Method for manufacturing steel structure bridge T-shaped longitudinal rib braces

A manufacturing method and steel structure technology, which is applied in the field of bridge manufacturing, can solve the problems of low stiffening efficiency, poor quality, and high cost of T-shaped longitudinal ribs, and achieve the effects of mechanized operation, shortening the manufacturing cycle, and preventing bouncing and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

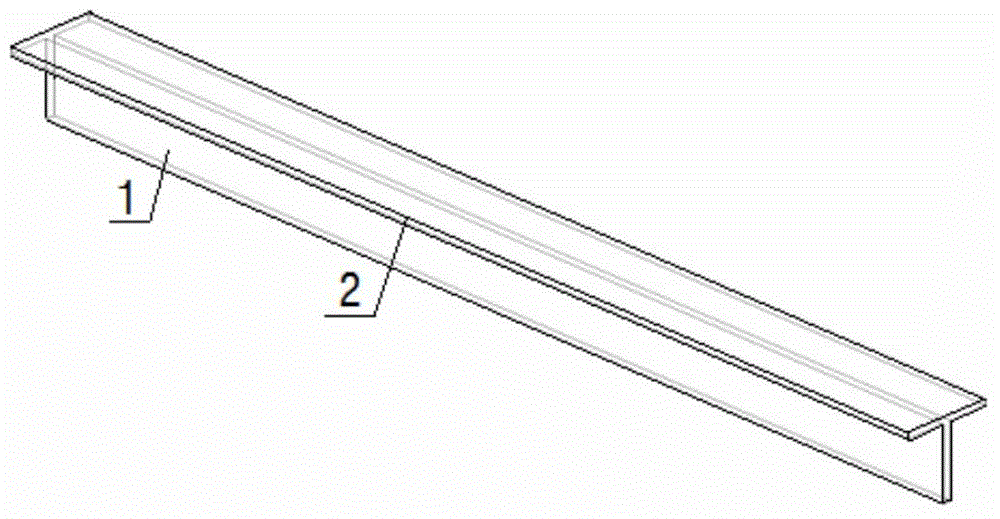

[0036] Embodiment 1: the present invention provides a kind of manufacturing method of T-type longitudinal rib stiffening of steel structure bridge, T-type longitudinal rib stiffening structure such as figure 1 As shown, it includes a T-shaped longitudinal rib stiffening web 1 and a T-shaped longitudinal rib stiffening flange 2, and the two parts are formed by welding.

[0037] The manufacturing method of T-type longitudinal rib stiffening of the present invention, operates as follows:

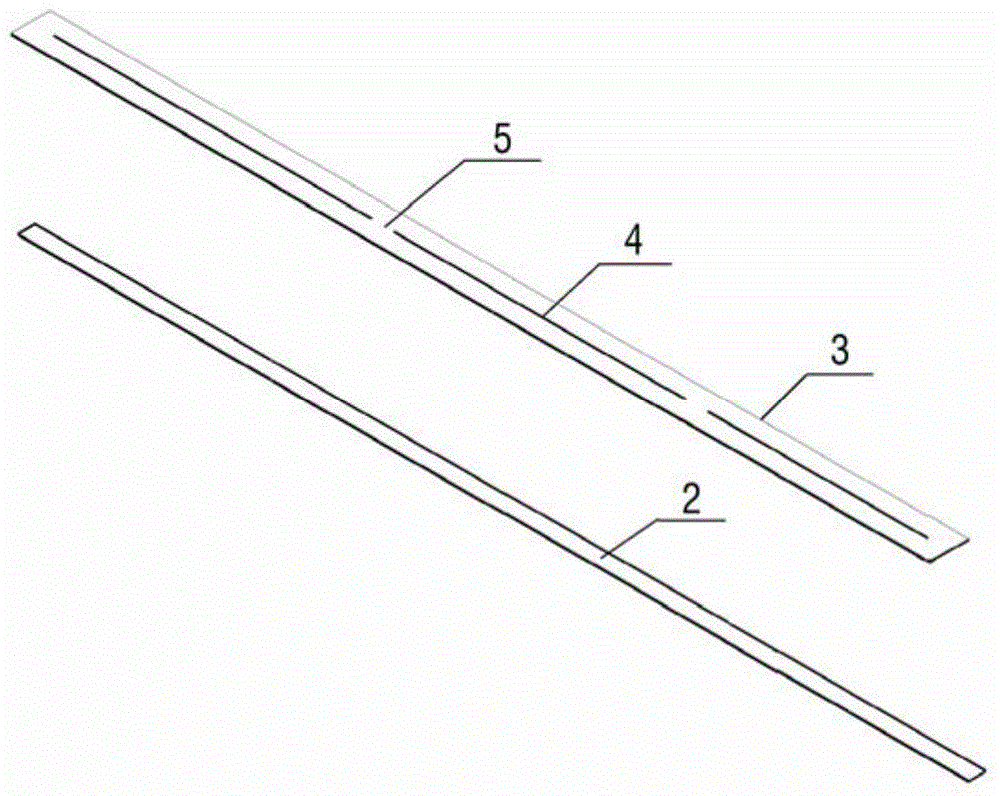

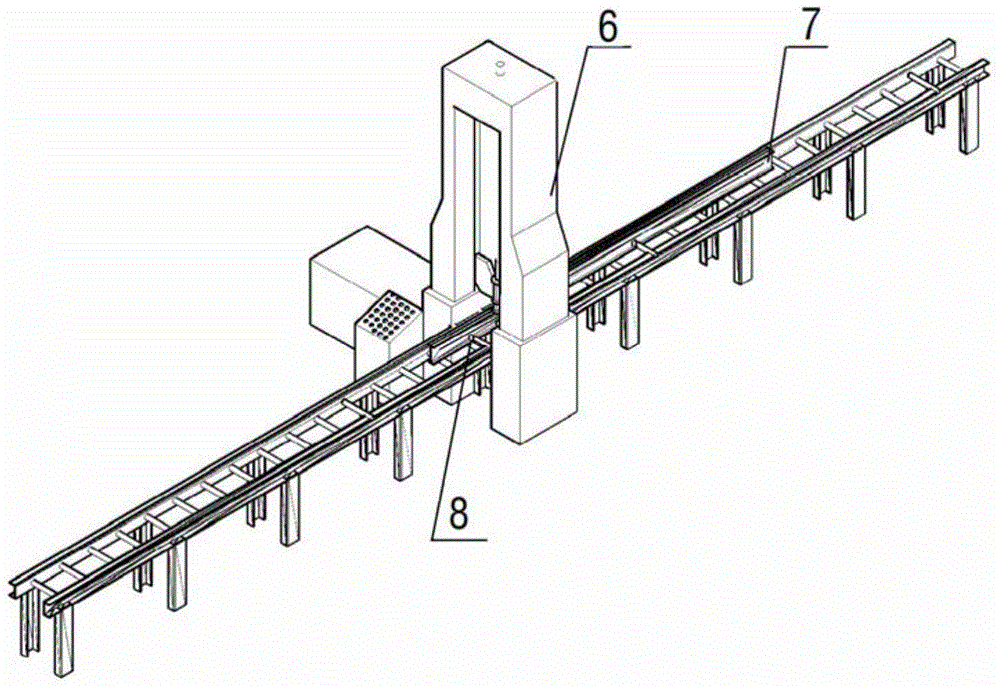

[0038] Step 1. Stake out the T-shaped longitudinal rib stiffener according to the steel structure bridge design drawings, and determine the specifications and dimensions of the T-shaped longitudinal rib stiffened web and flange, including the length, width and width of the T-shaped longitudinal rib stiffened web 1 and flange 2 Thickness; adopt the design that two symmetrical T-shaped longitudinal ribs are stiffened to form the H-shaped part 7, and draw the manufacturing drawing of the H-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com