Patents

Literature

35results about How to "Prevent sliding offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

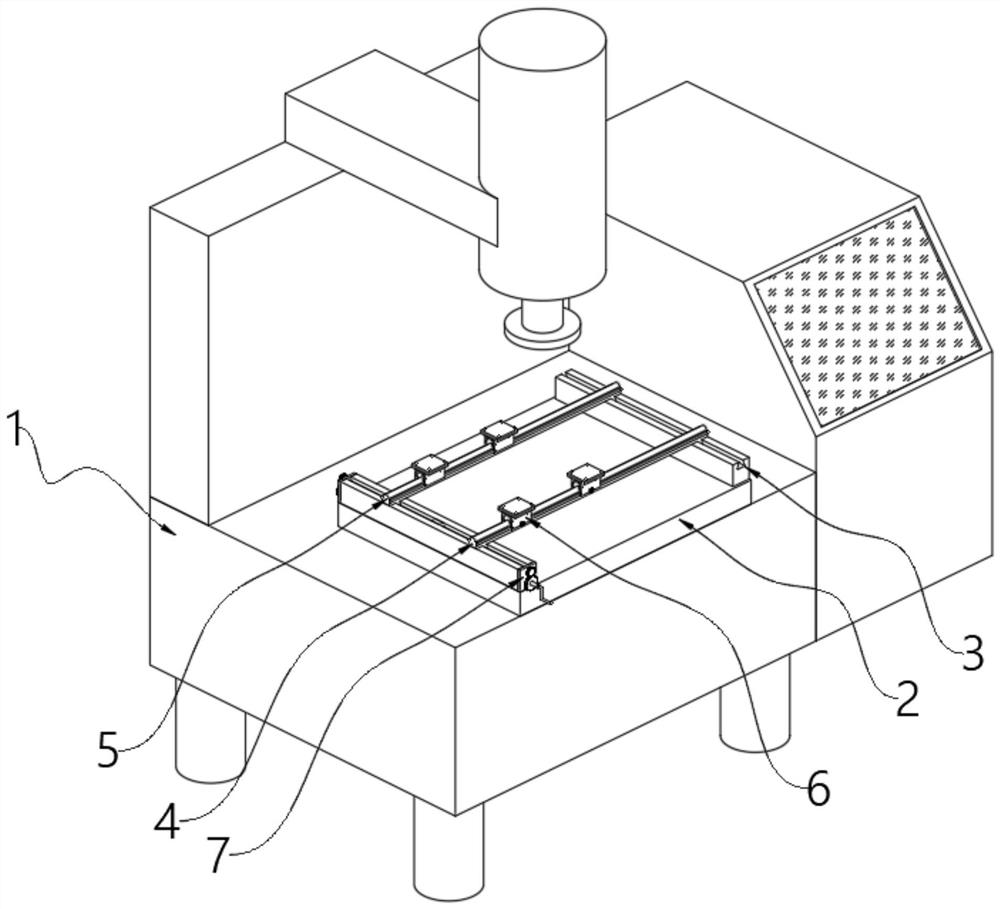

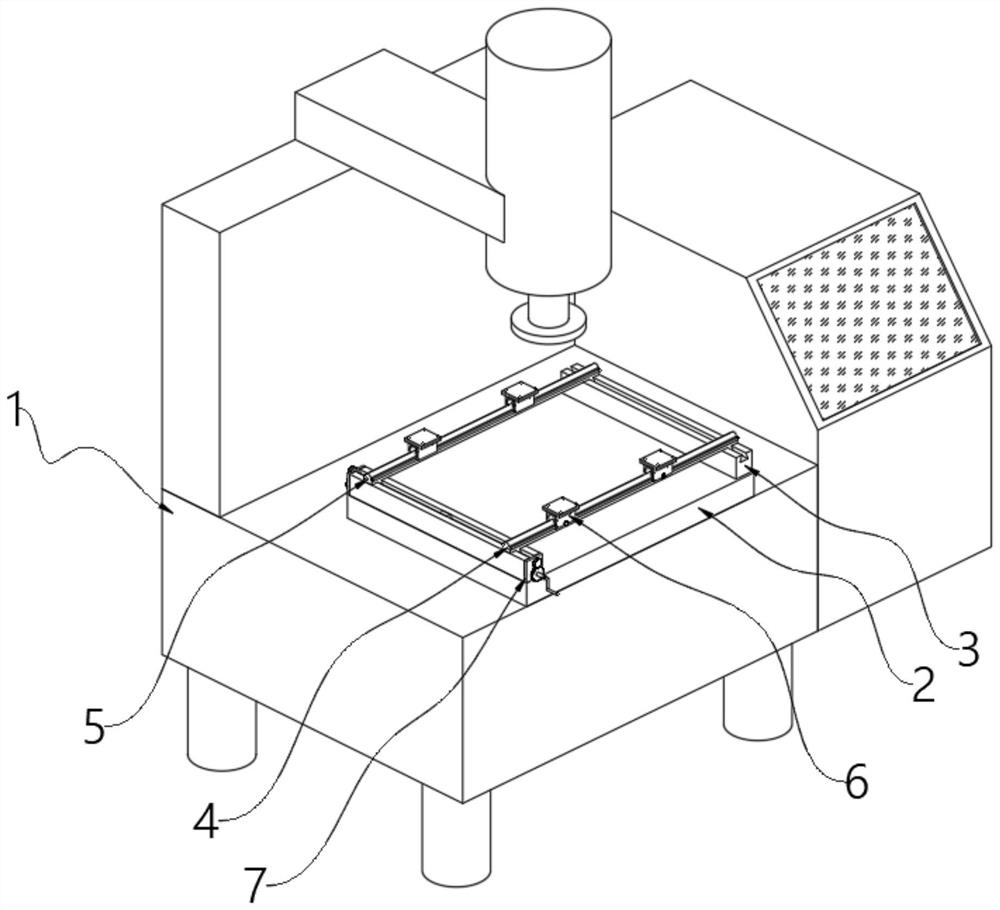

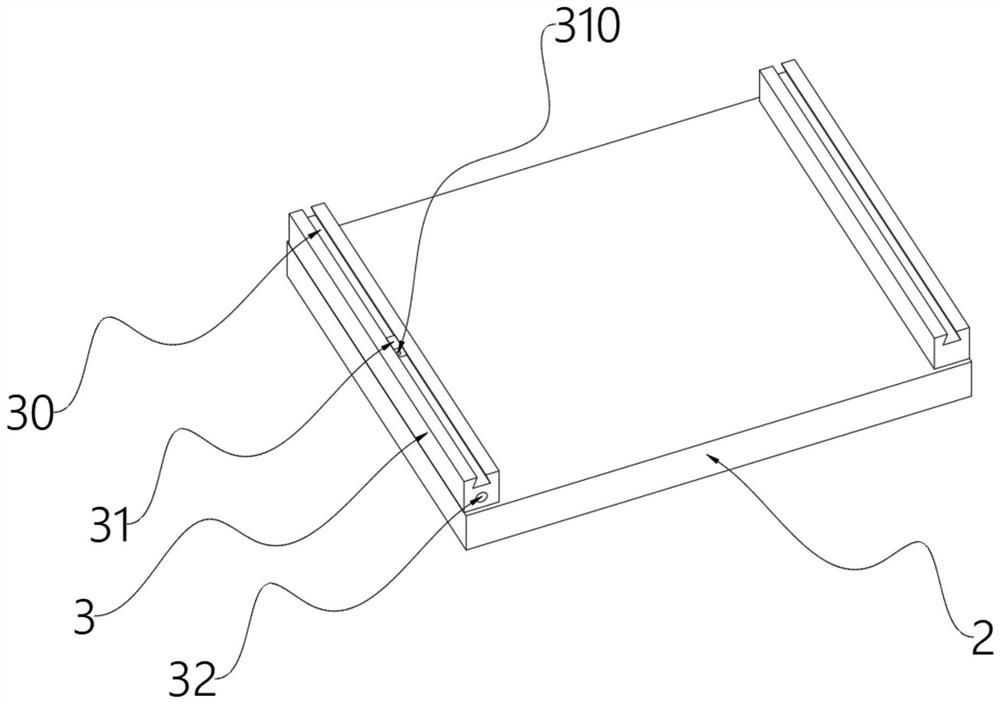

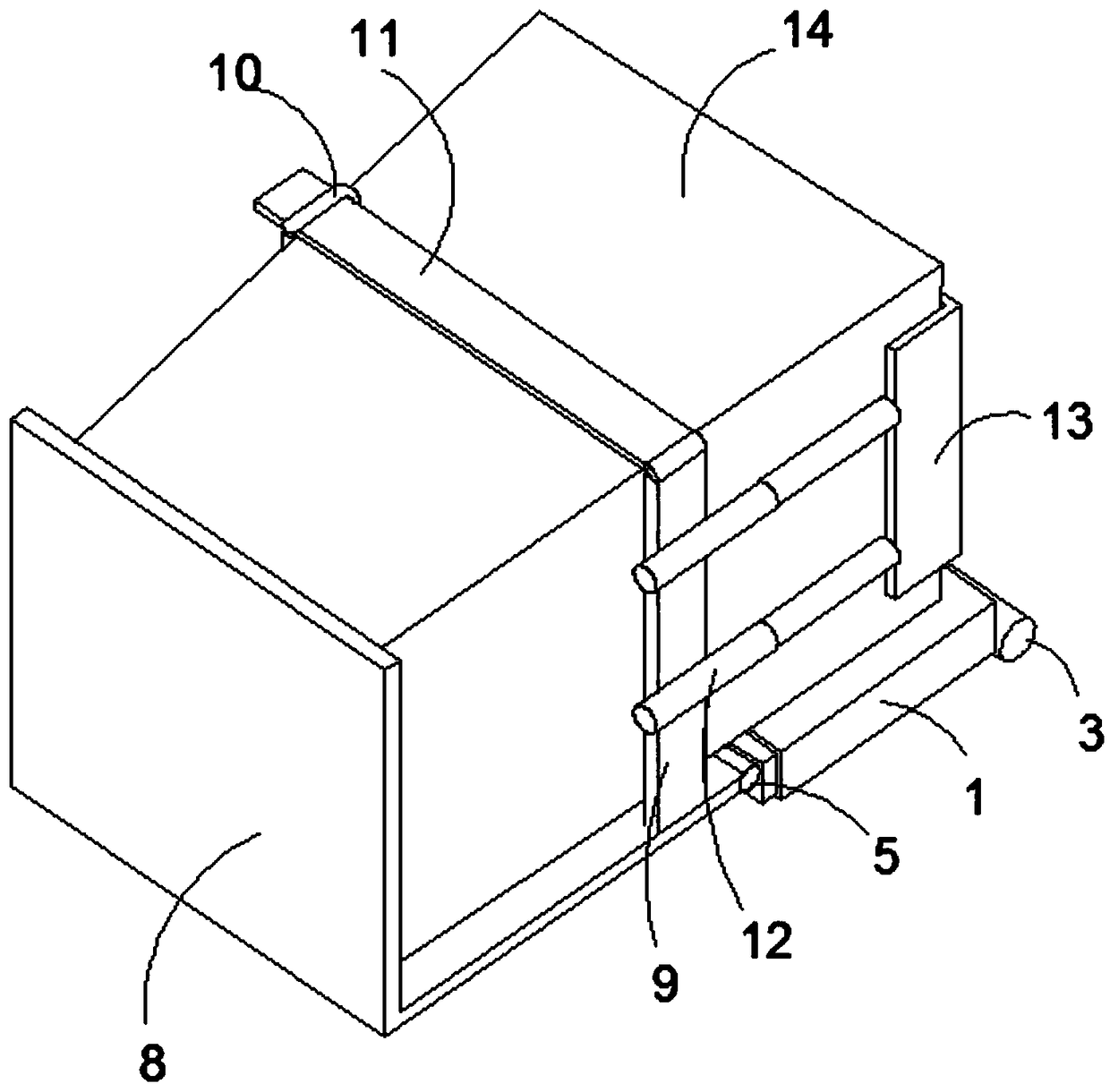

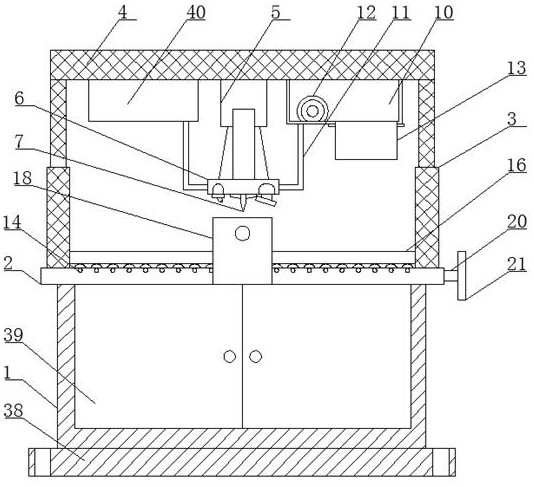

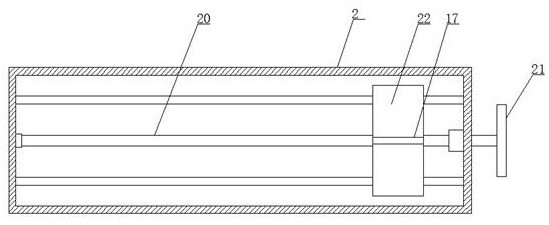

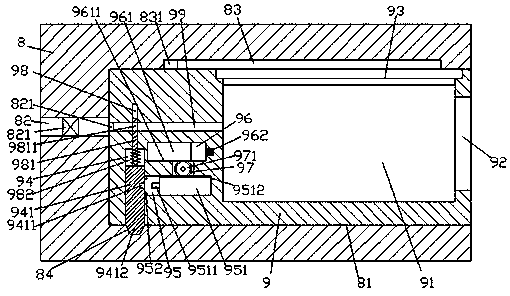

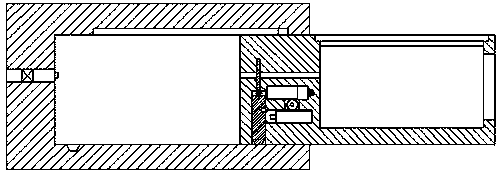

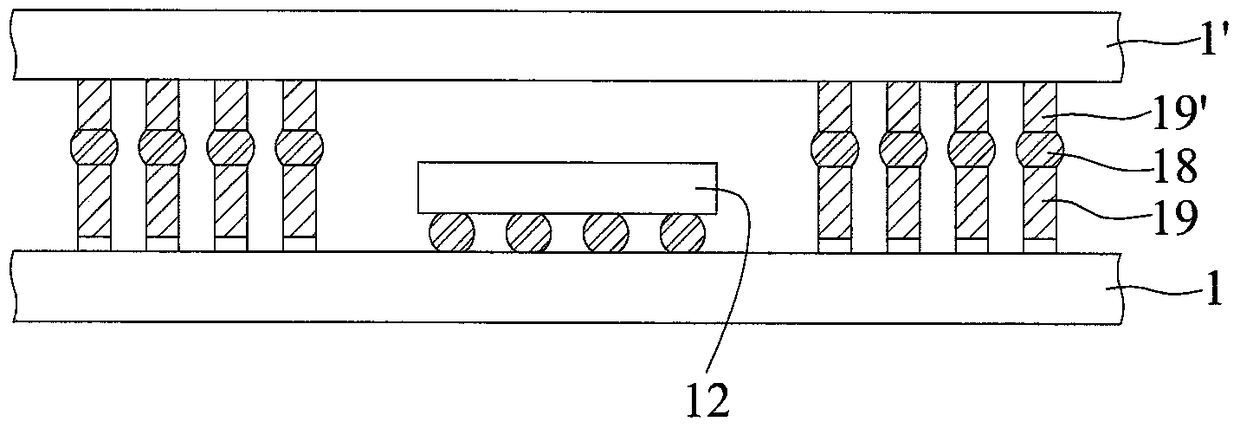

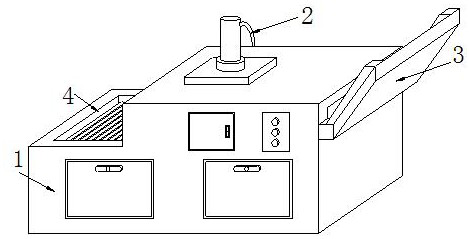

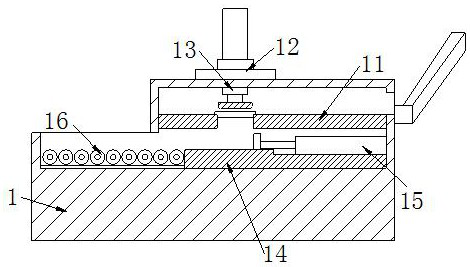

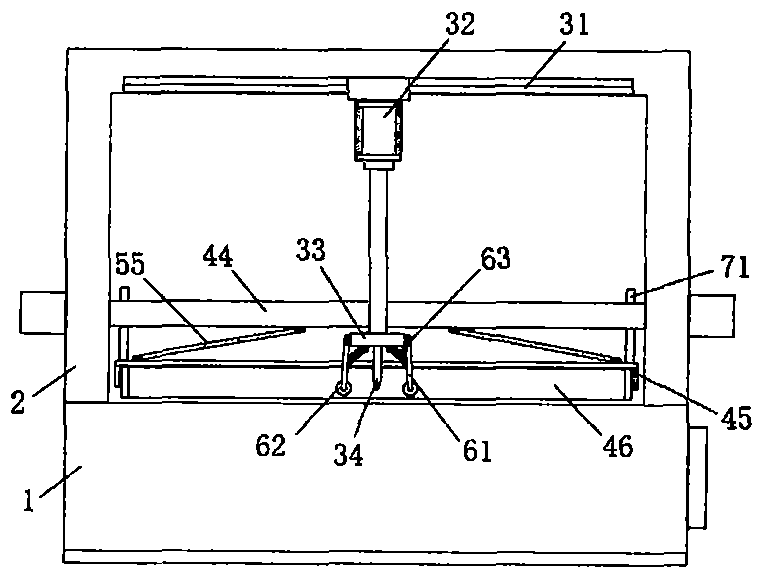

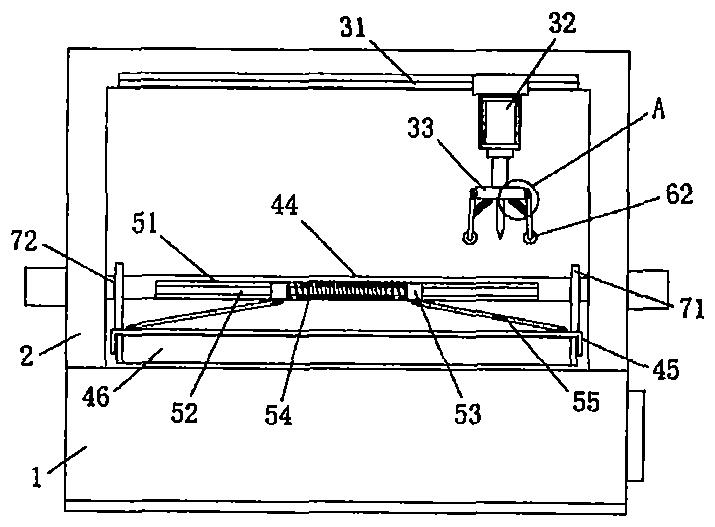

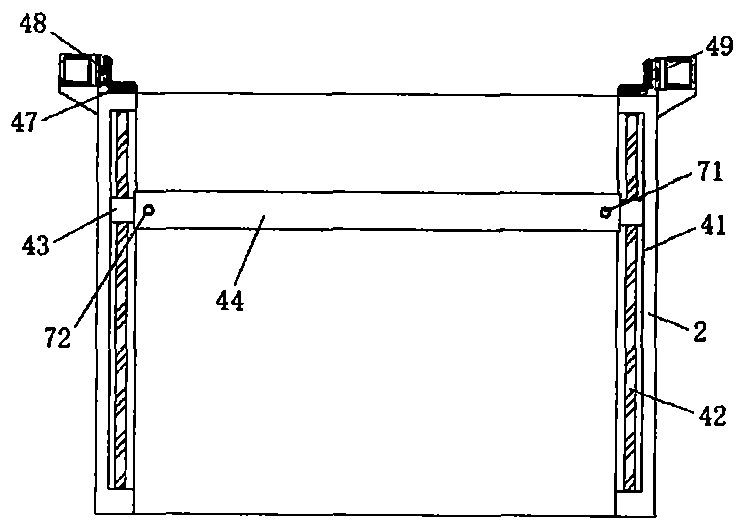

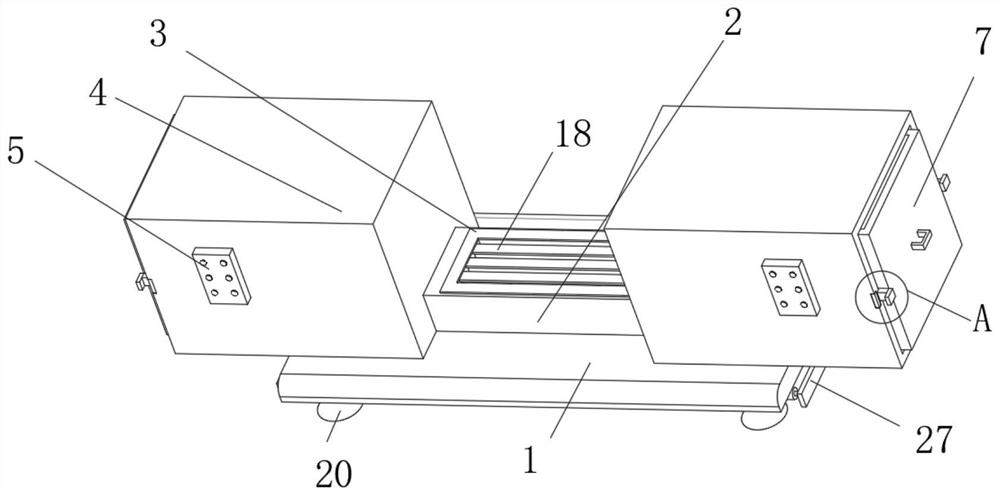

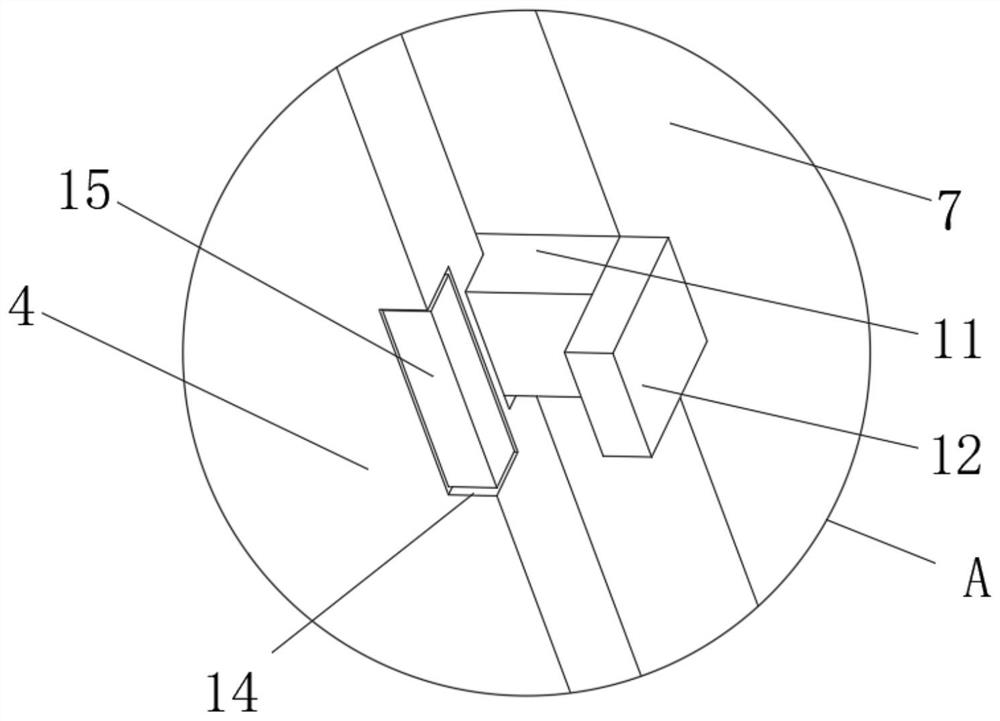

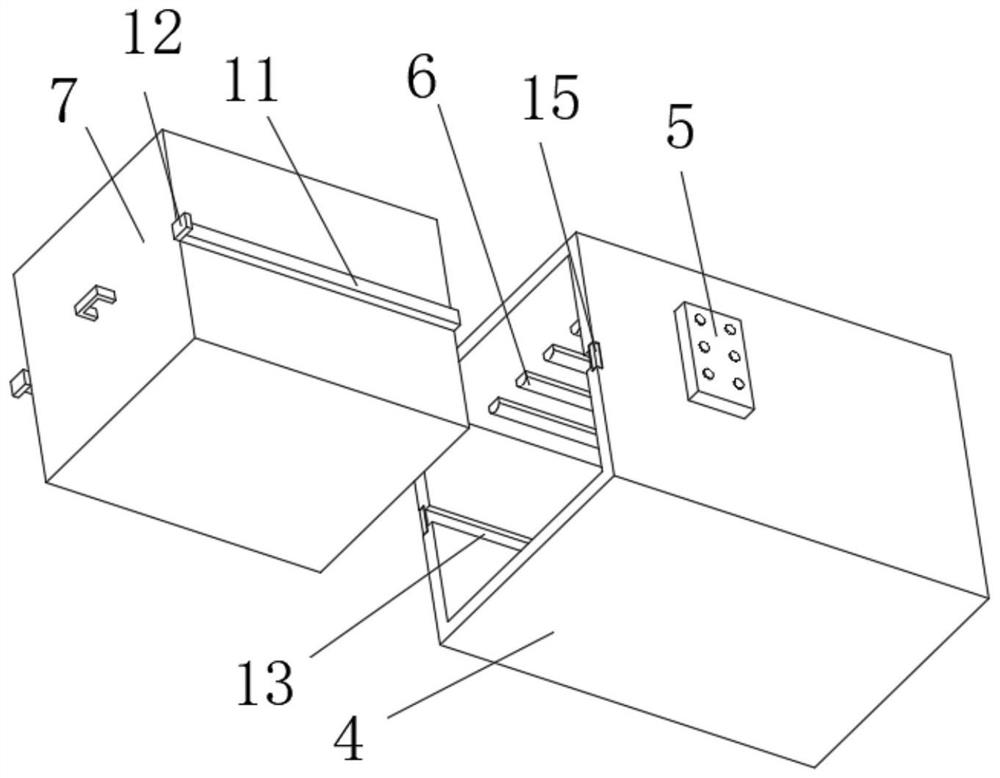

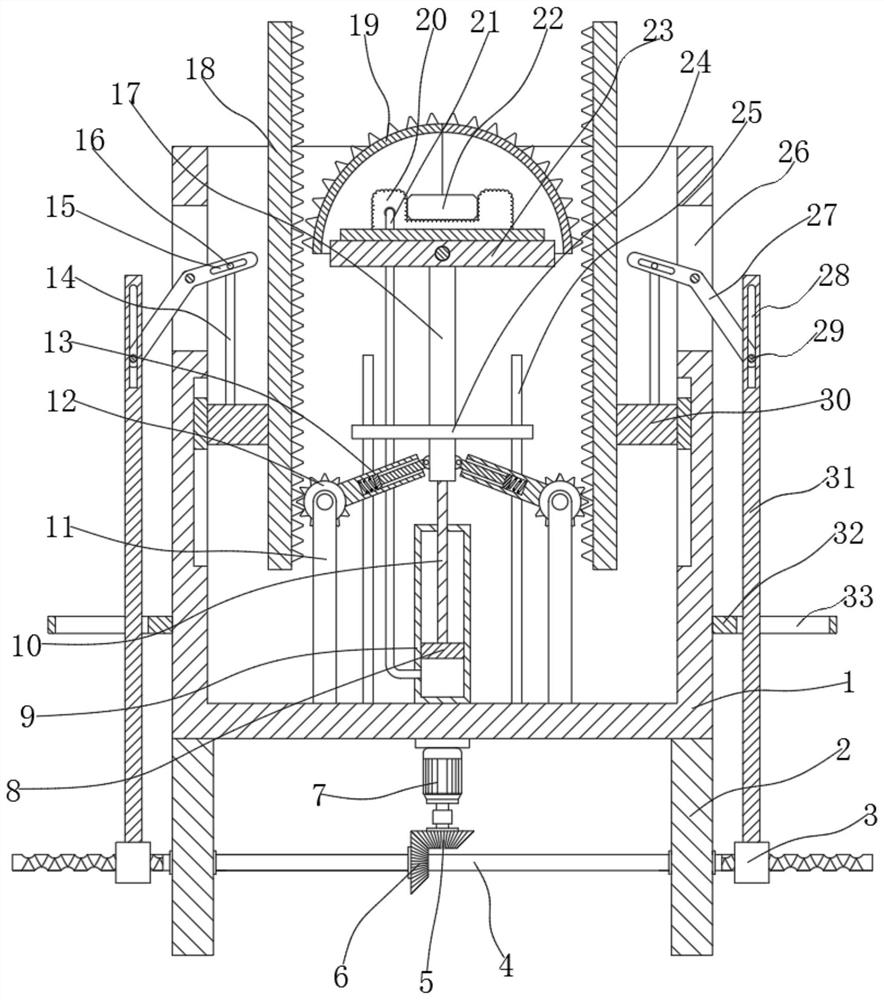

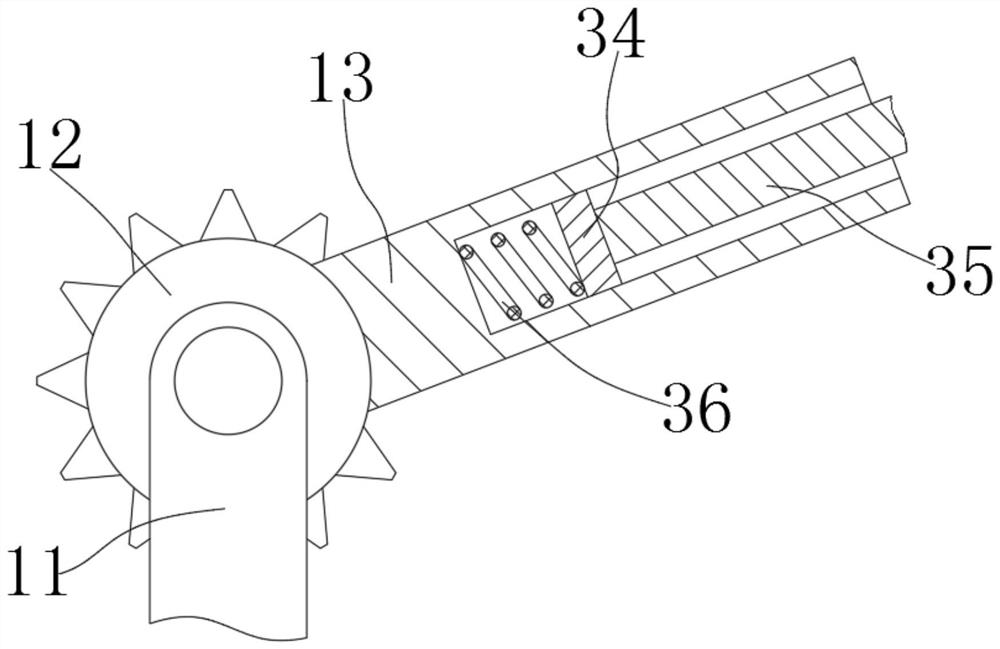

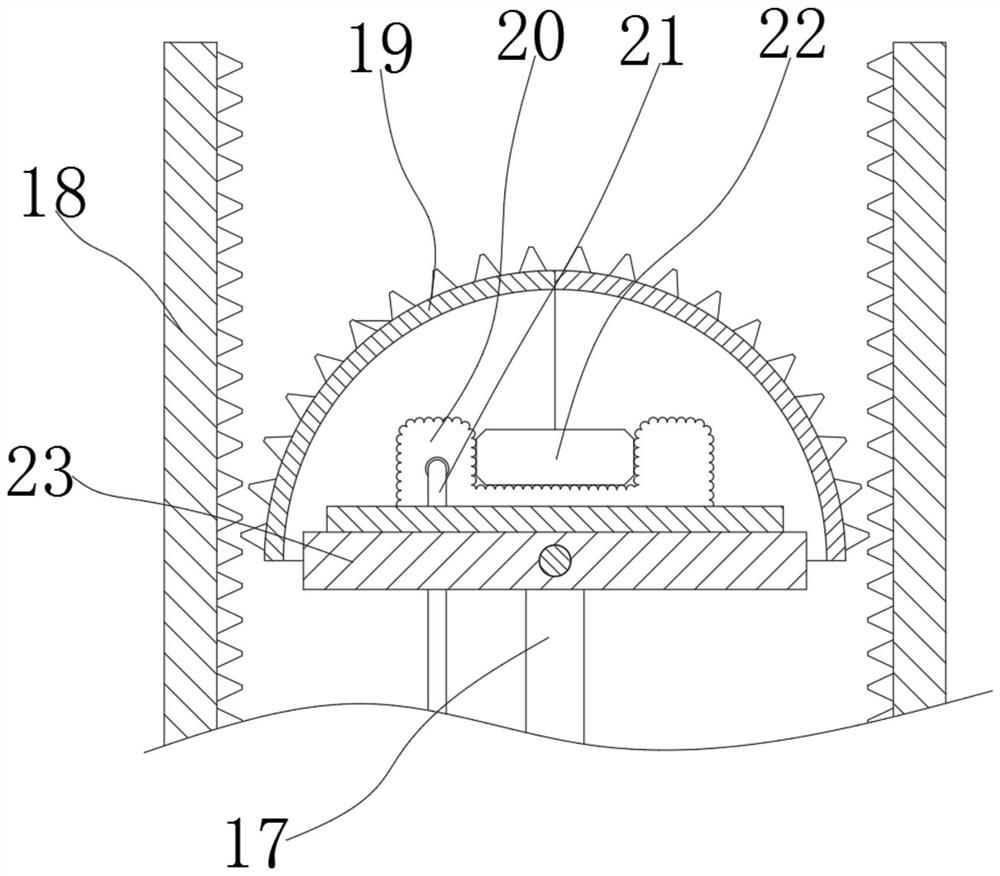

Electric spark machine tool with adjustable movable guide rail pairs

InactiveCN113199096ASteady turn adjustment operationEasy to connect and fixLarge fixed membersElectrical-based auxillary apparatusCrankEngineering

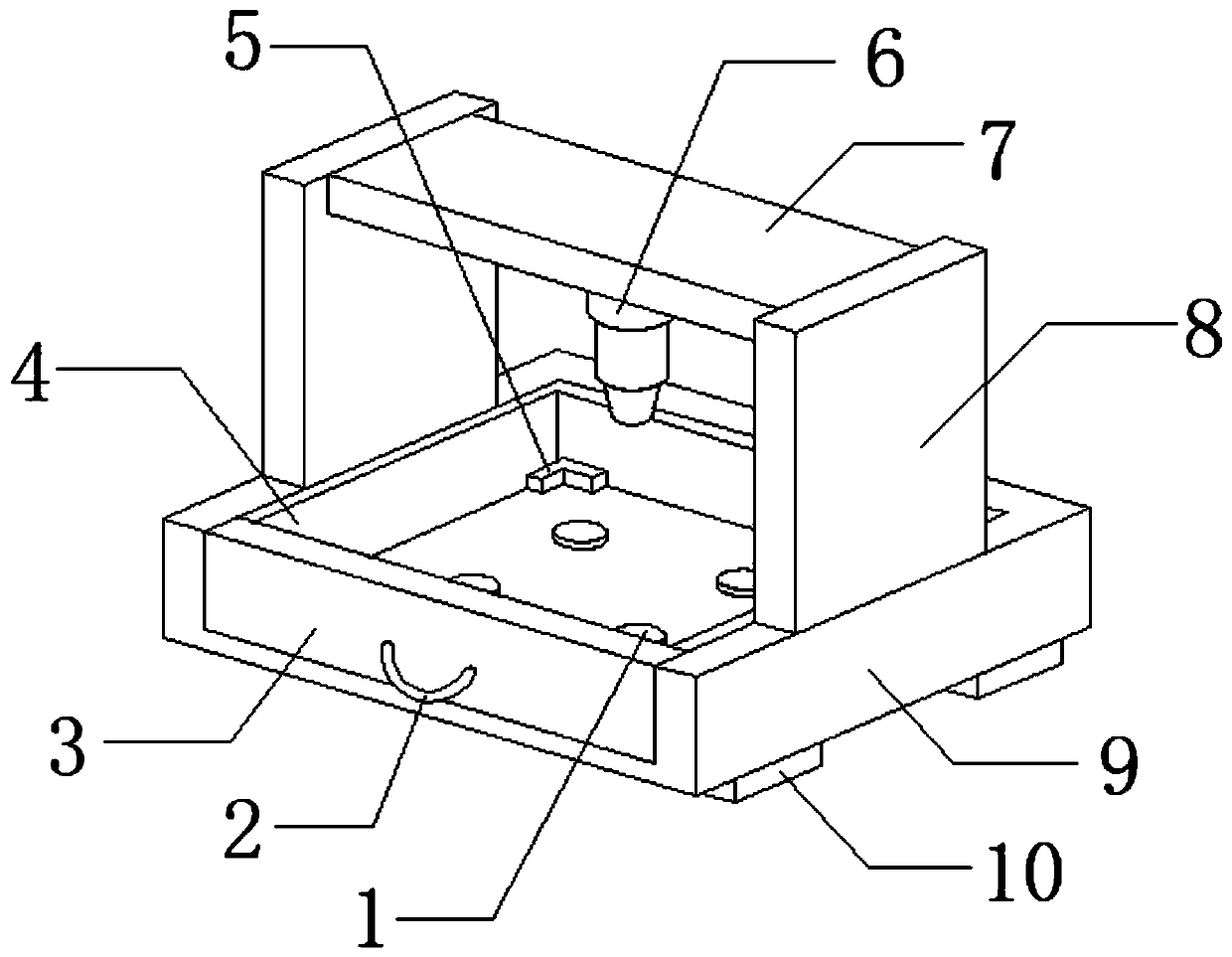

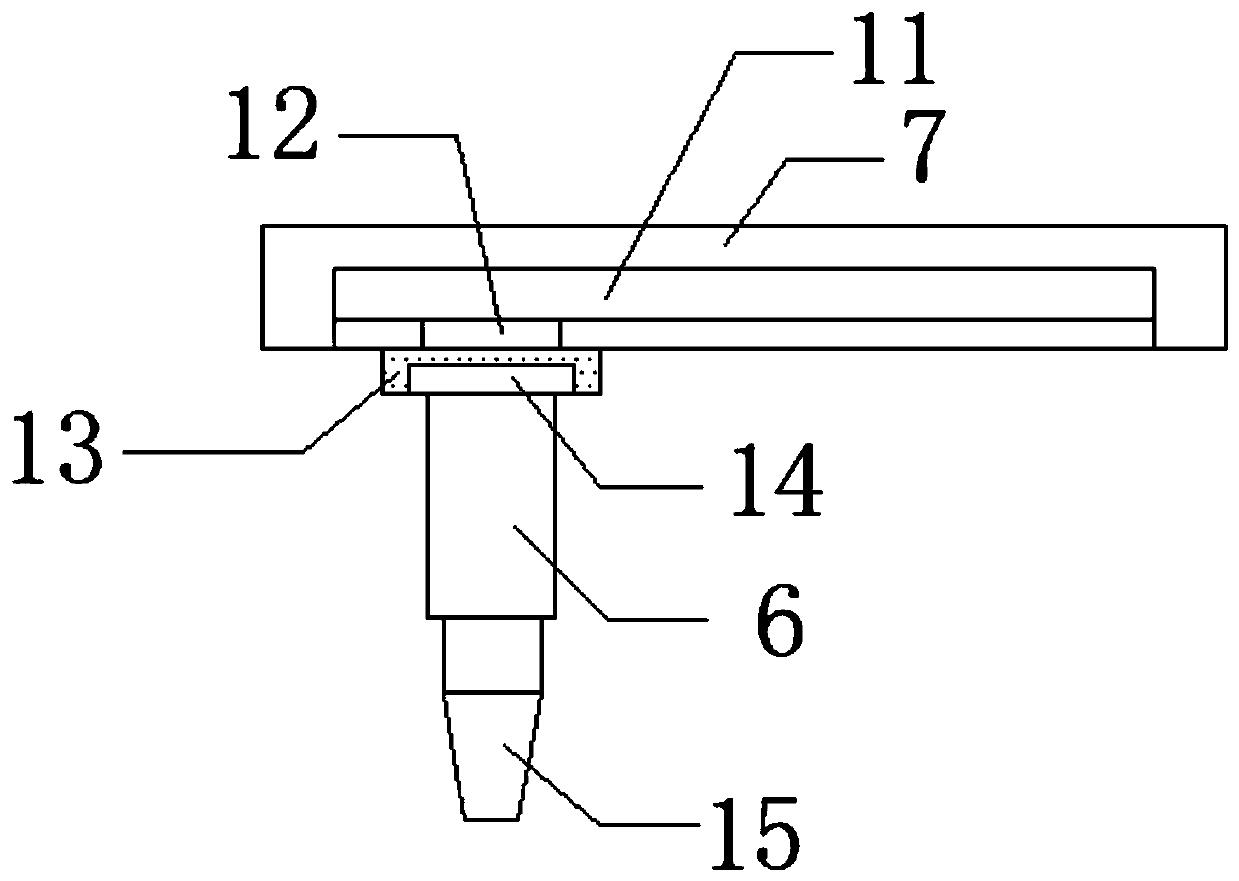

The invention relates to the technical field of electric spark machine tools, in particular to an electric spark machine tool with adjustable movable guide rail pairs. The electric spark machine tool with the adjustable movable guide rail pairs comprises an electric spark machine tool, wherein a base is mounted on the electric spark machine tool; a first guide rail pair and a second guide rail pair are sequentially arranged above sliding rails from front to back; pulley seats are arranged on the first guide rail pair and the second guide rail pair; trapezoidal sliding grooves are formed in the sliding rails; first trapezoidal sliding blocks are arranged at the positions, corresponding to the trapezoidal sliding grooves, of the lower surface of the first guide rail pair; and second trapezoidal sliding blocks are arranged at the positions, corresponding to the trapezoidal sliding grooves, of the lower surface of the second guide rail pair. According to the electric spark machine tool with the adjustable movable guide rail pairs, through the base and the two sliding rails, under the cooperation of baffles and rotating shaft rods, a crank rotates, the first guide rail pair is matched with the first trapezoidal sliding blocks, the second guide rail pair is matched with the second trapezoidal sliding blocks, and left-hand threaded rods and right-hand threaded rods are matched jointly; and through the joint matching of the left-hand threaded rods and the right-hand threaded rods, the first guide rail pair and the second guide rail pair move oppositely to perform longitudinal movement adjustment.

Owner:NANJING COMM INST OF TECH

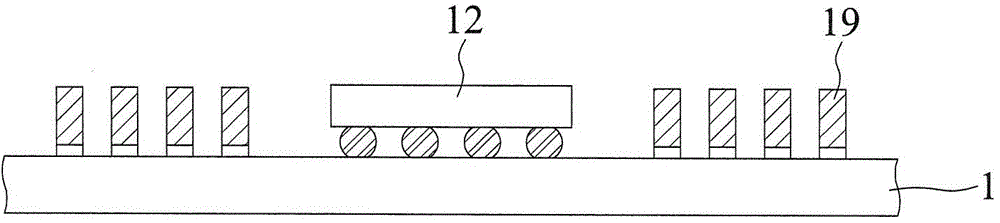

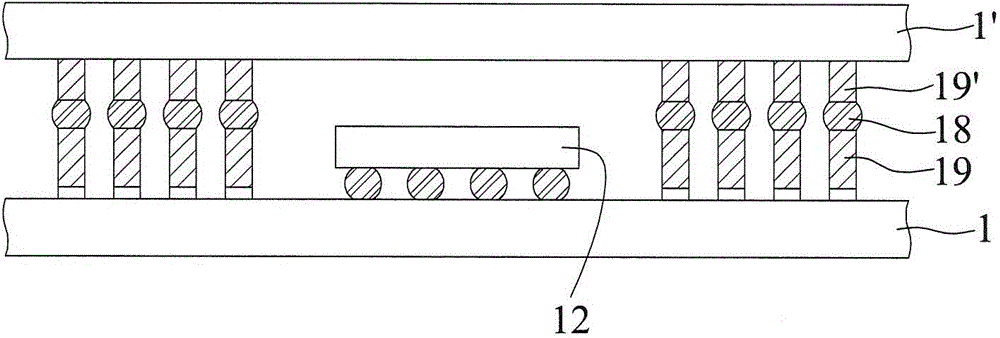

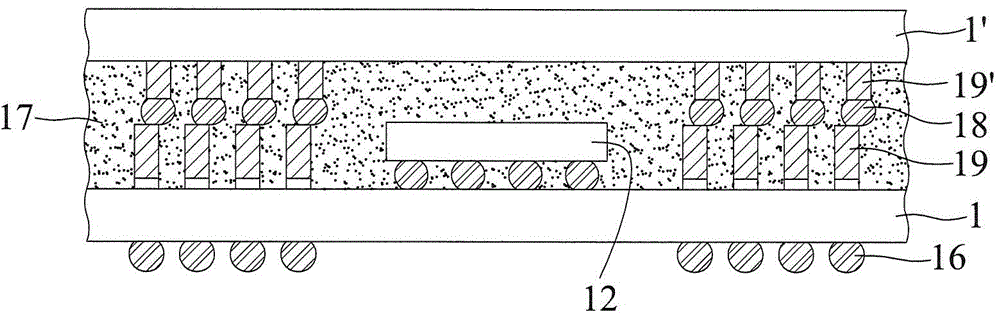

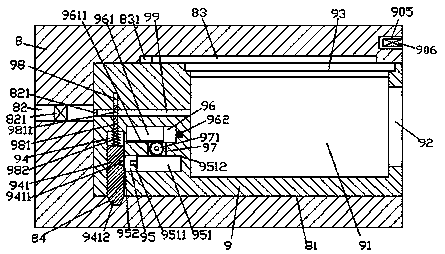

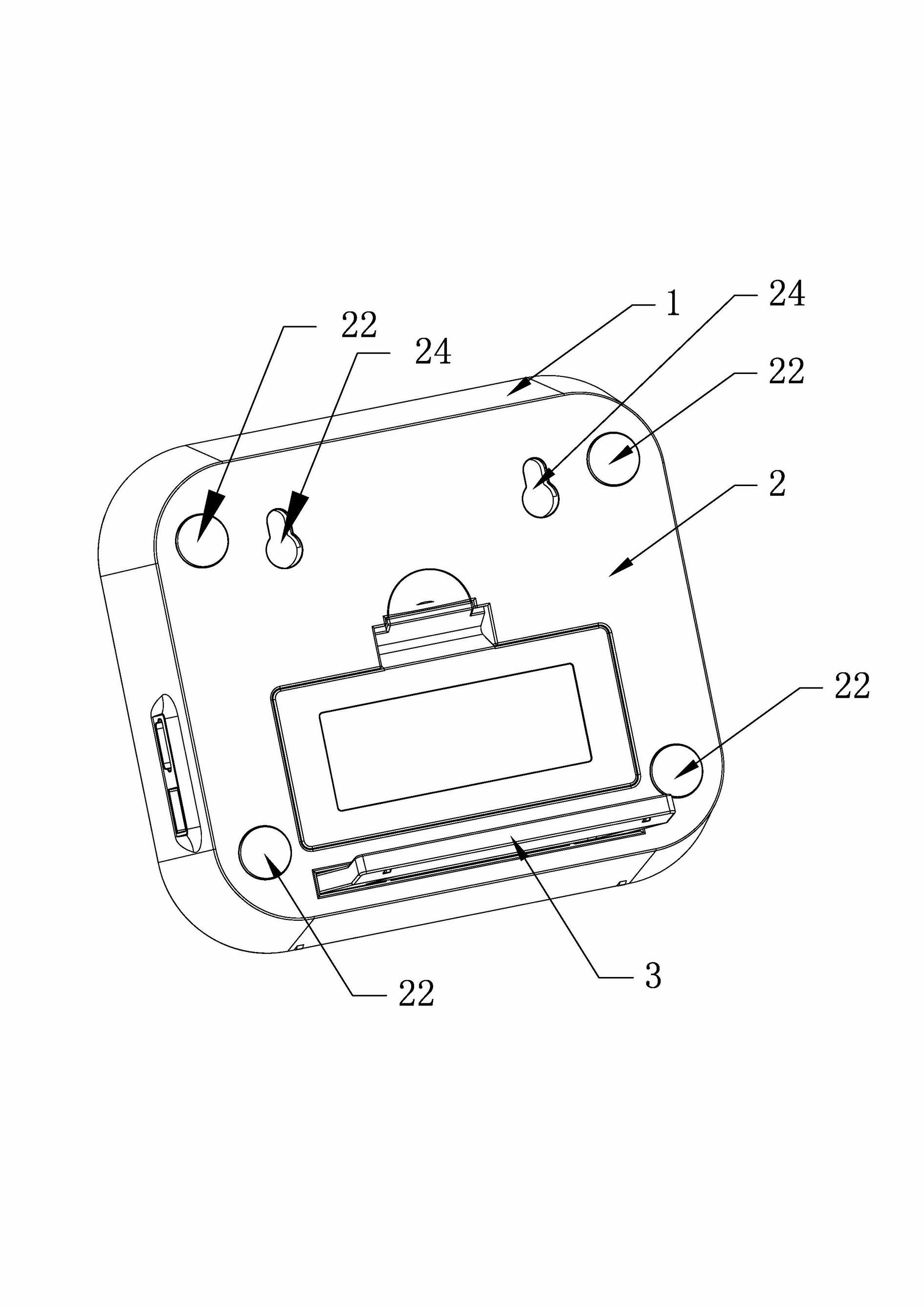

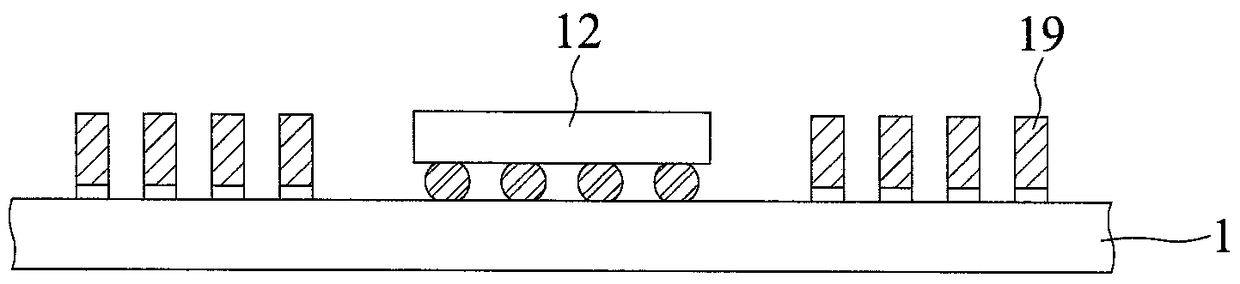

Packaging substrate, preparing method thereof, semiconductor package, and preparing method thereof

ActiveCN104810339AImprove positioning of jointsPrevent sliding offsetSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a packaging substrate, a preparing method thereof, a semiconductor package and a preparing method thereof. The packaging substrate comprises the components of a layered body; a plurality of conductive components which are formed on the surface of the layered body; and a positioning structure which is formed on each corresponding conductive component, thereby settling a problem of positioning joint between packaging components in the vertical direction by means of the positioning structure, and improving manufacture yield and product quality.

Owner:SILICONWARE PRECISION IND CO LTD

Strength detection device for glass processing

InactiveCN110672419AImprove stabilityImprove convenienceMaterial strength using tensile/compressive forcesStructural engineeringManufacturing engineering

The invention discloses a strength detection device for glass processing. The device comprises a supporting base and four supporting pads; the four supporting pads are installed on the outer walls ofthe four corners of the bottom of the supporting base through bolts respectively; a first groove is formed in the outer wall of one end of the top of the supporting base; a groove plate is inserted into the inner wall of the first groove; a first supporting plate is fixedly installed on the outer wall of one end of the groove plate; and limiting blocks are fixedly installed on the inner walls of the four corners of the bottom of the groove plate respectively. According to the strength detection device for glass processing provided by the invention, the first groove is formed in the supportingbase; the groove plate is inserted into the first groove; the limiting blocks and rubber pads are arranged in the groove plate; glass can be effectively limited and fixed through the limiting blocks,so that the slide deviation of the glass in the detection process is avoided, and therefore, detection stability is improved; and, the groove plate can be pulled out through a pulling handle, so thatthe glass is disassembled and assembled, and therefore, the convenience of glass detection and replacement is improved.

Owner:徐州市威固特种玻璃有限公司

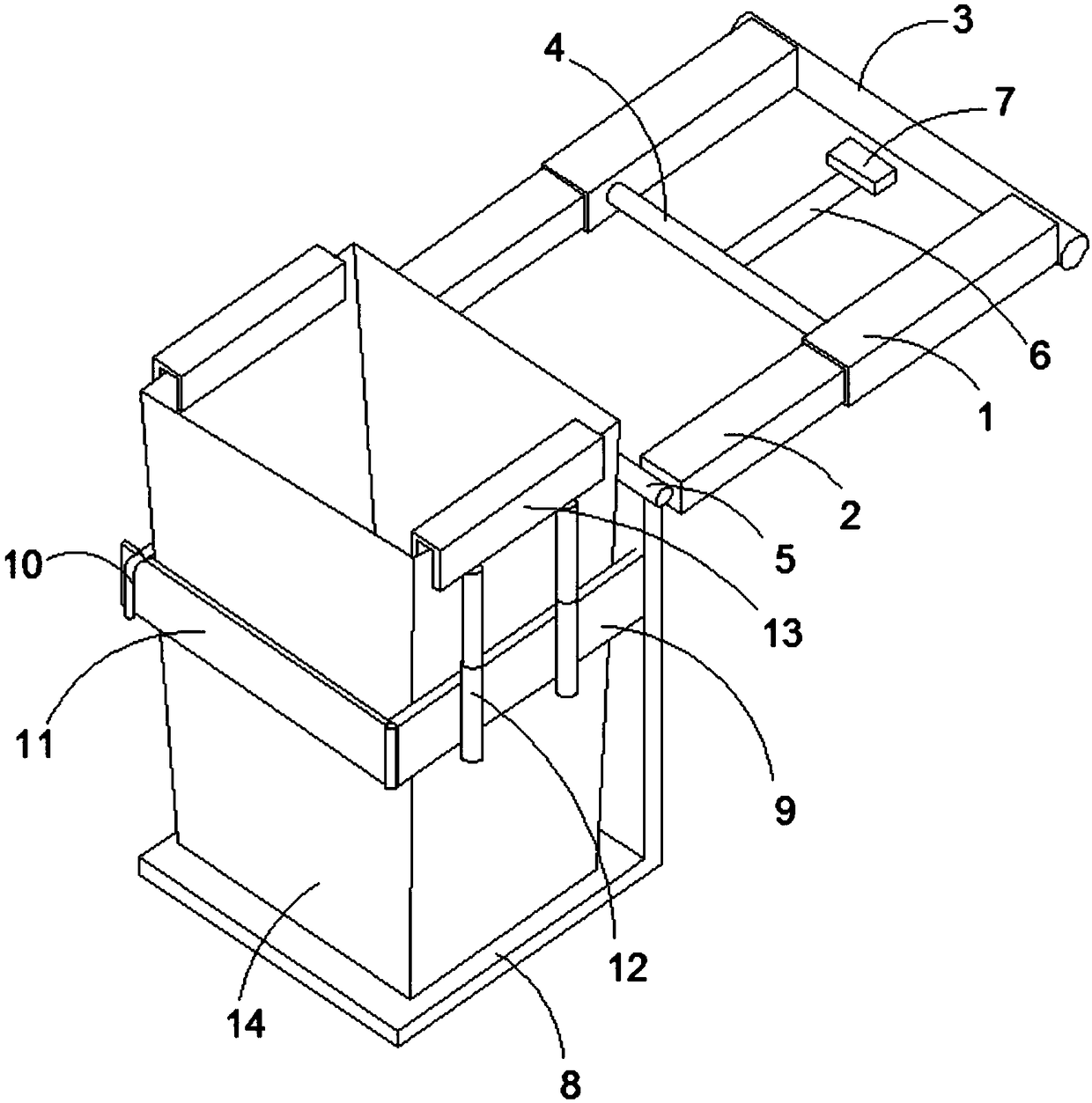

Rotary carrying robot

InactiveCN111422610APrevent slidingAvoid damageConveyor partsElectric machineryStructural engineering

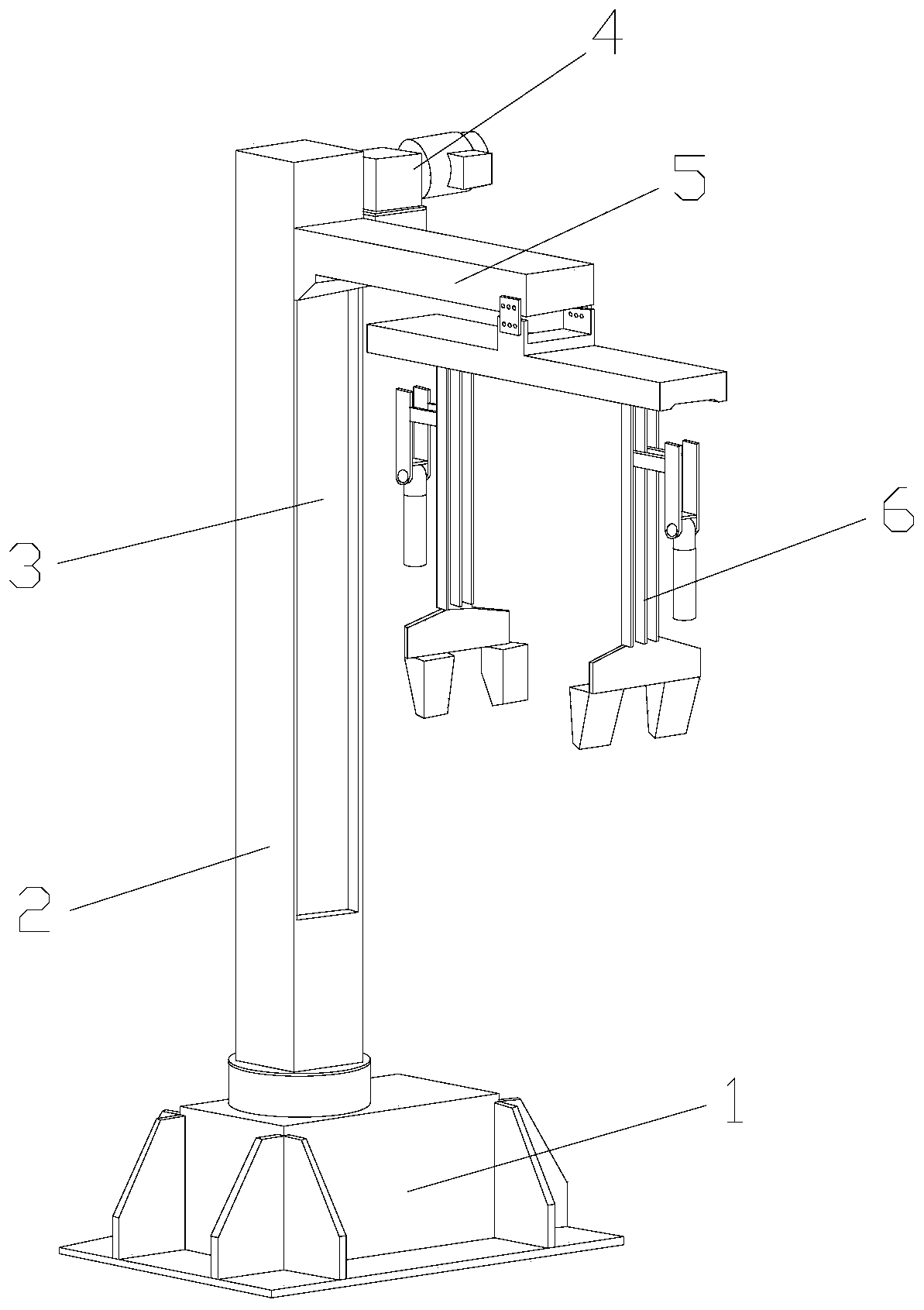

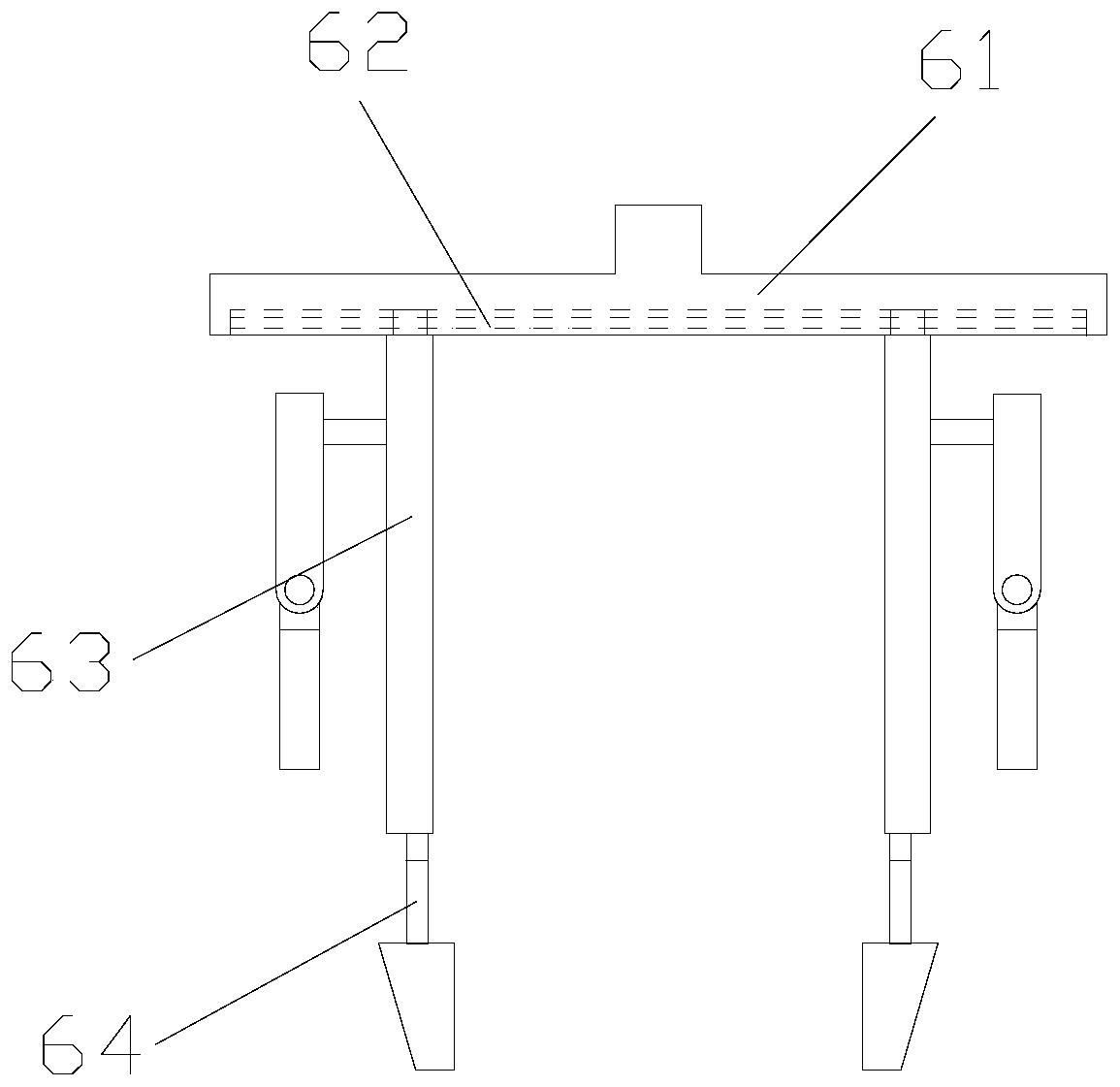

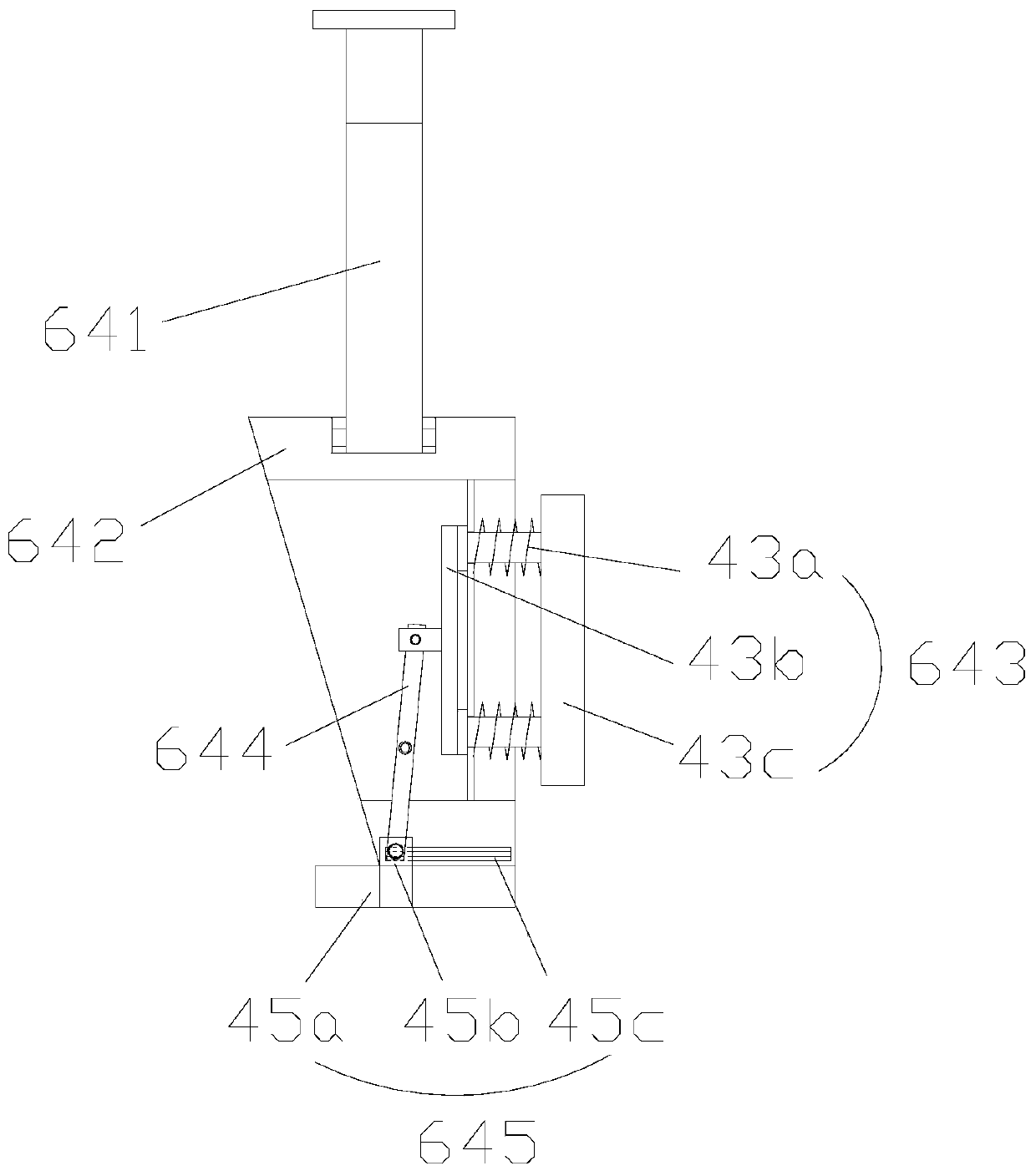

The invention discloses a rotary carrying robot. The rotary carrying robot structurally comprises a driving seat, a supporting column, a sliding way, a motor, a transverse frame and a clamping jaw, wherein the supporting column is vertically installed at the upper end of the driving seat; the sliding way is arranged on the inner side of the supporting column; the transverse frame is vertically installed on the inner side of the sliding way; the motor is installed on the side face of the transverse frame; the clamping jaw is horizontally installed at the lower end of the transverse frame; and the clamping jaw comprises a fixing frame, a guide rail, a side clamping body and a clamping mechanism, the guide rail is arranged on the inner side of the fixing frame, the side clamping body is vertically installed at the lower end of the fixing frame, and the clamping mechanism is embedded into the inner side of the side clamping body. According to the rotary carrying robot, the clamping mechanism is arranged at the lower end of the side clamping body, due to limitation of the bottom and the side face, the clamping mechanism is kept balanced, and then damage to corners is prevented; and theside clamping body is arranged at the lower end of the fixing frame, the side face of a box is effectively limited, the upper end is also limited, thus sliding deviation caused by centrifugal force isprevented during rotation, and the integrity of the box corners and the quality of inner side products are ensured.

Owner:黄金榜

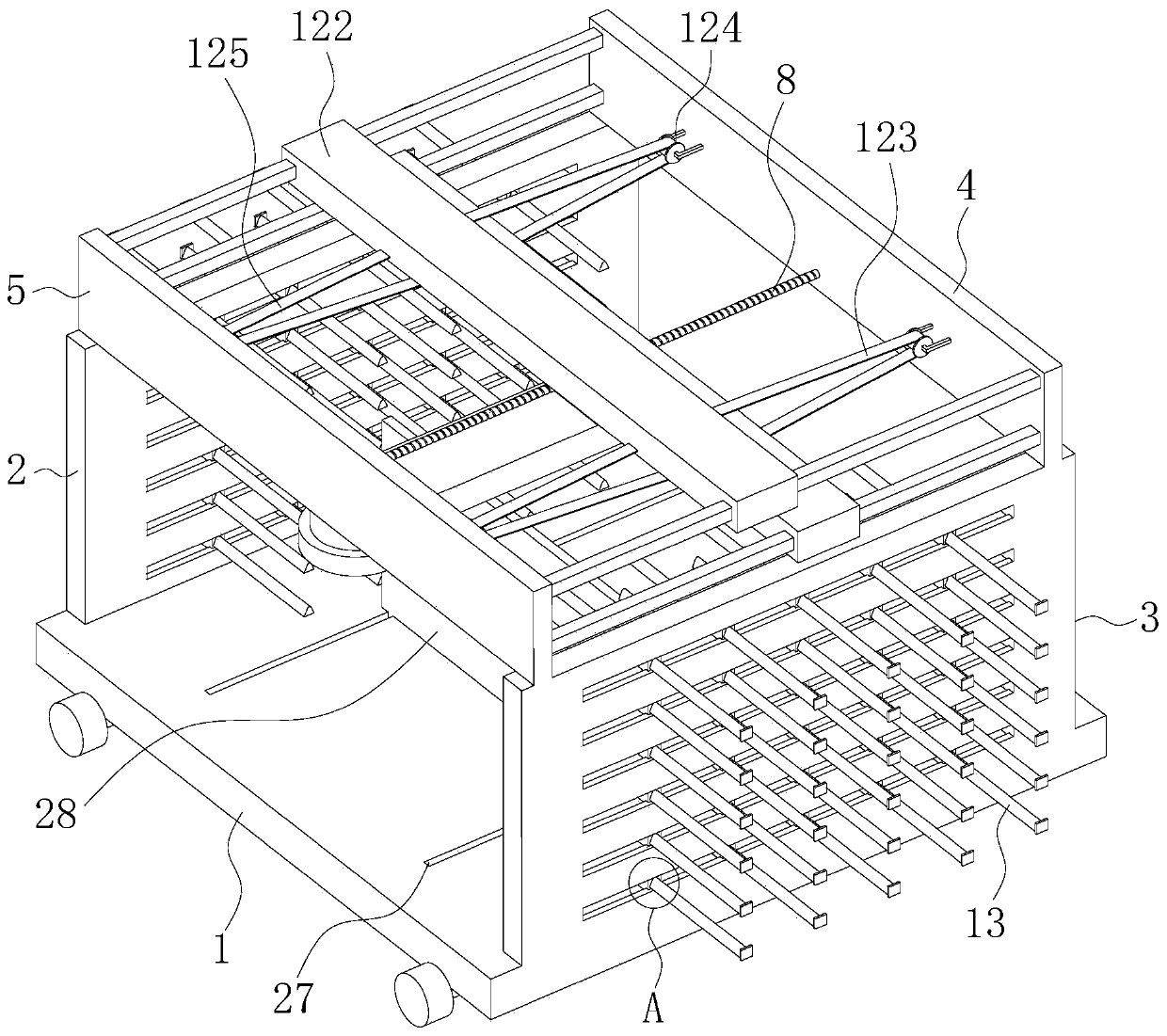

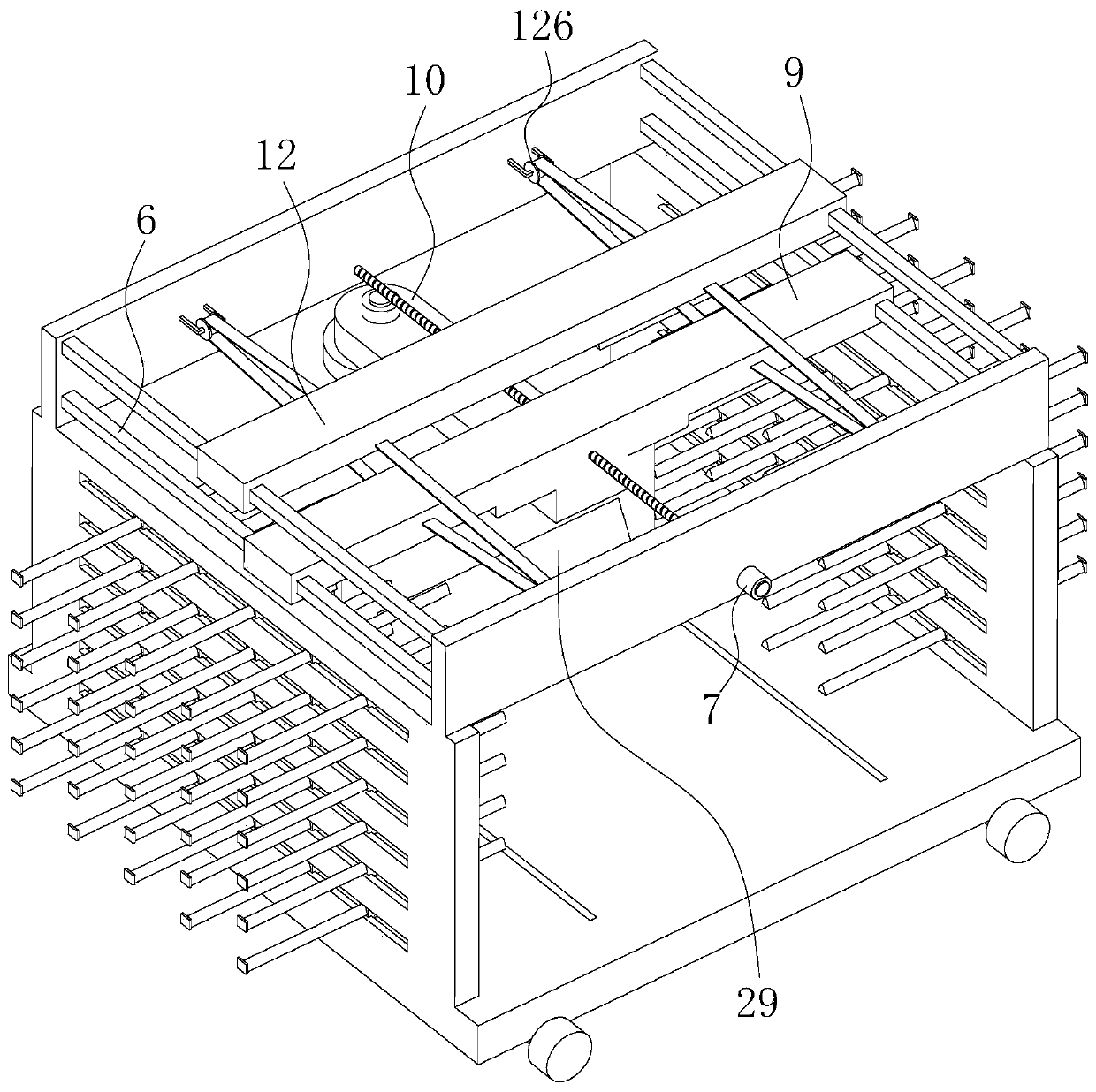

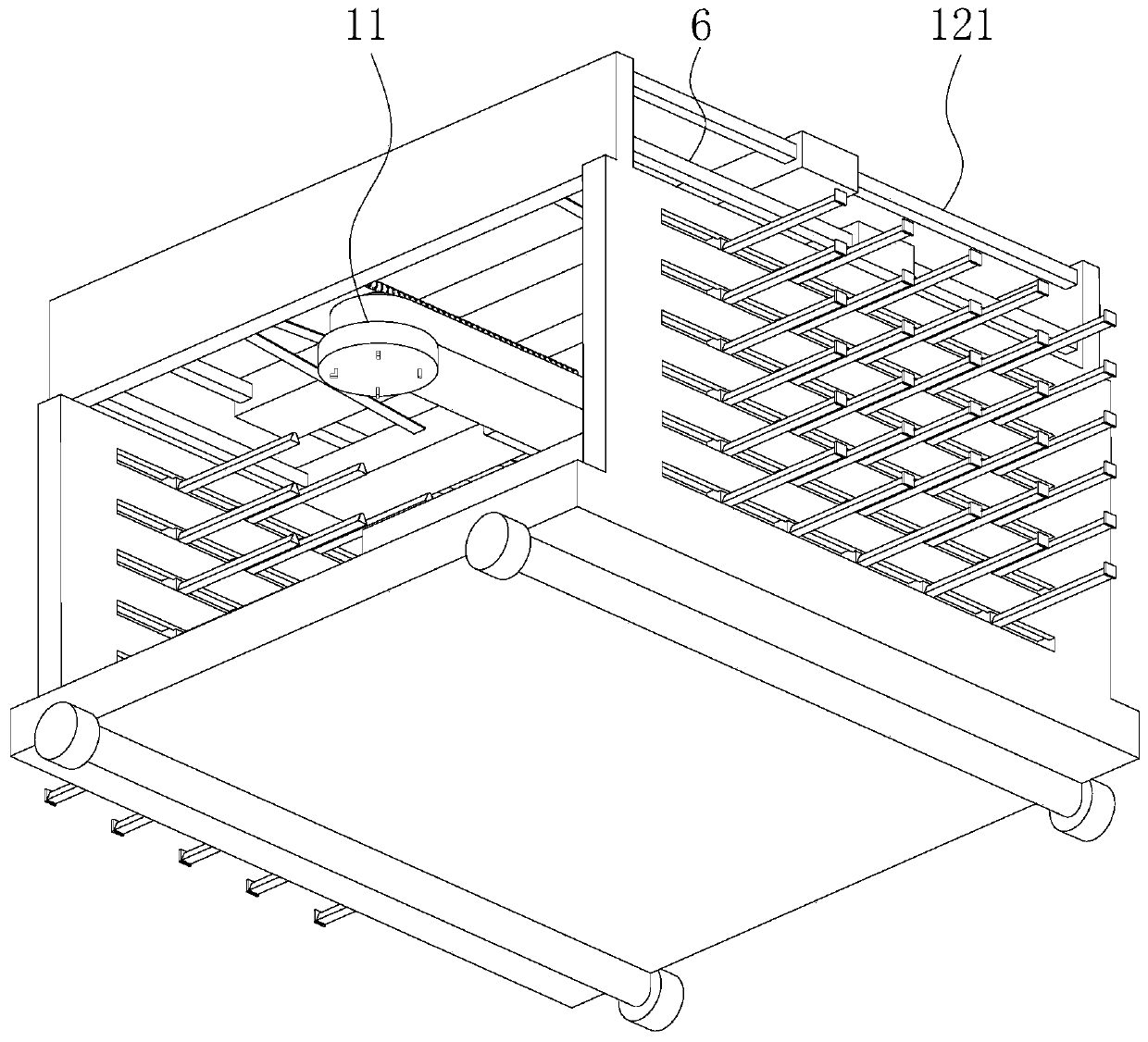

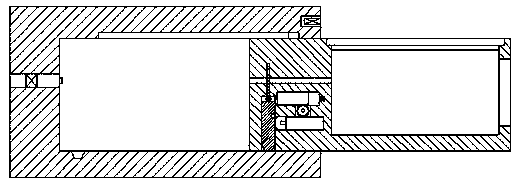

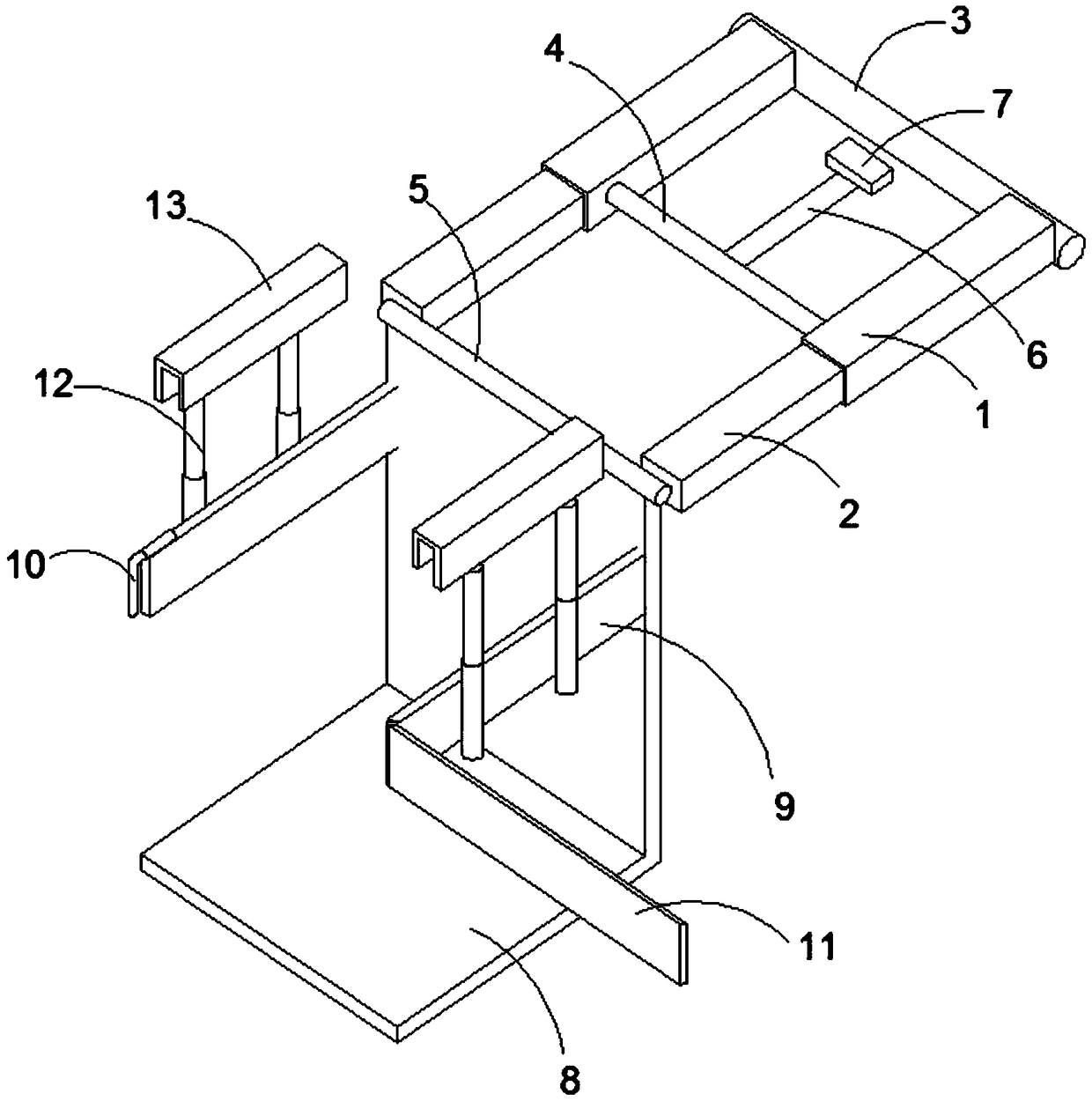

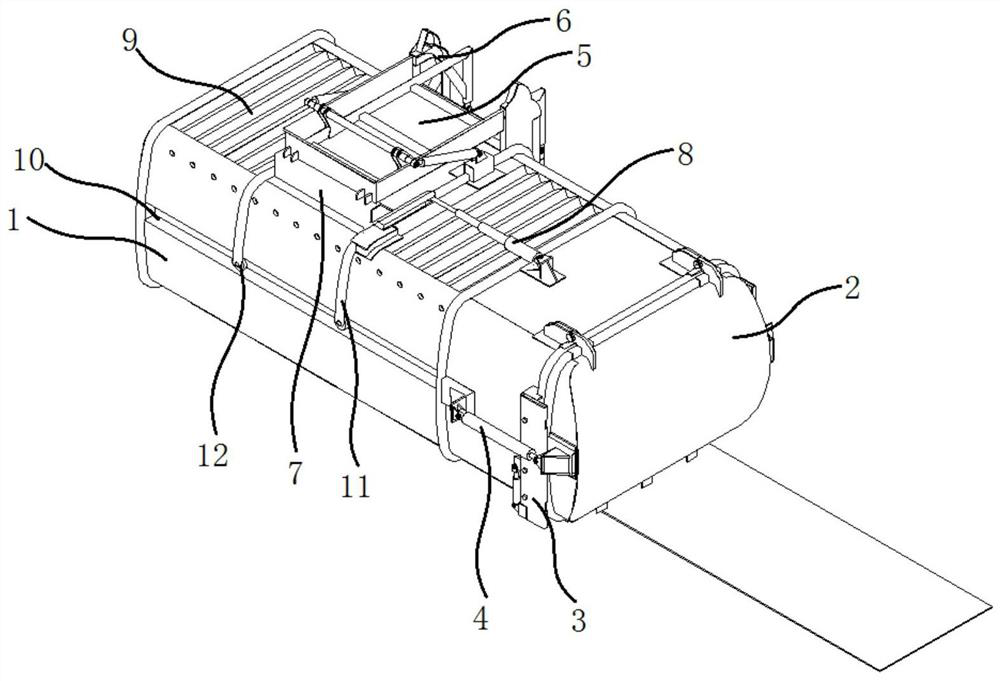

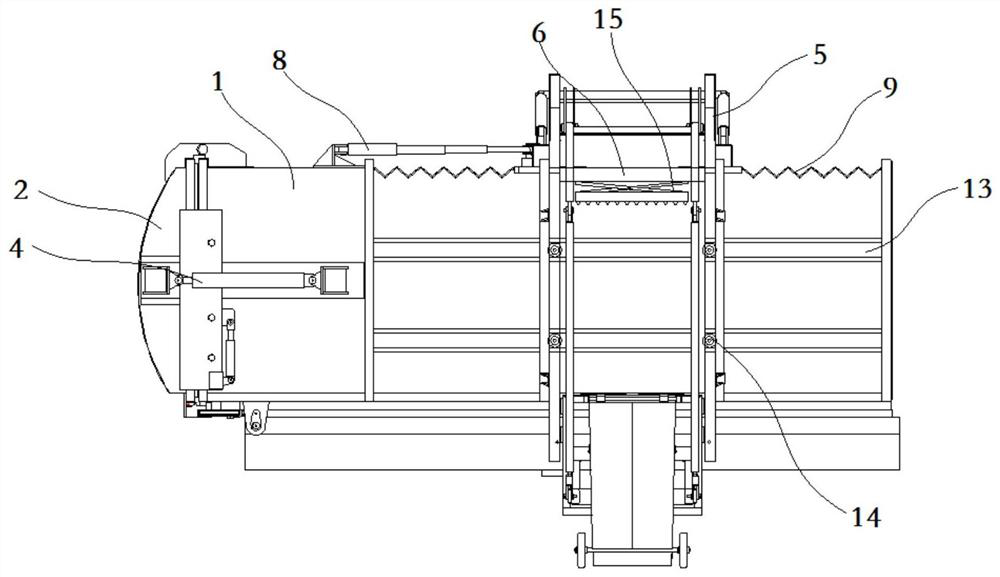

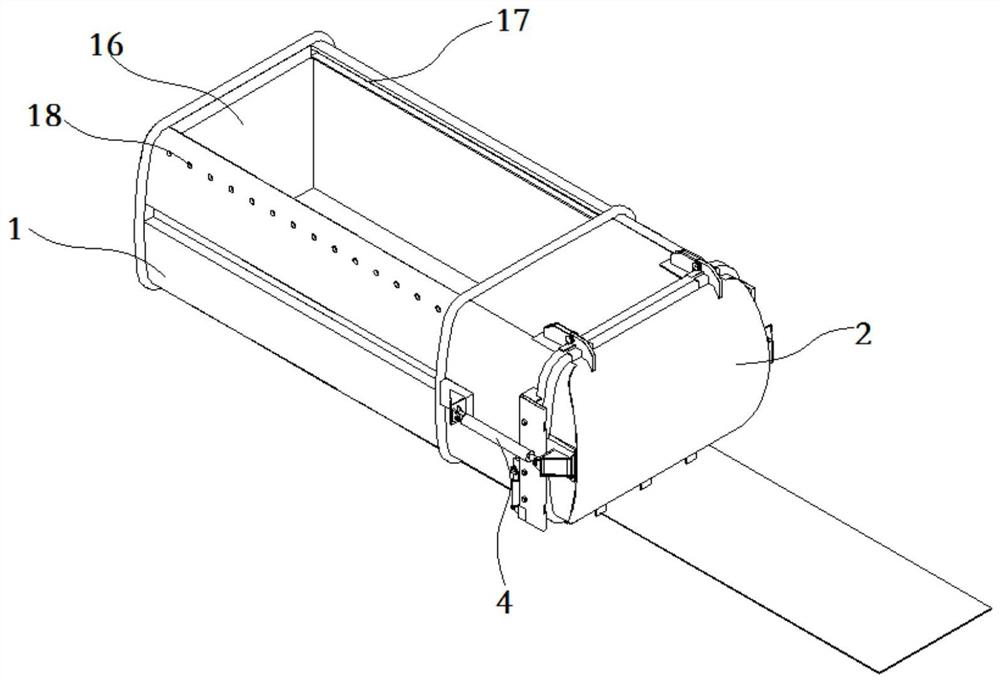

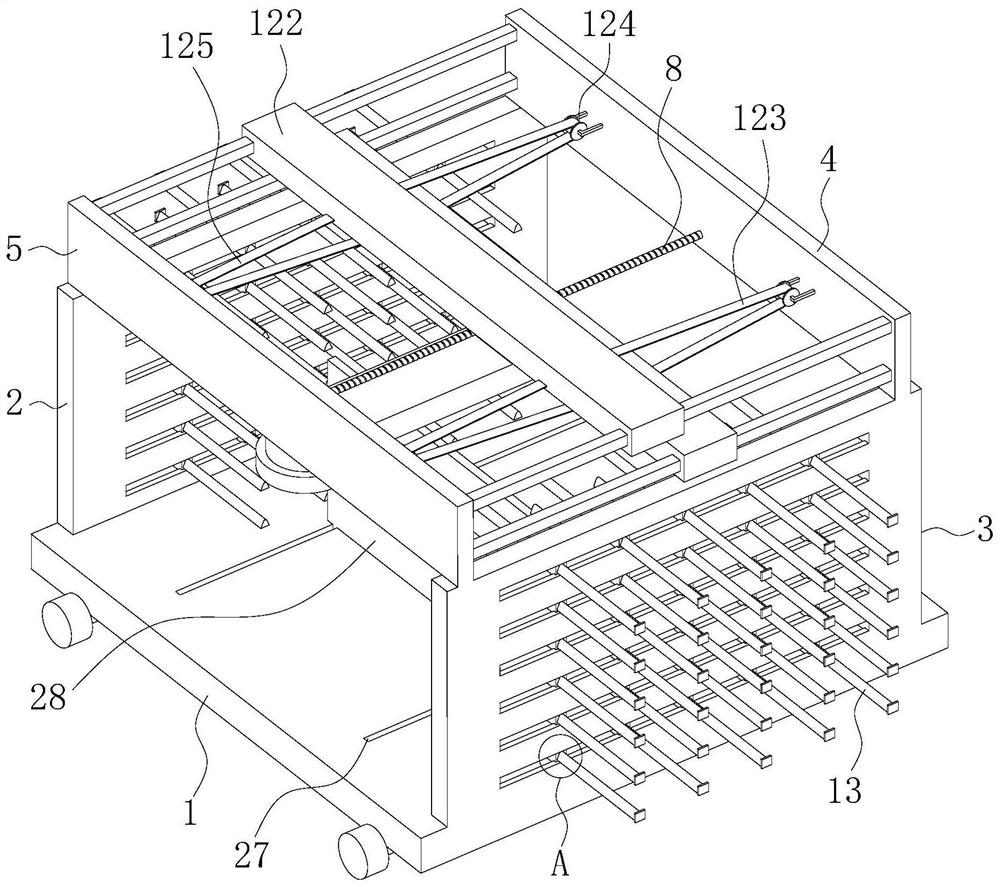

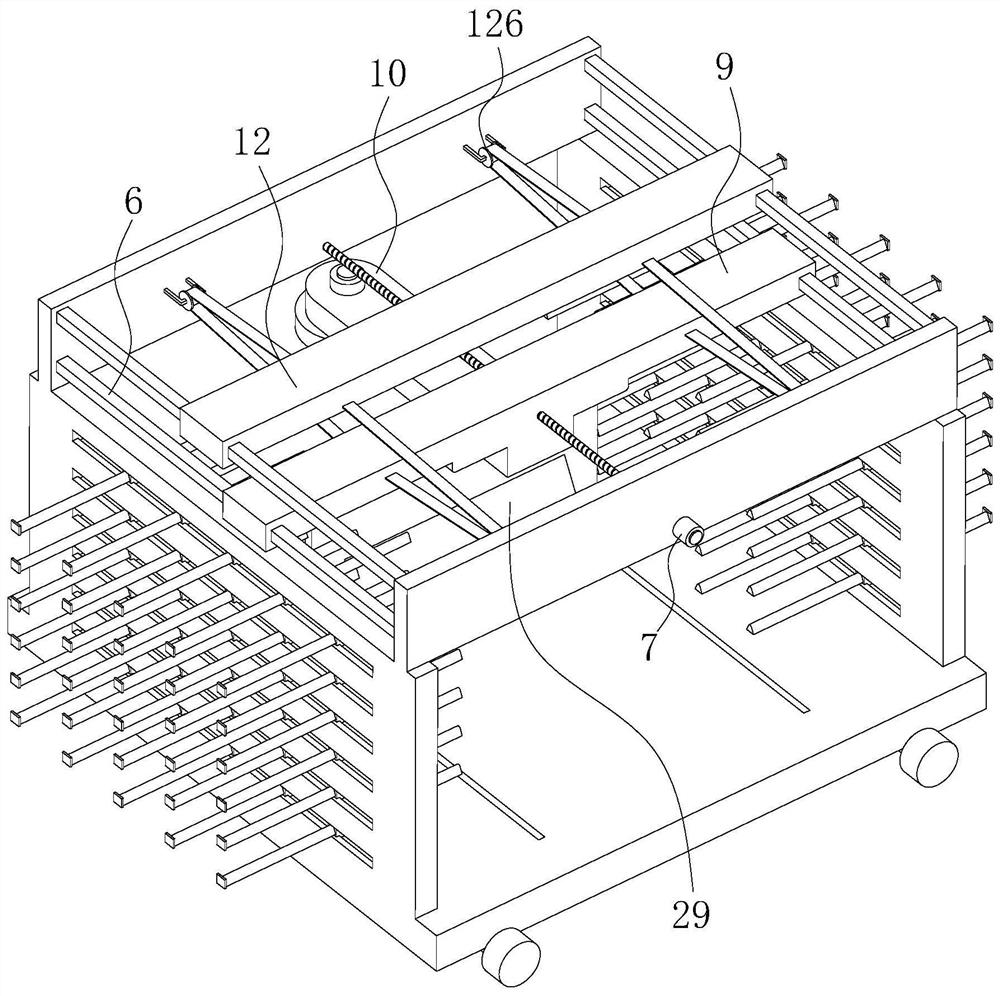

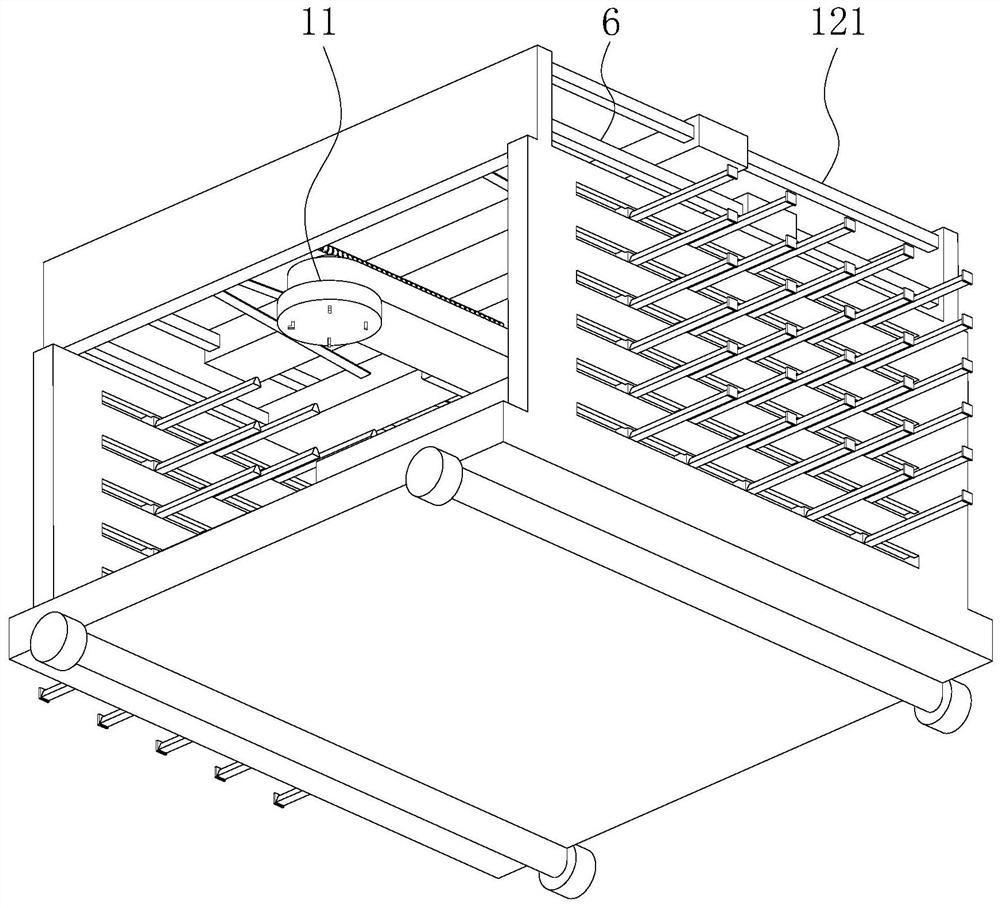

Assembly type building reinforced concrete prefabricated plate carrying machine

ActiveCN111017735AHandling will not happenPlay the role of internal supportConveyorsTravelling cranesReinforced concreteArchitectural engineering

The invention belongs to the technical field of building materials, and particularly relates to an assembly type building reinforced concrete prefabricated plate carrying machine, which comprises a bottom plate provided with rotating wheels. Two side plates are installed on the bottom plate; two mounting plates perpendicular to the side plates are mounted at the tops of the two side plates; a first sliding rail is mounted between the two mounting plates; a first motor is mounted on the mounting plate; the first motor is connected with a lead screw; the lead screw is in running fit with the twomounting plates; a strip-shaped hoisting table is in sliding fit with the first sliding rail; a connecting frame is installed on the bottom face of the hoisting table; a hoisting disc is installed onthe bottom face of the connecting frame; a counterweight mechanism is mounted between the two mounting plates; a plurality of pressure bearing rods perpendicular to the side plates are arranged on the two side plates in a sliding fit mode; and the edges of the longitudinal sections of the pressure bearing rods are matched with the inner sides of web member steel bars of the reinforced concrete prefabricated plate. When the reinforced concrete prefabricated plate is carried, the reinforced concrete prefabricated plate cannot slide, the carrying stability is improved, operation is convenient, and the transportation efficiency is high.

Owner:日照汇川建材有限公司

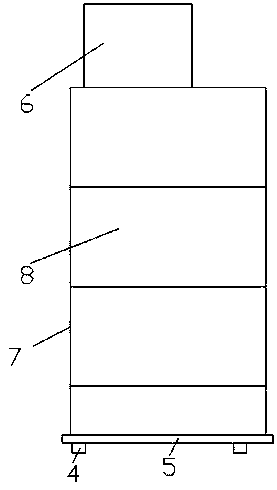

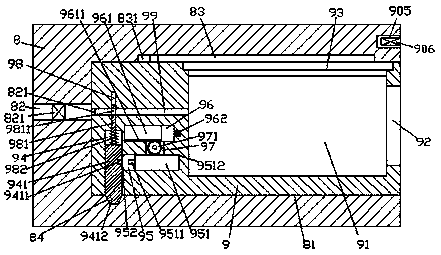

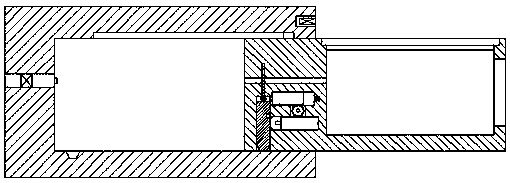

Improved machine room server device for big data collection and processing

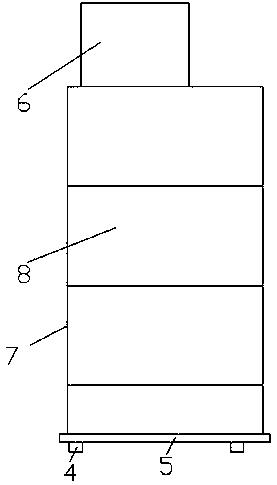

InactiveCN108037807ASimple structureEasy to operateDigital processing power distributionCold airAutomatic control

The invention discloses an improved machine room server device for big data collection and processing, which comprises a main cabinet body consisting of multiple installing cabinets; the end face of the top part of the main cabinet body is fixedly provided with a cold air device, and a holding cavity is arranged in the right side end face of the installing cabinet; a host machine body is glidinglyand adaptively connected to the holding cavity, an air supply pipe extended crossly is arranged in the inner wall body of the installing cabinet at the left side of the holding cavity, and the tail end of the right side of the air supply pipe is provided with a plug opening extended to the holding cavity; a dual-oblique groove is arranged in the bottom end face of the holding cavity, and a placing cavity is arranged in the top end face at the right side of the main machine body; an air inlet arranged crossly is arranged in the inner wall body of the host machine body at the left side of the placing cavity, and the left side of the air inlet extends the tail end and crosses through the outer end face of the left side of the host machine body; the left side of the air inlet extends to the tail end and is in opposite to the plug opening. The improved machine room server device can realize the automatic control and stable locking works, the automatic control connection and temperature reducing control work.

Owner:苏州玛斯堡威电子科技有限公司

Automatic loading and unloading mechanical arm of compression garbage truck

InactiveCN108689064AEasy to placePrevent sliding offsetRefuse vehiclesAssistive device/technologyEngineering

The invention relates to the technical field of garbage truck auxiliary equipment, in particular to an automatic loading and unloading mechanical arm of a compression garbage truck. The automatic loading and unloading mechanical arm comprises oil cylinders, telescopic rods, a first electric rotating shaft, a second electric rotating shaft, a third electric rotating shaft, a knock rod, a knock block, an object plate, baffles, a lock plunger, a rotating plate, electric telescopic rods, press plates and a garbage can. The number of the oil cylinders is two, and the telescopic rods are arranged inthe two oil cylinders. The tail ends of the two oil cylinders are fixedly connected through a first electric rotating shaft. The second electric rotating shaft is arranged between the inner side walls of the heads of the two oil cylinders. The third electric rotating shaft is arranged between the heads of the two telescopic rods. The knock rod is arranged on the second electric rotating shaft. The automatic loading and unloading mechanical arm is simple in structure and convenient to operate, the garbage can is fixed firmly, the garbage can is effectively prevented from sliding off from multiple directions, and safety of the garbage can is protected; and meanwhile, a knock vibration mechanism is arranged, garbage dumping work is accelerated, garbage is dumped more thoroughly, and high practicality is achieved.

Owner:浙江力工机械科技股份有限公司

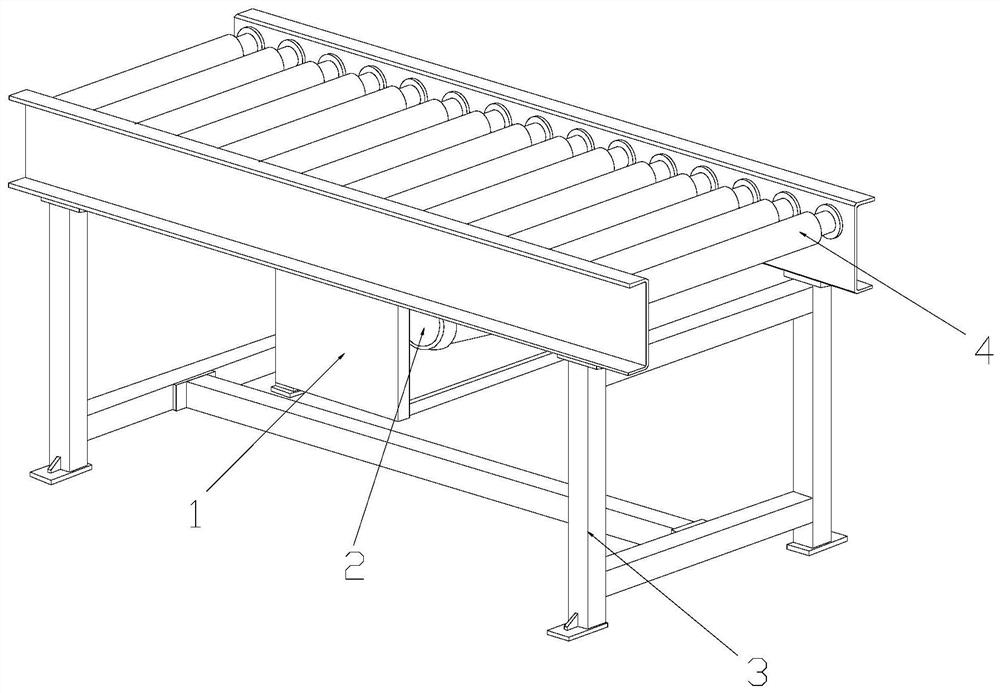

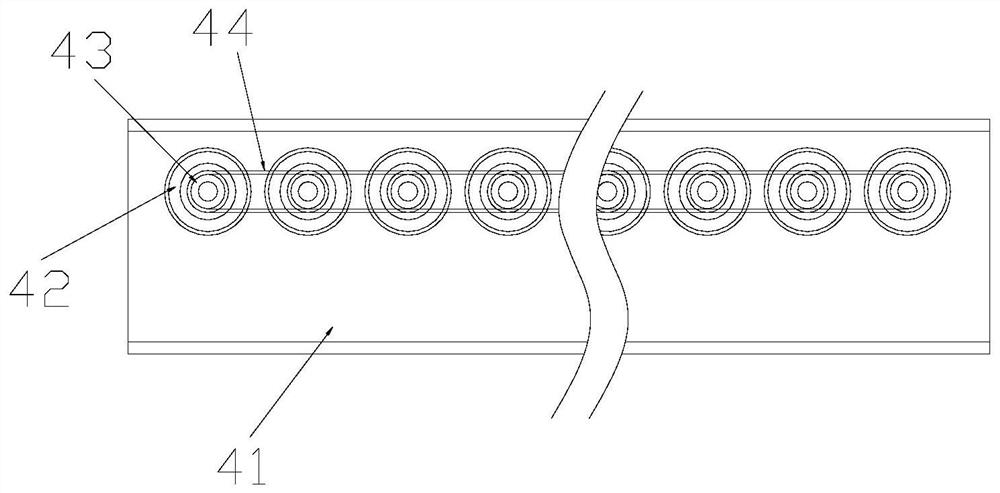

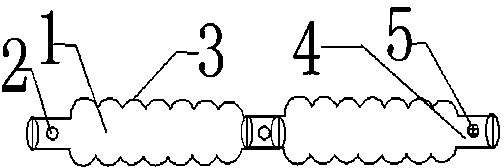

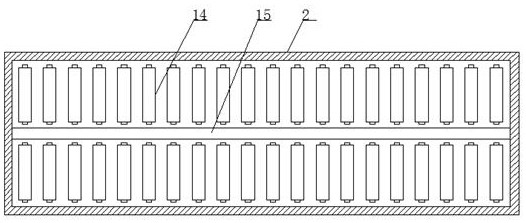

A kind of logistics sorting and conveying equipment

ActiveCN111361920BEasy to transportIncrease contact areaRollersRoller-waysLogistics managementElectric machine

Owner:临沂罗开投资有限公司

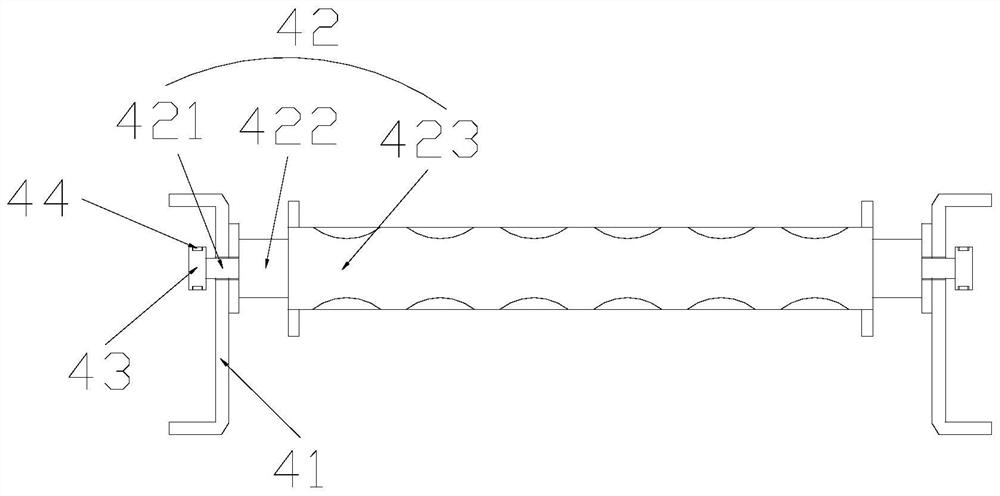

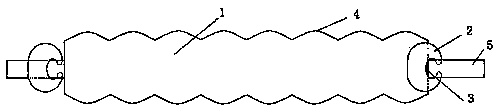

Attachable roller

InactiveCN103910177ASimple structureIngenious designConveyorsRollersEngineeringMechanical engineering

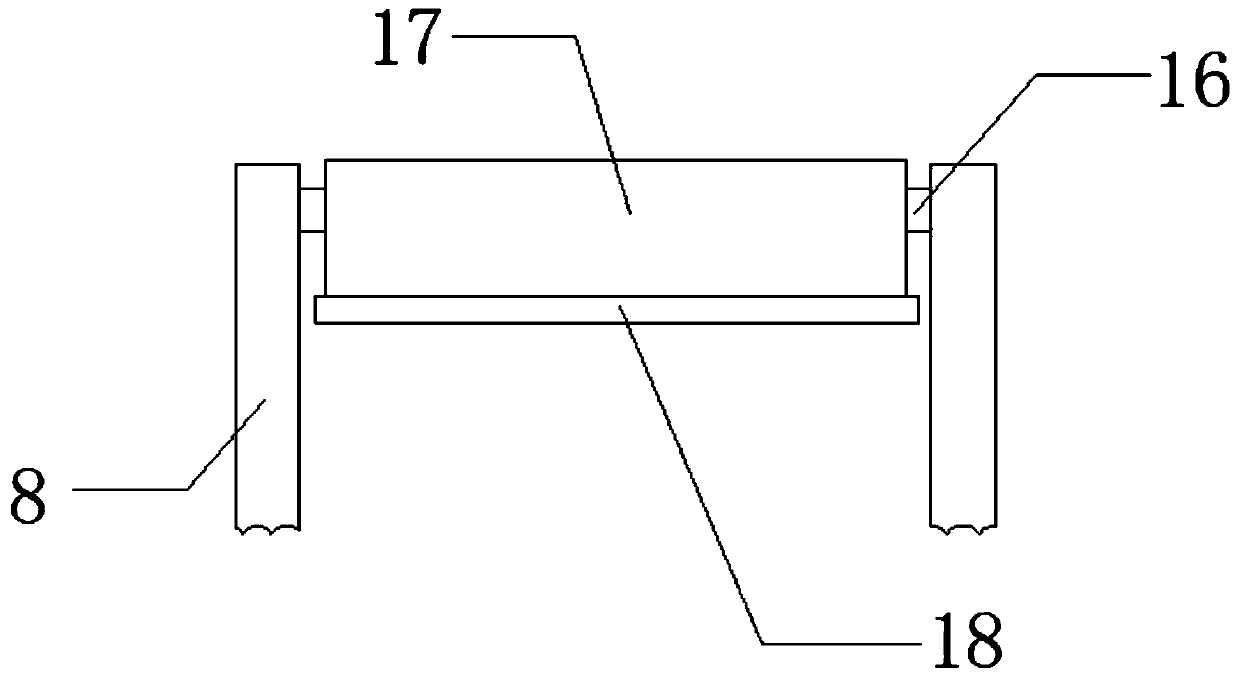

The invention discloses an attachable roller which comprises a roller body. A support lever is connected to two ends of the roller body, cross sections of two sides of the support lever are circular, one end of the support lever is provided with a spring bolt while the other end of the same is provided with a circular bolt hole matched with the spring bolt, and a plurality of circular protrusions are arranged on the outer side of the roller body. The attachable roller has the advantages that the attachable roller is simple in structure and ingenious in design; the length of the roller can be adjusted according to the actual length conveniently and rapidly; the attachable roller is convenient to mount, low in cost and simple in structure; sliding shift of a mesh belt is prevented, and material sliding at the edge of the mesh belt can be prevented and the like.

Owner:ANHUI KEXIN MINING MACHINERY MFG

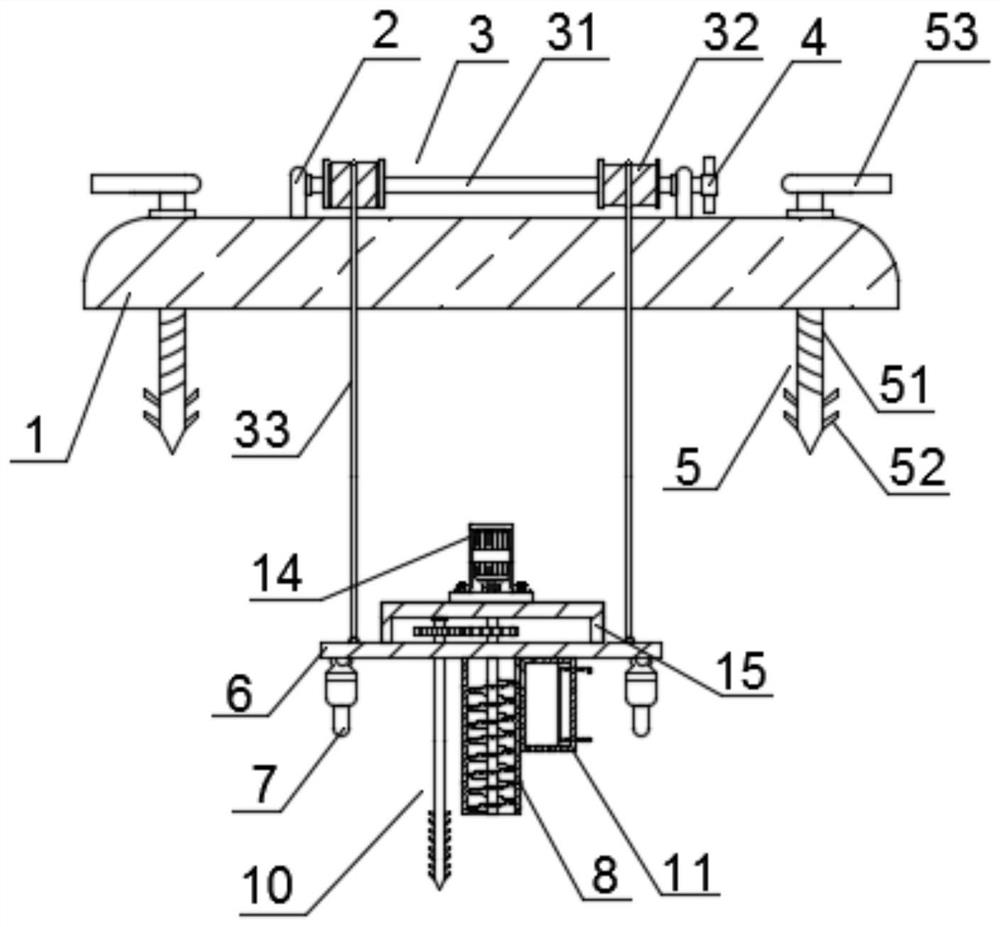

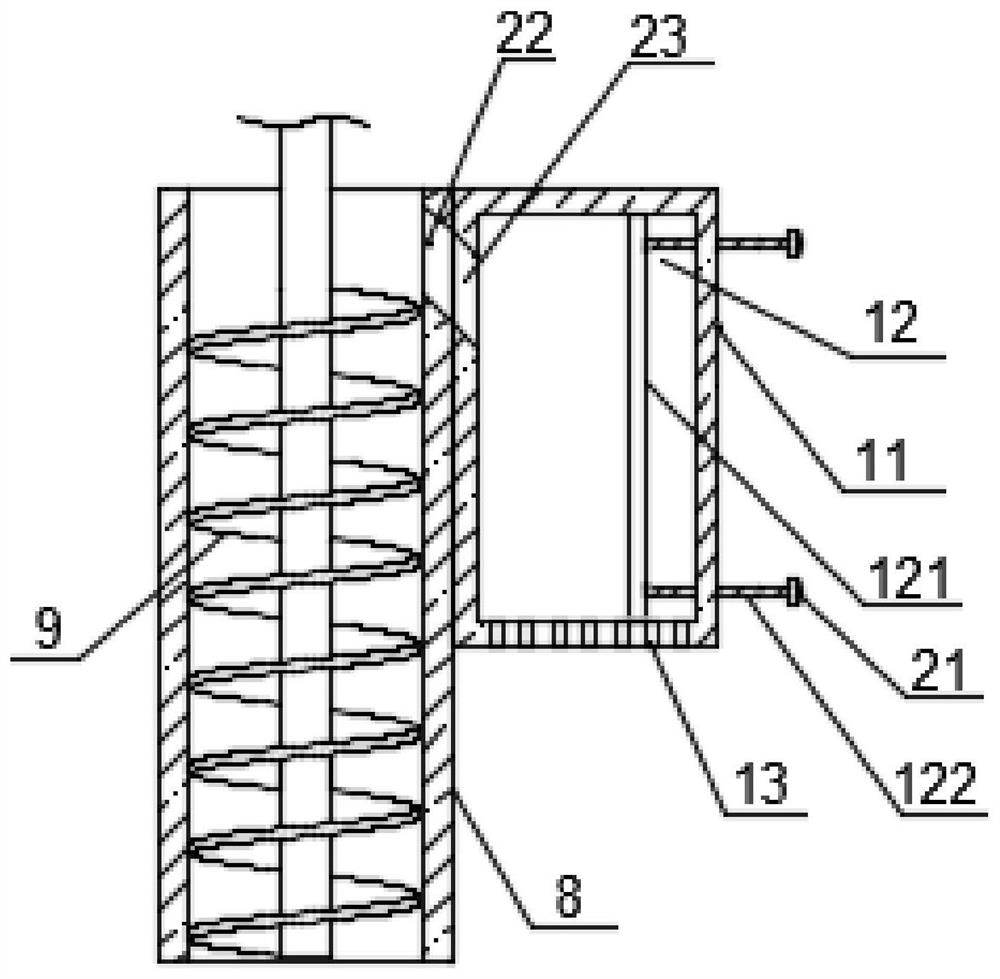

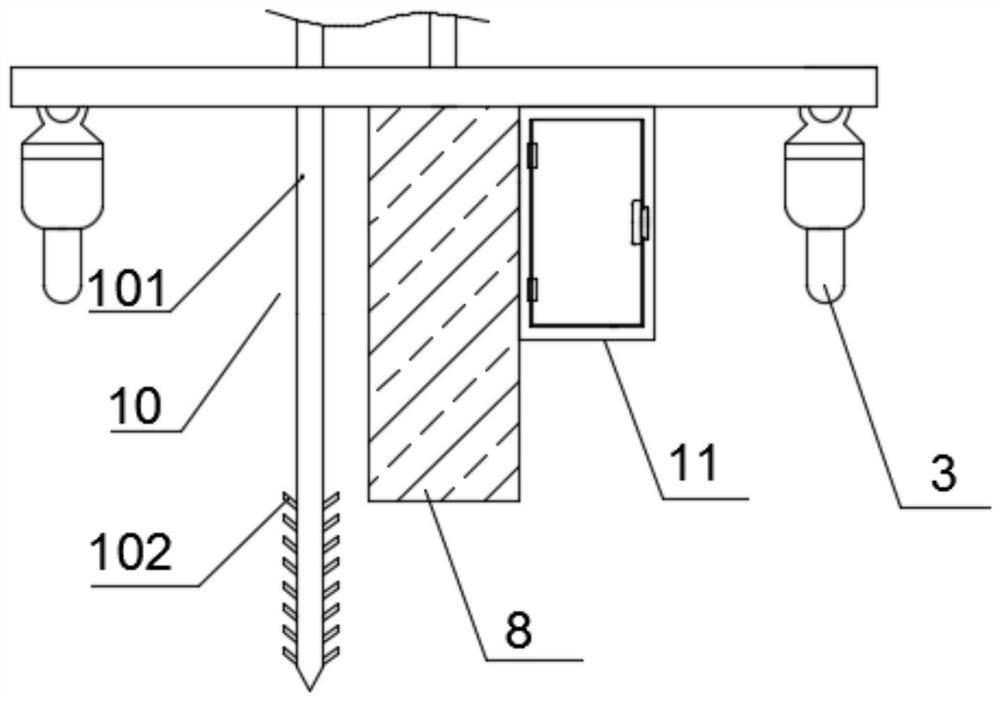

Sampling device for sludge treatment

InactiveCN112377783AAdjust sampling depthIncrease inhalationWithdrawing sample devicesPreparing sample for investigationSludgeAgricultural engineering

The invention discloses a sampling device for sludge treatment. The sampling device comprises a support plate, wherein fixed blocks are arranged at the two ends of the top end of the support plate; the fixed blocks are fixedly connected to the support plate; a lifting mechanism is arranged between the fixed blocks; the lifting mechanism comprises a connecting shaft; rope winding drums are connected to the two ends of the connecting shaft; limiting mechanisms are connected to the two ends of the support plate; each limiting mechanism comprises a threaded rod; a plurality of side blocks are connected to the surface of the lower part of each threaded rod; a connecting plate is arranged below the lifting mechanism; and a fixing cylinder is fixedly connected to the middle of the bottom end of the connecting plate. The sampling device has the beneficial effects that through the arrangement of the lifting mechanism, the sampling depth can be adjusted through the lifting mechanism according tothe water depth, a rotating handle is twisted to drive the connecting shaft to rotate, so that connecting ropes on the rope winding drums are unwound, the connecting plate is driven to descend into ariver, vertical blocks at the bottom end of the connecting plate have certain gravity and can drive the connecting plate to sink to make contact with river bottom sludge, and the sampling depth of the sludge can be adjusted according to different water depths.

Owner:肖梅芝

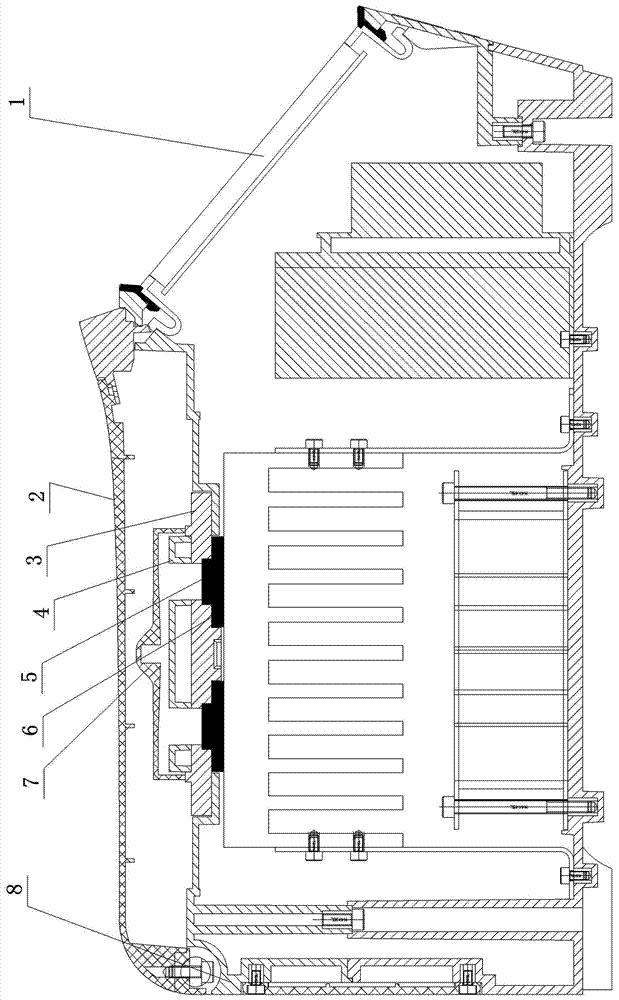

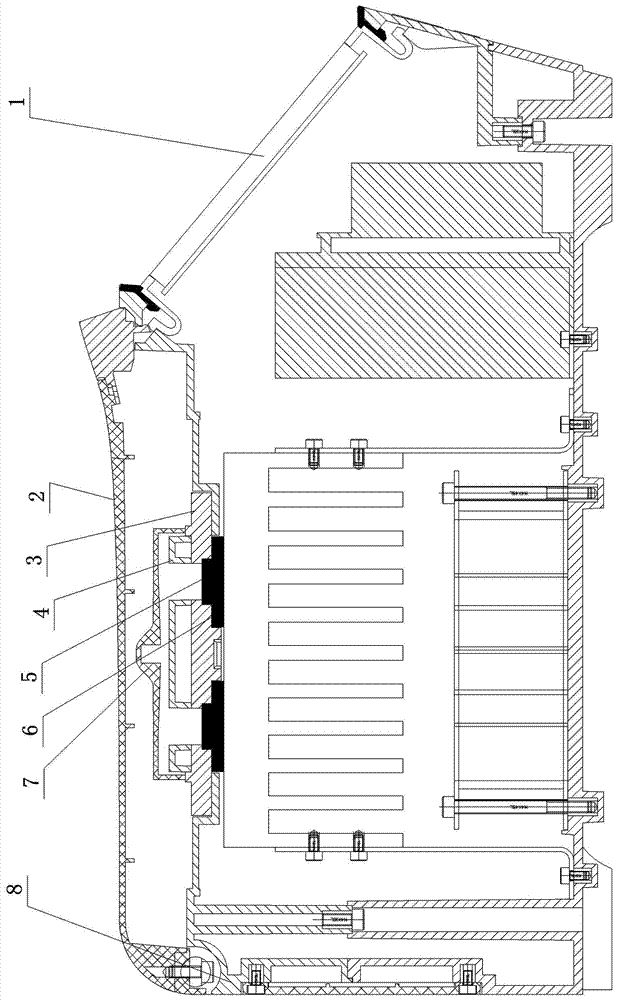

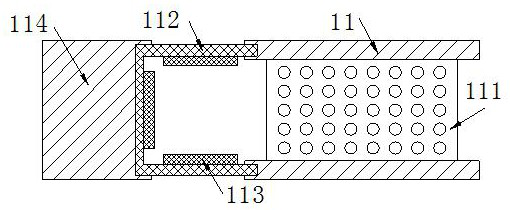

Low-temperature tissue embedding temperature control system

ActiveCN107463193AFast heatingFast coolingComputer controlTemperatue controlTemperature controlControl system

The invention provides a low-temperature tissue embedding temperature control system, and belongs to the technical field of biospecimen low-temperature tissue embedding. The low-temperature tissue embedding temperature control system is high in working efficiency, and good in use effect. The system comprises a heating and refrigerating semiconductor element and a control circuit; a control signal output end port of the control circuit is connected to a control signal input port of the heating and refrigerating semiconductor element; a detection signal input port of the control circuit is connected with a detection signal output port of a temperature sensor for detecting the temperature of the heating and refrigerating semiconductor element; the control circuit comprises a CPU, a power conversion part, a system control part, a storage, a system feedback part, a display part, a Bluetooth part and a heat dissipating control part; the control signal output port of the CPU is correspondingly connected with the control signal input port of the system control part and the control signal input port of the heat dissipating control part.

Owner:苏州碳卡智造科技有限公司

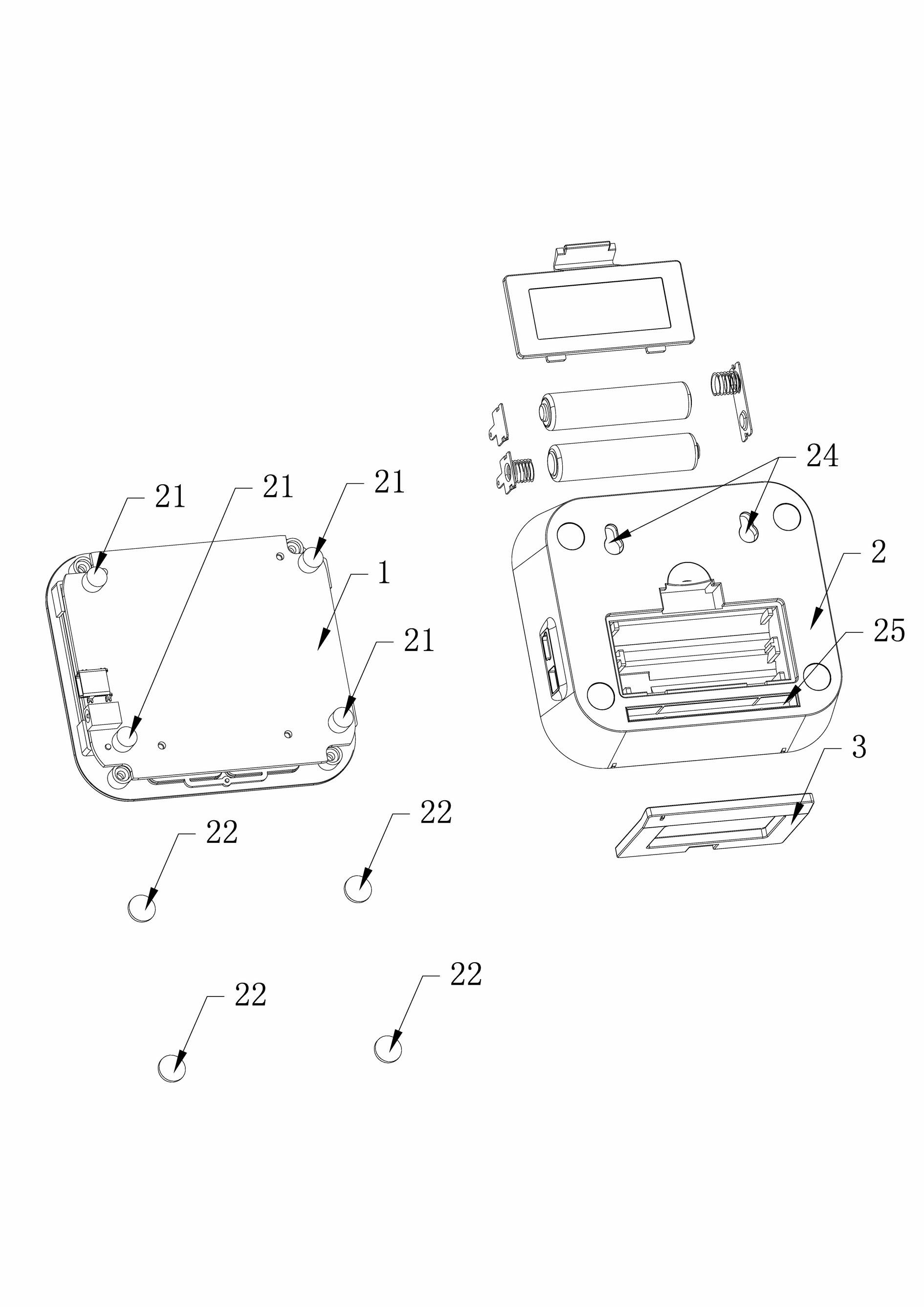

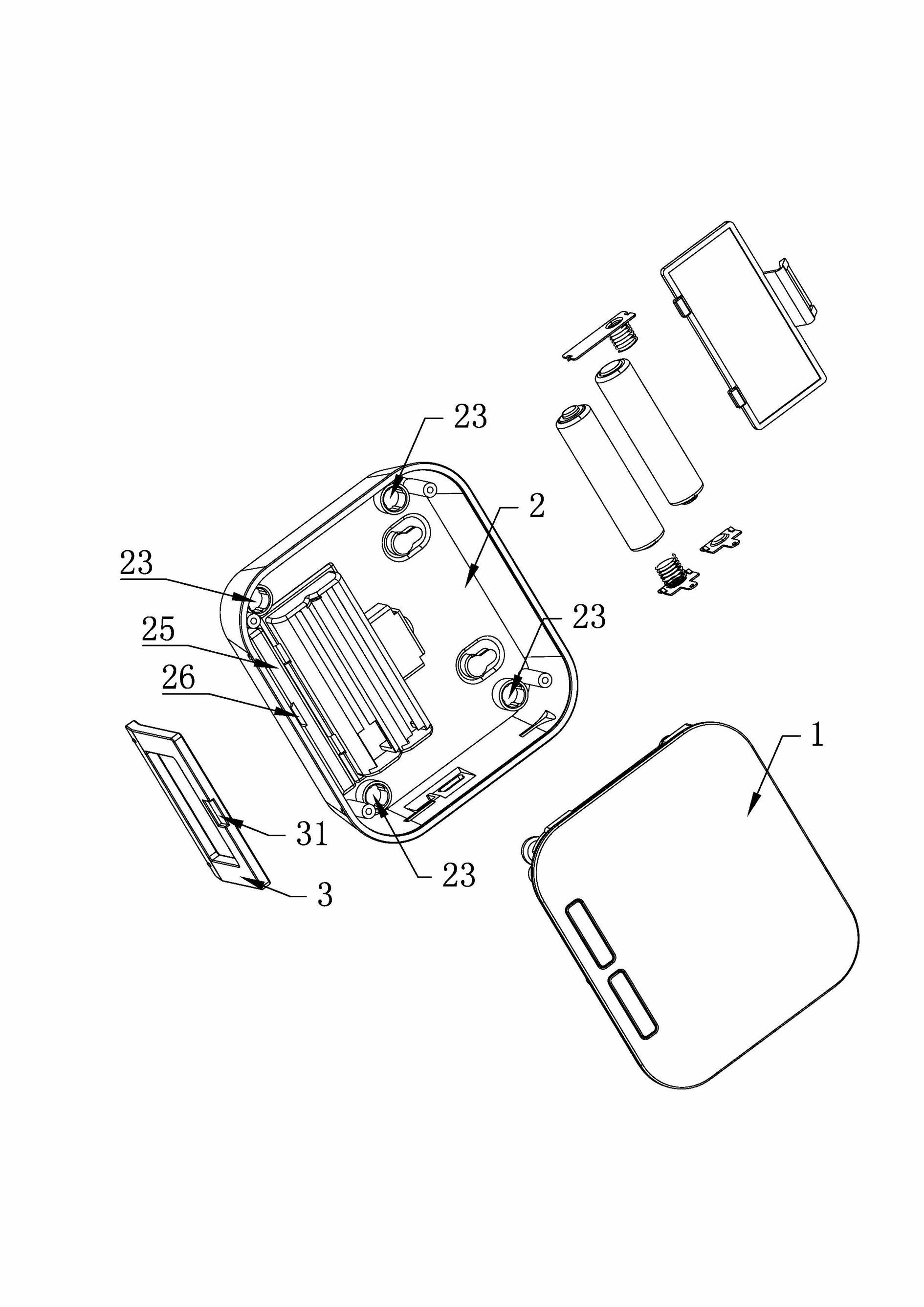

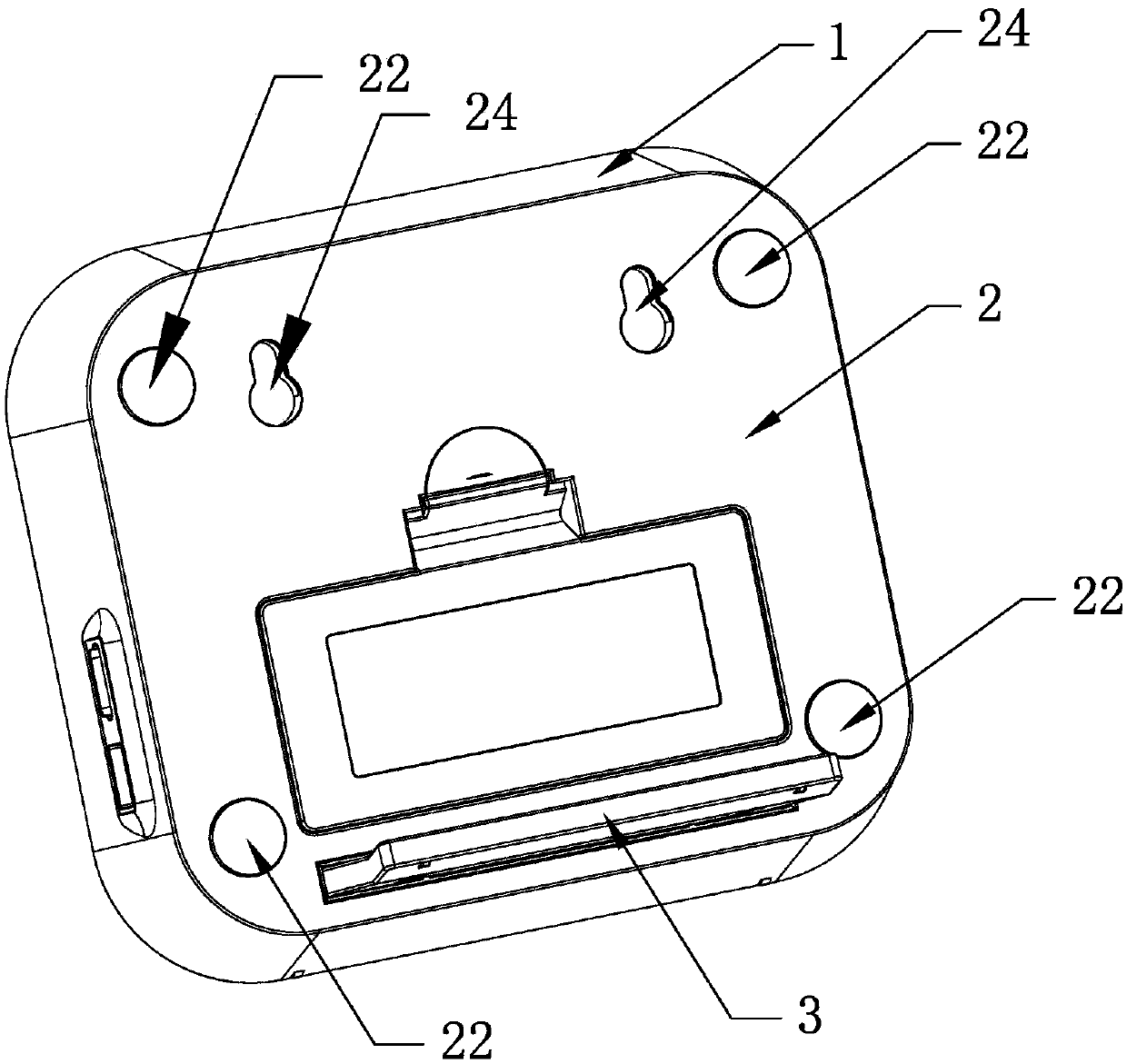

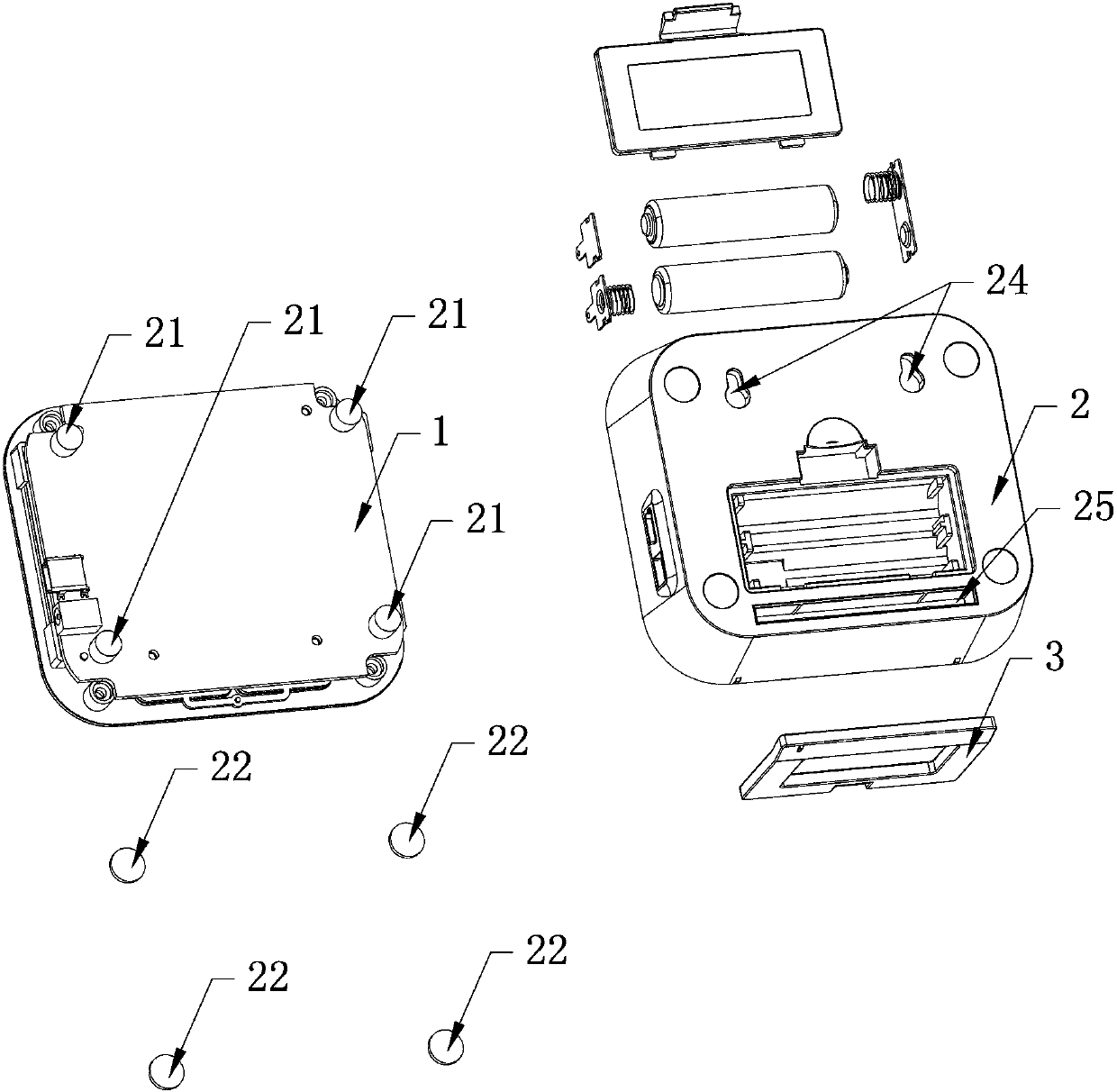

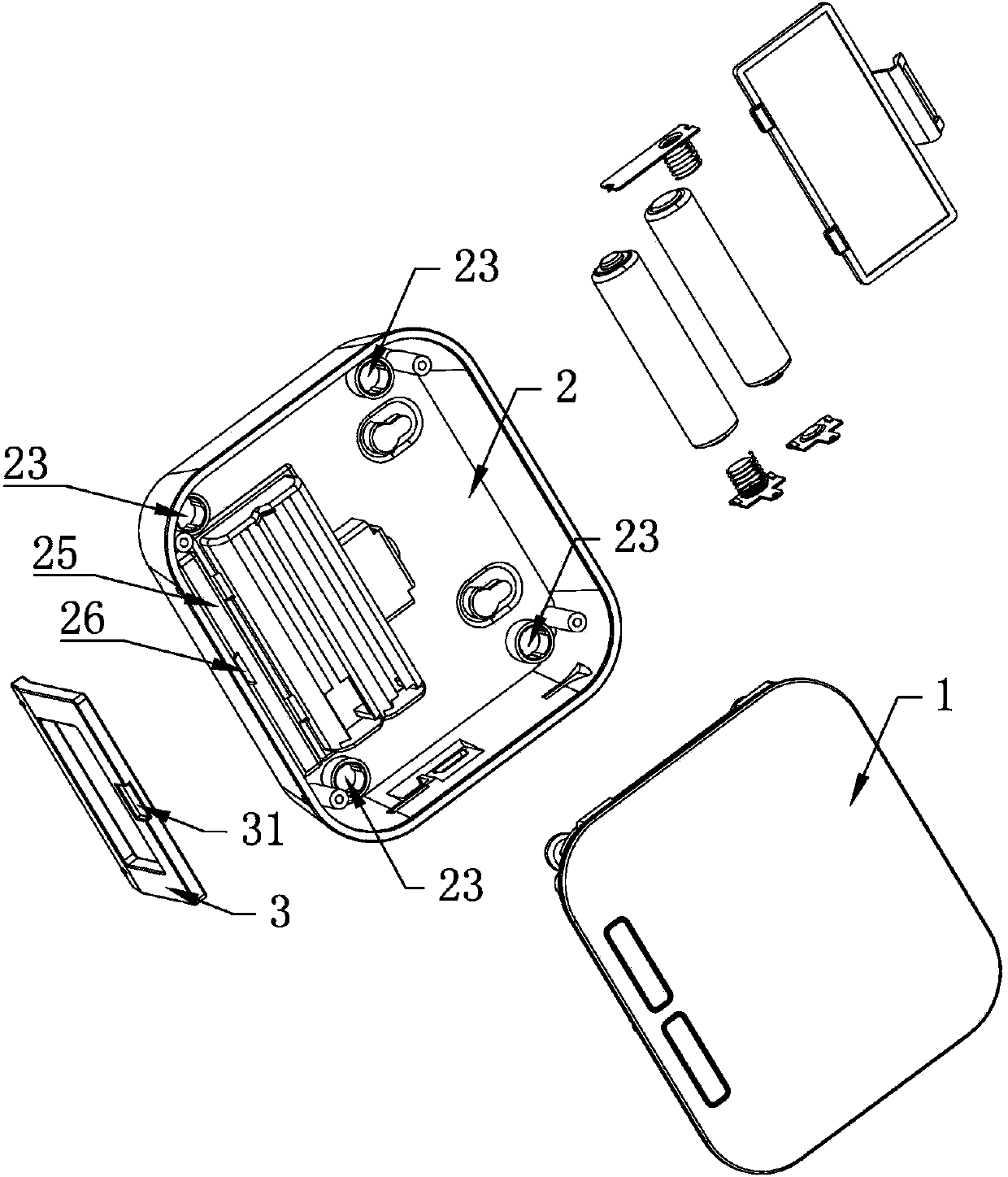

Anti-sliding displayer

ActiveCN102610166AEasy to fixPrevent sliding offsetCasings/cabinets/drawers detailsIdentification meansStructural engineeringMechanical engineering

Owner:湖南省瑞柯电子科技有限公司

Garbage truck

A garbage truck comprises a tank body, a tail door hinged to the tank body and an elevator connected to the side wall of the tank body in a sliding mode. A mounting frame synchronously moving with theelevator is arranged at the top of the tank body in a sliding mode, a feeding cabin door communicating with the interior of the tank body is rotationally connected to the mounting frame, and an angle-adjustable telescopic pressing mechanism is arranged on the face, towards the interior of the tank body, of the feeding cabin door; and a first telescopic mechanism for driving the mounting frame tomove transversely is arranged at one end of the tank body; and foldable telescopic plates symmetrically arranged at the two ends of the mounting frame are further included, and rainwater drainage holes communicating with wave troughs of the foldable telescopic plates are oppositely formed in the side wall of the tank body. According to the garbage truck, the elevator is driven by the first telescopic mechanism to slide to different positions of the tank body, so that garbage is uniformly poured into the tank body; and a telescopic pressing mechanism is adopted for compressing the garbage, multi-directional compression is achieved in cooperation with movement of the first telescopic mechanism in the compression process, and the storage capacity of the tank body is effectively increased.

Owner:NINGXIA WANXING FORCE CAR MFG

Automatic stone machining production line and production method thereof

InactiveCN113172773AReduce labor intensityPrevent sliding offsetWorking accessoriesStone-like material working toolsManufacturing lineManufacturing engineering

The invention discloses an automatic stone machining production line and a production method thereof. The automatic stone machining production line comprises a base and a workbench located at the top end of the base; telescopic air cylinders are symmetrically arranged on the two sides of the top end of the workbench; a cross beam is transversely arranged at the top ends of the telescopic air cylinders; a support is vertically arranged at the bottom end of the cross beam; a rack is arranged at the bottom end of the support; a cutting machine matched with the rack is arranged at the bottom end of the rack; a water spraying head and a dust collection head are arranged at the positions, located on the two sides of the cutting machine, of the bottom end of the rack respectively; and a box body is arranged at the bottom end of the cross beam. The automatic stone machining production line provided by the invention has the beneficial effects that the labor intensity of workers is reduced, stone raw materials are good in stability and smooth in cutting in the moving process, the product percent of pass is improved, in the specific use process, the stone is cut through the cutting machine, friction resistance in the moving process of a carrying plate is reduced, the carrying plate and the stone are made to move stably, cutting is accurate, and the working efficiency is high.

Owner:泉州市铭祥石材工艺有限公司

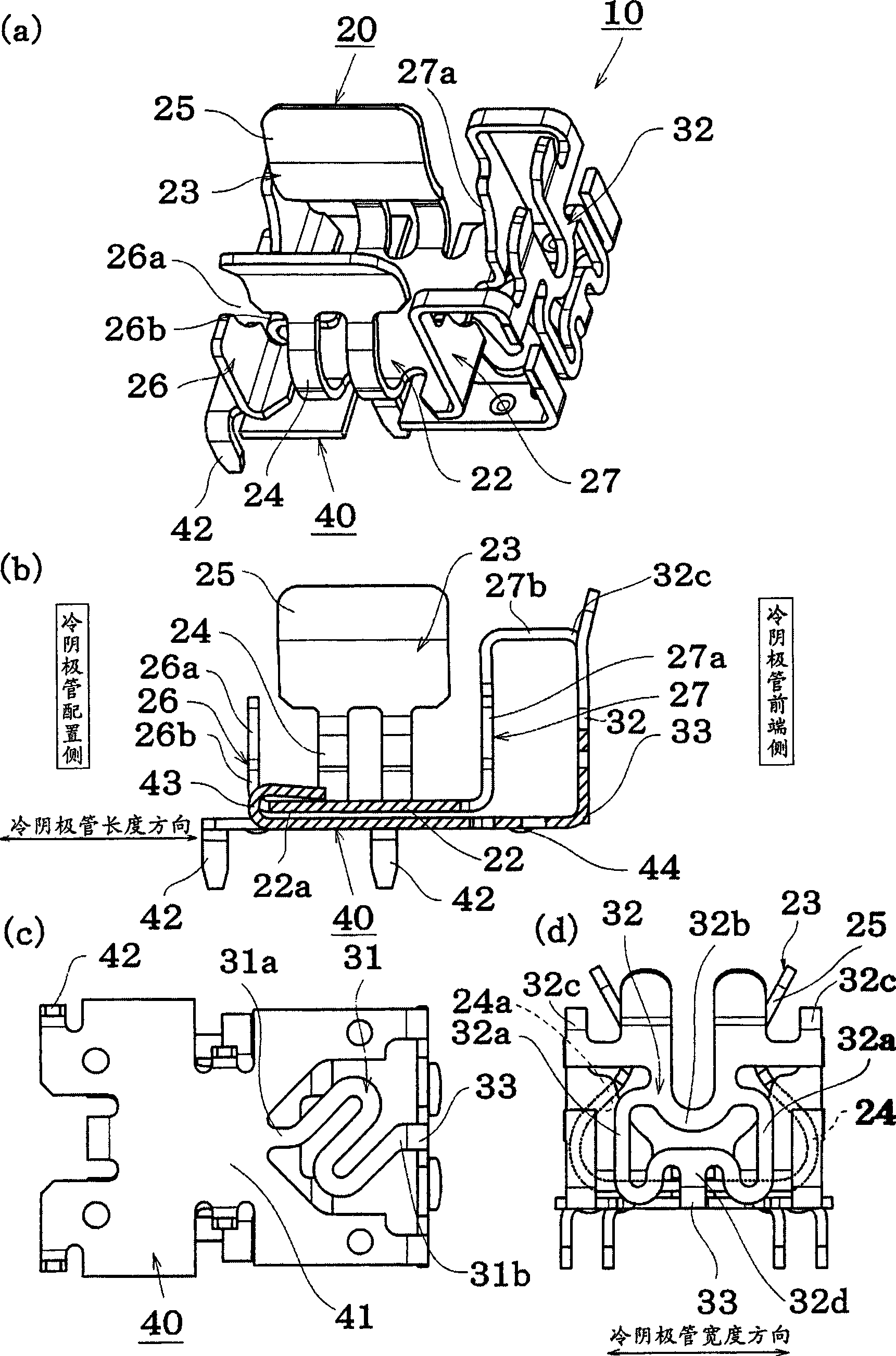

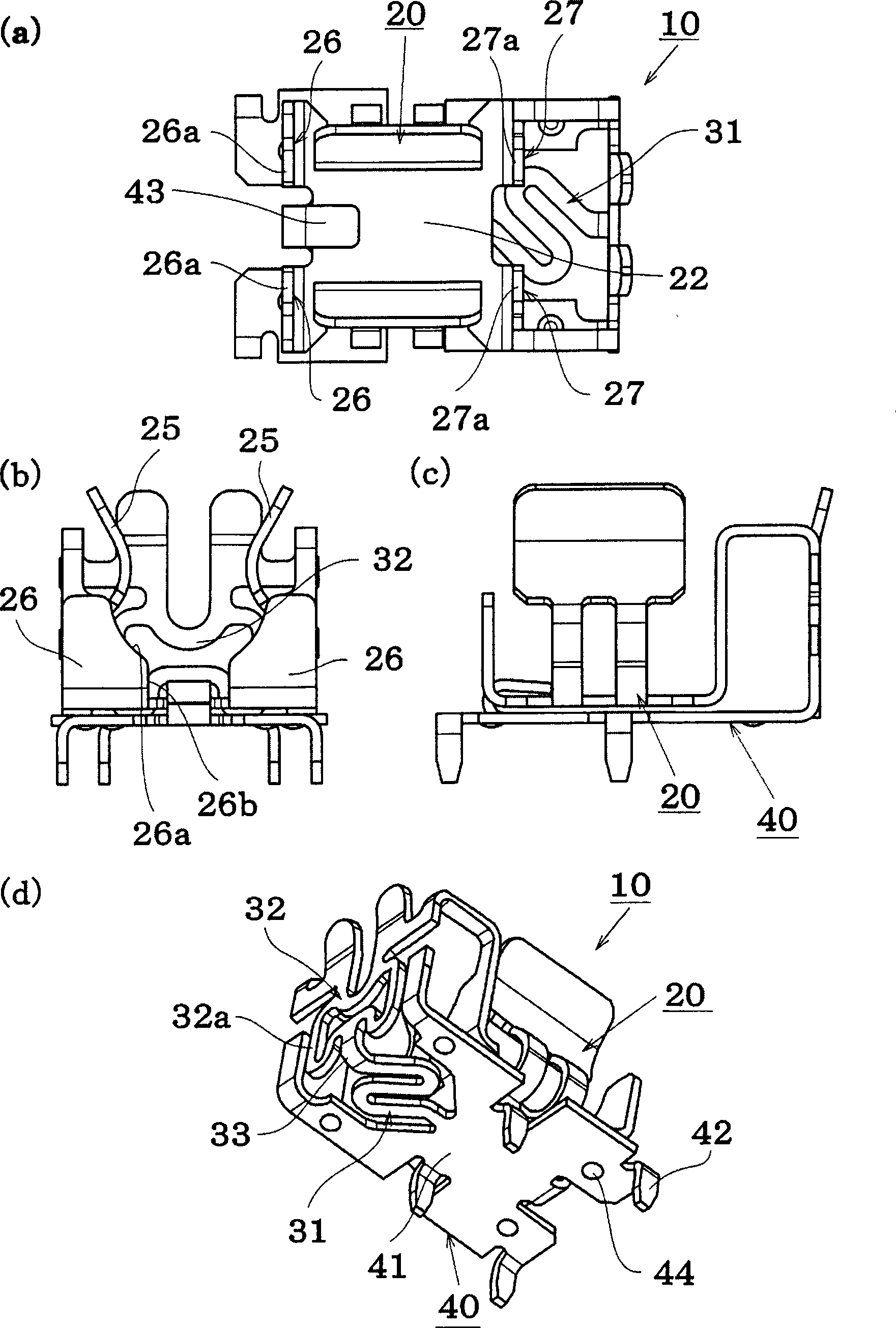

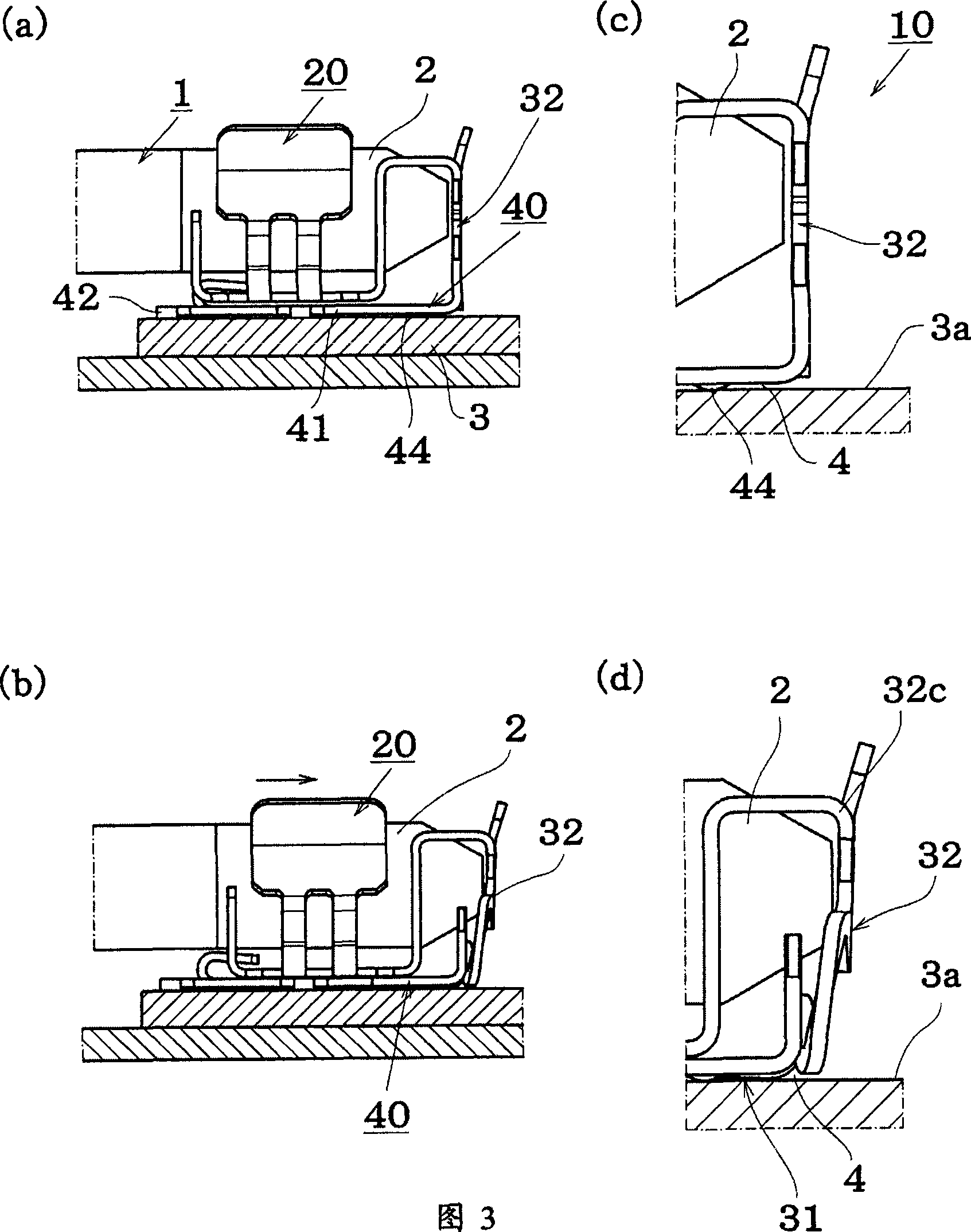

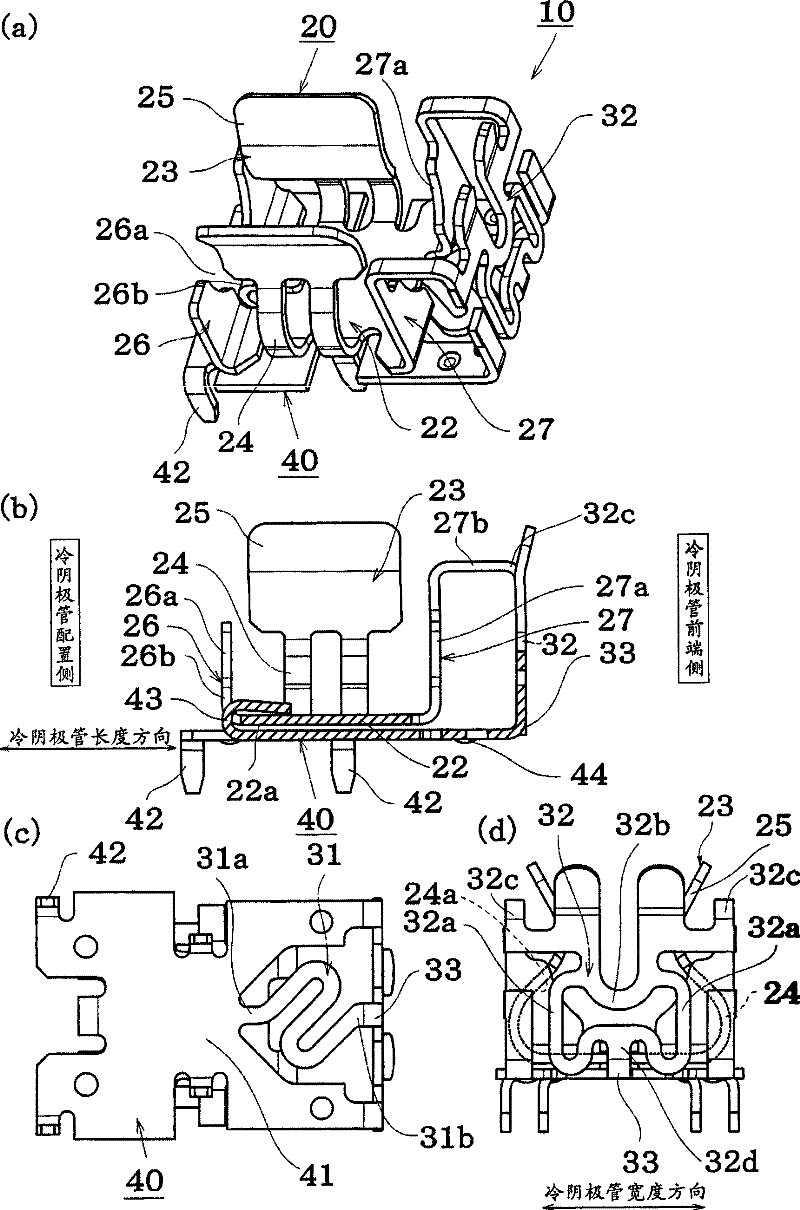

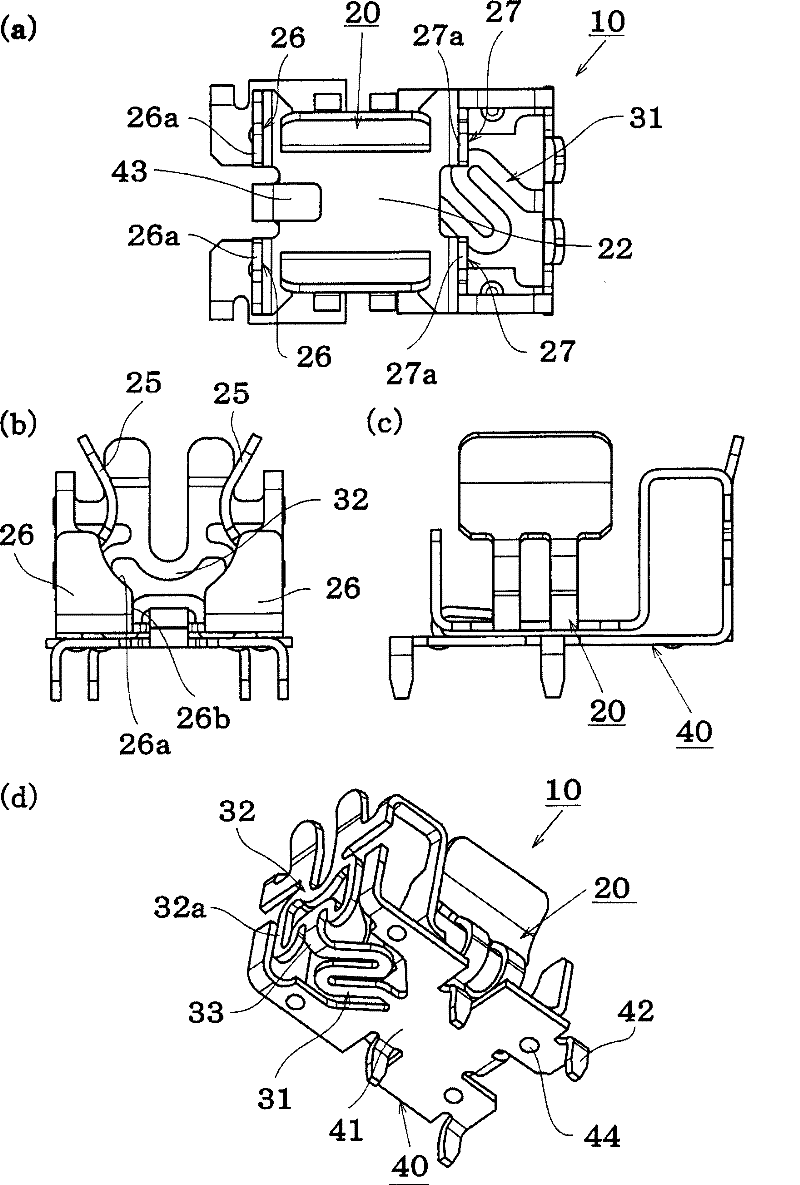

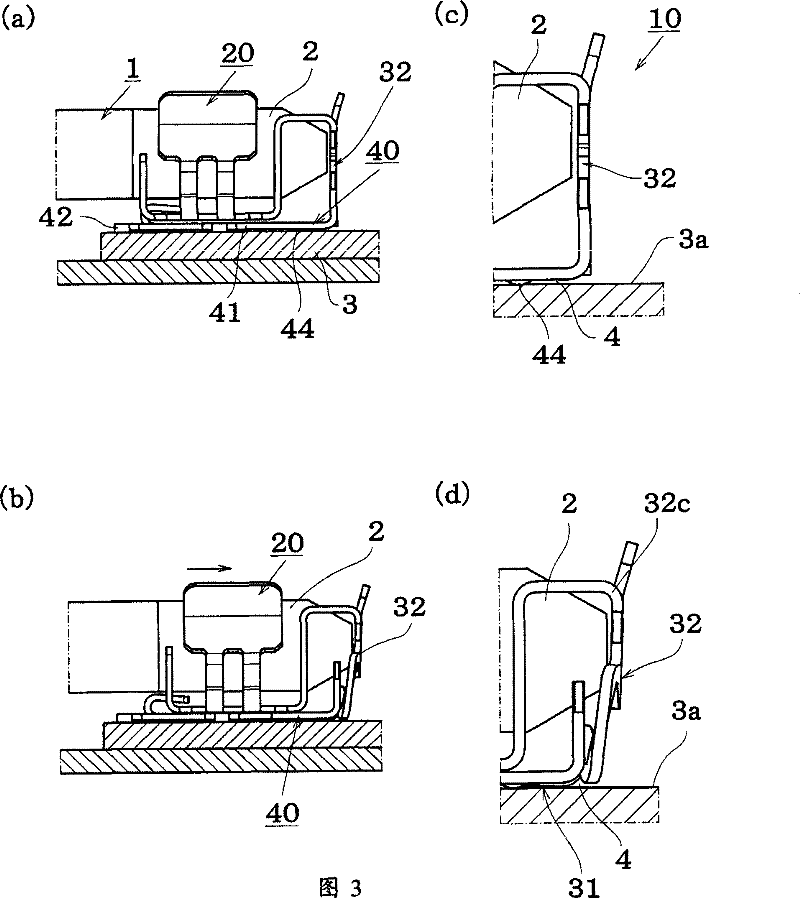

Socket for cathode tube

InactiveCN101447629AAvoid tensionPrevent sliding offsetElectric discharge tubesCoupling contact membersTemperature differenceEngineering

The present invention relates to a socket for a cathode tube. The aim of the invention is to provide a socket for a cathode tube, capable of easily absorbing a shrinking difference generated between the cathode tube and a circuit board, a frame and the like due to a temperature difference caused by turning on and off the cathode tube, and absorbing processing error and mounting error of the socket. The socket of the invention is characterized in that a clamping part for holding the side part of a cathode tube terminal part is connected with a mounting part electrically connected by a circuit board by two ends of a first elastic distortion part and a seond elastic distortion part arranged in a basal rightanglle direction relative to the first elastic distortion part.

Owner:SMK CO LTD

Electric welding machine equipment

The invention discloses electric welding machine equipment. The electric welding machine equipment comprises a machine cover body which is fixedly installed on a working table surface, supporting footcolumns are arranged on the bottom of the working table surface, a heat removing device is fixedly arranged on the top end surface of the machine cover body, and a holding groove is formed in the endsurface of the right side of the machine cover body. A welding machine body is connected into the holding groove in sliding fit mode, a gas transmission pipe which is arranged in a left-and-right extending mode is arranged in the inner wall body of the machine cover body and located on the left side of the holding groove, an inserting-connecting opening which jacks into the holding groove is fixedly formed in the tail end of the right side of the gas transmission pipe, and an inclined hole is formed in the bottom end surface of the holding groove. A placing cavity is formed in the top end surface of the right side of the welding machine body, a gas transmission hole which is arranged left and right is formed in the inner wall body of the welding machine body and located on the left side of the placing cavity, and an extended end of the left side of the gas transmission hole penetrates through the outer end surface of the left side of the welding machine body. According to the electricwelding machine equipment, automatic control and stable locking work can be realized, and automatic control connection and cooling control work can be realized.

Owner:王建刚

Anti-sliding displayer

ActiveCN102610166BEasy to fixPrevent sliding offsetCasings/cabinets/drawers detailsIdentification meansDisplay deviceStructural engineering

Owner:湖南省瑞柯电子科技有限公司

Low-temperature tissue embedding adapter

The invention belongs to the technical field of low-temperature tissue embedding of a biological sample, and especially relates to a low-temperature tissue embedding adapter. The adapter is high in work efficiency, and is good in use effect. The adapter comprises a housing, and a housing pedestal is provided with a semiconductor element limiting groove. The interior of the semiconductor element limiting groove is provided with a heating refrigeration semiconductor element, and the upper end of the semiconductor element limiting groove is covered by an embedding block limiting plate. The embedding block limiting plate is provided with an embedding block limiting port corresponding to the semiconductor element limiting groove. The interior of the housing pedestal is provided with a control circuit, and a control signal output port of the control circuit is connected with a control signal input port of the heating refrigeration semiconductor element. A detection signal input port of the control circuit is connected with a detection signal output port of a temperature sensor for detecting the temperature of the heating refrigeration semiconductor element.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

A prefabricated reinforced concrete plate handling machine for prefabricated buildings

ActiveCN111017735BHandling will not happenPlay the role of internal supportConveyorsTravelling cranesReinforced concreteArchitectural engineering

The invention belongs to the technical field of building materials, and in particular relates to a prefabricated prefabricated reinforced concrete slab handling machine, which includes a bottom plate equipped with runners, two side plates are installed on the bottom plate; Two mounting plates; the first slide rail is installed between the two mounting plates; the first motor is installed on the mounting plate, the first motor is connected to the lead screw, and the lead screw is in rotation with the two mounting plates; sliding on the first slide rail It is equipped with a strip hoisting platform, a connecting frame is installed on the bottom of the hoisting platform, and a hanging pan is installed on the bottom of the connecting frame; a counterweight mechanism is installed between the two mounting plates; there are several pressure bearings perpendicular to the side plates for sliding fit on the two side plates. The edge of the longitudinal section of the pressure rod cooperates with the inner side of the web bar reinforcement of the reinforced concrete prefabricated plate. When the reinforced concrete prefabricated plate is transported by the invention, the reinforced concrete prefabricated plate will not slide, the transport stability is improved, and the operation is convenient and the transport efficiency is high.

Owner:日照汇川建材有限公司

Carrier roller

InactiveCN103381955AExtended service lifePrevent sliding offsetRollersEngineeringMechanical engineering

Owner:南京金陵节能炉业科技有限公司

Electric power distribution equipment

InactiveCN108258596ASimple structureEasy to operateSubstation/switching arrangement cooling/ventilationAutomatic controlElectric power distribution

The invention discloses electric power distribution equipment. The electric power distribution equipment comprises a power distribution cabinet body; a heat dispelling apparatus is fixedly arranged onthe top end plane of the power distribution cabinet body; a supporting bottom plate is arranged on the bottom end plane of the power distribution cabinet body; four foot pads are mounted on the bottom end plane of the power distribution cabinet body; an accommodating cavity is formed in the right side end plane of the power distribution cabinet body; a mounting box body is glidingly matched and connected in the accommodating cavity; an input pipe which can extend left and right is arranged in the inner wall body of the power distribution cabinet body on the left side of the accommodating cavity; a bolt port which extends into the accommodating cavity is fixedly formed in the tail end of the right side of the input pipe; an inclined cavity is formed in the bottom end plane of the accommodating cavity; a placement groove is formed in the top end plane of the right side of the mounting box body; and an air inlet hole, which is formed left and right, is arranged in the inner wall body ofthe mounting box body on the left side of the placement groove. By virtue of the electric power distribution equipment, a locking and fixing operation can be automatically controlled and stabilized, and automatic connection control and cooling control operations can be realized.

Owner:佛山市畅意机械租赁有限公司

Packaging substrate and its manufacturing method and semiconductor package and its manufacturing method

ActiveCN104810339BImprove positioning of jointsPrevent sliding offsetSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:SILICONWARE PRECISION IND CO LTD

Bidirectional diaphragm pump without distributing valve

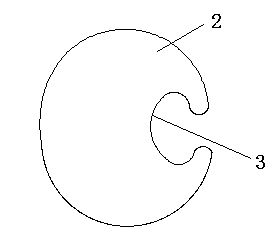

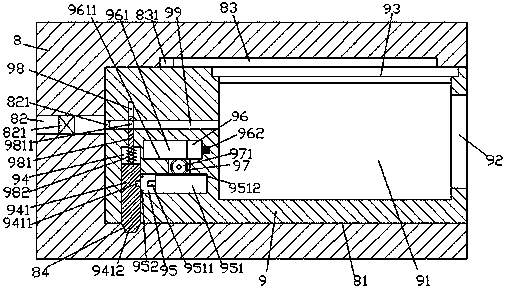

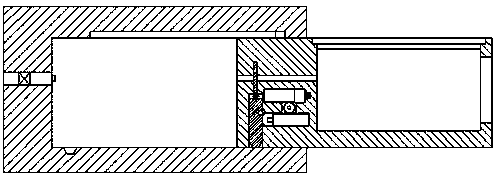

PendingCN113389714APrevent sliding offsetPrevent leakageEngine sealsPositive displacement pump componentsDiaphragm pumpDiaphragm structure

The invention discloses a bidirectional diaphragm pump without a distributing valve. The bidirectional diaphragm pump comprises a shell and a motor which are installed together, wherein two flow channels are formed in the outer wall of the shell, an eccentric shaft driven by the motor and a diaphragm made of flexible wear-resistant materials are arranged in the shell, the eccentric section of the eccentric shaft is sleeved with an extrusion bearing, and the two ends of the diaphragm and the shell are axially positioned and sealed; the radial side of the diaphragm is provided with an anti-skid protrusion connected with the shell, the other side of the diaphragm is provided with a ring sleeve arranged on the extrusion bearing in a sleeving manner, the two flow channels extend to the two sides of the anti-skid protrusion on the inner wall of the shell respectively and are isolated by the ring sleeve to be not communicated all the time, the eccentric side of the ring sleeve makes contact with the inner wall of a pump body, and the other side of the ring sleeve and the inner wall of the pump body form a working cavity; and when the motor drives the eccentric shaft, the extrusion bearing extrudes the ring sleeve to make continuous contact with the inner wall of the pump body in the eccentric movement direction. According to the bidirectional diaphragm pump, a brand new diaphragm structure is adopted, and a one-way flow distributing valve does not need to be arranged, so that two-way suction can be achieved; and a crank-link mechanism is not needed, so that reliability and stability are improved, and the application effect is good.

Owner:湖北天雄科技股份有限公司

Paper box forming machine

InactiveCN112223830AFree from wear and tearPrevent sliding offsetBox making operationsPaper-makingMolding machinePaperboard

The invention discloses a paper box forming machine. The paper box forming machine structurally comprises a forming box, an air conveying pipe, a feeding plate and a discharging port, wherein the airconveying pipe is installed at the top of the forming box, the bottom of the feeding plate is connected to the right wall of the forming box in a welded manner, and the discharging port is embedded inthe upper surface of the left side of the forming box. The paper box forming machine has the advantages that paperboards in the feeding plate fall onto a paperboard conveyer one by one, rotating shafts drive a conveying belt to rotate, then the conveying belt conveys the paperboards, at the moment, anti-slip blocks and anti-slip strips make contact with the bottoms of the paperboards, and thus the situation that the paperboards slip and deviate in the conveying process and paper box forming is affected is avoided; and air pressure in an air pressure cavity is increased when an extruder presses the paperboards, a push plate is pushed to drive a lifting rod to move downwards, pressing plates press the paperboards downwards, air in the air pressure cavity is released after a paper box is formed, then the lifting rod and the push plate rise up, the pressing plates retract inwards under the pull force of tension springs, and thus the situation that the pressing plates abrade or scratch thethe inner wall of the paper box is avoided.

Owner:GUANGZHOU LIANJIANG SOFTWARE DEV LLC

Socket for cathode tube

InactiveCN101447629BPrevent sliding offsetContact state is stableElectric discharge tubesCoupling contact membersElectrical connectionMaterials science

The present invention relates to a socket for a cathode tube. The aim of the invention is to provide a socket for a cathode tube, capable of easily absorbing a shrinking difference generated between the cathode tube and a circuit board, a frame and the like due to a temperature difference caused by turning on and off the cathode tube, and absorbing processing error and mounting error of the socket. The socket of the invention is characterized in that a clamping part for holding the side part of a cathode tube terminal part is connected with a mounting part electrically connected by a circuit board by two ends of a first elastic distortion part and a seond elastic distortion part arranged in a basal rightanglle direction relative to the first elastic distortion part.

Owner:SMK CO LTD

Leather cutting device for leather bag processing

InactiveCN113957181AEffective flatteningPrevent warping and deformationLeather clicking/perforating/clickingSupport planeManufacturing engineering

The invention belongs to the technical field of leather, and discloses a leather cutting device for leather bag processing. The leather cutting device comprises a workbench, a cutting mechanism and a flattening mechanism; the top of the workbench is provided with a support frame; the cutting mechanism comprises a linear guide rail, a lifting assembly installed on the linear guide rail, a fixing plate and a cutter connected to the fixing plate, the lifting assembly is installed on the support frame, and the fixing plate is connected to the lifting assembly; and the flattening mechanism comprises grooves symmetrically formed in the two sides of the interior of the support frame, lead screws rotationally installed in the grooves and movable sleeves arranged on the lead screws in a sleeving mode. According to the leather cutting device for leather bag processing, through cooperation of the grooves, the movable plates, a fixed frame, a pressing roller and other structures, the fixed frame can drive the pressing roller to stably move, so that the pressing roller presses leather to roll back and forth, the leather can be effectively flattened, the leather is prevented from tilting and deforming, the accuracy of the cutting position is greatly improved, operation is easy and convenient, and the using effect is extremely good.

Owner:YANGZHOU POLYTECHNIC INST

Improved electric power distribution equipment

InactiveCN108233200ASimple structureEasy to operateSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsAutomatic controlElectric power distribution

The invention discloses improved electric power distribution equipment. The improved electric power distribution equipment comprises a power distribution cabinet body, wherein a heat dispelling deviceis fixedly arranged on the end face of the top part of the power distribution cabinet body, a support bottom plate is arranged on the end face of the bottom part of the power distribution cabinet body, four foot pads are installed on the end face of the bottom part of the support bottom plate, an accommodating cavity is arranged in the end face of the right side of the power distribution cabinetbody, an installation box body is connected to the accommodating cavity by means of sliding matching, an input pipe extending left and right is arranged in the inner wall body of the power distribution cabinet body on the left side of the accommodating cavity, a pin clamp extending into the accommodating cavity is fixedly arranged at the tail end of the right side of the input pipe, an inclined cavity is arranged on the end face of the bottom part of the accommodating cavity, a placement groove is formed in the end face of the top on the right side of the installation box body, and air inlet holes are formed left and right in the inner wall body in the installation box body on the left side of the placement groove. The improved electric power distribution equipment automatically controls the stabilizing and locking work and automatically controls the connection work as well as temperature reduction control work.

Owner:广州猎狗信息咨询有限公司

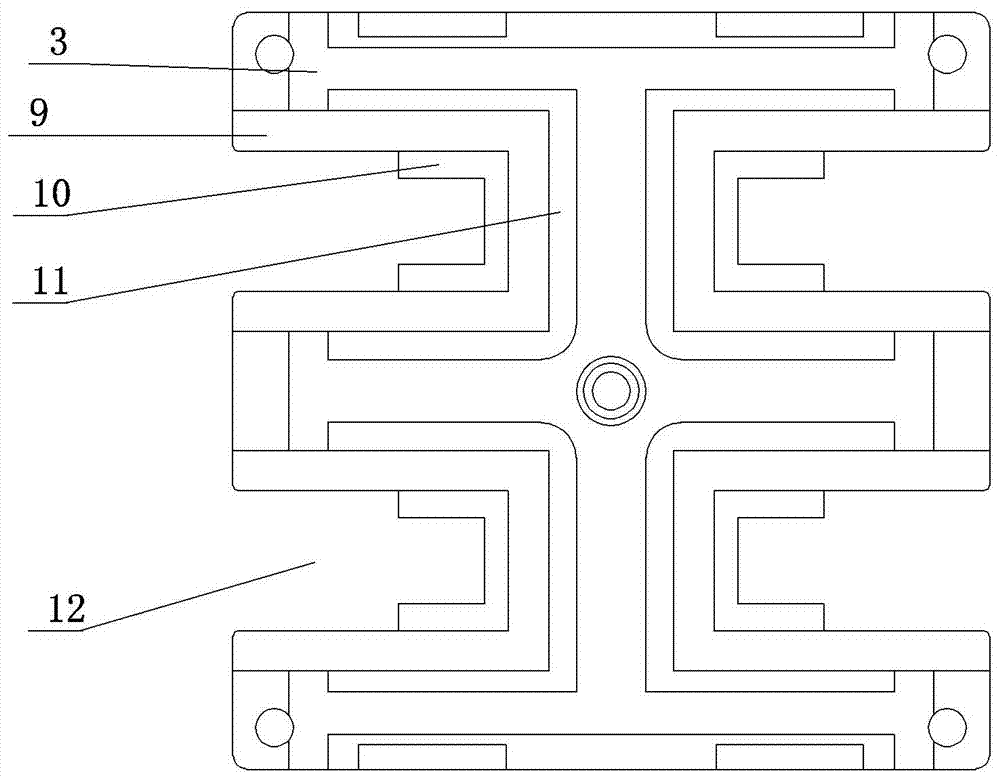

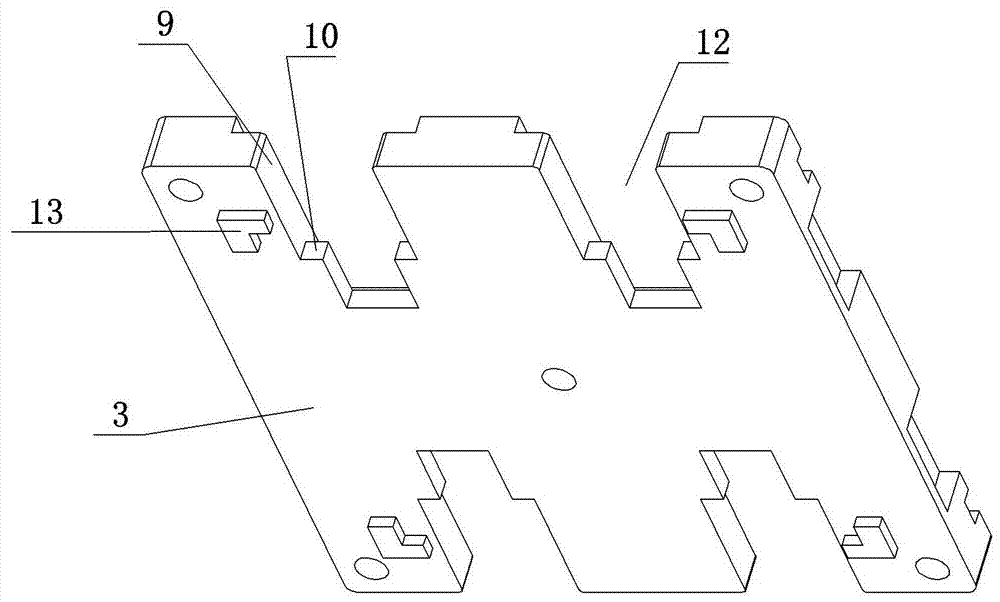

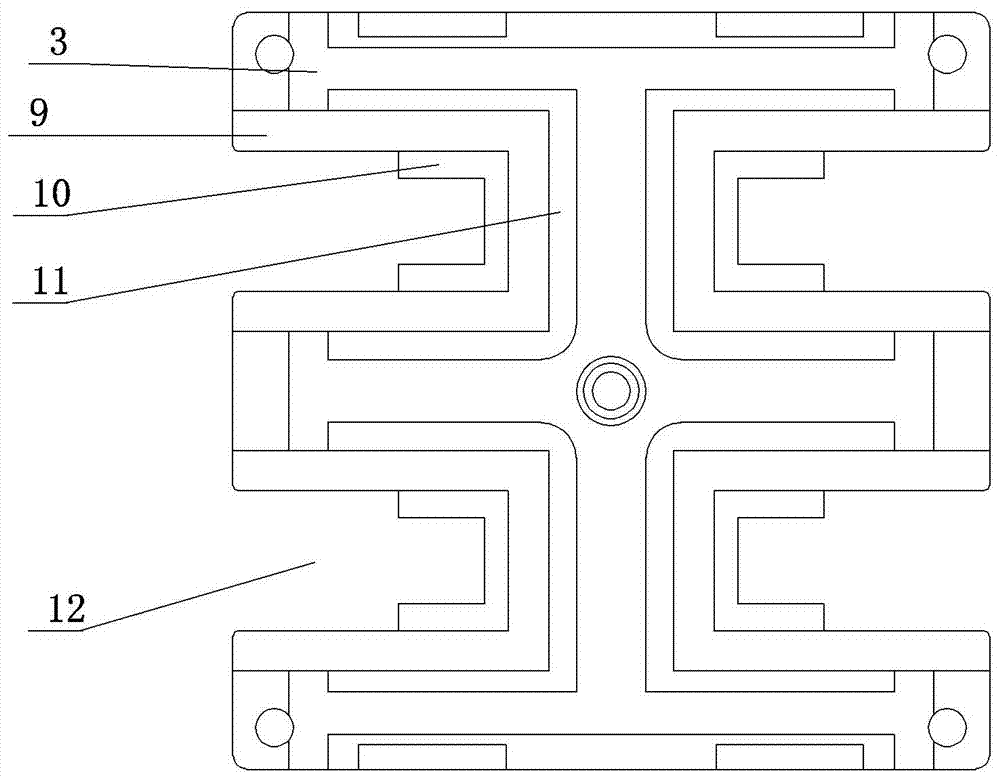

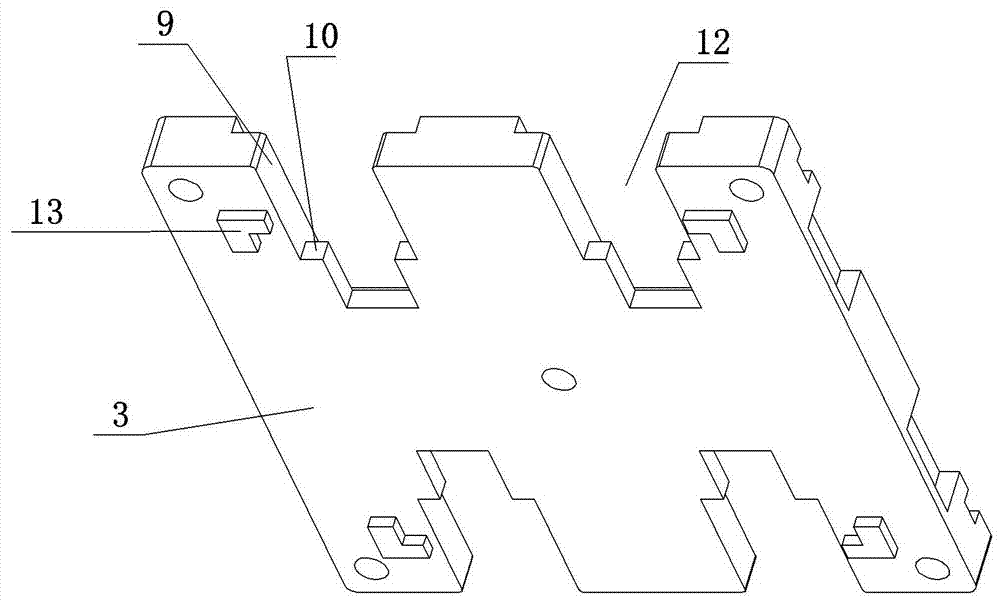

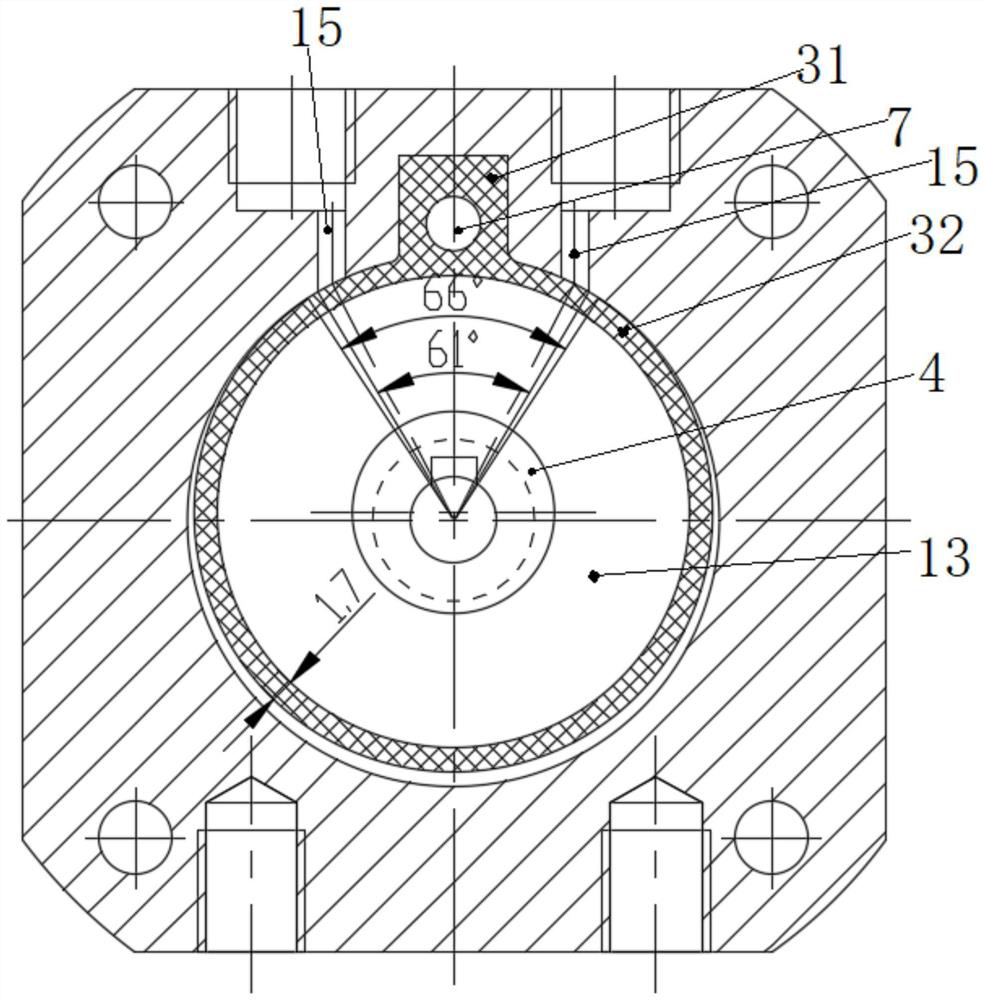

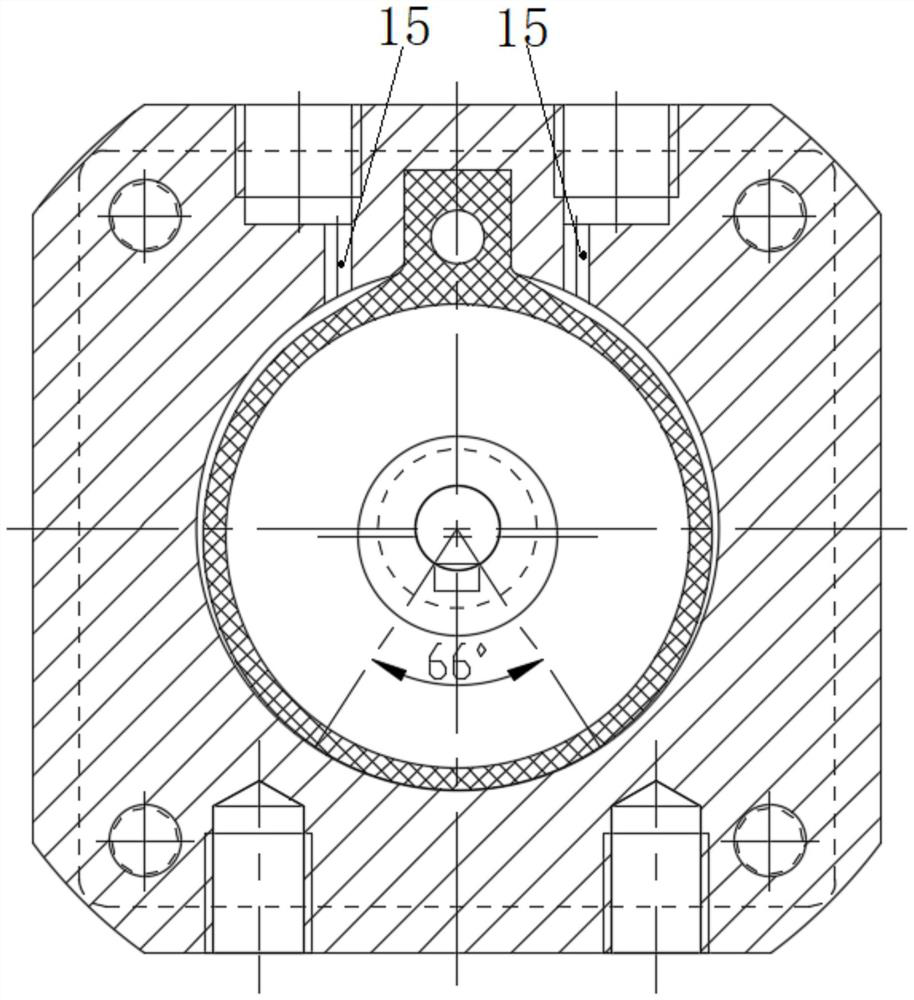

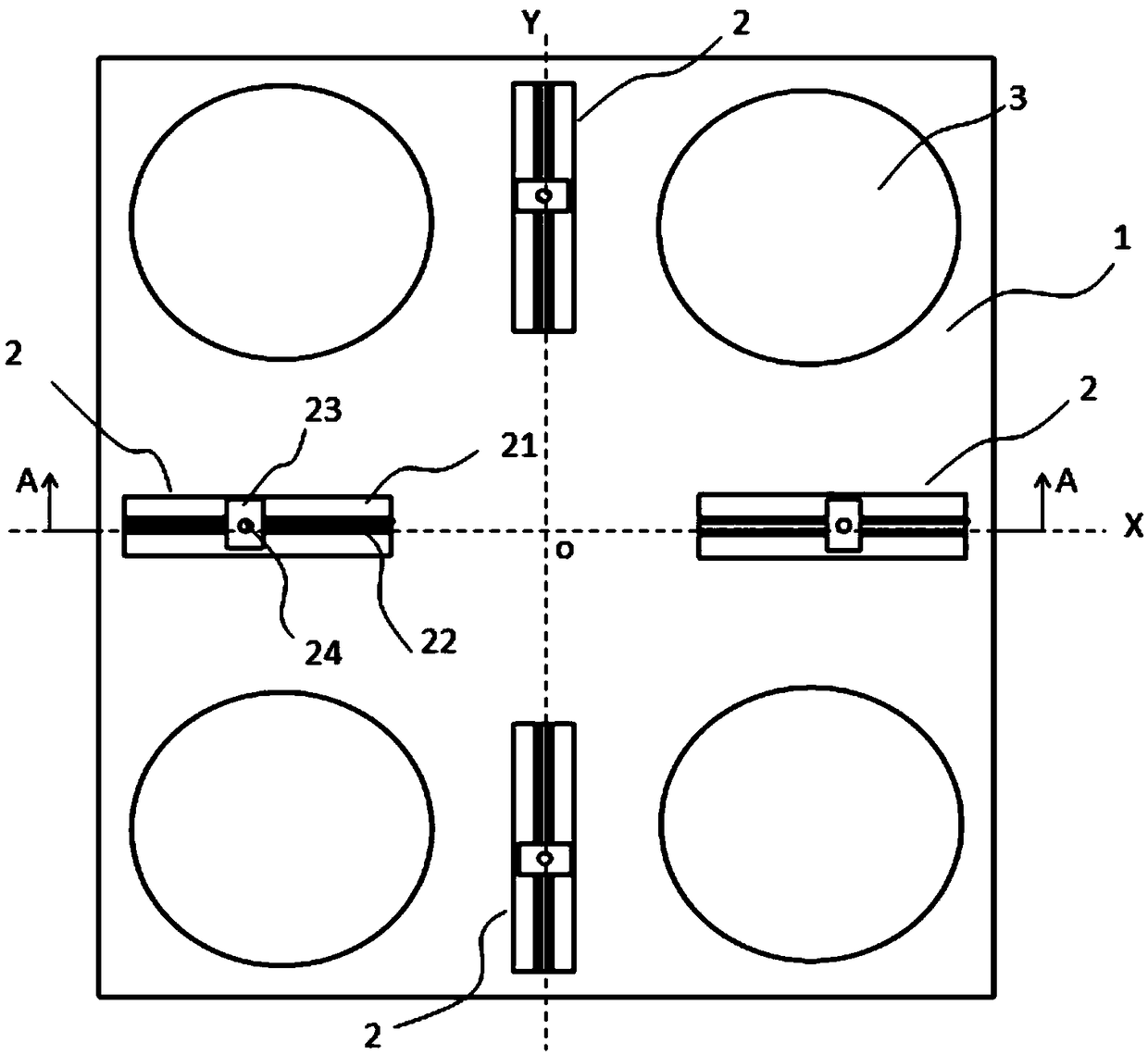

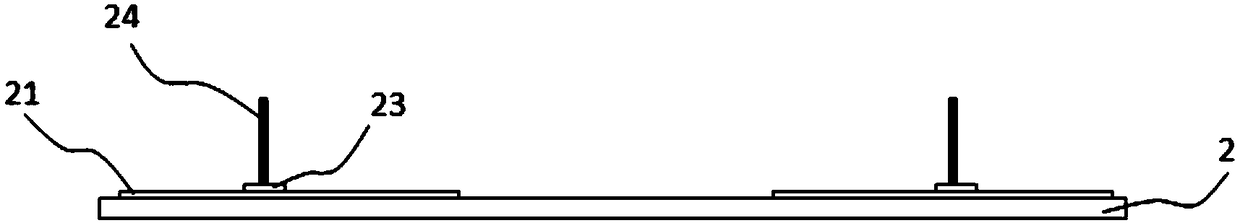

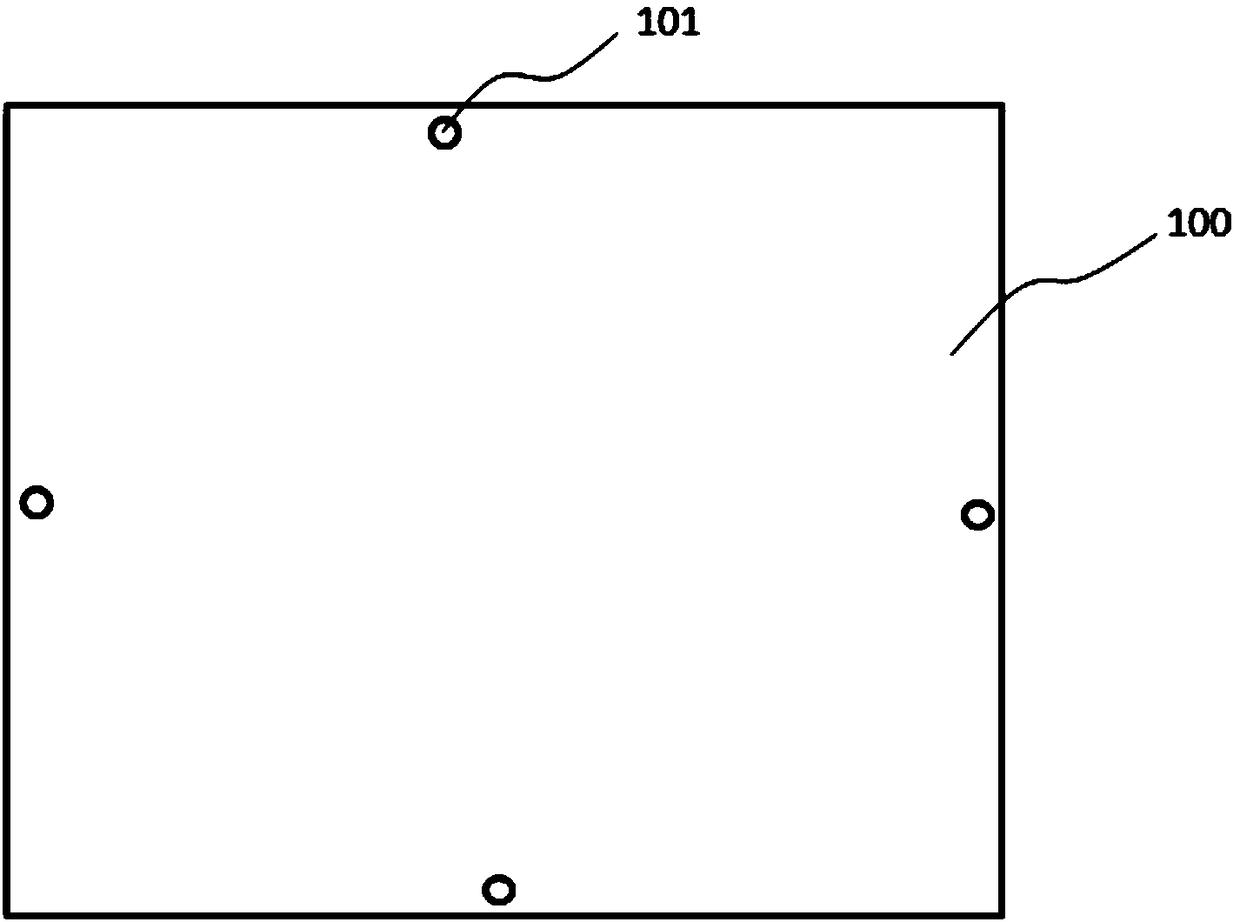

PCB board riveting anti-offset jig

PendingCN108513459APrevent sliding offsetGuaranteed riveting effectMultilayer circuit manufactureInter layerEngineering

The invention discloses a PCB board riveting anti-offset jig, which comprises a rectangular substrate, and four sliding positioning components disposed on the substrate, wherein two of the sliding positioning components are disposed on a long-edge middle line of the substrate and symmetrically distributed on the two sides of the short-edge middle line of the substrate, and the other two sliding positioning components are disposed on the short-edge middle line of the substrate and symmetrically distributed on the two sides of the long-edge middle line of the substrate; each of the sliding positioning components comprises a linear guide rail and a sliding block, which is connected to the linear guide rail and slidable along the linear guide rail; a positioning rod is connected to the slidingblock and perpendicular to the substrate; and the cross-sectional diameter of the positioning rod matches the aperture of the positioning hole on a PCB board to be riveted. The PCB board riveting anti-offset jig in the invention can satisfy riveting pre-positioning of PCB boards of various sizes, thereby preventing the superposed layer of the PCB board from inter-layer sliding offset before riveting, and finally ensuring the riveting effect.

Owner:JIANGSU BOMIN ELECTRONICS

Blood drawing protection device for cardiovascular surgery

InactiveCN111904440AGood effectHigh speedShaking/oscillating/vibrating mixersTransportation and packagingUltraviolet lightsEngineering

The invention relates to the technical field of medical care products, and discloses a blood drawing protection device for cardiovascular surgery. The device comprises a base, a fixing table is fixedly installed on the top face of the base, a mother hook-and-loop fastener is fixedly connected to the top face of the fixing table, and a sterilization box is fixedly installed on the top face of the base. A controller is fixedly installed on the front face of the sterilization box, the side face of the sterilization box is movably sleeved with storage boxes, and an ultraviolet lamp tube is fixedlyinstalled on the top face of the inner surface of the sterilization box. According to the blood drawing protection device for the cardiovascular surgery, the fixing table is fixedly connected to thetop face of the base, the mother hook-and-loop fastener is fixedly bonded to the top face of the fixing table, the sterilization box is fixedly installed on the top face of the base, the storage boxesare arranged in the sterilization box, protection pads bonded with child hook-and-loop fasteners are placed in the two sets of storage boxes, the protection pad bonding and tearing effects are good,the speed is high, replacement is convenient, the blood drawing speed is increased, blood drawing protection is guaranteed, and cross infection is avoided.

Owner:广州联优科技有限公司

ESD placement rack for optoelectronic product manufacturing

InactiveCN112497179AAvoid damageTo achieve the effect of closed placementWork tools storageStructural engineeringManufacturing engineering

Owner:滁州安飞信电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com