Method for assembling and welding cased crane-beam in circular rail of nuclear-power station

A technology of circular track and welding method, applied in welding equipment, track system, arc welding equipment, etc., can solve problems such as assembly and welding of box-shaped crane beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

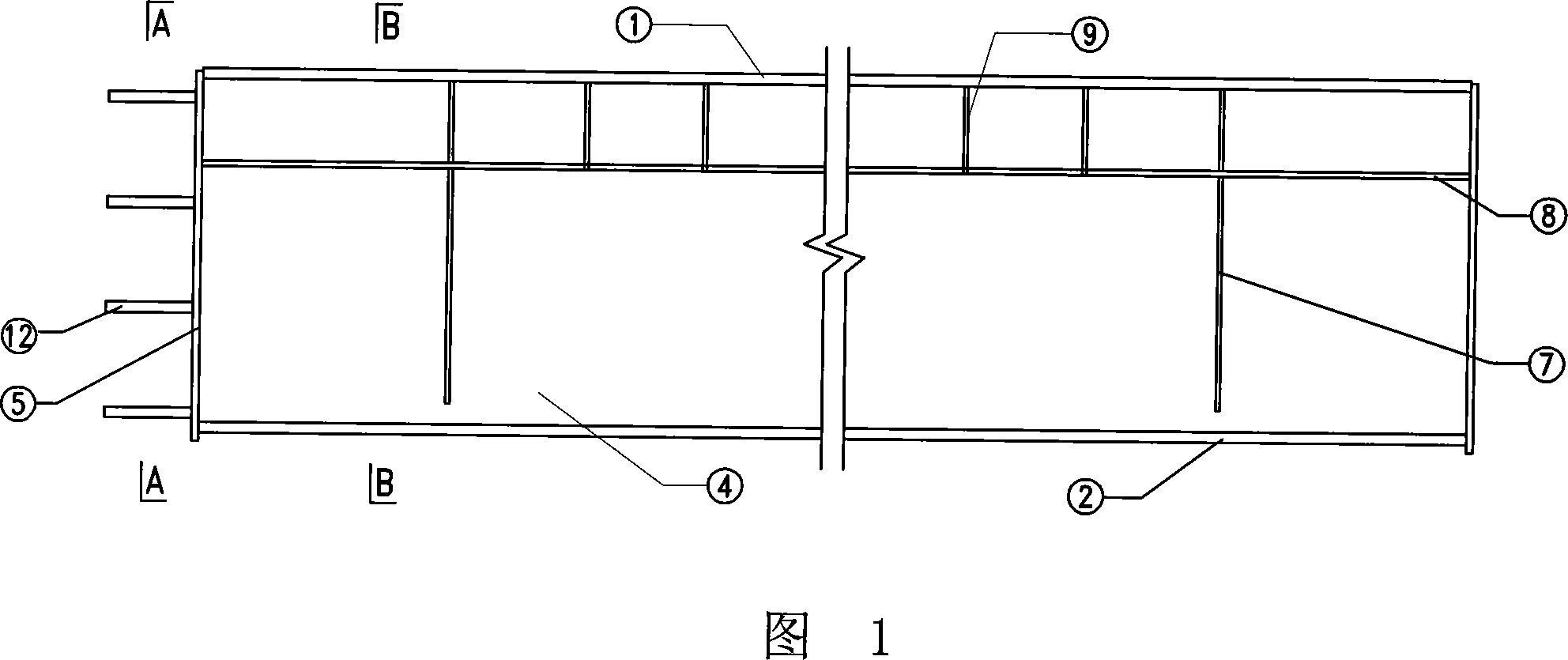

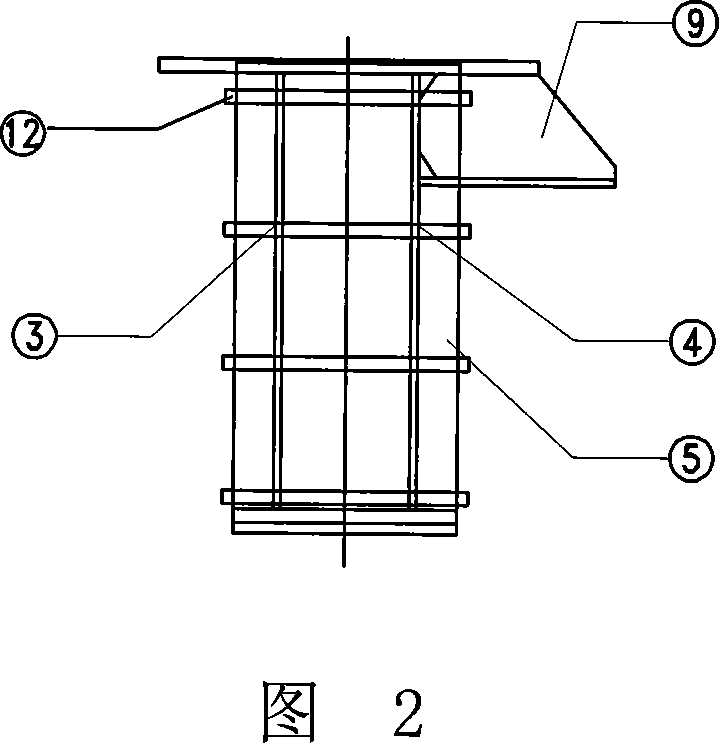

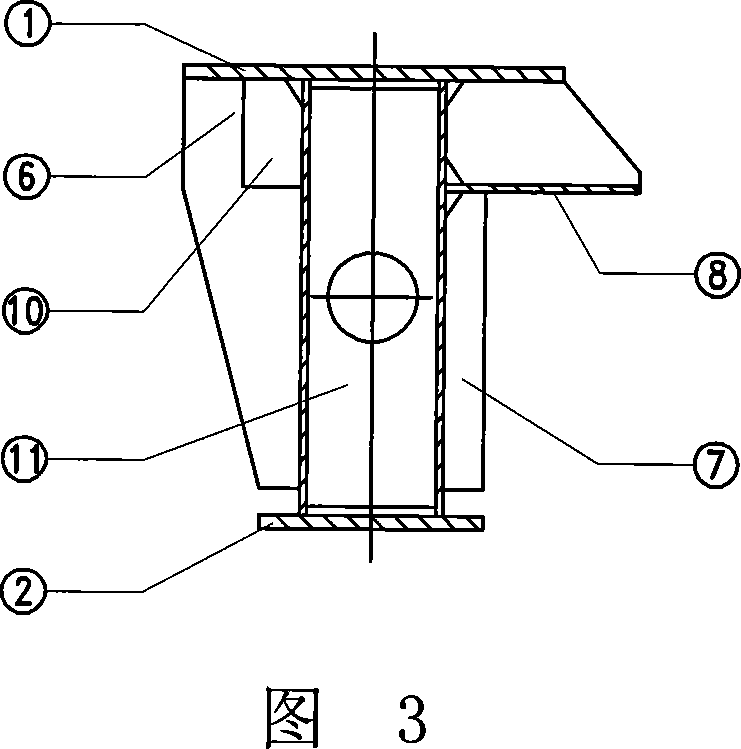

[0019] The ring track box crane girder of the nuclear power plant in this embodiment is shown in Fig. 1, Fig. 2 and Fig. 3. 6. The second stiffening plate 7, the longitudinal stiffening plate 8, the third stiffening plate 9, the fourth stiffening plate 10, and the partition plate 11 are welded to each other. The strength and shape after manufacture must meet the nuclear quality assurance level 1 and nuclear safety quality requirements, so the key is to strictly control the deformation while ensuring the welding strength.

[0020] After repeated experiments and research, the following specific process steps were drawn up.

[0021] Step 1: Prefabrication of the ring-hanging beam parts - typesetting and lofting according to the production details, and then carrying out numbering, marking and blanking.

[0022] Step 2: Lofting of the parts - according to the shape and size of the parts, make an arc-shaped template for the longitudinal stiffening plate at a ratio of 1:1.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com