Rail transit box girder framework welding process and lean production layout method thereof

A welding process and rail transit technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as unreasonable setting of process positions, difficult adjustment and repair, and inability to meet quality requirements, so as to facilitate centralized management and coordination of processes , smooth and safe material transfer path, flexible customization and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

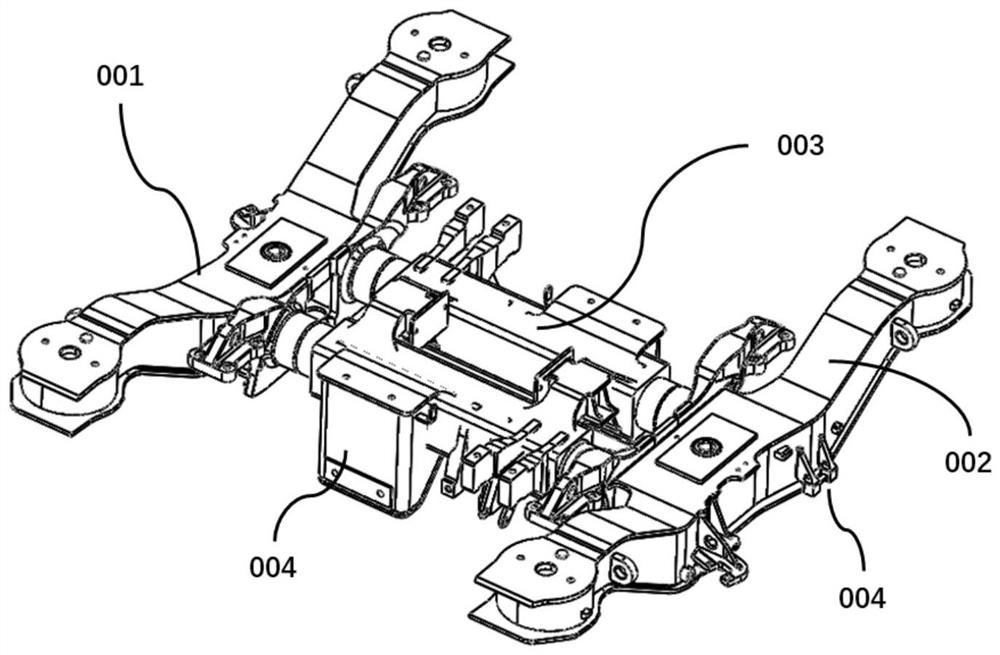

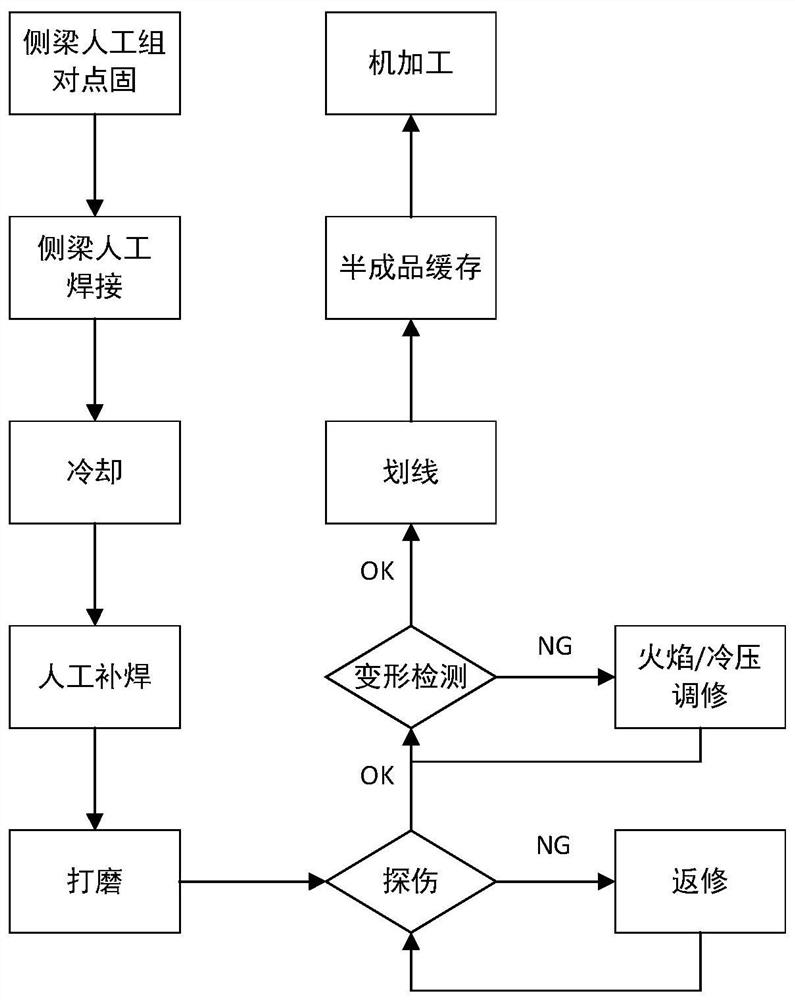

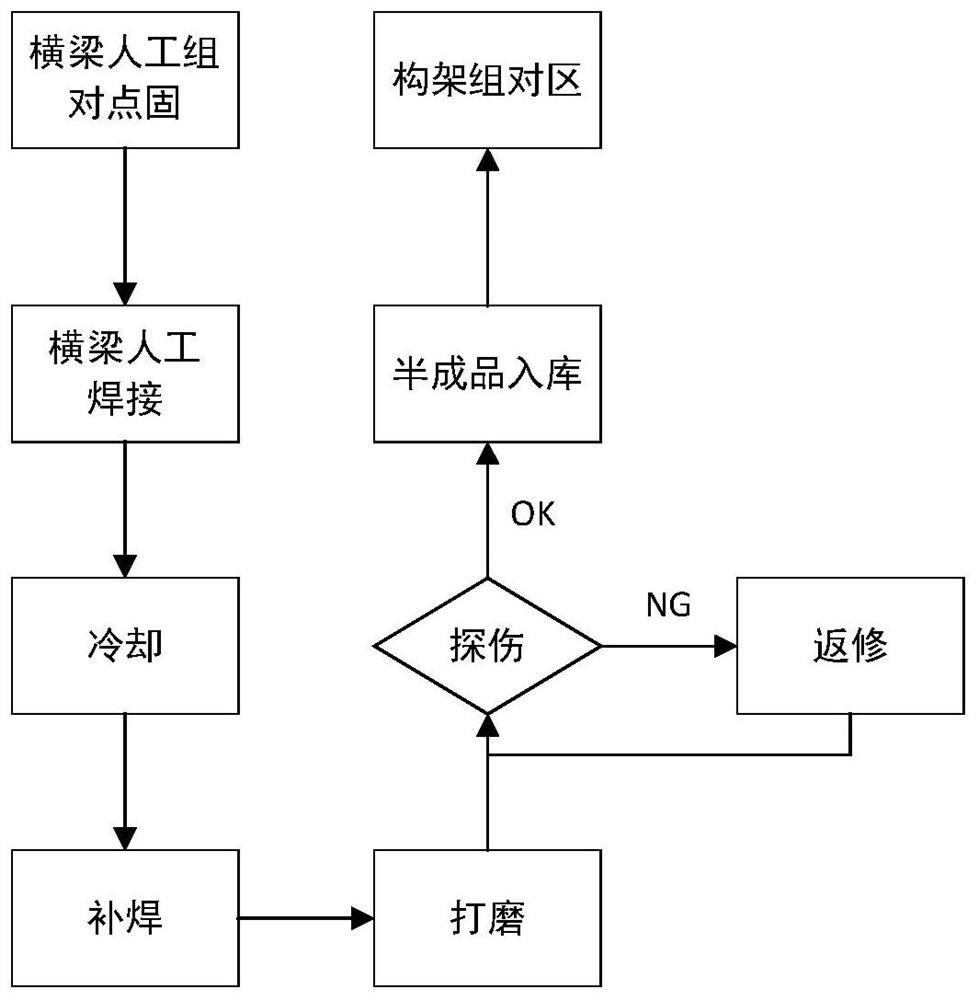

[0038] combined with Figure 8 to attach Figure 15 , a rail transit box girder frame welding process, which includes three sub-processes of side beam welding process, beam welding process and frame welding process; wherein there is no time sequence between the side beam welding process and the beam welding process, and the side beam welding process and the beam welding process are completed After the beam welding process, the frame welding process is carried out;

[0039] The welding process of the side beam includes the following steps: manual assembly of the inner cavity → automatic welding of the inner cavity → cooling → point fixing of the brake hanger and the inner cavity → automatic welding of the brake hanger and the inner cavity → cooling →Repair welding of inner cavity→Manual assembly and point fixing of upper cover→Priming of outer weld seam→Auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com