Electric welding machine equipment

A technology for electric welding machines and equipment, which is applied in the direction of arc welding equipment, welding equipment, metal processing equipment, etc., which can solve the problems of inconvenient maintenance, easy heating of electric welding machines, and the inability of heat dissipation equipment to fully achieve the heat dissipation effect of electric welding machines. The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

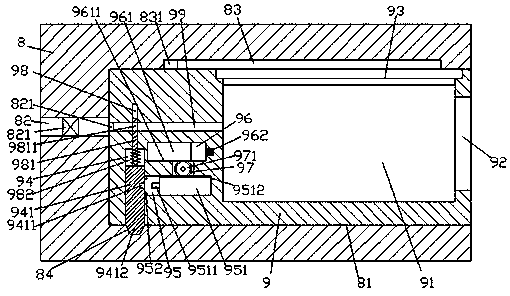

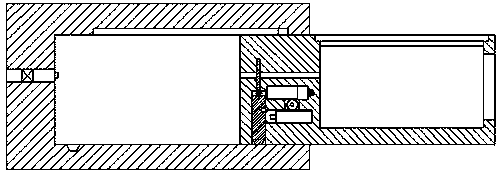

[0015] Such as figure 1 , figure 2 and image 3 As shown, a kind of electric welding machine equipment of the present invention includes a machine cover body 8 fixedly installed on the work surface 7, the bottom of the work surface 7 is provided with a supporting foot column 5, and the top end surface of the machine cover body 8 is fixed with a The heat removal device 6, the right end surface of the cover body 8 is provided with a container 81, the welding body 9 is slidably connected to the container 81, and the inner wall of the cover body 8 on the left side of the container 81 is The body is provided with a gas transmission tube 82 extended from left to right, and the right end of the gas transmission tube 82 is fixed with an insertion port 821 that pushes into the storage tank 81, and the bottom end surface of the storage tank 81 is provided with Slanted hole 84, the top end surface of the right side of the welding body 9 is provided with a placement cavity 91, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com