Preparation method of steel lining prefabricated moulding bed in nuclear power station

A manufacturing method and technology for steel lining, which are applied in the field of making prefabricated tire molds, can solve the problem of not conforming to the manufacturing process of steel lining prefabricated tire molds for nuclear power plants and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

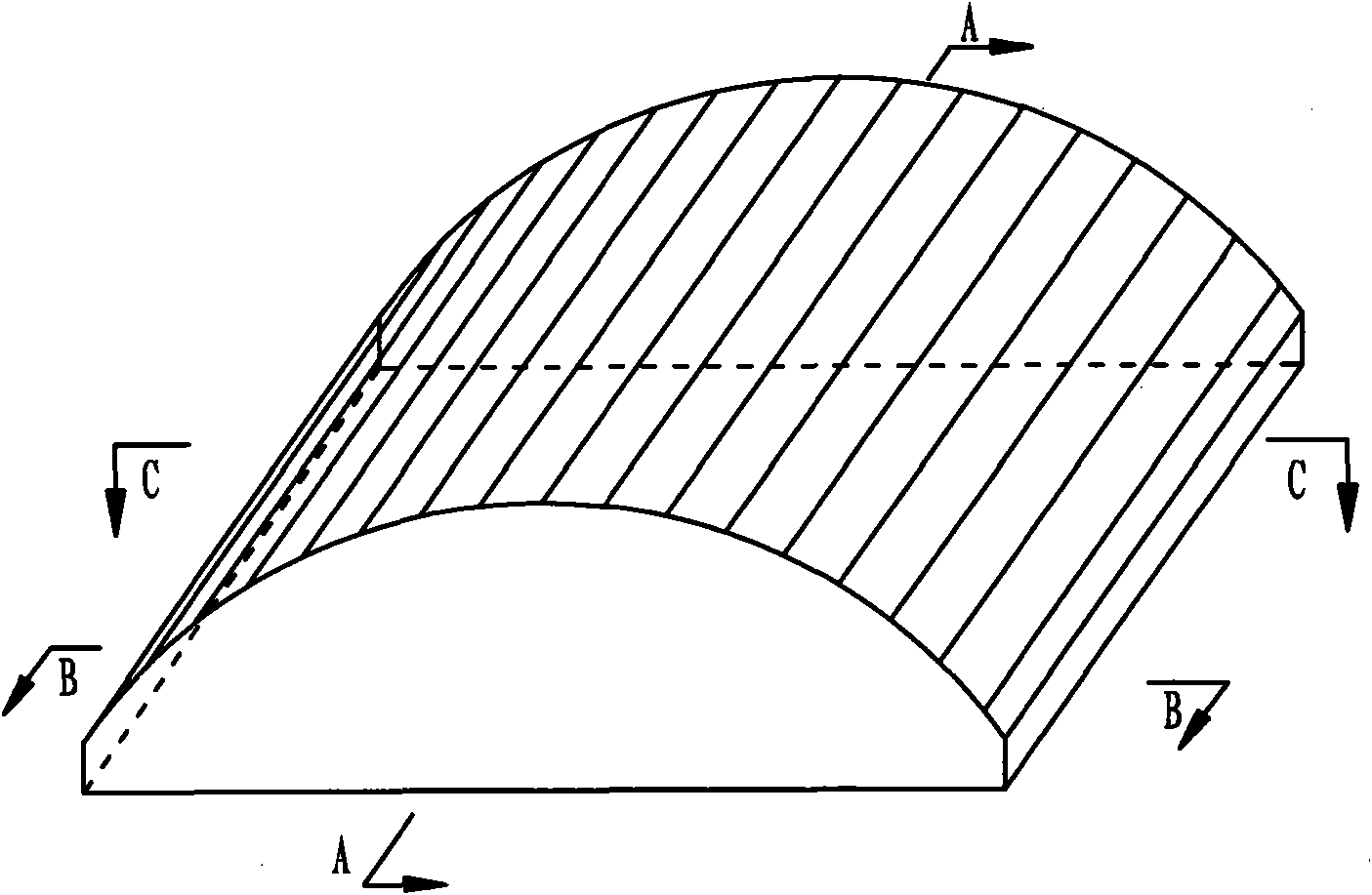

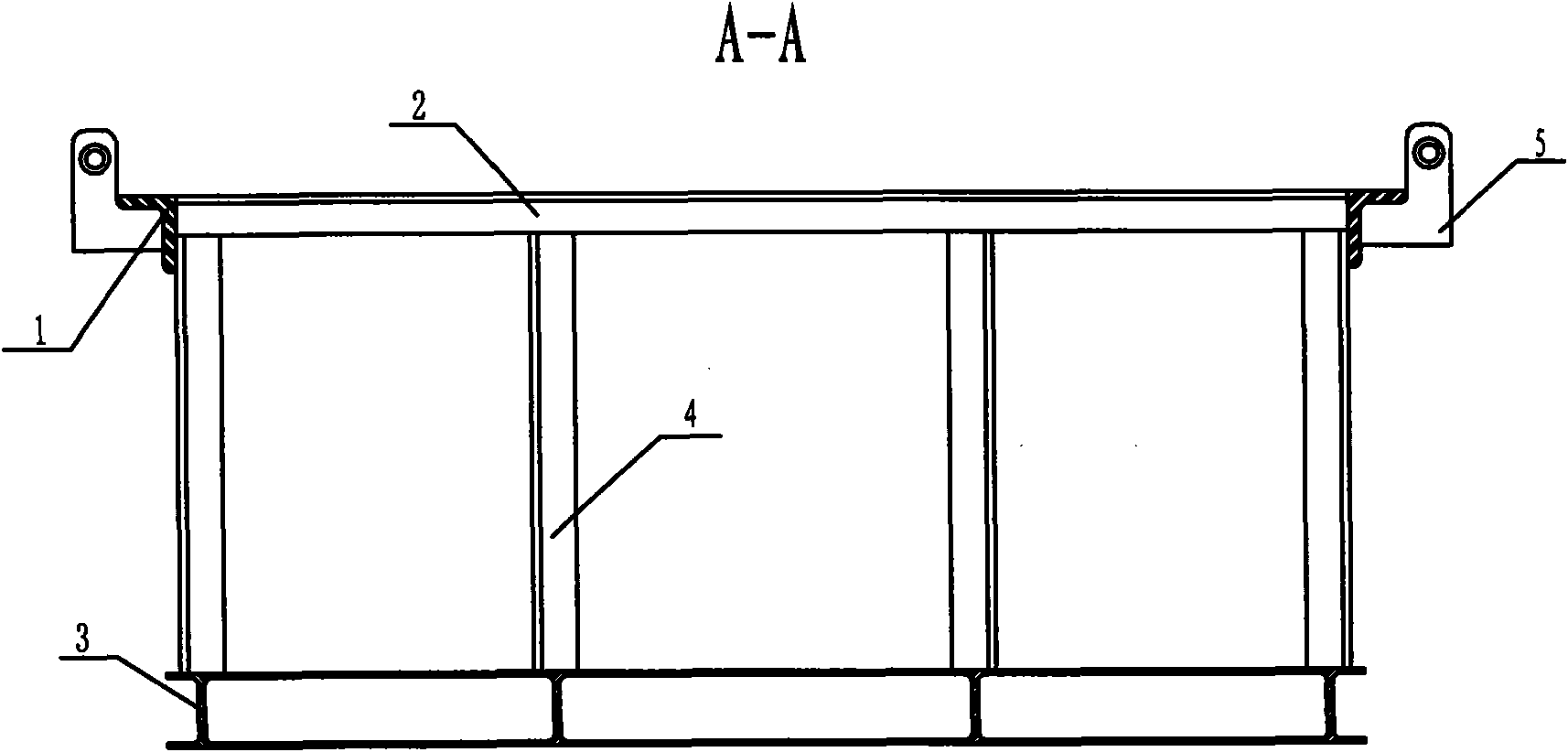

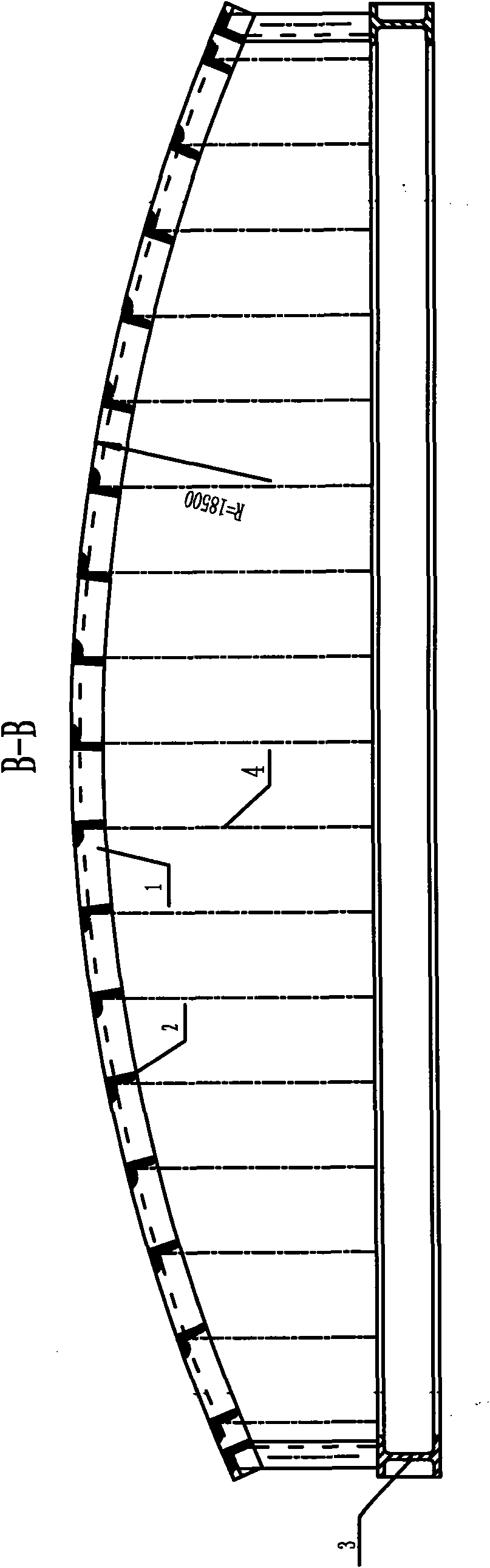

[0020] Such as figure 1 Shown, be the nuclear power plant steel lining prefabricated tire mold of the present embodiment, figure 2 , image 3 , Figure 4 respectively figure 1 A-A, B-B, C-C sectional views.

[0021] The nuclear power plant steel lining prefabricated tire mold manufacturing method provided by this embodiment comprises the following steps:

[0022] The first step, blanking cutting and correction - cut out the base section steel, the pole support 4 and the connecting angle steel between the pole supports according to the lofting diagram, and correct them (for parts with out-of-tolerance deformation after cutting, use cold and hot correction as appropriate) ), the connecting angle steel between the pole supports includes a longitudinal arc angle steel 1 and a transverse busbar angle steel 2, and the arc radius R=18500mm of the longitudinal arc angle steel 1 (the inner wall radius of the steel lining cylinder); the base section steel is the common type I25a I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com