Manufacturing process of smoke waste heat exchanger for radiant tube burner

A flue gas waste heat and manufacturing process technology, applied in manufacturing tools, heat exchange equipment, applications, etc., can solve problems such as low work efficiency and poor welding quality, and achieve the effects of high production efficiency, good cohesion, and proper method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] A manufacturing process of a flue gas waste heat exchanger for a radiant tube burner, the manufacturing process sequentially includes the following steps:

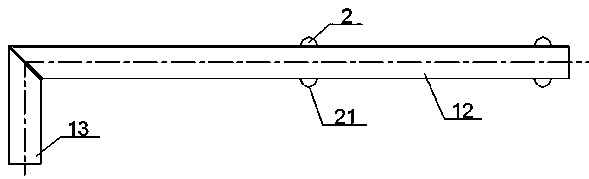

[0106] The first step: the assembly of the external air duct 12 and the air inlet duct 13, see figure 1 , figure 2 and image 3 :

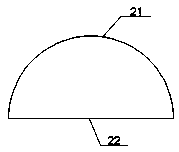

[0107] First weld the top of the air inlet pipe 13 to the left end of the external air duct 12 so that the air inlet pipe 13 and the external air duct 12 are vertically connected and communicated. During welding, the top of the air inlet pipe 13 and the external air duct The outer surface of the joint at the left end of 12 is fully welded, and at least one semicircular support group 2 is installed on the outer side of the external air duct 12 away from the air inlet pipe 13, and then the airtight leakage inspection is carried out. Complete the assembly of this step;

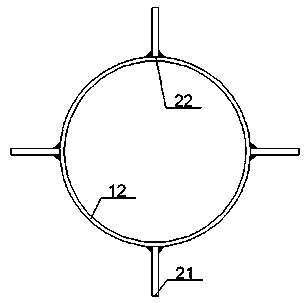

[0108] The semicircle support group 2 includes four semicircle supports uniformly arranged along the circular cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com