Patents

Literature

219results about How to "Improve manufacturing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

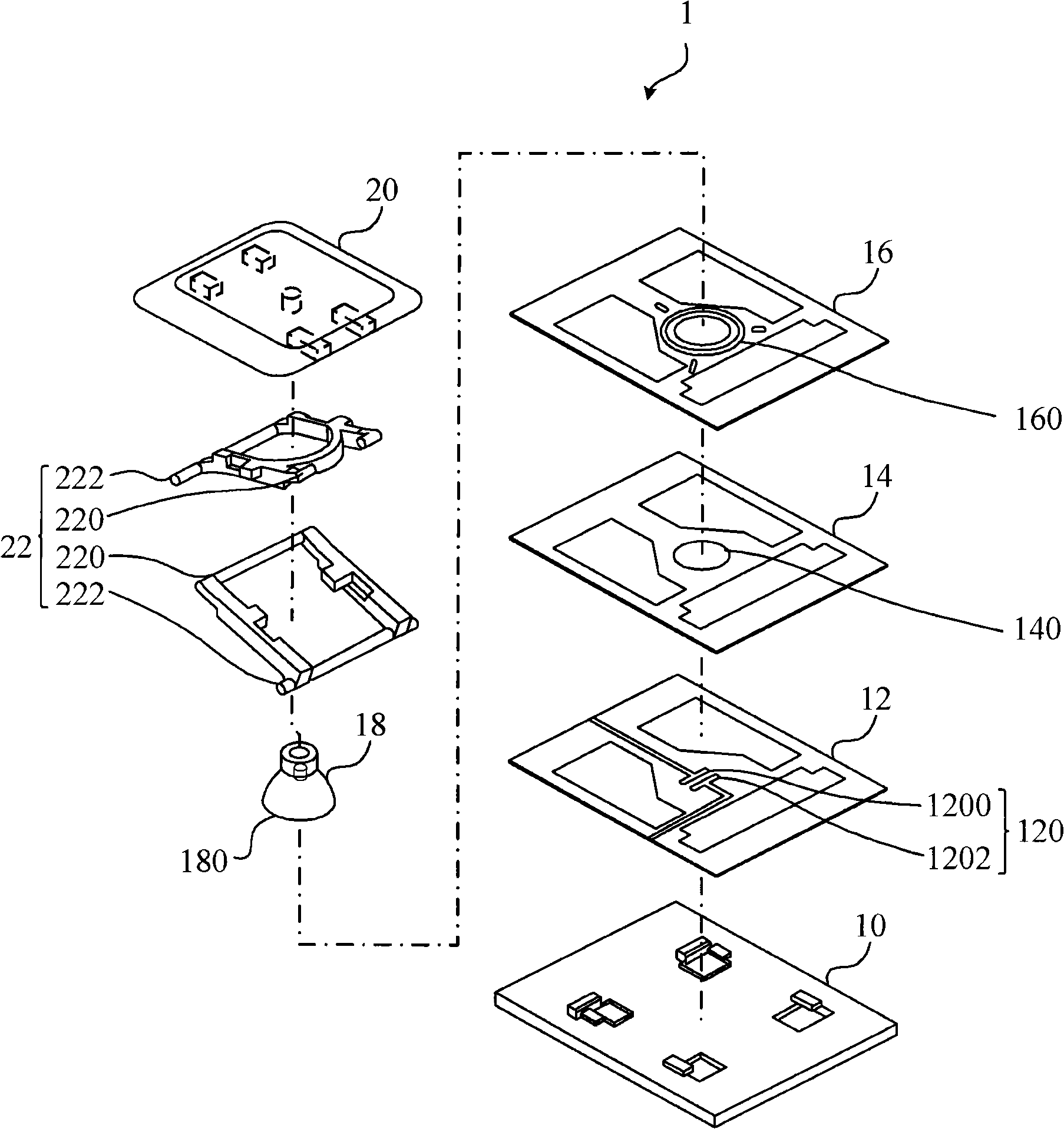

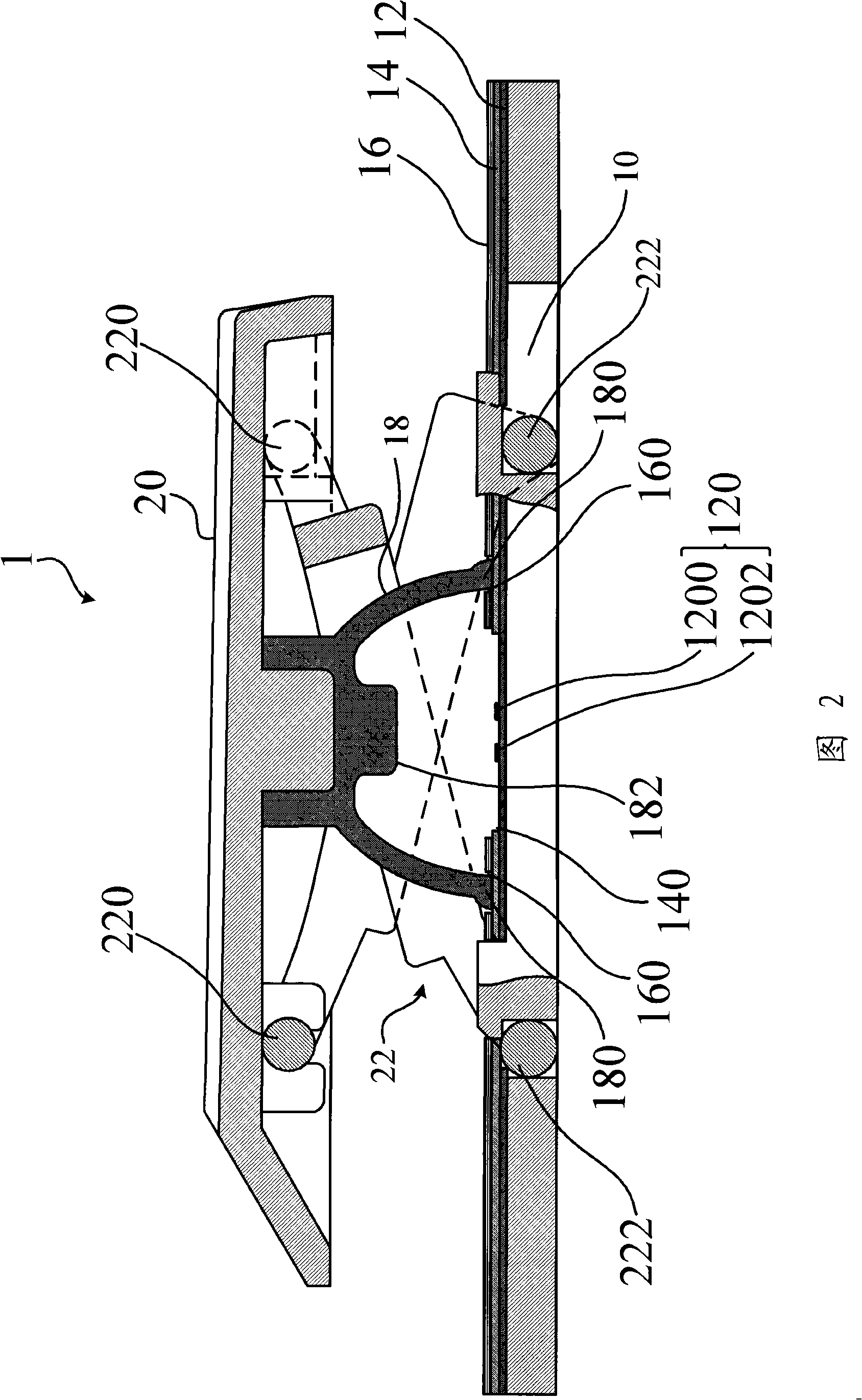

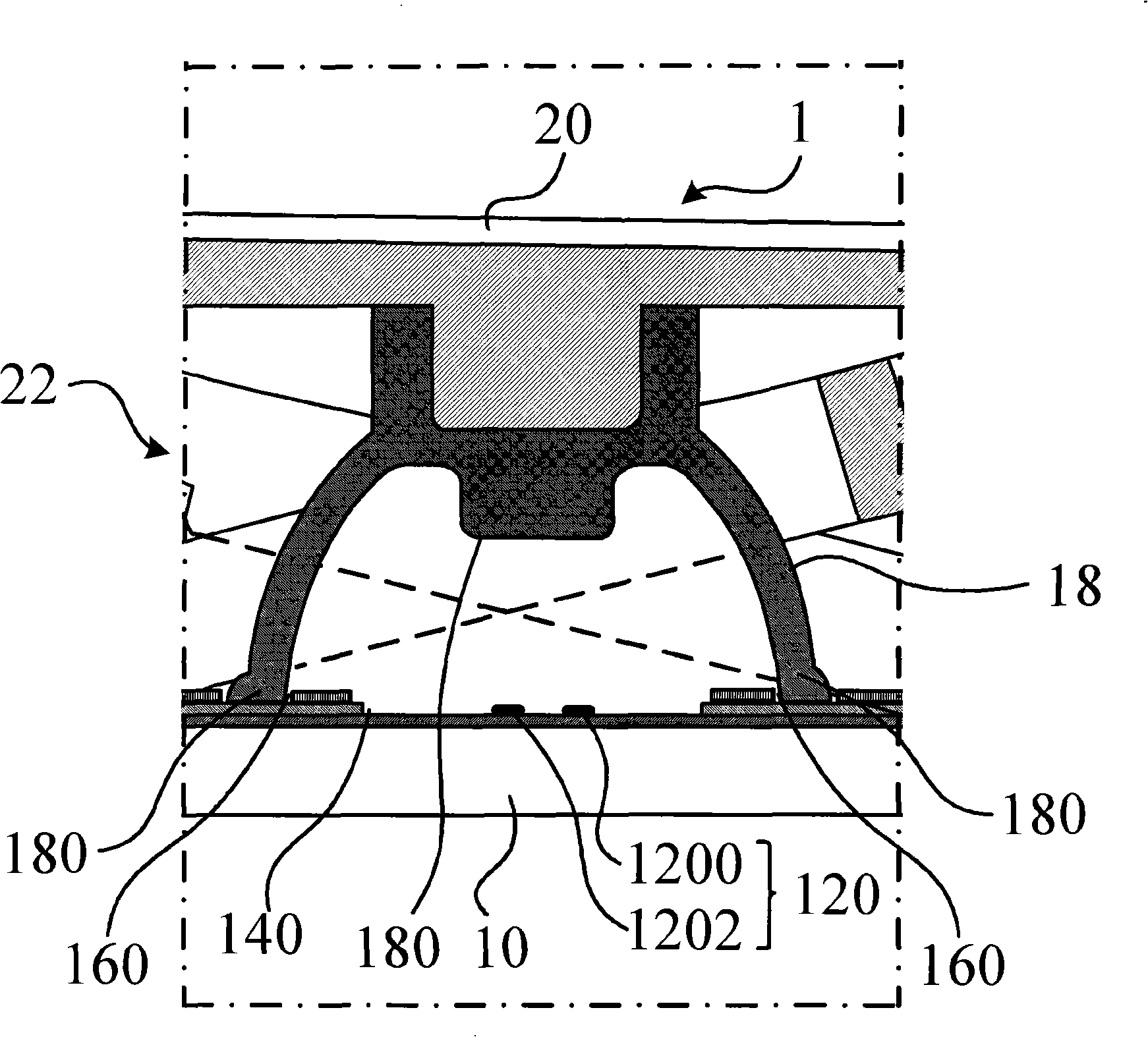

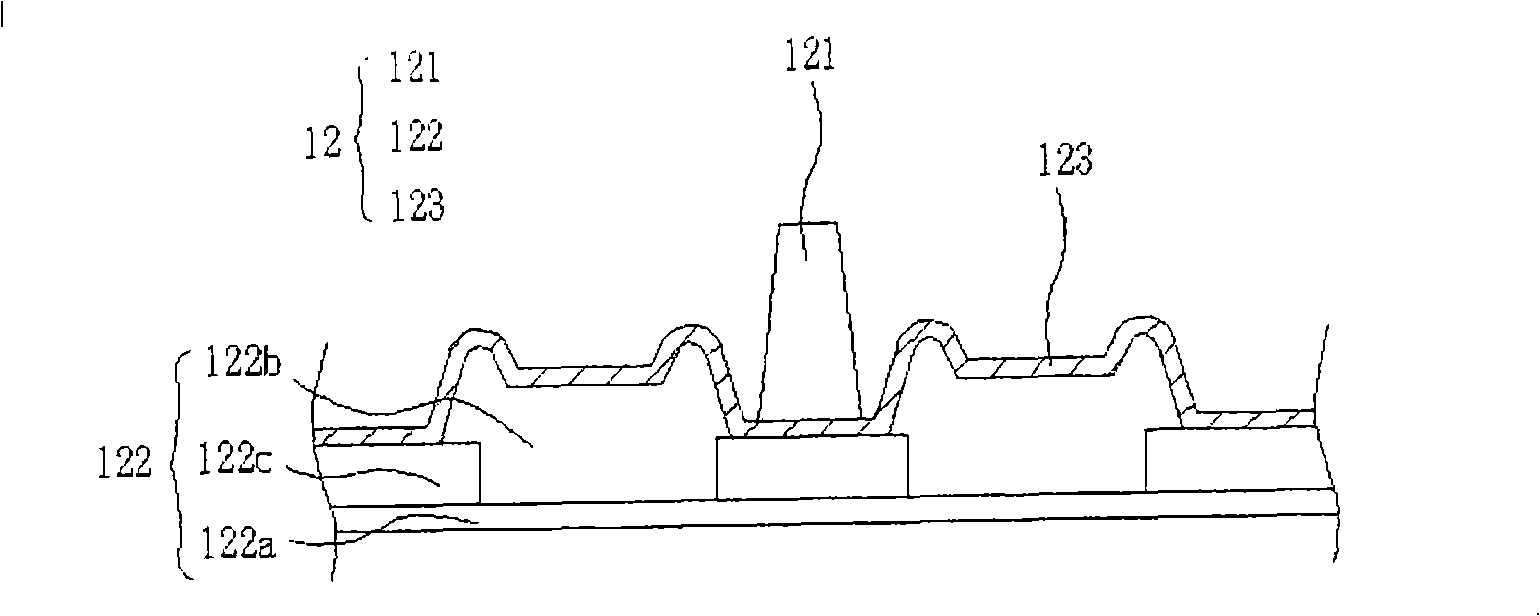

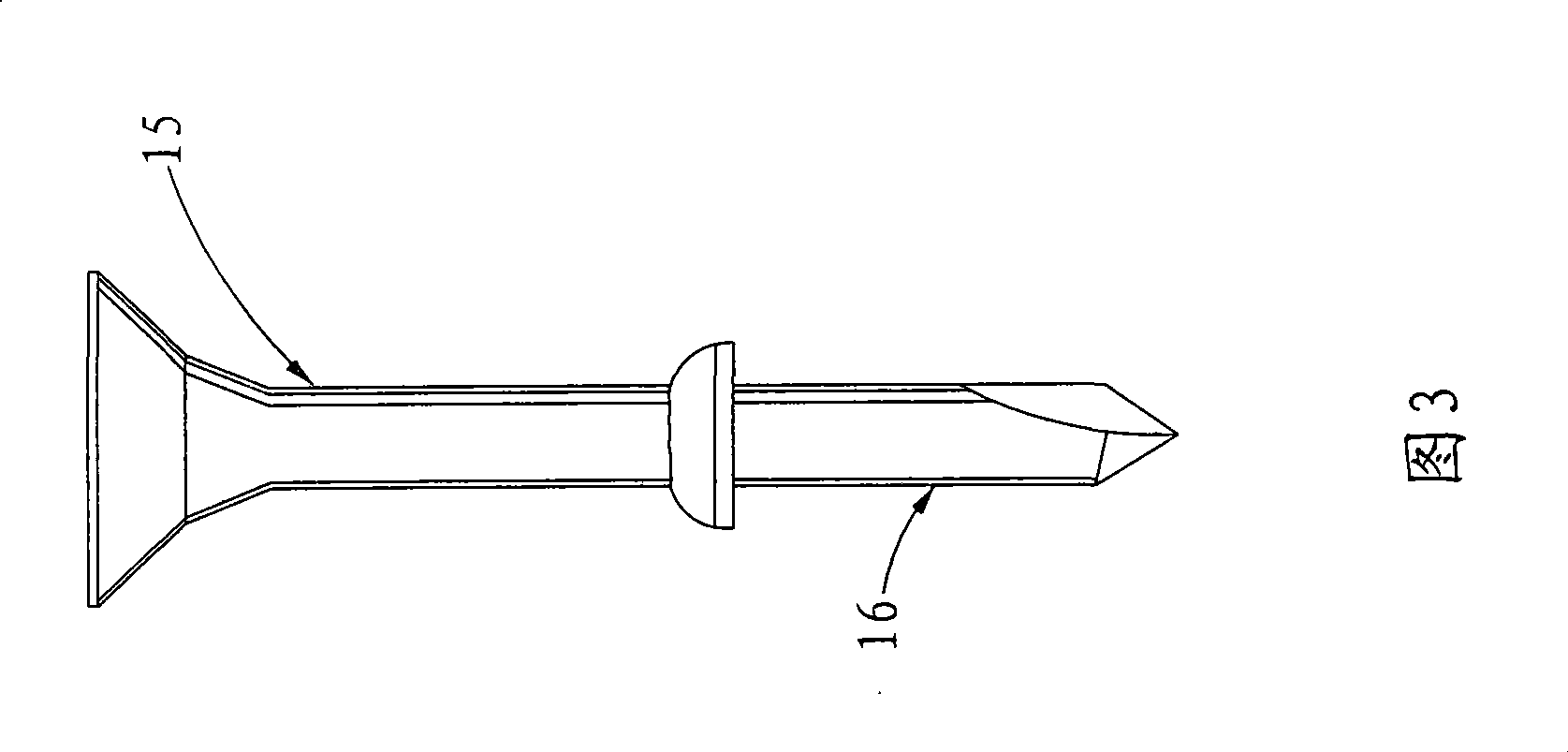

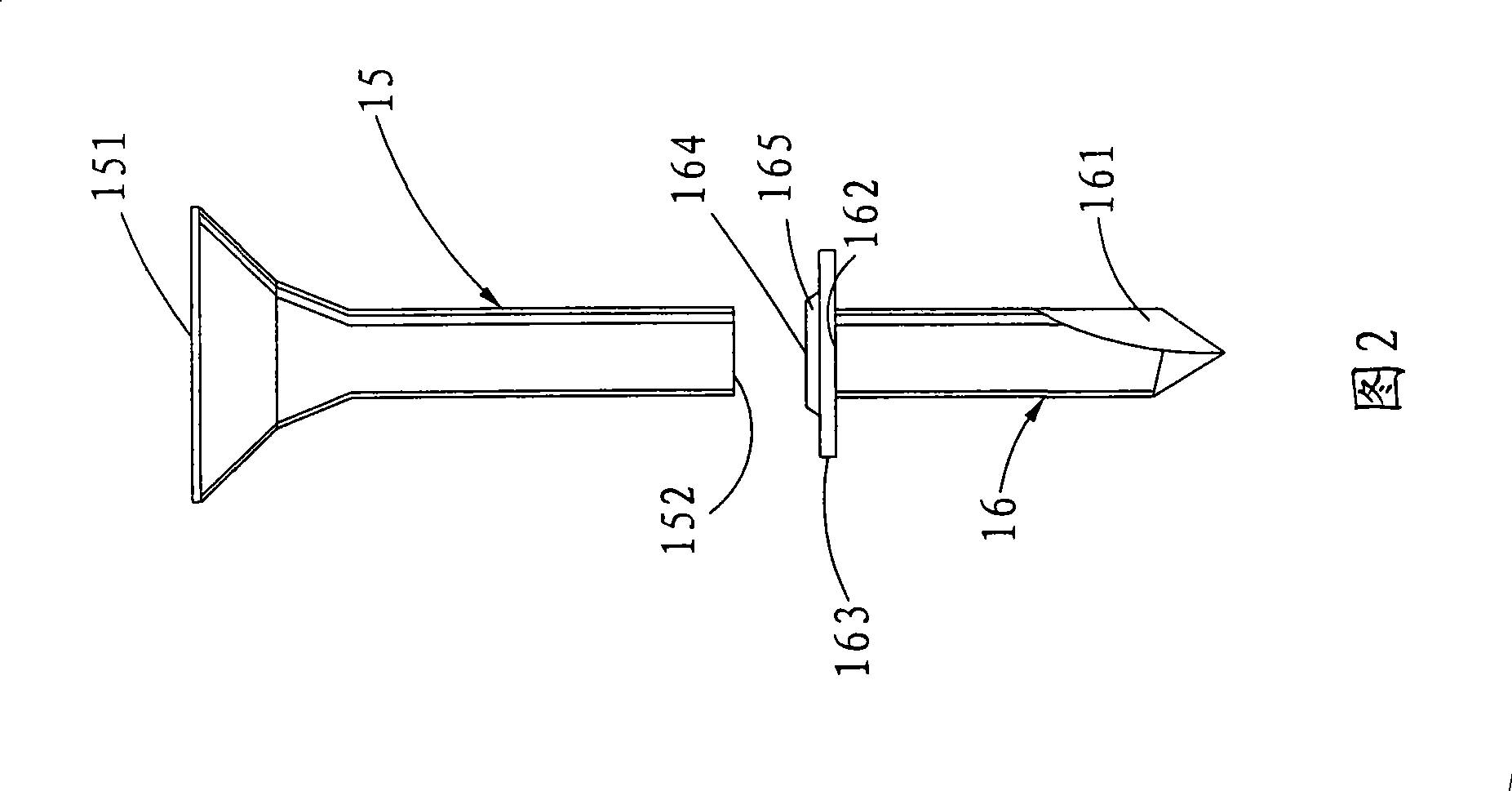

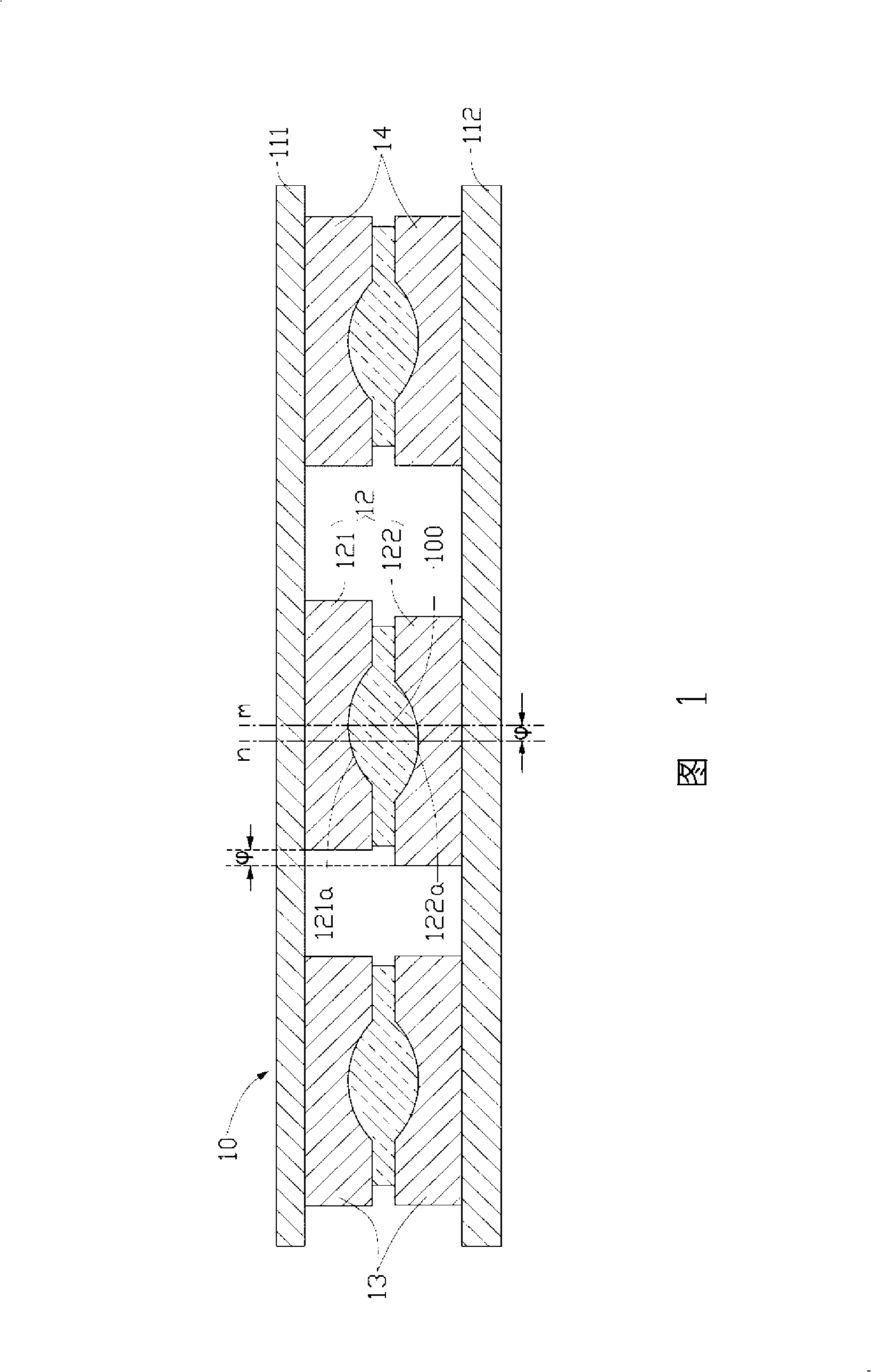

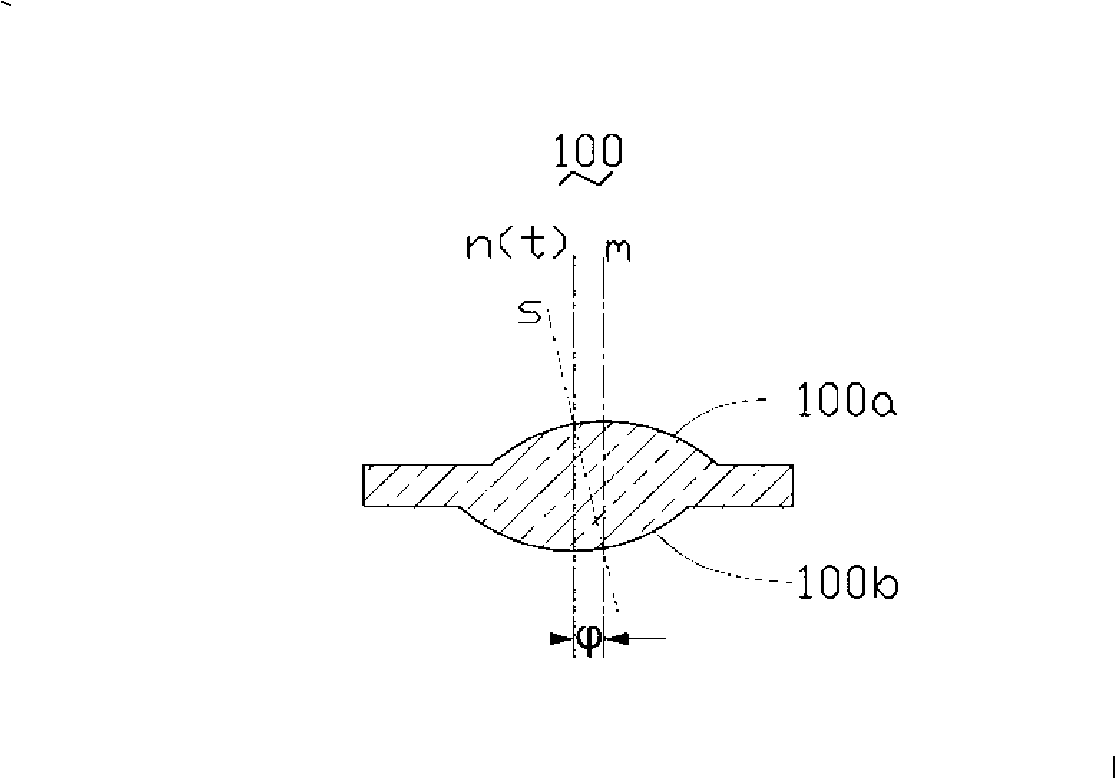

Press key using film switch circuit and manufacturing method thereof

InactiveCN101315841AImprove manufacturing qualityHigh product yieldInput/output for user-computer interactionElectric switchesMembrane switchEngineering

The invention provides a membrane switching circuit and a keystroke using the membrane switching circuit. An insulating layer of the membrane switching circuit is provided with an annular opening. The bottom of an elastic element is matched with the annular opening of the insulating layer and bonded to the annular opening by an adhesive. The annular opening can assist the elastic element to be accurately bonded to a designated position. In addition, the annular opening can prevent the adhesive from overflowing out of the annular opening.

Owner:DARFON ELECTRONICS CORP

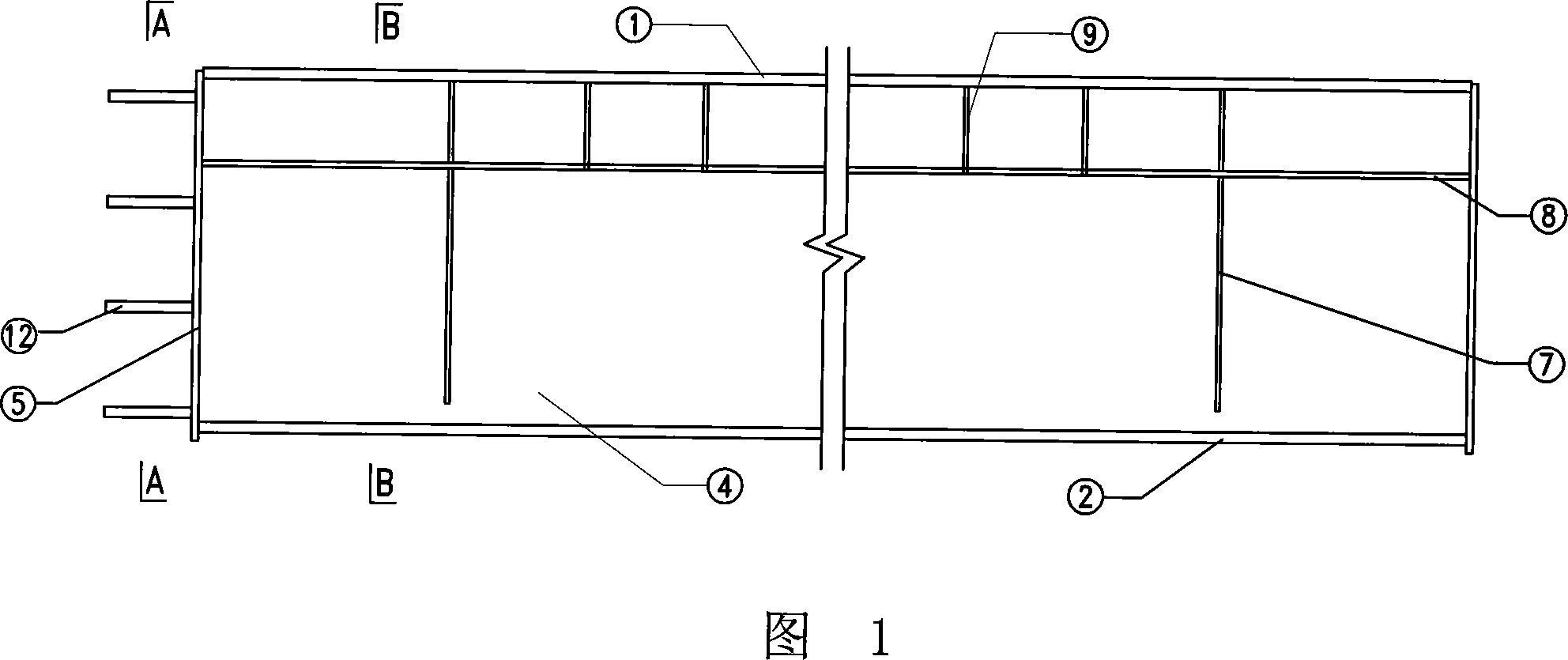

Method for assembling and welding cased crane-beam in circular rail of nuclear-power station

ActiveCN101074085ASmall amount of welding deformationGuarantee welding qualityArc welding apparatusRunwaysPower stationNuclear power

The invention is concerned with an assembled and seal method of box crane beam with ring type orbit using for nuclear power plant, belonging to the establishment construction technology field of nuclear power plant. It relates to rectification of stuff, sealing inner and outside webs and clapboard, sealing upper and down wing edge and the inner and outside webs, sealing stiffened panel, sealing end plate and the rectify after seal. Assemble and seal the web and inner muscle plate to a type of H to reduce the distortion and keep the seal quality, while the temporary backboard controls the final seal distortion when sealing the end plate. It will control the distortion effectively to reach the demand of the first level of nuclear quality and nuclear safety through easy adjustment of circle crane beam after sealed with steady quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

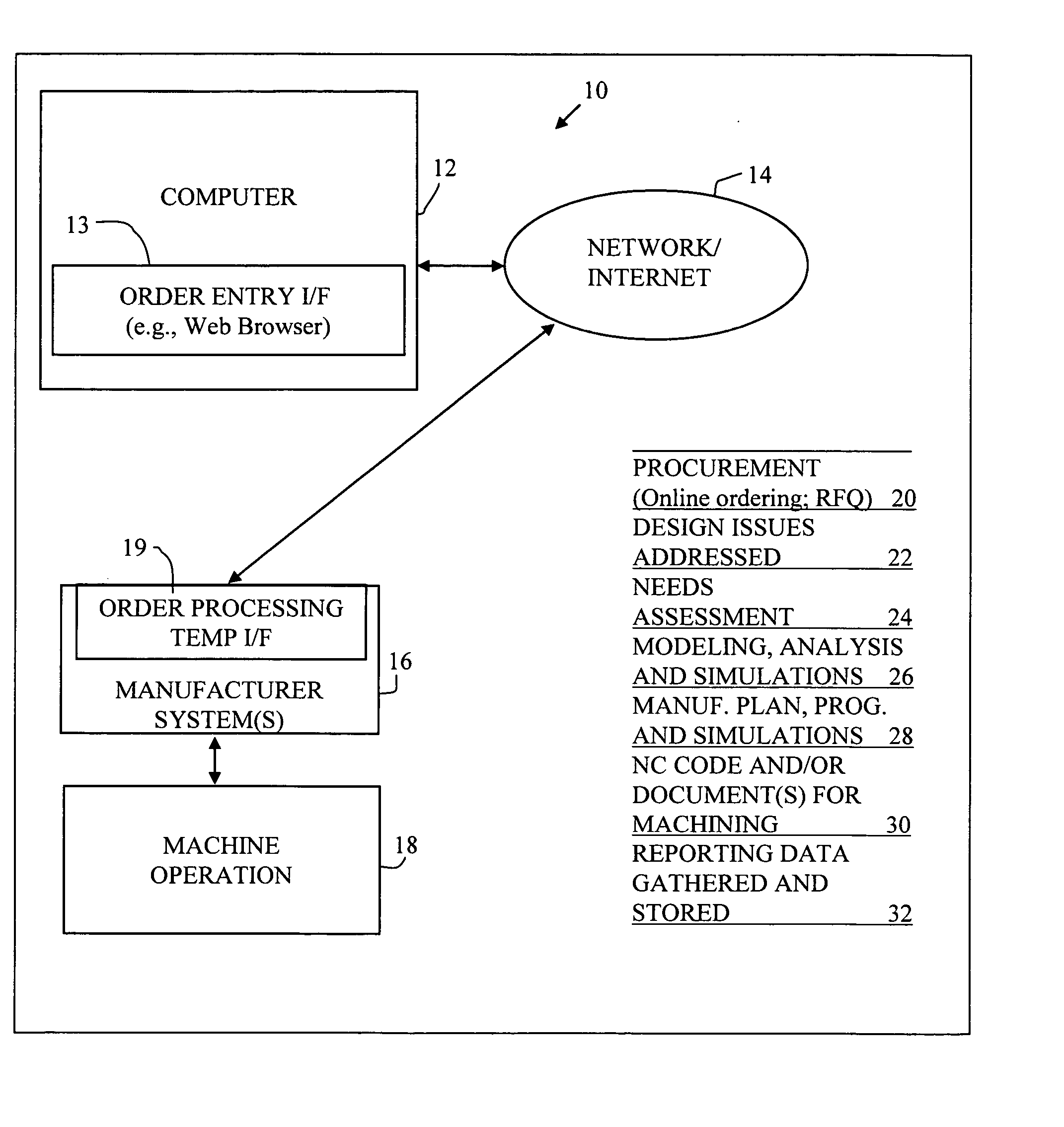

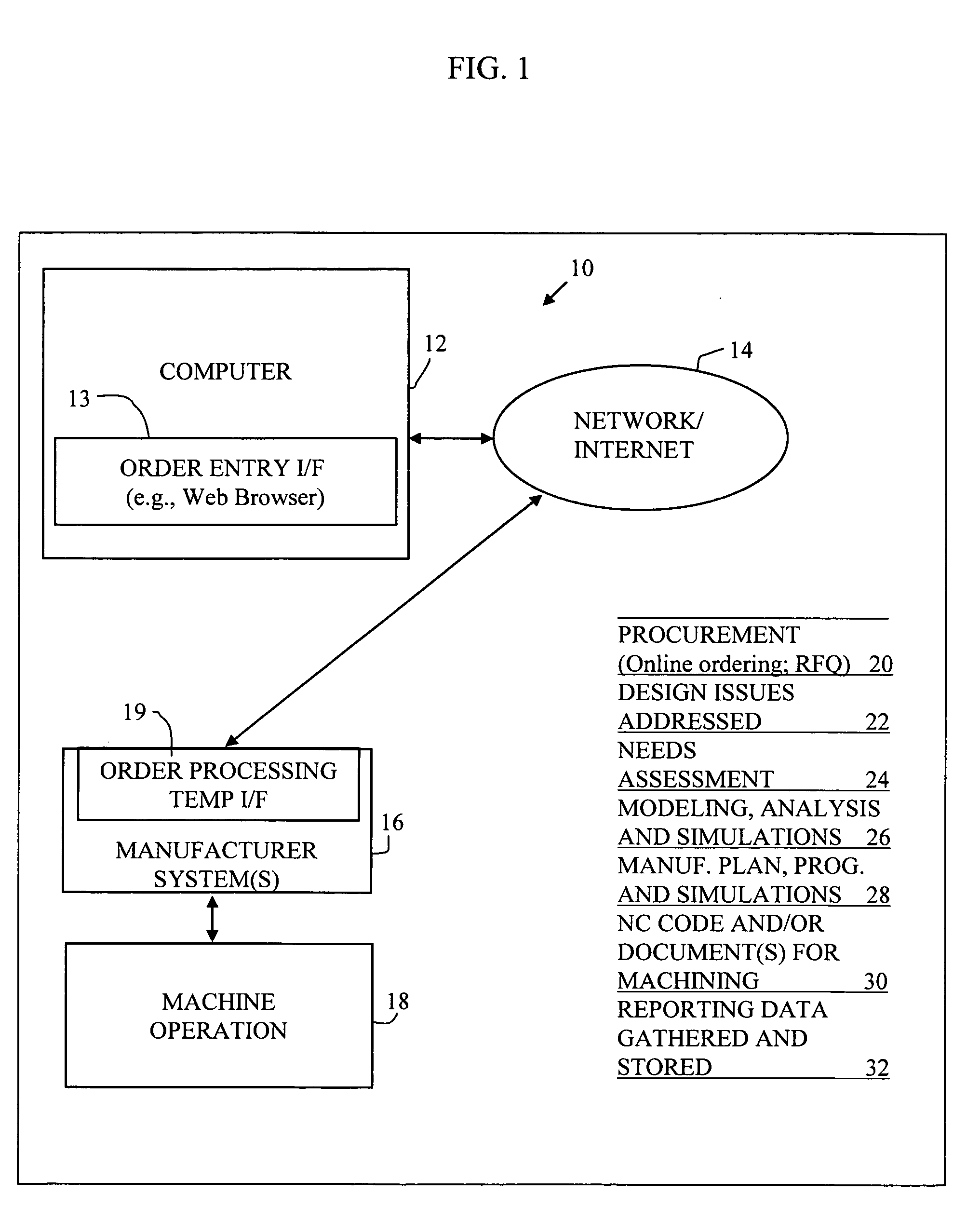

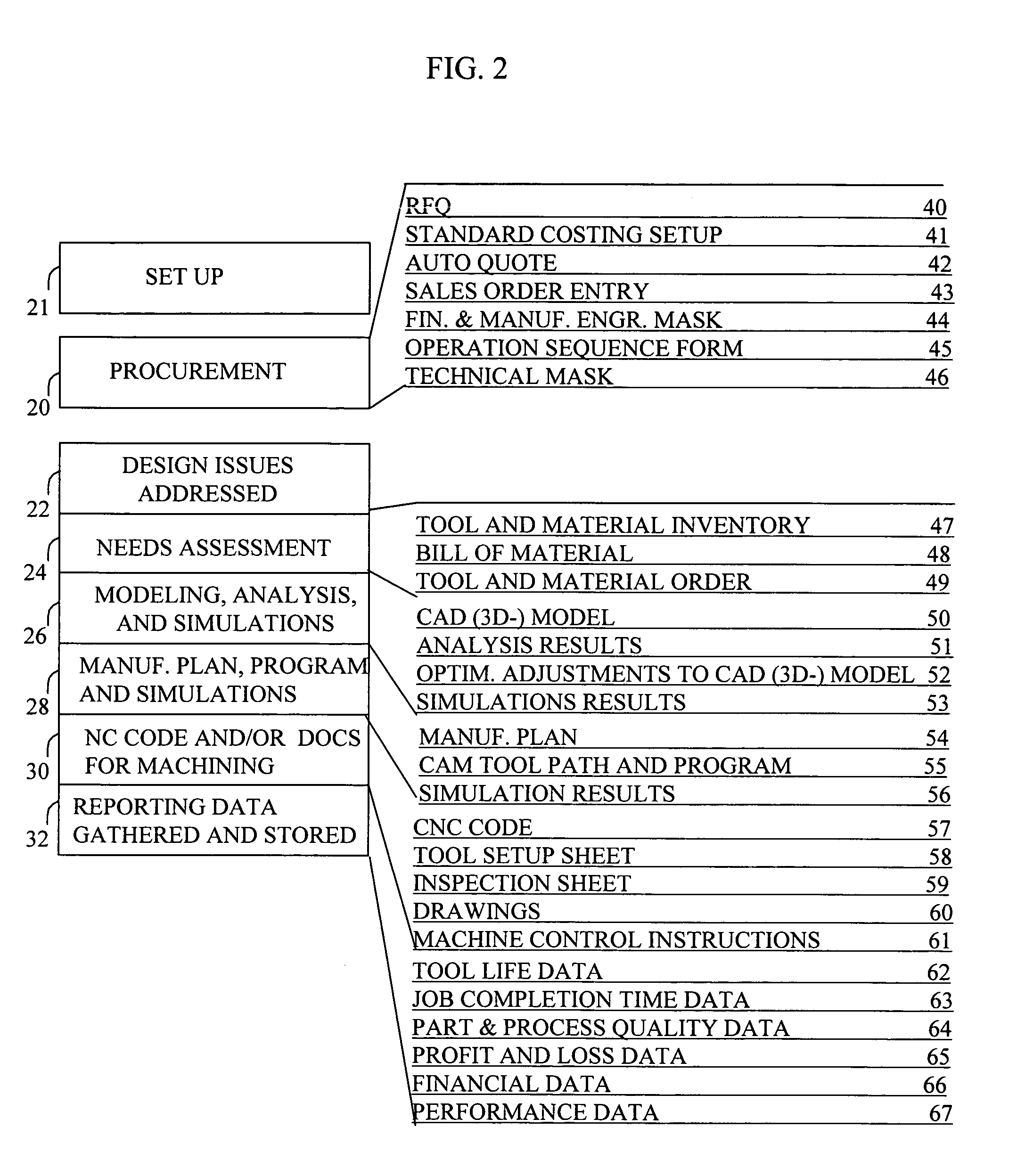

Data entry and system for automated order, design, and manufacture of ordered parts

InactiveUS20060129461A1Increased riskImprove product qualityProgramme controlCommerceManufacturing planningOrder form

A part data entry system is provided. In that system, an order processing template is provided to facilitate sales and order processing, tool planning, CA (computer aided) (e.g., CAD / CAM) parametric modeling, computer simulation, and the generation of a factory machine program. The order processing template comprises financial and manufacturing engineering planning fields and technical fields. A part information population mechanism is provided to populate the order processing template with the part information. An order template population mechanism is provided to populate other ones of the financial and manufacturing planning fields and the technical fields that are not populated by the part information population mechanism. An order processing template interface, or a set of such interfaces, is provided to provide, for a given ordered part, from the order processing template, CA-specific information to a CA computer system before the CA computer system performs CAD modeling on the part. The order processing template interface further provides, for the given ordered part, from the order processing template, ERP-specific information to an ERP computer system before the ERP computer system performs scheduling of machines and resources, material reservation, or RFQ calculations.

Owner:PANKL GEROLD +1

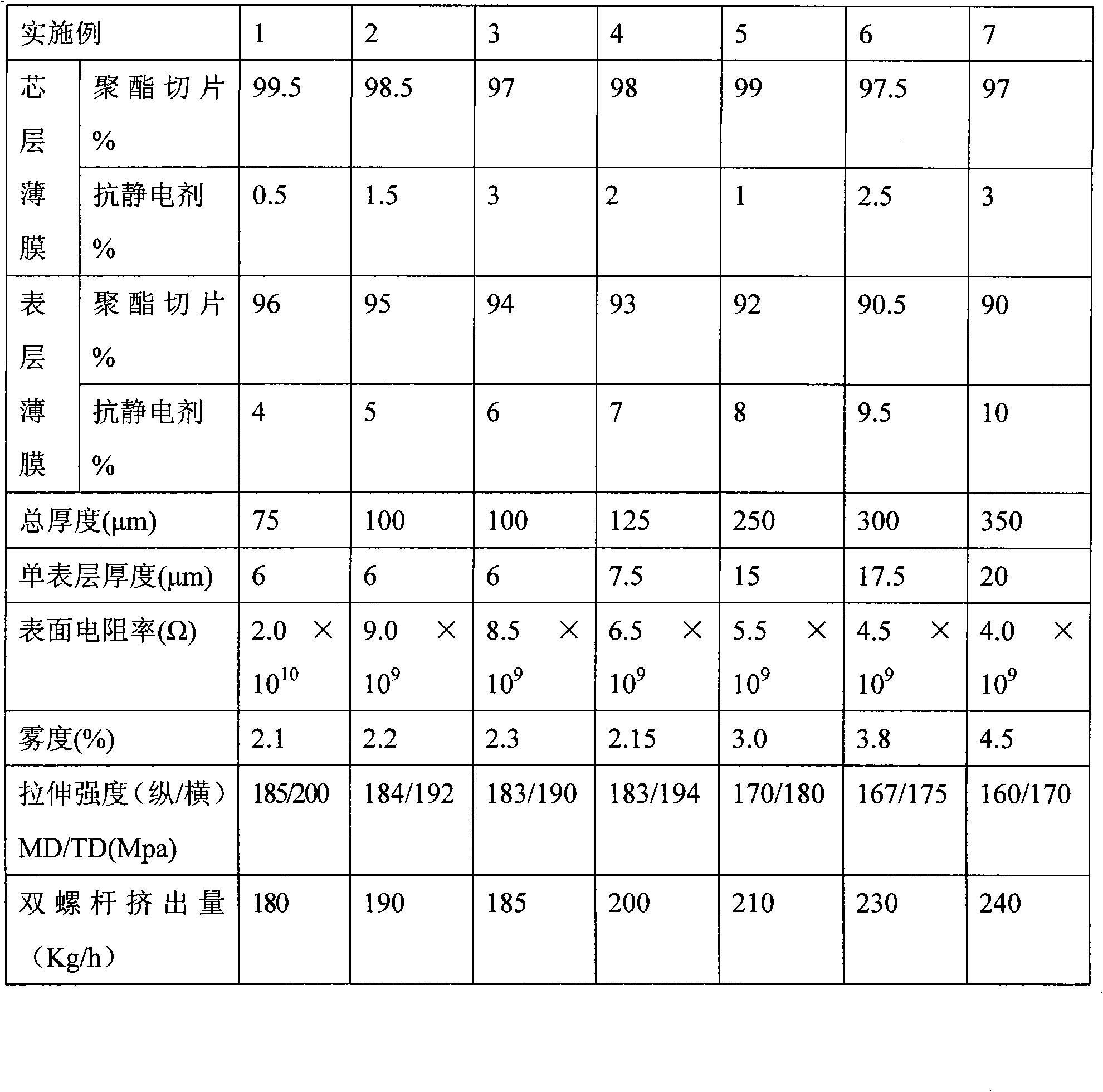

Electrostatic resistant heavy duty polyester film and method of preparing the same

ActiveCN101318393ALong-term antistatic protectionImprove antistatic performanceSynthetic resin layered productsPolyesterHigh concentration

The invention relates to an anti-static thick type polyester film which includes three layers of coextruded films. Calculated by the weight percentage, the film of a core layer is provided with 97 to 99.5 percent of polyester chips and 0.5 to 3 percent of an antistatic agent; the film of a surface layer is provided with 90 to 96 percent of the polyester chips and 4 to 10 percent of the antistatic agent; the thickness of the film of the core layer is between 0.075 to 0.31mm; the thicknesses of the films of the two surface layers are equal; besides, the thickness of the film of the surface layer is between 0.006 to 0.02mm. The invention adopts the anti-static polyester film of ABA three-layer structure to modify the conductive performance of a polyester substrate; especially, the film of the surface layer has high concentration of the antistatic agent and the antistatic agent added in the polyester substrate is capable of partially moving to the surface of the film; the anti-static thick type polyester film has the advantages of scrub resistance and solvent resistance, thus leading the polyester film to have the anti-static function for a long period.

Owner:JIANGSU YUXING FILM TECH

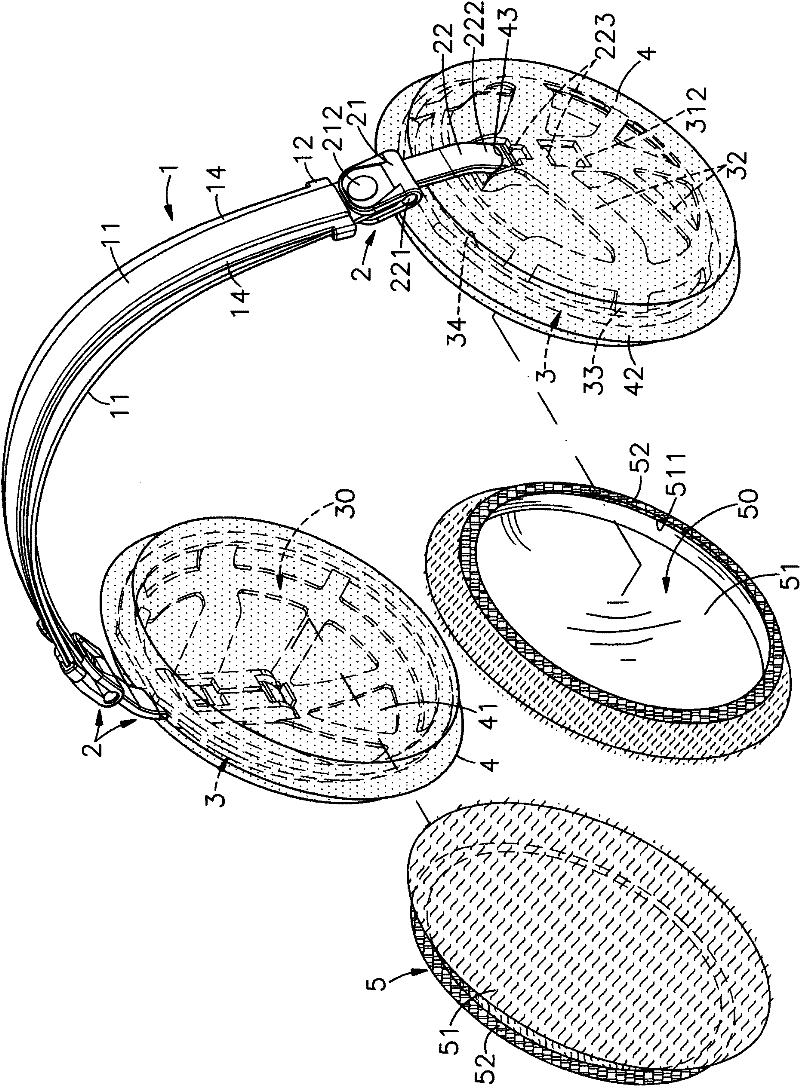

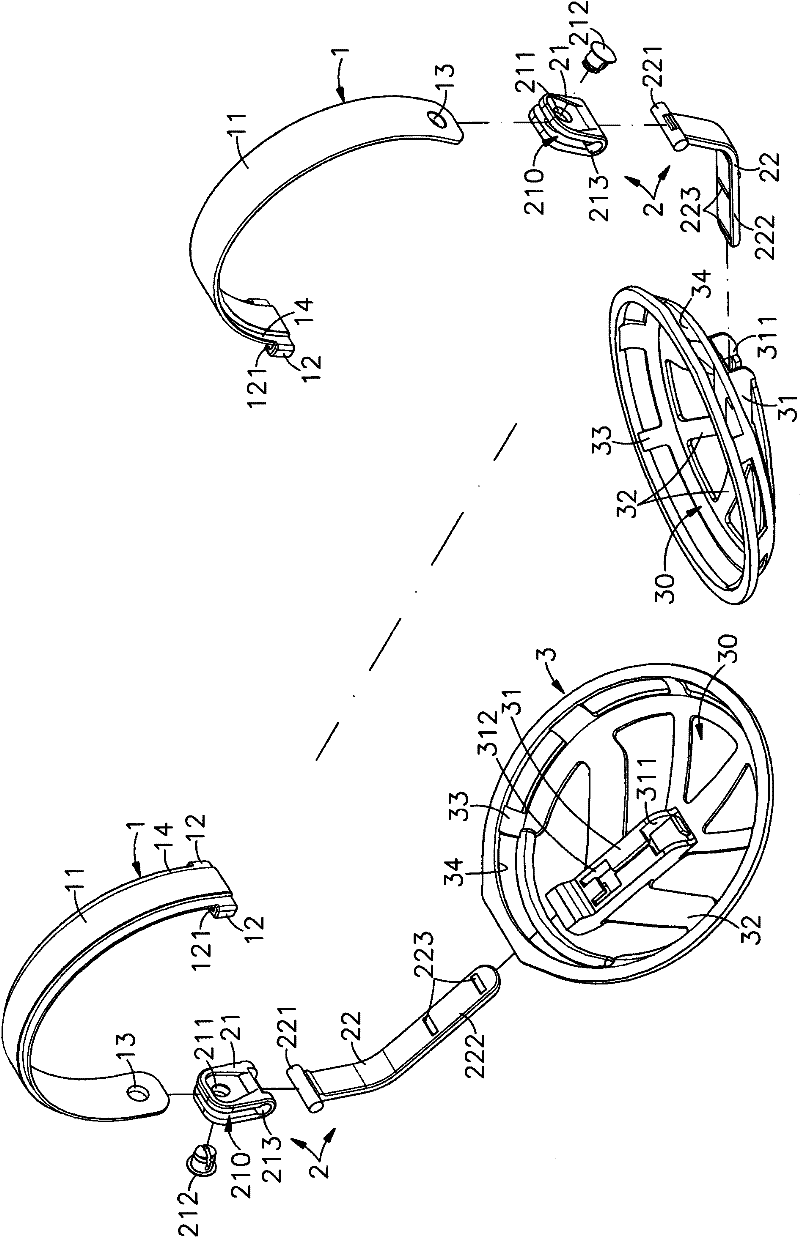

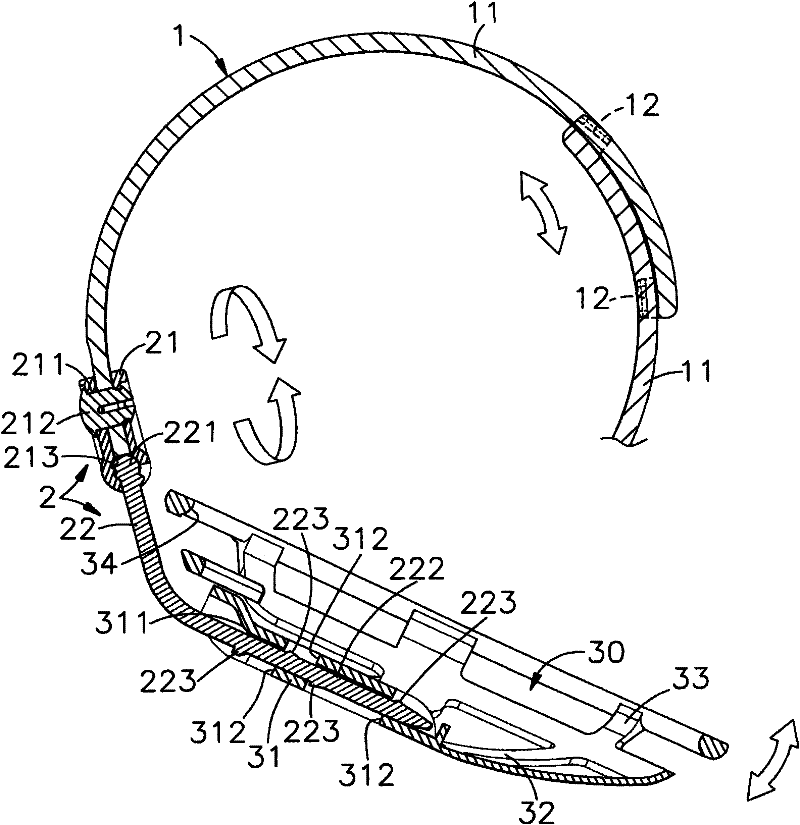

Ear muff structure

InactiveCN102232888AEasy to assembleAchieve modular productionEarpiece/earphone attachmentsEarmuffsEngineeringEarmuffs

Owner:SOUND TEAM ENTERPRISE

Ultrathin copper foil with carrier and printed circuit board

ActiveCN1984526AEasy to peelAvoid foamingInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentLayer interfaceCopper foil

The invention provides an ultrathin copper foil with a carrier not causing blistering at a release layer interface, having a low carrier peeling force, friendly to the environment, and enabling easy peeling of a carrier foil and an ultrathin copper foil even under a high temperature environment and a printed circuit board enabling a stable production quality of a base of a printed circuit board for fine pattern applications using the ultrathin copper foil with the carrier. The ultrathin copper foil with a carrier of the invention comprises a carrier foil, a diffusion prevention layer, a release layer, and an ultrathin copper foil, wherein the release layer is formed by a metal A for retaining a release property and a metal B for facilitating plating of the ultrathin copper foil, a content a of the metal A and a content b of the metal B forming the release layer satisfying a formula 10<=a / (a+b)*100<=70. In addition, a printed circuit board can be manufactured by using the ultrathin copper foil with a carrier.

Owner:FURUKAWA ELECTRIC CO LTD

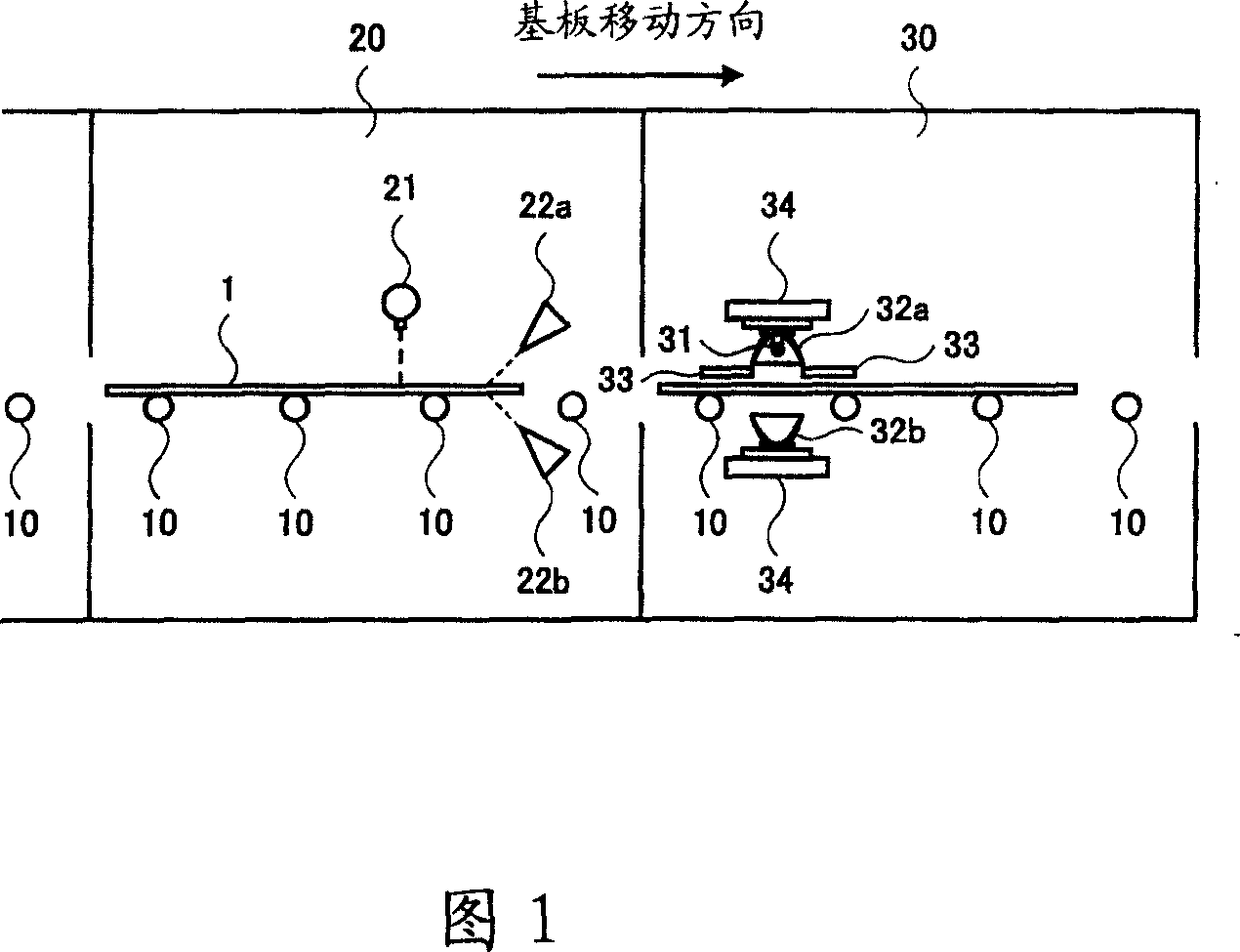

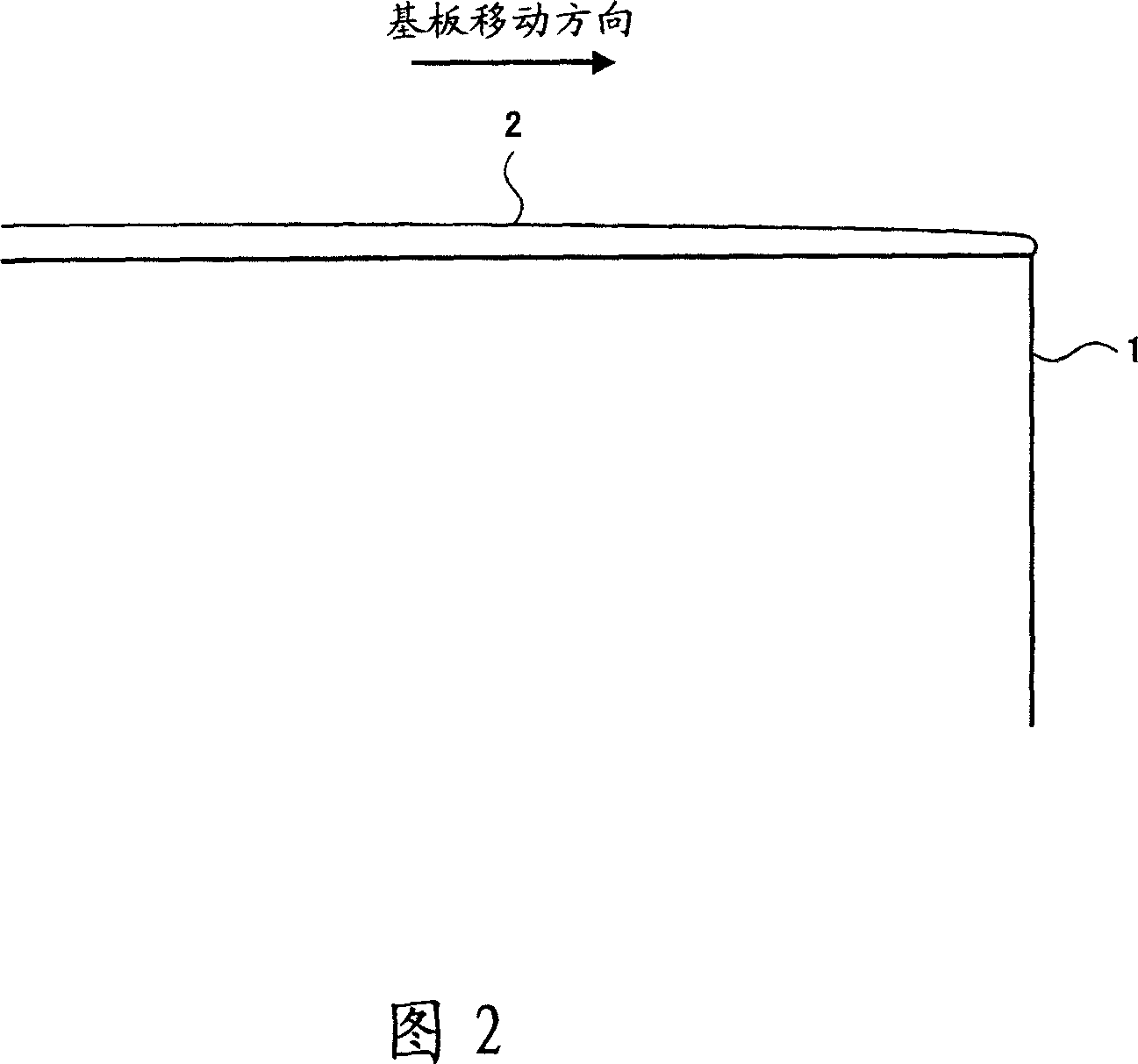

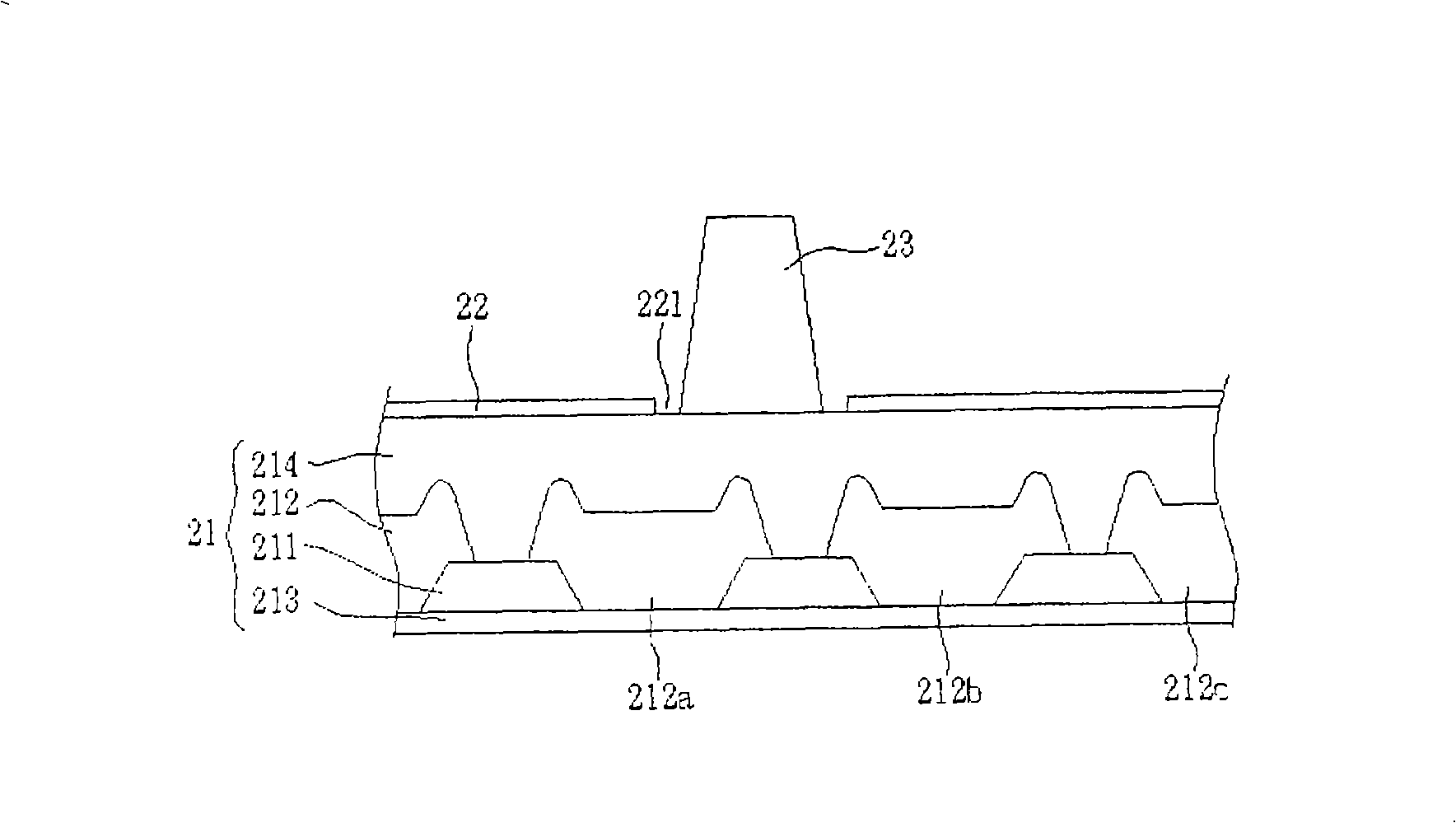

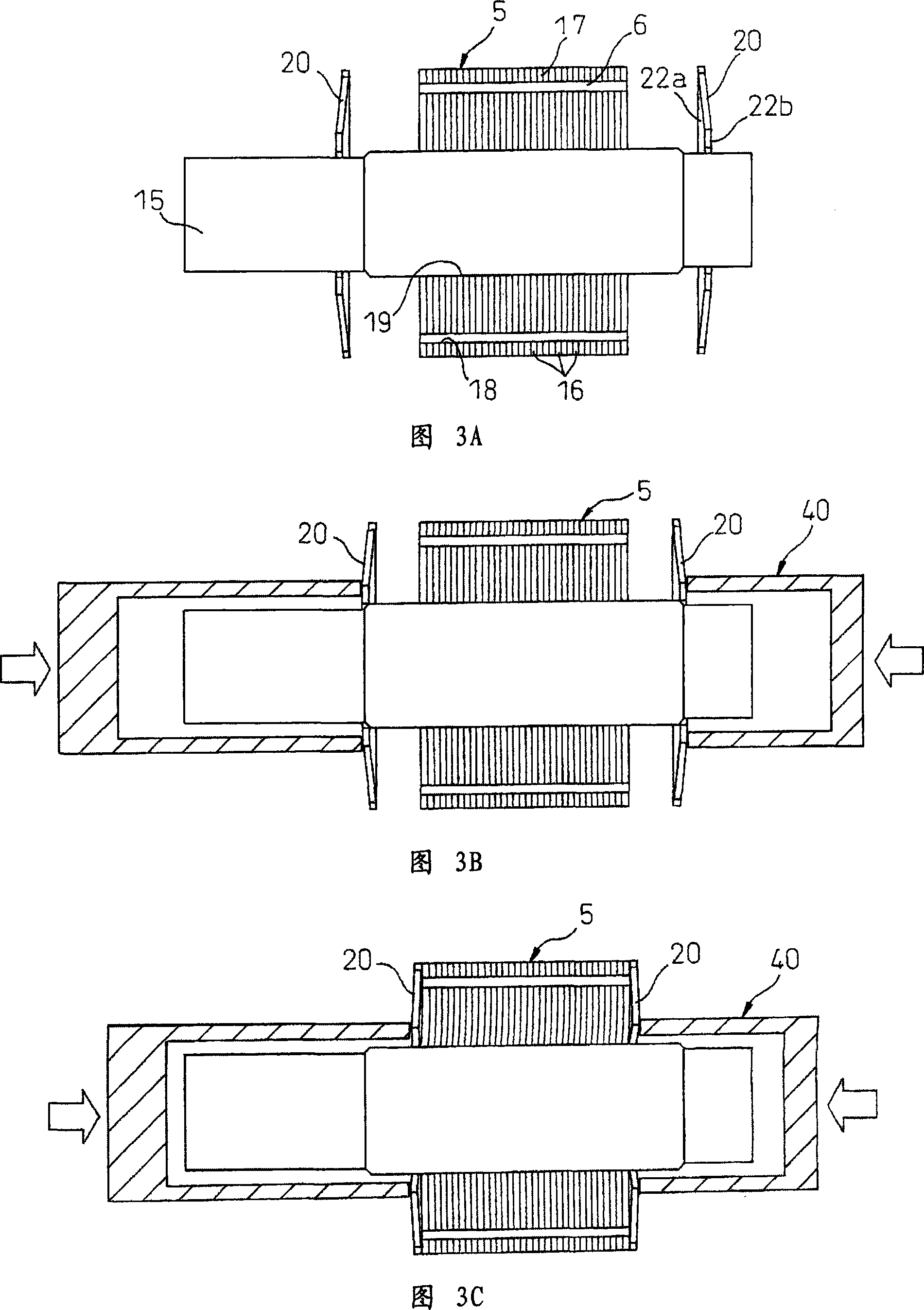

Substrate drying device and method, and substrate producing method

InactiveCN1941282ADry evenlyReduce air usageDrying using combination processesSemiconductor/solid-state device manufacturingAir knifeMoving speed

The present invention can move substrates with high speed, at the same time equably dry substrates. Nozzle (21) supplies cleaning liquid to the surface of the substrate 1, air knives (22a, 22b) eject air to the surface of back of the substrate (1). The air ejected from air knife (22a) makes the cleaning liquid supplied by nozzle (21) move toward the opposite direction of the substrate moving direction on the substrate (1). Adjusting the quantity of the cleaning liquid supplied by nozzle (21) and the quantity and speed of the air ejected from air knife (22a) in order to make the cleaning liquid moving speed slower than the substrate moving speed. Therefore, forming the continuous and thin liquid film of cleaning liquid on the whole surface of the substrate (1) under the air knife (22a). The liquid film forming on the surface of the substrate (1) is vaporized when it through the lower part of the halogen lamp (31), and is wiped off from one end of the substrate (1) continuously.

Owner:HITACHI HIGH-TECH CORP

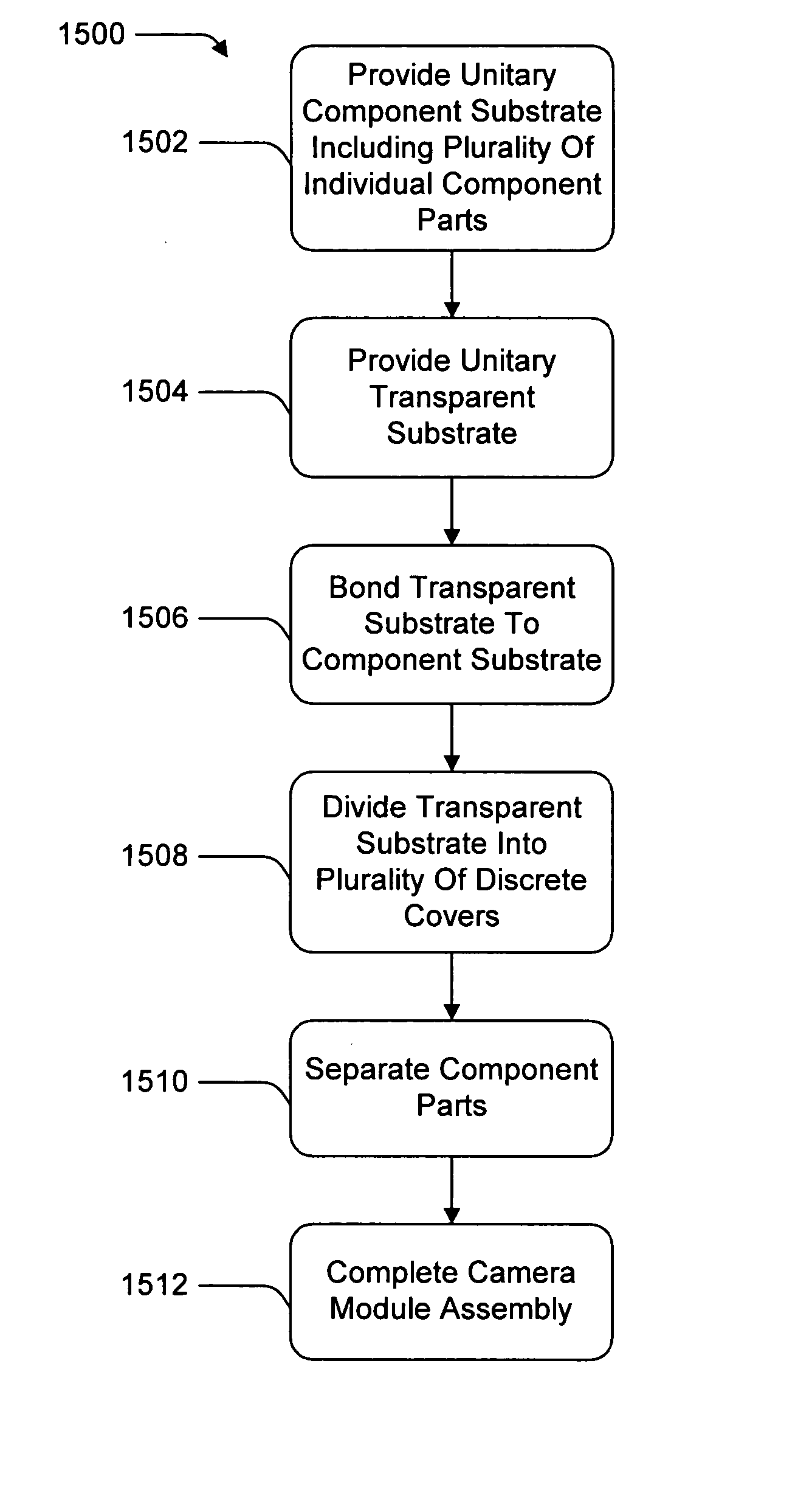

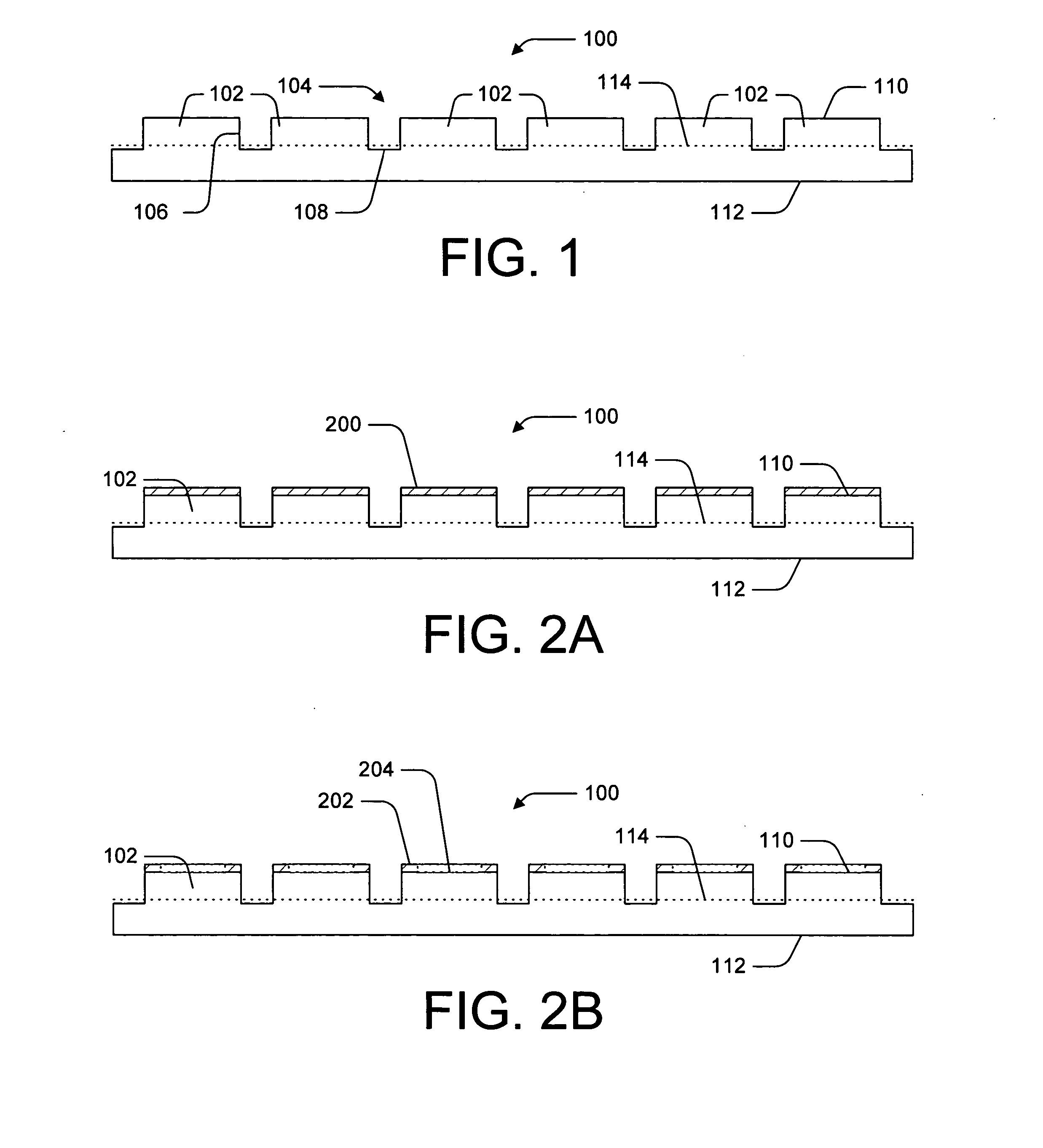

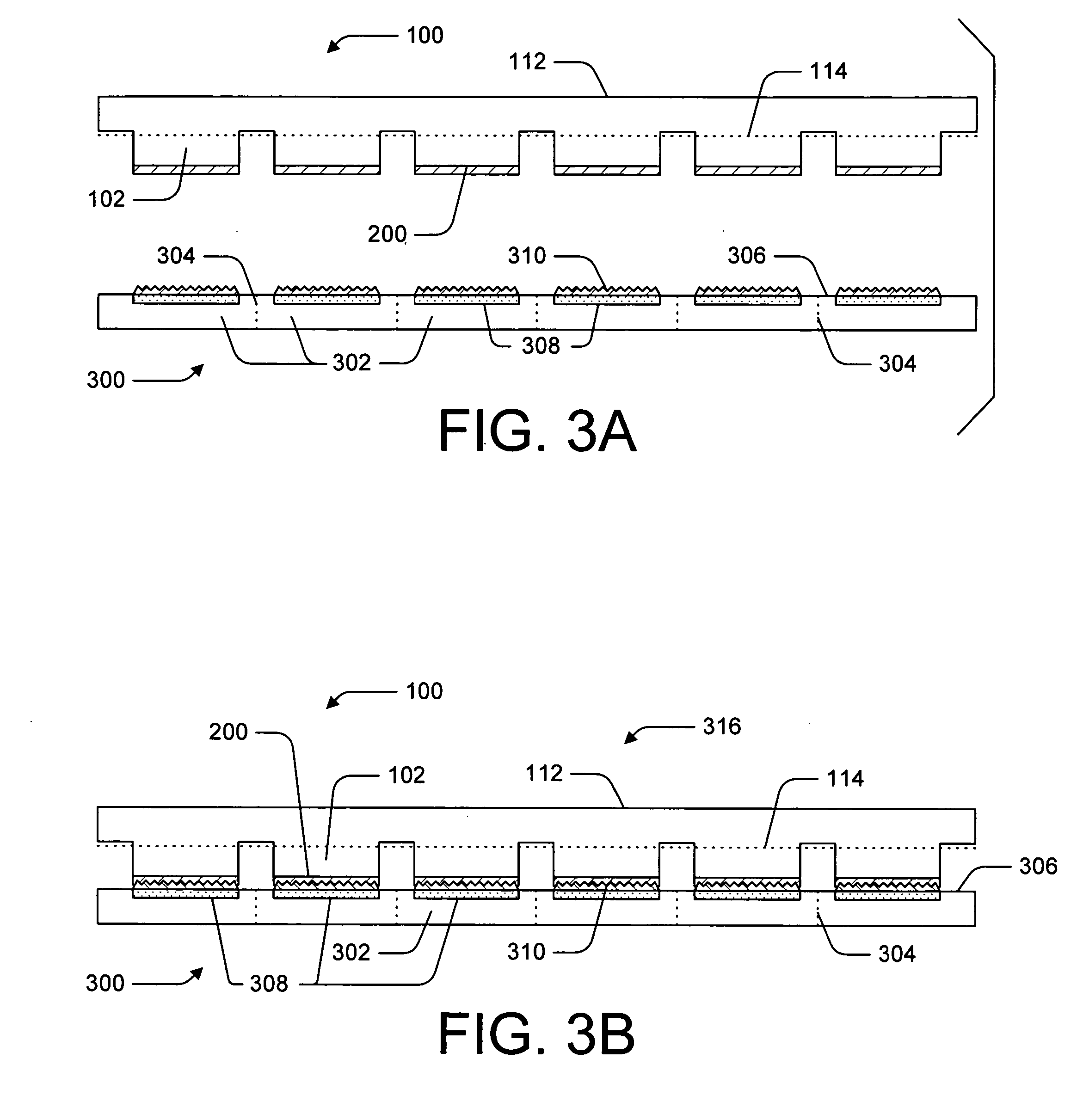

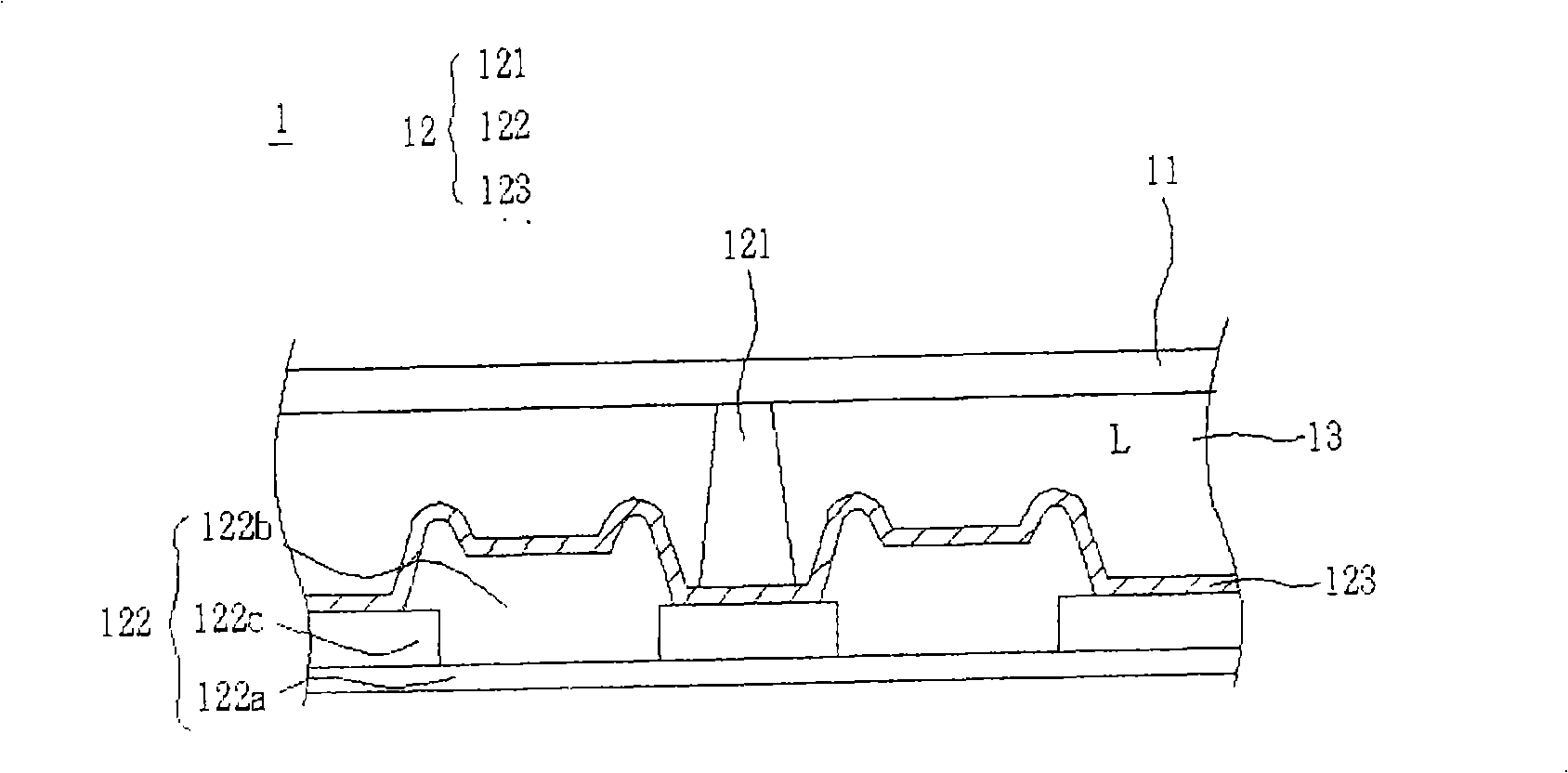

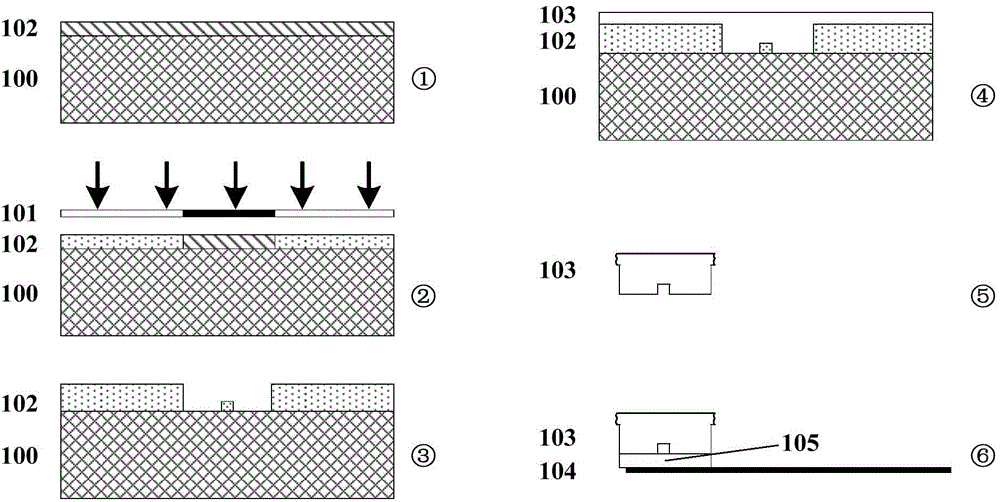

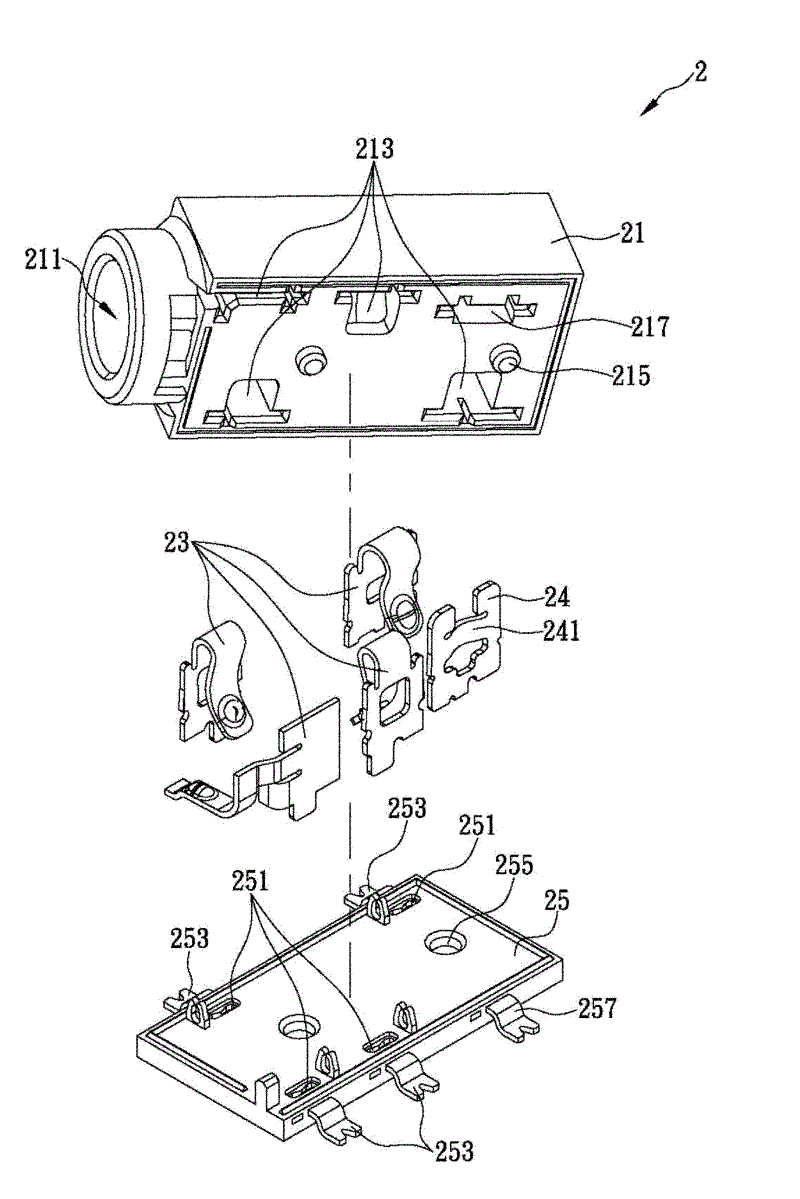

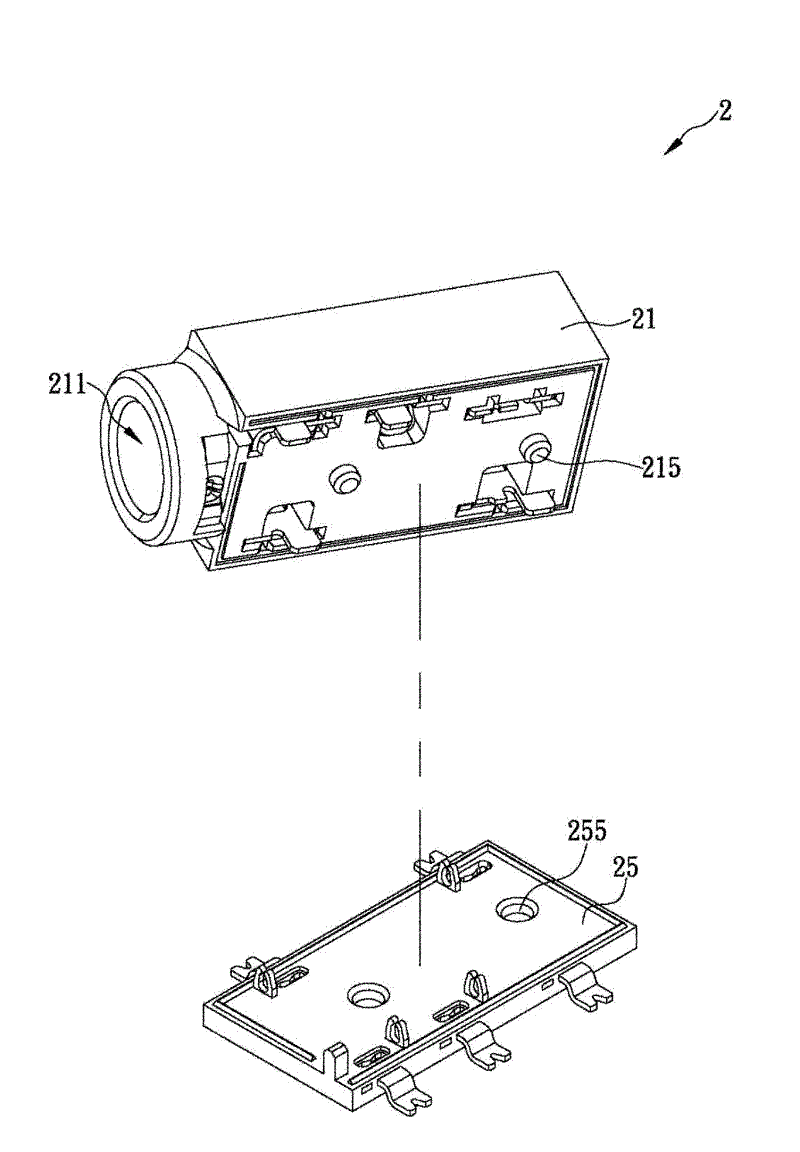

Method for mounting protective covers over image capture devices and devices manufactured thereby

InactiveUS20070236591A1Improve manufacturing qualityHigh yieldTelevision system detailsPrinted circuit assemblingDevice formEngineering

A method for manufacturing camera modules including image capture devices with protective covers is disclosed. The method includes providing a unitary transparent substrate including a plurality of individual protective covers, providing a unitary component substrate including a plurality of individual component parts, bonding the unitary transparent substrate to the unitary component substrate, dividing the transparent substrate into a plurality of discrete protective covers, and separating the component parts from one another. According to one particular method, the component substrate is a semiconductor wafer having a plurality of integrated electronic image capture devices formed therein. According to another particular method, the component substrate is a circuit board having a plurality of individual device circuit boards formed therein.

Owner:FLEXTRONICS AP LLC

Colorful optical filter and manufacturing method thereof

InactiveCN101276011AImprove pressure resistanceImprove production qualityNon-linear opticsOptical elementsColor gelLight filter

The present invention discloses a colorful optical filter which comprises a colorful optical filtering substrate, a conducting layer and a spacer. The colorful optical filter is provided with a shading layer and a colorful filtering layer. The conducting layer is provided on the colorful optical filtering substrate, and the conducting layer is provided with at least one opening at the position relative to the shading layer and / or colorful filtering layer. The spacer is provided in the opening. The invention also discloses a method for preparing the colorful optical filter.

Owner:INNOLUX CORP

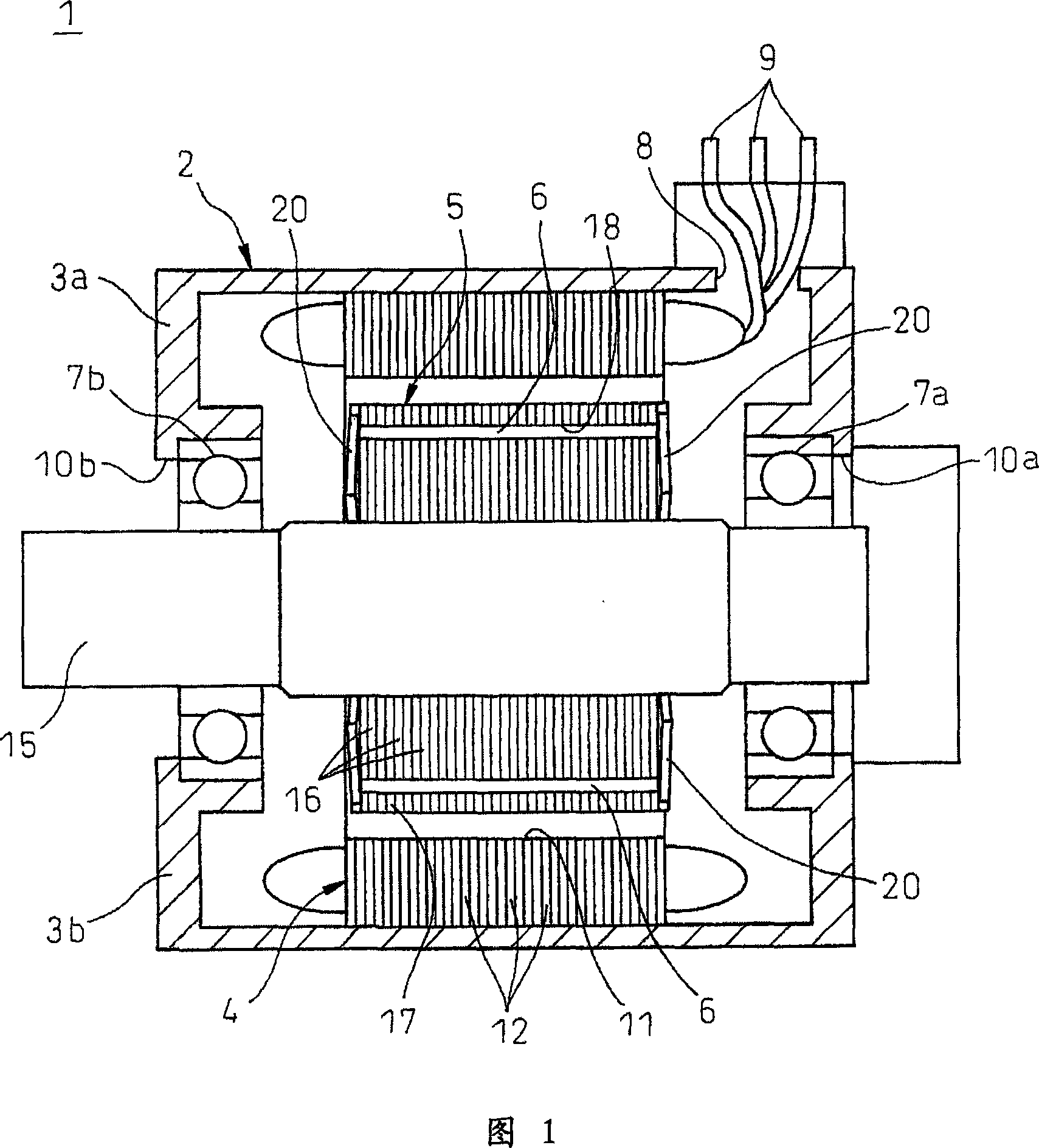

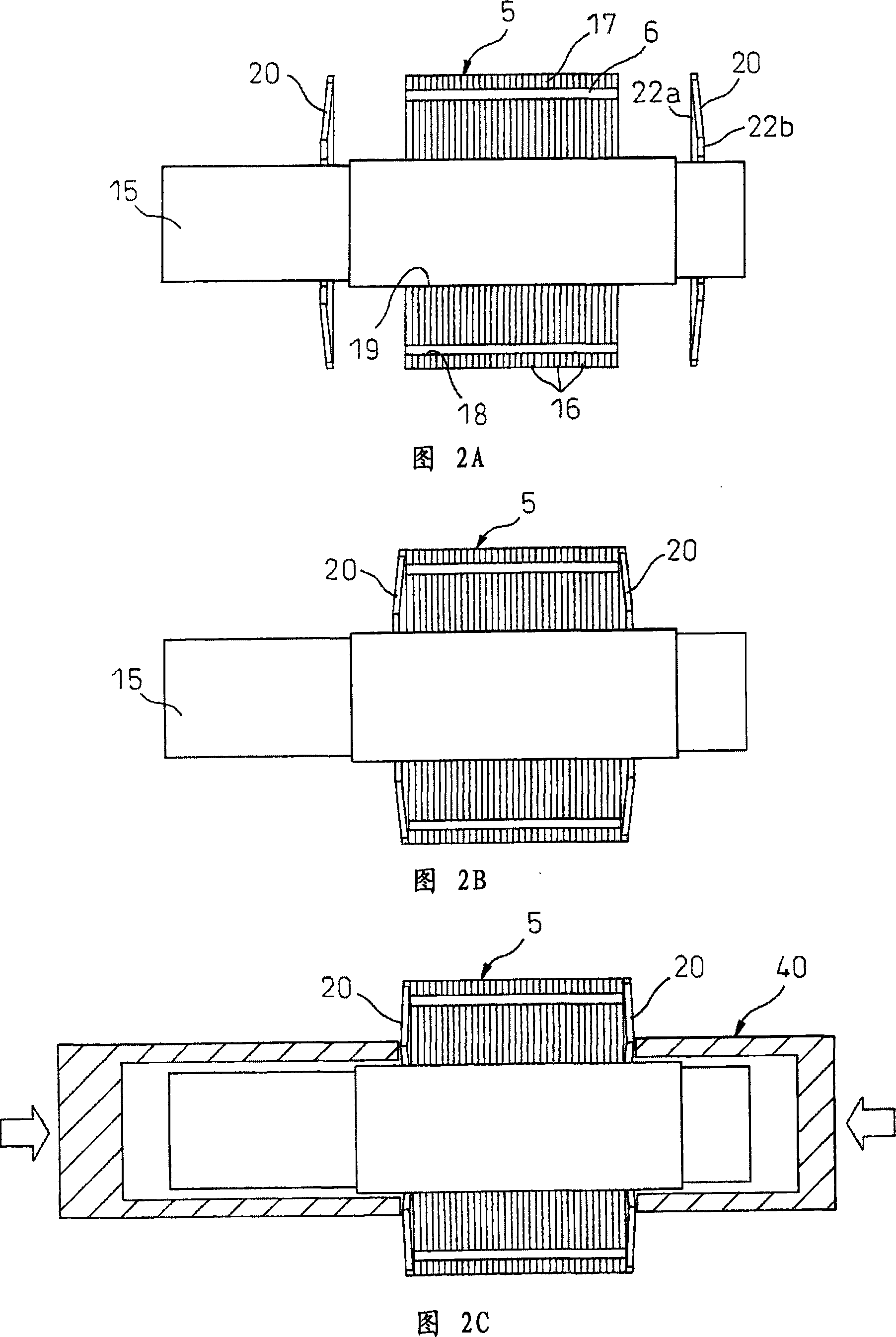

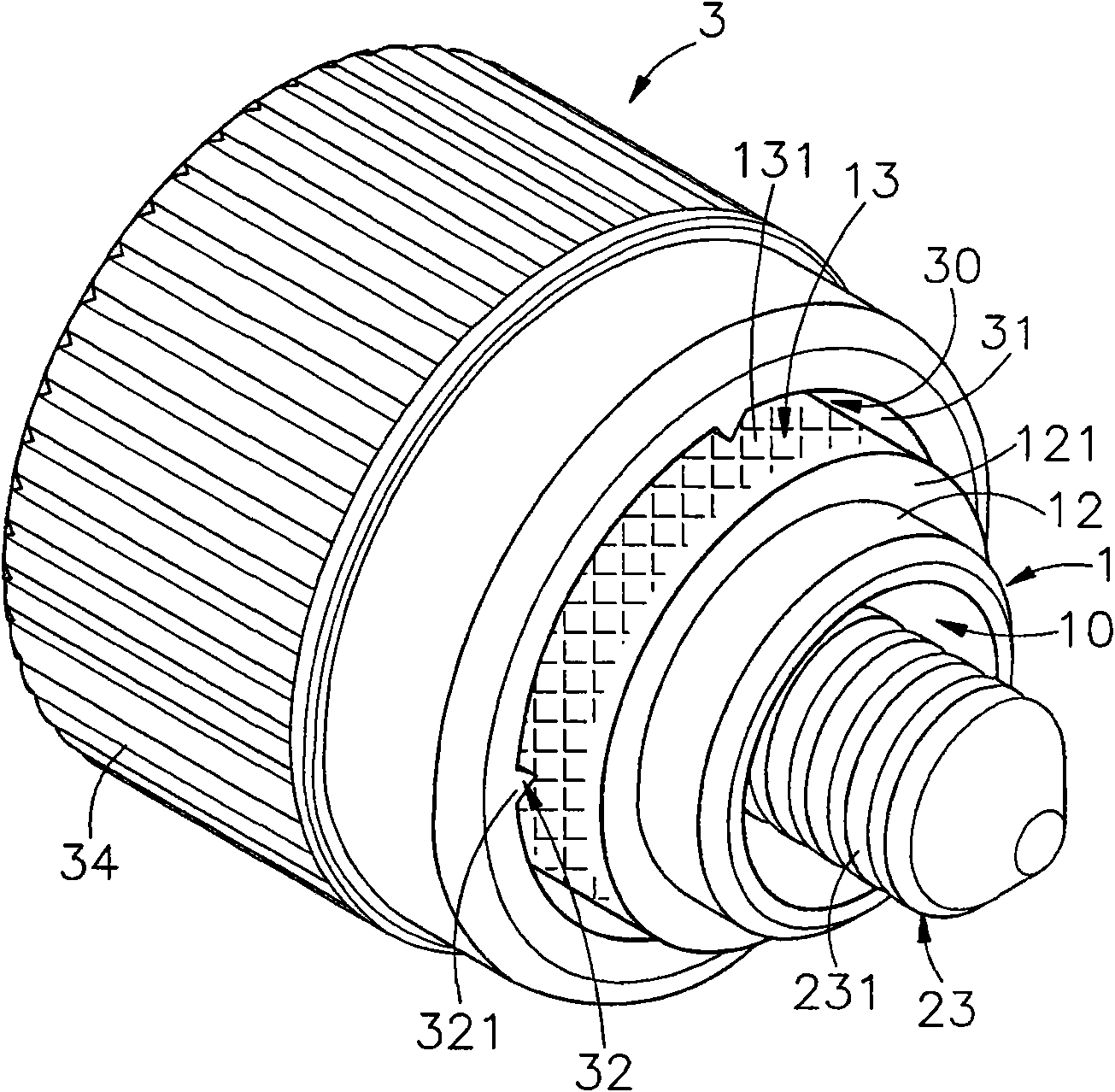

Method of manufacturing rotor of electric motor and electric motor

InactiveCN101227125AImprove manufacturing qualityEasy to installMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringElectric motor

A method of manufacturing a rotor of an electric motor, the rotor including a laminated core of multilayer structure formed from electromagnetic thin plates laminated in an axial direction of a rotational shaft, and a pair of end plates disposed on opposite sides in the axial direction of the laminated core, and the rotor being rotatably disposed in an inside of a stator, the method including: fitting the rotational shaft into an insertion hole formed in a center region of the end plates having elasticity in a direction of plate thickness; positioning the end plates at specified position on the rotational shaft; and abutting either one of the end plates in elastically deformed state to at least one end of the laminated core.

Owner:FANUC LTD

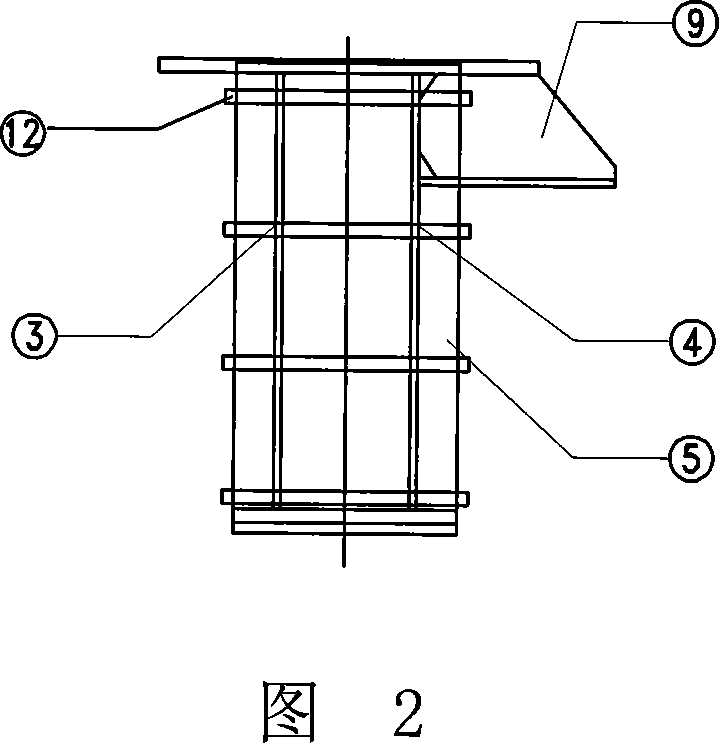

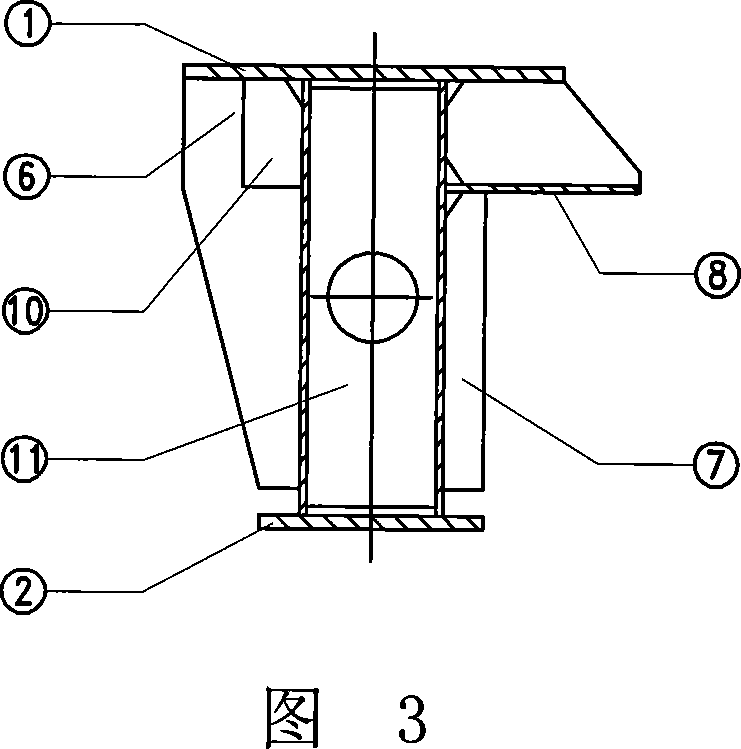

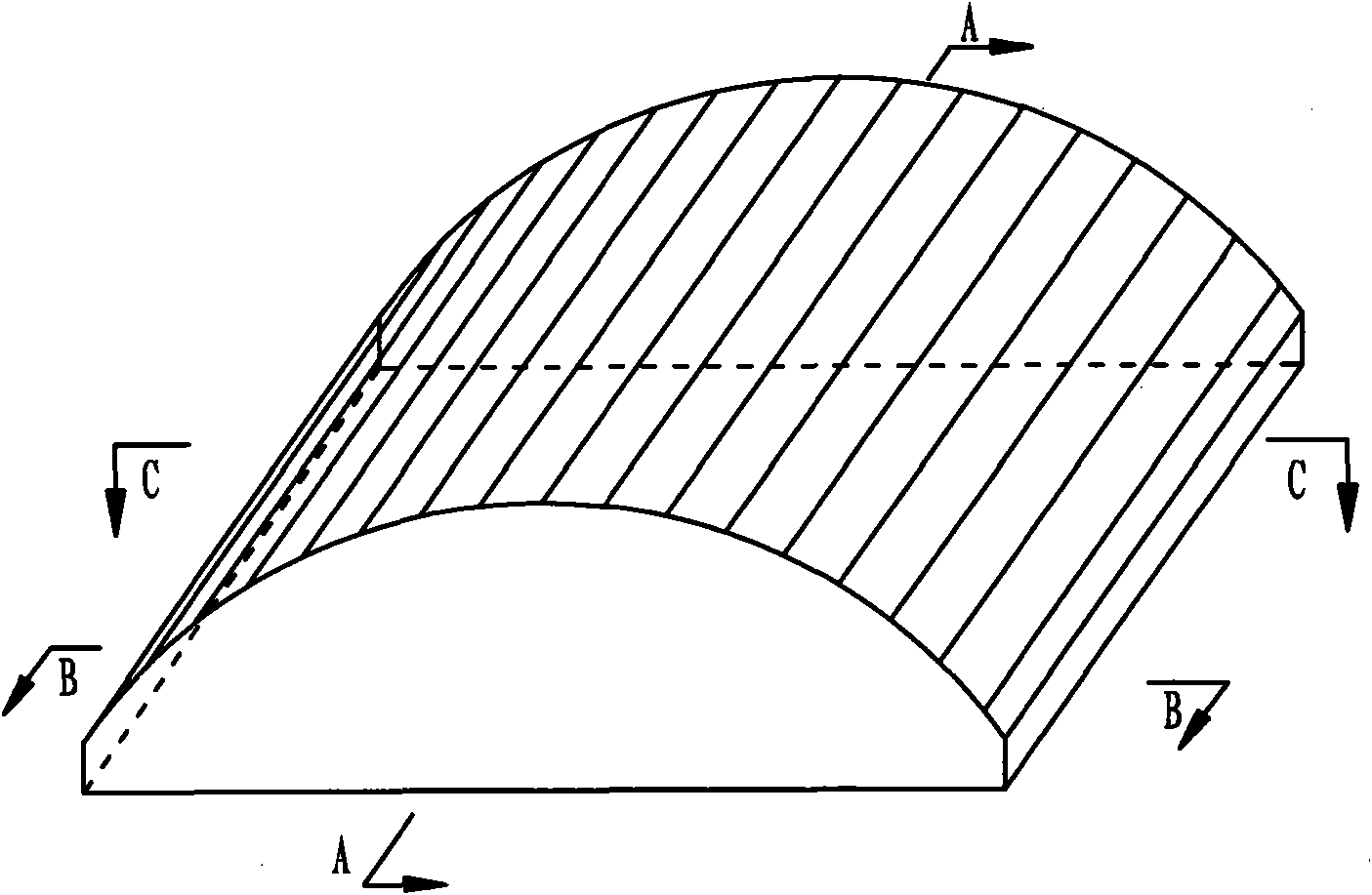

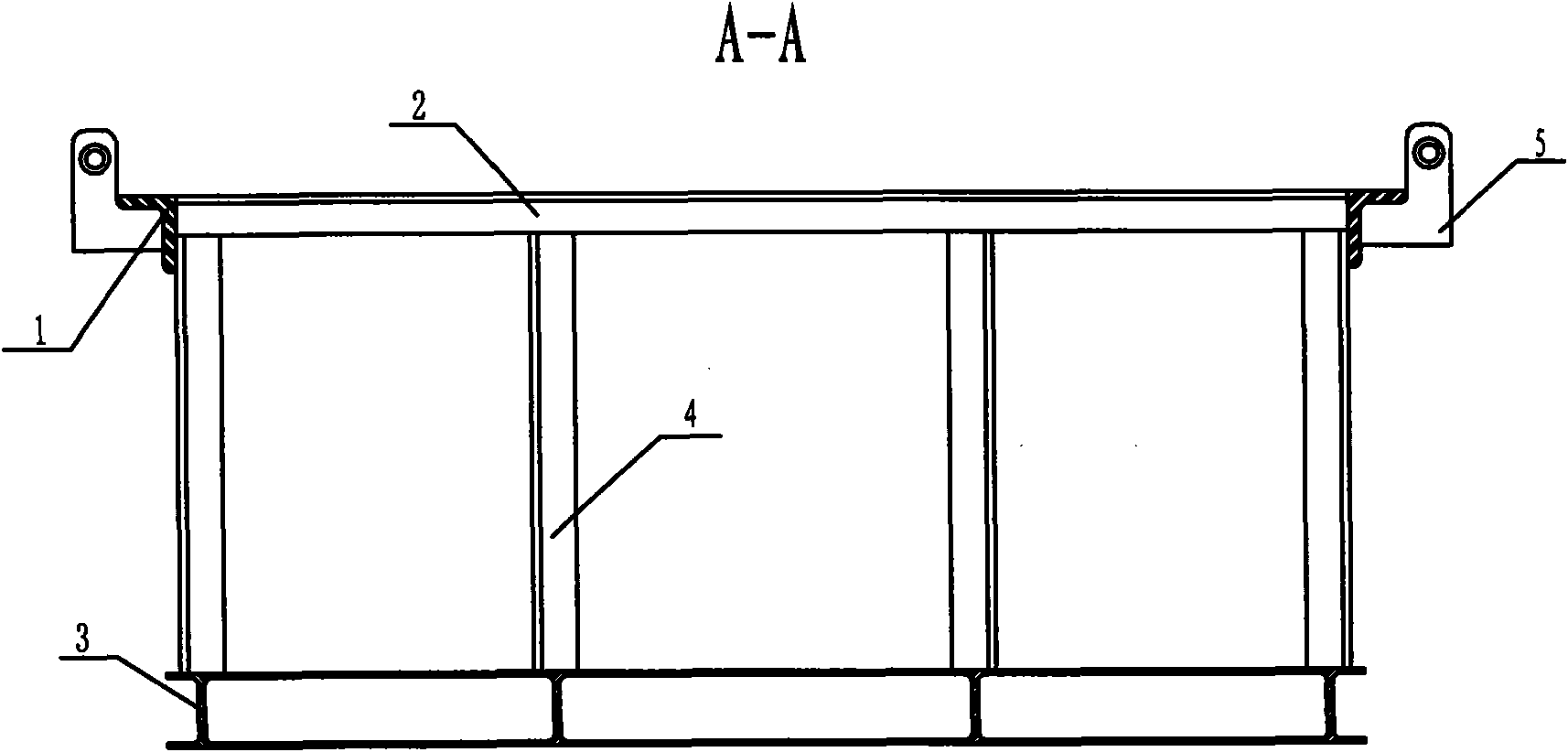

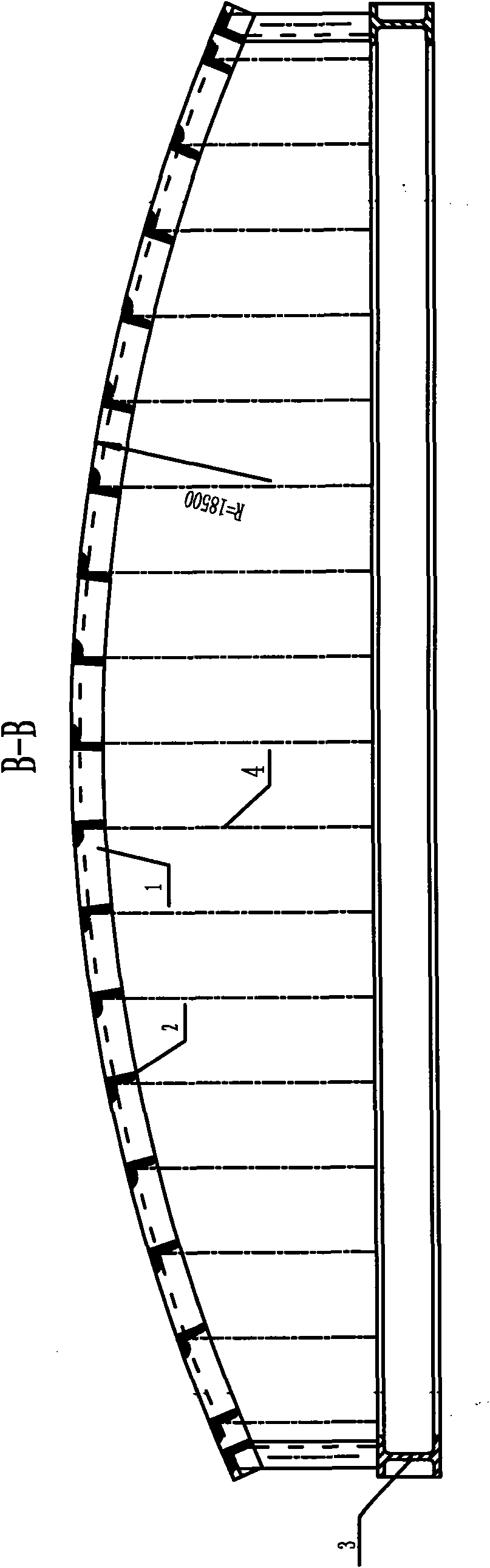

Preparation method of steel lining prefabricated moulding bed in nuclear power station

ActiveCN101913068AEnsure stabilitySmall amount of welding deformationBlock structureNuclear power plant

The invention relates to a preparation method of a prefabricated moulding bed, which is widely applied to steel lining prefabrication construction in a nuclear power station particularly and belongs to the technical field of construction of the nuclear power station. The preparation method comprises the following steps of, firstly, welding base H-shaped steel into a meshy block structure; welding an upright post on the meshy block structure; respectively welding longitudinal arc angle steel with a longitudinal upright post support, and welding traverse bus angle steel with a traverse upright post support respectively; and connecting the two upright post supports mutually to form a support structure. The process can effectively decrease the integral welding deflection, and is favorable for guaranteeing the integral stability of a construction member. The moulding bed structure prepared according to the steps can completely achieve the prefabricating precision of a nuclear island steel lining, meet the strict requirements on the level 1 nuclear quality and the nuclear safety, and guarantee the stability of production quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

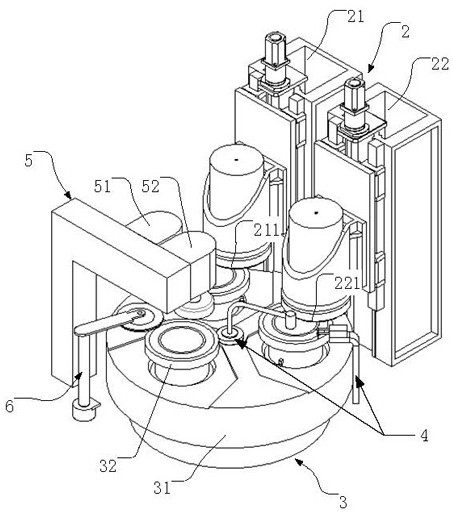

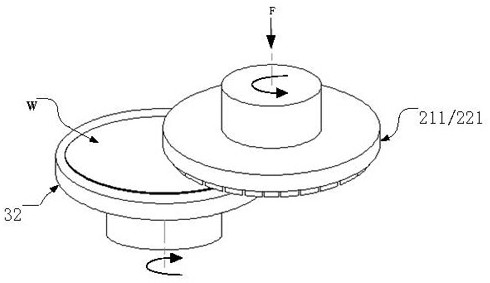

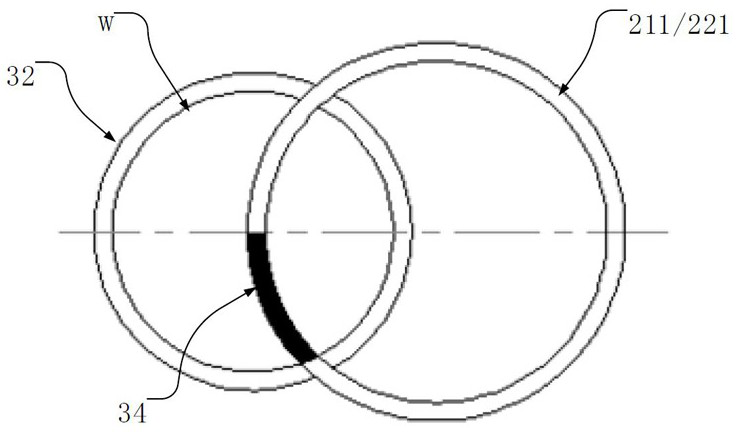

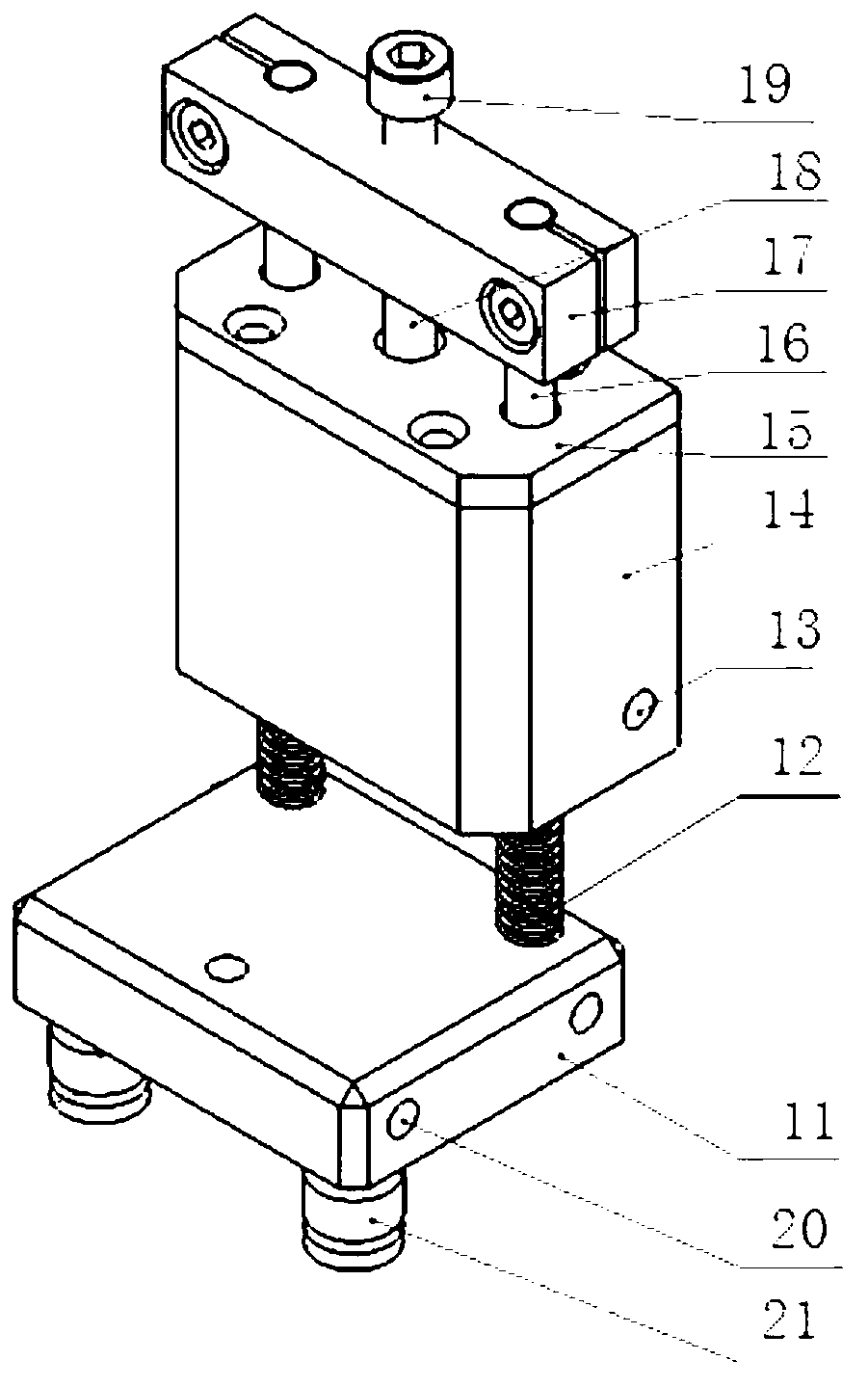

Grinding device for controlling grinding surface shape of wafer

PendingCN111775001AEasy to processImprove manufacturing qualityGrinding carriagesGrinding drivesWaferEngineering

The invention discloses a grinding device for controlling grinding surface shape of a wafer. The grinding device comprises a workbench, sucker turntables, a measuring unit and an angle adjusting device; the workbench is used for supporting a plurality of sucker turntables; the sucker turntables are used for holding the wafer and driving the wafer to rotate; the measuring unit is used for measuringthe thickness of the wafer to obtain the grinding surface shape of the wafer; and the angle adjusting device is used for adjusting the sucker turntables, and the angle adjusting device is connected with the sucker turntables to adjust the angle of inclination of the sucker turntables in at least two directions so as to adjust the grinding surface shape of the wafer. According to the grinding device for controlling the grinding surface shape of the wafer, accurate control of the grinding surface shape of the wafer can be controlled, and the processing effect and the manufacturing quality of the wafer are improved, and therefore technical guarantee for the stacking process of ultra-high-density semiconductors is provided.

Owner:华海清科(北京)科技有限公司

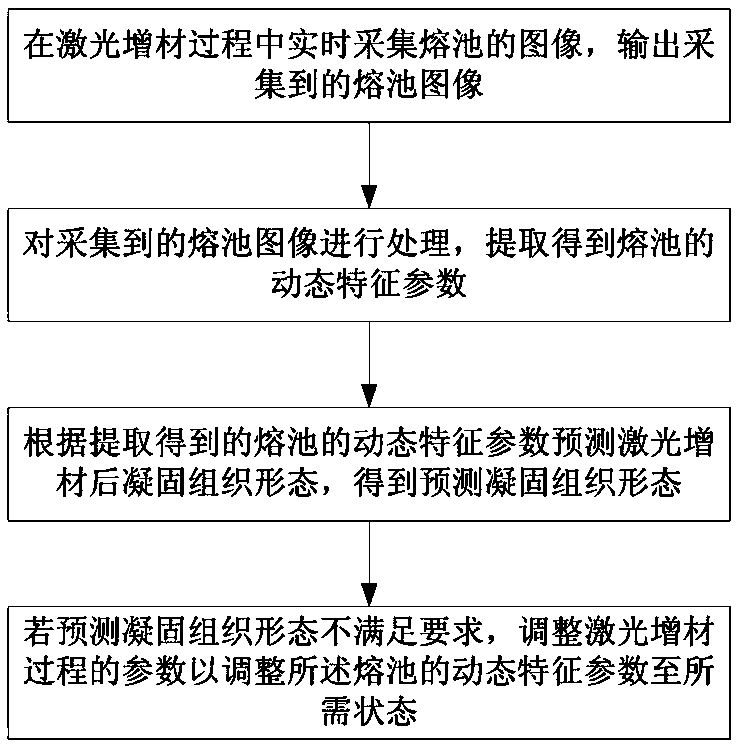

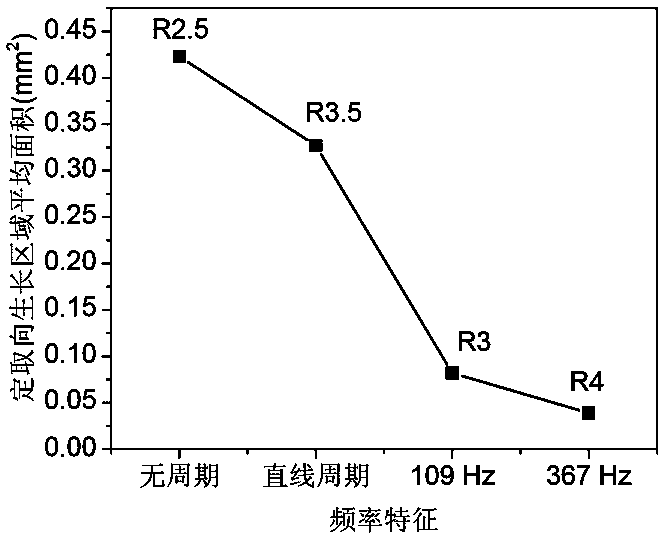

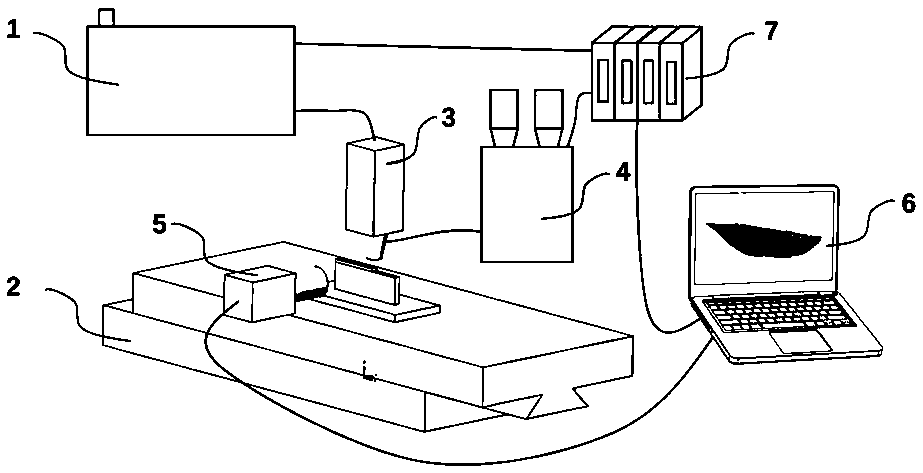

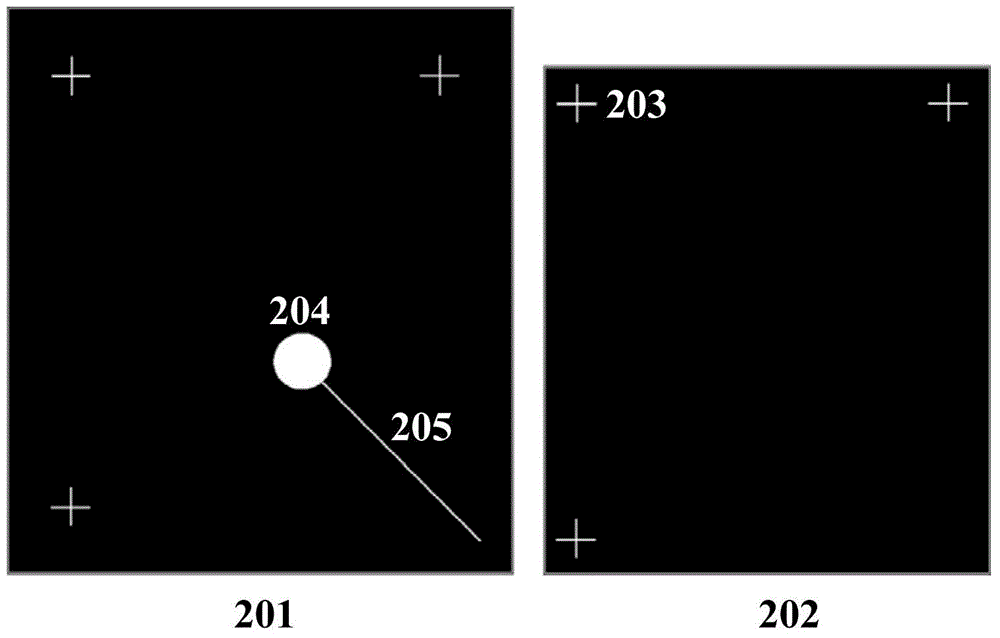

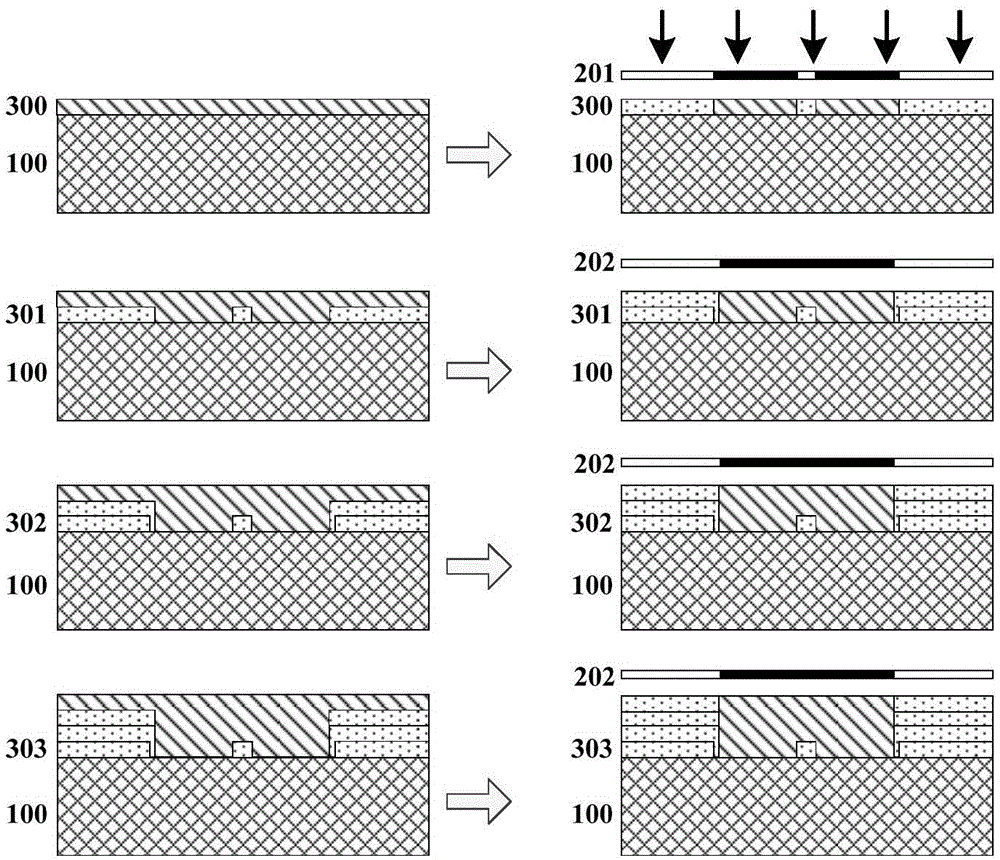

Monitoring and controlling method and system of solidification structure form of laser additive manufacturing based on pictures

ActiveCN109482874ARealize online monitoringImplement predictive controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMonitoring and control

The invention discloses a monitoring and controlling method and system of a solidification structure form of laser additive manufacturing based on pictures. The monitoring and controlling method of the solidification structure form of laser additive manufacturing based on pictures comprises the steps that step 1, pictures of a molten pool are collected in real time in the process of laser additivemanufacturing, and the collected pictures of the molten pool are output; step 2, the collected pictures of the molten pool are subjected to treatment, and dynamic characteristic parameters of the molten pool are obtained; step 3, a solidification structure form after the process of laser additive manufacturing is forecasted according to the obtained dynamic characteristic parameters of the moltenpool; and step 4, if the forecasted solidification structure form does not meet requirements, machining parameters in the process of laser additive manufacturing are adjusted, and thus the dynamic characteristic parameters of the molten pool are adjusted to required states. The monitoring and controlling system of the solidification structure form of laser additive manufacturing based on picturescomprises a molten pool picture collecting module, a molten pool picture processing module, a structure form forecasting module and a structure form controlling module. According to the monitoring and controlling method and system of the solidification structure form of laser additive manufacturing based on pictures, online monitoring and predictive controlling of the solidification structure form of laser additive manufacturing are achieved, and the advantages that the implement method is simple, the cost is low, the control efficiency is high, the reliability is high and the like are realized.

Owner:HUNAN UNIV

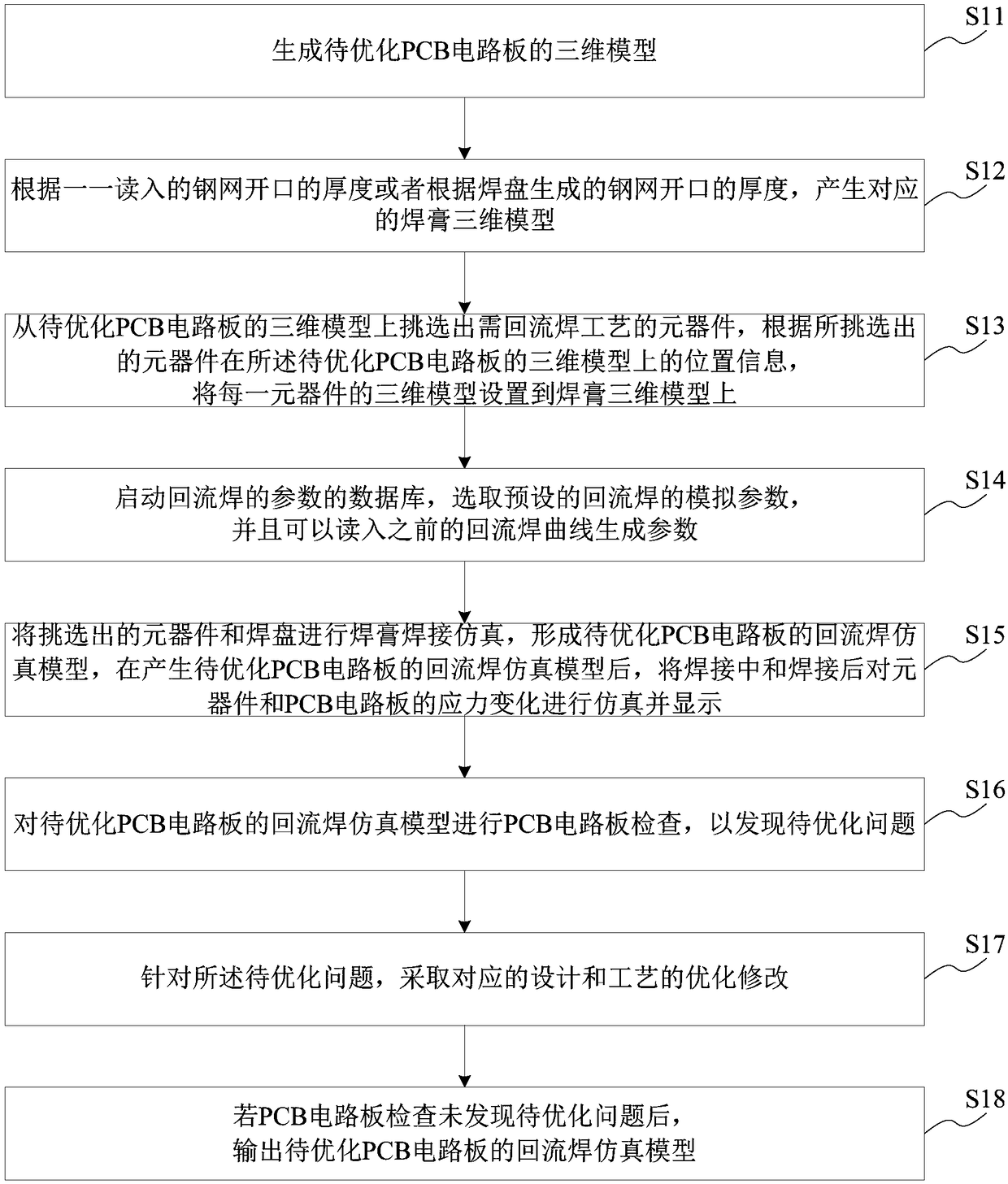

Reflow soldering simulation optimization method, system, computer storage medium and apparatus

ActiveCN109241681AImprove manufacturing quality and manufacturing efficiencyImprove manufacturing qualityCAD circuit designSpecial data processing applicationsThree dimensional modelReflow soldering

The invention provides a simulation optimization method, a system, a computer storage medium and a device for reflow soldering. The method comprises the following steps: generating a three-dimensionalmodel of a PCB circuit board to be optimized; Generating a corresponding solder paste three-dimensional model; selecting the components that need to be reflow soldered, and arranging each component on the solder paste three-dimensional model according to the position information of the selected components on the three-dimensional model of the PCB circuit board to be optimized. According to the preset simulation parameters of reflow soldering, solder paste soldering simulation is carried out on the selected components and pads to form the simulation model of PCB reflow soldering to be optimized. The reflow simulation model of PCB to be optimized is checked to find the problem to be optimized. For the problem to be optimized, the corresponding design and process optimization modifications are adopted. The invention can detect possible soldering problems in advance through the technology of reflow soldering simulation in the design stage, thereby enabling technicians to modify the designand optimize the process.

Owner:VAYO SHANGHAI TECH

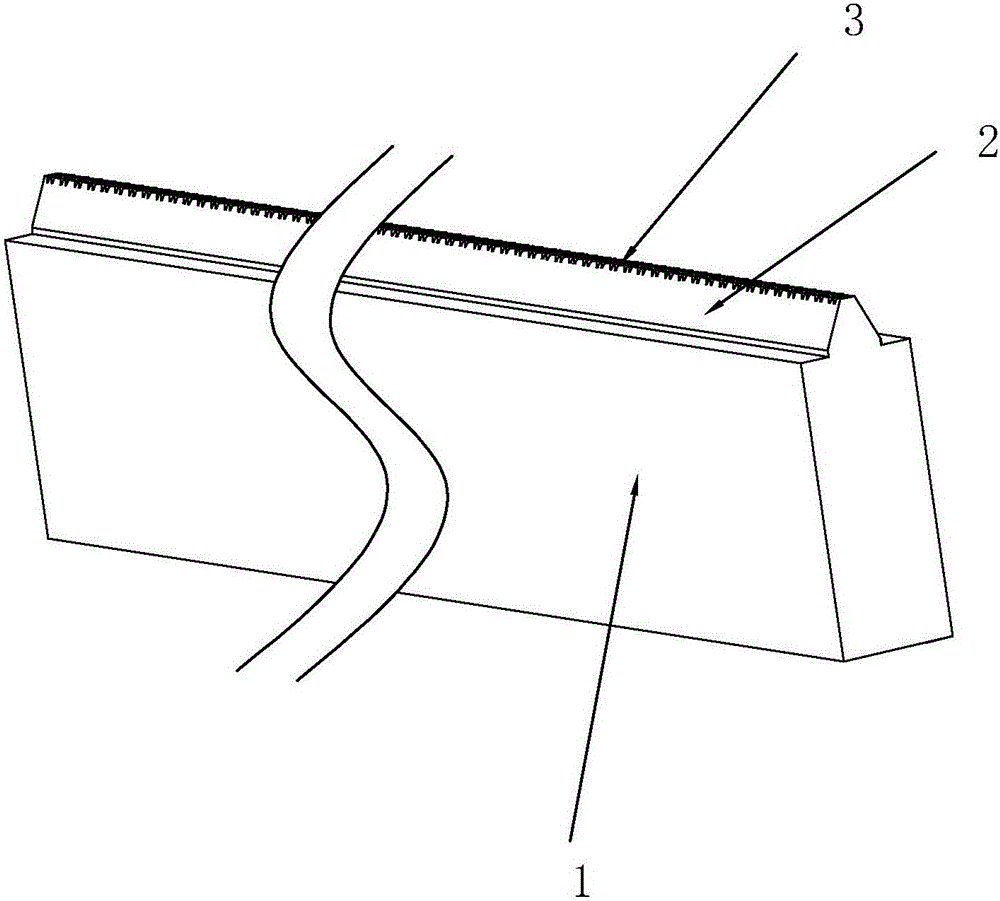

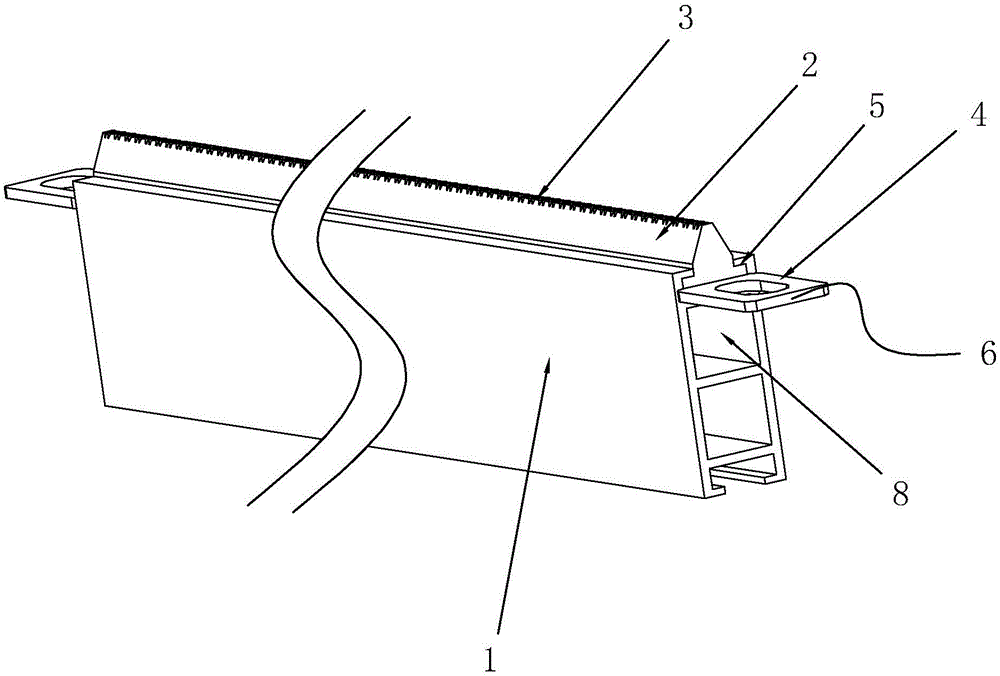

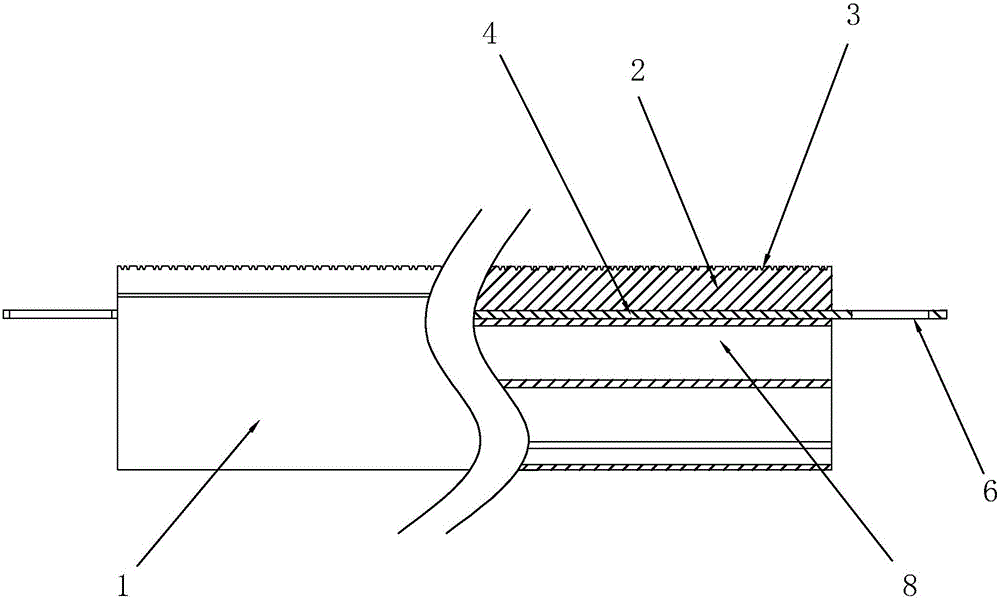

Mold special for wire harness winding, winding device and lamp manufacturing process

ActiveCN106115372AImprove the degree of adaptationReduce manufacturing costFilament handlingLight fasteningsEngineeringConductor Coil

The invention discloses a mold special for wire harness winding, a winding device and a lamp manufacturing process. According to the technical scheme, the mold special for wire harness winding comprises a main mold plate and an auxiliary mold plate; the outer plate wall of the auxiliary mold plate is provided with a plurality of inserting line grooves distributed along a straight line; and the distance between the adjacent inserting line grooves is kept to be consistent; the mold special for wire harness winding further comprises inserting-connection plates; the main mold plate is provided with a slide groove, and the auxiliary mold plate is slidably arranged in the slide groove; the edge of the auxiliary mold plate with the inserting line grooves is protruded out of the main mold plate; and the production cost of the mold special for wire harness winding can be substantially reduced; the winding device has the characteristic of being capable of enabling a tandem connection wire to be efficiently wound on the mold special for wire harness winding; and the lamp manufacturing process can improve the lamp manufacturing quality.

Owner:TAIZHOU WANLI LIGHTING MFG CO LTD

Electro-spraying microfluid chip, making method and mask plate equipment

ActiveCN104056674AElectrospray effect is goodSolve the problem of poor electrospray effectLaboratory glasswaresPhotomechanical exposure apparatusElectro sprayTest equipment

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

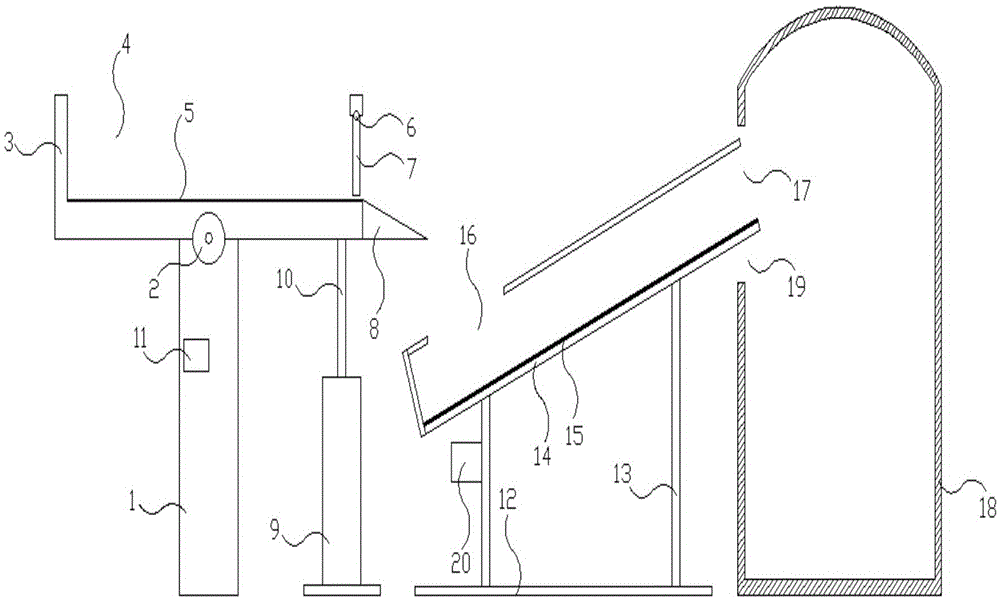

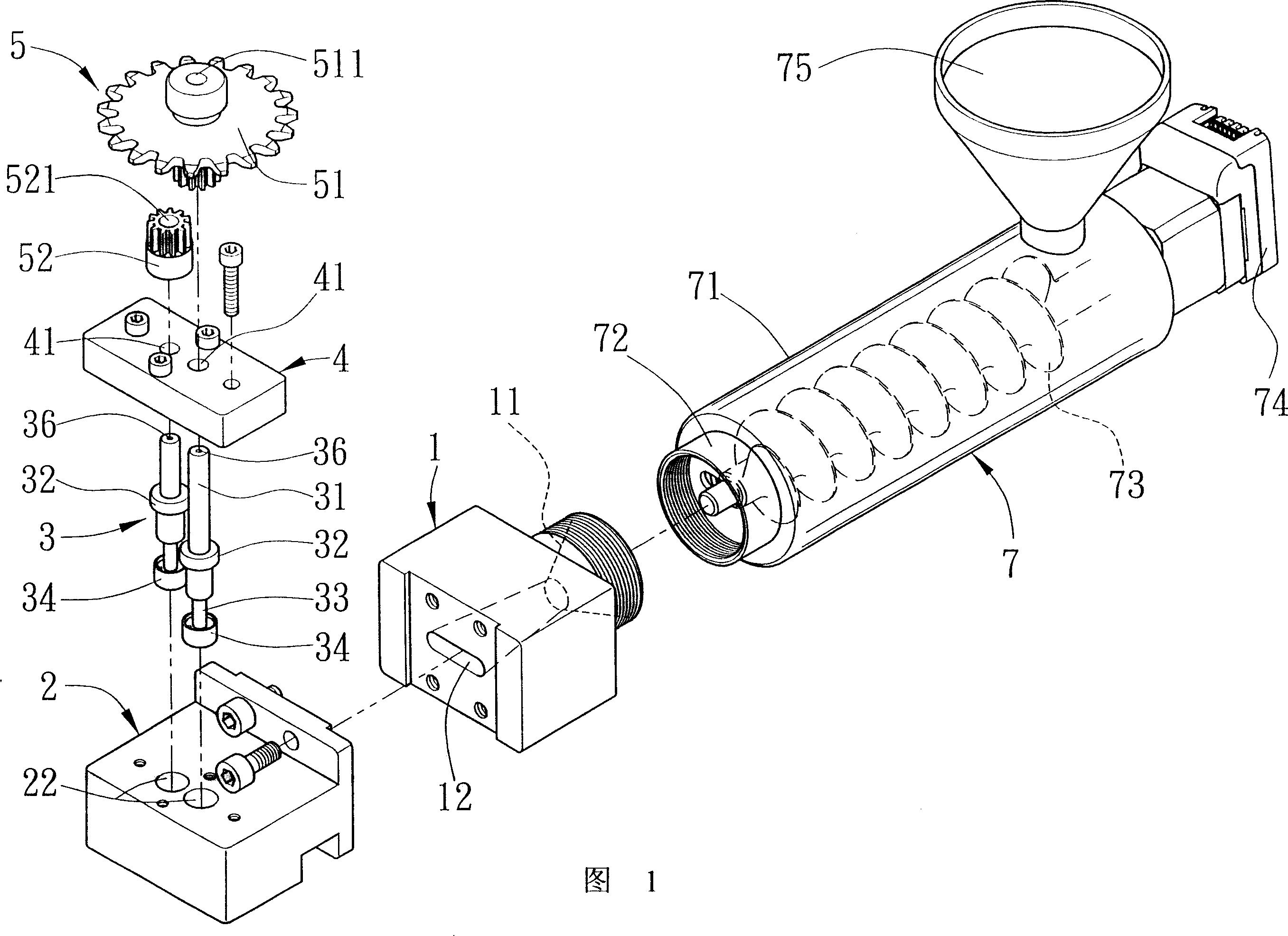

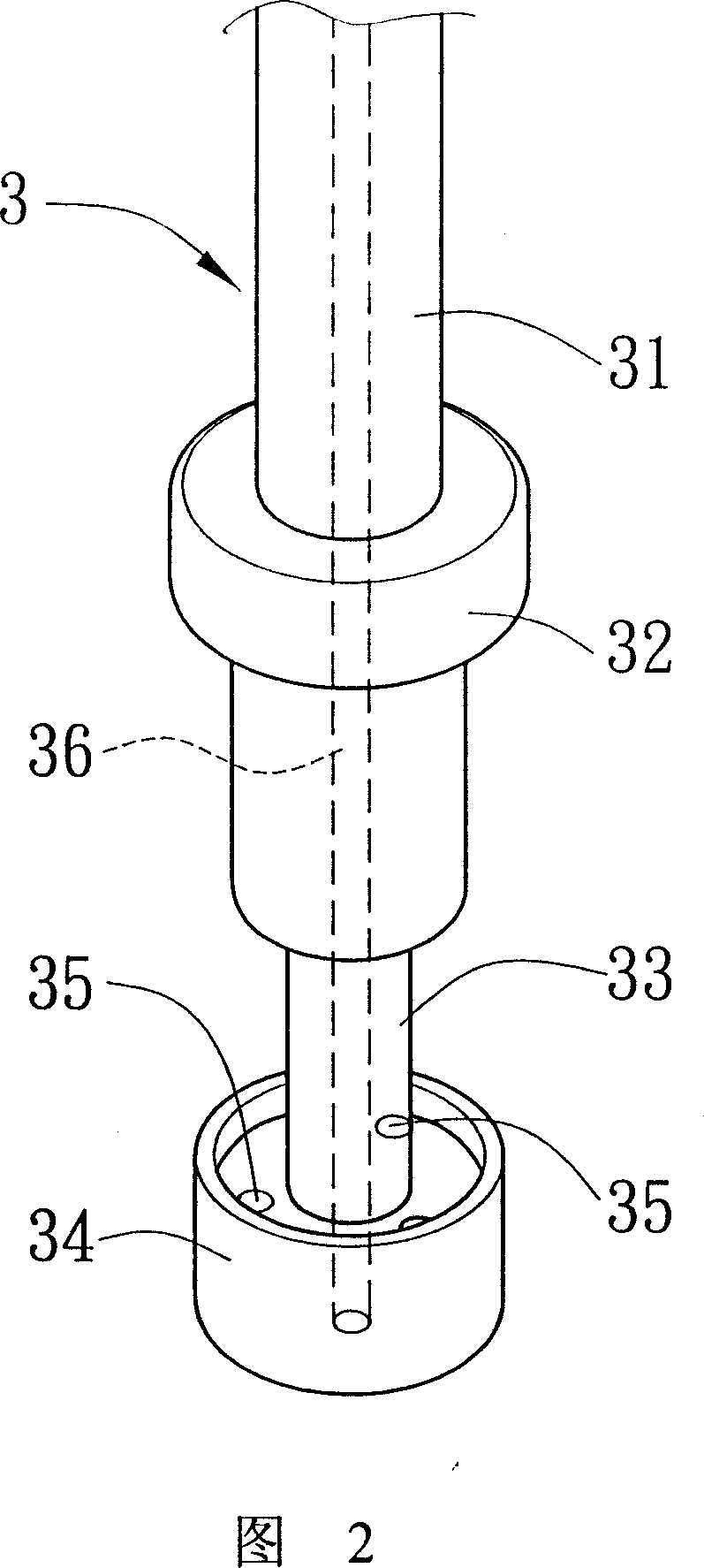

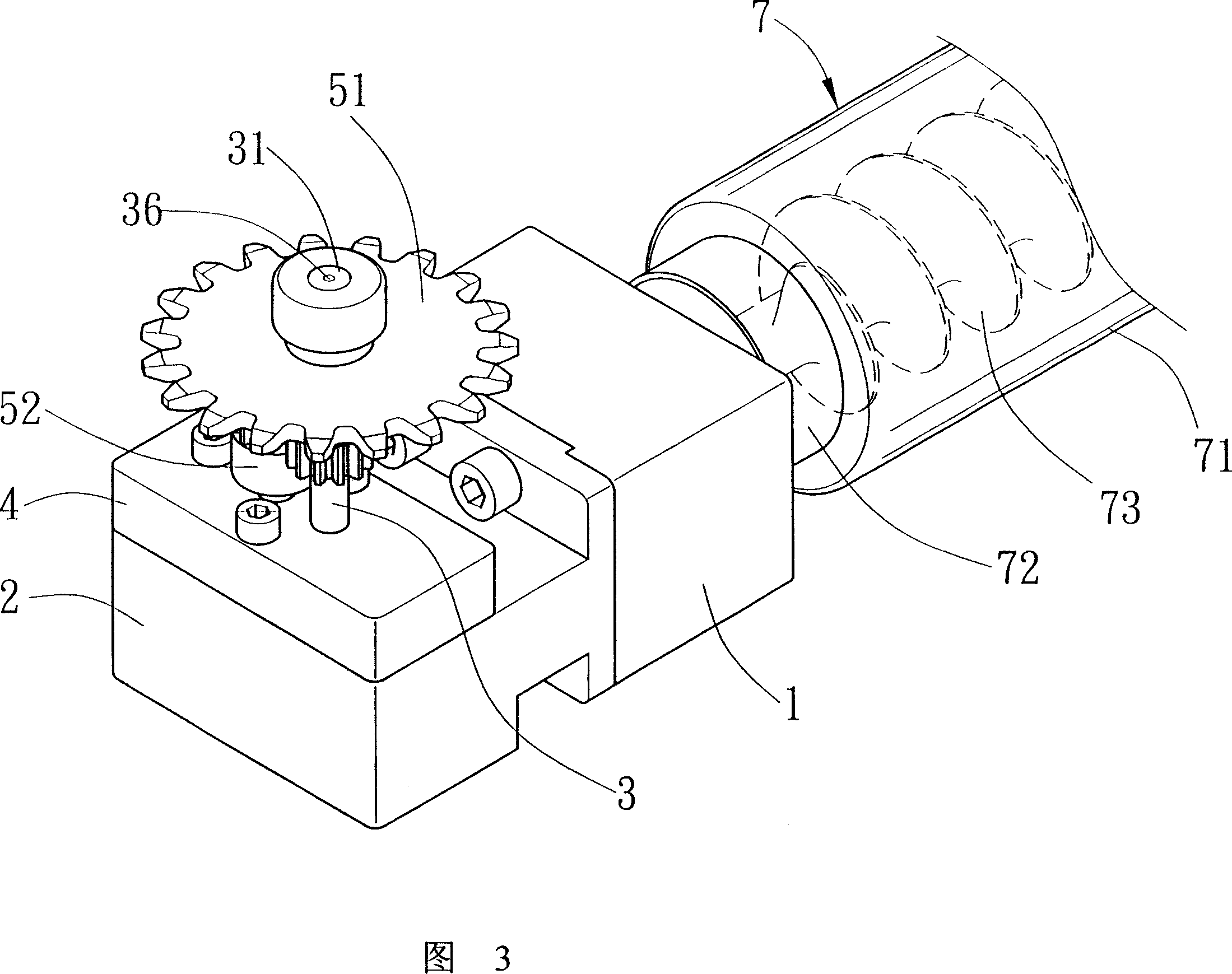

Pipeline conveying structure of raw materials and auxiliary materials of additive production line

InactiveCN105642181AImprove manufacturing qualityImprove stabilityTransportation and packagingMixer accessoriesProduction lineInductor

The invention provides a pipeline conveying structure of raw materials and auxiliary materials of an additive production line. The pipeline conveying structure comprises a supporting column and a first rotary shaft arranged at one end of the supporting column, wherein a feeding box is mounted on the first rotary shaft and a feeding hopper is arranged in the feeding box; a pressure inductor is arranged at the bottom end of the feeding hopper; a second rotary shaft is arranged at one side of the feeding box and a movable baffle is mounted on the second rotary shaft; an inclined side plate is arranged at one side of the movable baffle; an air cylinder is arranged at one side of the supporting column and an air cylinder supporting rod is arranged at one end of the air cylinder; one end of the air cylinder supporting rod is connected to the bottom end of the feeding box; a controller is arranged at one side of the first rotary shaft. According to the pipeline conveying structure provided by the invention, the weight of the raw materials entering the feeding hopper can be accurately induced through the pressure inductor; when the needed weight is reached, the feeding box is controlled to be overturned; the raw materials are conveyed into a reaction kettle through a feeding pipeline and accurate feeding can be carried out; the preparation quality of an additive is improved, and the quality stability of the prepared product is improved.

Owner:魏乾坤

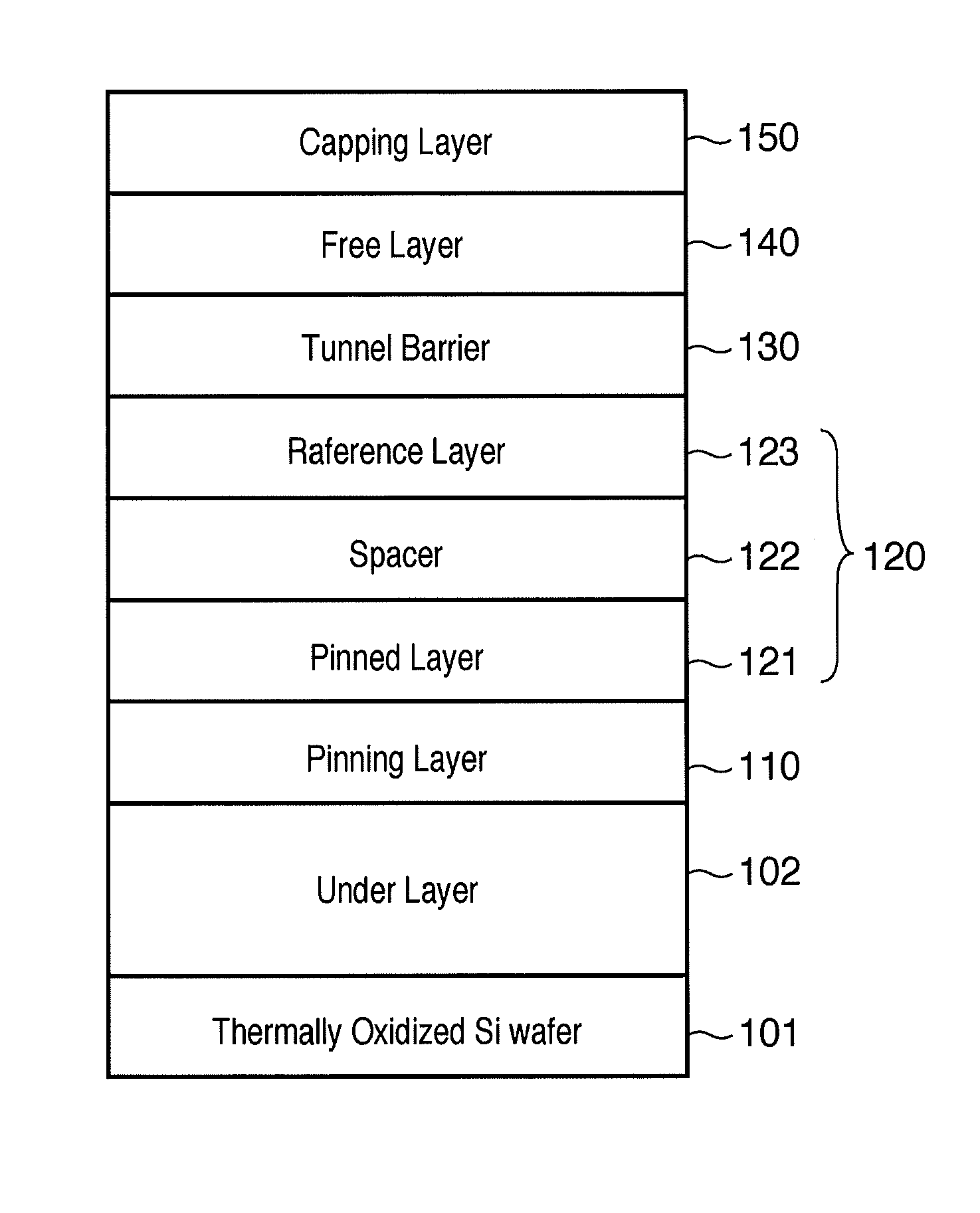

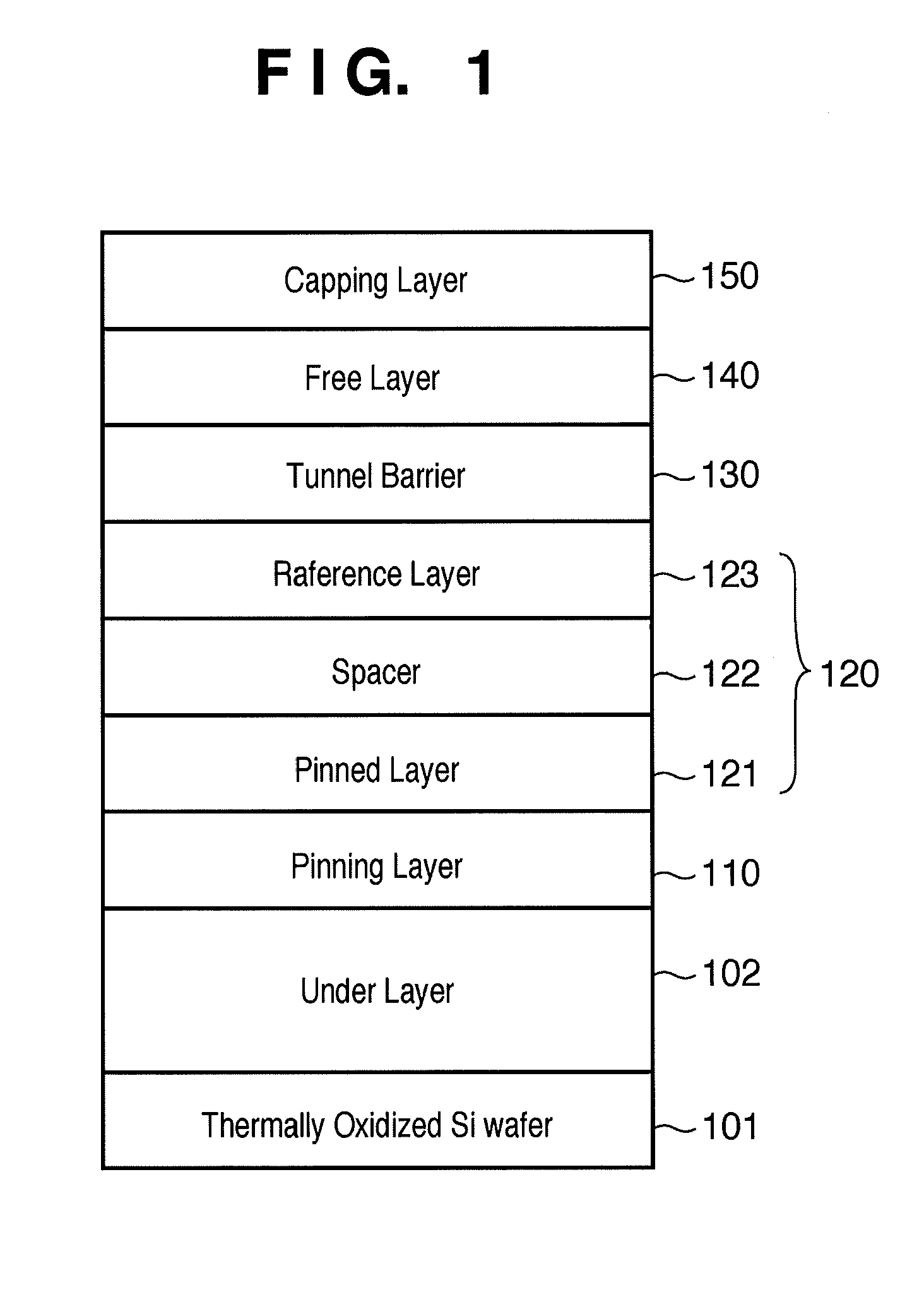

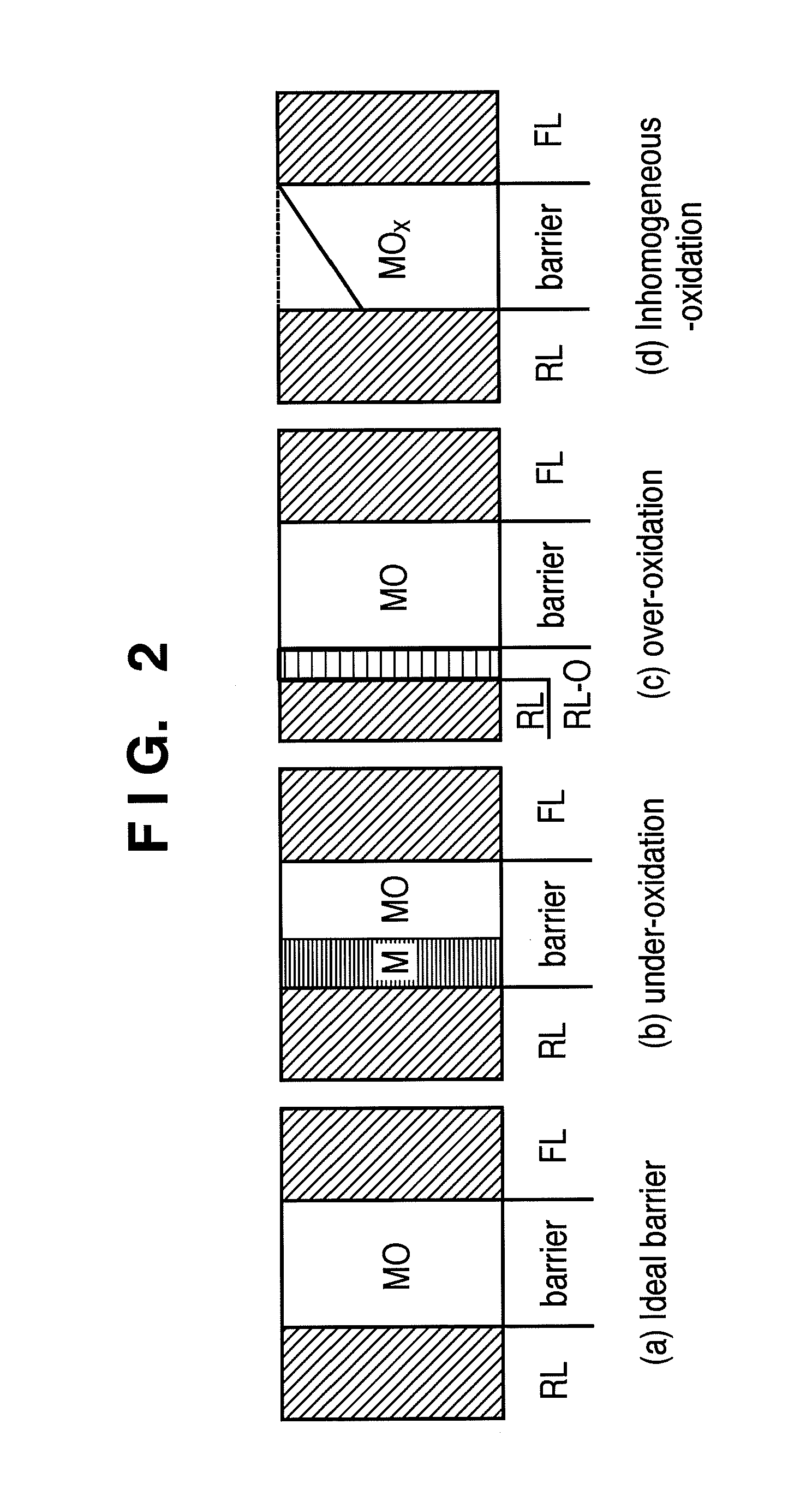

Method of Manufacturing Magnetic Tunnel Junction Device and Apparatus for Manufacturing the Same

ActiveUS20110081732A1Uniform thicknessHigh TMR ratioNanomagnetismNanoinformaticsOxygenSURFACTANT BLEND

A method of manufacturing a magnetic tunnel junction device includes a barrier layer forming step of forming a tunnel barrier layer. The barrier layer forming step comprises a step of depositing a first metal layer, an oxygen surfactant layer forming step of forming an oxygen surfactant layer on the first metal layer, a step of deposing a second metal layer above the first oxygen surfactant layer, and an oxidation step of oxidizing the first metal layer and the second metal layer to form a metal oxide layer.

Owner:CANON ANELVA CORP

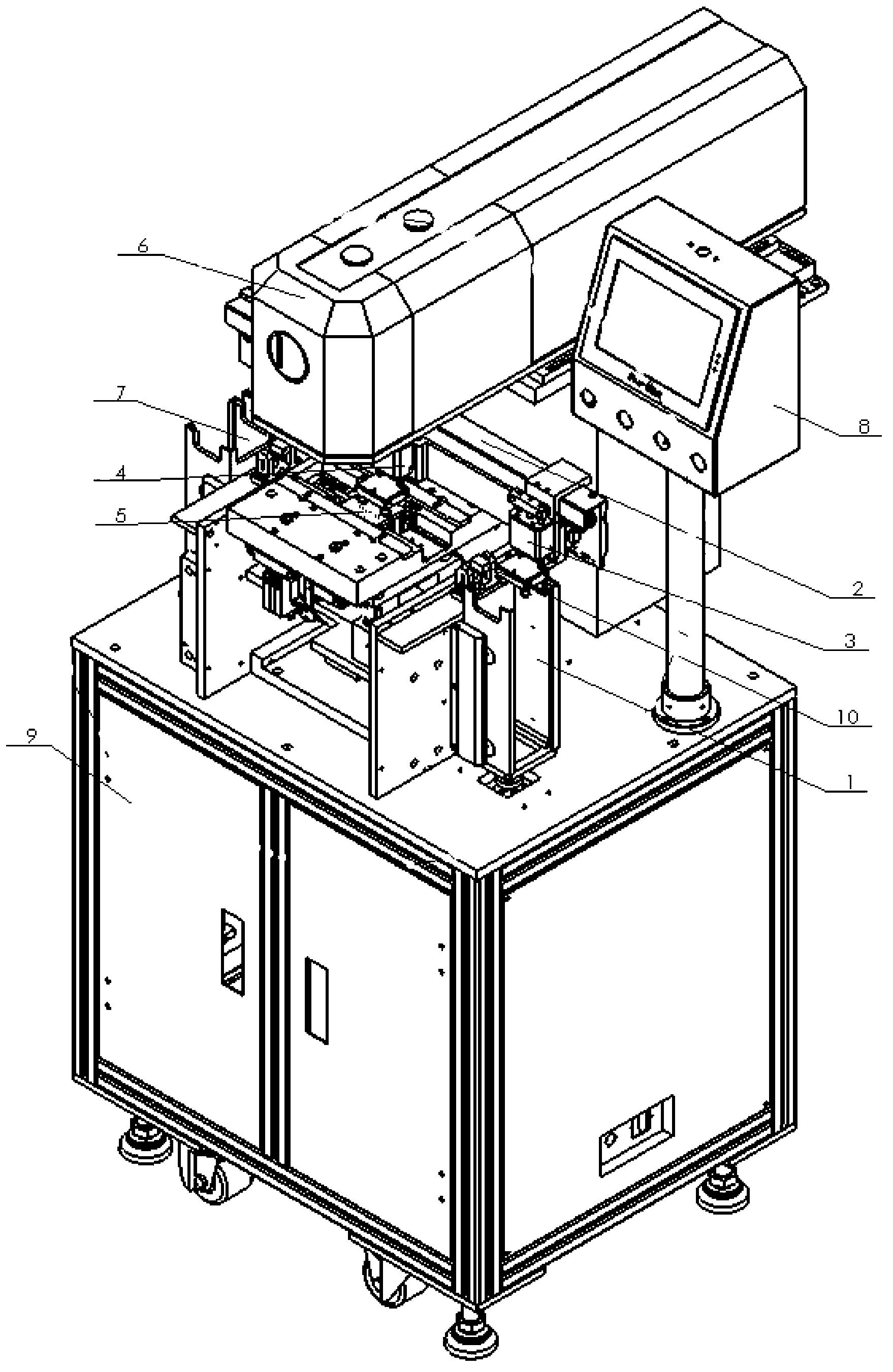

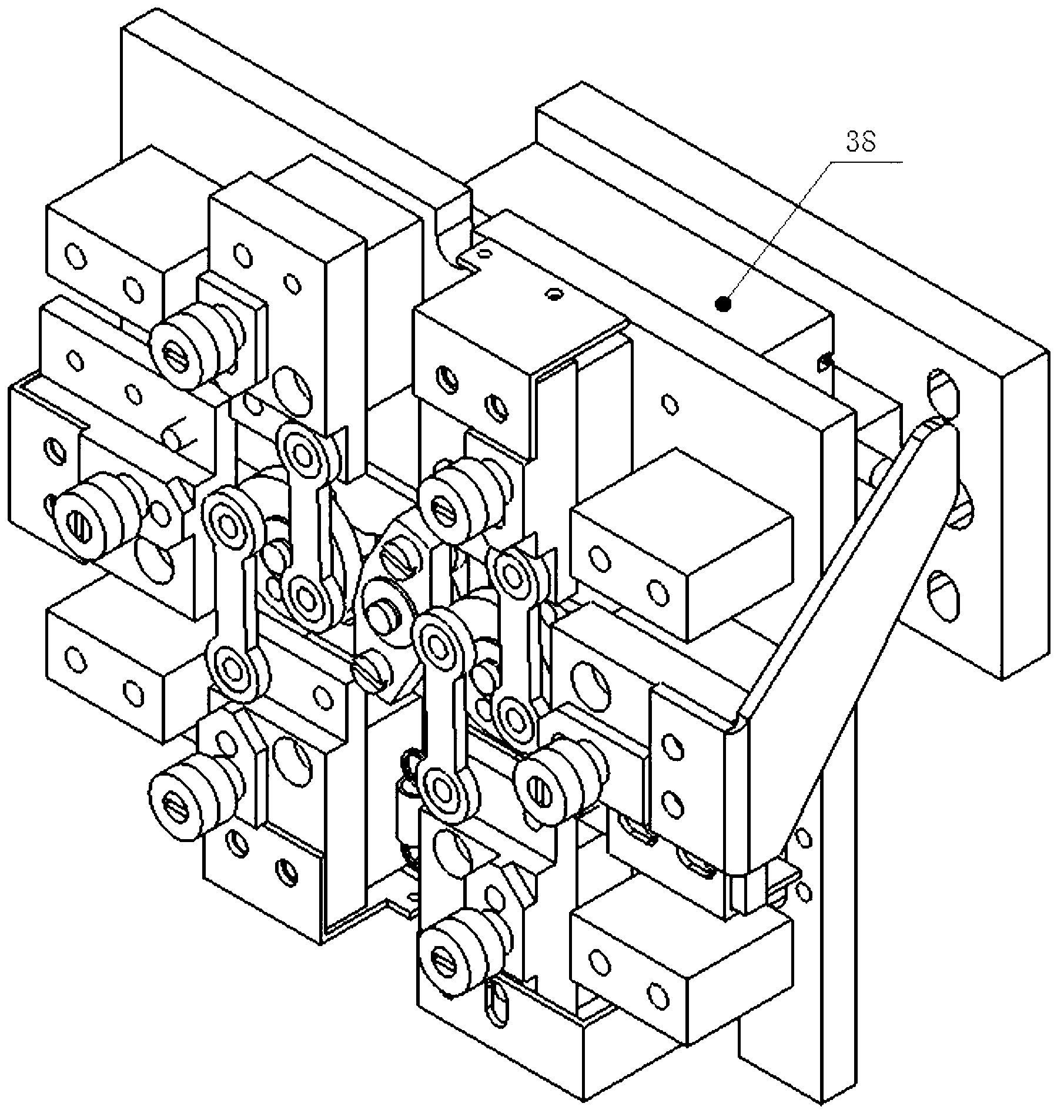

Automatic laser marking device for wafer resistor

ActiveCN102794569AImprove manufacturing qualityRealize elastic operationLaser beam welding apparatusMechanical engineeringLaser

The invention discloses an automatic laser marking device for a wafer resistor, which comprises a frame, a receiving mechanism, a conveying mechanism, an air blowing mechanism, a six-wheel eccentric link center positioning mechanism, an optical fiber laser device and a control box, wherein the receiving mechanism is used for holding a to-be-processed base plate or conveying the processed base plate to a receiving bin; the receiving mechanism is moveably connected with the conveying mechanism; the receiving mechanism can move on the conveying mechanism; a conveying bin is arranged on the lower part at one end of the conveying mechanism; the receiving bin is arranged on the lower part at the other end of the conveying mechanism; the six-wheel eccentric link center positioning mechanism is arranged at the lower end on the middle part of the conveying mechanism; the air blowing mechanism is used for performing air-blowing dust-removing treatment on the to-be-processed base plate held by the receiving mechanism; the six-wheel eccentric link center positioning mechanism is used for positioning the to-be-processed base plate held by the receiving mechanism; the optical fiber laser device is used for cutting lines for the base plate positioned by the six-wheel eccentric link center positioning mechanism; and the control box is used for controlling the receiving mechanism, the conveying mechanism, the air blowing mechanism, the six-wheel eccentric link center positioning mechanism and the optical fiber laser device to work.

Owner:昆山市和博电子科技有限公司

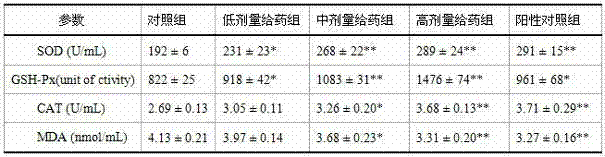

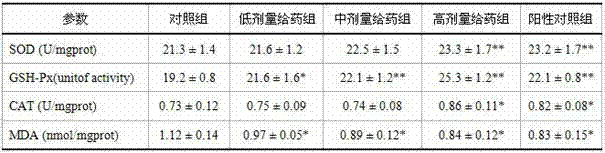

Chinese herbal medicinal compound preparation used for treating macular degeneration of old people and preparation method thereof

InactiveCN102813780APreparation quality is stableDefinite curative effectSenses disorderCardiovascular disorderCompounded preparationsChinese cinnamon

The invention relates to a Chinese herbal medicinal compound preparation used for treating macular degeneration of old people and a preparation method thereof. The Chinese herbal medicinal compound preparation disclosed by the invention is in various medically acceptable dosage forms such as oral liquid and solid preparations comprising tablets, granules and capsules which are composed of extracts of ten traditional Chinese medicinal materials, namely rehmannia glutinosa, root bark of tree peony, poria, Chinese yam, rhizoma alismatis, cornus, cinnamon, monkshood, bat dung and rhizoma atractylodis, and pharmaceutic adjuvants. The invention also discloses a preparation method of the Chinese herbal medicinal compound preparation. The Chinese herbal medicinal compound preparation disclosed by the invention has the effects of tonifying kidnety and warming yang, replenishing qi to invigorate the spleen, invigorating blood circulation to promote the secretion of saliva or body fluid and dredging collaterals to improve eyesight and has obvious therapeutical effect on the macular degeneration of the old people.

Owner:TONGHUA NORMAL UNIV

Forming die for screwy plastic splint

InactiveCN101085546AImprove production efficiencyImprove manufacturing qualityEngineeringMechanical engineering

The spiral plastic vane forming mold comprises the first mold with hollow and extended plug hole, the second form mold at the plug hole of the first mold with sprue at the plug hole and at least one through channel vertical to the sprue, at least one mold core going through the channel of the second form mold with fixed part, leaning part, material assembly part and out surrounded bulge material output part, with two guide holes at the plug hole, one fixed mold set on the second form mold with pivot hole corresponding to the channel of the second form mold, a drive set connected to the power source with its axial core going through the circle hole, driving the core rotation after fixed with the mold core. It uses material strip left temperature to form spiral strip, without secondary process, and simplified in process and improved in working efficiency.

Owner:陈明祥

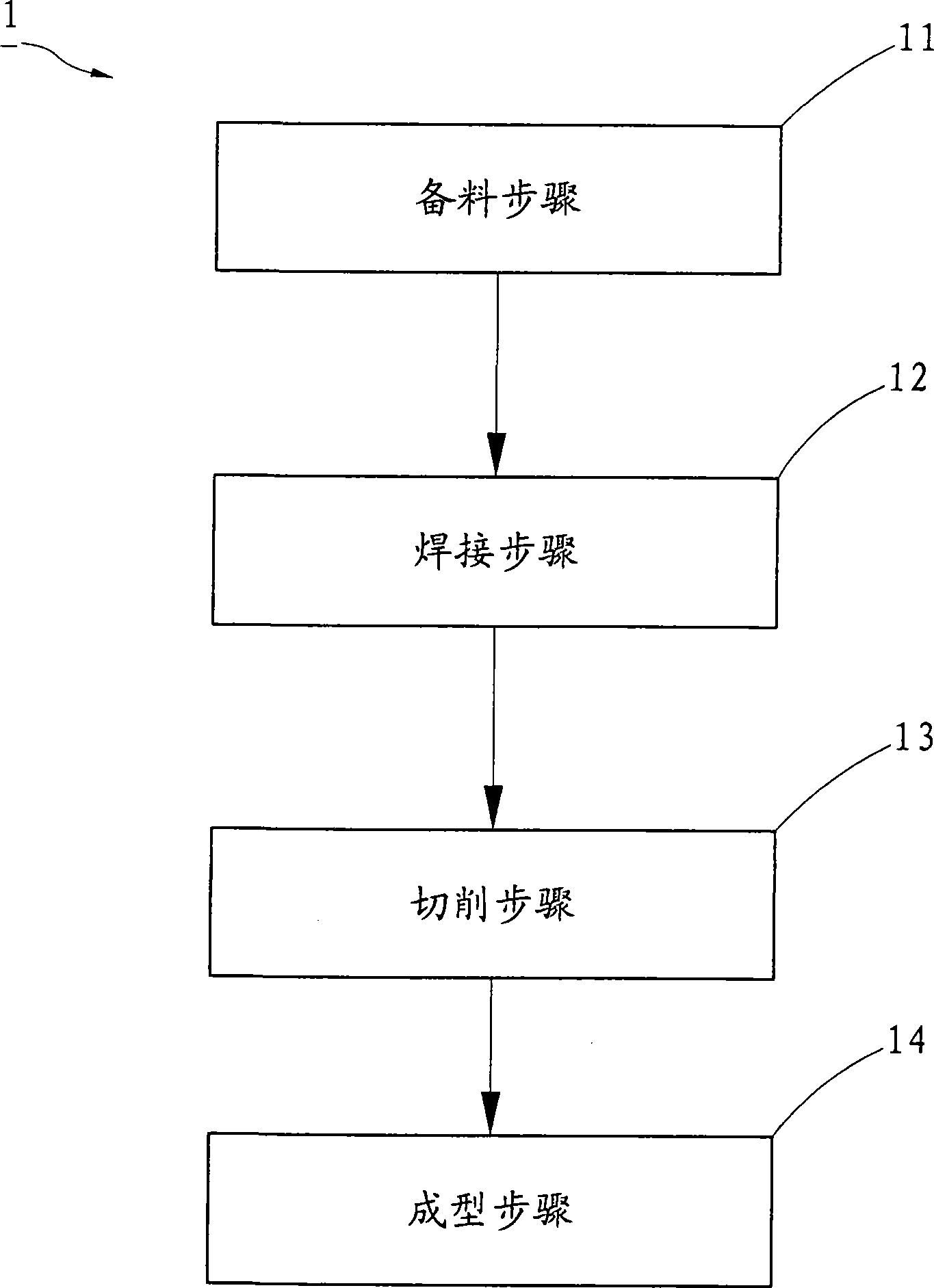

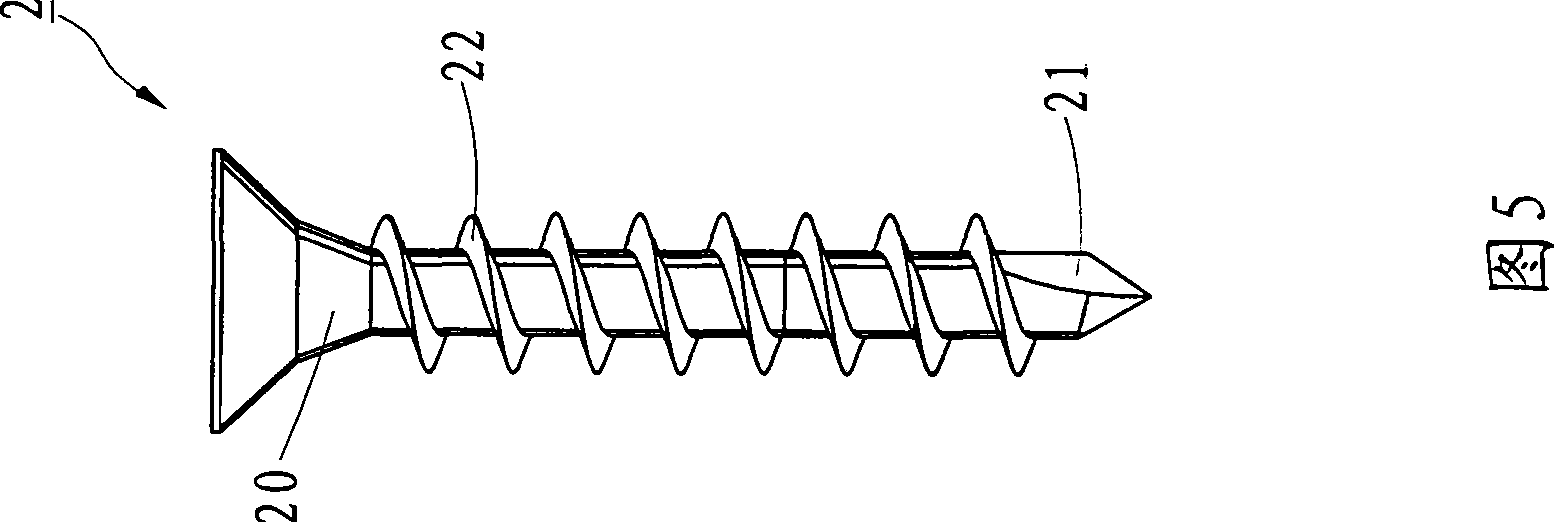

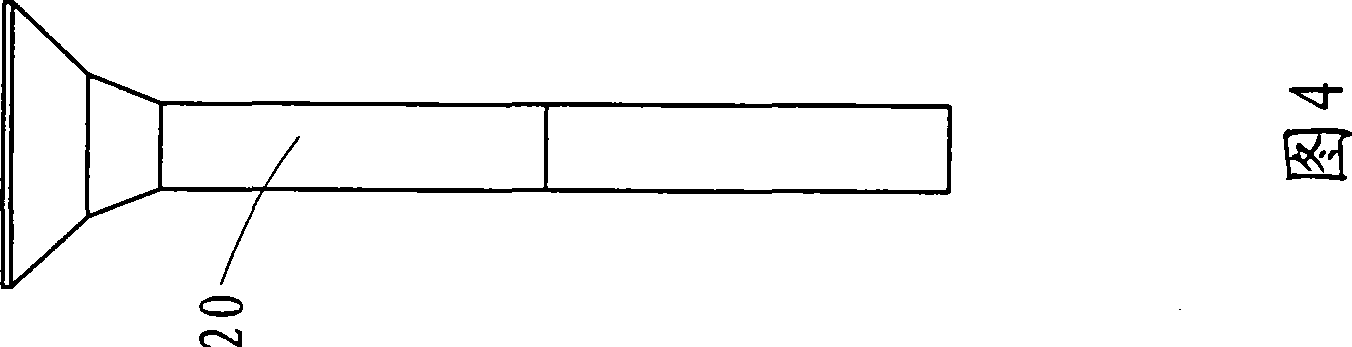

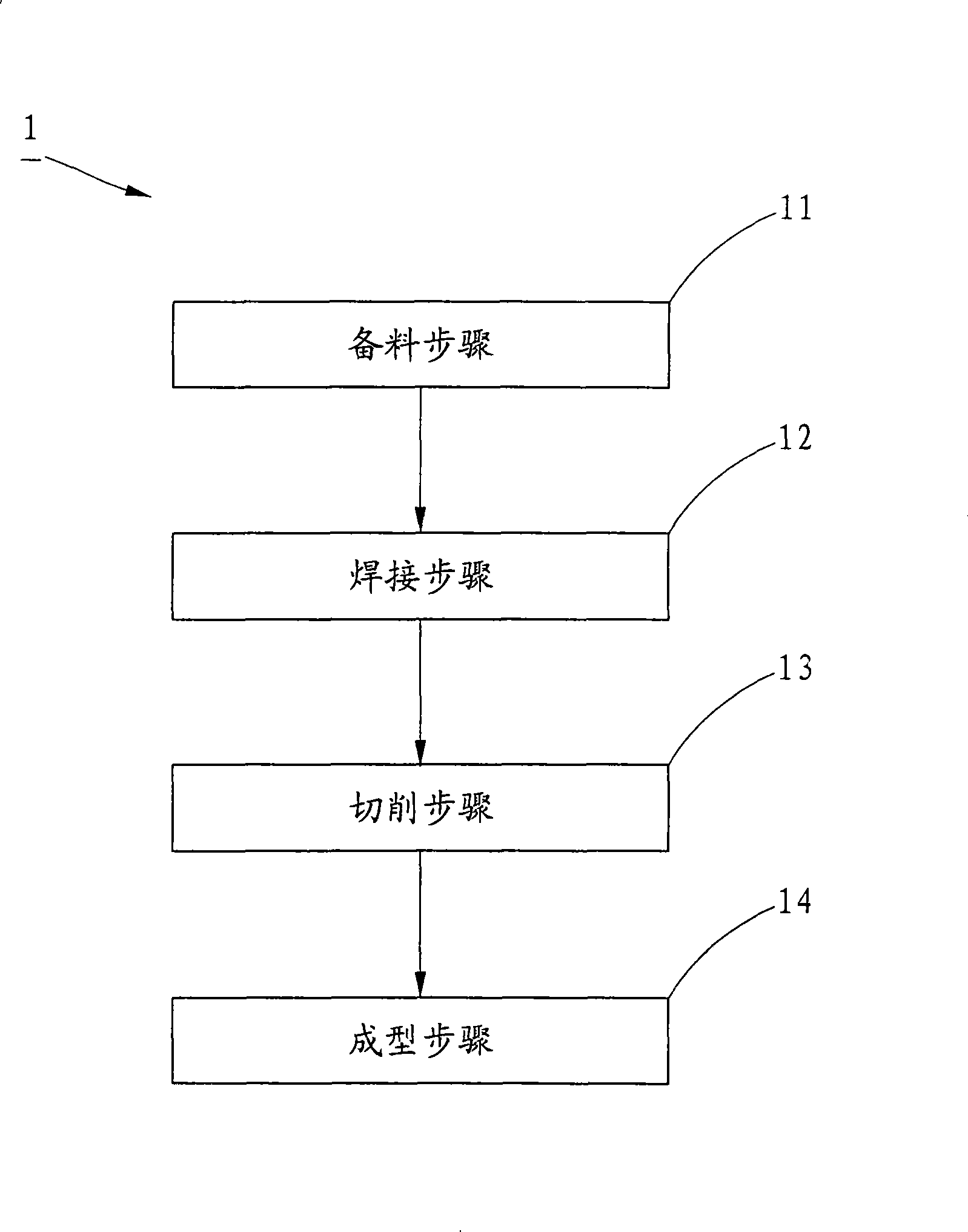

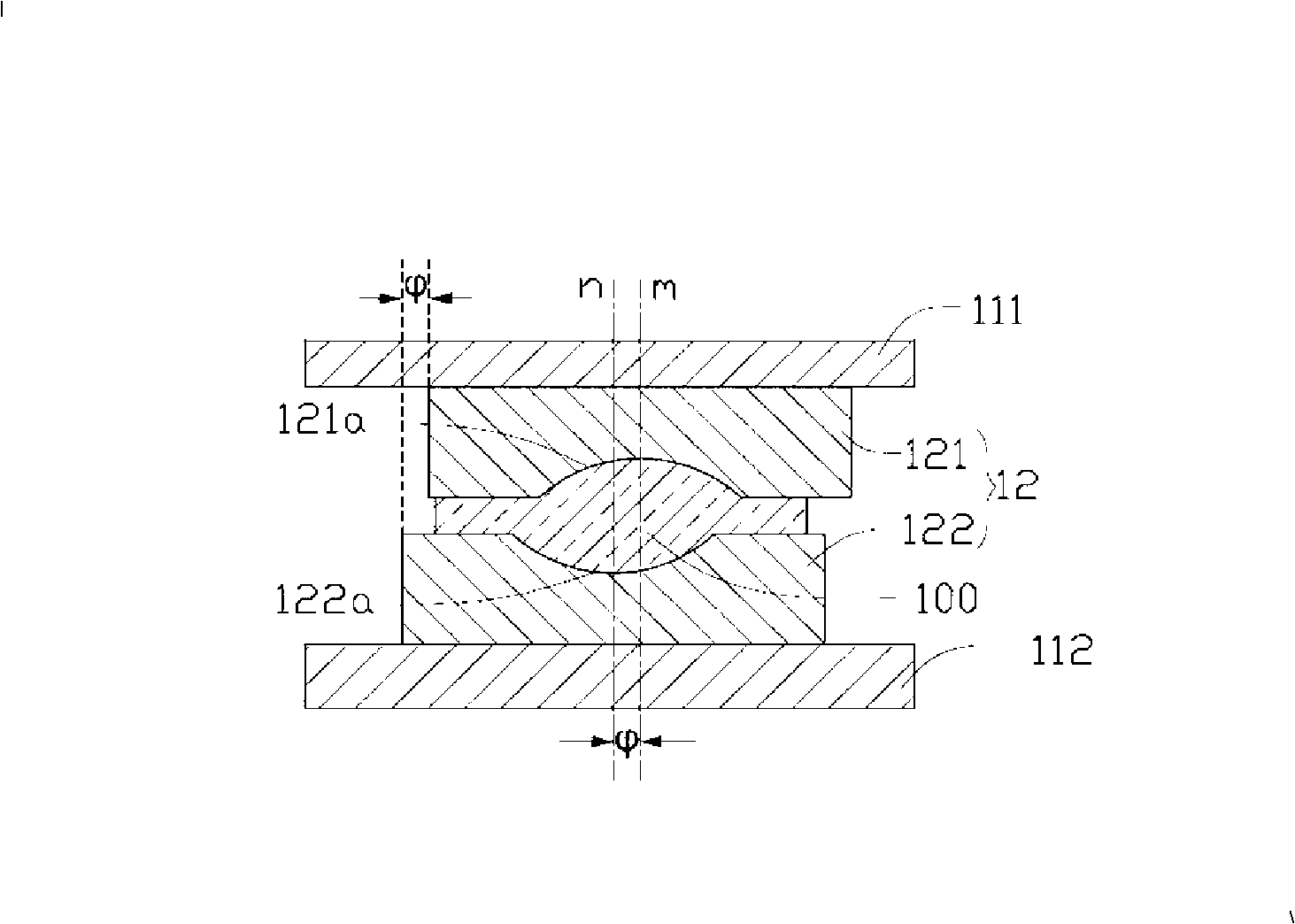

Manufacture method of screws of different material

The invention relates to a method for manufacturing screws of different materials, and the method comprises a preparation step, and engagement step, a stamping step and a forming step sequentially; wherein, the preparation step aims at forming a first engagement part and a second engagement part on a rod body and a rod end of different materials, and the first engagement part and the second engagement part are used for locating first. Then, stamping location of the stamping step together with the first location of the first engagement part and the second engagement part form a preliminary-linked compound blank. The manufacturing method has the advantages of that a welding process can be canceled, the difficulty of following processing caused by the hardening of the materials during the welding process is also avoided and cutting operation after the welding is removed. Finally, screws of different materials and having good quality and hard falling off are formed after screw tooth twisting and forming operation. The manufacturing method simplifies the manufacturing process of the screws and reduces the production cost.

Owner:苏美铃

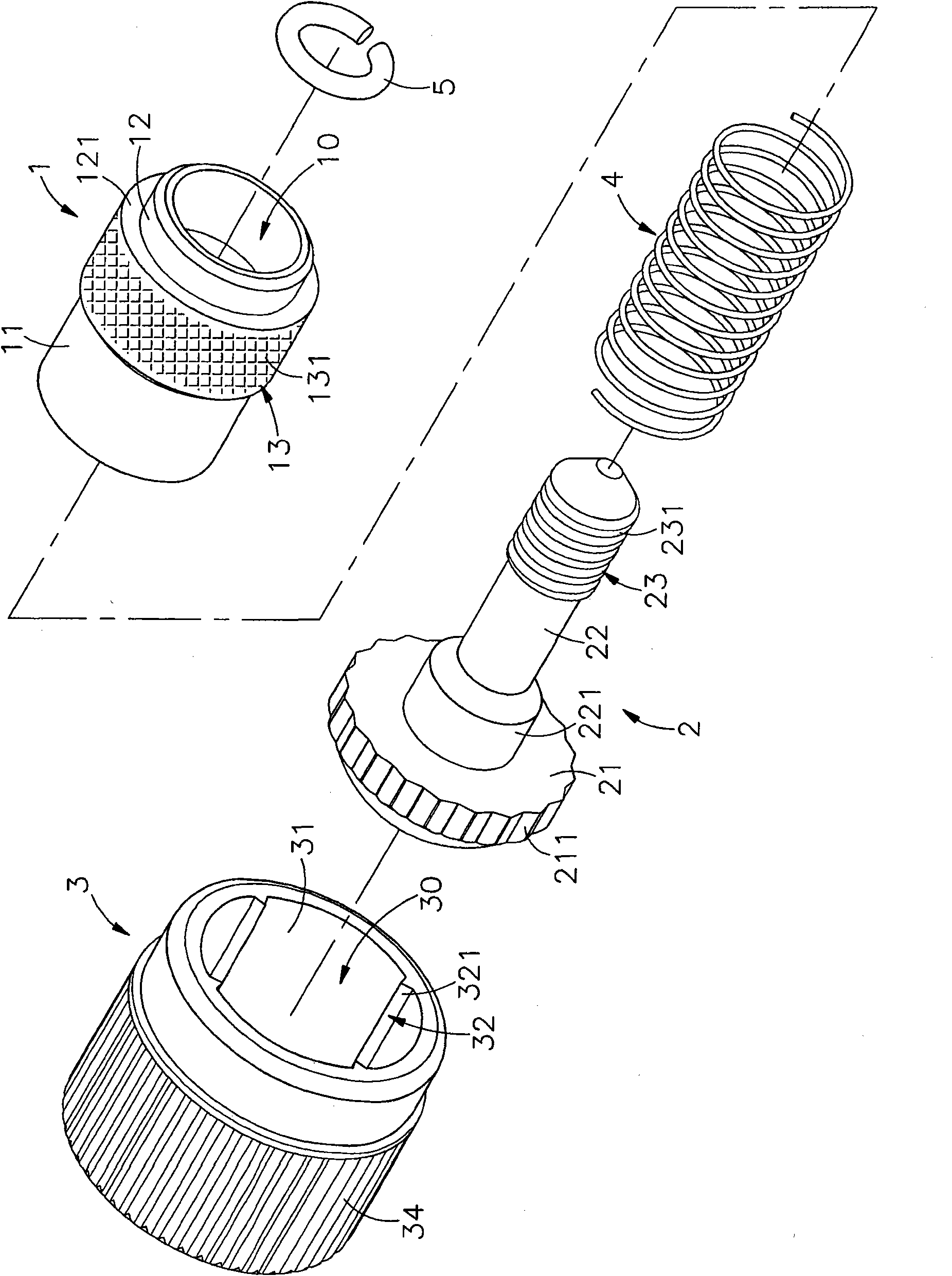

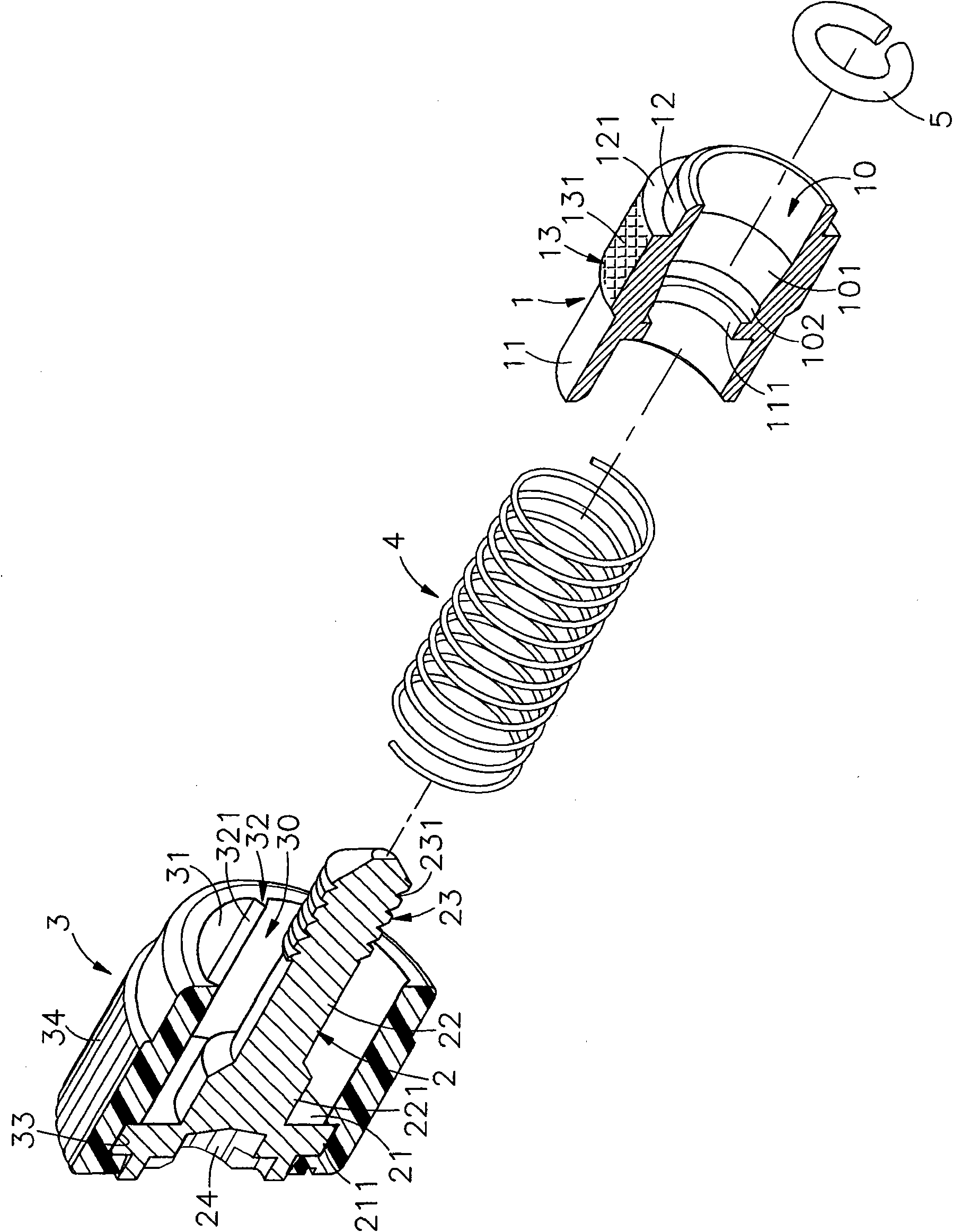

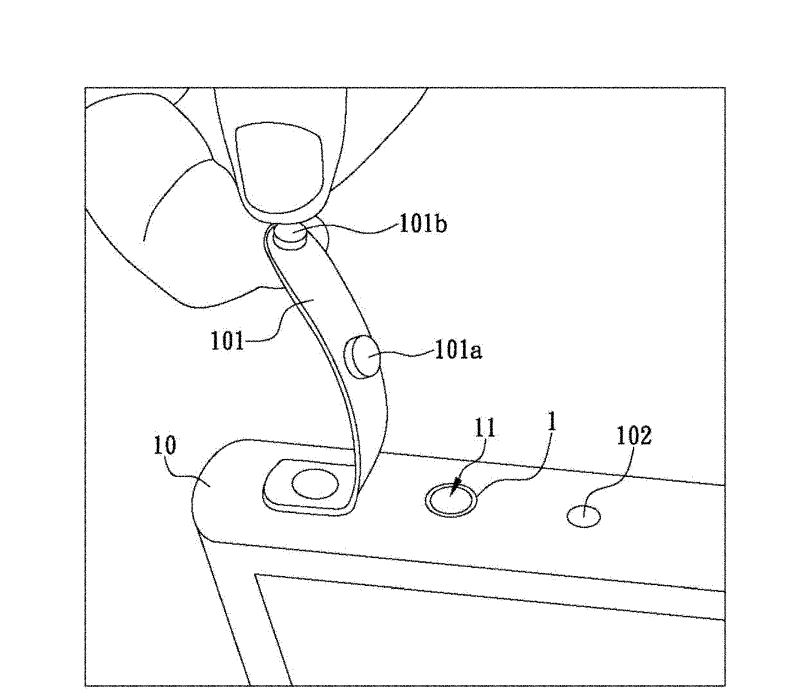

Fixing device

InactiveCN101943201AEasy to pick up for mass productionImprove manufacturing qualityScrewsSheet joiningRubber materialButt joint

The invention provides a fixing device. In the fixing device, a combining part is formed at the front edge of a butt joint sleeve, and the periphery at the outer side behind the combining part is provided with a friction part; a locking element is an outer sleeve pipe combined with a plastic rubber or a rubber material at the outer side of a rotating head end, and the butt joint sleeve and a spring are accommodated in the outer sleeve pipe; an interference part is arranged on the inner side surface of a front opening of the outer sleeve pipe, and the interference part of the outer sleeve pipe and the friction part of the butt joint sleeve are aligned and pressed to form preset positioning; the outer sleeve pipe is temporarily pressed and connected to the butt joint sleeve so as to be convenient for an automatic machine to take up the outer sleeve; the combining part is aligned and tightened into a joint hole of a first plate and welded into a whole; then the outer sleeve pipe is held and rotated to ensure that the interference part forms interference and abrasion with the friction part on the butt joint sleeve to form a separation state, thus a movable opposite locking state can be formed through the butt joint sleeve, a locking element and a stopping ring body capable of preventing coming off; and the effects of being convenient for volume production of taking pieces, improving the manufacturing quality and the yield rate and reducing the production cost are achieved.

Owner:王国仲

Waterproof audio socket

InactiveCN102623834AImprove production efficiencyImprove manufacturing qualityCouplings bases/casesAgglutinationMechanical engineering

The invention provides a waterproof audio socket. The socket comprises a body, a plurality of first connection terminals and an insulating plate body. The body is provided with a plug groove and the other adjacent side is provided with a plurality of first plug holes. The each first plug hole is communicated with the each plug groove respectively. One end of the each first connection terminal can pass through the corresponding first plug holes respectively so as to be accommodated in the plug groove. The insulating plate body is provided with a plurality of second plug holes and a plurality of second connection terminals are fixedly arranged in the insulating plate body in a watertight mode. One end of the each second connection terminal is exposed from the corresponding second plug hole and the other end is extended outward from the insulating plate body so as to be welded on a circuit board of one electronic product. Under the condition that the insulating plate body is combined to another side of the body through an ultrasonic wave or agglutination mode, the each first connection terminal can be electrically connected with the corresponding second connection terminal. Therefore, moisture and dampness can not infiltrate into the product via the plug groove so that a problem that the electronic product can not be waterproof can be solved.

Owner:GUIMA SCI & TECH

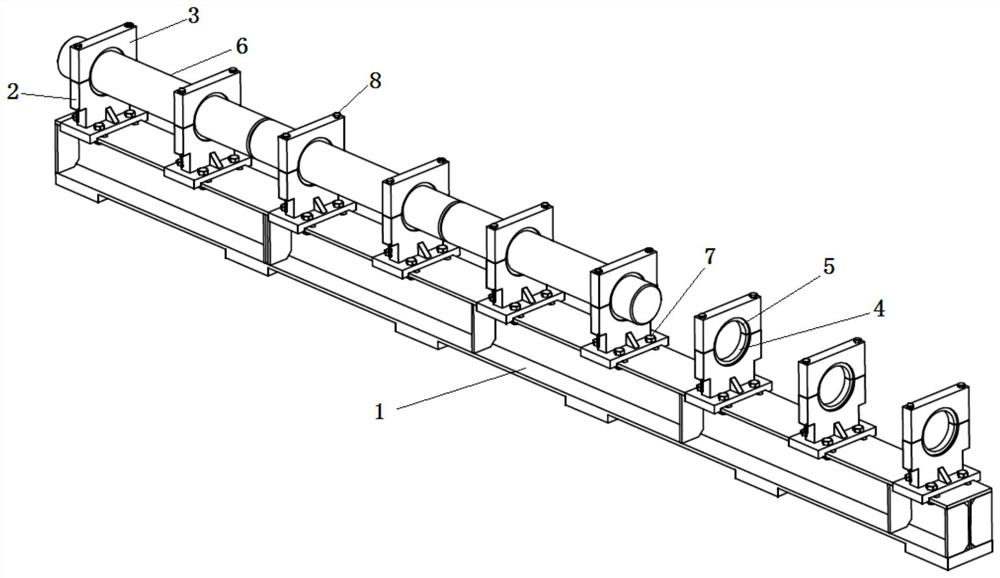

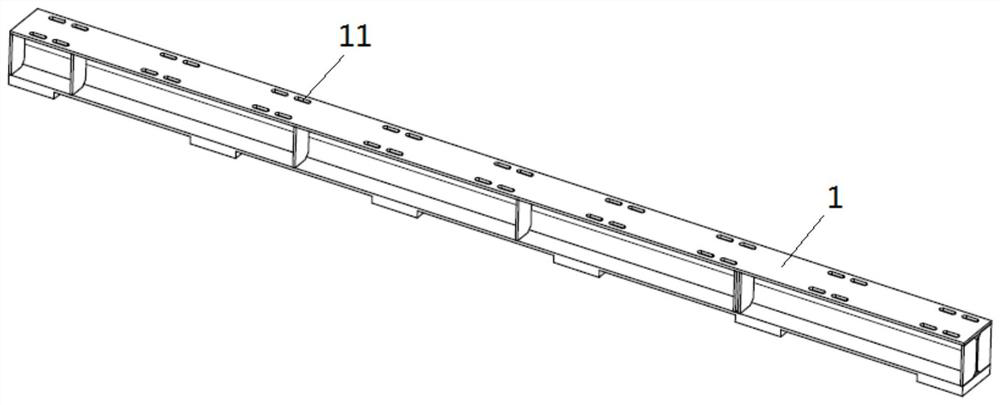

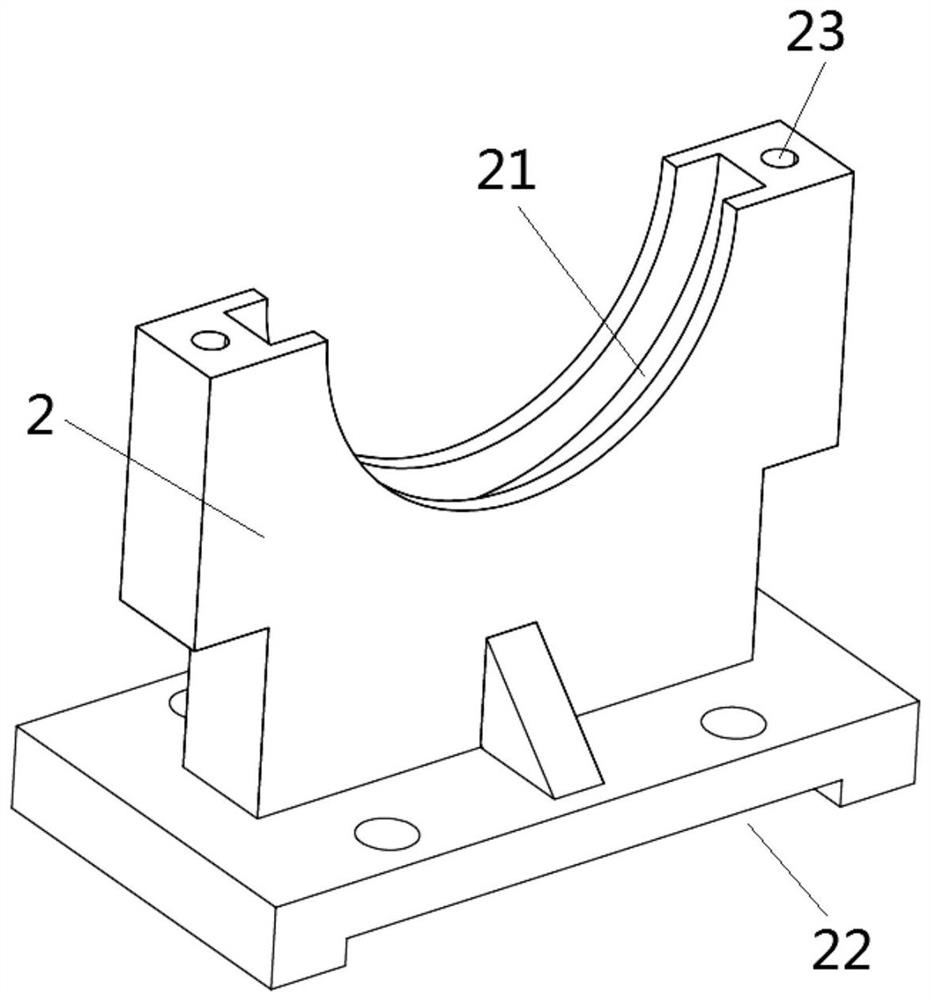

Pipe fitting welding tool and method capable of guaranteeing butt-joint concentricity

InactiveCN112222741ASolve the problem that welding deformation is difficult to controlImprove production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingButt joint

The invention discloses a pipe fitting welding tool and method capable of guaranteeing butt-joint concentricity, which is used for assembly welding of an inner tube of a stainless steel dual-wall tubefor a marine low-speed diesel engine. The pipe fitting welding tool comprises a platform, a base, an upper cover, a copper lining and a copper outer lining, wherein the platform is positioned on thebottom of the whole device; the base is fixedly arranged on the upper part of the platform, and a semicircular groove is formed in the upper part; the upper cover is fixedly connected to the base through a fastening bolt, and a semicircular groove is formed in the lower part of the upper cover; the copper lining is in the shape of a semi-circular ring and is embedded into the semicircular groove of the base; the copper outer lining is the same with the copper lining in structure, and is embedded into the semicircular groove of the upper cover; and the copper lining is in butt joint with the copper outer lining for clamping an inner tube therein, so that concentricity of pipe fittings is guaranteed. Through stage-by-stage operation, deformation is corrected time by time, so that dimension precision is guaranteed, product quality is stabilized, and operation efficiency is improved, and thus, the pipe fitting welding tool can be used for welding assembly of all stainless steel pipe fittings.

Owner:CSSC MES DIESEL

Character processing method of PCB ultra-thick copper plate

ActiveCN110802963ASolve the problem of not printing oilClear and beautiful guaranteeDuplicating/marking methodsOther printing apparatusMechanical engineeringComposite material

The invention discloses a character processing method of a PCB ultra-thick copper plate. When character printing is performed on a single side of a PCB and a character spans a substrate surface and acopper surface, the method comprises the following steps of performing character ink-jet on the substrate surface, where the character is to be printed, on a production plate; using a silk screen to perform silk printing on a character on the copper surface on the production plate, wherein the silk screen comprises a copper surface region and a substrate region, the substrate region corresponds tothe substrate surface on the production plate, the copper surface region corresponds to the copper surface on the production plate, and the silk screen is provided with an image-text mesh hole only at the corresponding character of the copper surface region; and baking the production plate so that ink subjected to silk printing on the production plate can be cured. According to the method, the problems that the characters on the PCB ultra-thick copper plate are not inked and distinct can be avoided, it is ensured that the produced characters cannot fall off due to friction, and distinction and attraction of the characters can be guaranteed.

Owner:SIHUI FUJI ELECTRONICS TECH

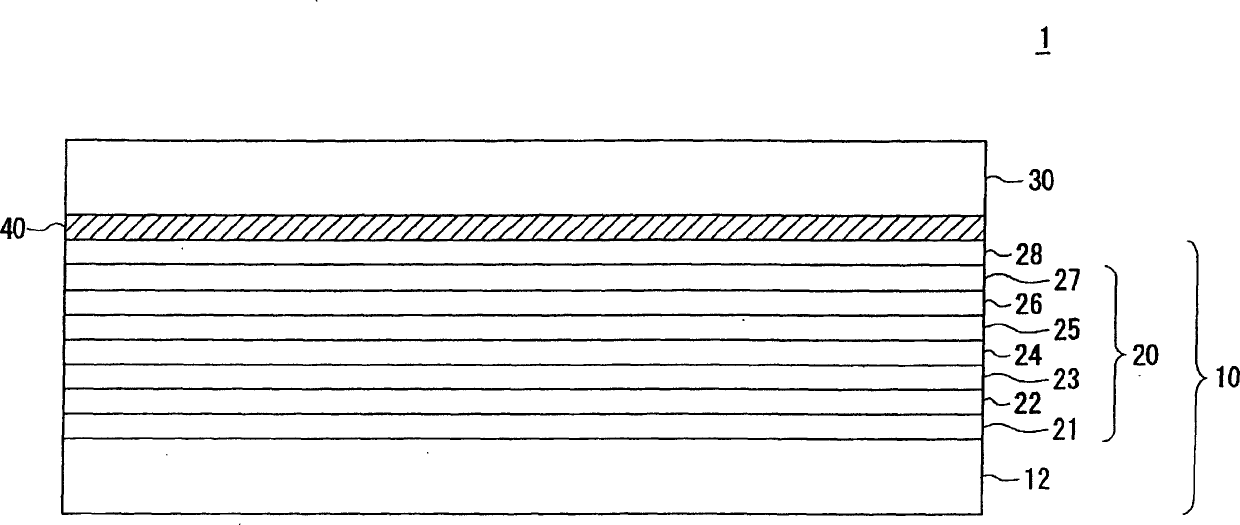

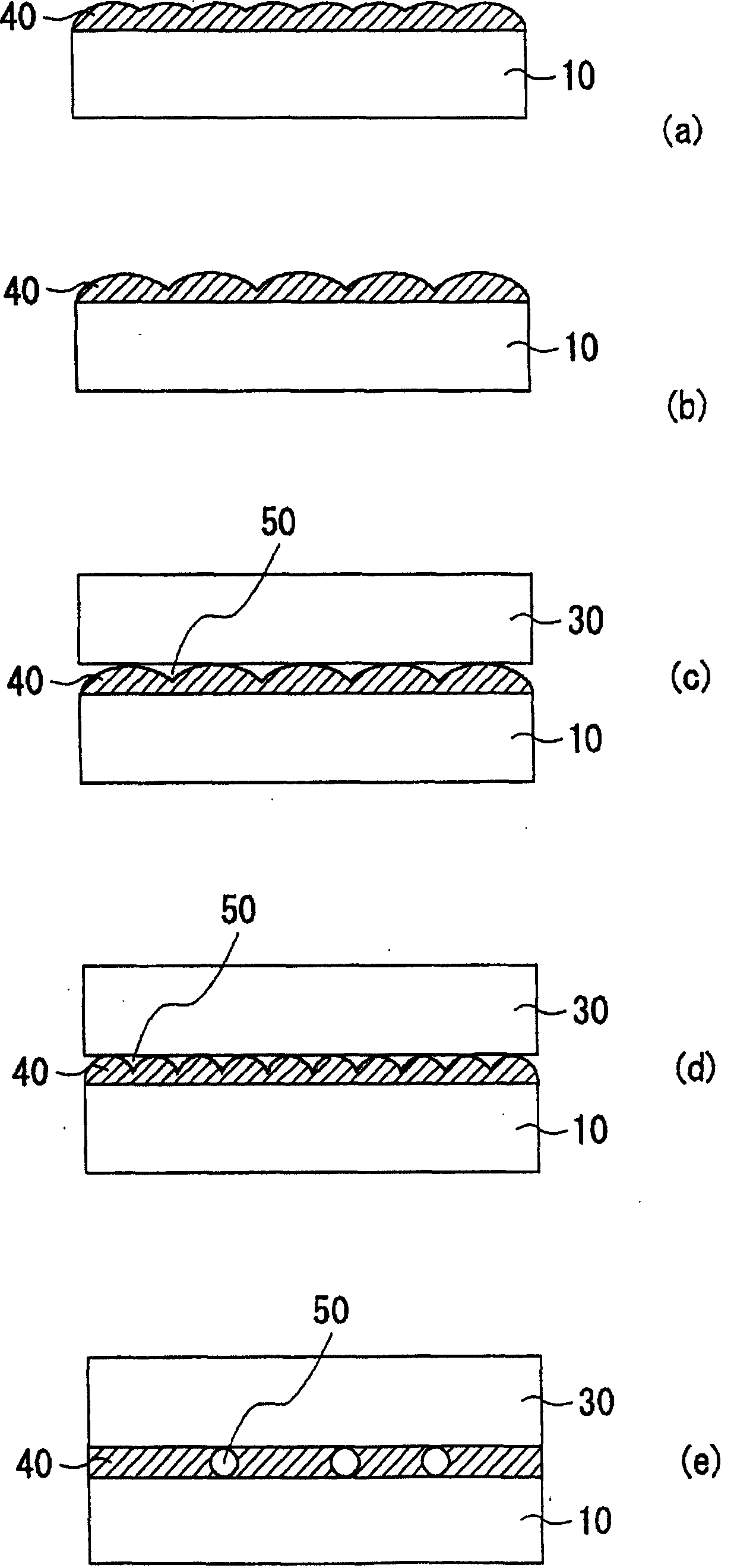

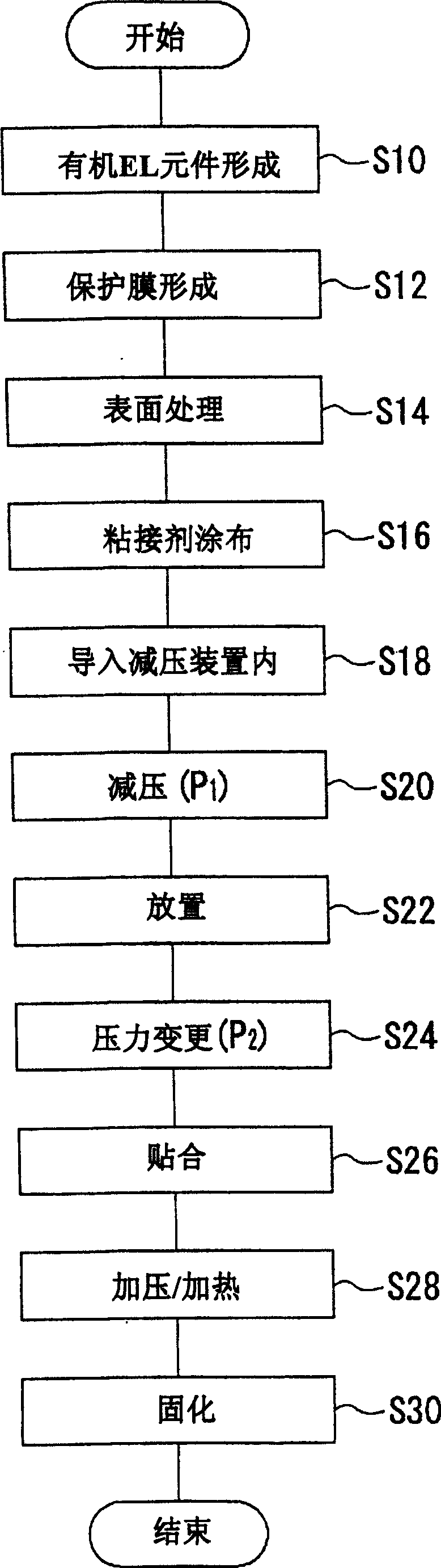

Electroluminescence panel and manufacturing process therefor

InactiveCN1575055AImprove manufacturing qualityDischarge tube luminescnet screensElectroluminescent light sourcesScreen printingAdhesive

A method for manufacturing an electroluminescence panel comprises a step of forming an organic electroluminescence element (S10) on a glass substrate; a step of forming a protective film (S12) on the organic electroluminescence element; a step of performing an ozone treatment or plasma treatment (S14) on a surface of the glass substrate or a sealing substrate; a step of depositing an adhesive (S16) on the surface of the glass substrate or the sealing substrate, through a screen printing process; a step of disposing the glass substrate and the sealing substrate in a chamber (S18) of a pressure reduction device; a step of reducing pressure to P1 (S20) in the chamber; a step of leaving the substrate until foaming of volatile components contained in the adhesive is stabilized (S22); a step of suppressing foaming (S24) of the volatile components by increasing the pressure to P2 in the chamber; a step of bonding the substrates (S26); a steps of applying pressure and heat (S28) to the bonded substrates so as to remove micro spaces; and a step of hardening (S30) the adhesive.

Owner:SANYO ELECTRIC CO LTD

Manufacture method of composite screw

The invention relates to a method for producing a screw of composite material. The method comprises the steps of material preparation, welding, cutting and shaping in sequence, wherein, in the material preparation step, two different materials are divided into a rod body part and a drilling tail part; a welding part is formed on the rod body part, and a taper body is formed on the drilling tail part. Through the taper surface formed on the taper body, not only air can be smoothly exhausted when the rod body part is welded with the drilling tail part (namely, the welding step), so as to avoid air covering in the welding process, and ensure that pores can not appear at the welding positions, but also the composite blank can not be deflected after welding; finally, through the cutting of residual material in the cutting step, and shaping operations of screw thread rolling and the like, the screw of the composite material can be shaped, therefore, the quality of the screw of the composite material can truly be improved through the method.

Owner:TOP WELL TECH CORP

Method of preparing mould core, mould core and mould using the mould core

InactiveCN101333065AImprove manufacturing qualityGlass pressing apparatusMaterials scienceManufacturing quality

The invention provides a die-core manufacturing method, which comprises the following steps: providing an eccentric die core and testing the deviation of the eccentric die core; providing a first blank and forming a first molding surface on one surface of the first blank so as to form a first template, while a deviation consistent with the deviation of the eccentric die core is arranged between the geometric centerline of the first template and the centerline of the first molding surface; providing a second blank and processing a second molding surface on one surface of the second blank so as to form a second template; the first template and the second template are oppositely arranged based on the location of the eccentric die core, so that the centerline of the first molding surface and the centerline of the second molding surface can be superposed to form a die core. In addition, the invention also relates to a die core which is made based on the die-core manufacturing method, and a die which adopts the die core. The die-core manufacturing method, the die core and the die using the die core can eliminate the eccentric phenomena existing in the optical lens molding process and improve the manufacturing quality of optical lenses.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

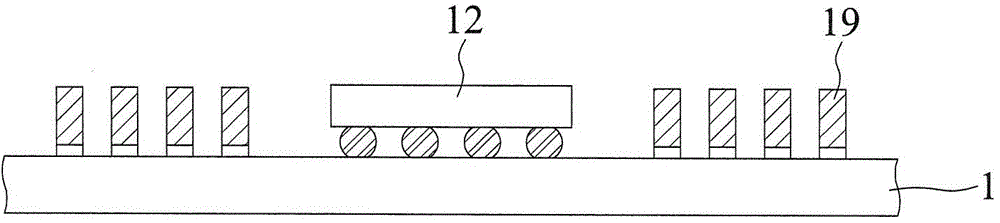

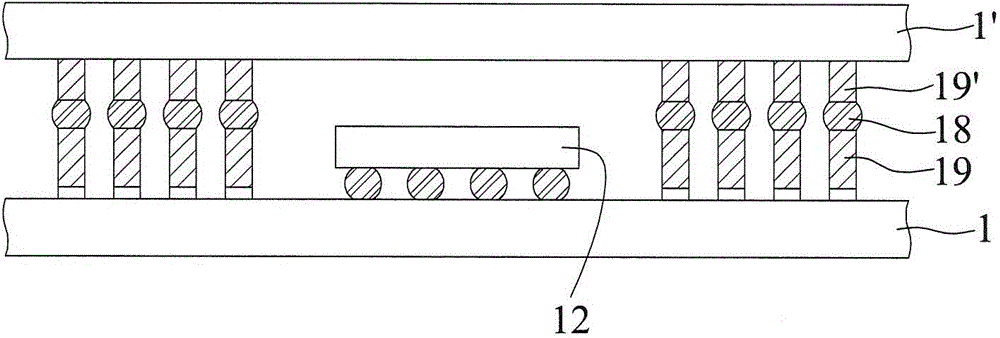

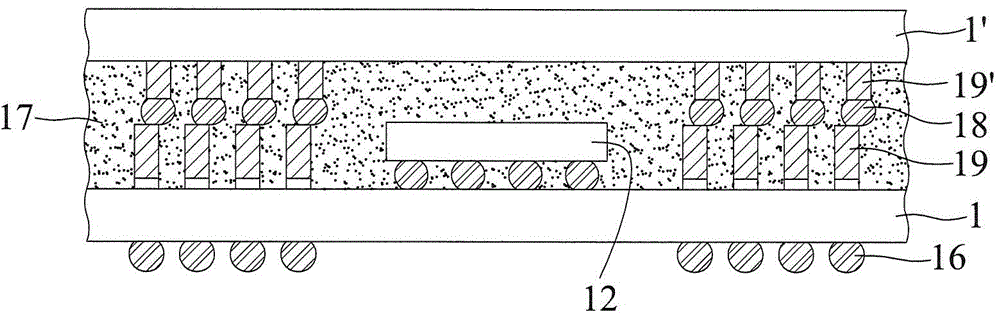

Packaging substrate, preparing method thereof, semiconductor package, and preparing method thereof

ActiveCN104810339AImprove positioning of jointsPrevent sliding offsetSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a packaging substrate, a preparing method thereof, a semiconductor package and a preparing method thereof. The packaging substrate comprises the components of a layered body; a plurality of conductive components which are formed on the surface of the layered body; and a positioning structure which is formed on each corresponding conductive component, thereby settling a problem of positioning joint between packaging components in the vertical direction by means of the positioning structure, and improving manufacture yield and product quality.

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com