Slender part welding deformation control method

A deformation control, part welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to correct, low efficiency, long manufacturing cycle, etc., to improve work efficiency, strong operability, The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

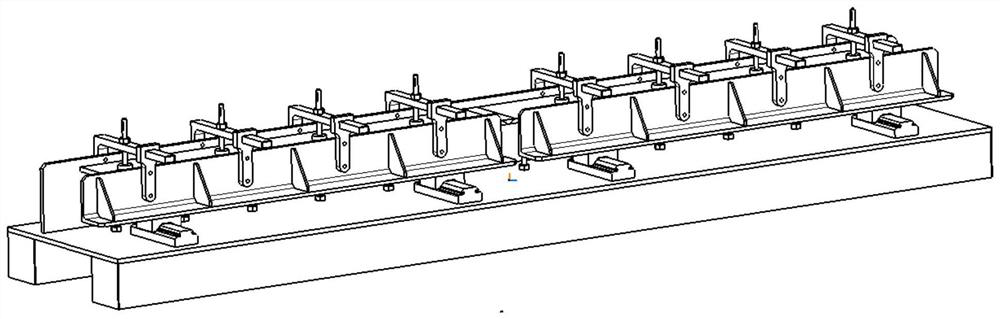

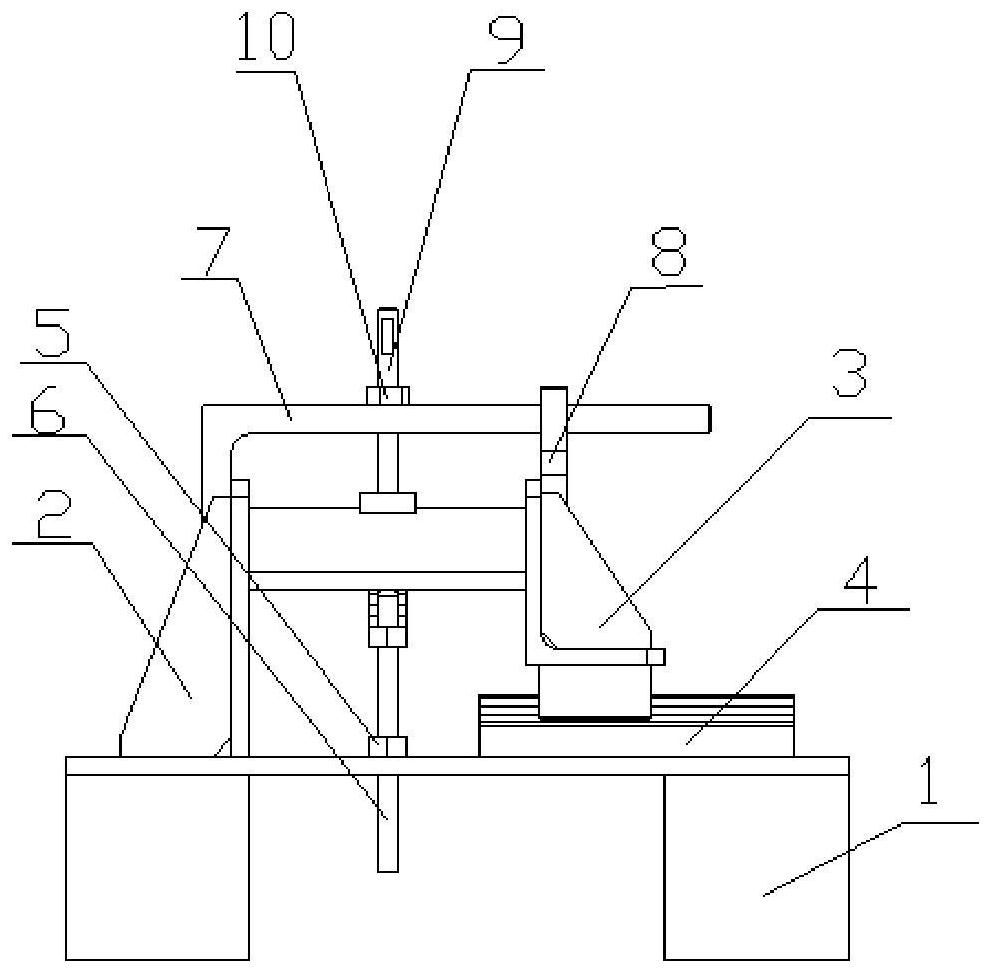

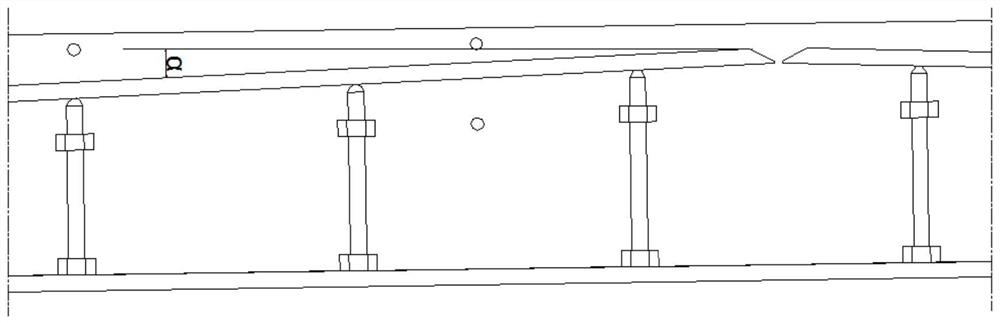

[0030] see Figure 1 to Figure 5 , a welding deformation control method for slender parts, the deformation is controlled by a flexible welding device and a flexible conformal device.

[0031] The flexible welding device includes a base 1, a fixed baffle 2, and a movable baffle 3. The base 1 is composed of two rectangular steel plates and a flat plate welded thereon, and a screw installation through hole is arranged along the center line of the rectangular steel longitudinal flat plate, and the screw rod 6. It can move up and down in the screw installation through hole, and its height position is fixed by the nut 5; a fixed baffle 2 is set on one side of the center line of the plate, and a slide rail 4 is set at the corresponding position of the fixed baffle on the other side along the vertical direction of the center line of the plate , the movable baffle 3 can slide along the slide rail 4; the flexible shape-retaining device is arranged at the position above the screw rod 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com