Oil seal

An oil seal and sealing lip technology, which is applied to engine components, engine seals, mechanical equipment, etc., can solve the problems of no reverse thread part and thinning, and achieve thickening of the oil film, preventing static leakage and good sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Embodiments of the present invention will be described below with reference to the drawings.

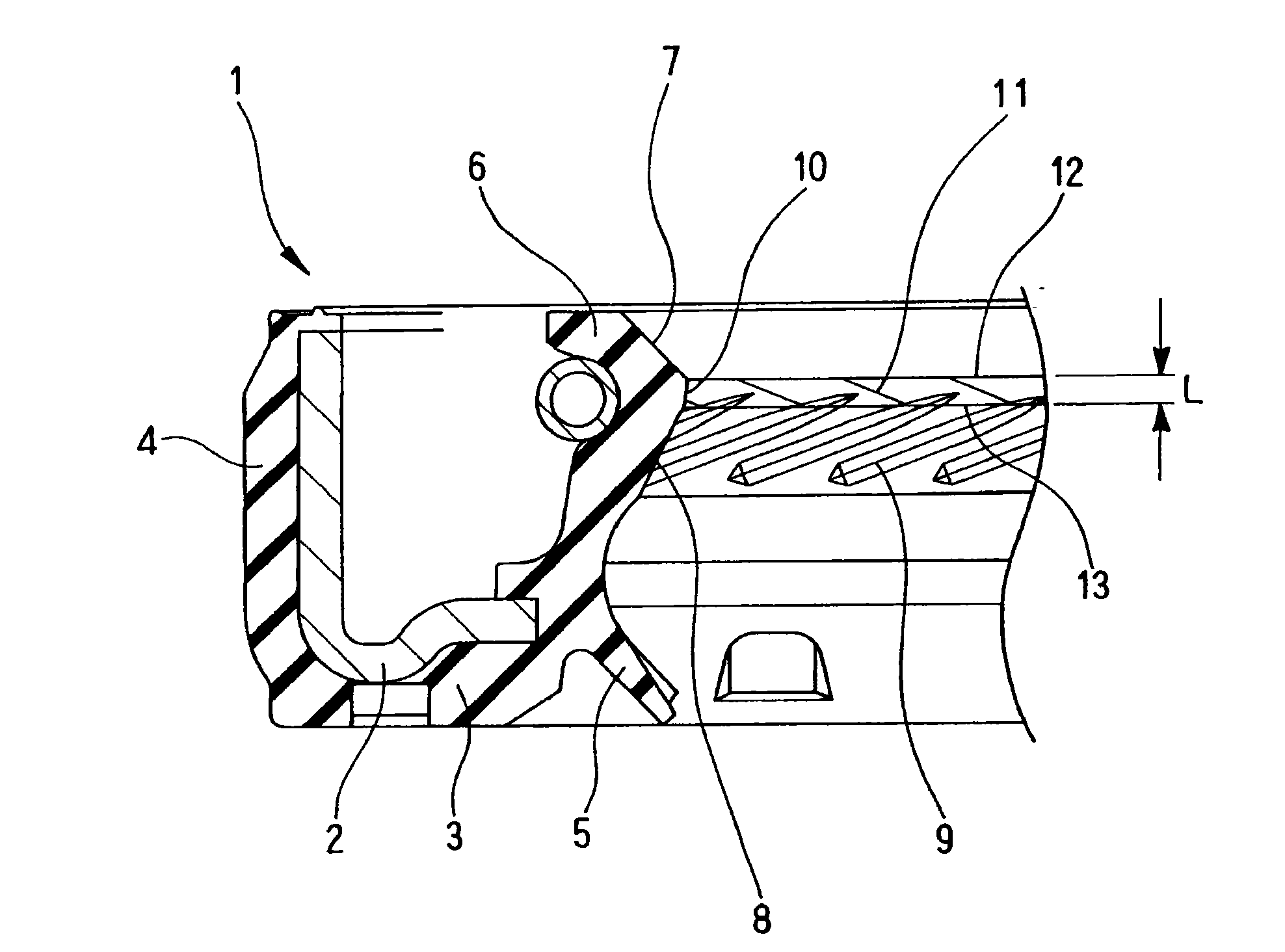

[0058] figure 1 A sectional view of main parts of the oil seal 1 according to the embodiment of the present invention is shown, and the oil seal 1 of the present embodiment is constituted as follows.

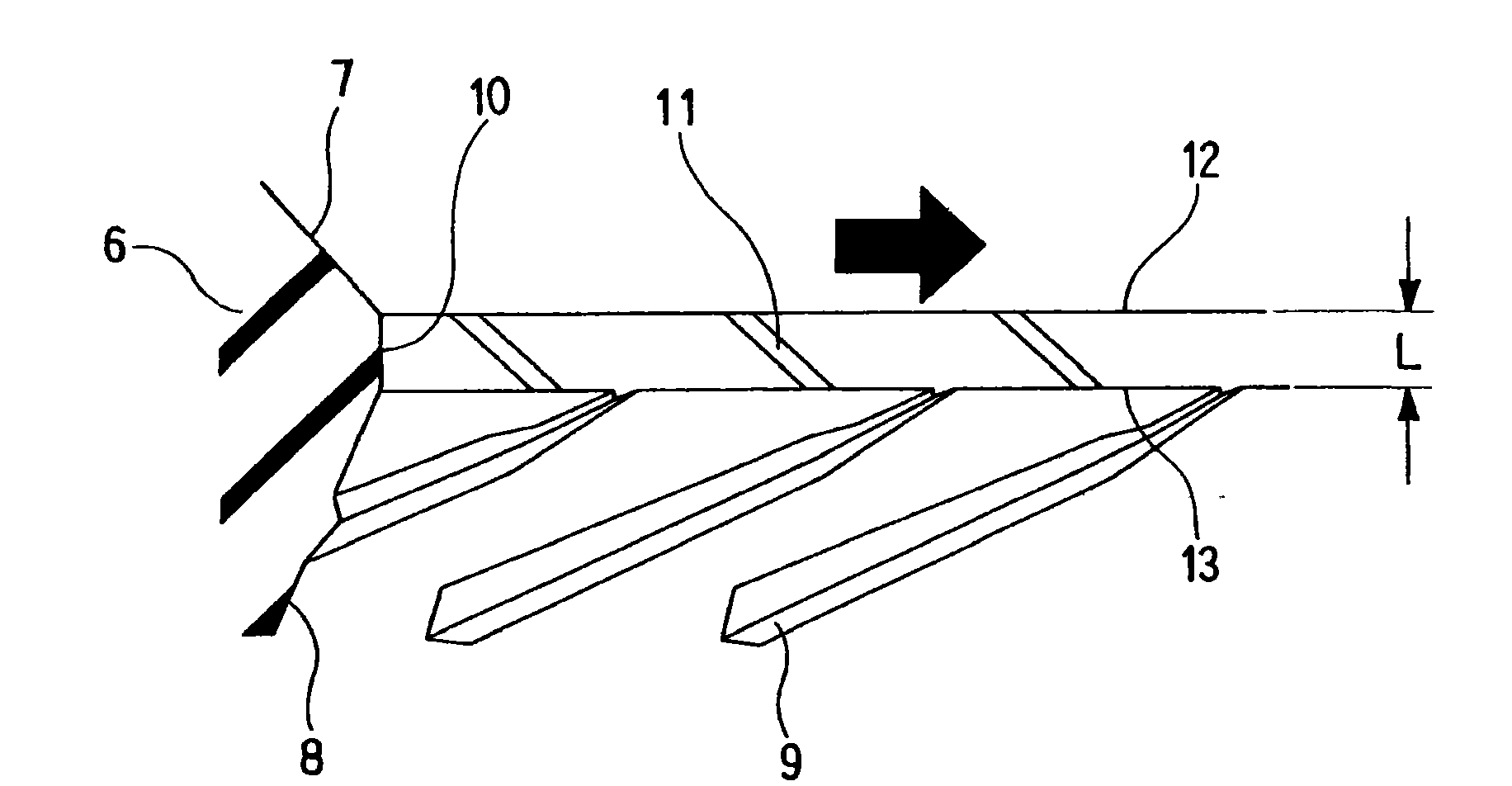

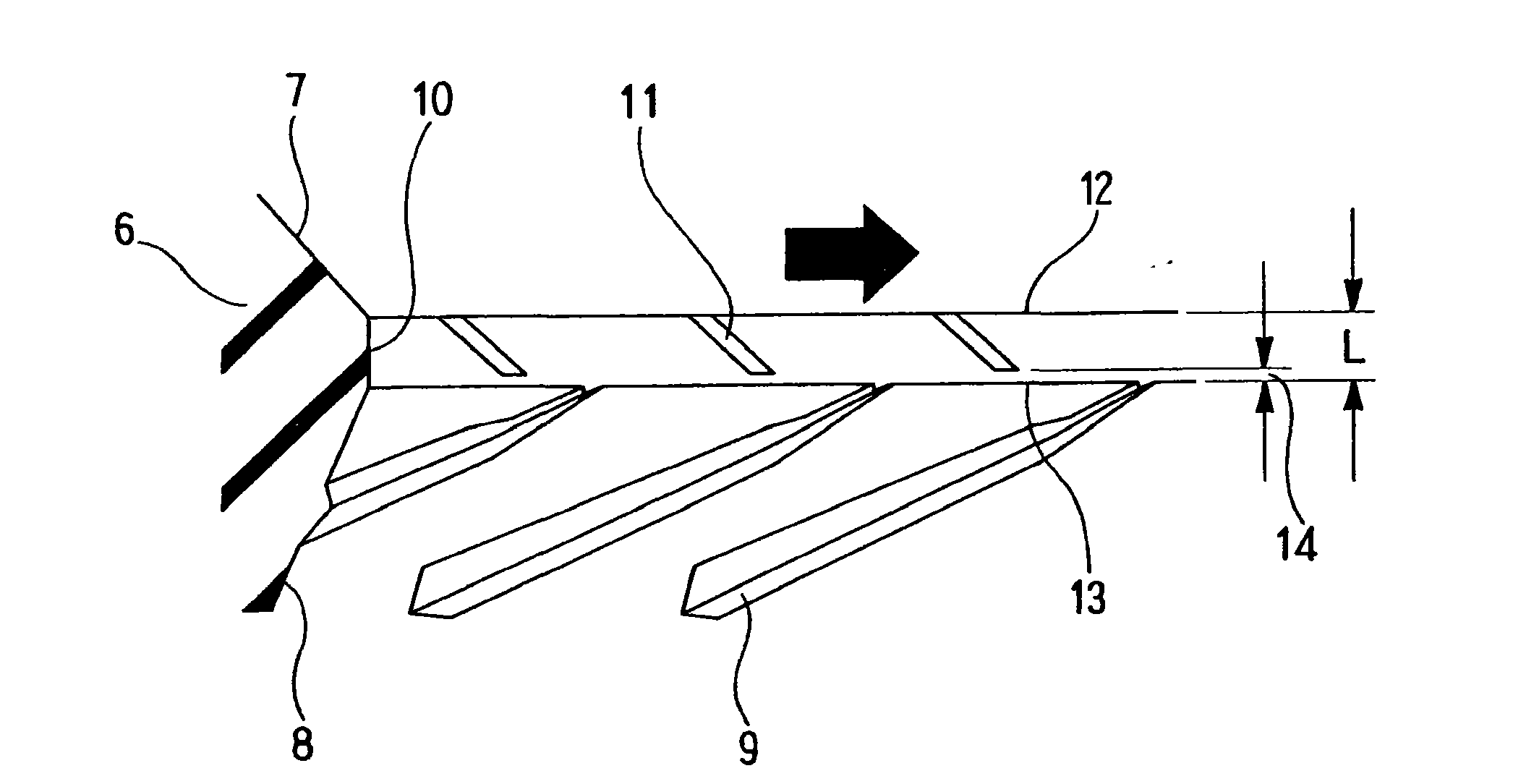

[0059] That is, first, the seal lip 6 is provided, and the seal lip 6 is in close contact with the shaft slidably together with the outer peripheral seal portion 4 and the dustproof lip 5 through the rubber elastic body 3 adhered (vulcanized) to the metal ring 2. (Cooperating components, not shown) on the front end sliding part of the sealing lip 6, the sealing fluid side slope 7 and the anti-sealing fluid side slope 8 are arranged, and on the latter anti-sealing fluid side slope 8, a rotary The threaded part (positive threaded part) 9 that presses back the sealing fluid is realized by the suction action at the time. The threaded portion 9 is composed of a plurality of helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com