness of the adjacent two cavities 1 is 5mm, and the largest cavity 1 size is: 160 (length) × 80 (width) × 33 (height ) mm. It is required that the weld has no cracks, no unfused, less pores, less deformation, and less decrease in tensile strength. Because the total length of the weld is long, the heat is relatively concentrated; and the machining allowance of the workpiece after welding is required to be small, so the welding of the workpiece adopts the electron beam welding technology with less deformation. However, due to the special structural form of the thin-walled workpiece in cavity 1, all welding is performed on the same side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com