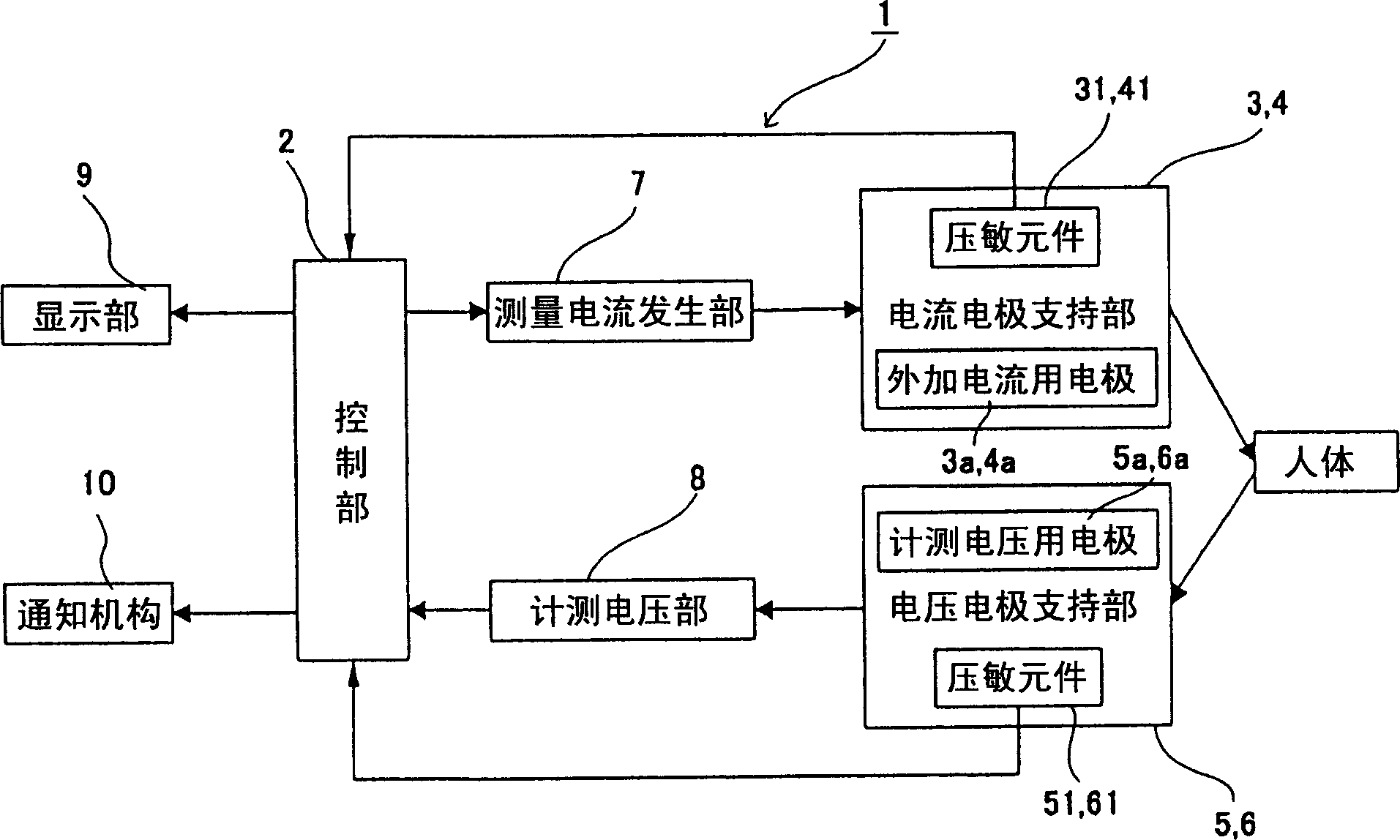

Patents

Literature

82results about How to "Contact state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

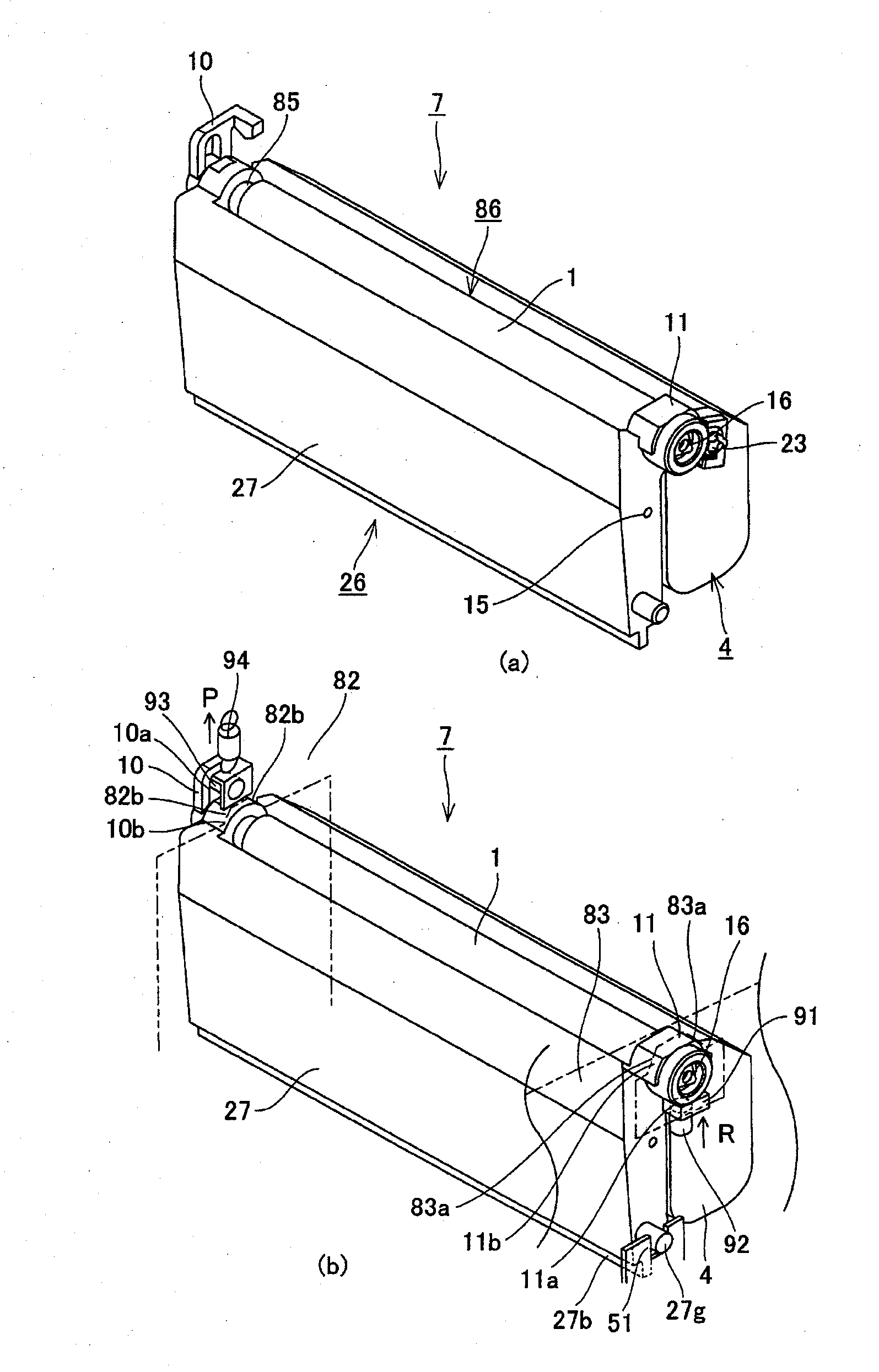

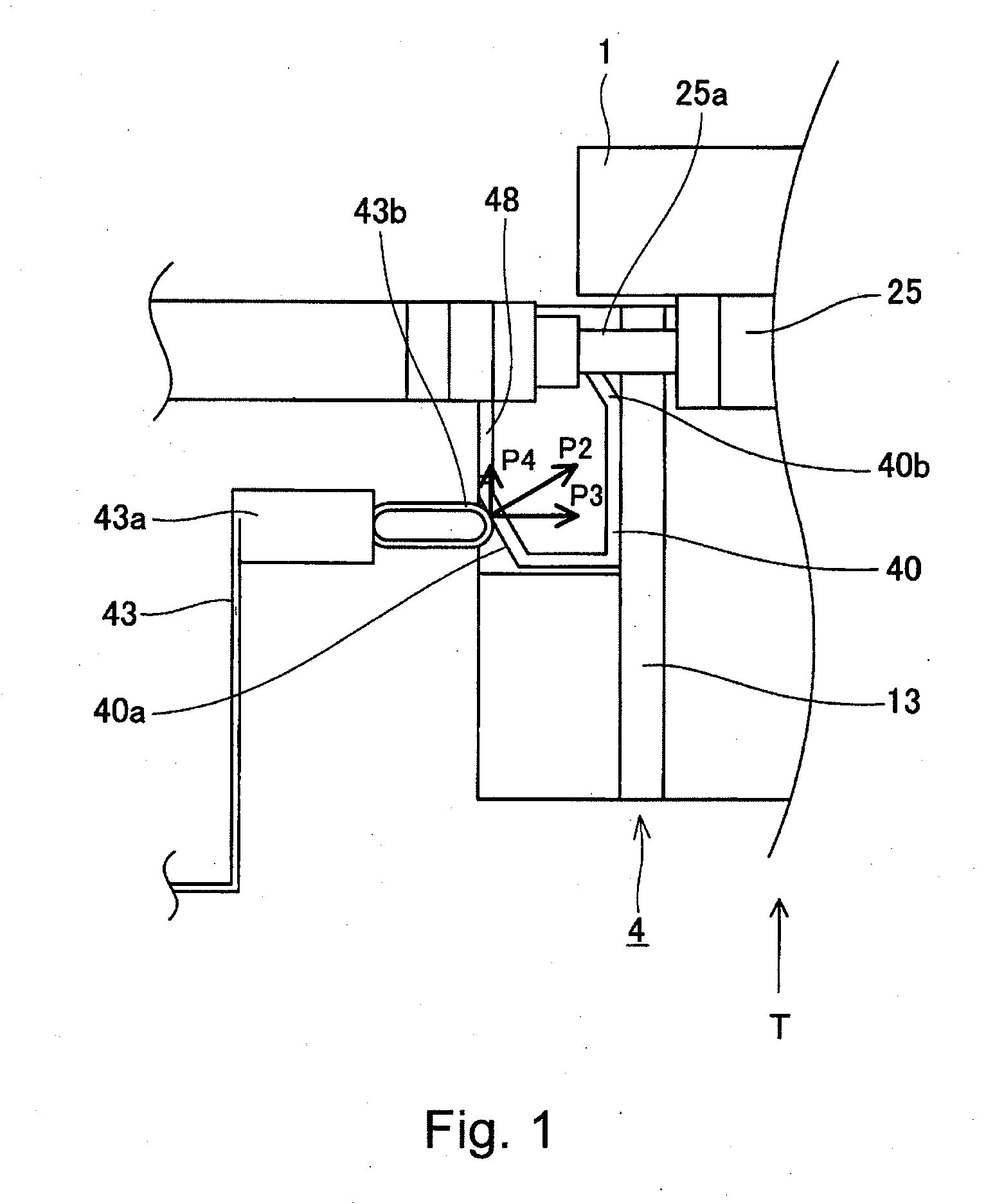

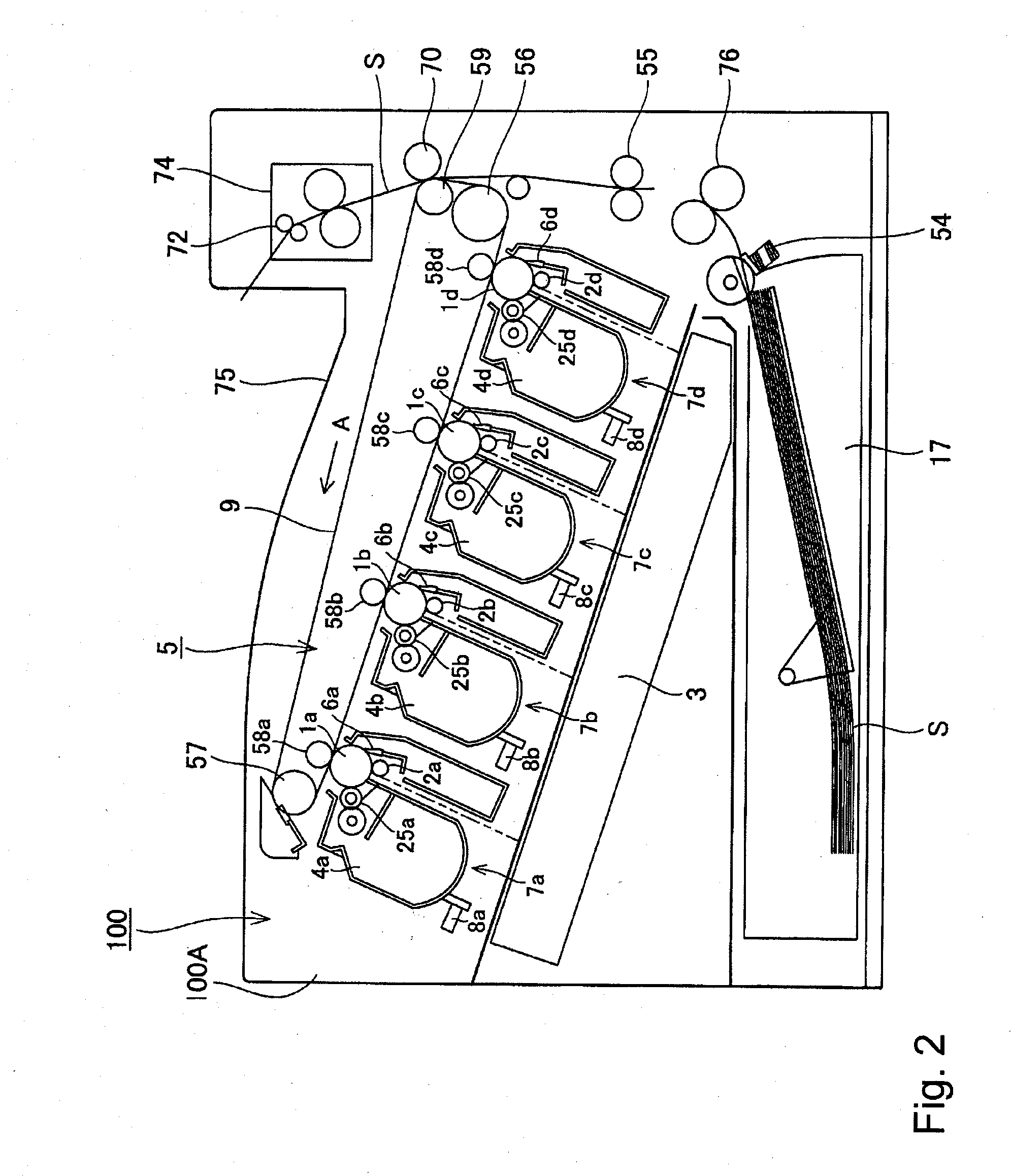

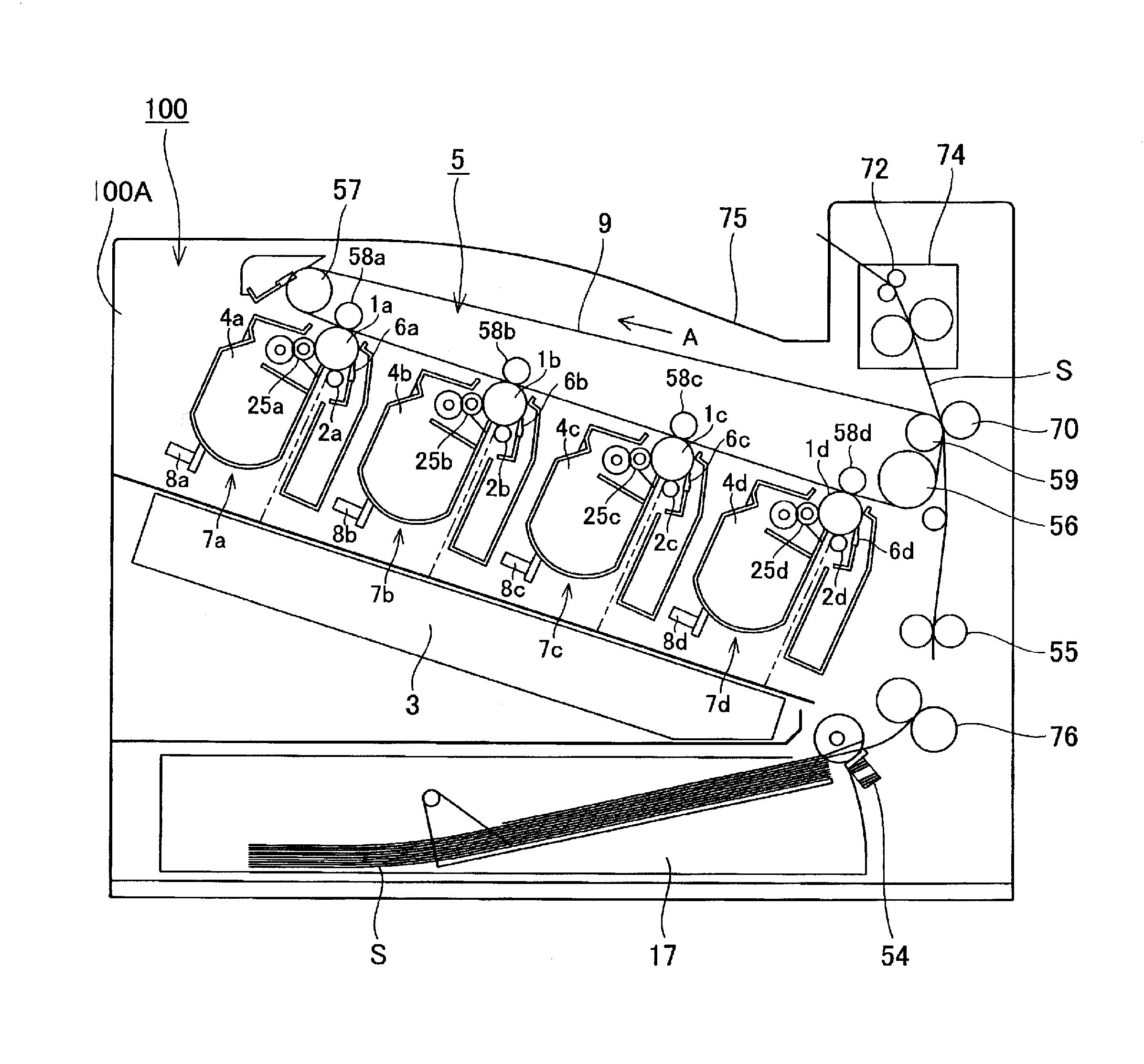

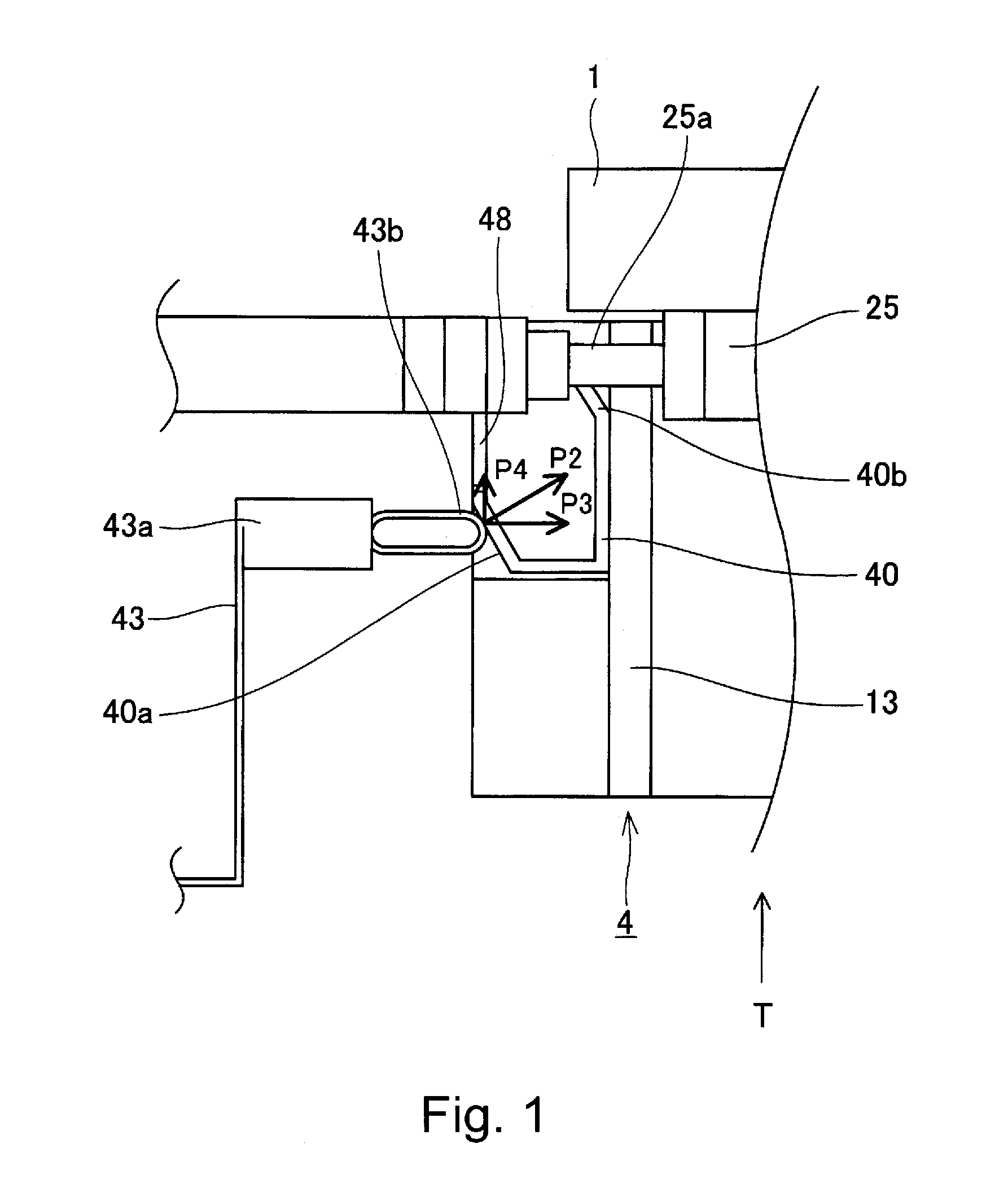

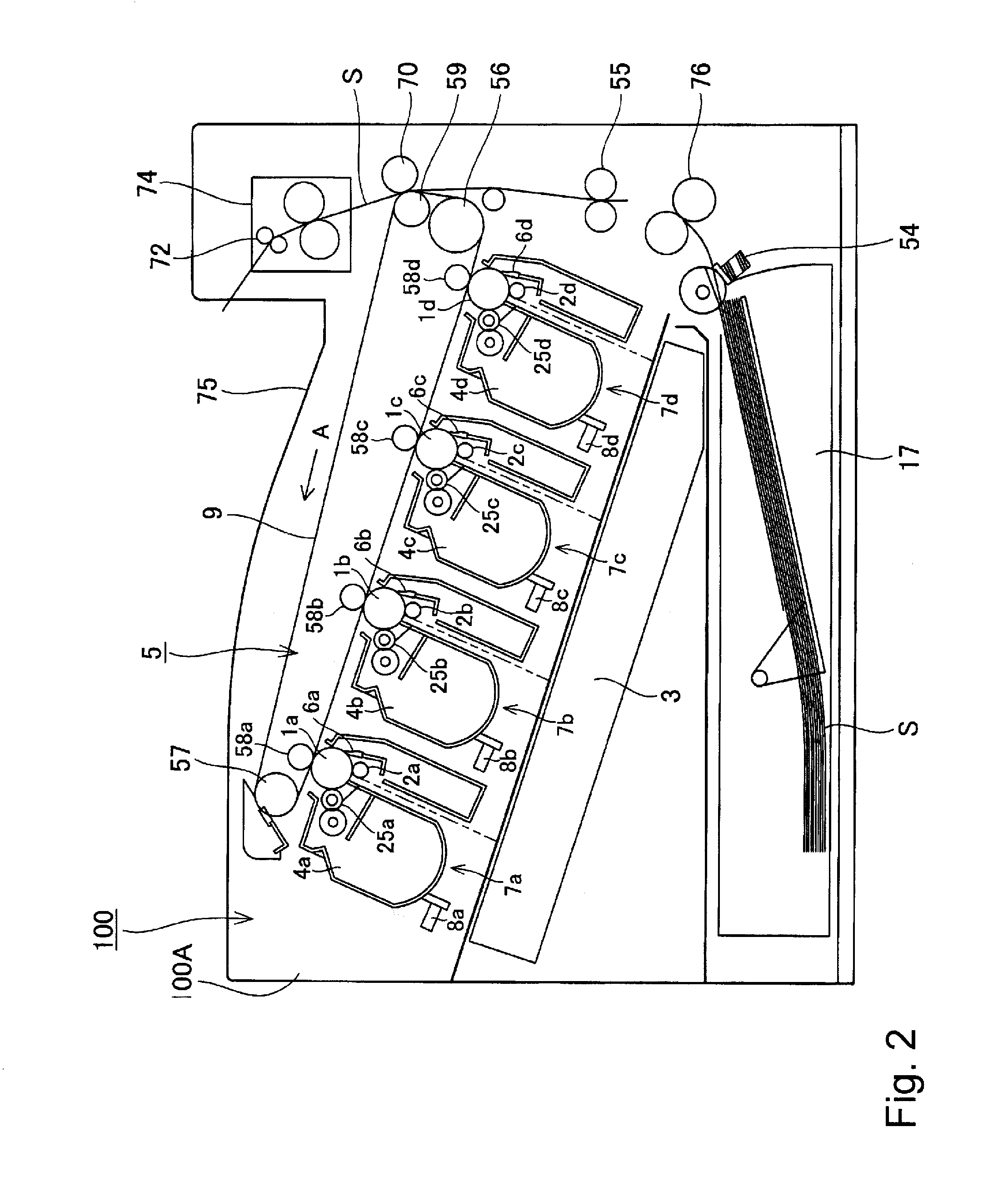

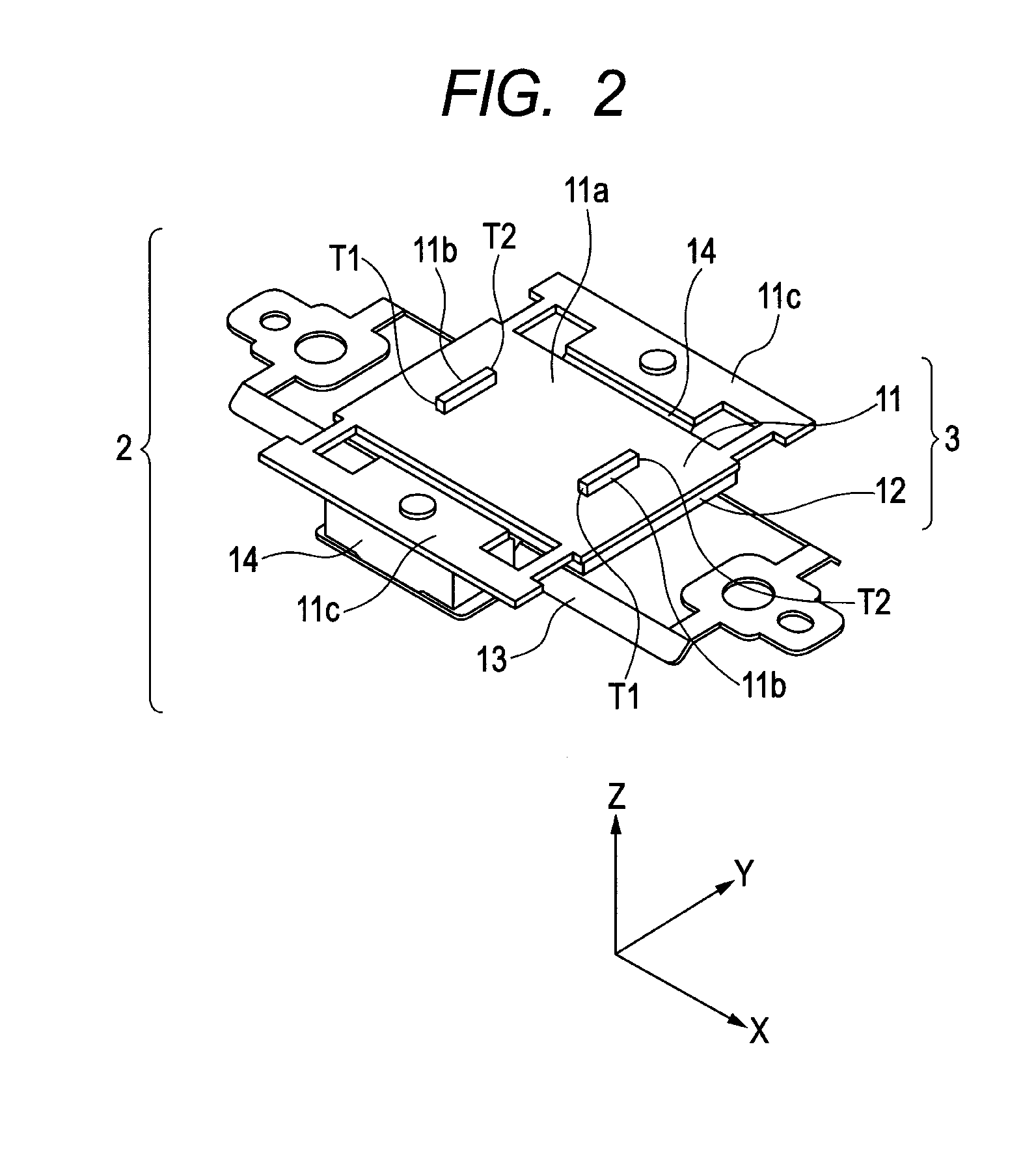

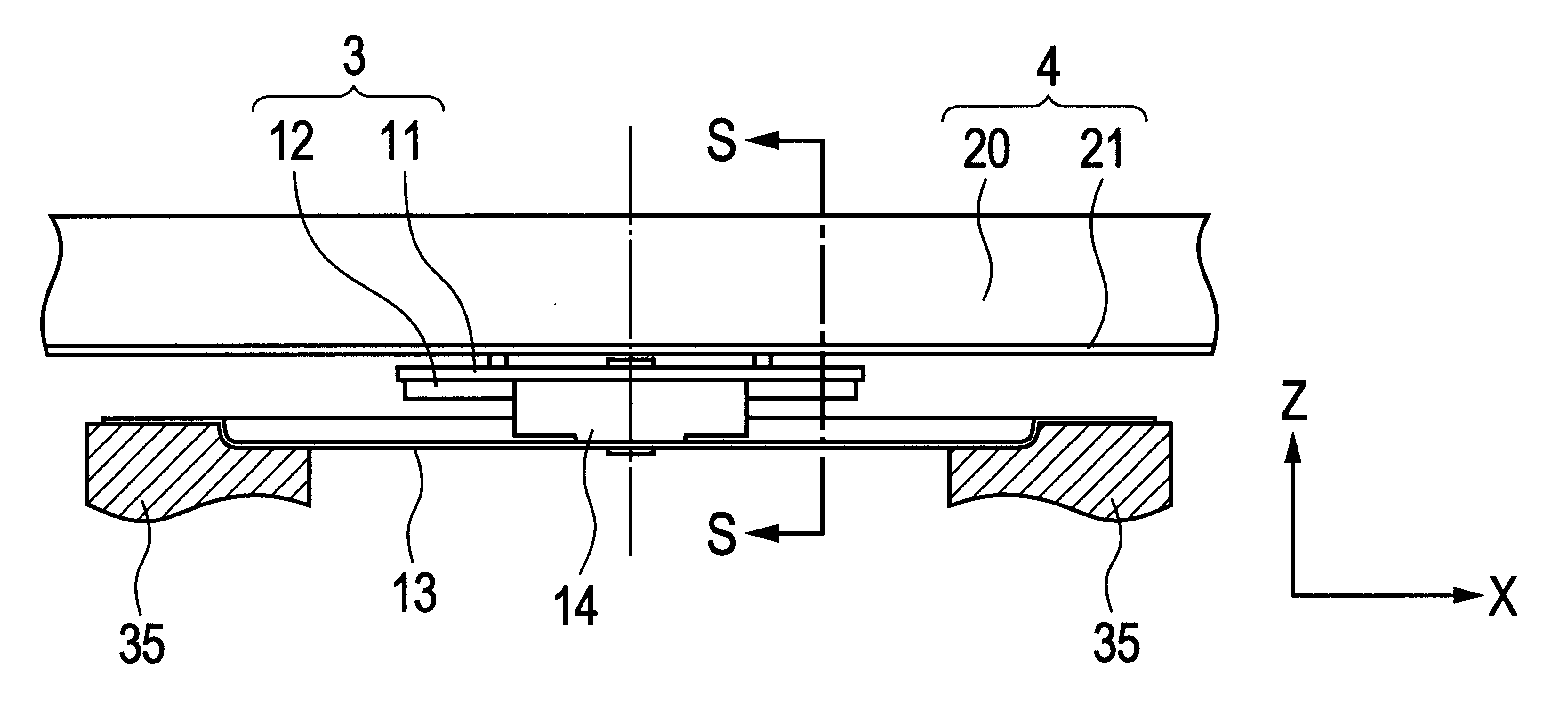

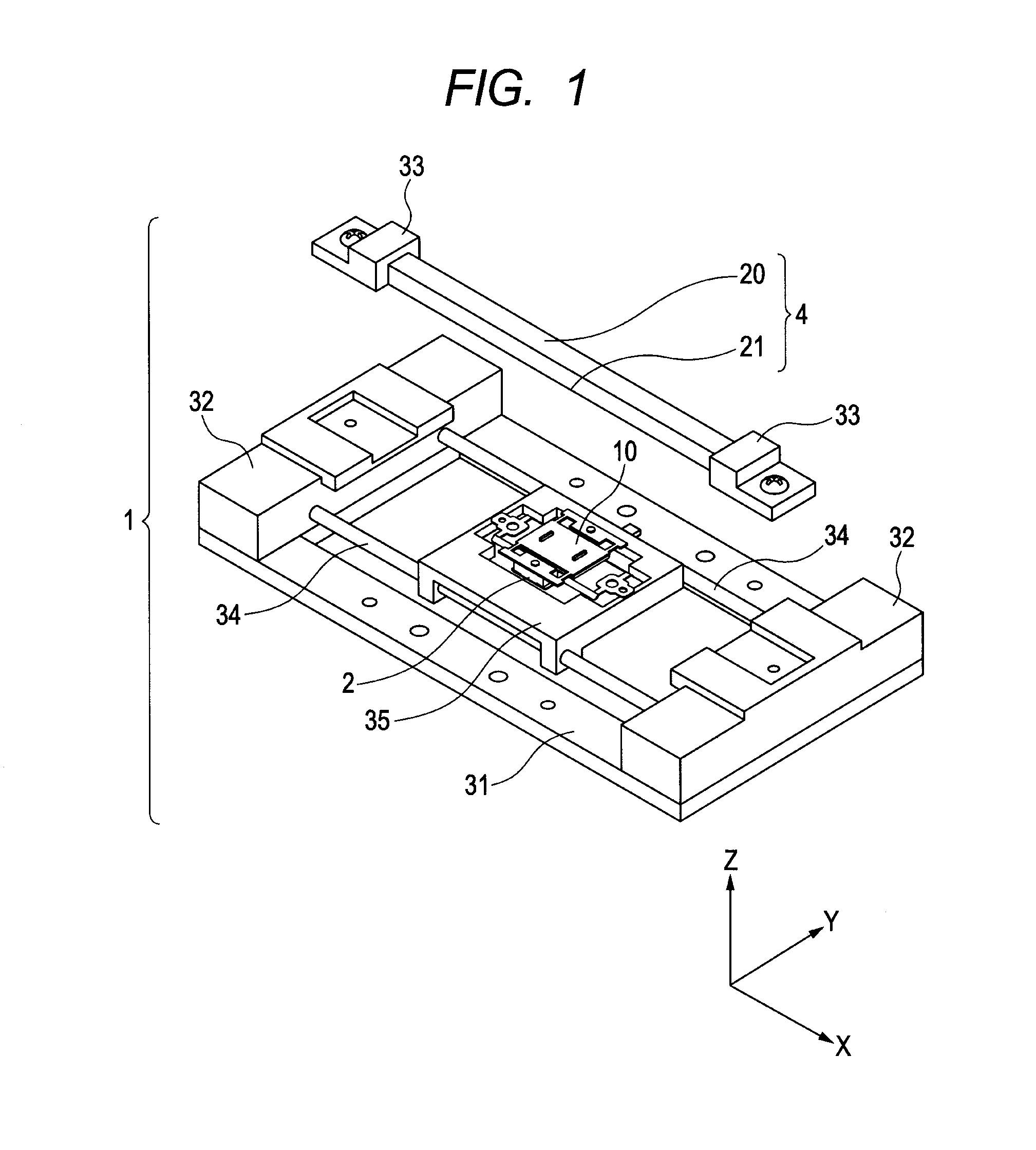

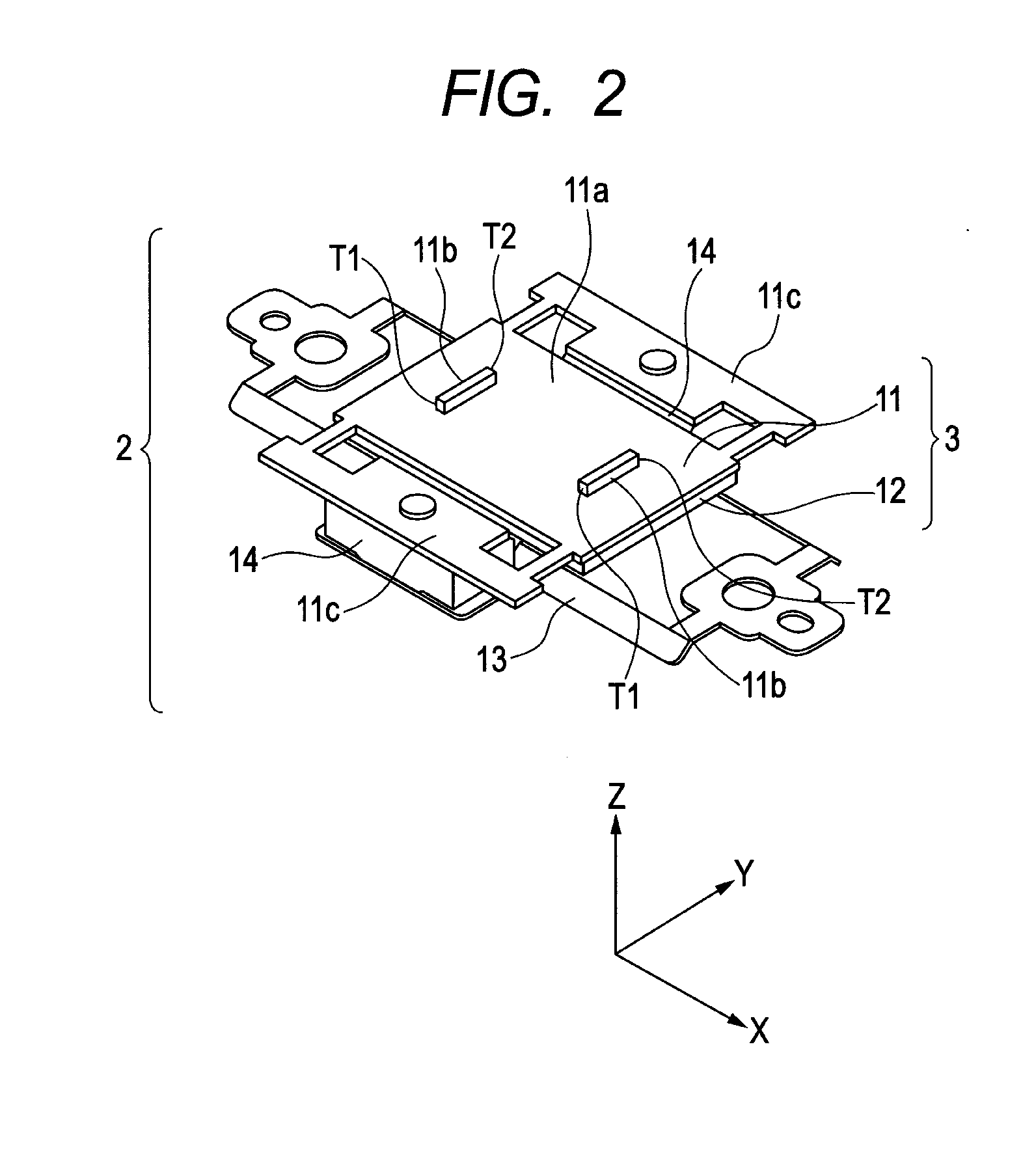

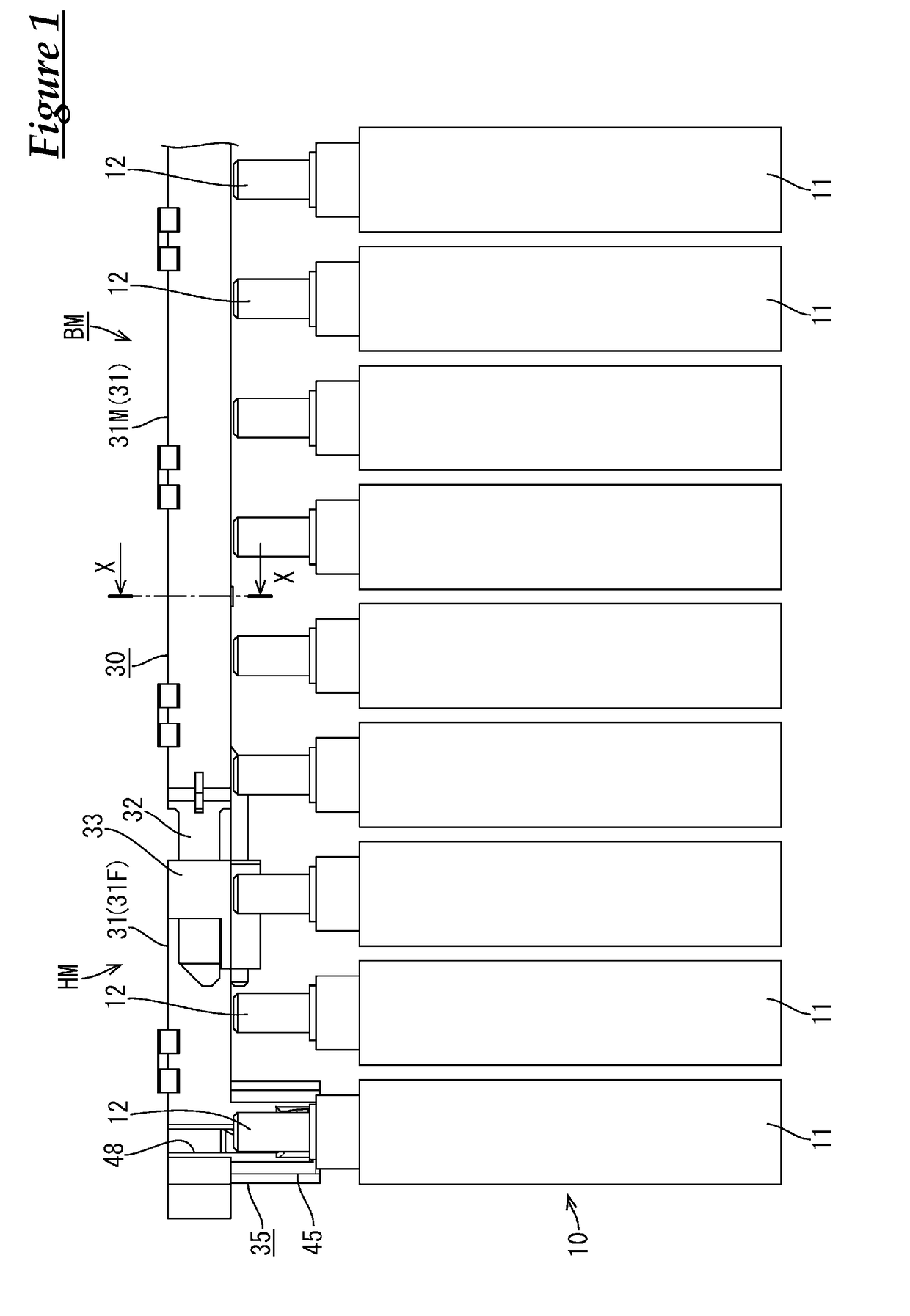

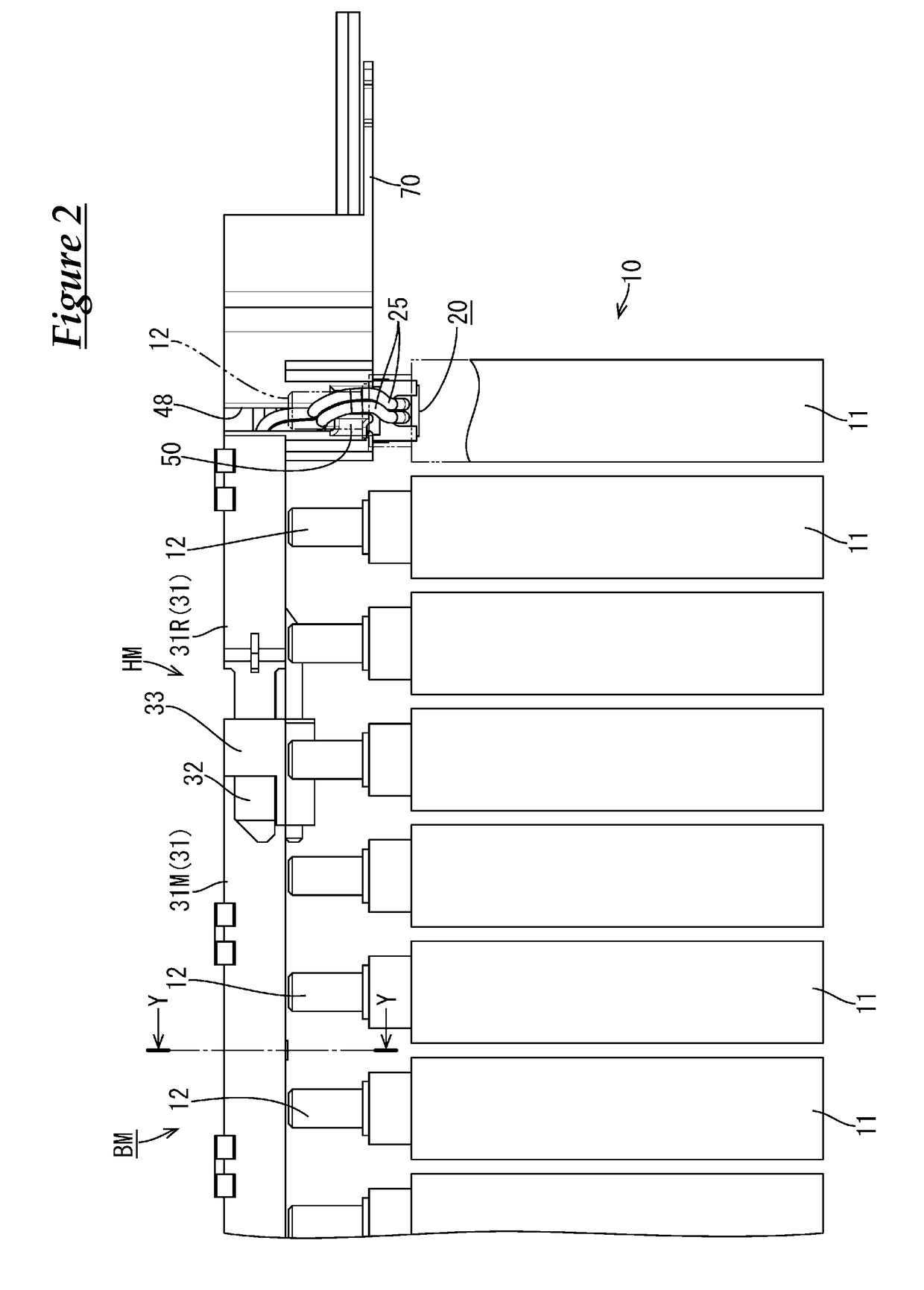

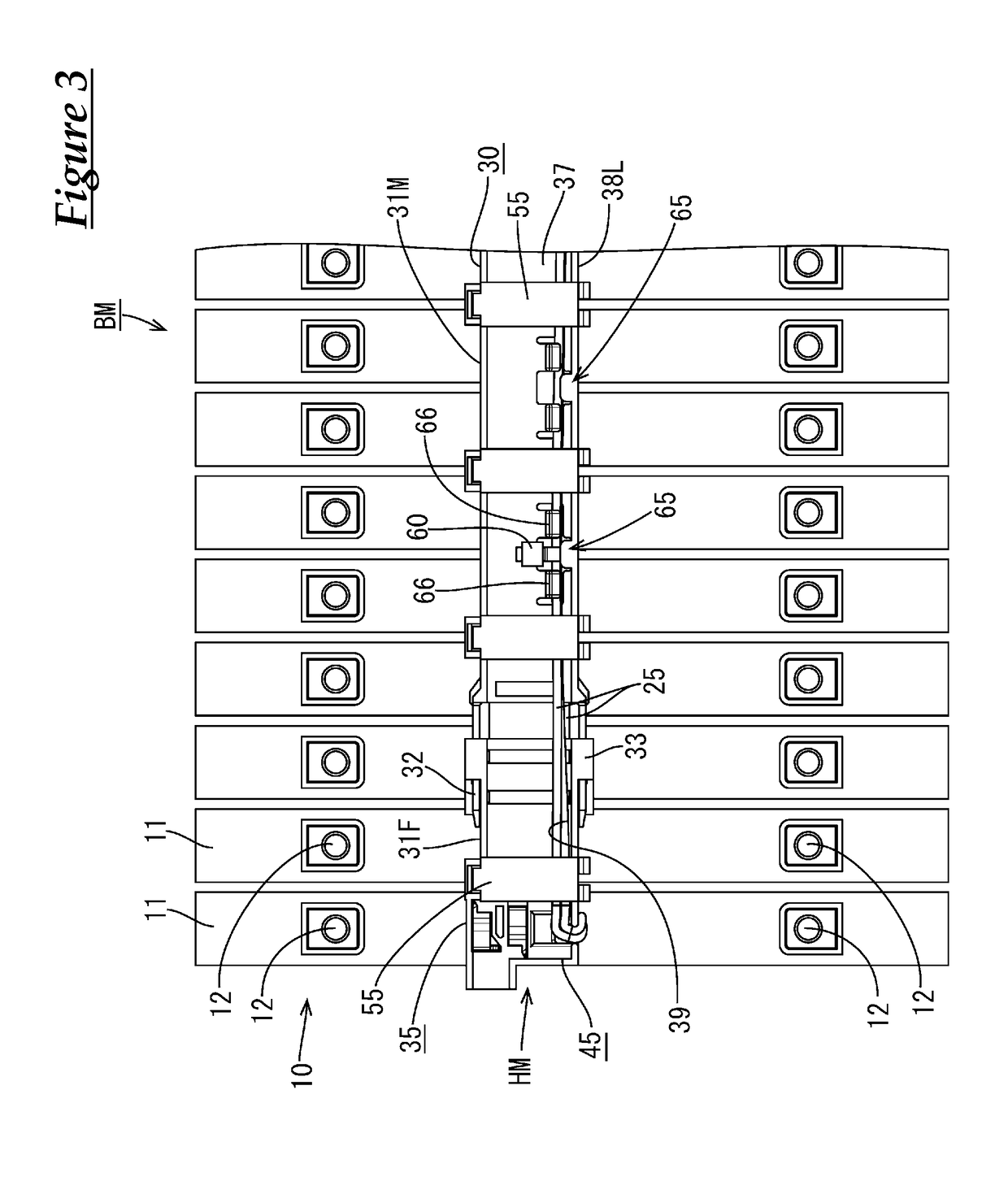

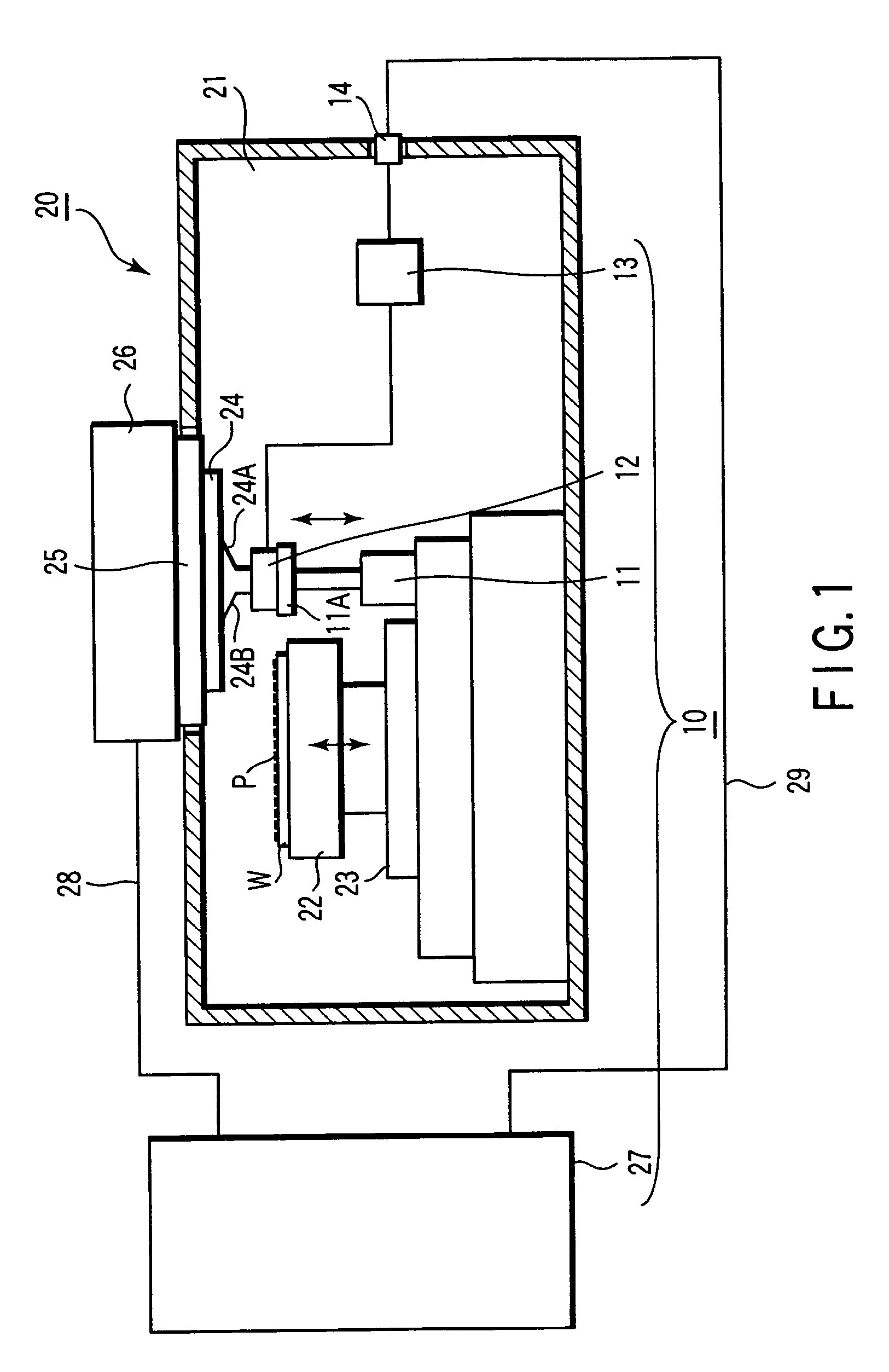

Process cartridge and image forming apparatus

InactiveUS20110280620A1Increase pressureHigh strengthElectrographic process apparatusContact methodContact force

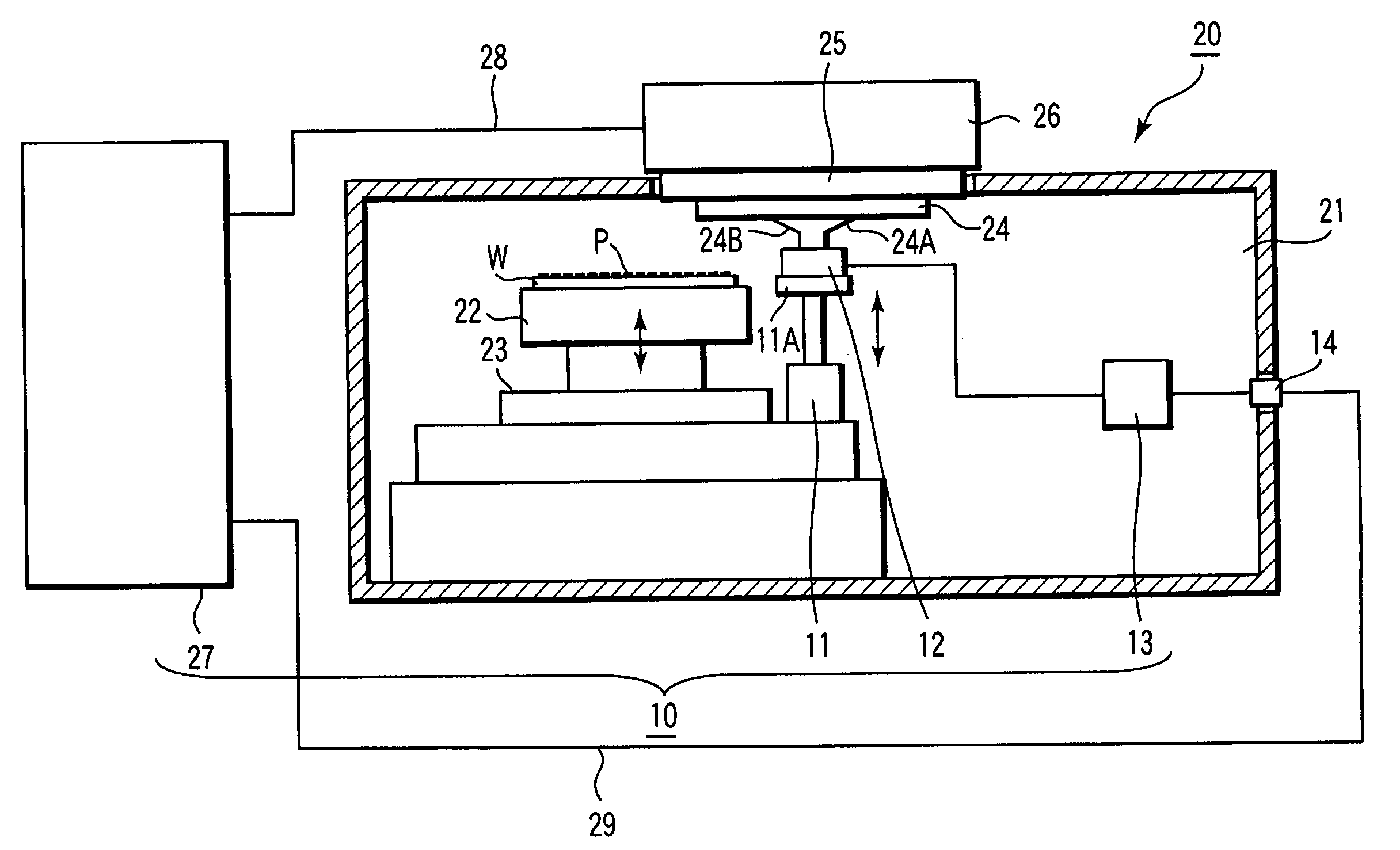

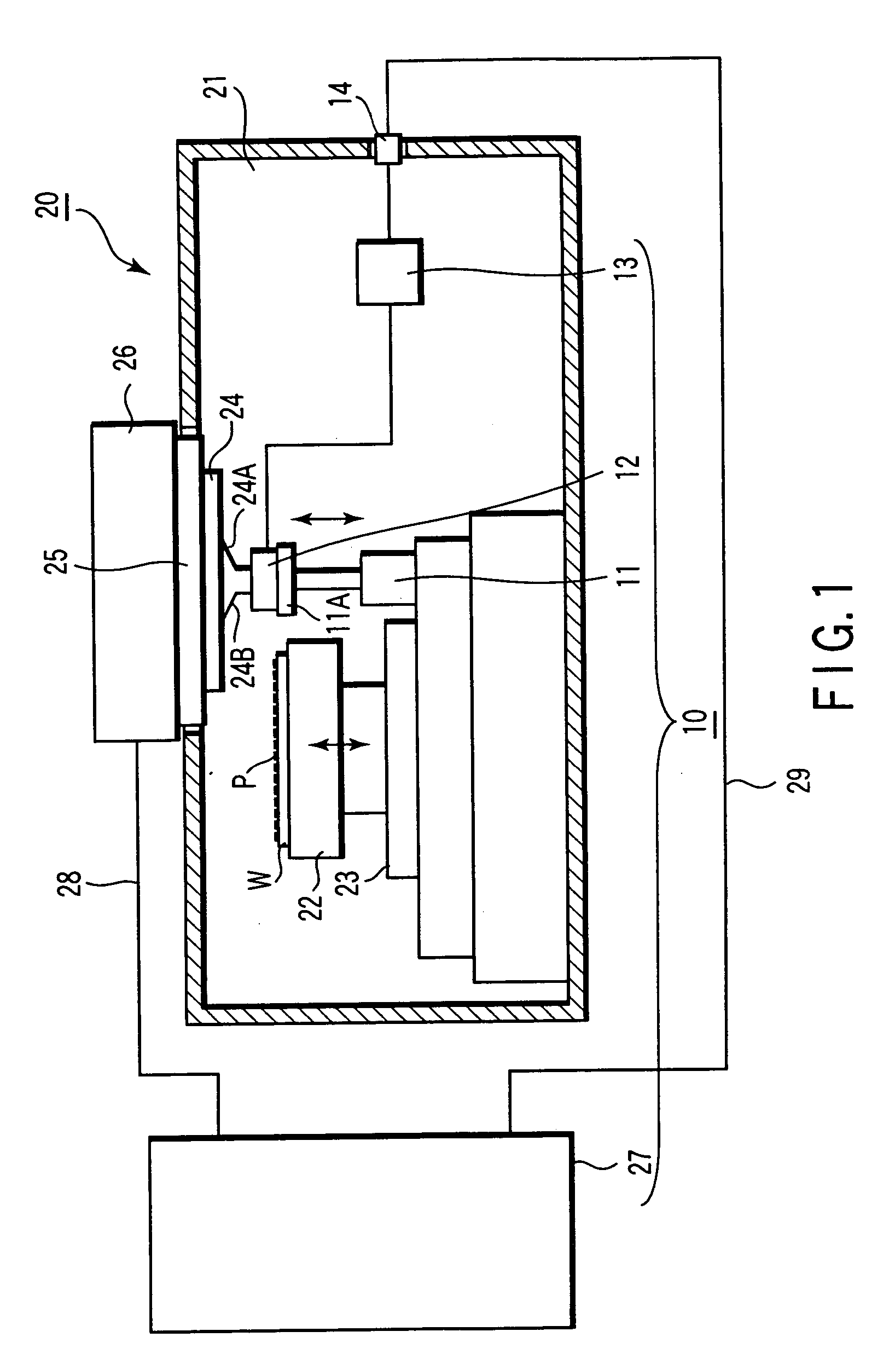

A process cartridge detachably mountable to a main assembly of the apparatus of an image forming apparatus, the process cartridge includes a first unit provided with a photosensitive drum; and a second unit provided with a developer carrying member and connected with the first unit so as to be movable between a contact position in which the developer carrying member is contacted with the drum and a spacing position in which the developer carrying member is spaced from the drum, and the second unit including a first contact portion for contacting to a main assembly electrical contact provided in the main assembly and for receiving a first contact force therefrom when the process cartridge is mounted to the main assembly and the second unit is positioned in the spacing position, and a second contact portion for contacting to the main assembly electrical contact and for receiving a second contact force therefrom to electrically connect with the main assembly electrical contact when the process cartridge is mounted to the main assembly and the second unit is positioned in the contact position; wherein the second contact force has a component oriented in a moving direction of moving the second unit away from the spacing position toward the contact position, and the component is greater than that of the first contact force.

Owner:CANON KK

Process cartridge and image forming apparatus

InactiveUS20140050503A1Increase pressureHigh strengthElectrographic process apparatusImage formationEngineering

Owner:CANON KK

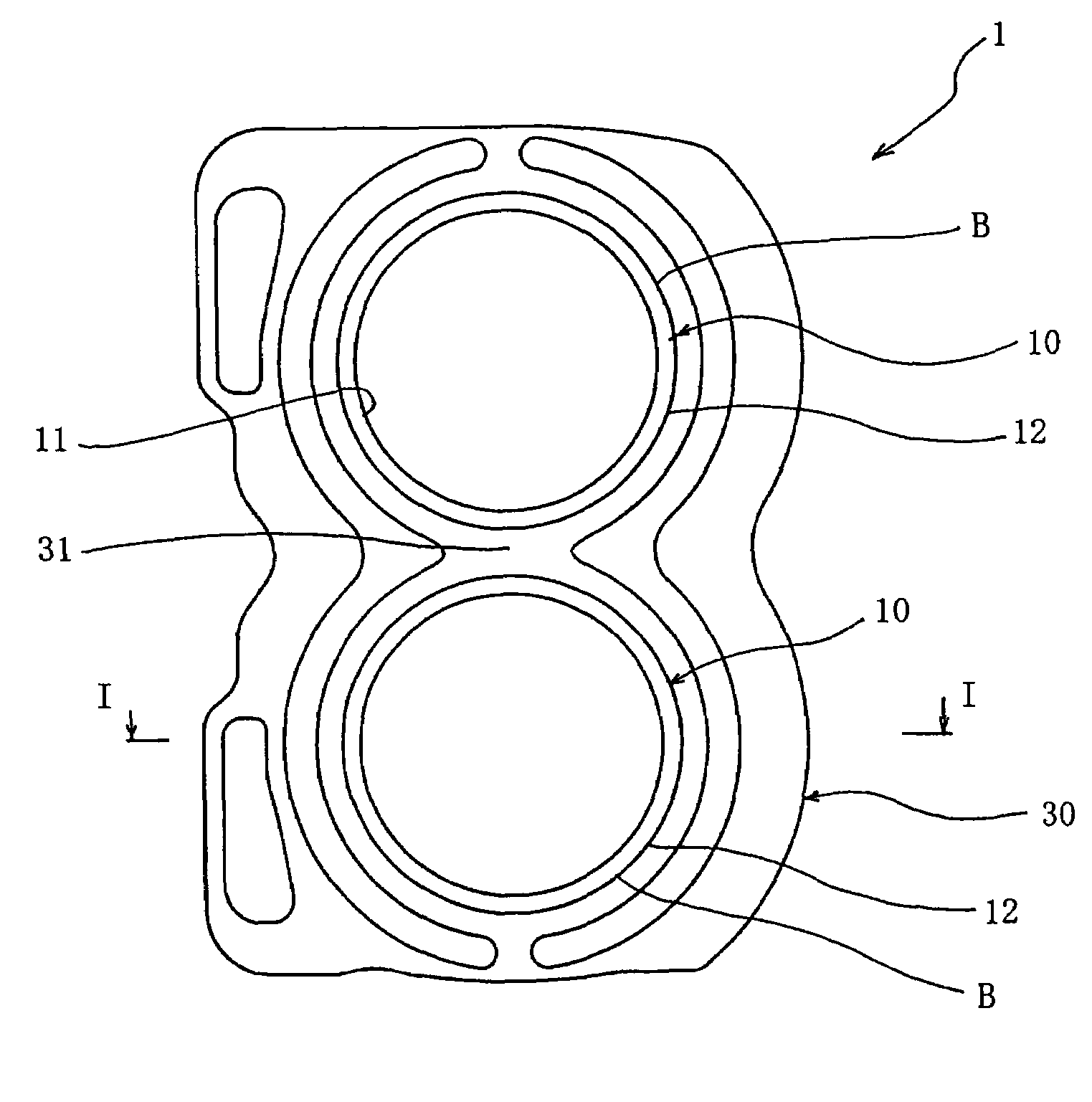

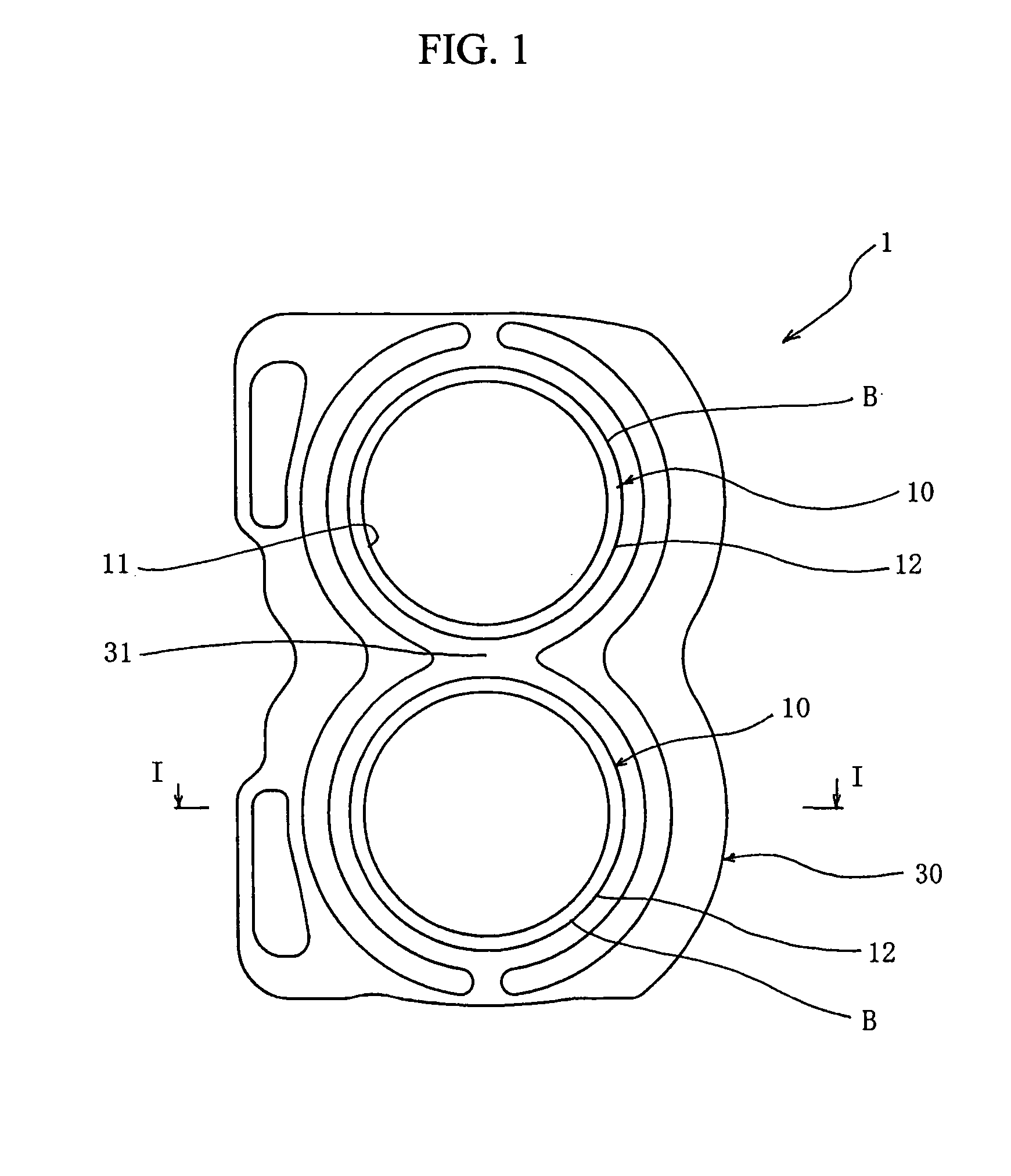

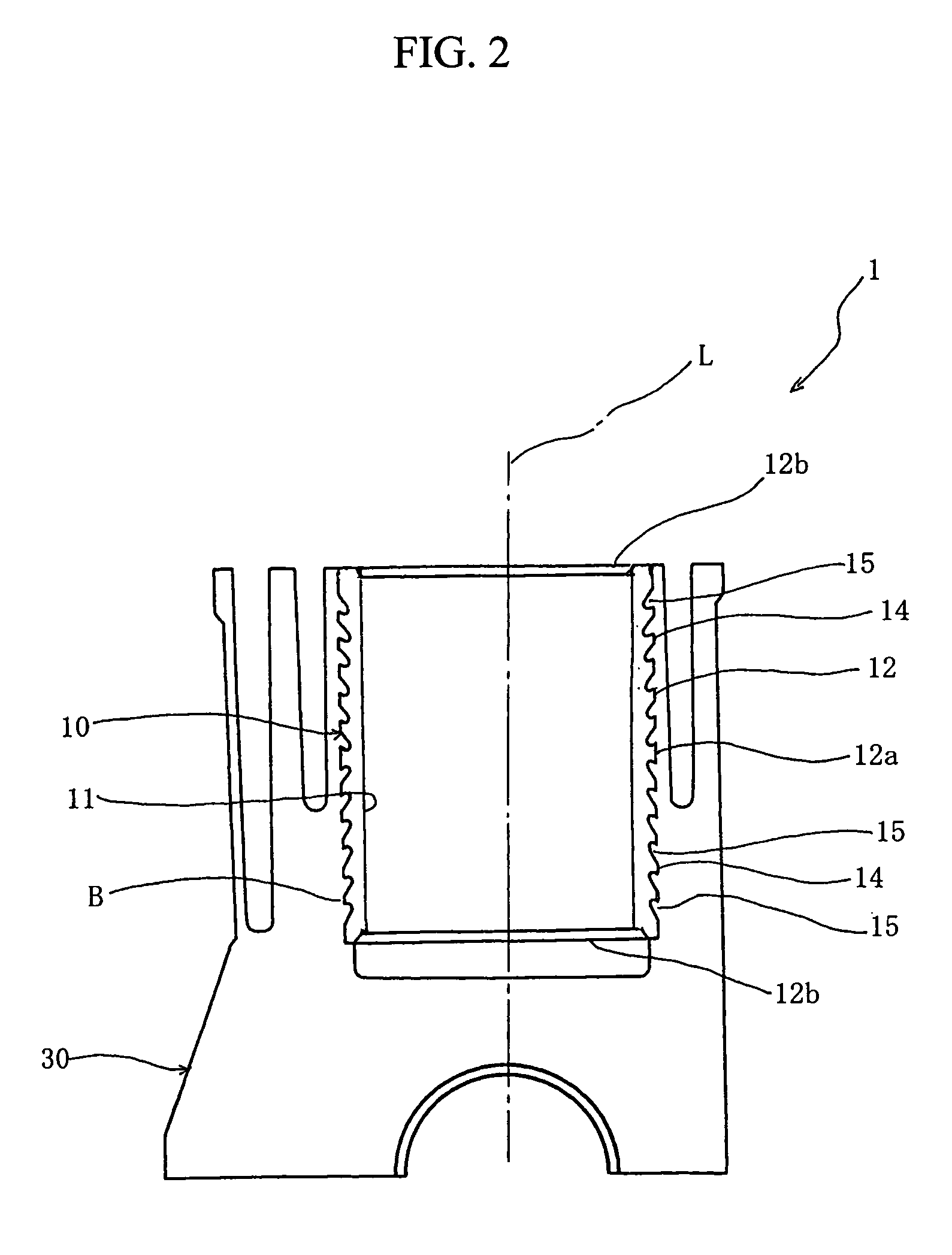

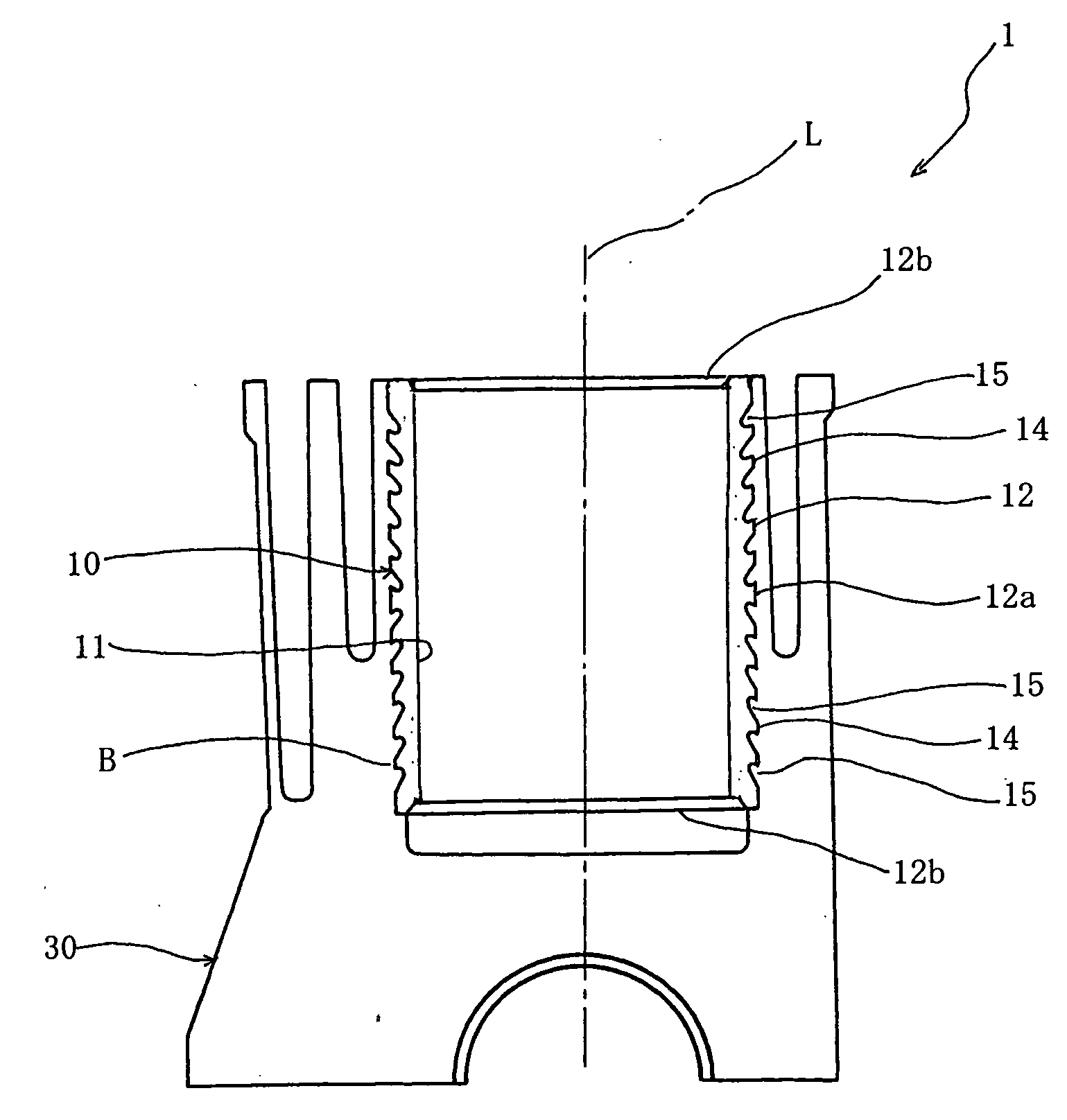

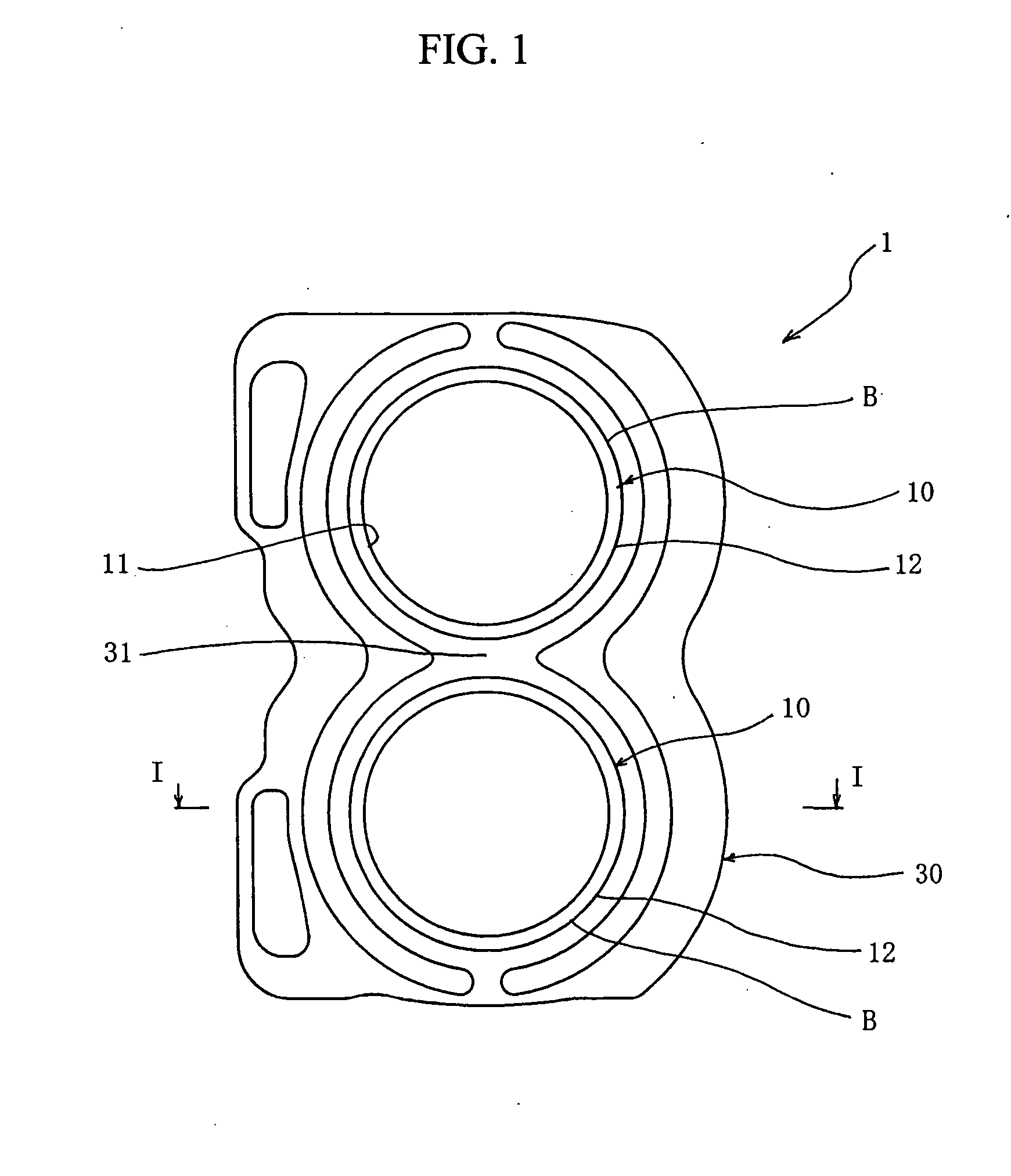

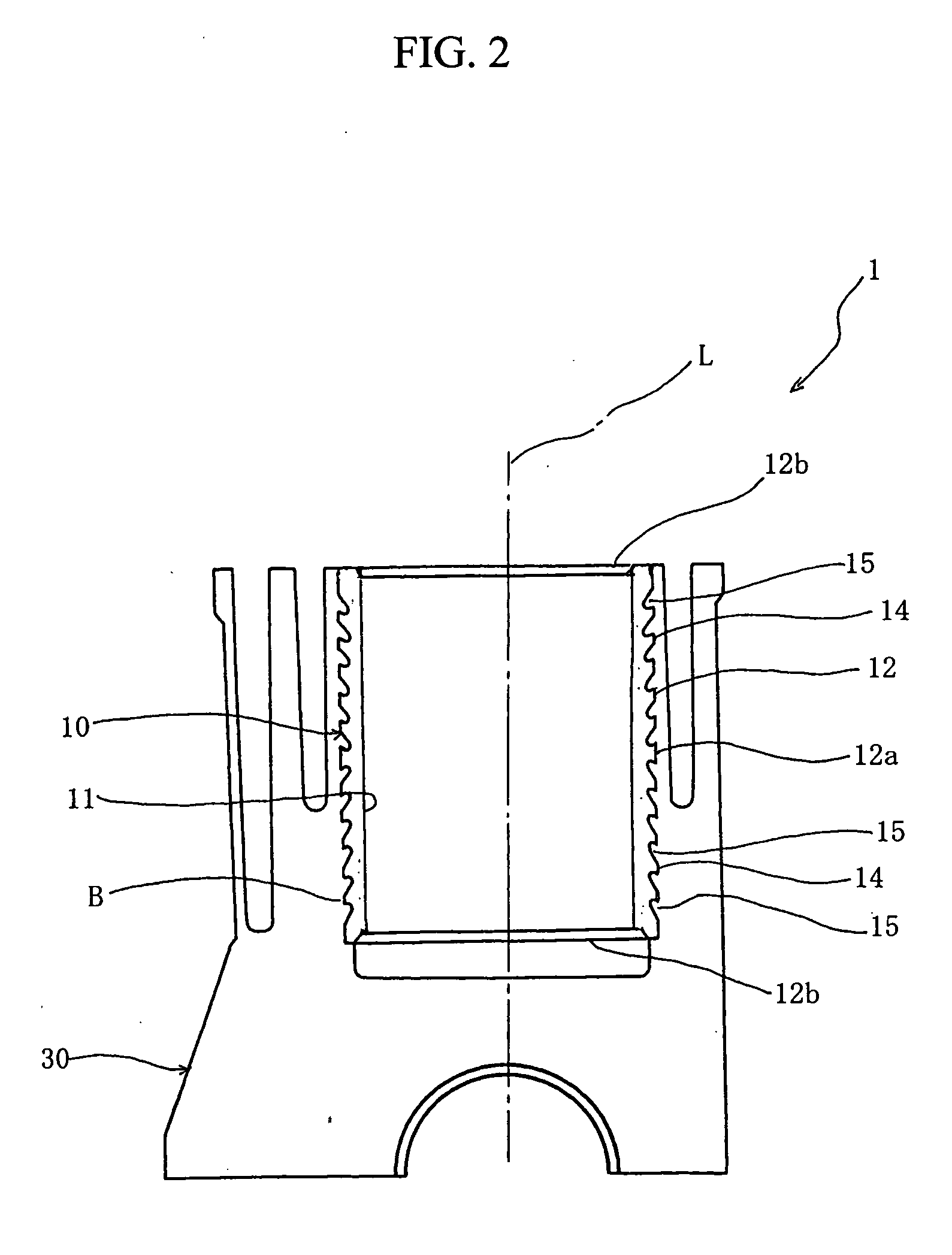

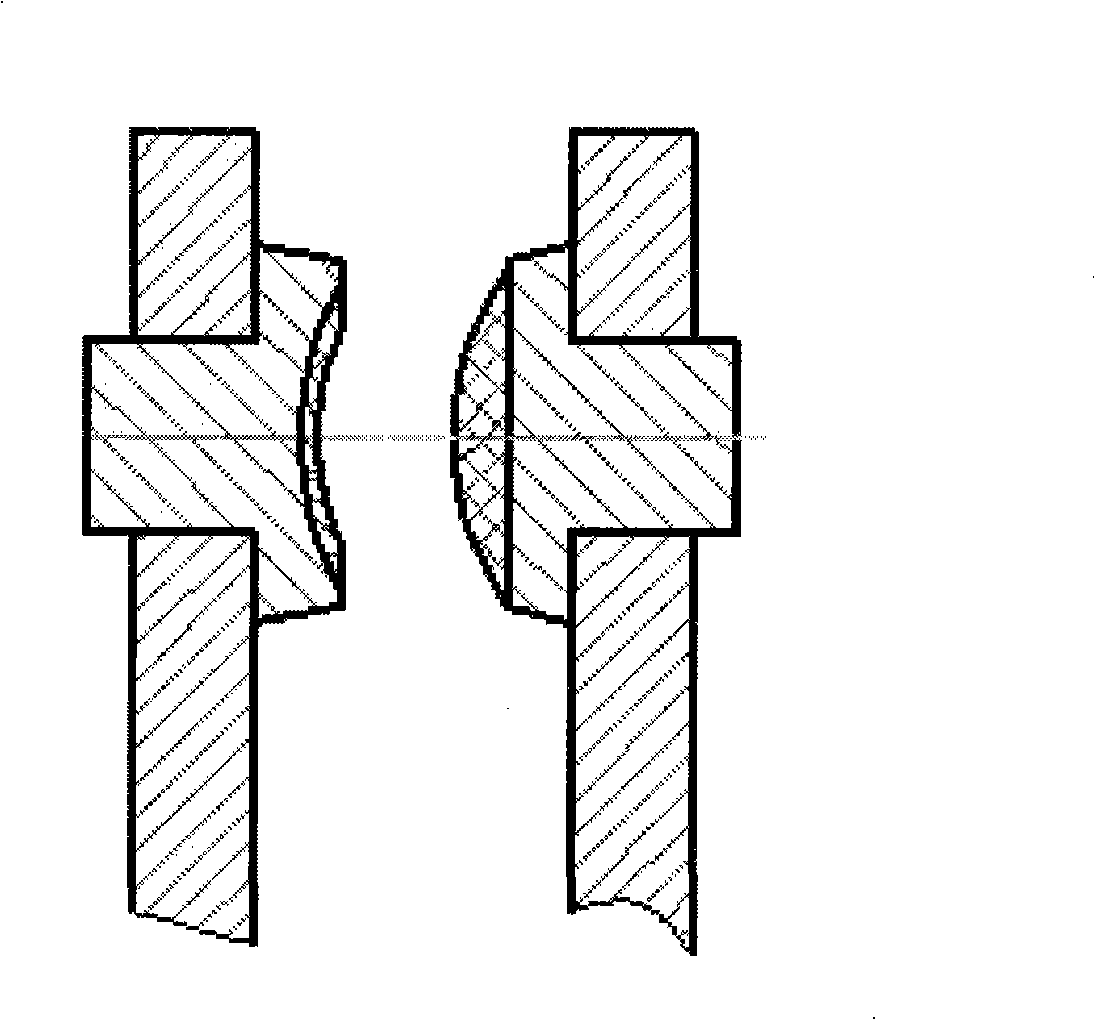

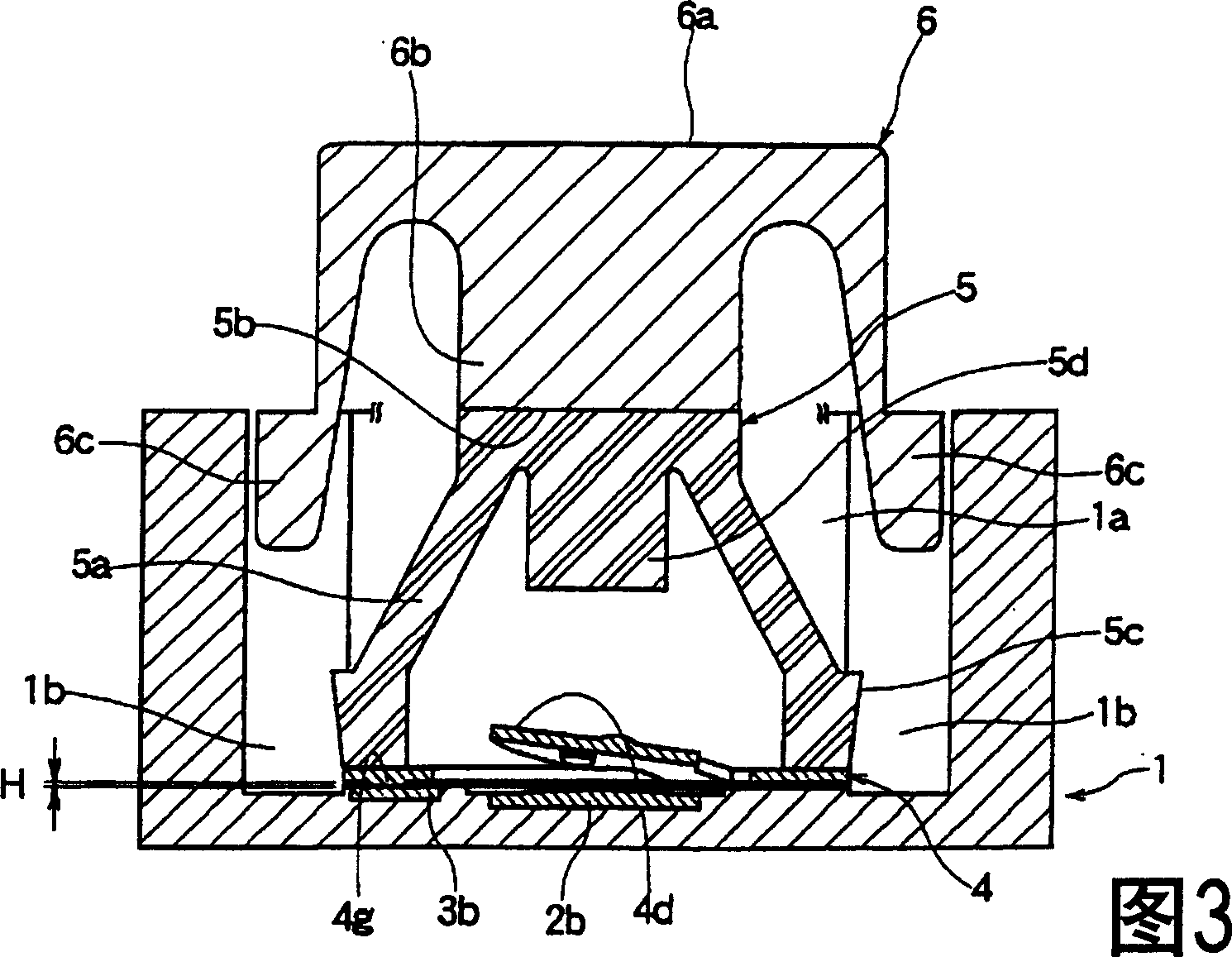

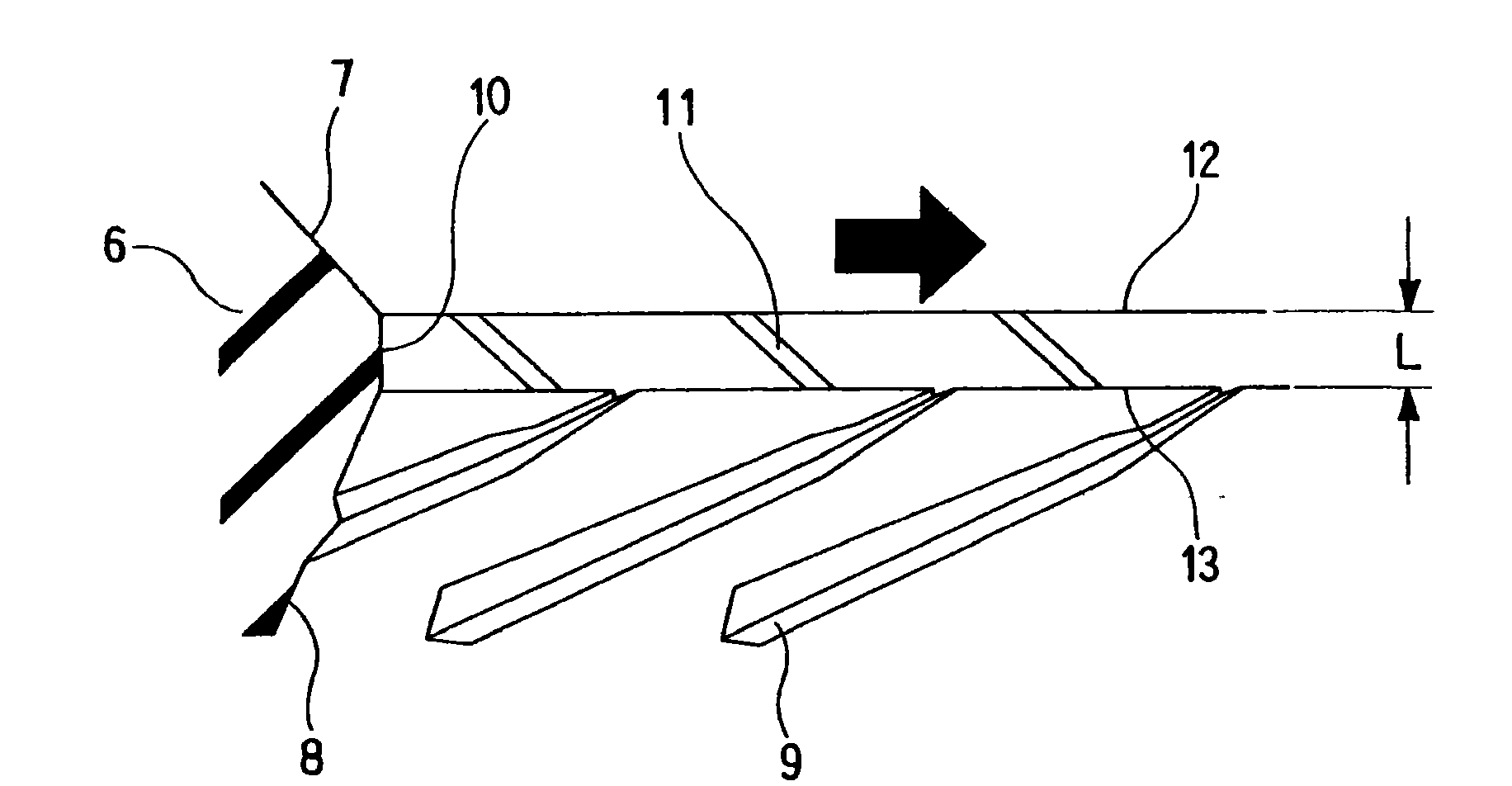

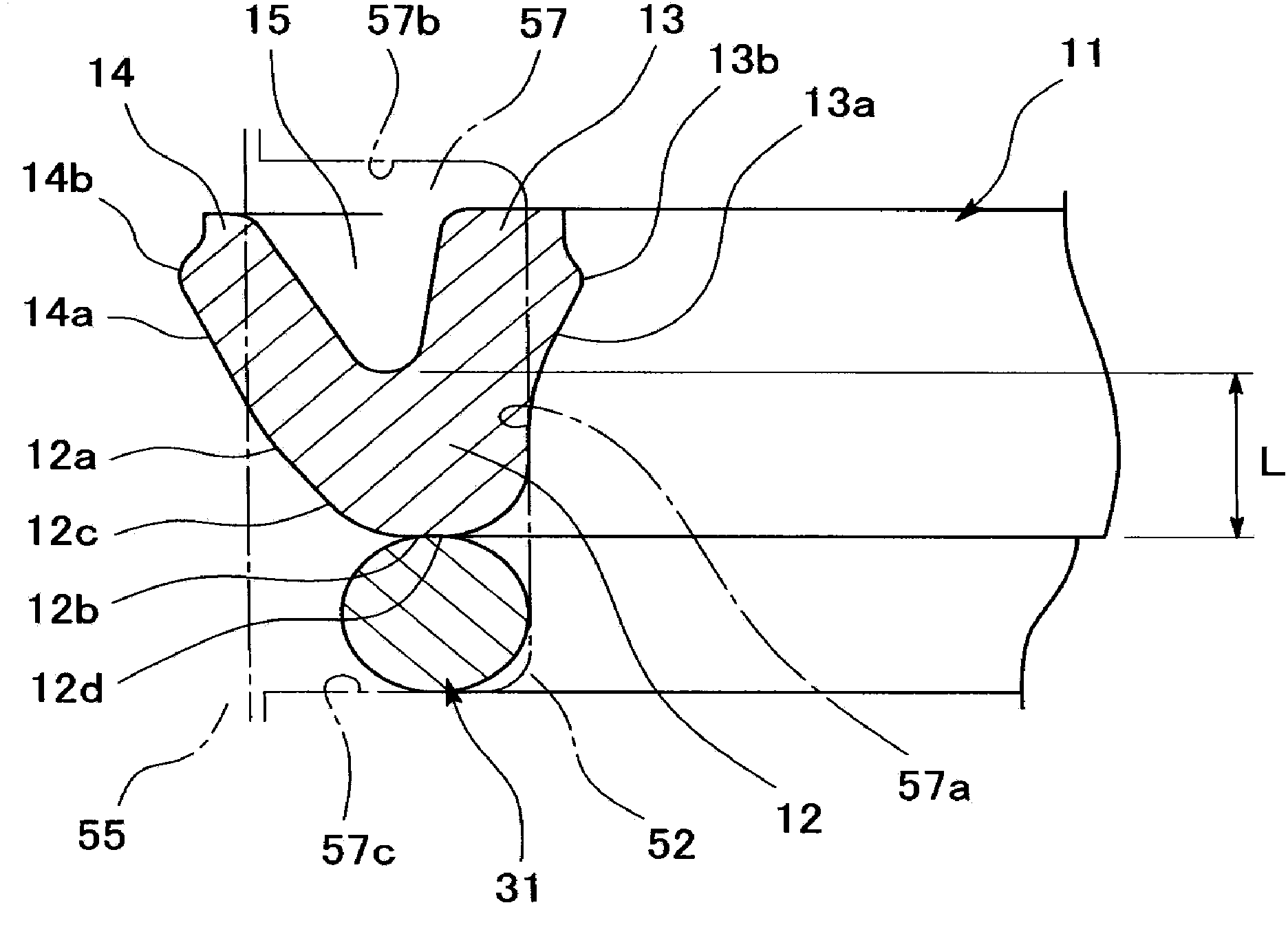

Cylinder liner and cylinder block

ActiveUS7273029B2Improve adhesion strengthContact state is stableCylinder headsCylindersEngineeringCylinder block

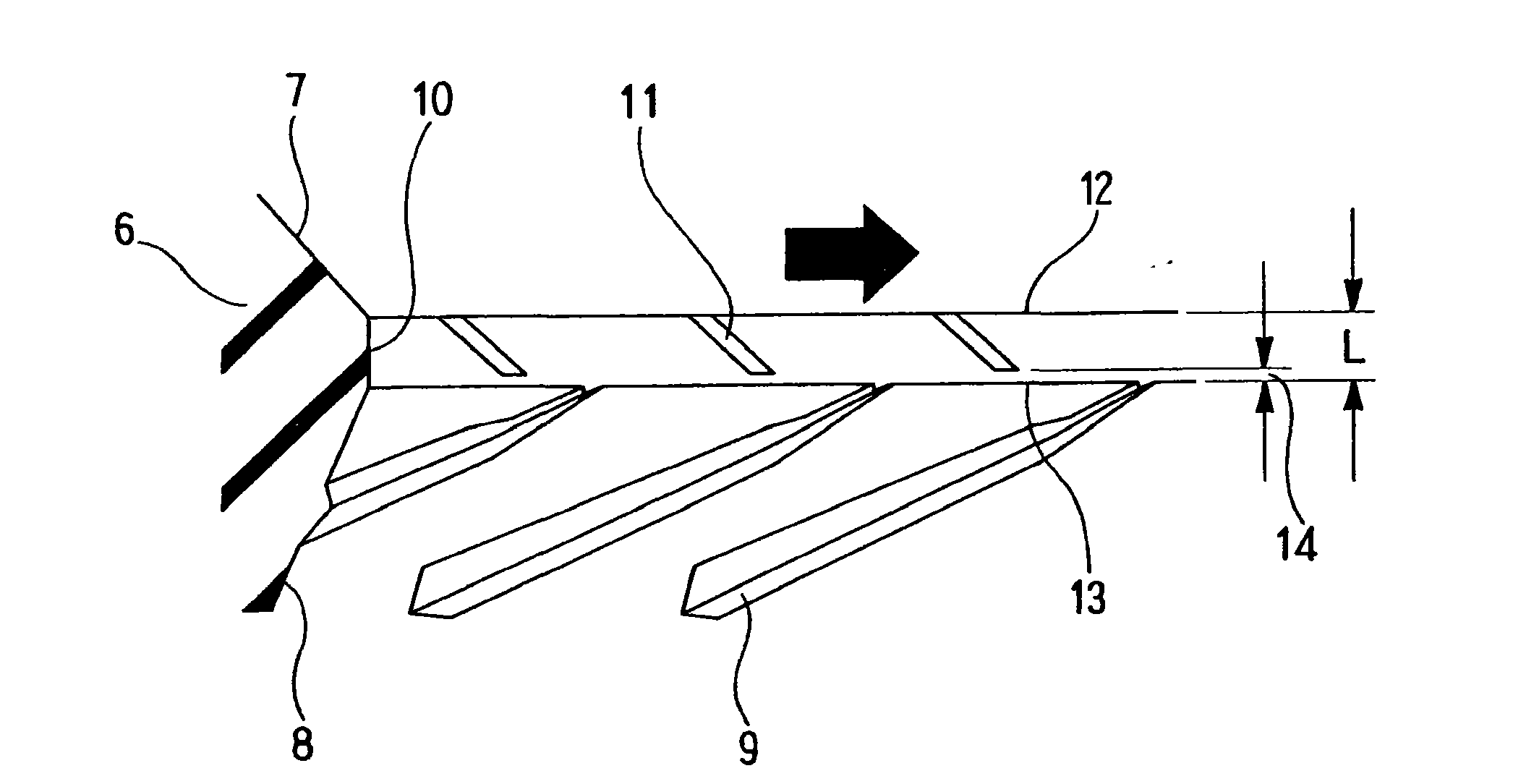

A cast iron cylinder liner of the present invention includes a plurality of grooves formed on an outer surface of the cylinder liner. Each of the grooves extends in a circumferential direction of the cylinder liner in a ring or spiral shape, and the grooves divide the outer surface of the cylinder liner into a plurality of ring or spiral sections. The outer surfaces of the ring sections have a uniform distance from the central axis of the cylinder liner over the entire area of the outer surfaces, and the grooves being arranged symmetrically with respect to the center of the cylinder liner in an axial direction thereof. Each of the grooves has a J-shaped longitudinal cross-section including a first inclination part and a groove bottom part. The first inclination part extends from the outer surface of one of the ring sections or of one turn of the spiral sections toward the center of the cylinder liner in an axial direction thereof. The groove bottom part has a longitudinal cross-section approximately in the form of a circular arc, and extends from the first inclination part in a direction away from the center of the cylinder liner in an axial direction thereof.

Owner:SUBARU CORP +1

Cylinder liner and cylinder block

ActiveUS20060156917A1Improve adhesion strengthContact state is stableCylinder headsCylindersEngineeringCylinder block

A cast iron cylinder liner of the present invention includes a plurality of grooves formed on an outer surface of the cylinder liner. Each of the grooves extends in a circumferential direction of the cylinder liner in a ring or spiral shape, and the grooves divide the outer surface of the cylinder liner into a plurality of ring or spiral sections. The outer surfaces of the ring sections have a uniform distance from the central axis of the cylinder liner over the entire area of the outer surfaces, and the grooves being arranged symmetrically with respect to the center of the cylinder liner in an axial direction thereof. Each of the grooves has a J-shaped longitudinal cross-section including a first inclination part and a groove bottom part. The first inclination part extends from the outer surface of one of the ring sections or of one turn of the spiral sections toward the center of the cylinder liner in an axial direction thereof. The groove bottom part has a longitudinal cross-section approximately in the form of a circular arc, and extends from the first inclination part in a direction away from the center of the cylinder liner in an axial direction thereof

Owner:SUBARU CORP +1

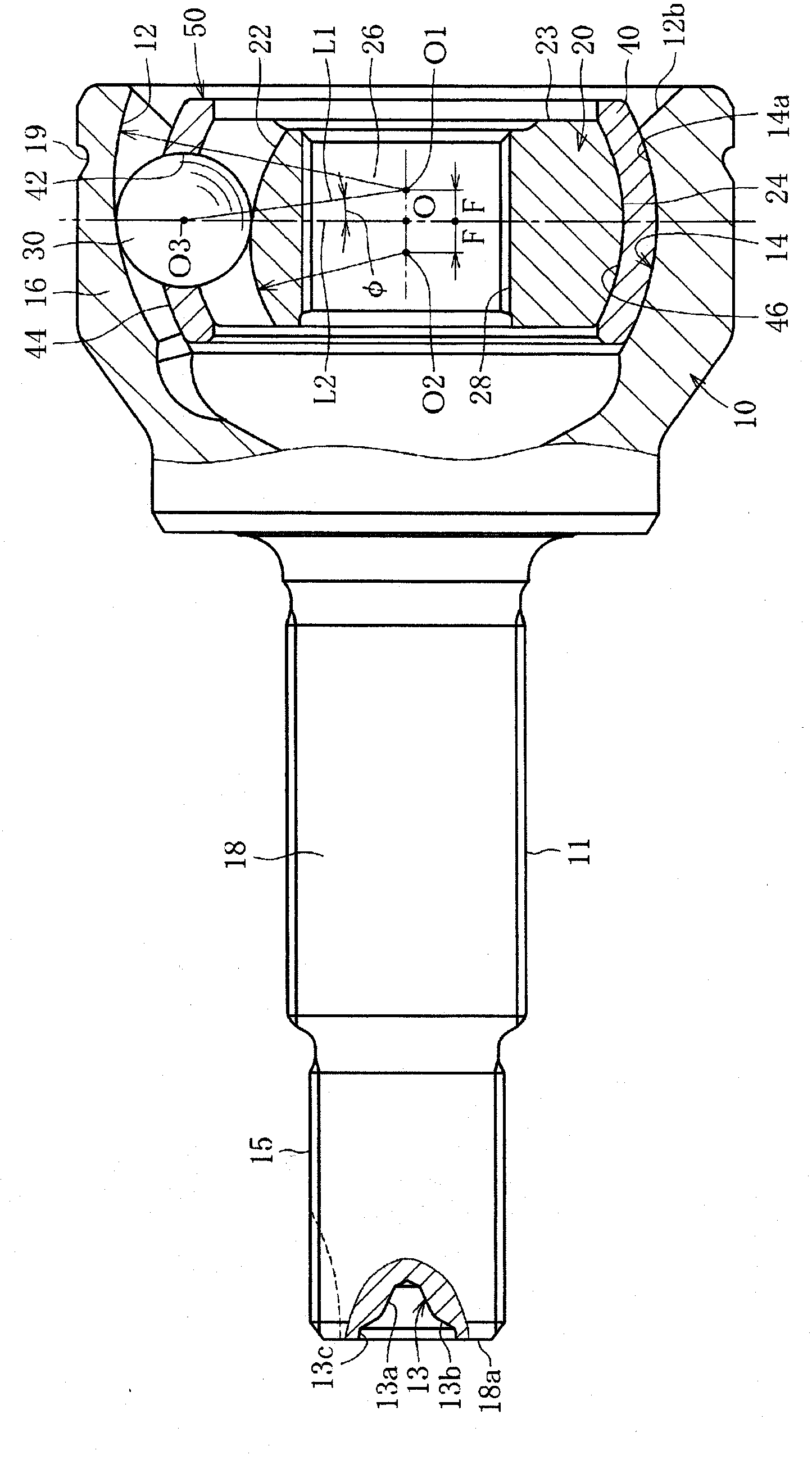

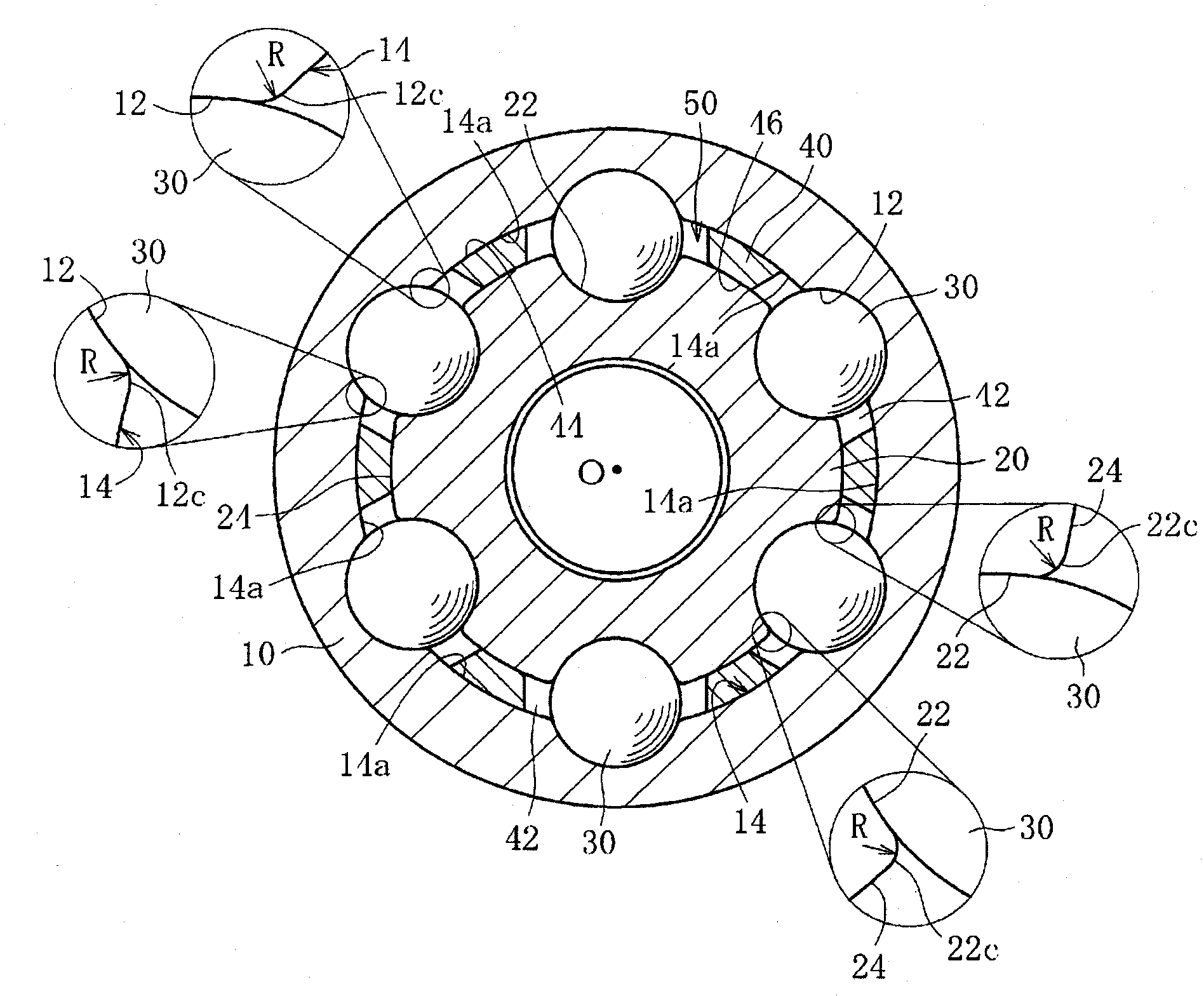

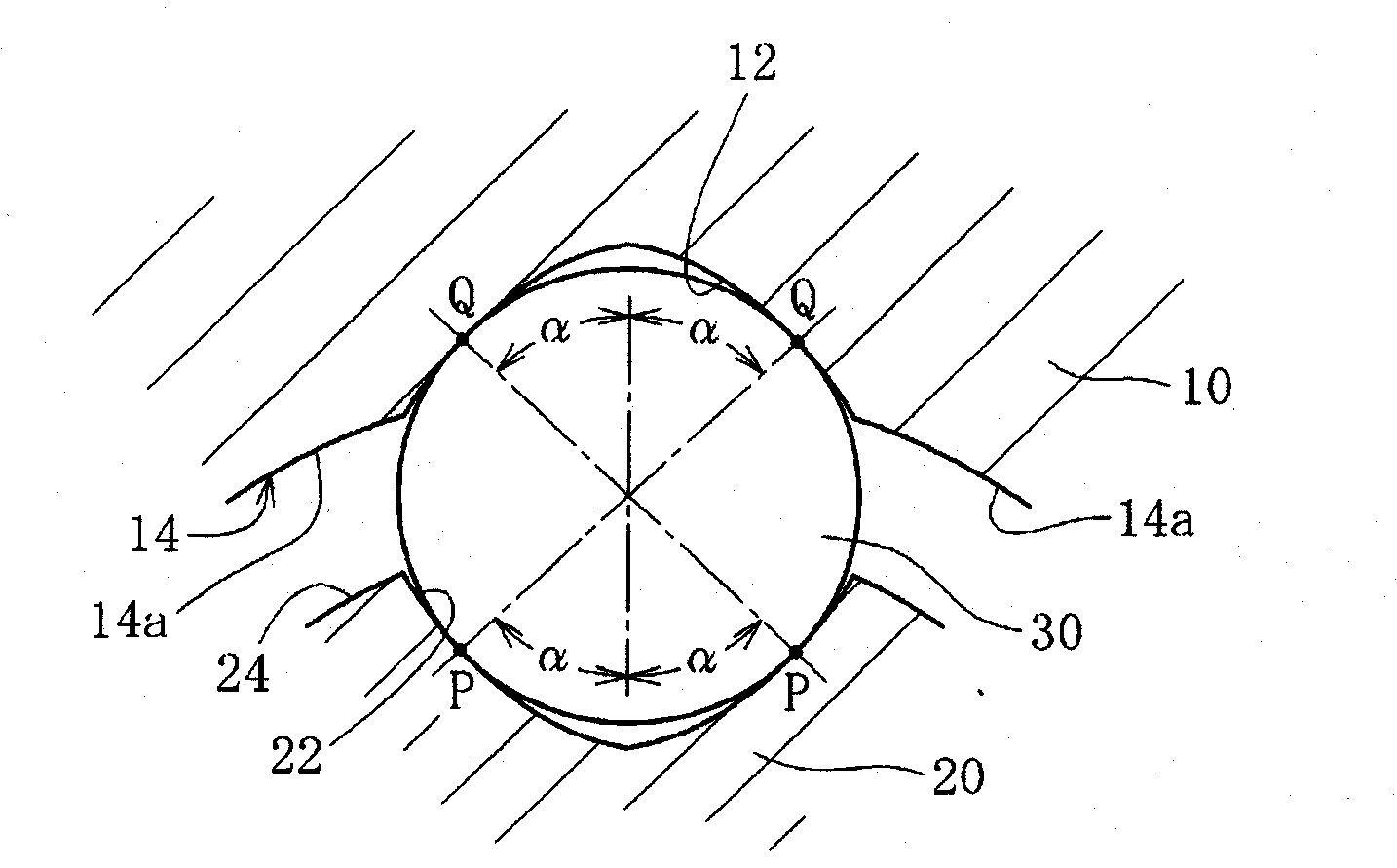

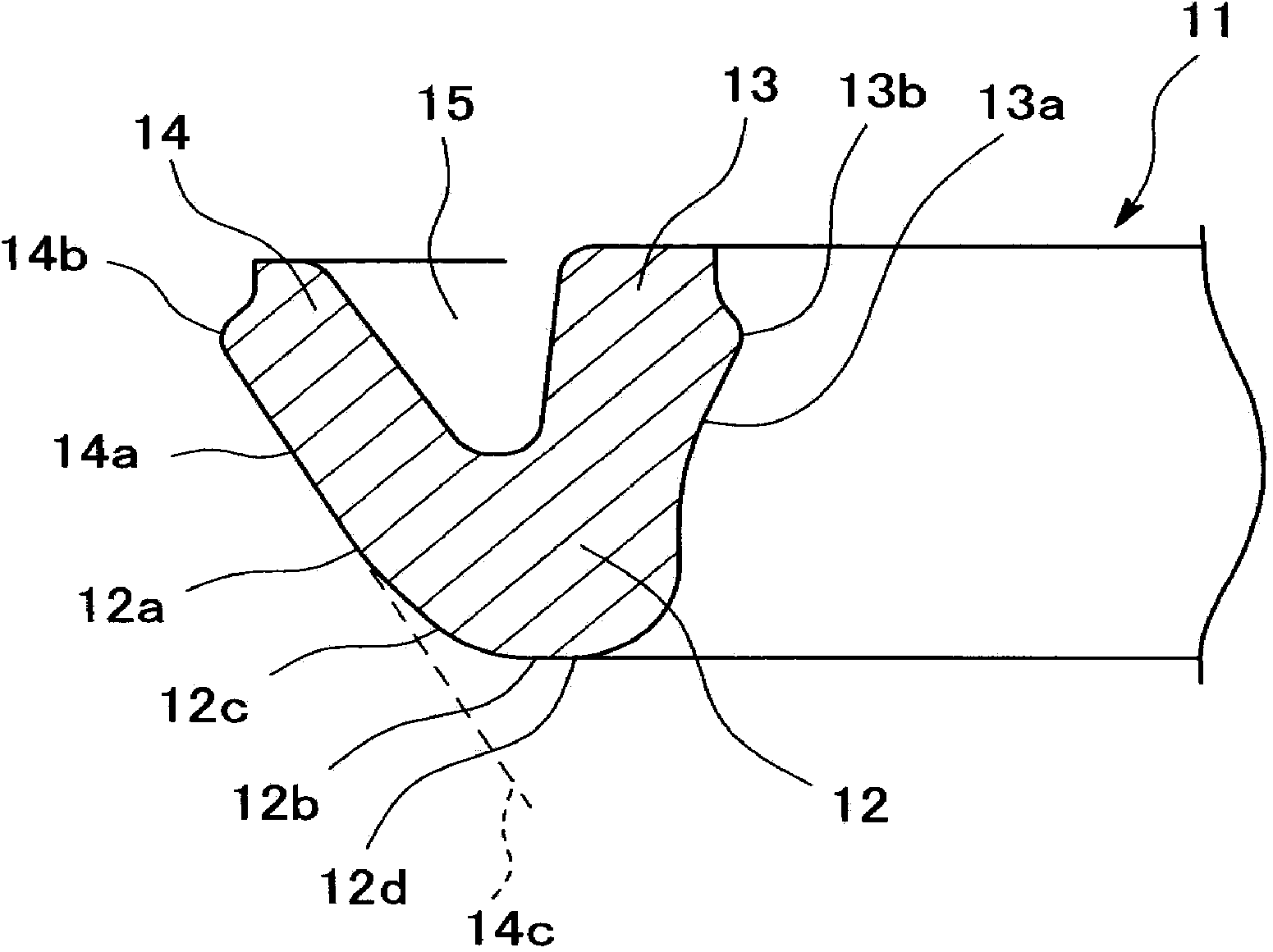

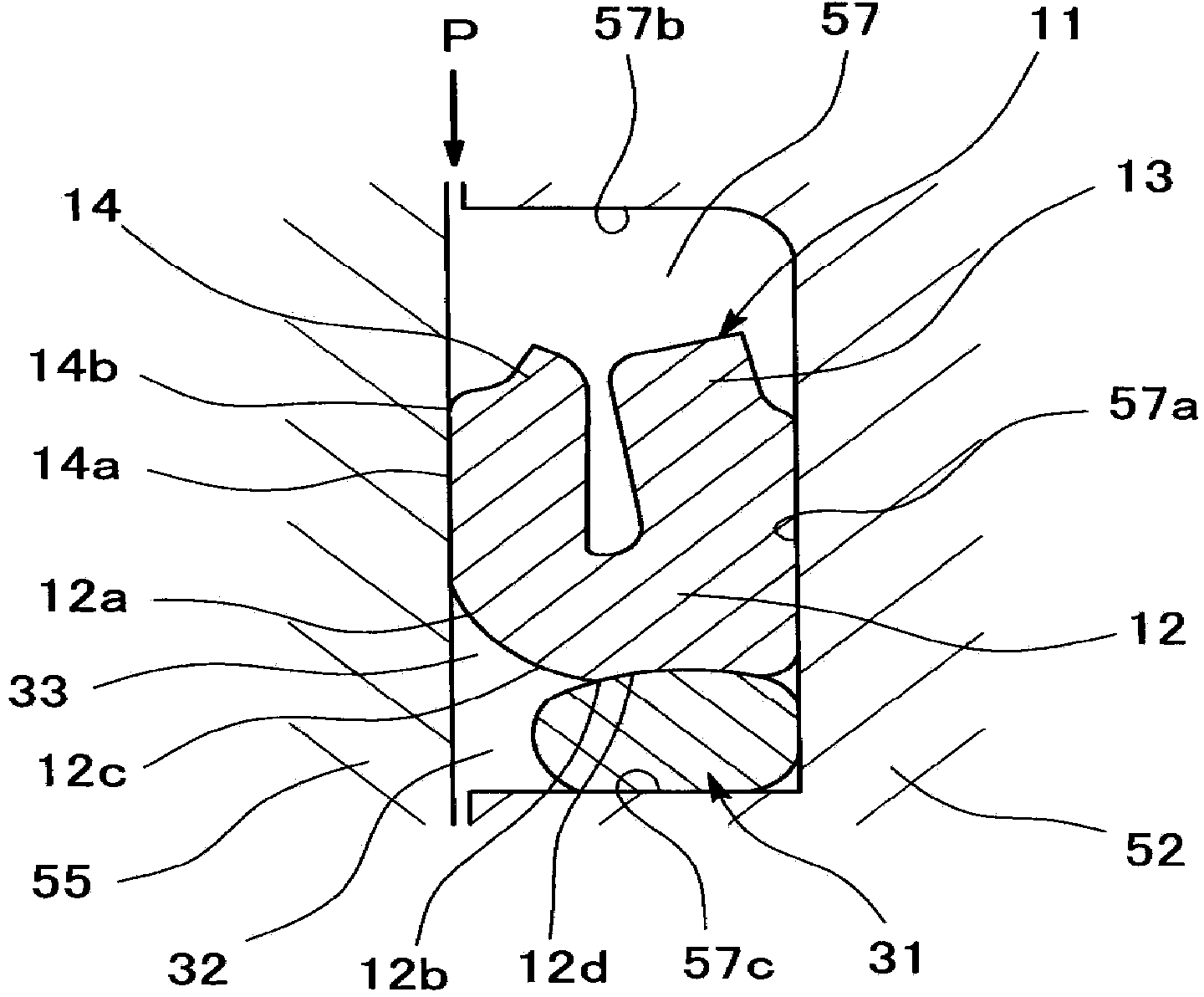

Outer joint member for fixed constant velocity universal joint

ActiveCN102257289AReduce manufacturing costImprove yieldYielding couplingEngine componentsUniversal jointMan-hour

Provided is an outer joint member for a fixed constant velocity universal joint, capable of being produced with an improved yield ratio and reduced production cost by reducing the number of man-hour by a reduction in the amount of work after forging. An outer joint member for a fixed constant velocity universal joint, provided with a cup section (16) and a shaft section (18) which extends in the axial direction from the bottom of the cup section (16). The outer joint member consists of carbon steel for mechanical structures, and the following portions of the outer joint member are finished by cold forging: track grooves (12), inner diameter spherical surface sections (14a), chamfers (12b) at the cup entrance, track chamfers (12c), chamfers (12a) at the track entrances, portions of the outer diameter surface of the cup section (16), said portions excluding a boot mounting section (19), and a center hole (13) in an end surface (18a) of the shaft section (18).

Owner:NTN CORP

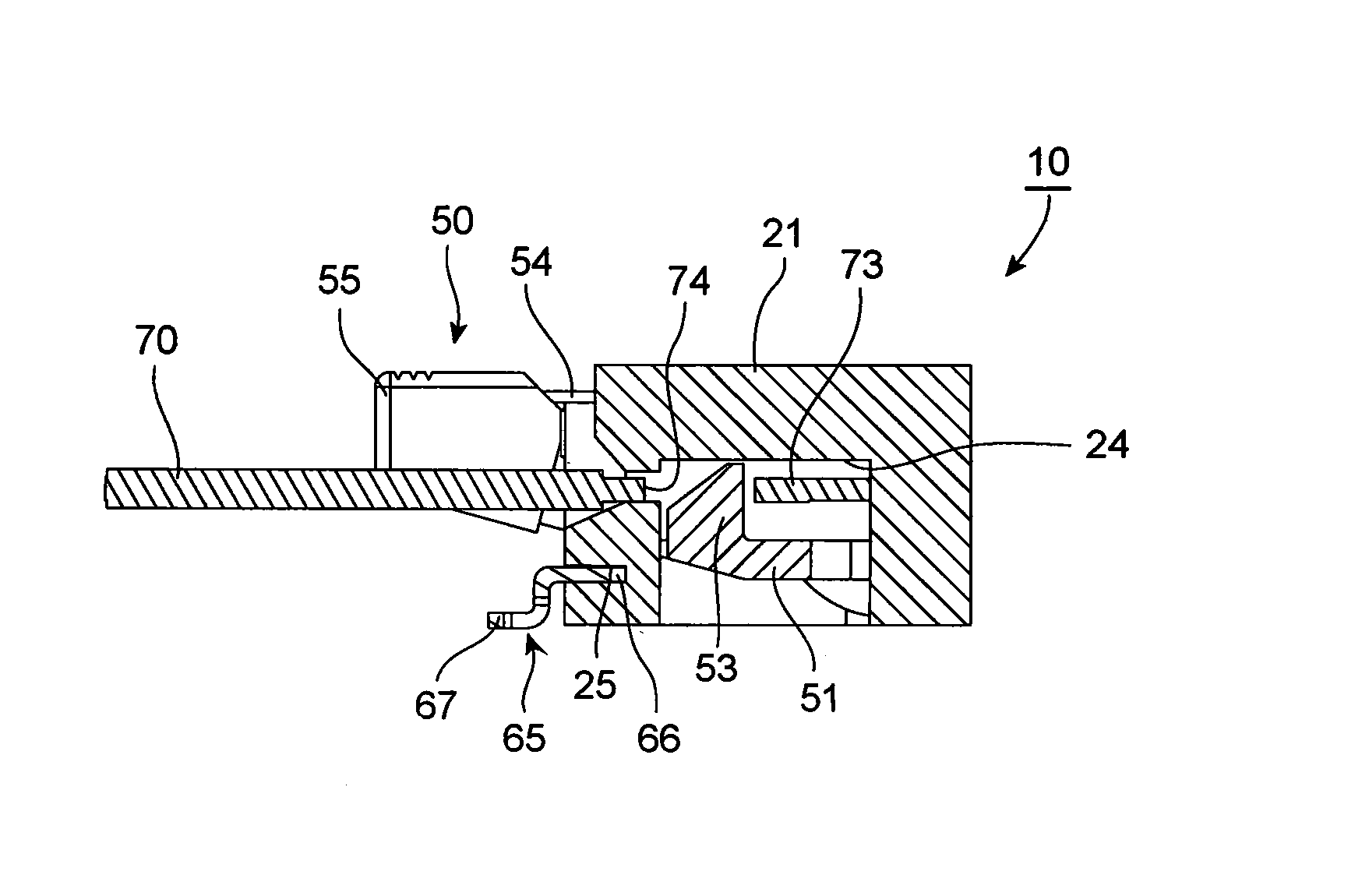

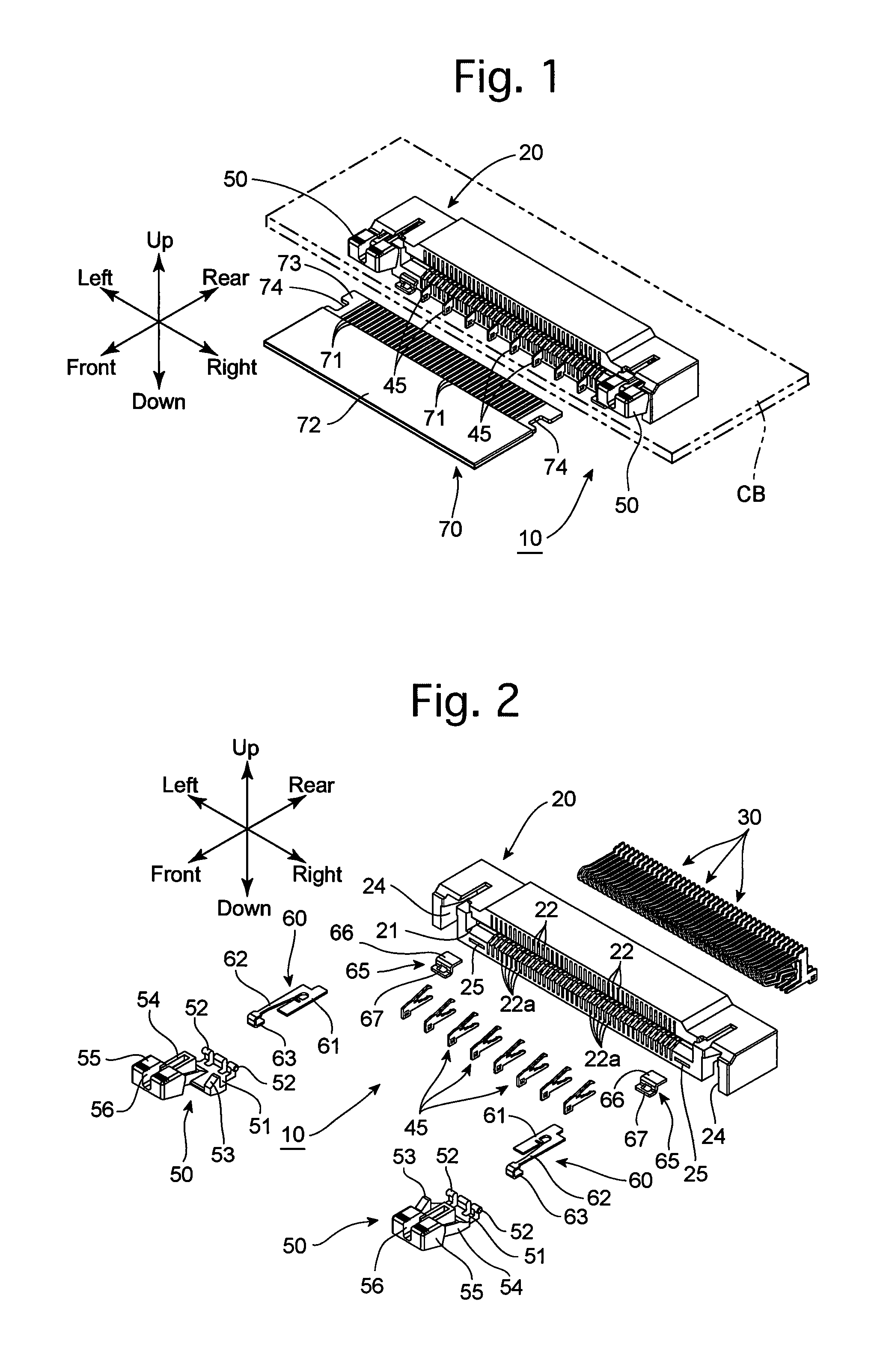

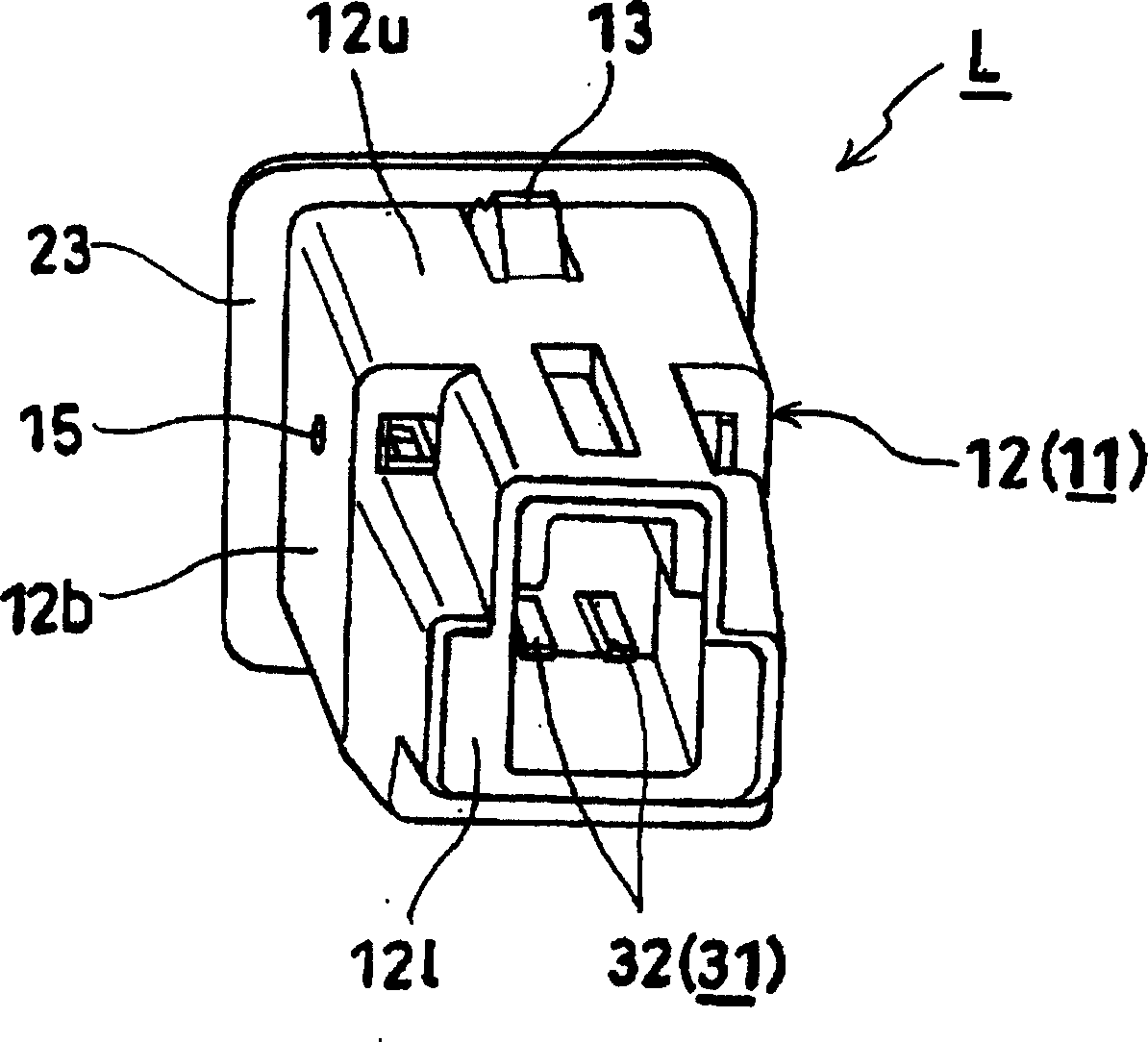

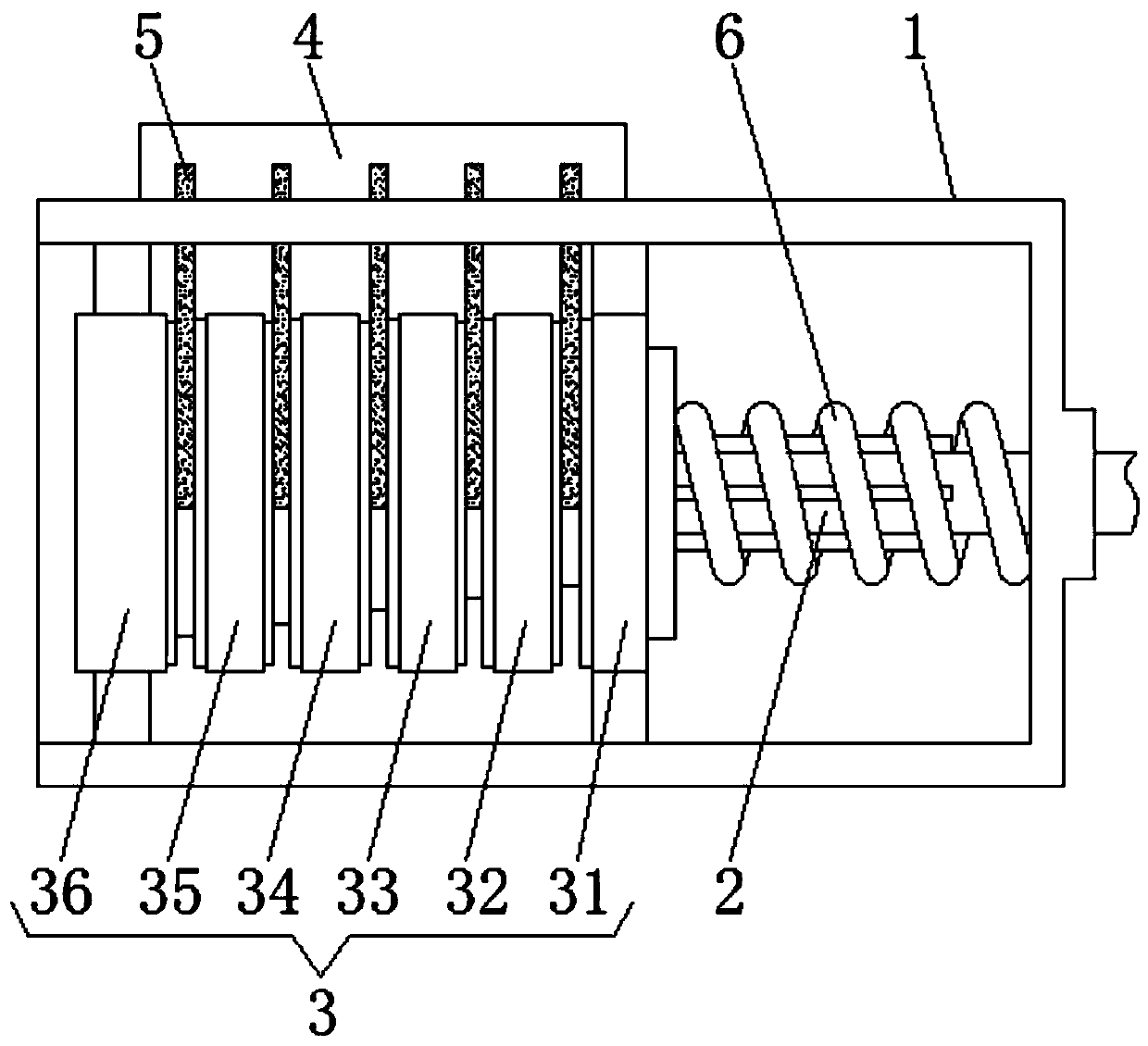

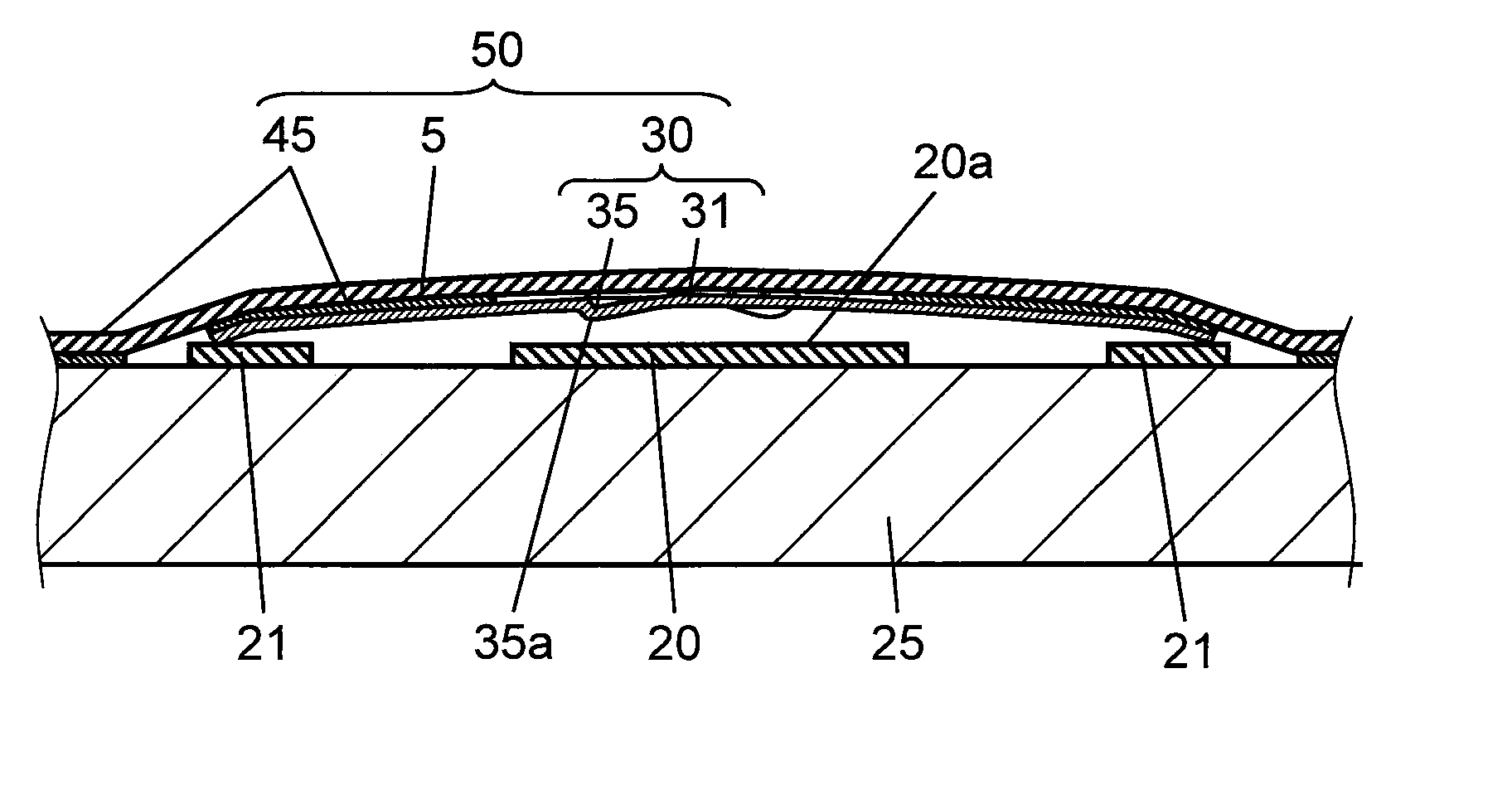

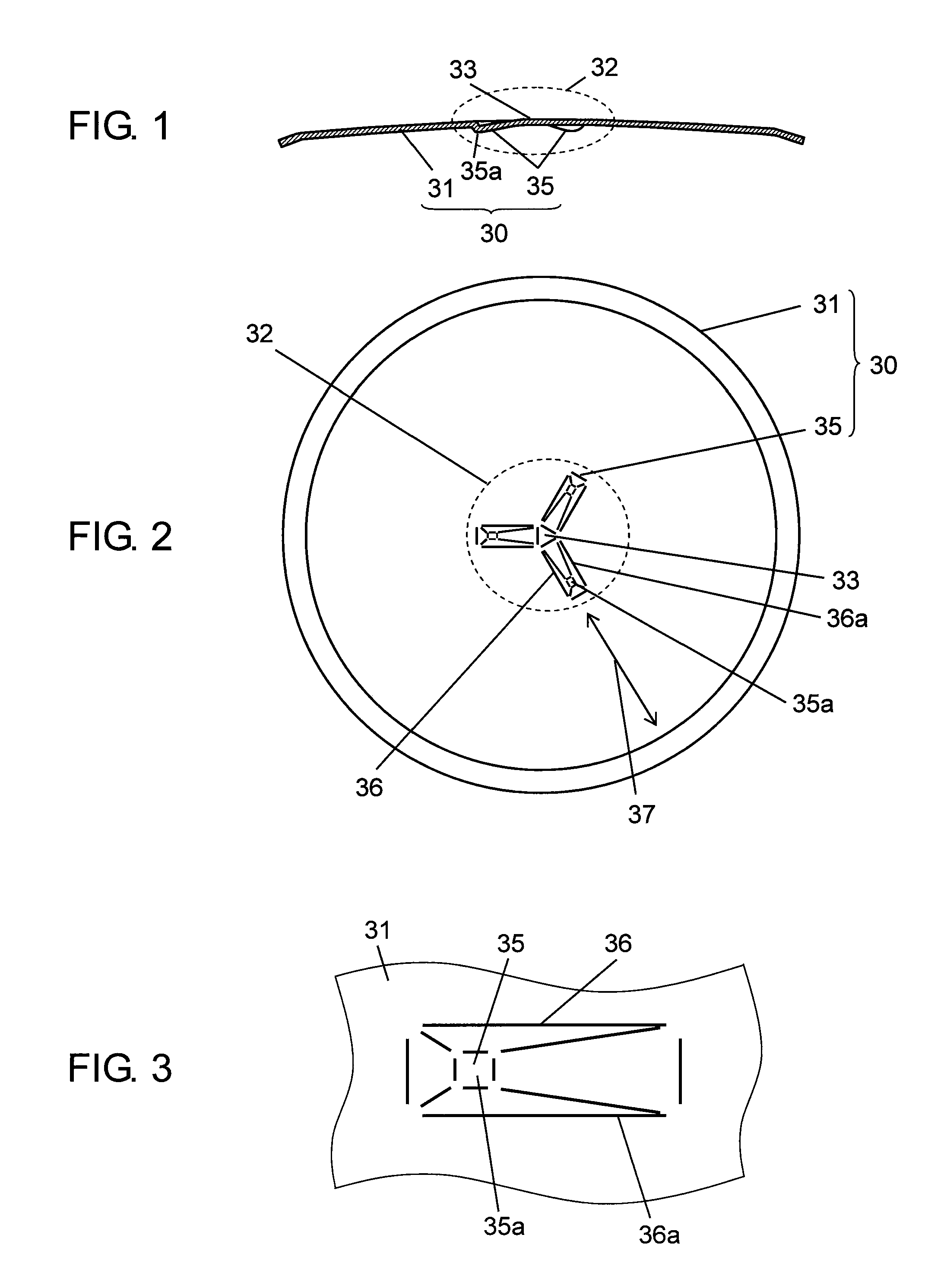

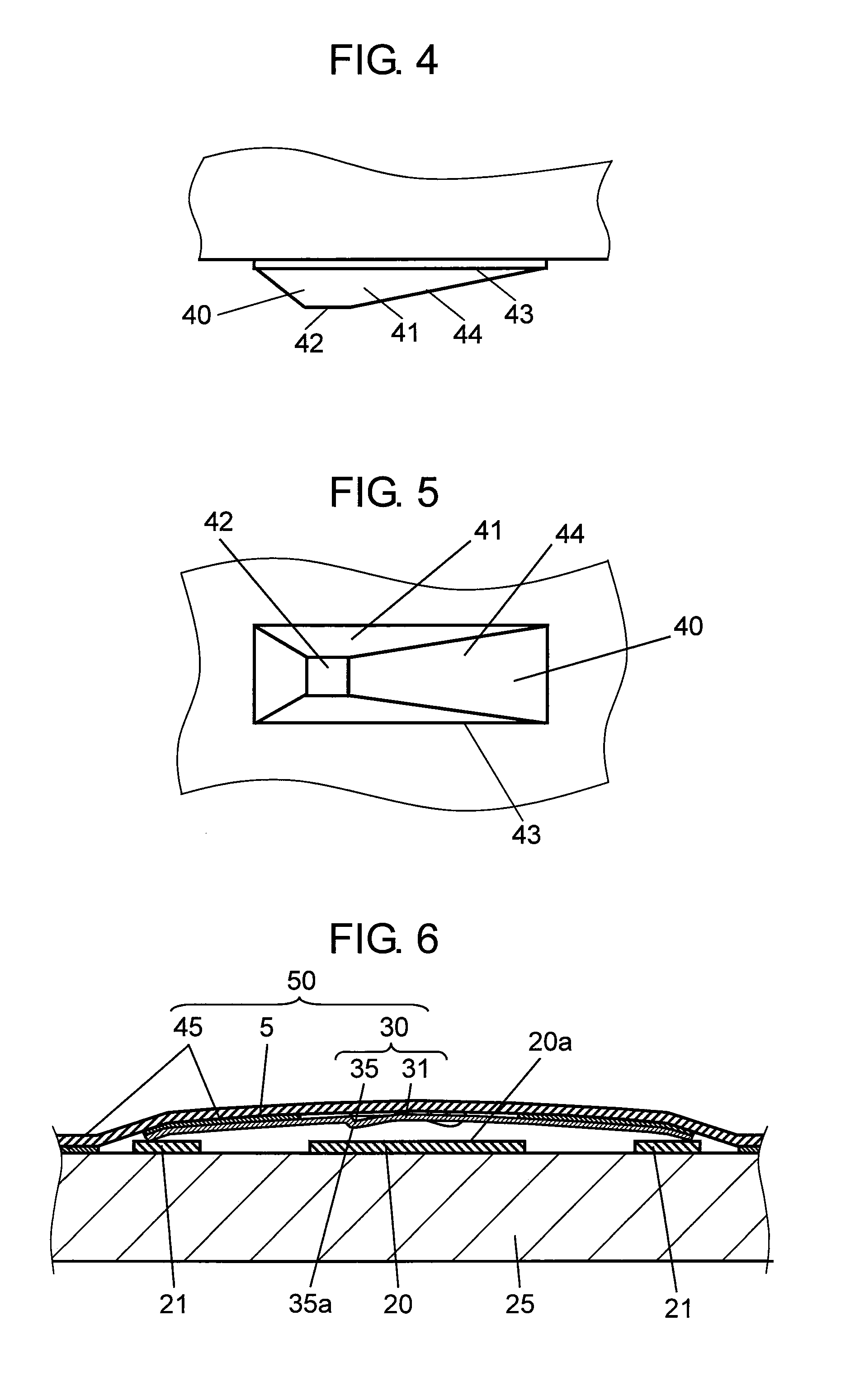

Connector

InactiveUS20140045383A1Contact state is stableGood followabilityCoupling contact membersTwo-part coupling devicesEngineering

A connector includes an insulator having a connecting-object insertion groove and at least one contact supported by the insulator to be contactable with a trace of a circuit pattern formed on a connecting object. The contact includes a first resilient deformable portion, a first contact protrusion protruding from the first resilient deformable portion and contacting the trace, a second resilient deformable portion extending toward the innermost end of the connecting-object insertion groove from the first contact protrusion and thereafter extending back toward the first contact protrusion, and a second contact protrusion protruding from the second resilient deformable portion, positioned closer to the innermost end of the connecting-object insertion groove than the first contact protrusion, and contacting a portion of the trace at a position closer to the innermost end than that at which the first contact protrusion contacts.

Owner:KYOCERA CONNECTOR PRODS CORP

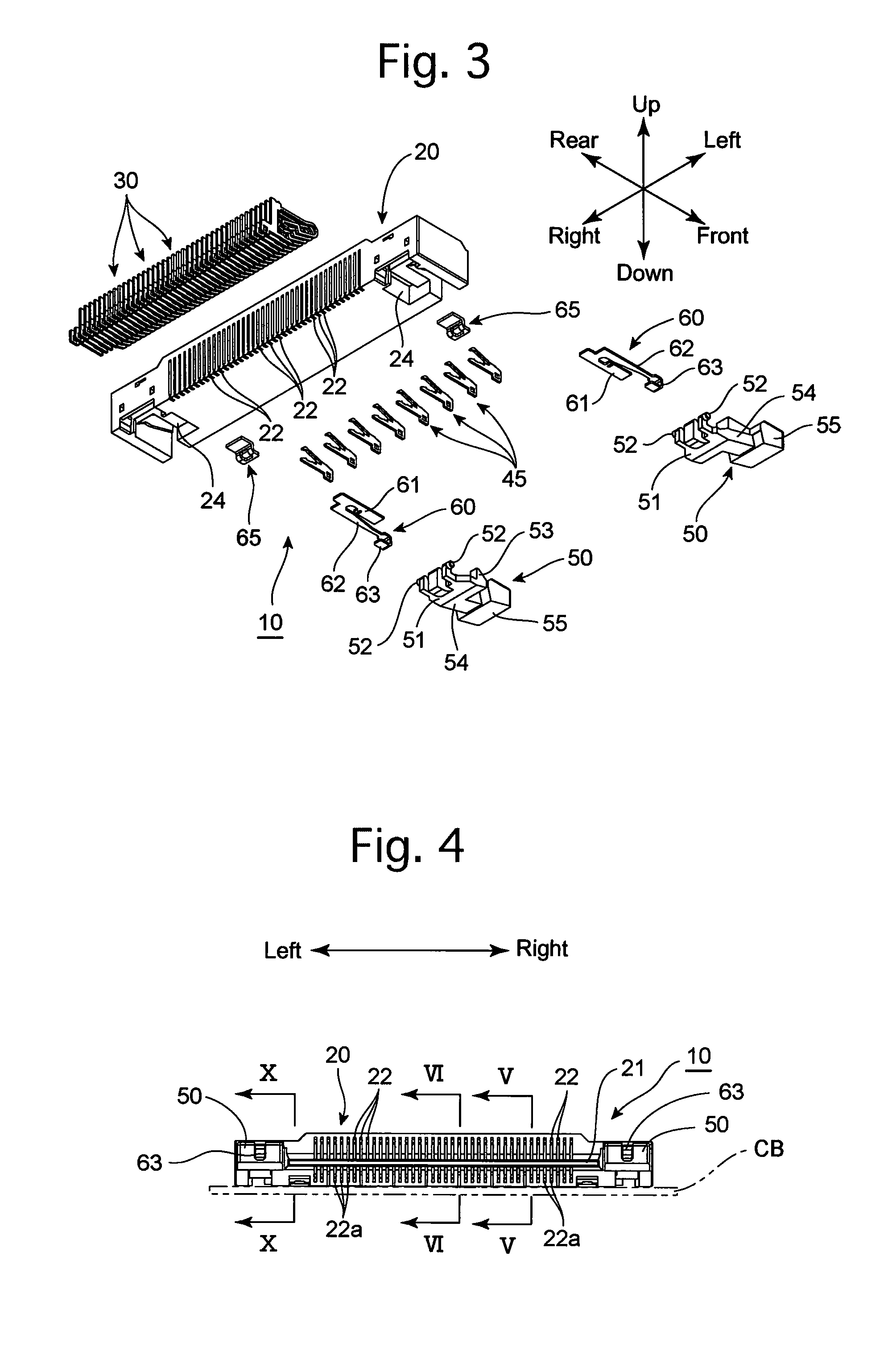

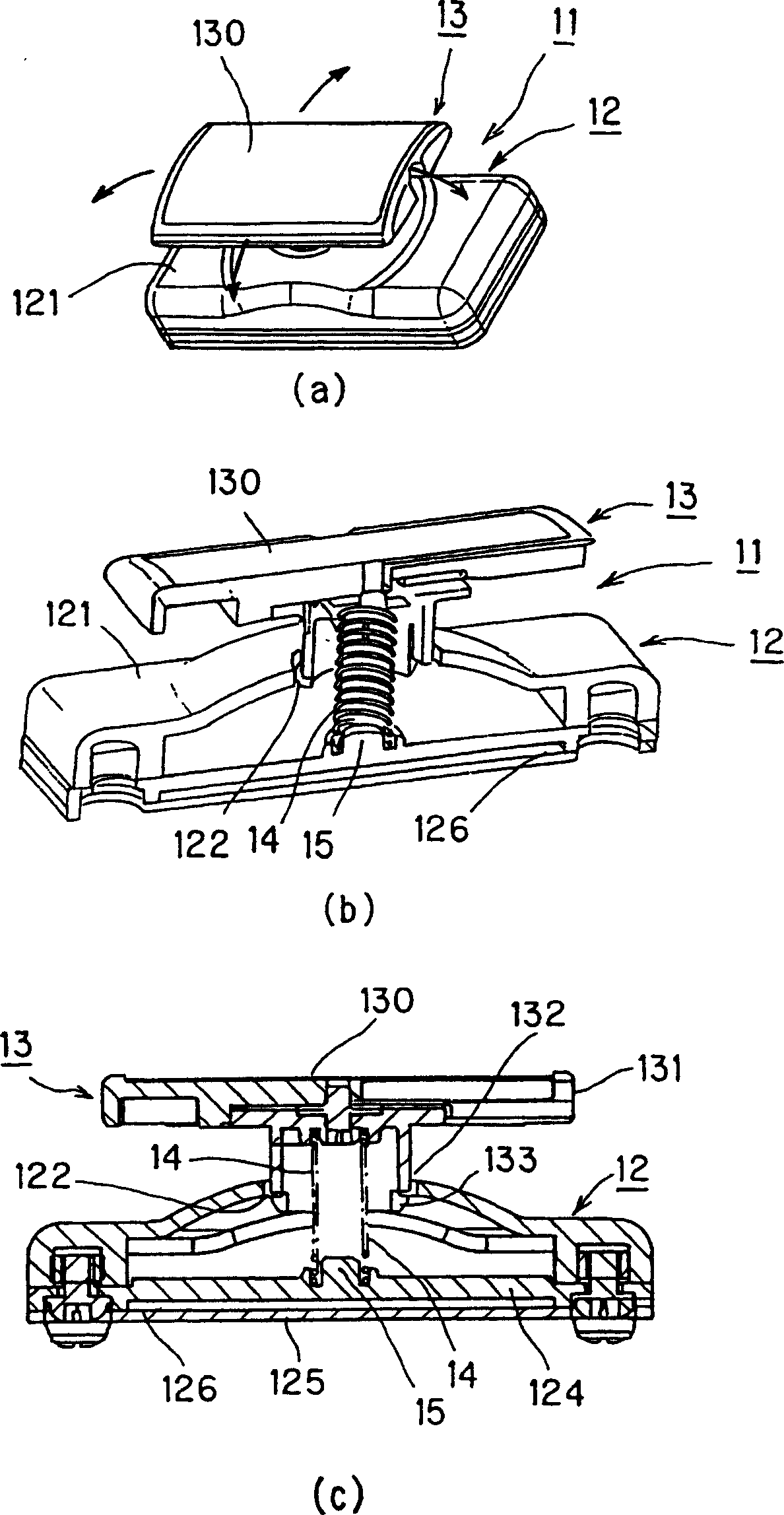

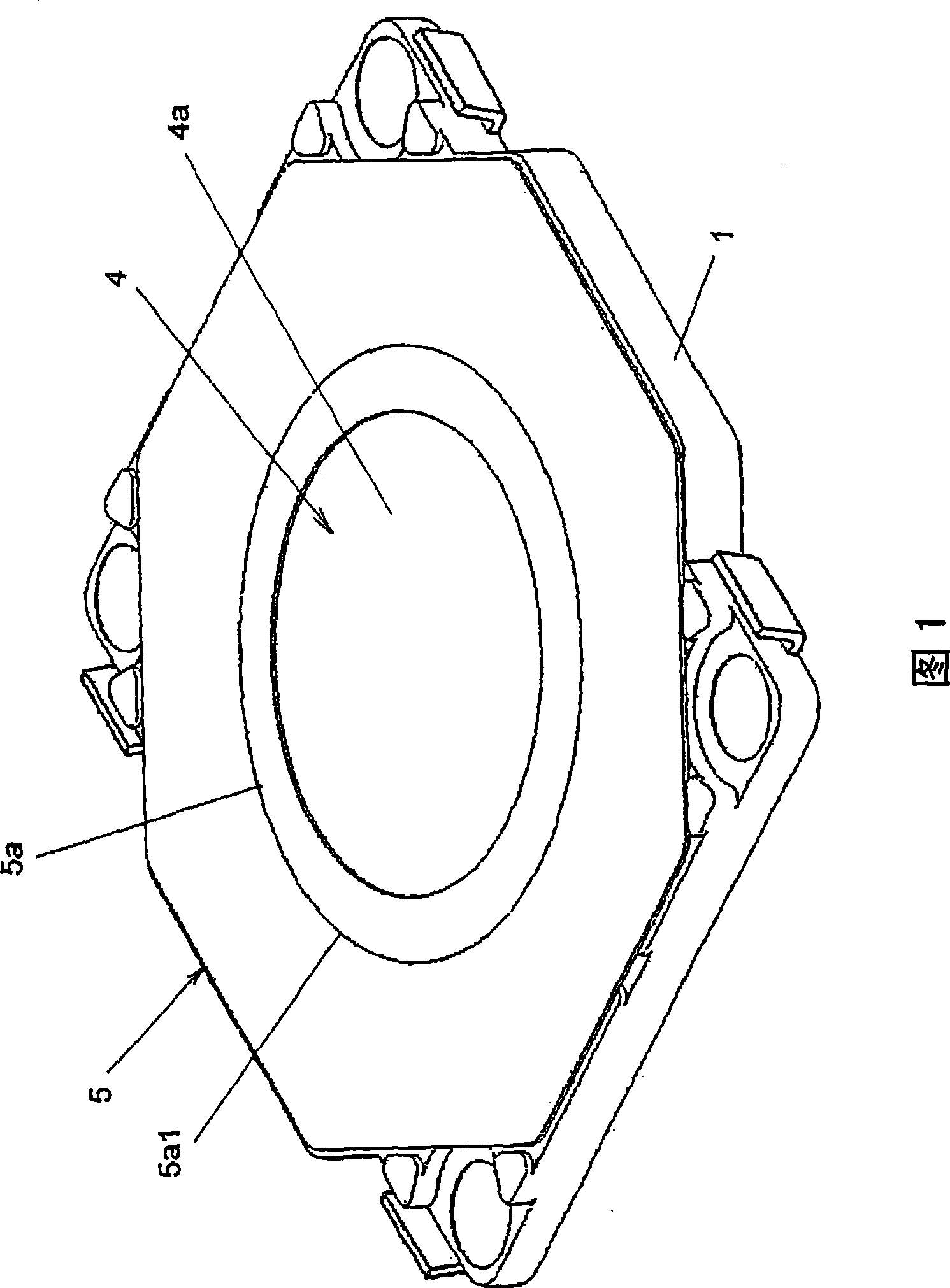

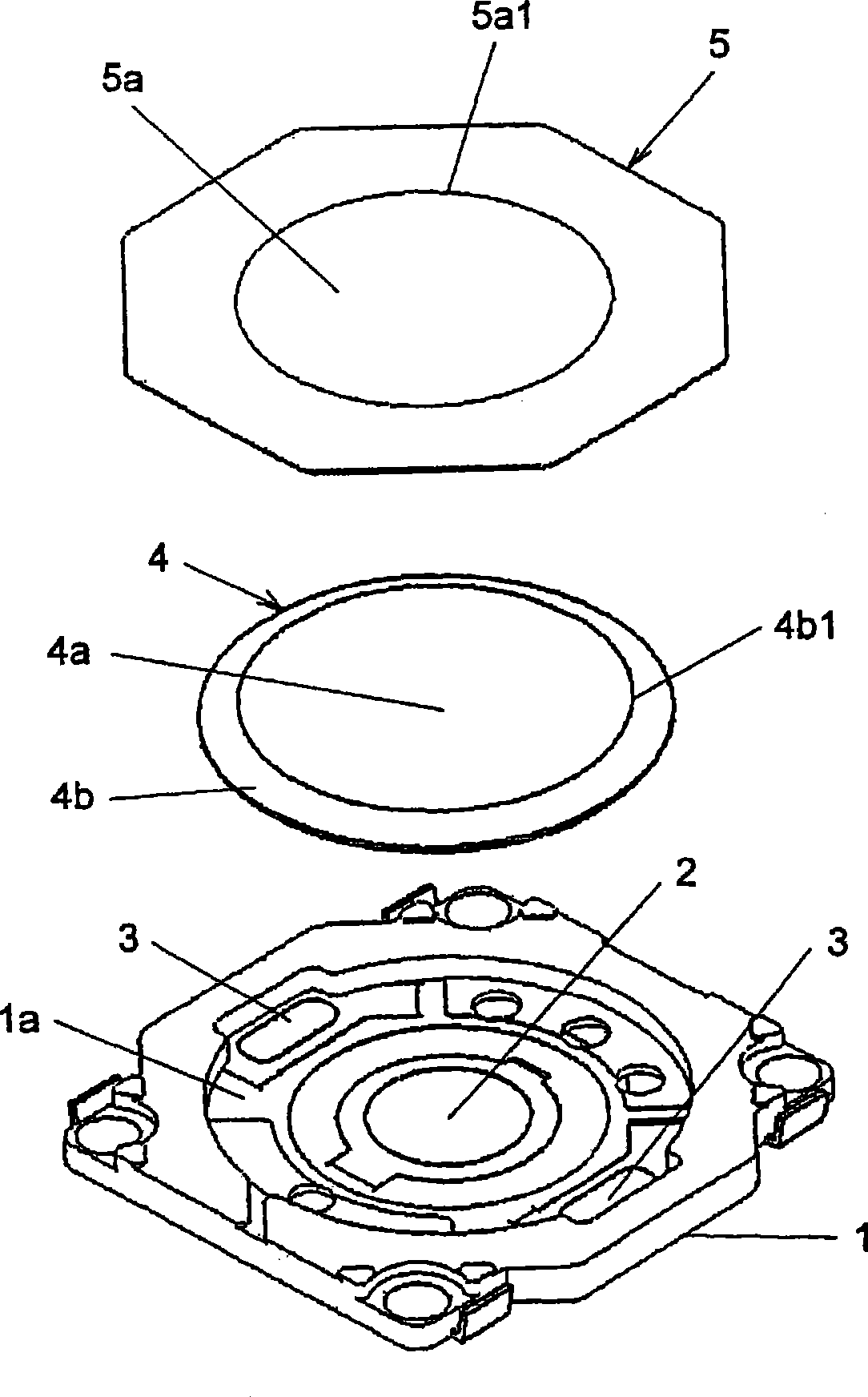

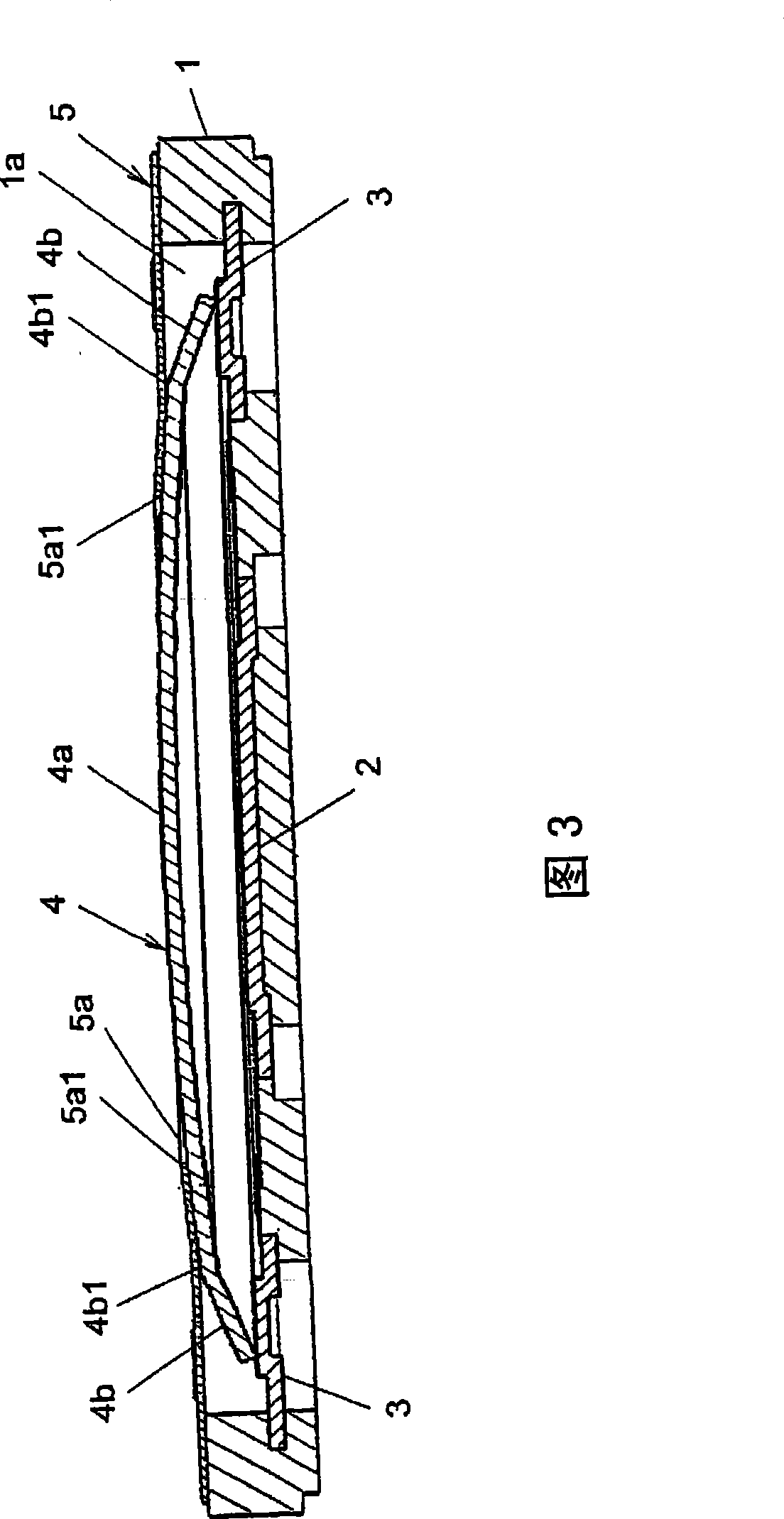

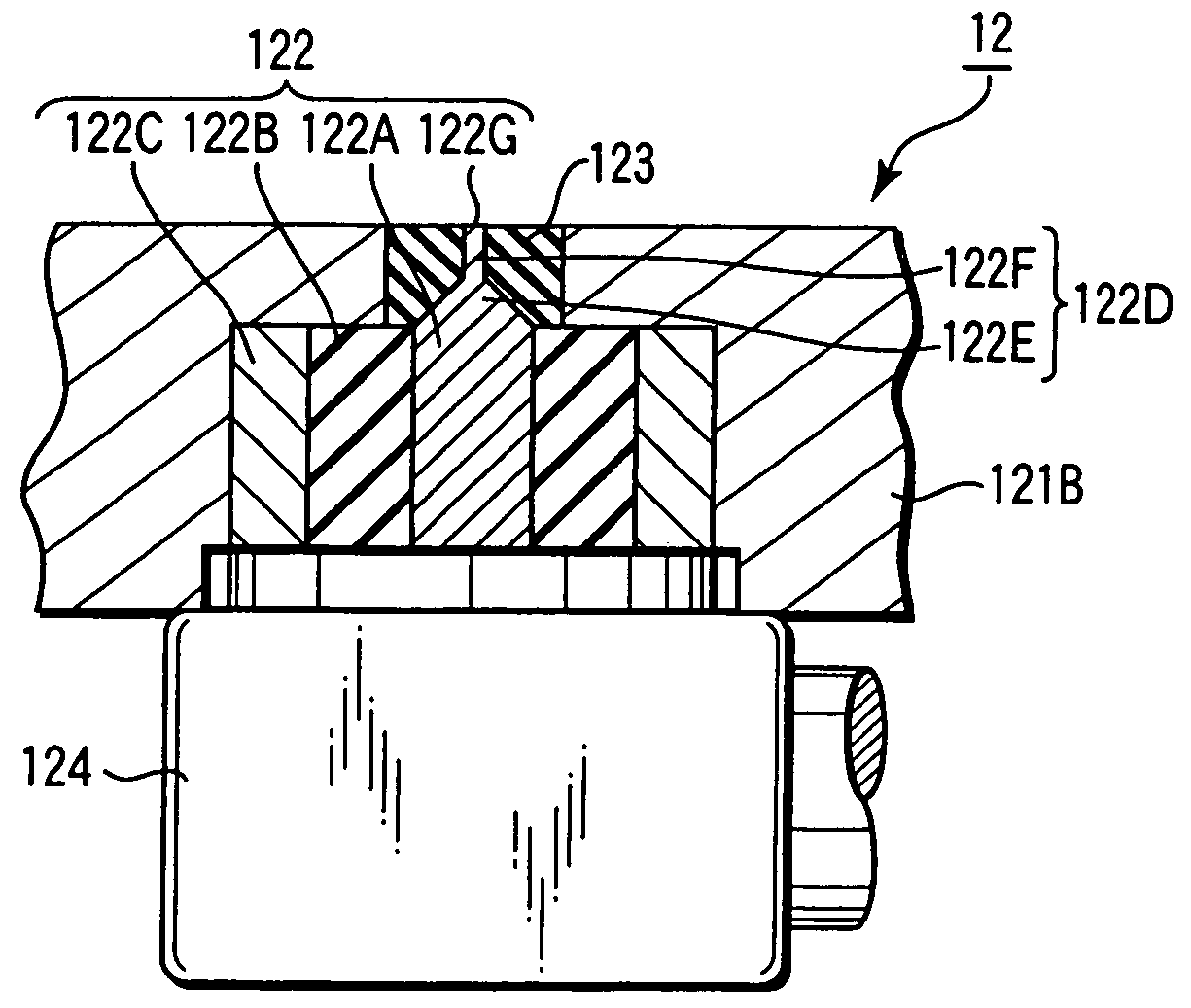

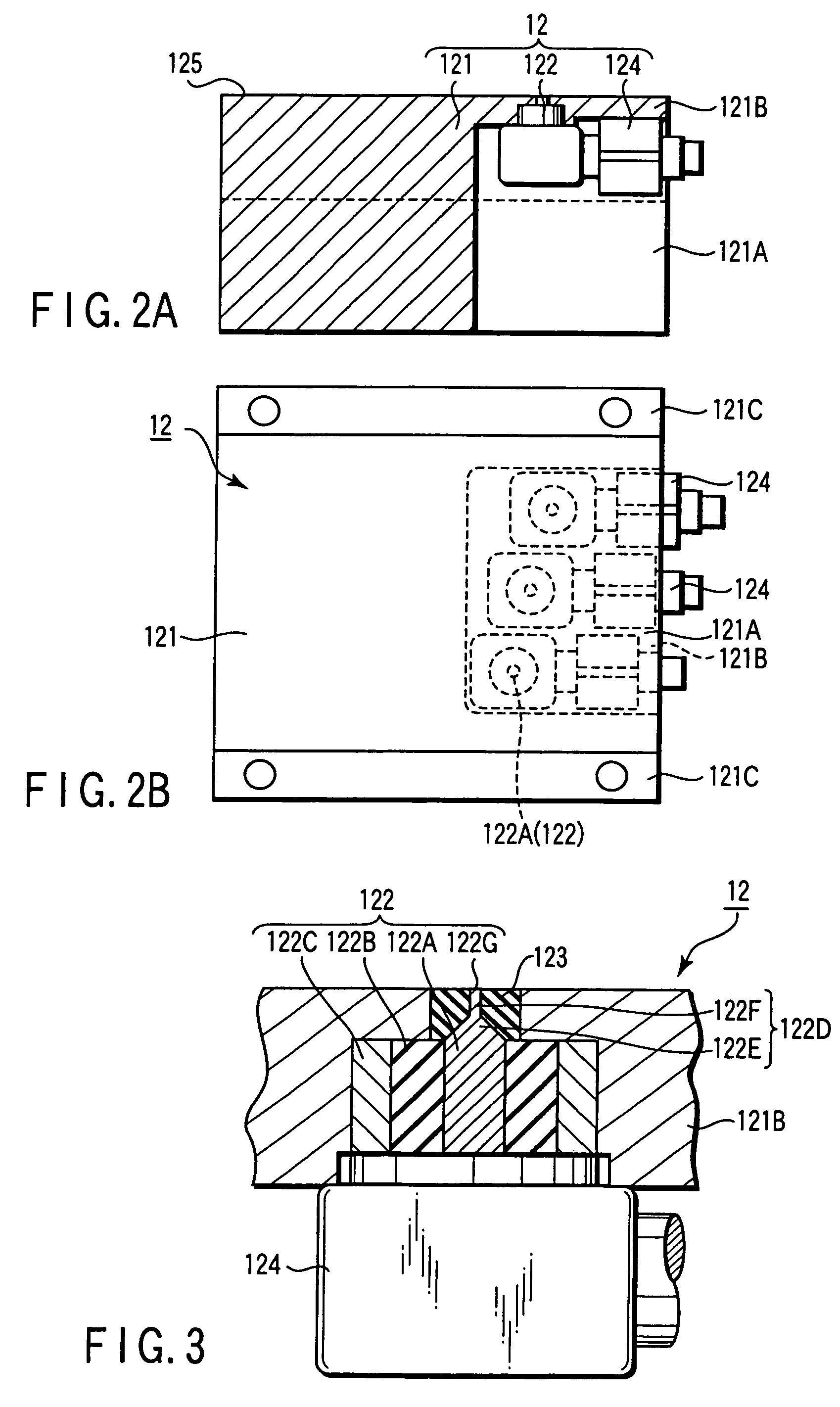

Impedance measuring apparatus and health management directing and suggesting apparatus

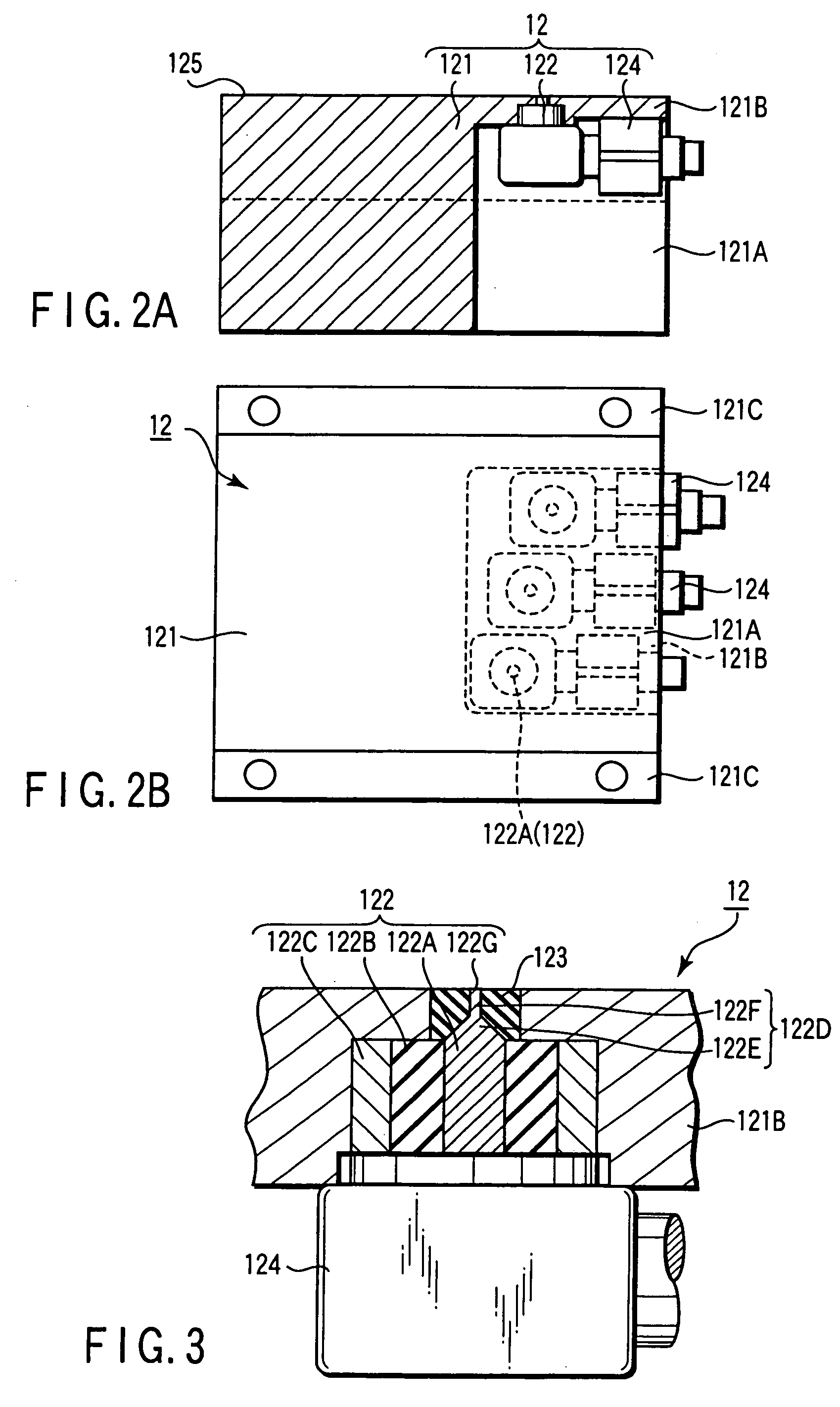

InactiveCN1608586AContact state is stableHigh precision measurementElectrocardiographySensorsCoil springPressure sense

The electrode supporting portion 11 is formed of the base 12 attached to the belt and the electrode portion 13 having the electrode 130. The pillar portion 132 of the electrode portion 13 is inserted into the hole 122 formed through the cover 121, and is oscillatably supported via the gap formed between the outer peripheral surface of the pillar portion 132 and the inner peripheral edge of the hole 122. There is provided the coiled spring 14 disposed between the hollow inside of the pillar portion 132 and the bottom plate 124, and the pressure sensing element 15 is provided in the center of the bottom plate 124 which receives the load of the end portion of the spring 14. The expansion and contraction of the spring 14 and the oscillation of the electrode portion 13 allows the electrode 130 to follow the movement of the body surface, thereby reducing changes in the contact condition between the electrode 130 and the subject's body.

Owner:OMRON HEALTHCARE CO LTD

Push button switch

Owner:ALPS ALPINE CO LTD

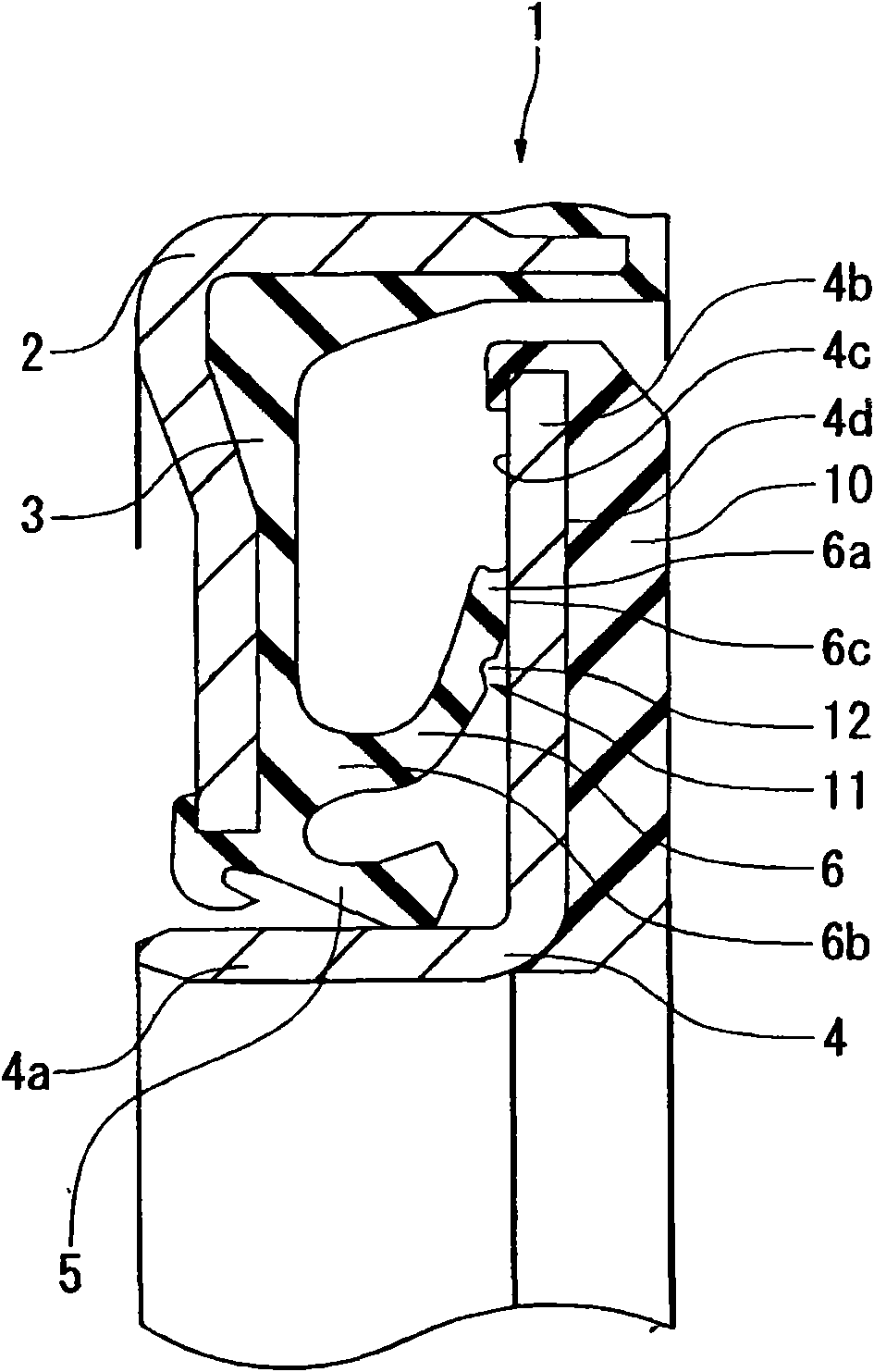

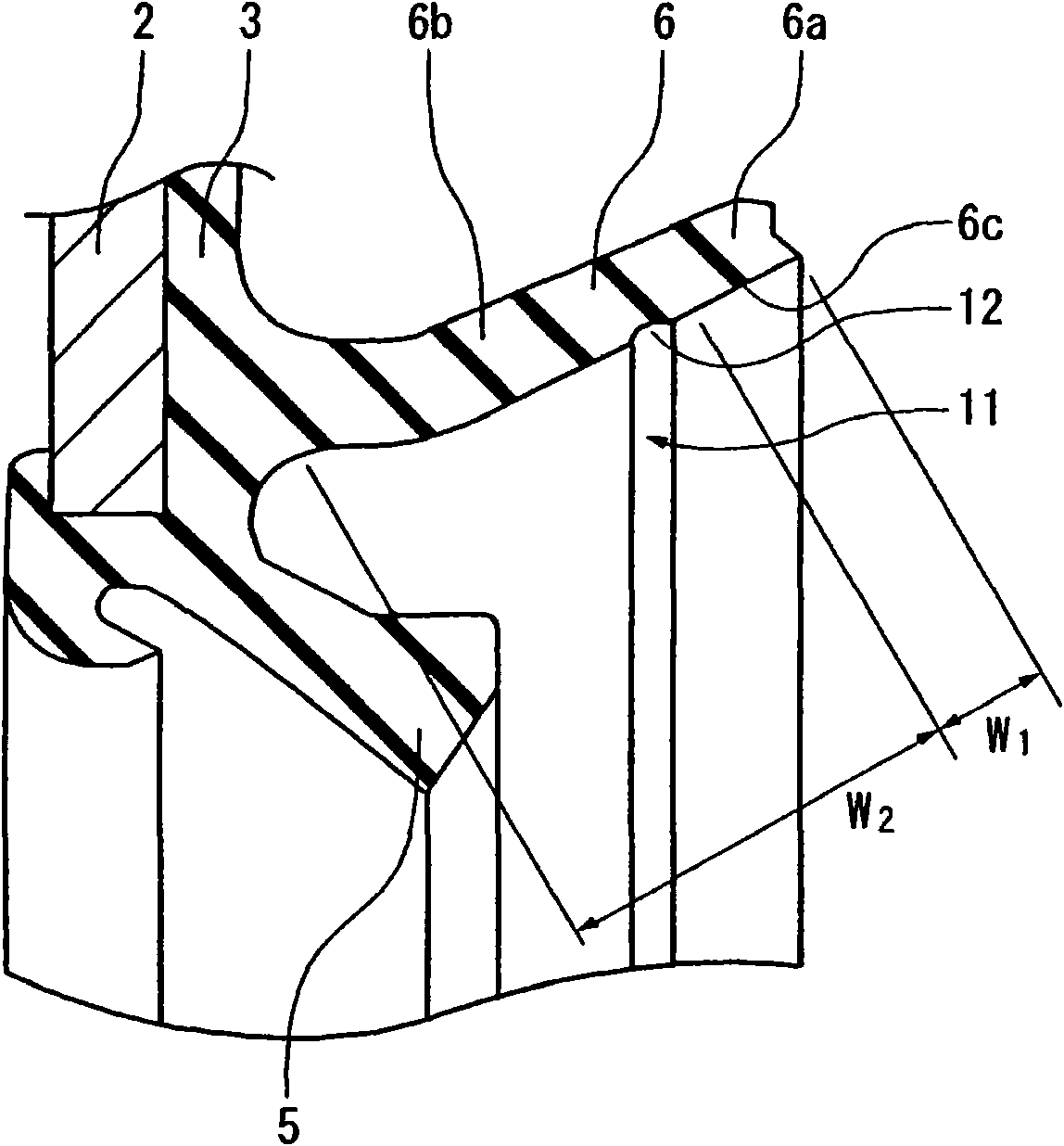

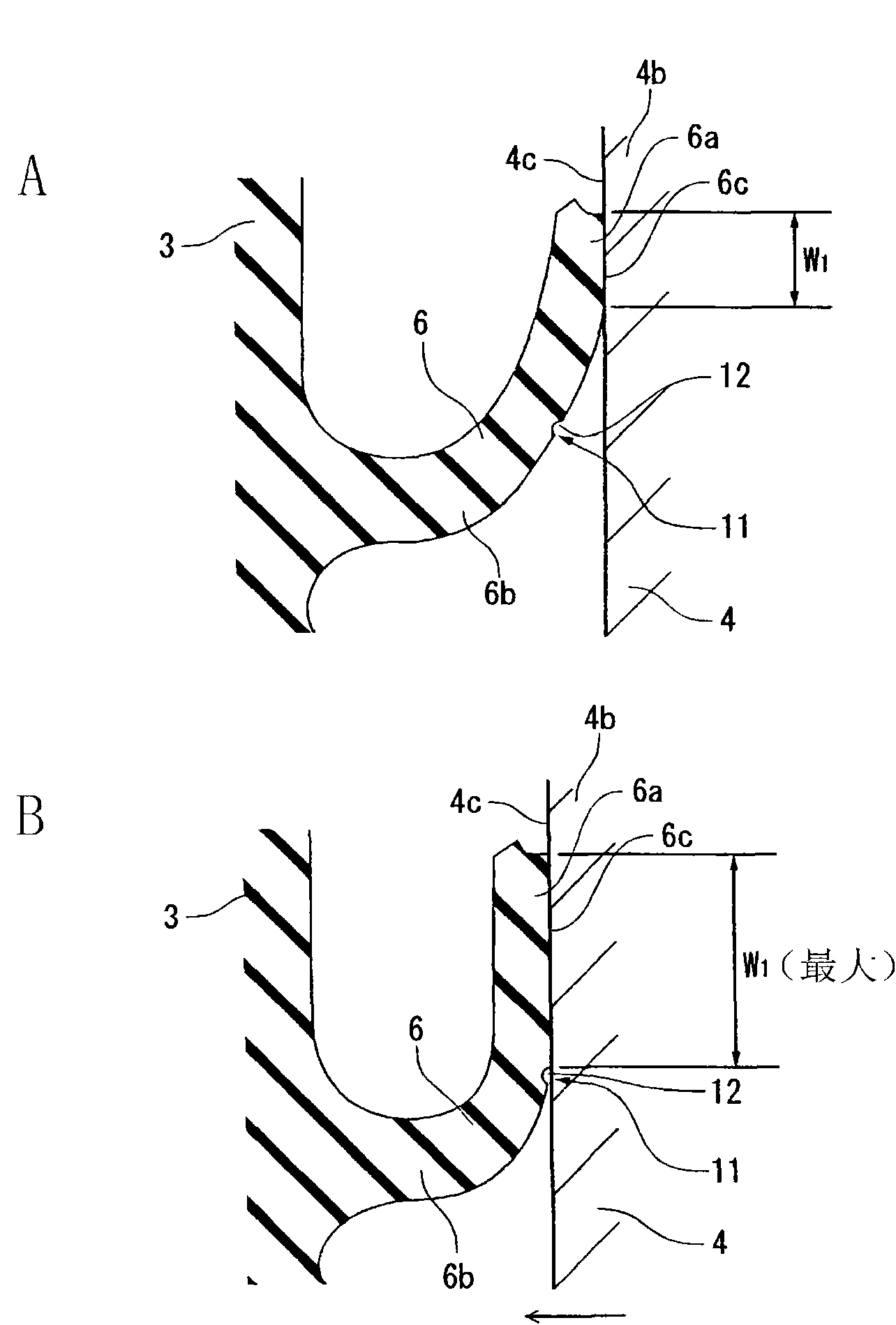

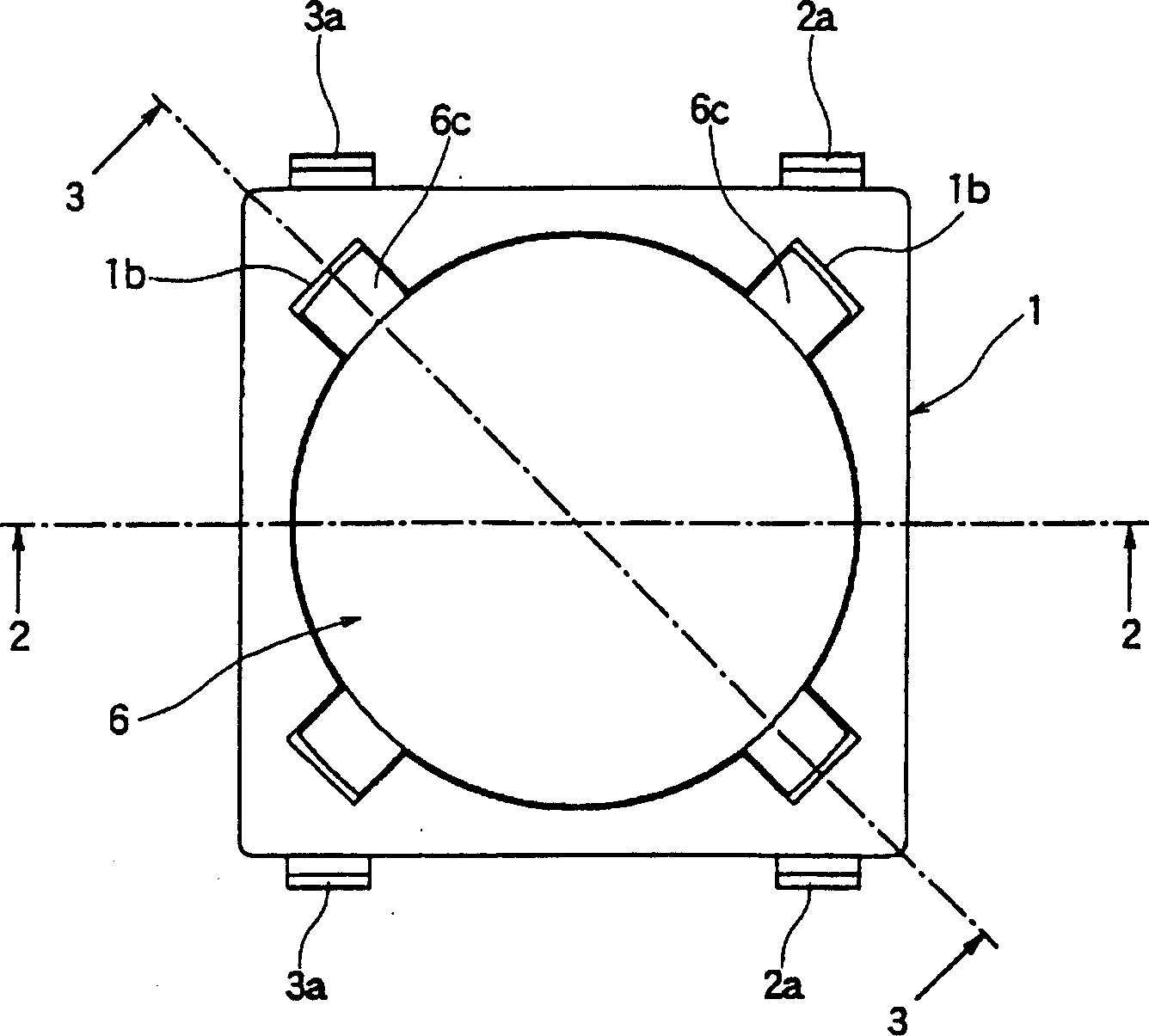

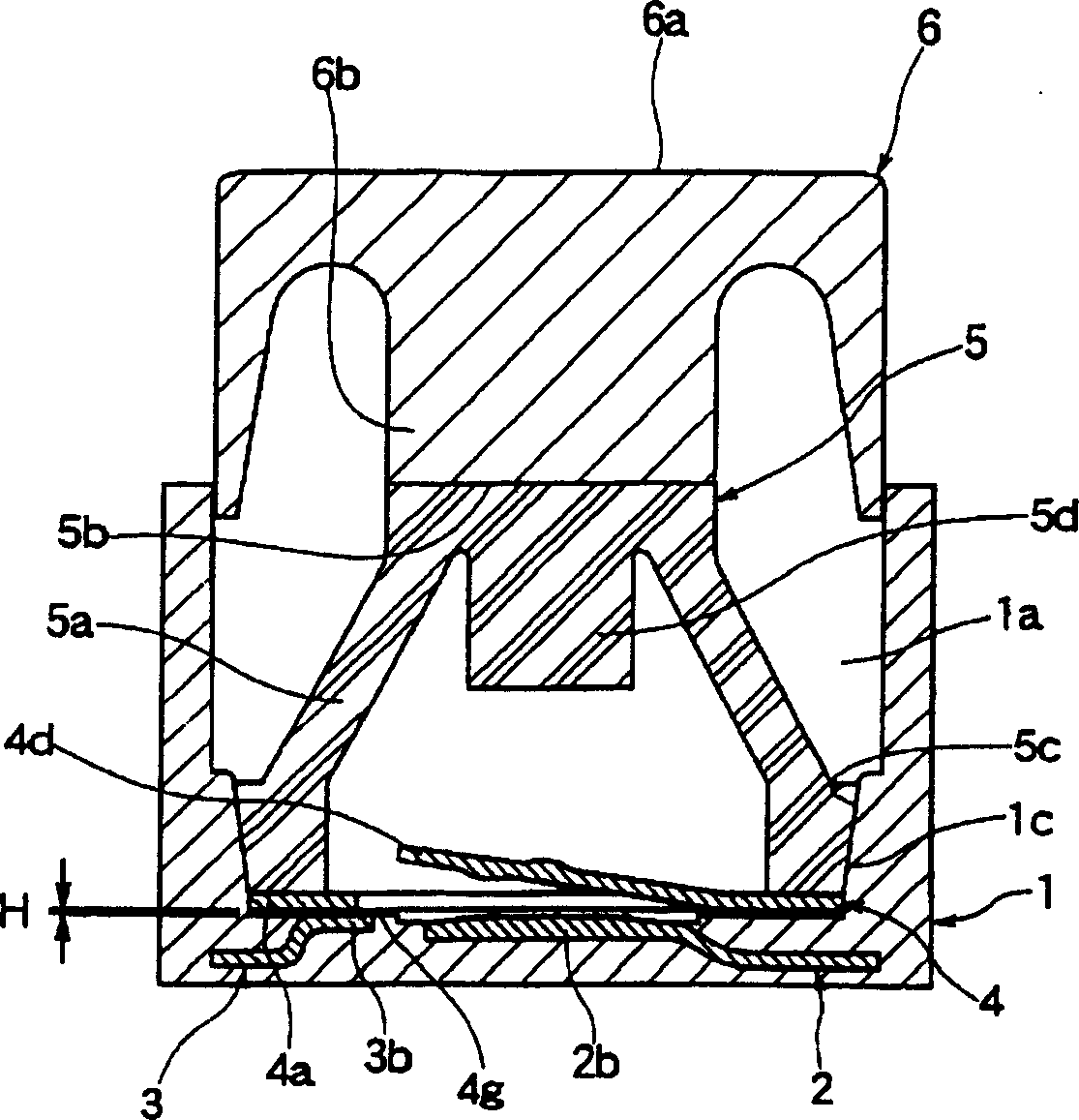

Hermetic sealing device

InactiveCN101600896AStable sealing performanceSuppresses sliding frictionEngine sealsEngineeringHermetic seal

A hermetic sealing device having a side lip coming into slidable tight contact with a partner member such as a slinger in which contact state of the side lip can be stabilized and sliding resistance of the side lip can be reduced when lip tightening margin becomes maximum. The contact surface (6c) at the contact part (6a) of the side lip (6) has a cross-section of a straight shape in a free state. The noncontact part (6b) of the side lip (6) is provided with a grease holding portion (11) for holding grease being supplied to the contact part (6a). The grease holding portion (11) provided at the noncontact part (6b) of the side lip (6) is arranged at a position becoming the boundary between the contact part (6a) and the noncontact part (6b) when the width (W 1 ) of the contact part (6a) and lip tightening margin become maximum. The grease holding portion (11) consists of an annular groove (12) or a radial groove.

Owner:NOK CORP

Conductive contact

InactiveCN101404217AMaximize contact areaContact state is stableContact surface shape/structureContact engagementsWeak currentEngineering

The invention relates to a conductive contact, in particular to a zigzag secondary camber conductive contact used for switches, relays and contactors, comprising a group of two contacts: a movable contact and a fixed contact; the movable contact and the fixed contact are respectively a concave camber and a convex camber which are coincident to each other; the invention uses the curve contact to replace a planar contact or point contact, solves the problems that the contact area of the conductive contact is extremely finite and the contact state is unstable, and overcomes the shortages that the existing conductive contact technique and product have weak current passing capability and the contacts are easy to be burned.

Owner:李健全 +2

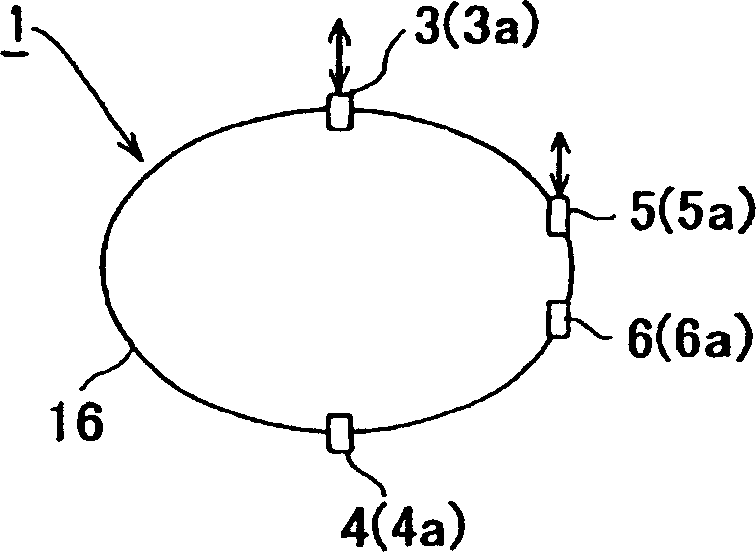

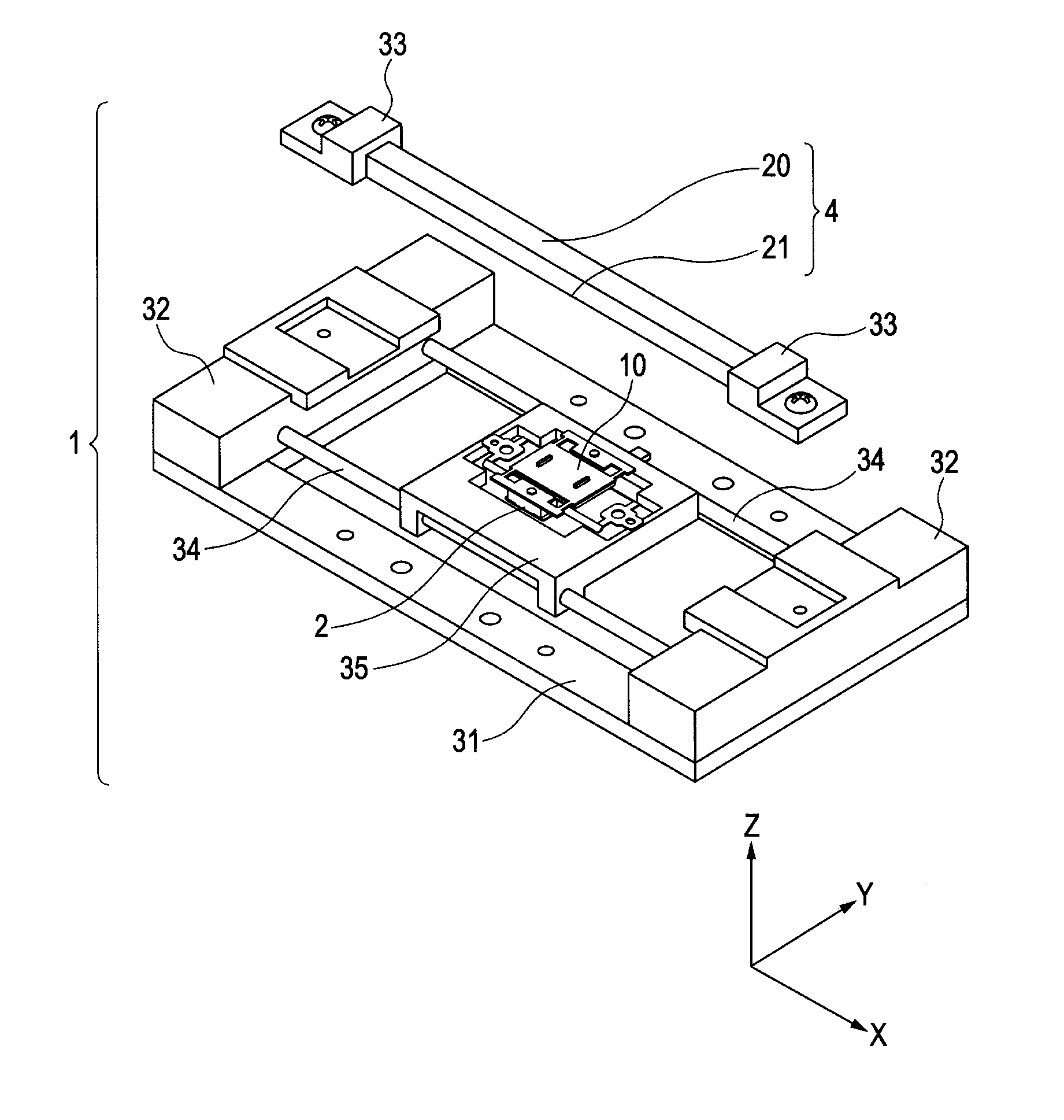

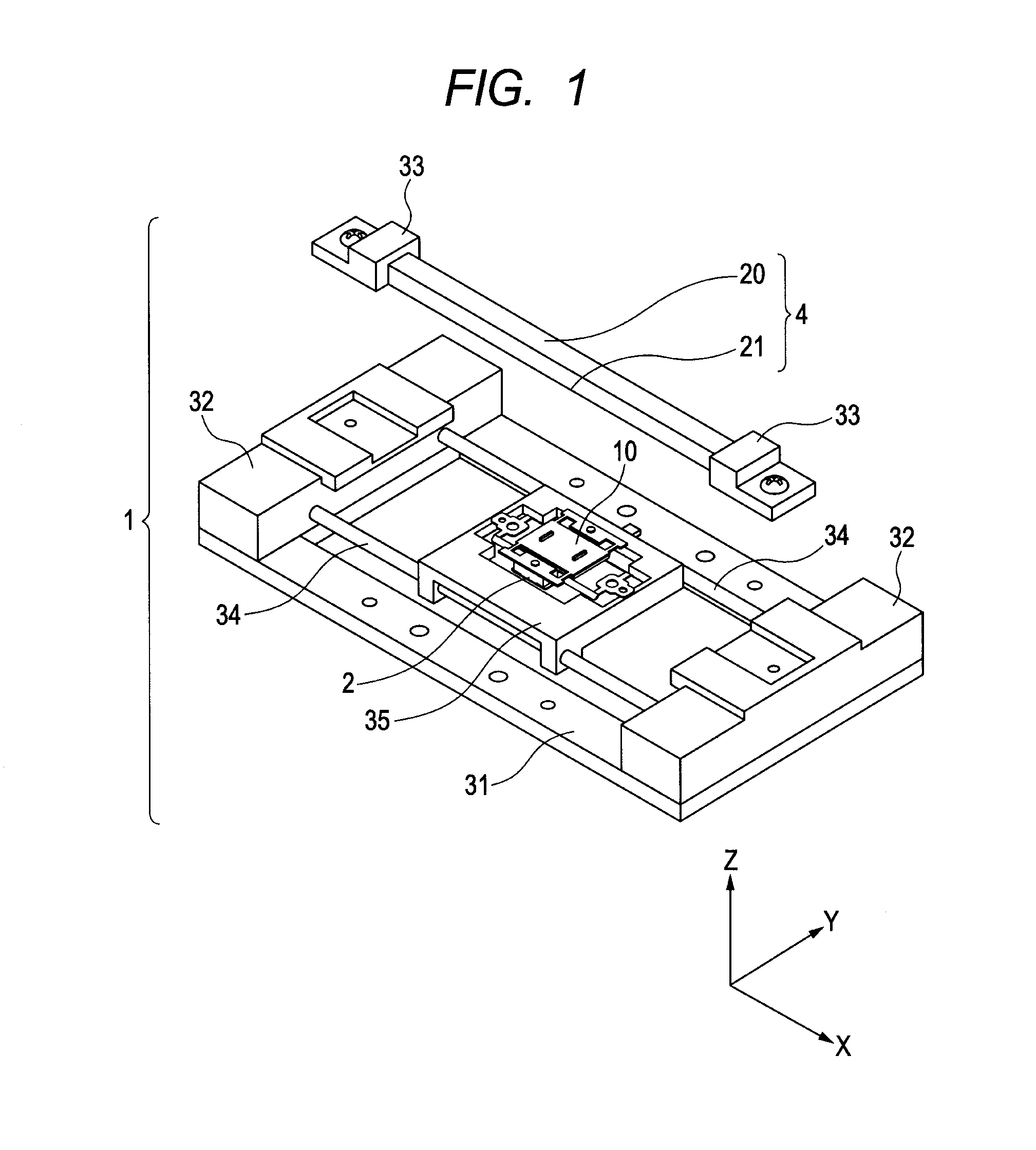

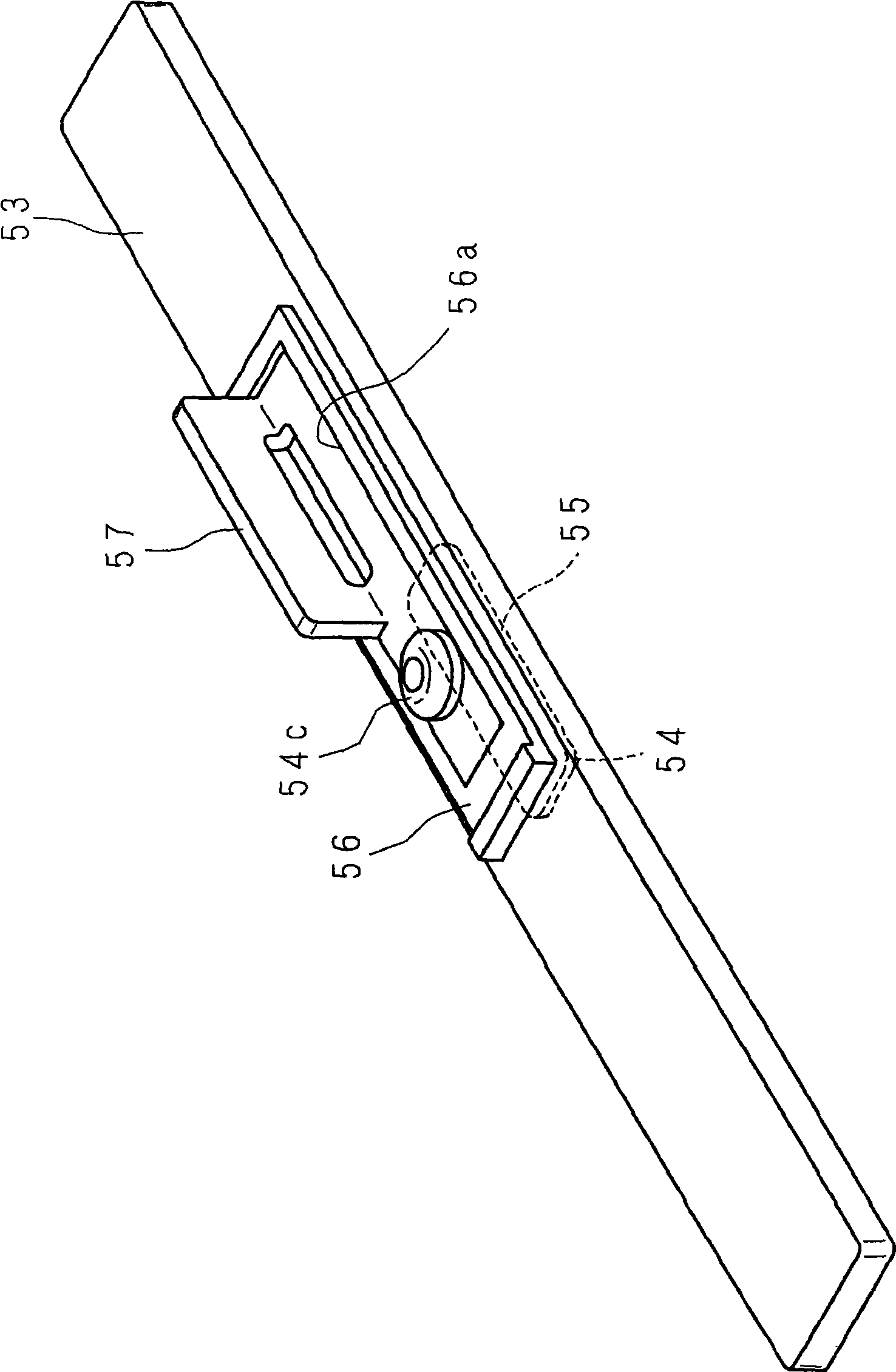

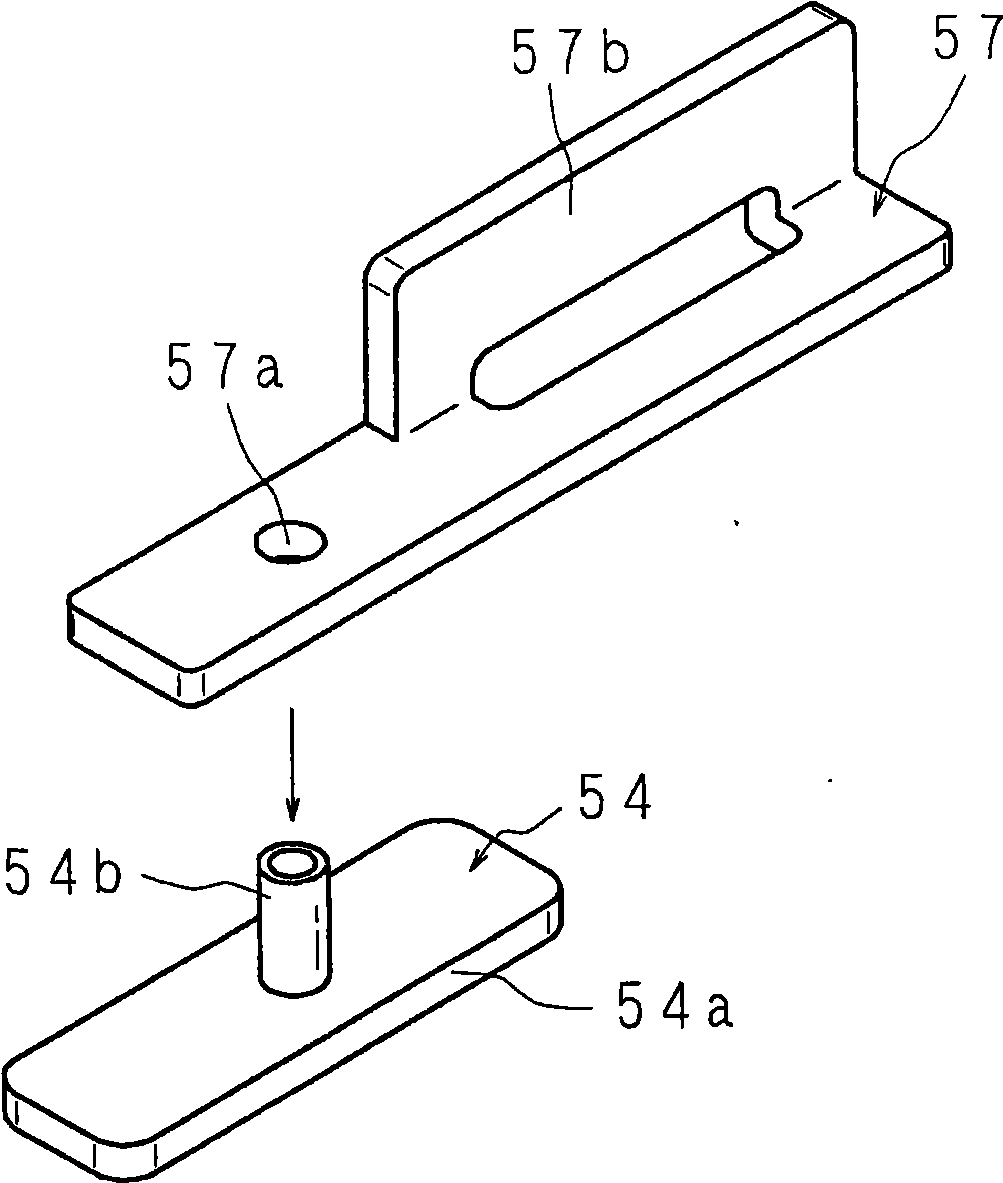

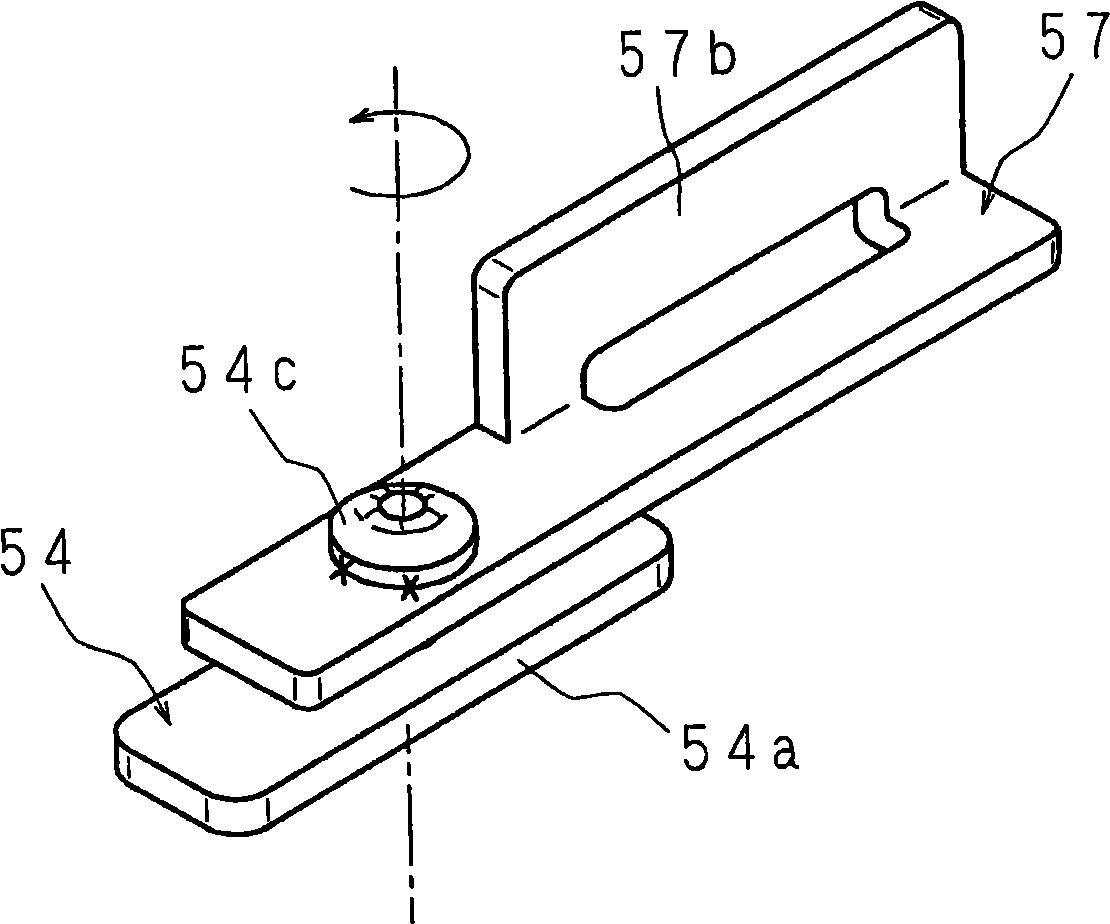

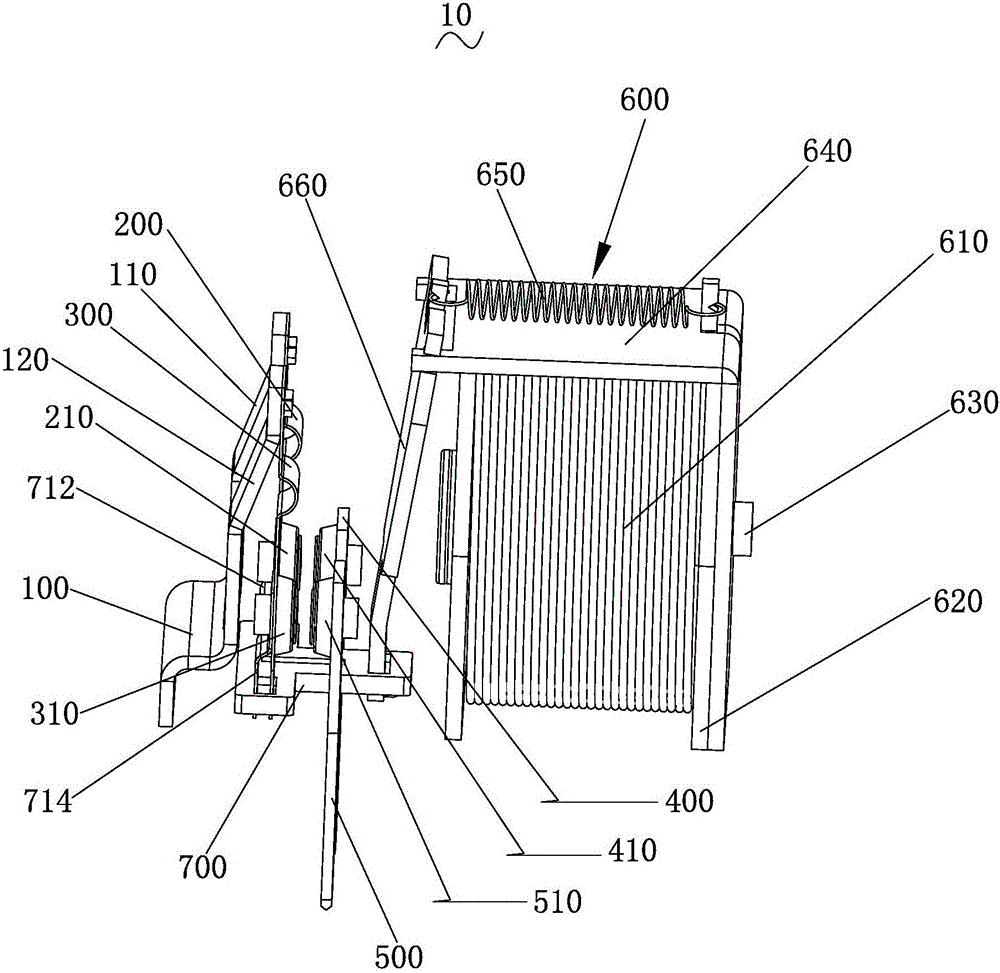

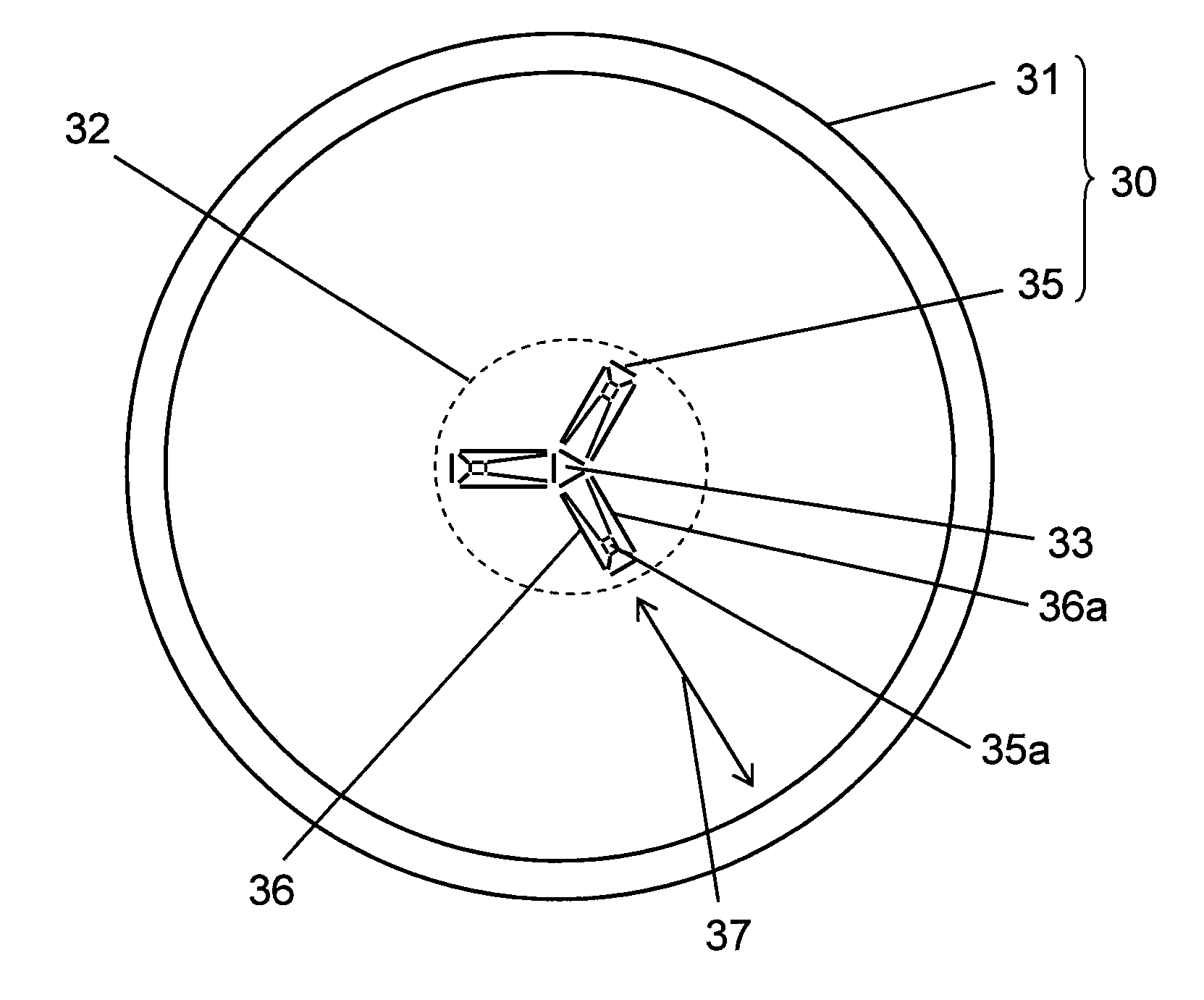

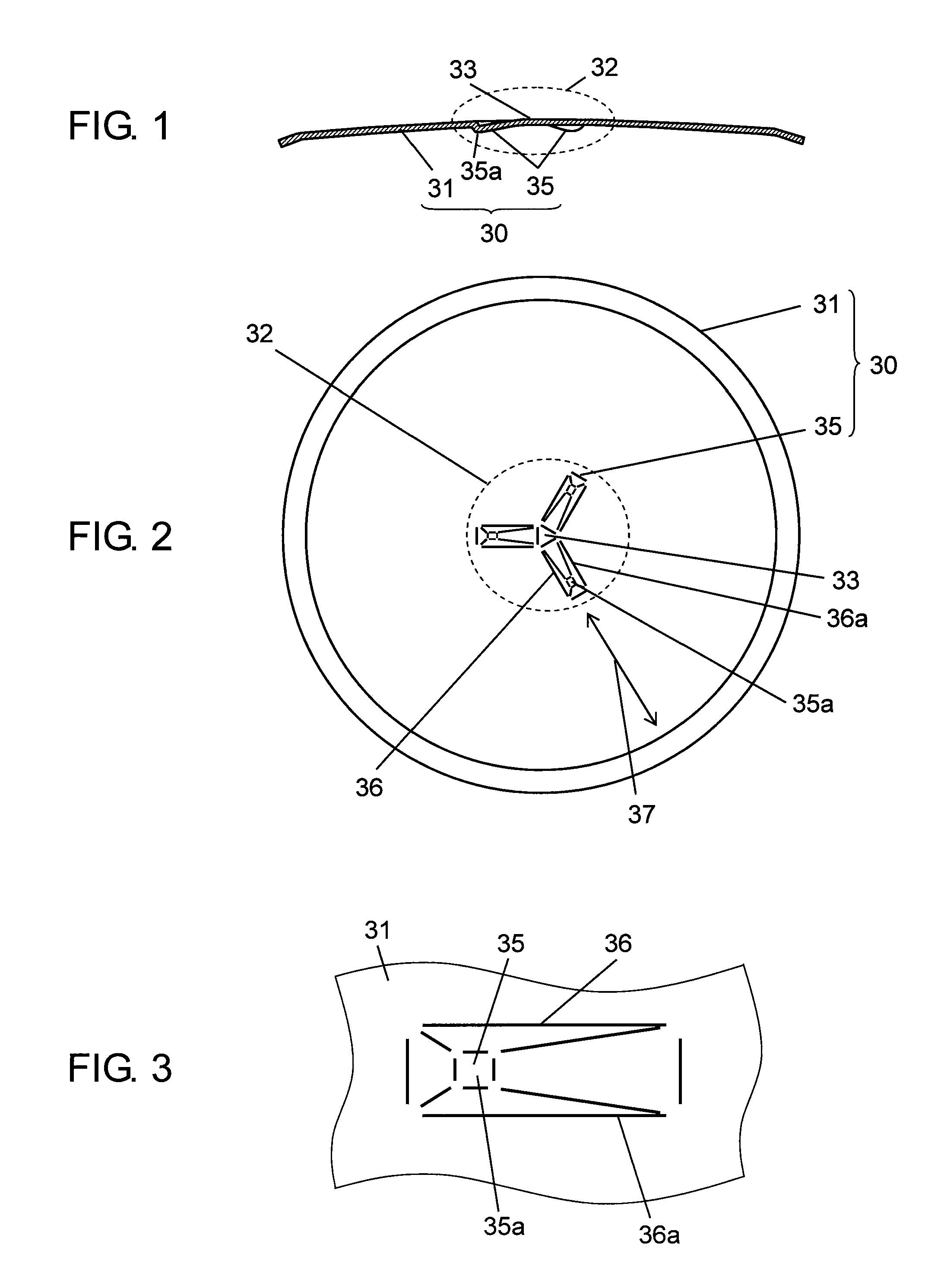

Vibration wave driving apparatus

InactiveUS8760036B2Increase in numberIncrease in of in spacePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineering

Owner:CANON KK

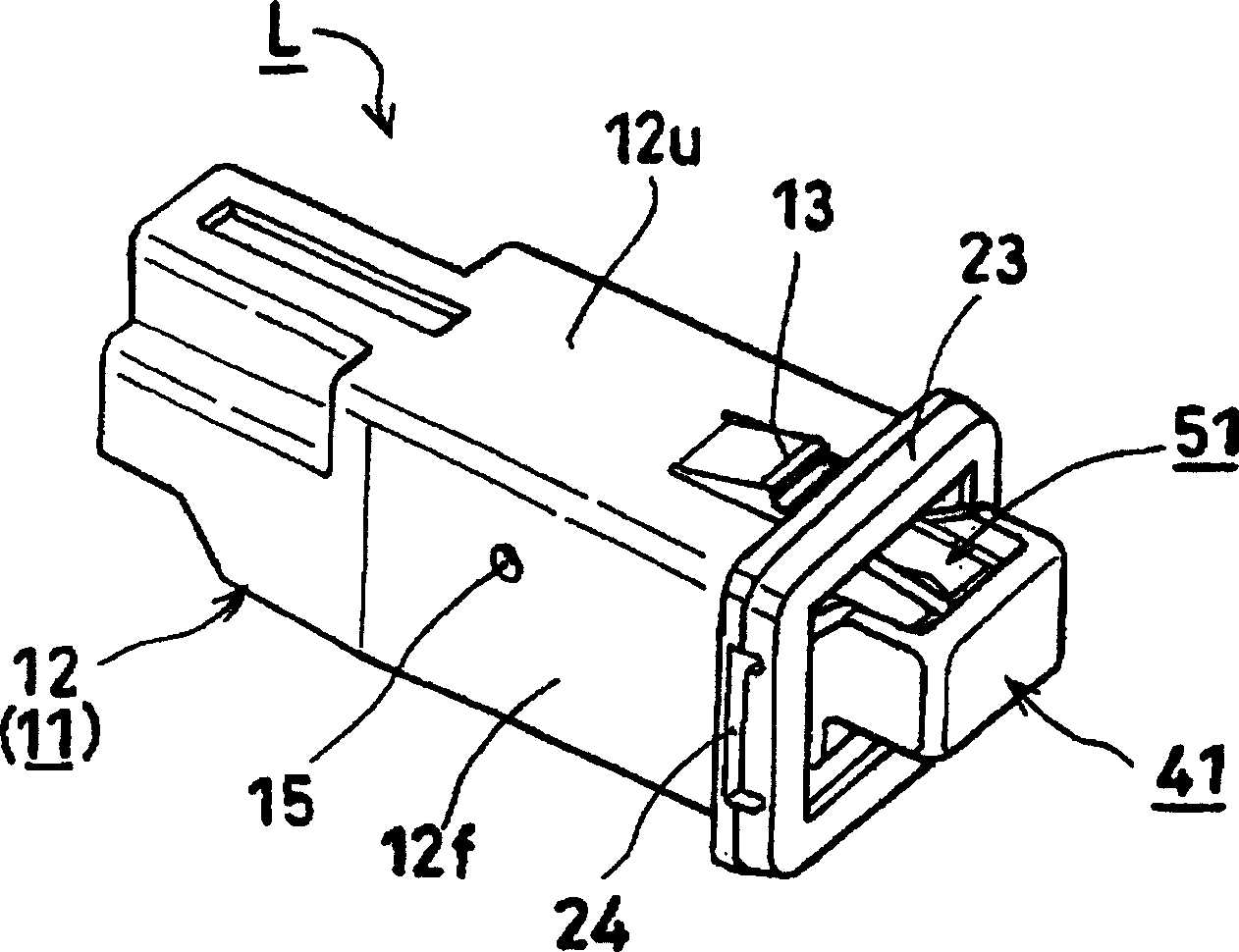

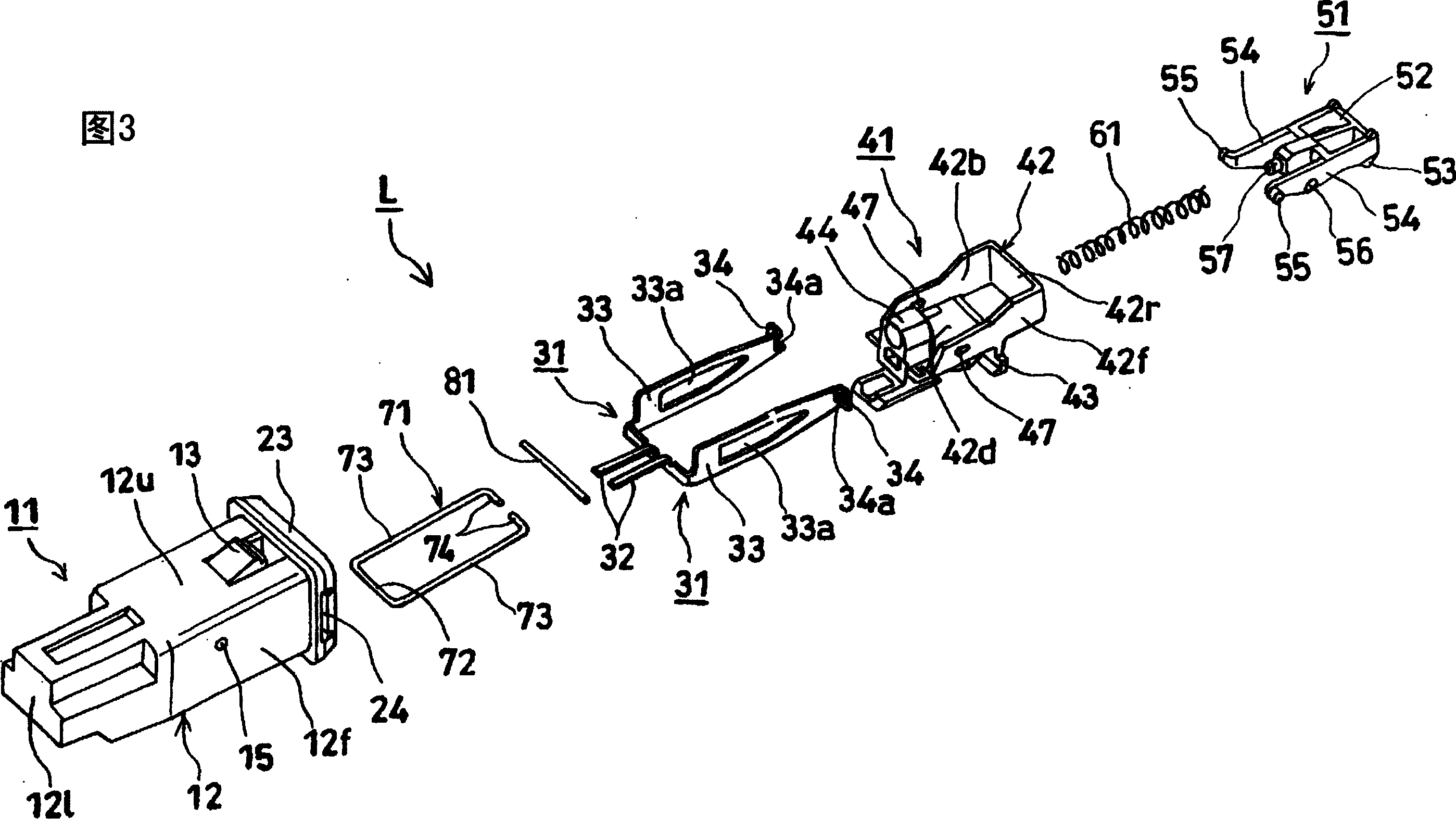

Latch with switch

InactiveCN1610493AGuaranteed reliabilityCheap manufacturingContact driving mechanismsCasings/cabinets/drawers detailsLocking mechanismCoil spring

Provided is a latch with a switch enabling a movable terminal to be easily attached. This latch with a switch is so structured that, when a movable terminal 41 is pushed into a housing 11 against energizing force of a coil spring, the movable member is locked at the pushed-in position by a lock mechanism to turn on the switch; and when the movable member is pushed into the housing against the energizing force of the coil spring again, the lock mechanism is brought into an unlocking state to restore the movable member to a projected position by the energizing force of the coil spring. The switch is composed of: a pin 81 attached to the movable member and having both ends projecting from two facing side faces of the movable member; and a pair of fixed terminals 31 fixed to the facing inner side faces of the housing, brought into a conducting state by bringing both the ends of the pin into contact with them when the movable member is in the projected position, and brought into a non-conducting state by separating both the ends of the pin from them when the movable member is in the pushed-in position. The pin is incorporated from a movable terminal insertion hole 15 formed in the side faces of the housing.

Owner:NIFCO INC

Button switches

The present invention provides a push-button switch with high contact reliability, which provides a desired operation feeling, and prevents the invasion of dusts and the like to stabilize the contact state between a movable contact and a fixed contact when a rubber spring is pushed to perform the verse operation. The push-button switch is characterized in having: a housing having a housing part, fixed contacts fixed in the housing part, a movable contact arranged opposed to the fixed contacts, and a rubber spring having a lower end peripheral edge part in the holding part bendable skirt part provided in a space formed together with an upper end pressing surface part, and contacts / disconnects the movable contact to / from the fixed contact due to the bending of this skirt part. The lower end peripheral edge part of the rubber spring and opposed faces of a housing wall part of the housing 1 having this lower end peripheral edge part held therein are formed of inclined faces or arc faces each opening from the under face side toward the top face side.

Owner:ALPS ALPINE CO LTD

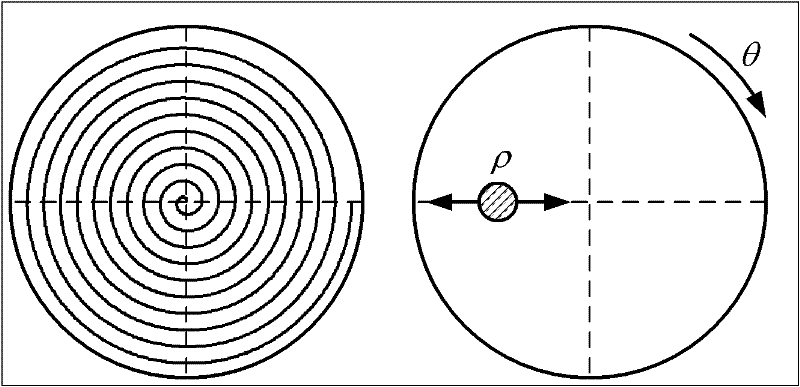

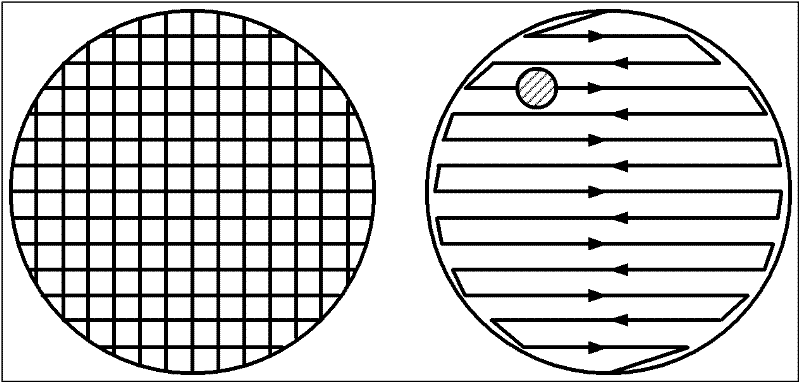

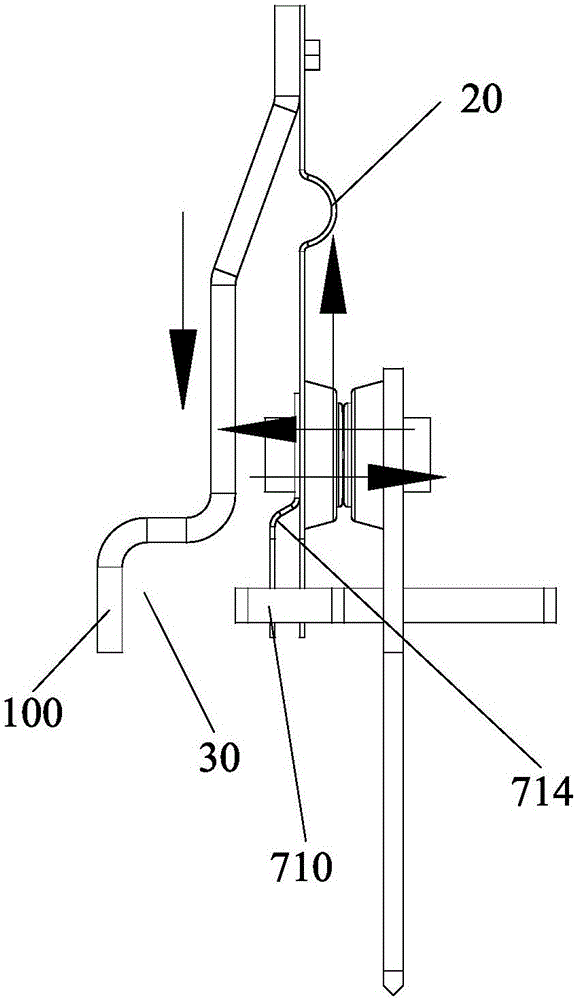

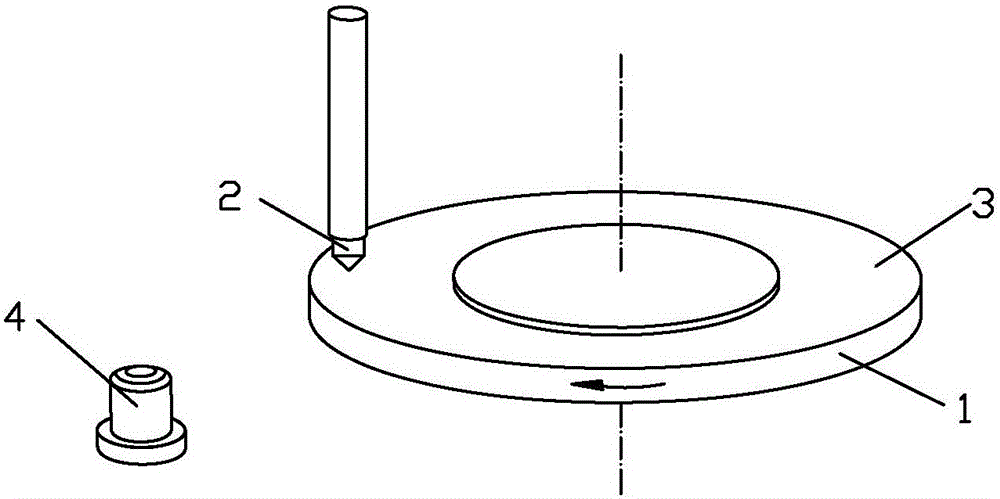

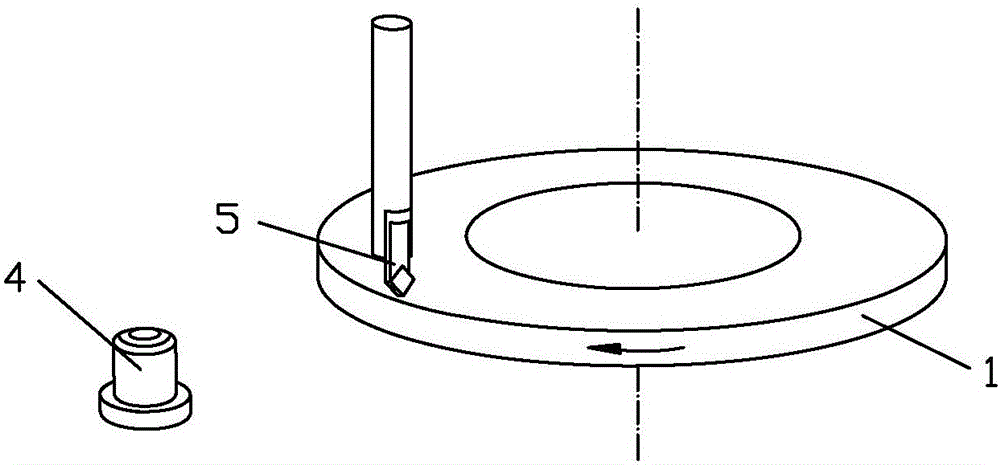

Modification processing method of optical element surface and numerical control machine used thereby

ActiveCN101898325BUniform movement speedDwell time calculation is simpleOptical surface grinding machinesNumerical controlCoupling

The invention discloses a modification processing method of an optical element surface, comprises the following steps: planning a processing and scanning route, converting coordinates, calculating processing dwell time, modifying and processing, converging step by step and the like, is combined with the advantages of an X-Y scanning mode and a rho-theta scanning mode, has the advantages of good stability, strong controllability, simple processing operation and high processing precision, and is especially suitable for the modification processing of the optical element surface of a high gradient workpiece. The invention also discloses a numerical control machine used in the modification processing method, an abrasive disk thereof and a rotation axis thereof are connected with a universal coupling, the rotation axis of a removal function generator is aslant arranged on an engine base in a mode of having an included angle beta with the optical axis of a workpiece to be processed, and the numerical control machine has the advantages of simple structure, low cost and the like.

Owner:NAT UNIV OF DEFENSE TECH

Battery

InactiveCN101533899AContact state is stablePrevent leakageFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineeringCurrent collector

A battery has current collectors and terminals in stable contacing status that represses the poor contact caused by applying impact such as falling, and fine quality and outer casing sealing performance. At a central portion of a lid (3) of a battery, a negative terminal (4), which has a T-shaped section view, is provided so as to be surrounded by a gasket (5) and pierce the lid (3). An insulator (6) is provided at the inner face side of the lid (3). A plate-like current collector (7) is placed in a recess (6a) of the insulator (6). Notches (72a) are provided at two positions of an insertion hole which is provided at one end portion side of the current collector (7). By inserting the negative terminal (4) into the insertion hole and crimping an end portion of a leg portion (42) of the negative terminal (4), the negative terminal (4) is fixed to the current collector (7) with a deforming part of the end portion eating into the notches (72a) and being locked.

Owner:GS YUASA INT LTD

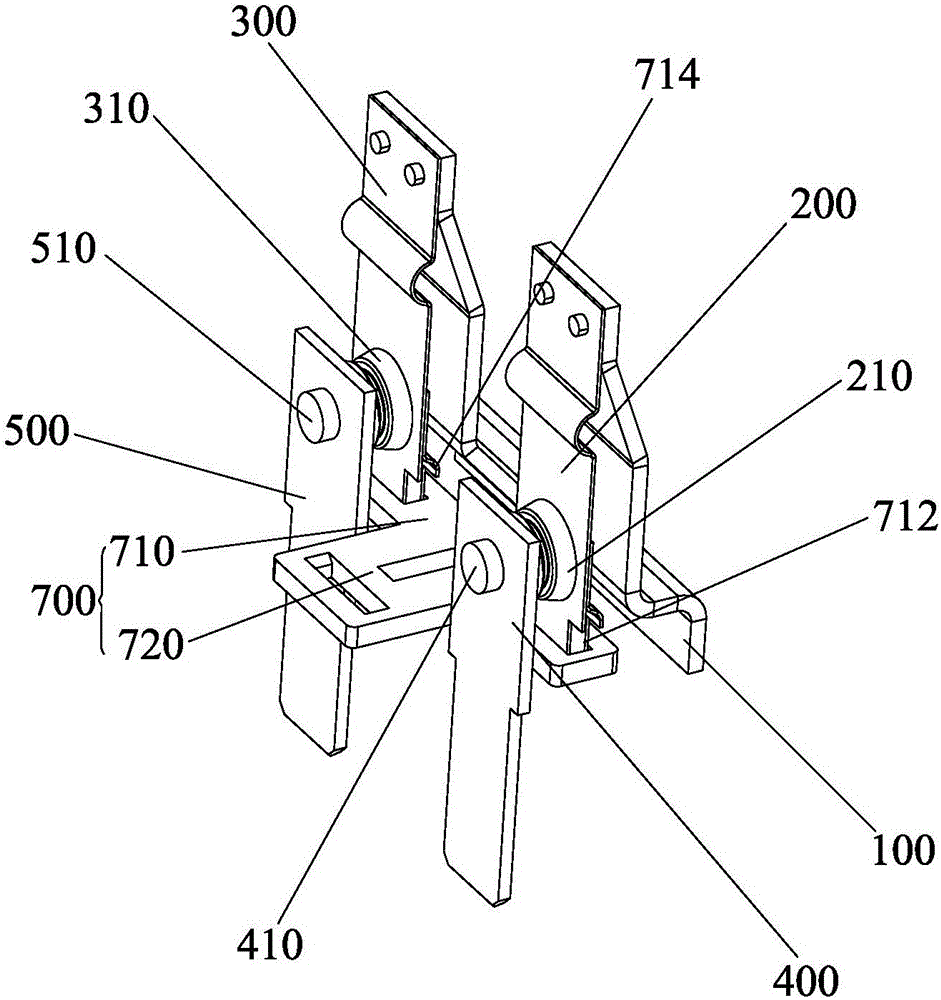

Beat-type electromagnetic relay used for high-voltage direct current

ActiveCN106024526ACounteract electrodynamic repulsionIncrease pressureElectromagnetic relay detailsContactsReciprocating motionHigh-voltage direct current

The invention discloses a beat-type electromagnetic relay used for high-voltage direct current. The beat-type electromagnetic relay comprises a connecting plate, a first movable spring plate, a second movable spring plate, a first static conducting plate, a second static conducting plate, a beat-type drive assembly and a pushing plate. The connecting plate is provided with a first conducting plate and a second conducting plate, each of the first movable spring plate and the second movable spring plate is provided with a fixed end and a free end, the fixed end of the first movable spring plate is fixed onto the first conducting plate, the free end of the first movable spring plate is connected with the pushing plate, the fixed end of the second movable spring plate is fixed onto the second conducting plate, and the free end of the second movable spring plate is connected with the pushing plate; the pushing plate is used for driving the free end of the first movable spring plate and the free end of the second movable spring plate to be connected or disconnected with the first static conducting plate and the second static conducting plate respectively; and the beat-type drive assembly is used for driving the pushing plate to perform a reciprocating motion. The beat-type electromagnetic relay used for high-voltage direct current disclosed by the invention has the advantages of simple structure, low price, cost reduction and the like.

Owner:HUIZHOU EVE TECH CO LTD

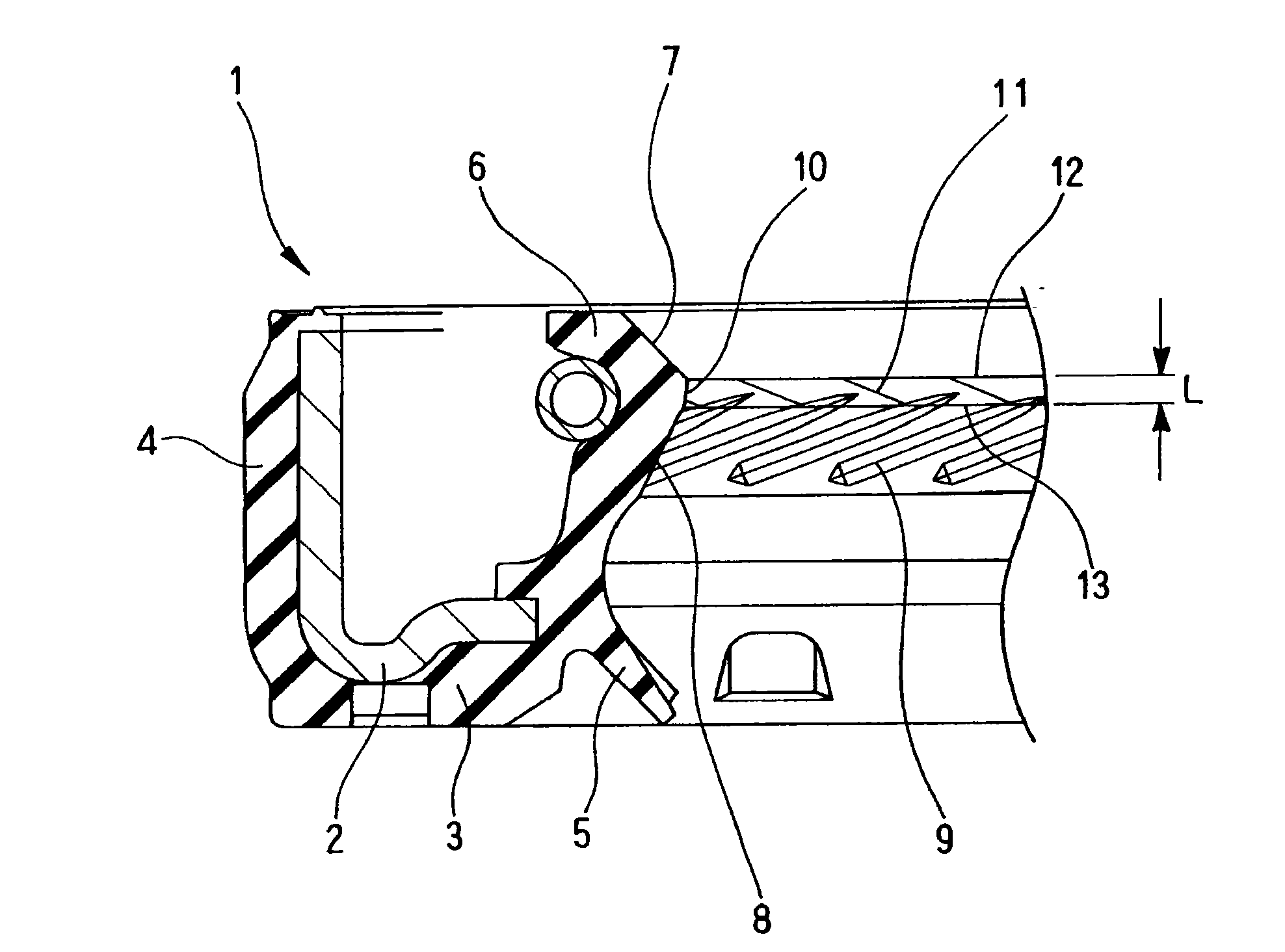

Oil seal

An oil seal (1) has a seal lip (6) in slidable intimate contact with the circumferential surface of a mating member, a slope (7) on the side of sealed fluid and a slope (8) on the side opposite to the sealed fluid that are provided on the seal lip (6), and a screw section (9) provided on the slope (8) on the side opposite to the sealed fluid and performing a function of pushing back the sealed fluid by a pumping effect induced by rotation of the mating member. The oil seal (1) has low torque characteristics based on fluid lubrication, and such characteristics are achieved by increasing the thickness of an oil film on sliding surfaces. An intermediate surface (10) is provided between the slopes (7, 8), and an oppositely threaded screw section (11) for performing a function of sucking the sealed fluid by a pumping effect induced by rotation of the mating member is provided on the intermediate surface (10). The oppositely threaded screw section (11) on the intermediate surface (10) is provided in such a way that the screw section (11) does not reach the boundary (13) between the intermediate surface (10) and the slope (8), and this provides a threadless region that lies in the entirecircumference between the screw section (11) and the boundary (13) and is in intimate contact with the circumferential surface of the mating member.

Owner:NOK CORP

Signal detection contactor and signal calibration system

InactiveUS20060006859A1Reliably detect signalImprove RF characteristicsSemiconductor/solid-state device testing/measurementMeasurement leads/probesPhase differenceTester device

A signal detection contactor has a contactor main body and a plurality of coaxial bodies. Each coaxial body includes a core wire. The core wire is used for coming into contact with a probe of a prober and for receiving a signal transmitted from a tester, in order to calibrate a phase difference among signals transmitted through a plurality of probes.

Owner:TOKYO ELECTRON LTD

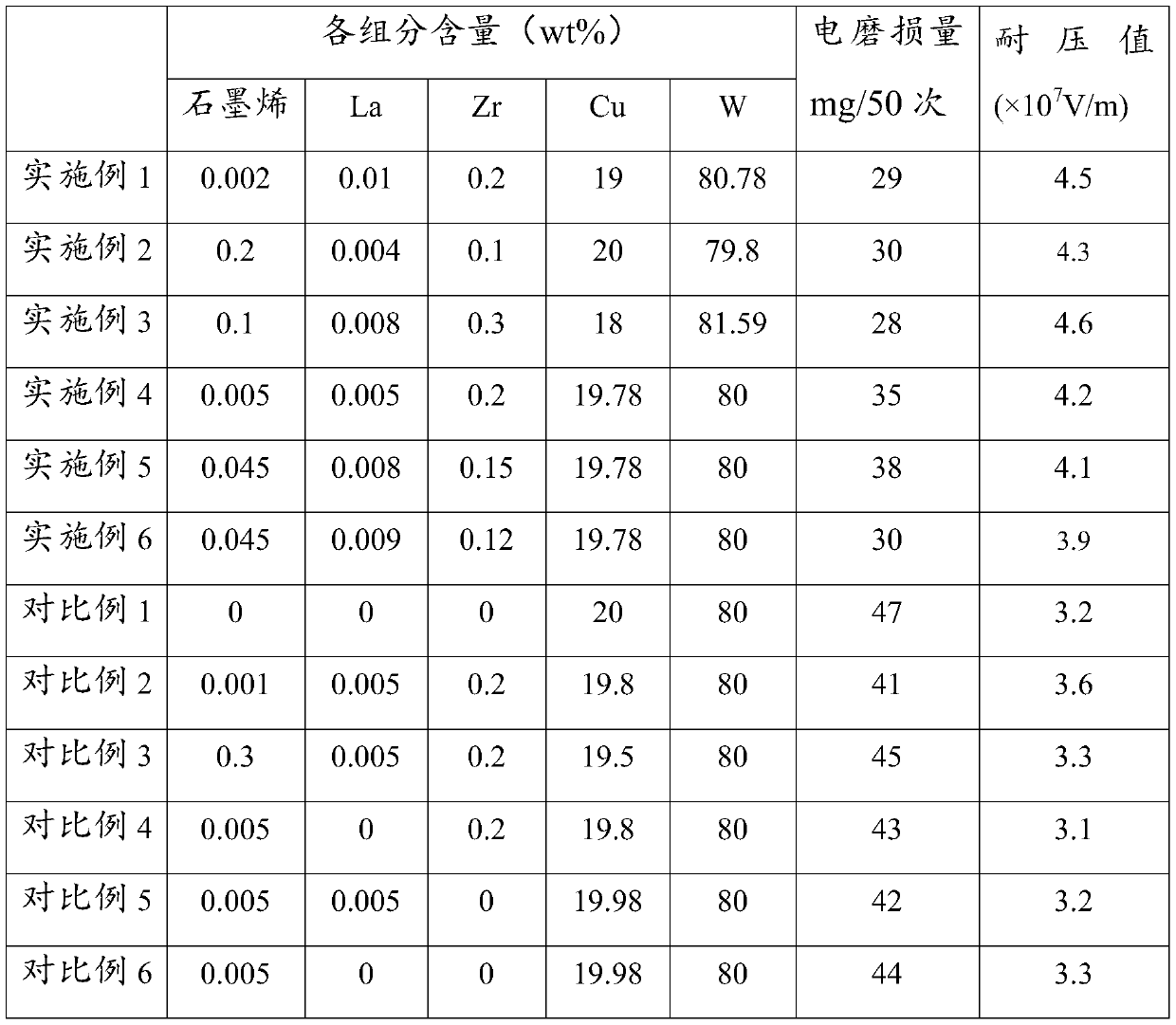

Movable contact point

InactiveUS7525060B2Increased durabilityReduce frequencyContact surface shape/structureContact with seperate bridge contactEngineeringSpherical shaped

A movable contact point according to the present invention includes a dome-shaped portion protruded upwardly at its center portion and at least three protrusions formed, on the dome-shaped portion, to protrude downwardly at positions which are evenly spaced apart from the center position of the dome-shaped portion, wherein the protrusions are formed to have a quadrangular-pyramid shape protruding downwardly and having a spherical-shaped apex portion.

Owner:PANASONIC CORP

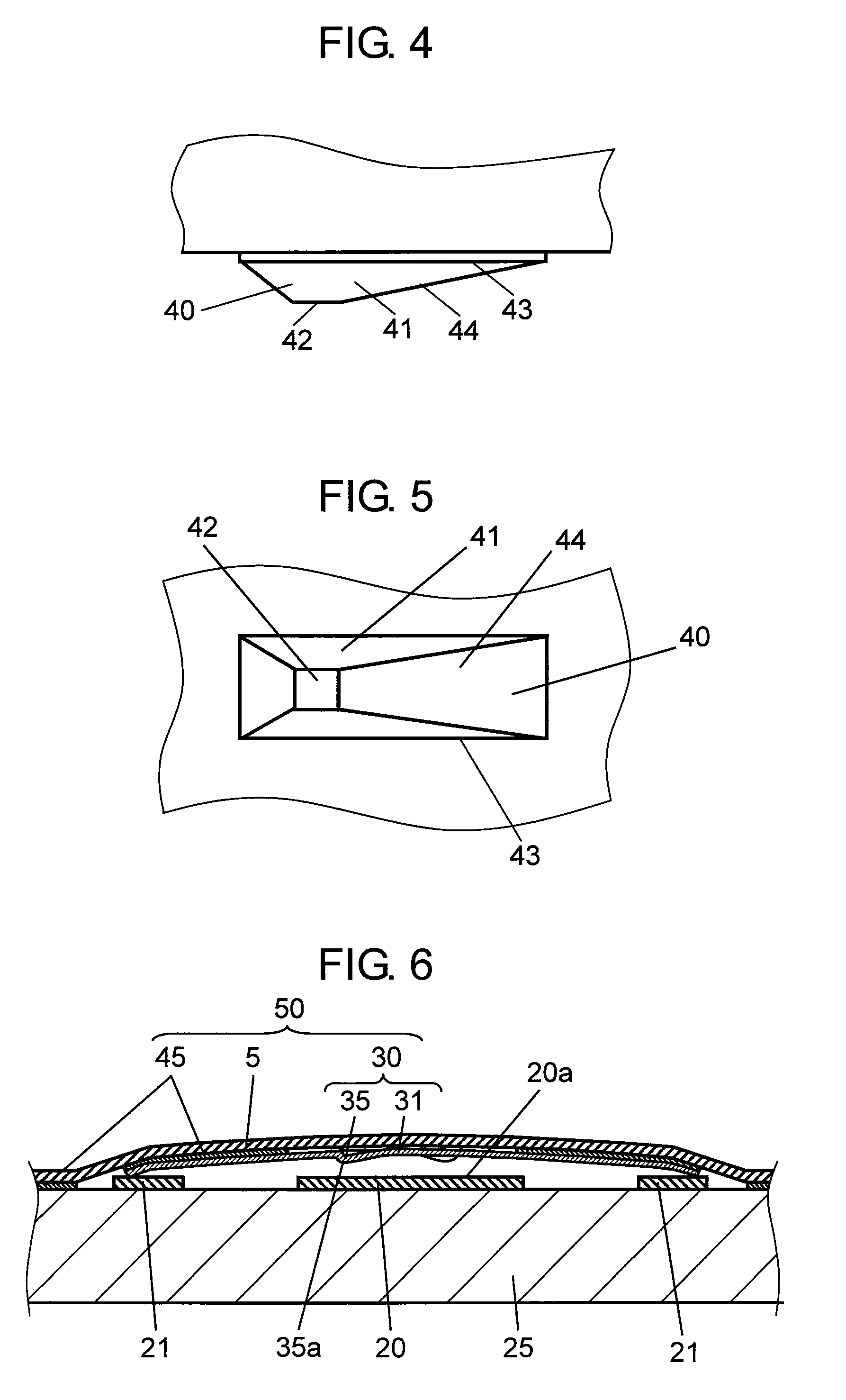

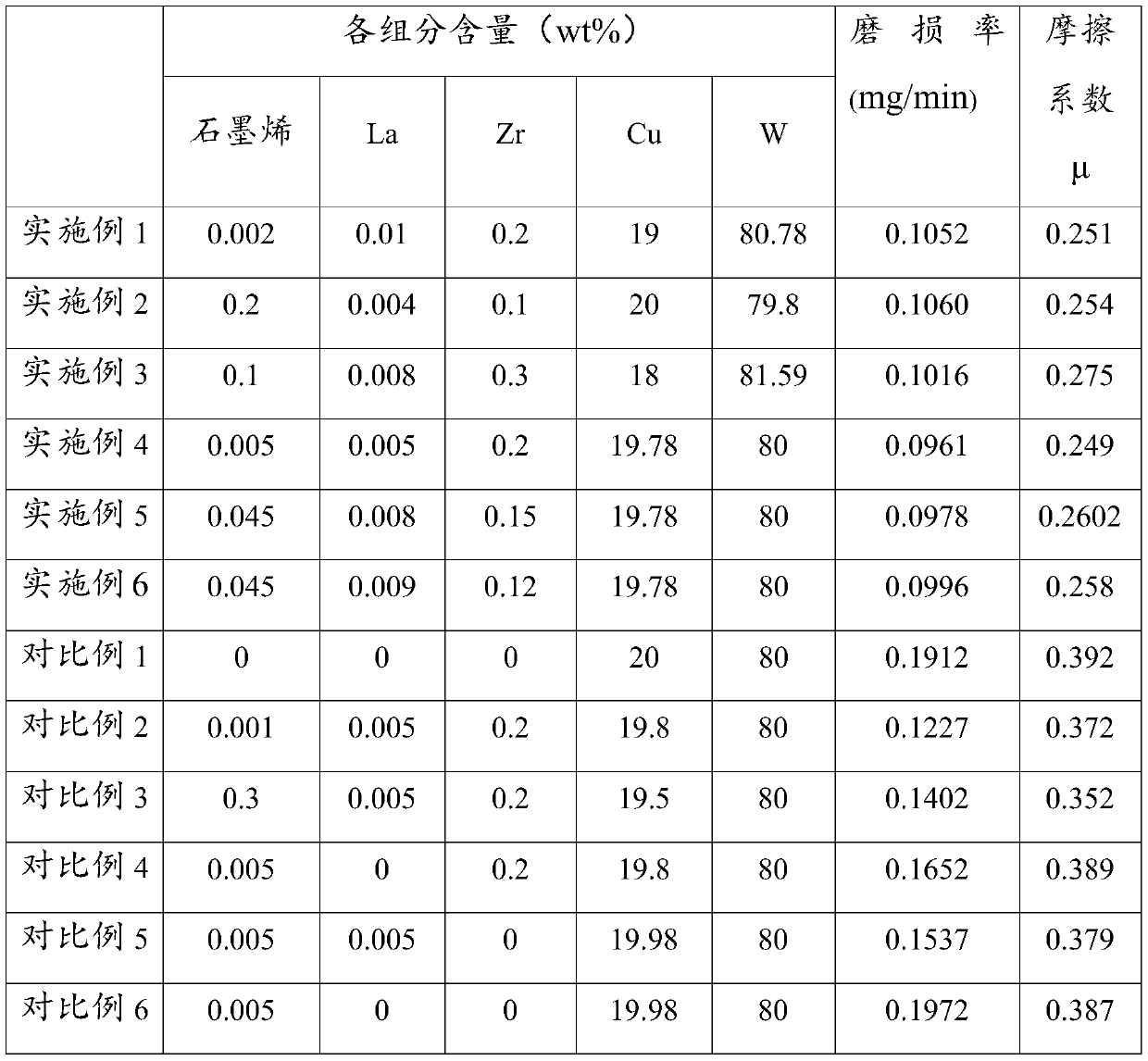

Anti-arc ablation material and preparation method and application thereof

PendingCN110438383AImprove toughnessImprove wear resistanceTransportation and packagingMetal-working apparatusLanthanumContact resistance

The invention provides an anti-arc ablation material and a preparation method and application thereof. The anti-arc ablation material comprises the following components of, in percentage by mass, 0.002%-0.2% of grapheme, 0.004%-0.01% of lanthanum, 0.1%0.3% of zirconium, 18%-20% of copper, and the balance tungsten. According to the method, the graphene, the lanthanum and the zirconium are added andthe contents of the grapheme, the lanthanum and the zirconium are limited, the graphene precursor is prepared in a chemical co-deposition mode, then the graphene precursor is mixed with Cu, W, the lanthanum and the zirconium to obtain mixed powder, and furthermore, the powder forming and a mode of combining sintering and infiltration processes are adopted, the material is enabled to have high electric arc ablation resistance, low contact resistance and low mechanical abrasion loss, and meanwhile good lasting strength under the extra-high-voltage and high-current working conditions.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Vibration wave driving apparatus

InactiveUS20120248934A1Increase in number of componentIncrease in of in necessary spacePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

Owner:CANON KK

Temperature detection module

ActiveUS20190041273A1Tensile forceReduce tensionThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceElectrical battery

A temperature detection module includes a thermistor configured to detect the temperature of an electric cell, a thermistor electrical wire drawn from the thermistor, a thermistor holding portion configured to hold the thermistor movably in a direction in which the thermistor comes into contact with and separates from the electric cell in a form in which the thermistor is biased to move toward the electric cell, and an electrical wire routing path in which the thermistor electrical wire is routed in one direction. The electrical wire routing path is provided with a holding means for holding a midpoint of the thermistor electrical wire that is drawn from the thermistor and routed along the electrical wire routing path in a form in which a drawing end of the thermistor electrical wire is provided with an excess length portion having a predetermined length in order to allow movement of the thermistor.

Owner:AUTONETWORKS TECH LTD +2

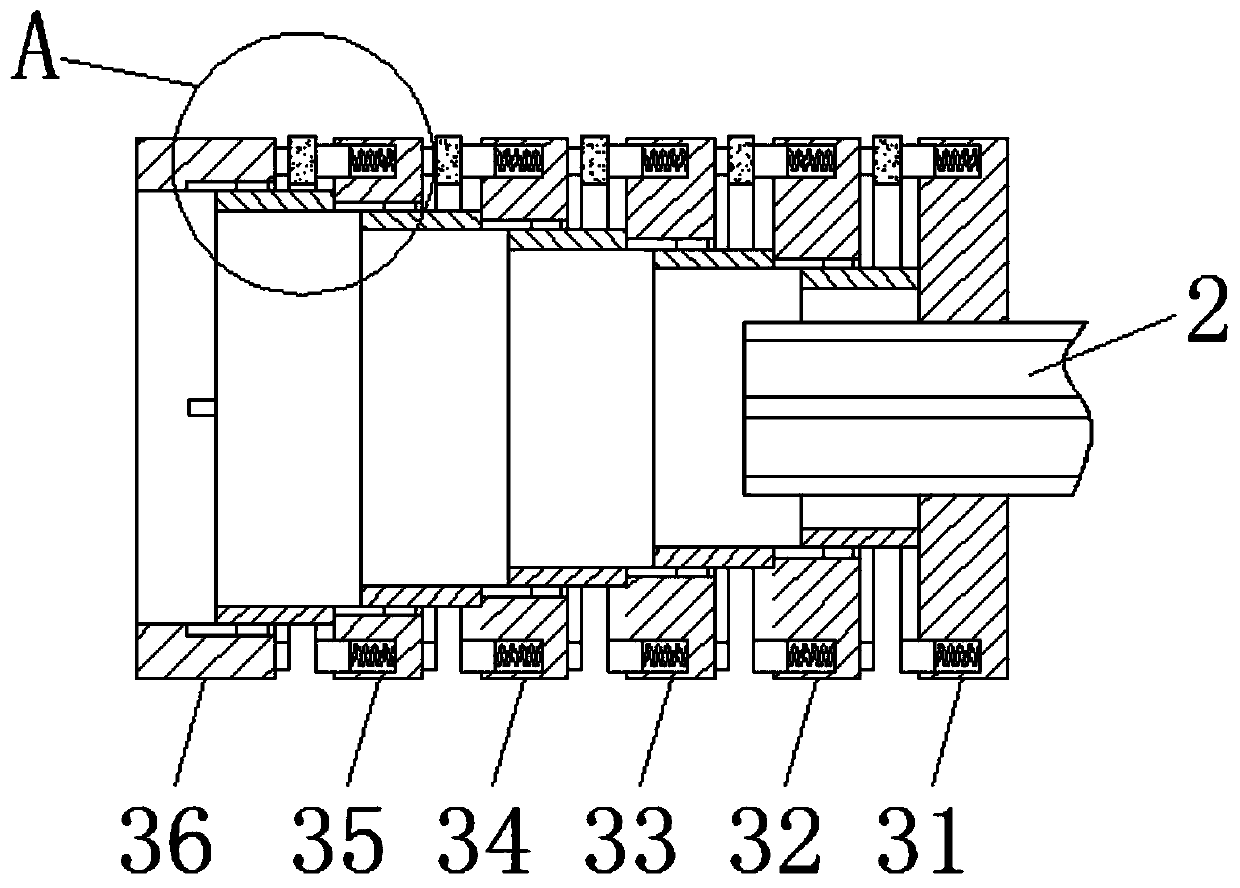

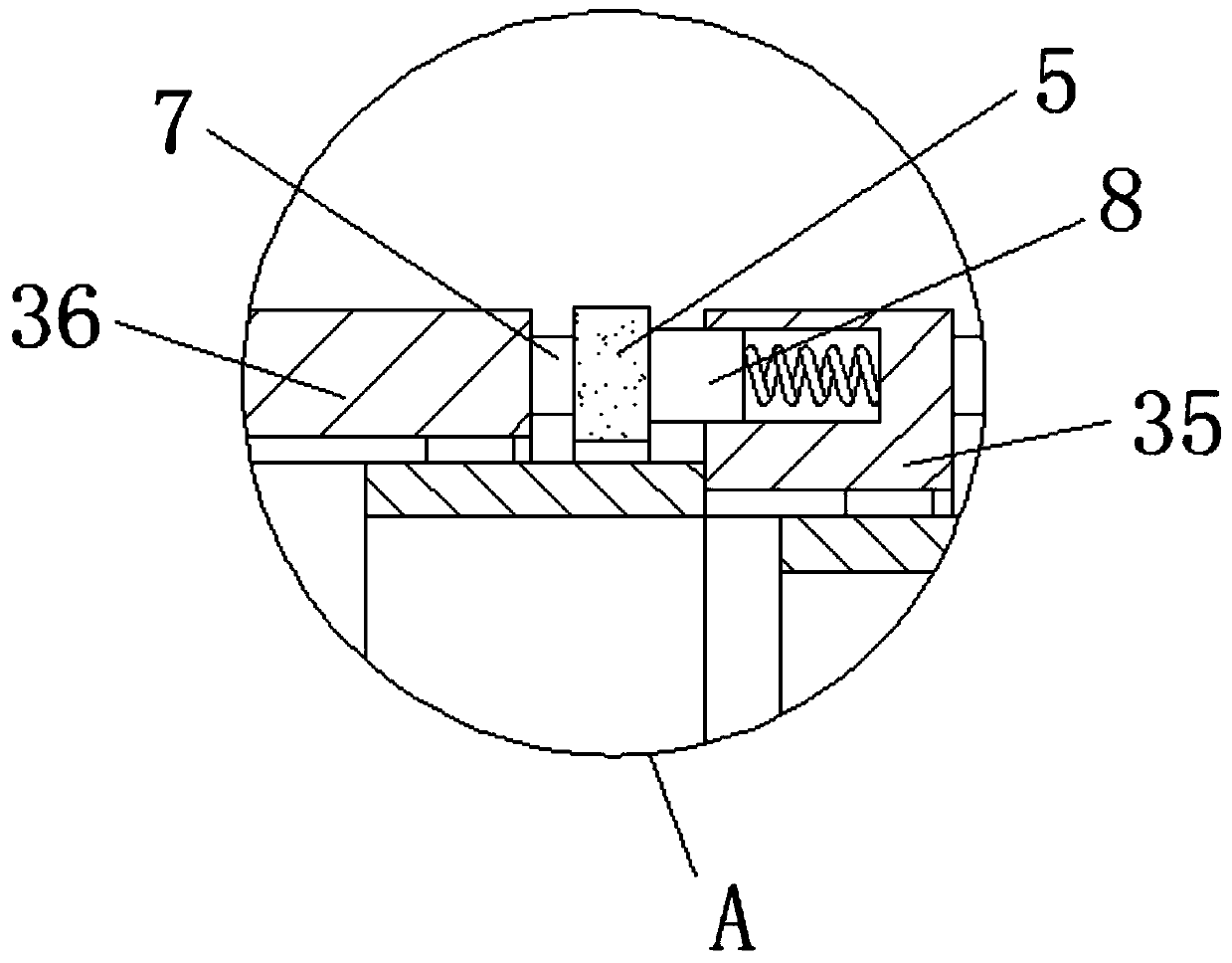

Electric slip ring with long service life

ActiveCN111129895AExtended service lifeEasy to useRotary current collectorElectric power equipmentStructural engineering

The invention relates to the field of power equipment devices and discloses an electric slip ring with a long service life. A protection shell is included, a transmission shaft is connected to one side in a sliding manner, a sliding ring assembly located in the protection shell is slidably provided with one end of the transmission shaft, the sliding ring assembly rotates along with the transmission shaft and can slide on the transmission shaft, a wiring terminal is arranged at a top of the protection shell, and conductive brushes making contact with the sliding ring assembly are arranged on afront surface and a back surface of the wiring terminal. By using the electric slip ring with the long service life, each group of slip rings is movably connected with each other, conductive rings incontact with the conductive brushes are arranged on the side surfaces of each group of slip rings, and an elastic action of a compensation spring can be utilized so that each conductive brush and theconductive ring can be kept in a stable contact state, a mode that an elastic force of the conductive brush keeps contact is canceled, phenomena that the conductive brush is deformed due to overheating and cannot be in stable contact with the conductive ring are effectively avoided, and long-term stable use of the electric slip ring is ensured.

Owner:福建华开电力科技有限公司

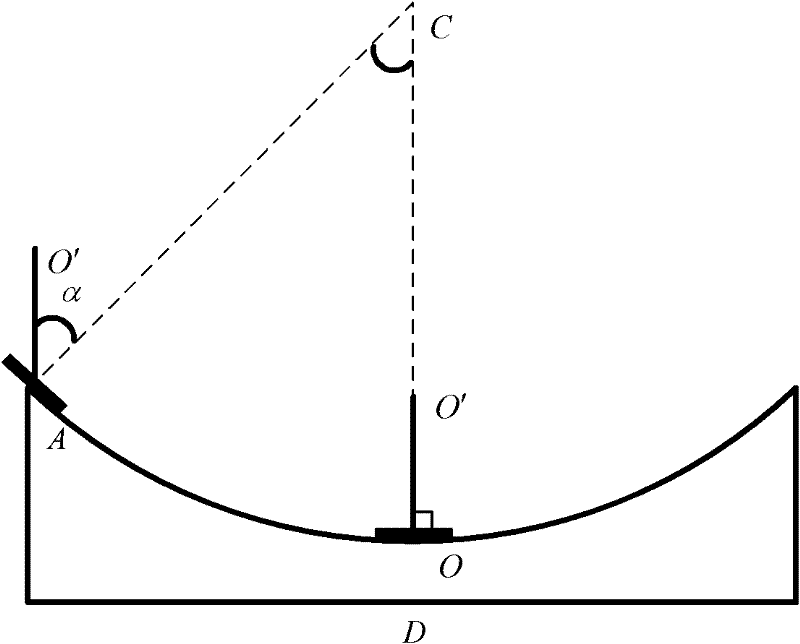

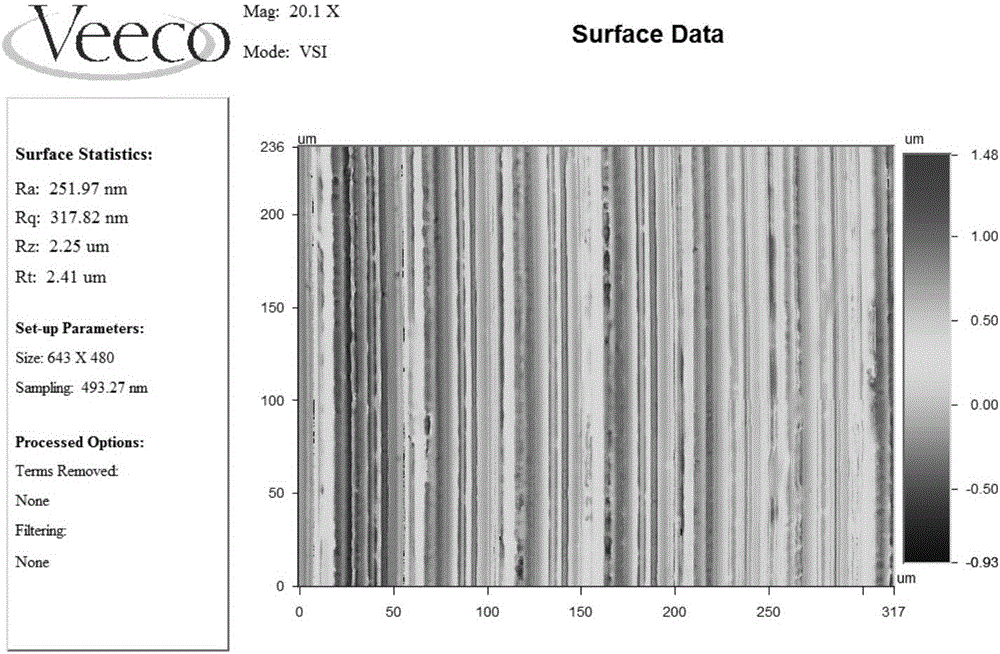

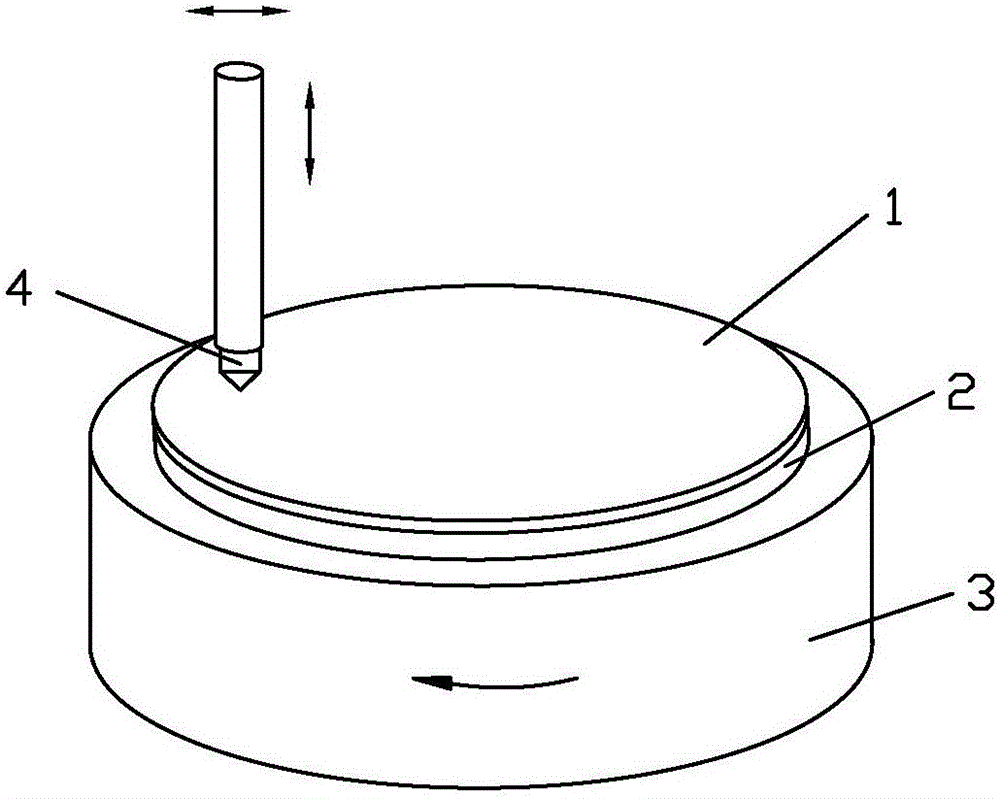

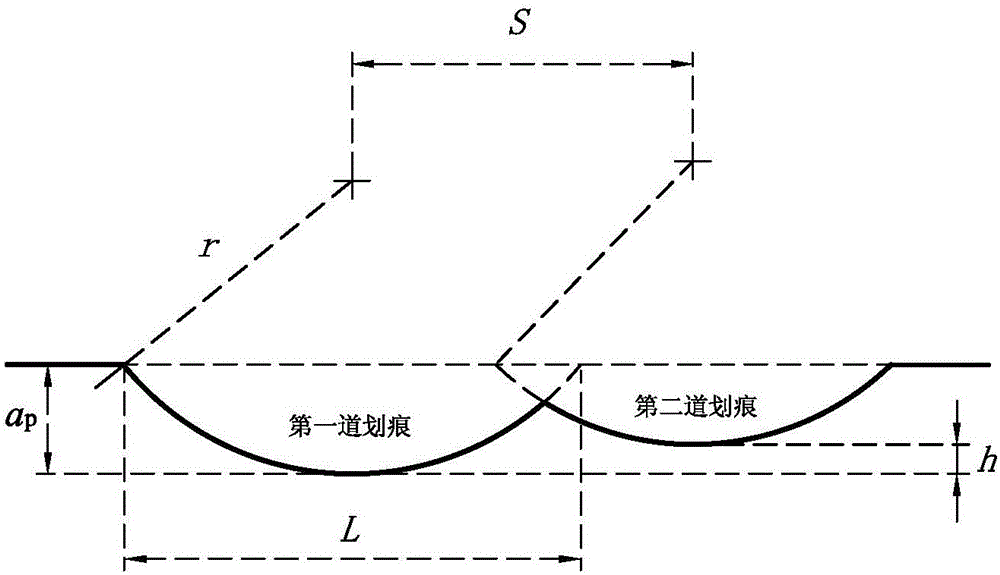

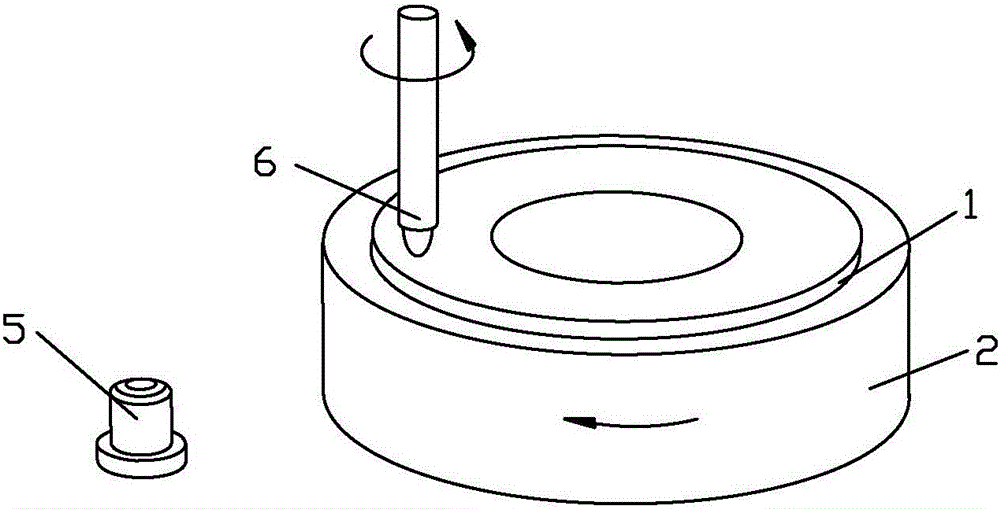

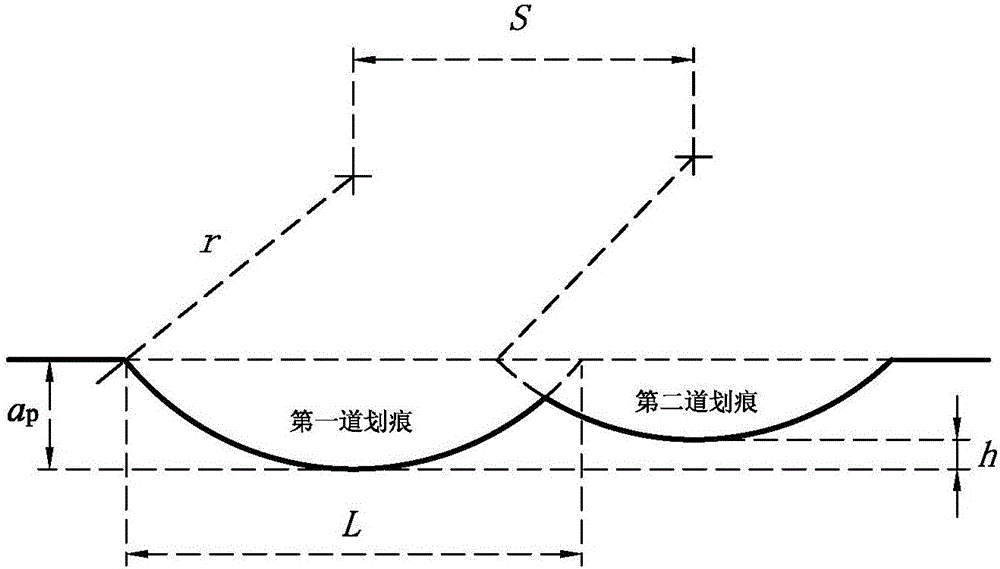

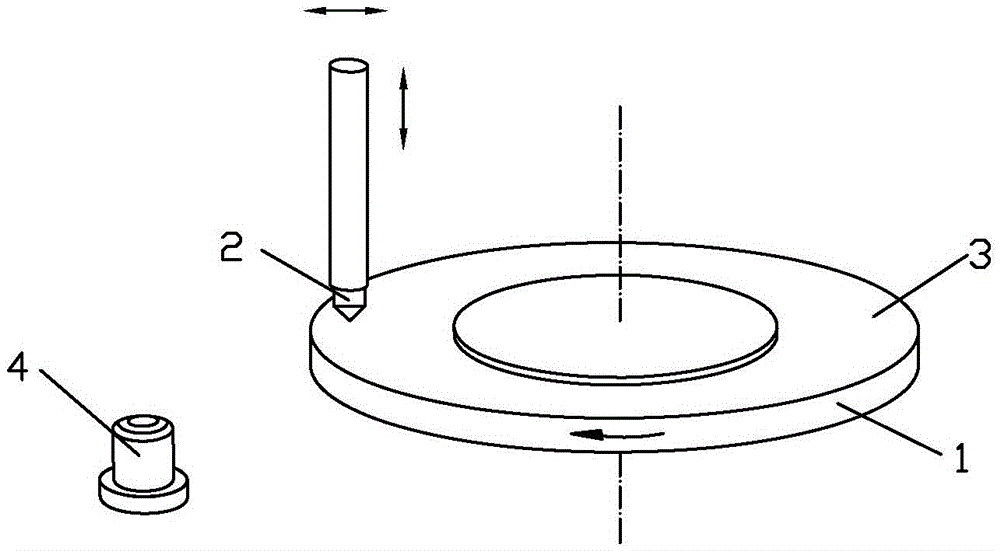

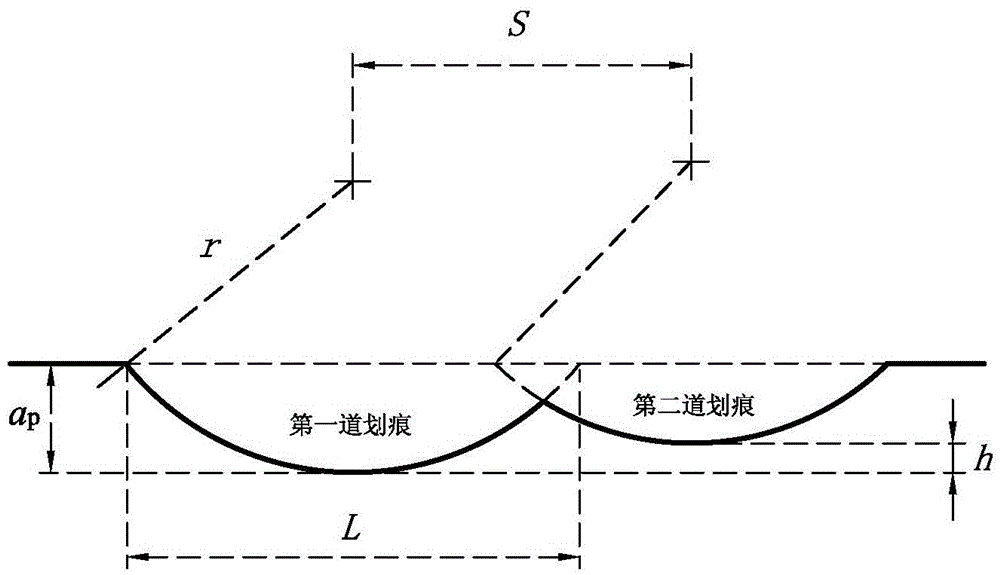

Single abrasive particle continuous scratching test method for CBN tool pre-maintenance ferrous metal test piece

ActiveCN105717031AHigh shape accuracyHigh surface finishIndividual particle analysisMaterial removalAcoustic emission

The invention discloses a single abrasive particle continuous scratching test method for a CBN tool pre-maintenance ferrous metal test piece, and belongs to the field of material performance testing in machining and precision and ultra-precision machining.The ferrous metal test piece is fixed to an electric main shaft, and online dynamic balance is conducted on the test piece; a CBN tool is used for conducting plate repairing on the test piece to meet the requirements for end face run-out and roughness needed for testing; a tool head with the top end fixedly connected with a single abrasive particle is replaced, and tool setting is conducted in the replacing process; finally, scratching testing is conducted, the test piece rotates at an appointed rotating speed, the tool head undercuts to the appointed cutting depth and conducts radial feeding, spiral scratches are formed on the end face of the test piece, and scratching force, acoustic emission signals and physical quantity are acquired by a measuring system in the process.By means of the method, it can be guaranteed that the abrasive particle and the test piece make stable contact on a long scratching distance, high-speed and high-precision scratching is achieved, and related test results can be used in studies of material removal mechanism in the frictional abrasion process and abrasion machining.

Owner:HUAQIAO UNIVERSITY

Movable contact point

InactiveUS20090032378A1Large thicknessIncreased durabilityContact surface shape/structureContact with seperate bridge contactEngineeringSpherical shaped

A movable contact point according to the present invention includes a dome-shaped portion protruded upwardly at its center portion and at least three protrusions formed, on the dome-shaped portion, to protrude downwardly at positions which are evenly spaced apart from the center position of the dome-shaped portion, wherein the protrusions are formed to have a quadrangular-pyramid shape protruding downwardly and having a spherical-shaped apex portion.

Owner:PANASONIC CORP

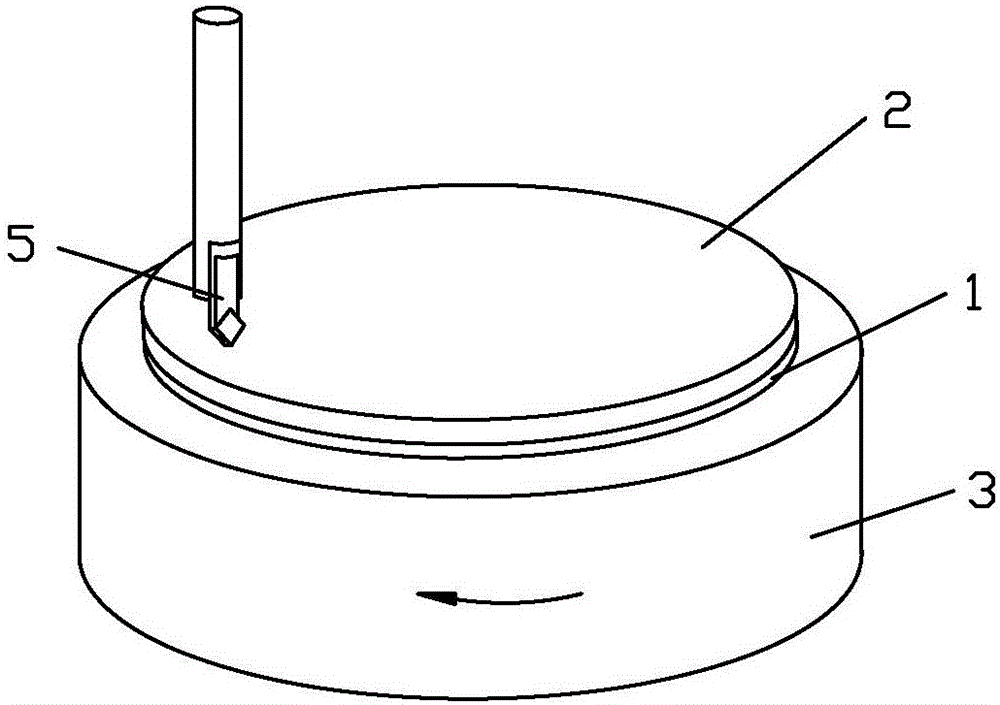

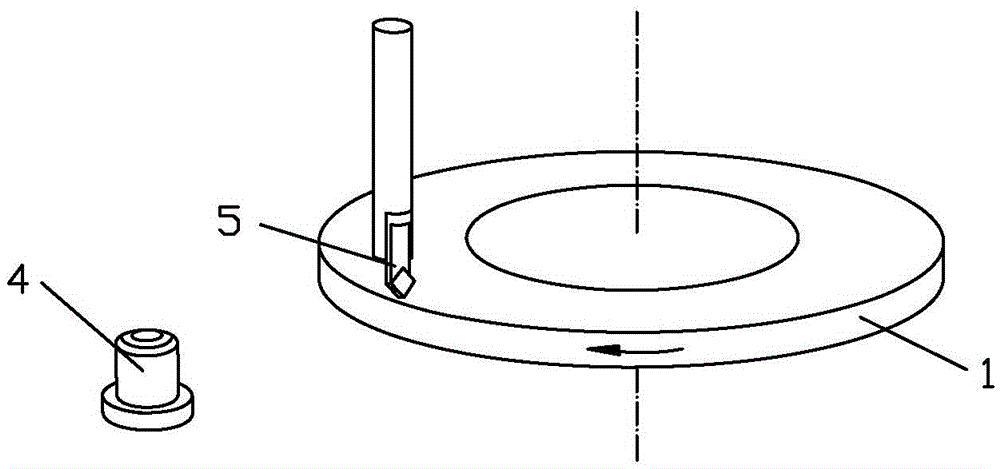

Single abrasive particle continuous scratching interference behavior test method using mutual reference method to pre-repair hard and brittle test piece

ActiveCN105699291AHigh control precisionAccurate and stable collectionUsing mechanical meansMaterial analysisHigh-speed grindingAcoustic emission

The invention discloses a single abrasive particle continuous scratching interference behavior test method using a mutual reference method to pre-repair a hard and brittle test piece and belongs to the fields of material performance test and precision and ultra-precision machining in machining.The method includes: subjecting the hard and brittle test piece to back lining, and using the mutual reference method to treat the test piece and the back lining so as to reach the surface quality and parallelism requirement needed by the test; changing a tool head with a single abrasive particle fixedly connected to the top end, and performing tool setting during the changing process; performing the scratching test, to be more specific, allowing the test piece to rotate at appointed rotation speed, radially feeding the tool head at appointed knifing to form interference spiral scratches on the end face of the test piece, and by a measuring system, collecting physical quantities such as scratching force and acoustic emission signals.The method has the advantages that the interference behavior between abrasive particles during a high-speed grinding process can be simulated, and related test results are applicable to the deep researches of the grinding mechanism and grinding parameter optimization.

Owner:HUAQIAO UNIVERSITY

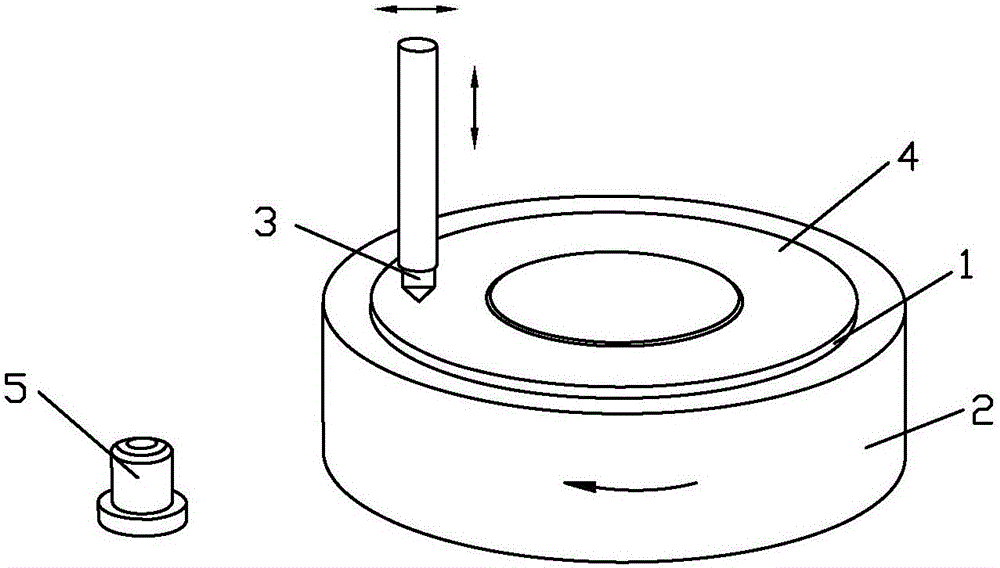

Single-grain continuous scratching interference behavioral testing method for spherical grinding head pre-maintenance rigid and brittle test piece

ActiveCN105738281AHigh control precisionAccurate and stable collectionUsing mechanical meansMaterial analysisElectricityHigh-speed grinding

The invention discloses a single-grain continuous scratching interference behavior testing method for a spherical grinding head pre-maintenance rigid and brittle test piece, and belongs to the field of material performance testing and precision and ultra-precision machining in machining.The method comprises the steps that the rigid and brittle test piece is fixed to an electric spindle, and online movable balance is performed on the test piece; then, a spherical grinding head is adopted for performing disc maintenance on the test piece, and the requirement for testing needed end face run-out and roughness is met; then, a reloading top end is fixedly connected with a tool head for single grains, and tool setting is performed in the displacement process; finally, scratching testing is performed, the test piece rotates at the designated rotating speed, a tool head performs radial feed with the designated cutting depth, interference spiral scratches are performed on the end face of the test piece, and a measuring system collects scratching force, acoustic emission signals and other physical quantity in the process.According to the single-grain continuous scratching interference behavior testing method, interference behaviors among the grains in the high-speed grinding process can be simulated, and the related testing result can be used for intensive study of a grinding mechanism and optimization of grinding parameters.

Owner:HUAQIAO UNIVERSITY

Signal detection contactor and signal calibration system

InactiveUS7414390B2Reliably detect signalImprove RF characteristicsSemiconductor/solid-state device testing/measurementMeasurement leads/probesPhase differenceVIT signals

A signal detection contactor has a contactor main body and a plurality of coaxial bodies. Each coaxial body includes a core wire. The core wire is used for coming into contact with a probe of a prober and for receiving a signal transmitted from a tester, in order to calibrate a phase difference among signals transmitted through a plurality of probes.

Owner:TOKYO ELECTRON LTD

Reciprocating sealing device

InactiveCN103988004AReduce deformationIncreased volume absorbencyEngine sealsSpringsEdge surfaceEngineering

Provided is a reciprocating sealing device shaped so that volume absorbing performance is improved, preventing full-surface contact of the packing from readily occurring even when there is an increase in internal pressure, and therefore an excellent sealing performance can be obtained. In order to achieve this purpose, the reciprocating sealing device is a sealing device in which a packing is mounted on a mounting groove provided to one of two members that perform a reciprocating motion relative to each other and the packing is brought into intimate contact with the other member to obtain a seal between the two members. The packing is provided with an annular base part, a stationary-side lip, and a sliding-side lip. A pack ring having a lower hardness than that of the packing is interposed between the annular base part and the groove side surface of the mounting groove. A pack ring forms a space region between the pack ring and the other member. The annular base part is shaped so that the heel part has an arc-shaped or tapered cross-section and the annular base part does not protrude beyond an extension line of a peripheral surface of the sliding-side lip in a free state. The edge surface of the annular base part is provided with a flat part within the range at which contact is made with the pack ring.

Owner:NOK CORP

Testing method of continuous scratching interference behavior of single abrasive grain of black metal test piece pre-repaired by CBN tool

ActiveCN105538154AHigh control precisionAccurate and stable collectionGrinding feed controlGrinding machinesElectricityDynamic balance

The invention discloses a testing method of a continuous scratching interference behavior of a single abrasive grain of a black metal test piece pre-repaired by a CBN tool and belongs to the fields of material performance testing and precise and ultra-precise machining during machining. Due to the fact that the black metal test piece is fixed to an electric main shaft and subjected to online dynamic balance; then the CBN tool is adopted for repairing a disk of the test piece, and the requirements for end face bouncing and roughness required for testing are met; a tool bit with the top end fixedly connected with the single abrasive grain is installed through replacement, and tool setting is performed in the replacement process; finally, a scratching test is started, the test piece rotates at an assigned speed, the tool bit performs radial feeding at assigned cutting depth, interference spiral scratches are formed on the end face of the test piece, and a measurement system acquires scratching force, an acoustic emission signal and other physical quantity in the process. The method can simulate the interference behavior between abrasive grains in the high-speed grinding process. A relevant testing result can be used for deep research of a grinding mechanism and optimization of grinding parameters.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com