Outer joint member for fixed constant velocity universal joint

一种等速万向接头、外侧接头的技术,应用在发动机元件、齿轮变速机构、弹性联轴器等方向,能够解决没有记载精加工等问题,达到成品率提高、低成本生产、制造成本降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

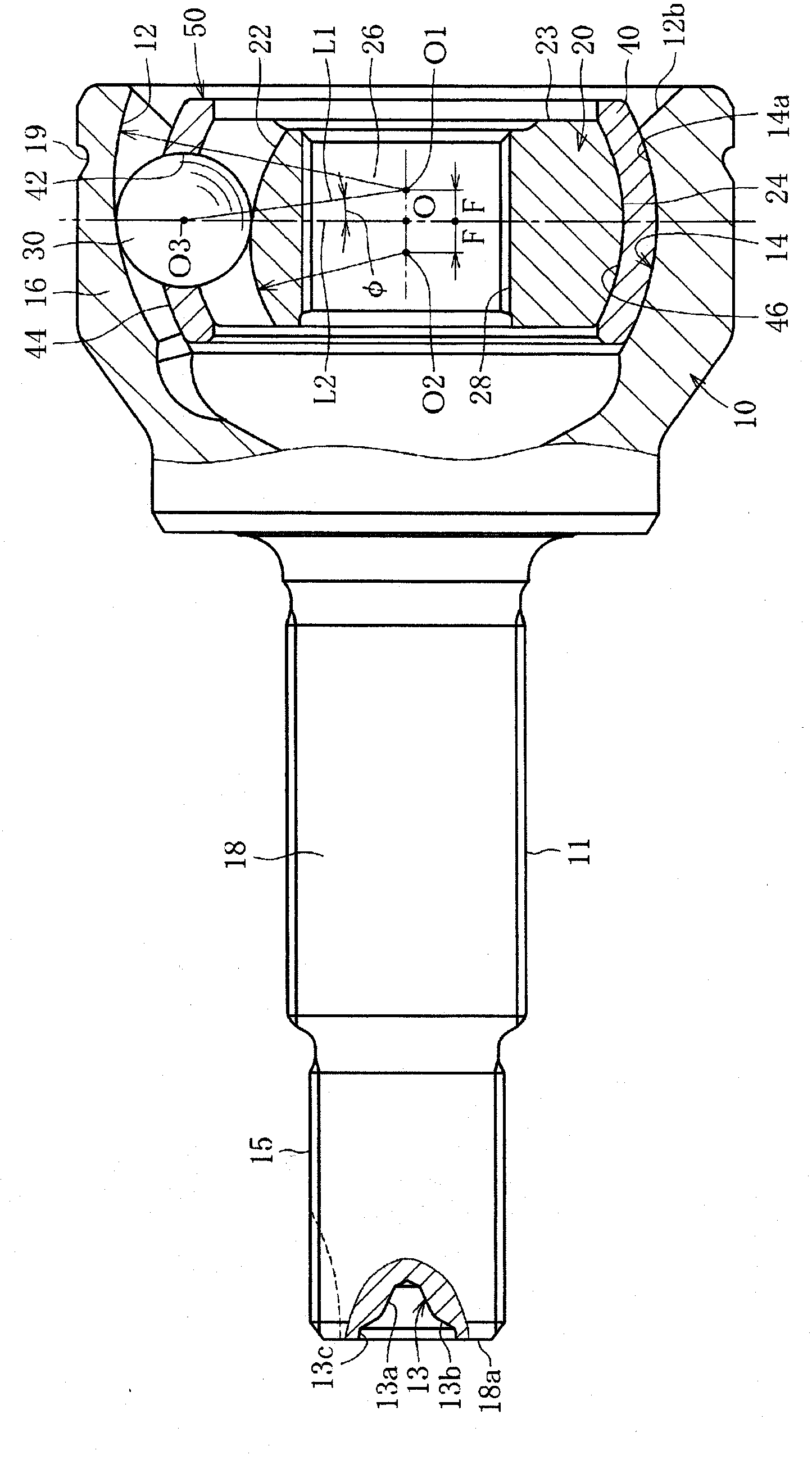

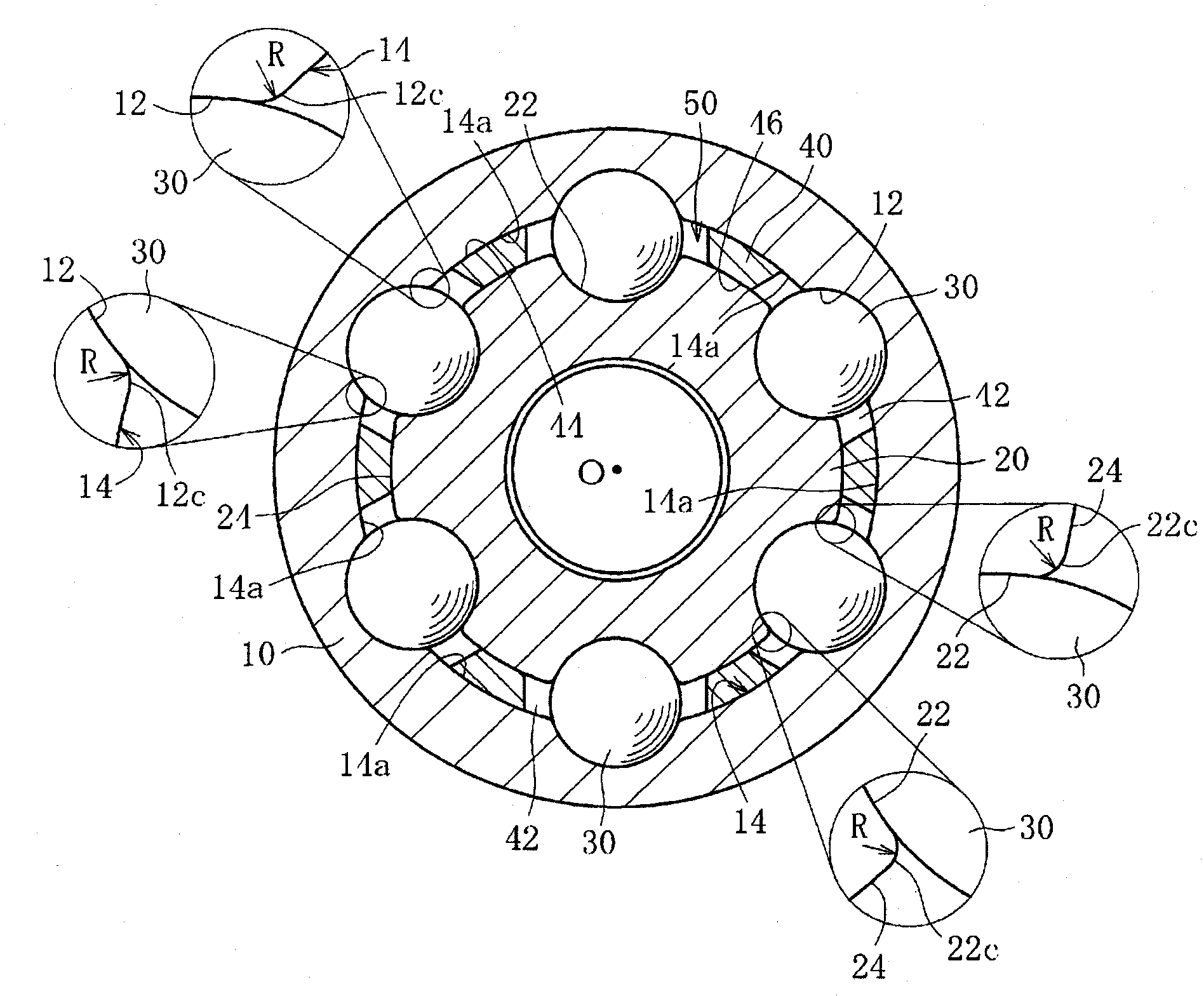

[0056] The following is based on Figure 1 to Figure 19 Embodiments of the present invention will be described. figure 1 with figure 2 It is a fixed type constant velocity universal joint using the outer joint member of the present invention. This fixed constant velocity universal joint is a birfield type, and its main constituent elements are: an outer ring 10 as an outer joint part, an inner ring 20 as an inner joint part, balls 30, and a spacer 40, and includes The inner part 50 which consists of the inner ring 20, the ball 30, and the spacer 40 is accommodated in the outer ring 10 so that angular displacement may be performed.

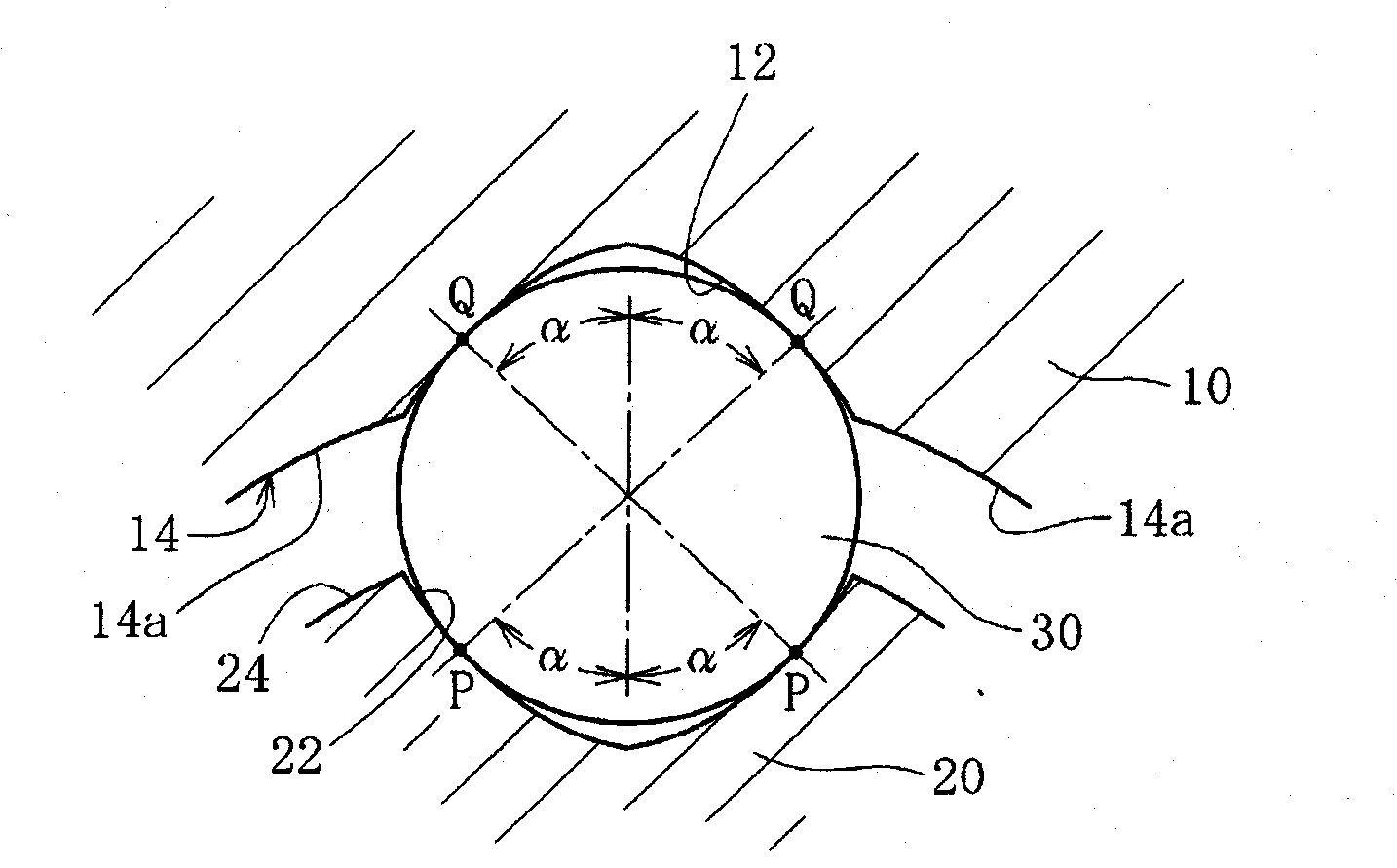

[0057] The outer ring 10 is made of carbon steel for mechanical structure, and has a cup shape with one end open, and a plurality of raceway grooves 12 extending in the axial direction are formed on the inner diameter surface 14 at equal intervals in the circumferential direction. In addition, the space between the adjacent track grooves in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com