Reciprocating sealing device

A reciprocating motion and sealing device technology, which is applied to the sealing of the engine, engine components, springs, etc., can solve the problems of unfavorable wedge shape maintenance, oil leakage, internal pressure rise, etc., to reduce deformation, prevent oil leakage, and improve The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

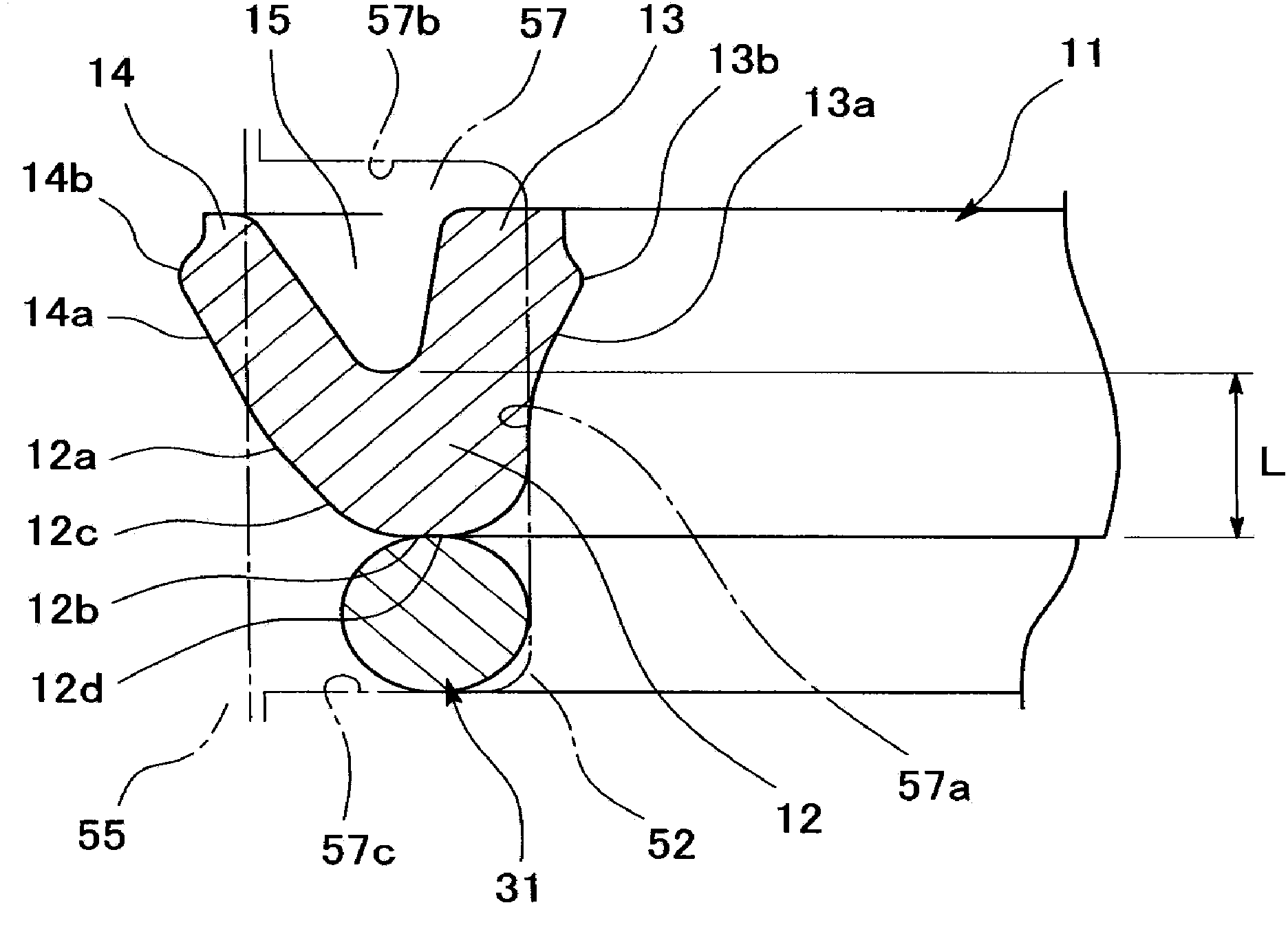

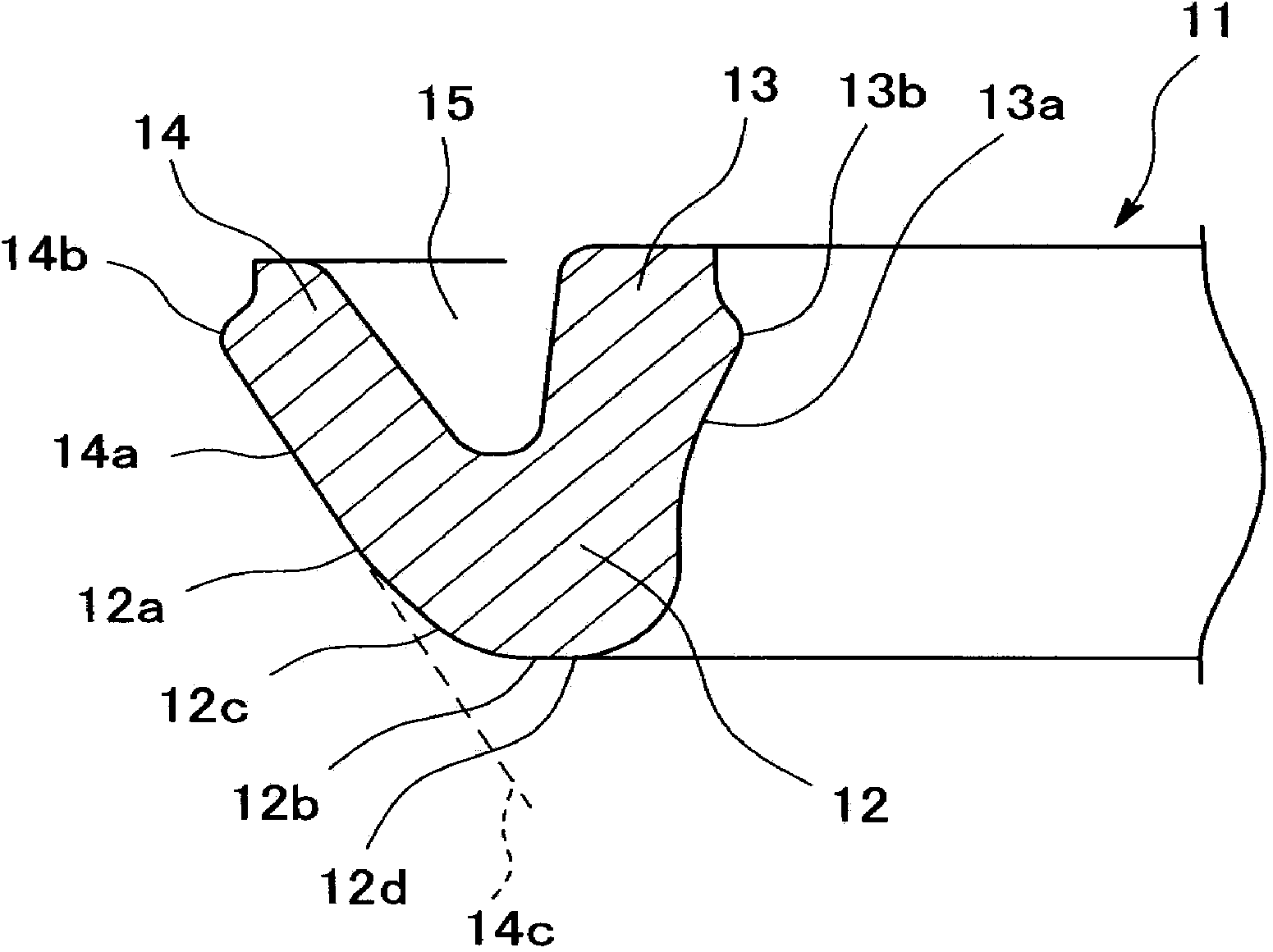

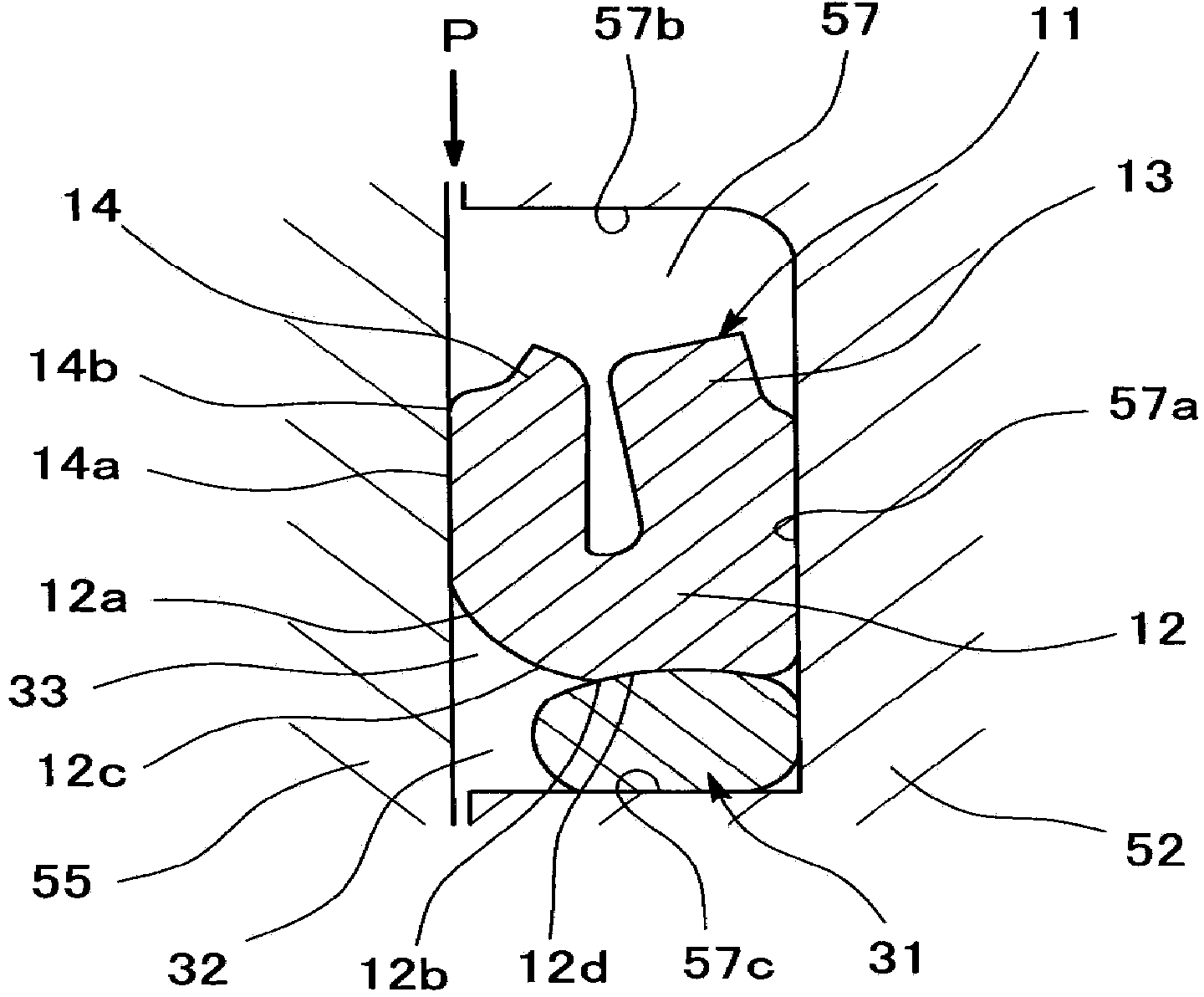

[0066] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0067] figure 1 The cross-section of the main part of the gasket 11 and the gasket 31 included in the sealing device according to the embodiment of the present invention is shown, and the gasket 11 and the gasket 31 are attached to, for example, the above-mentioned Figure 6 The annular mounting groove 57 provided on the outer peripheral surface of the shock absorber shaft 52 in the shock absorber mechanism 51 constitutes a sealing device for reciprocating motion (axial reciprocating motion). As described above, the damper mechanism 51 is composed of a damper shaft (one component in the technical solution of the present invention) 52 provided with a piston 53 having an orifice 54 at the front end, and a damper elastically supported by a spring unit 56 . The shock absorber case (the other part in the technical solution of the present invention) 55 is combined, and is assembled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com