A kind of logistics sorting and conveying equipment

A conveying equipment and logistics technology, applied in the field of logistics, can solve the problems of package deviation, affecting conveying speed, blocking, etc., to achieve the effect of increasing friction, preventing sliding deviation, and improving logistics conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

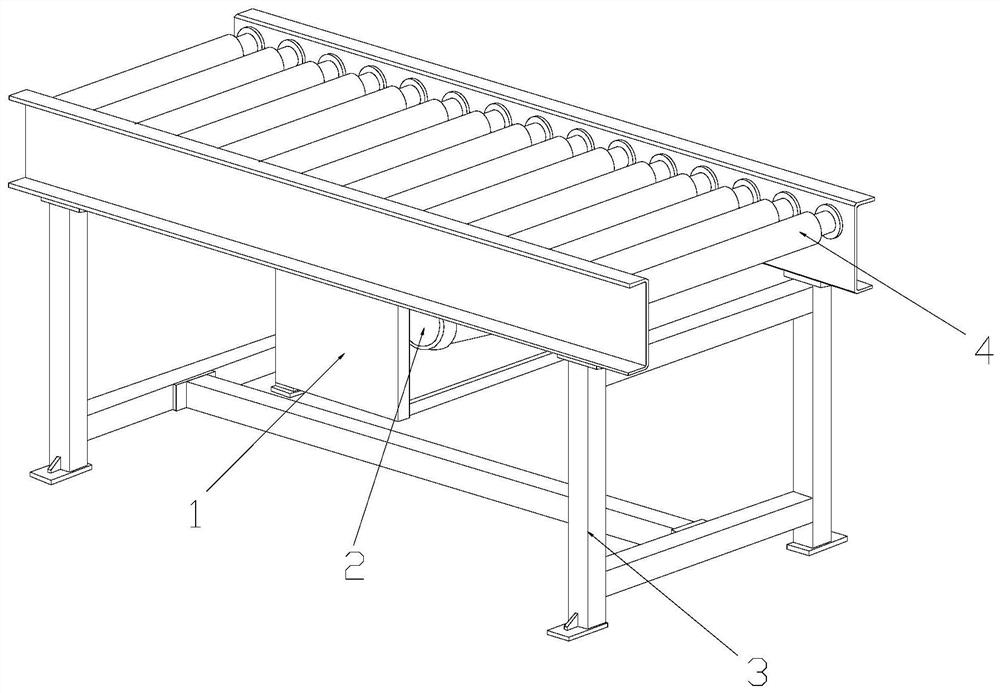

[0028] Example 1: Please refer to Figure 1-Figure 4 , the specific embodiments of the present invention are as follows:

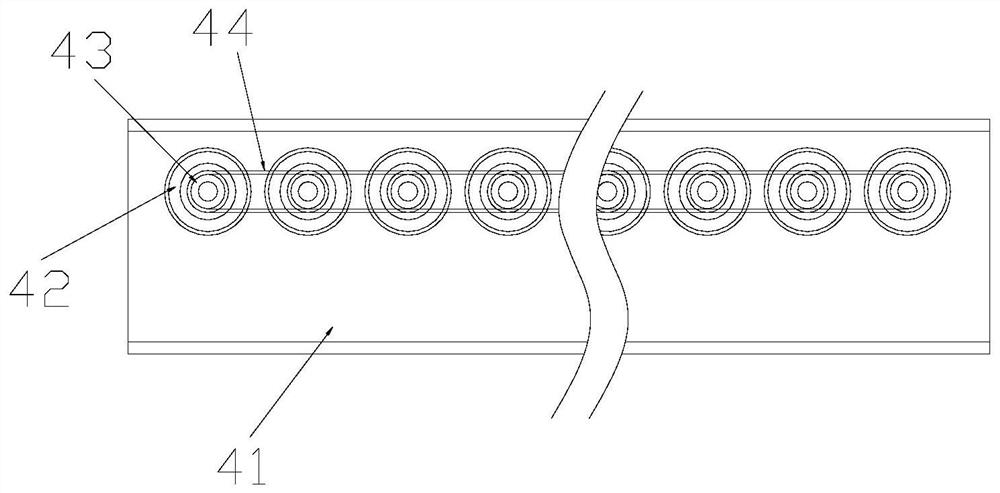

[0029] Its structure includes a chassis 1, a motor 2, a frame 3, and a conveying structure 4. The motor 2 is horizontally installed inside the chassis 1 and fixed with bolts. The frame 3 is fixed on the lower end of the conveying structure 4 and welded together. The chassis 1 is horizontally installed on the inner upper end of the frame 3, and the motor 2 is mechanically connected to the conveying structure 4 through a chain; the conveying structure 4 includes side plates 41, conveying rollers 42, pulleys 43, and belts 44 Horizontally installed between the side plates 41 and connected by hinges, the pulley 43 is installed on the side of the conveying roller 42 and engaged with each other, and the pulleys 43 are connected by a belt 44 .

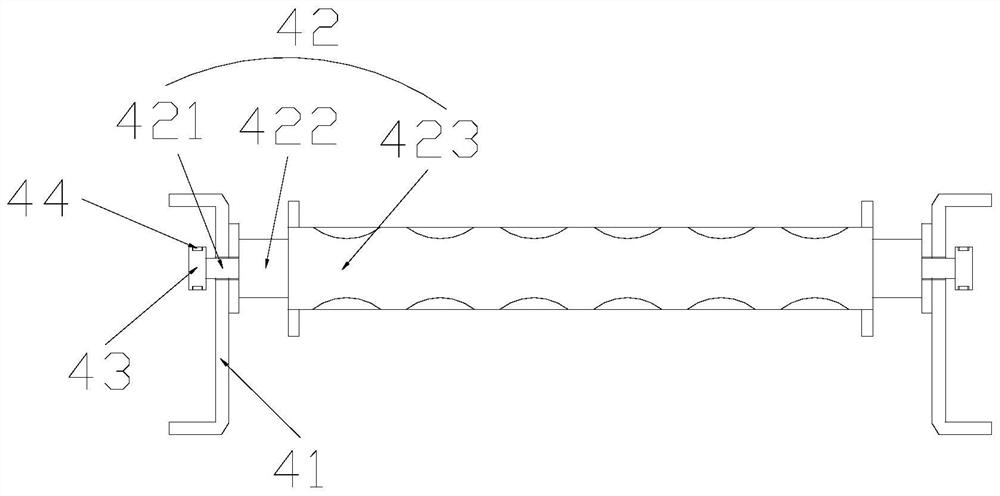

[0030] refer to image 3 The conveying roller 42 includes a rotating shaft 421, a connecting shaft 422, and an adaptin...

Embodiment 2

[0035] Example 2: Please refer to Figure 4-Figure 7 , the specific embodiments of the present invention are as follows:

[0036] The adaptive roller 423 includes a protective plate 23a, a roller body 23b, a bump 23c, and a groove 23d. The protective plate 23a is installed on both sides of the roller body 23b and welded together, and the bump 23c is annularly installed outside the roller body 23b. surface, and is located between the grooves 23d, the grooves 23d are embedded in the inner side of the roller body 23b and are an integral structure, and the protrusions 23c protrude from the outer surface of the roller body 23b, and slowly move from a high place to both sides. The slowing down slope is on the same arc surface as the groove 23d.

[0037] refer to Figure 4 , Image 6 , the inner side of the groove 23d is provided with a movable structure d1, the movable structure d1 is provided with multiple and evenly distributed in the inner side of the groove 23d, the movable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com